Method for preparing nanometer cerium oxide by hydrothermal method

A technology of nano-cerium oxide and hydrothermal method, which is applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of high cost, complex formula, harsh production conditions, etc., and achieve low production cost, simple preparation process, The effect of low requirements on production equipment and process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Prepare 0.05mol / L Ce(NO 3 ) 3 ·6H 2 O aqueous solution;

[0033] 2) Take 91mL of Ce(NO 3 ) 3 ·6H 2 O aqueous solution was placed in a flask, and under magnetic stirring, 9.1 mL of ammonia water was added dropwise to the flask;

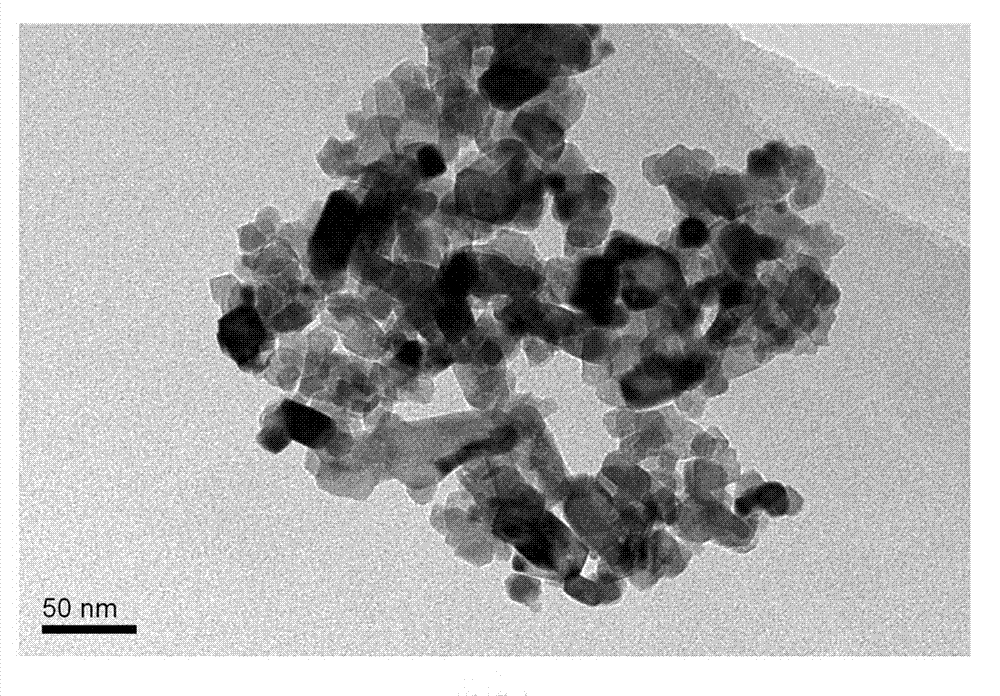

[0034] 3) The above mixed solution was reacted under magnetic stirring, and 1 mL of the mixed solution was taken at the end of the reaction for 2 hours, 8 hours and 24 hours, respectively, and the sample was centrifuged to remove the upper liquid. Wash the powder obtained by centrifugation with pure water, then place it in a drying oven and dry it into a solid powder, observe it with a transmission electron microscope, and find that the obtained product is cerium oxide nanoparticles with a particle size of 10-30nm, see attached figure 1 .

Embodiment 2

[0036] 1) Prepare 0.08mol / L Ce(NO 3 ) 3 ·6H 2 O aqueous solution;

[0037] 2) Take 83mL of Ce(NO 3 ) 3 ·6H 2 O aqueous solution is placed in the flask, and under magnetic stirring, 16.6mL of ammonia water is added dropwise to the flask;

