Method for rapidly preparing SiC nanowire

A nanowire, fast technology, applied in the nano field, can solve the problems of difficult conditions, high cost, long cycle, etc., and achieve the effect of reducing the requirements of process conditions, reducing costs, and reducing residue pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The method for preparing SiC nanowires in this embodiment is realized through the following steps:

[0023] a, according to the mass percentage, the SiO powder with a purity of 99.9% is 33.3%, and coke is 66.7% to mix;

[0024] b, the mixture was put into a ball mill, and ball milled at a speed of 400 rpm for 6 hours to prepare the reaction raw materials;

[0025] c. Put the reaction raw materials into a crucible made of graphite tube, place it in a sealed quartz tube, and use a vacuum pump to evacuate to 50Pa;

[0026] d. Introduce argon or nitrogen into the quartz tube, adjust the intake flow, and control the air pressure in the tube to 0.02MPa;

[0027] e. Use the high-frequency induction power coil wound outside the quartz tube to heat the graphite crucible, raise it to 1600°C within 3 minutes, and keep it warm for 20 minutes;

[0028] f. Under the protection of argon or nitrogen, cool down to room temperature with the furnace to obtain SiC nanowires.

[0029] In...

Embodiment 2

[0031] The difference between this embodiment and embodiment one is that in step a, according to the mass percentage SiO is 50%, and coke is 50%; in step b, ball milling is carried out at a speed of 400 rpm for 12 hours; in step c, vacuum is drawn to 75Pa; In d, the air pressure is controlled at 0.03MPa; in step e, the holding time is 40min. Other steps are the same as in the first embodiment.