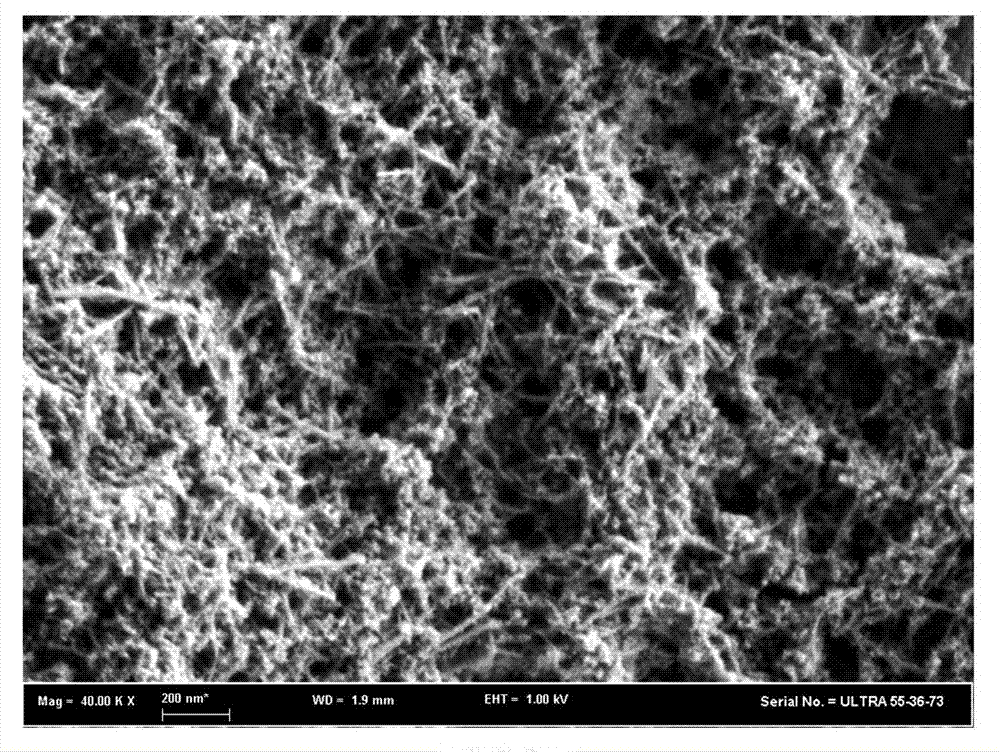

[0038] 3) The above-mentioned mixed solution was reacted under magnetic stirring respectively, and 1 mL of the mixed solution was taken at the end of the reaction for 2 hours, 8 hours and 24 hours, respectively, and the sample was centrifuged to remove the upper liquid. Wash the powder obtained by centrifugation with pure water, then place it in a drying oven and dry it into a solid powder, observe it with a field emission scanning electron microscope, and find that the obtained product is cerium oxide nanoparticles with a particle size of 10-30nm and a diameter of 10-30nm , a mixture of nanorods with a length of 100-300 nm, see attached figure 2 .

Embodiment 3

[0040] 1) Prepare 0.1mol / L Ce(NO 3 ) 3 ·6H 2 O aqueous solution;

[0041] 2) Take 77mL of Ce(NO 3 ) 3 ·6H 2 O aqueous solution was placed in a flask, and under magnetic stirring, 23.1 mL of ammonia water was added dropwise to the flask;

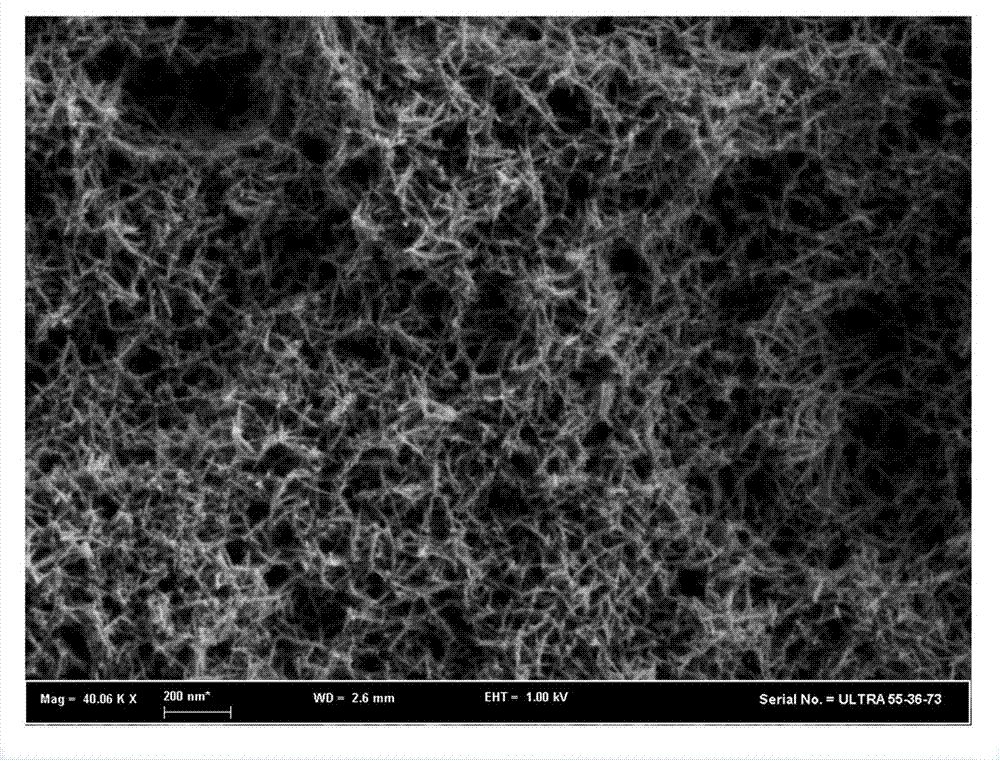

[0042] 3) The above-mentioned mixed solution was reacted under magnetic stirring respectively, and 1 mL of the mixed solution was taken at the end of the reaction for 2 hours, 8 hours and 24 hours, respectively, and the sample was centrifuged to remove the upper liquid. Wash the powder obtained by centrifugation with pure water, then place it in a drying oven and dry it into a solid powder, observe it with a field emission scanning electron microscope, and find that the obtained product is a nanorod with a diameter of 10-30nm and a length of 100-300nm. image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com