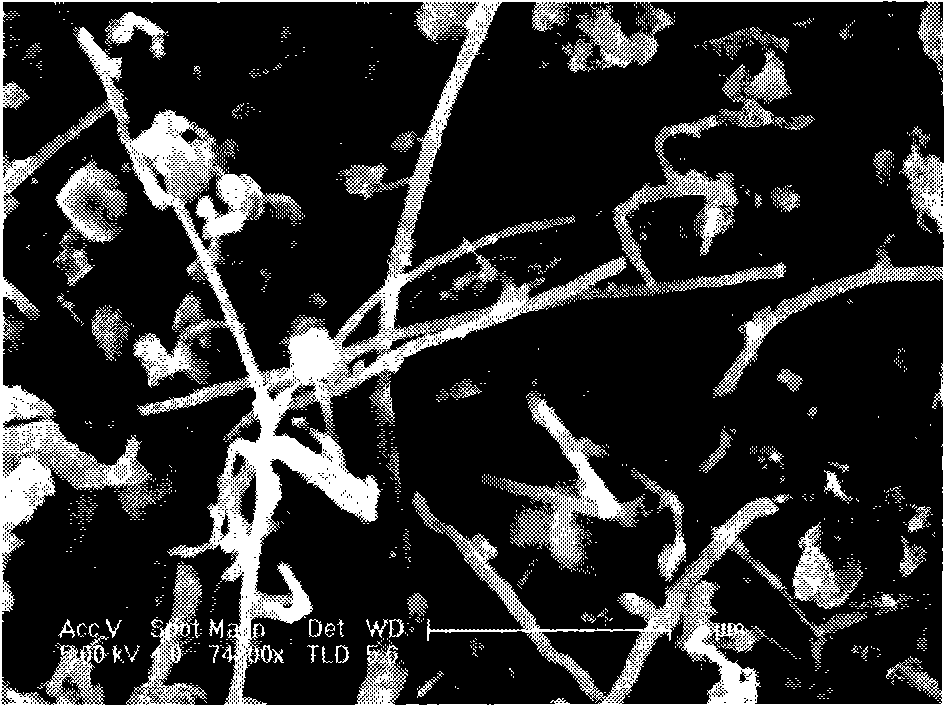

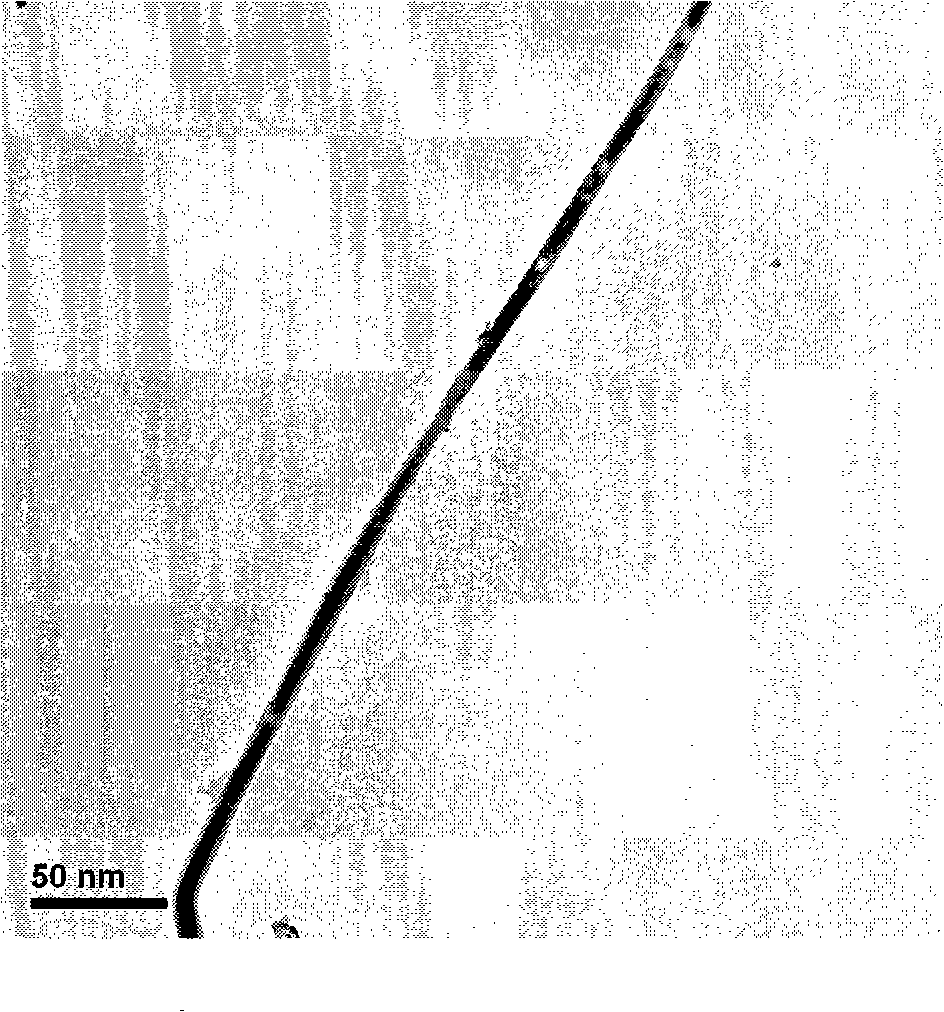

[0032] see figure 1 , 2 In this embodiment, SiC nanowires with a diameter of 10-100 nm and a length of up to 4 microns were obtained during the reaction process of 40 minutes. All the powders were reacted to form SiC nanowires, which enabled the rapid preparation of SiC nanowires within a reaction time of 43 min.

Embodiment 3

[0034] The difference between this embodiment and embodiment one is that in step a, according to the mass percentage SiO is 66.7%, and coke is 33.3%; in step b, ball milling is performed at a speed of 400 rpm for 24 hours; in step c, the vacuum is pumped to 100Pa; In d, the air pressure is controlled at 0.04MPa; in step e, the holding time is 60min. Other steps are the same as in the first embodiment.

[0035] In this example, SiC nanowires with a diameter of 10-150 nm and a length of up to 5 microns were obtained during the reaction process of 60 minutes. All powders were reacted to form SiC nanowires, which made it possible to rapidly prepare SiC nanowires within a reaction time of 63 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com