Patents

Literature

33results about How to "Maintain luminous performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light-emitting diode (LED) epitaxial structure and manufacturing method thereof

InactiveCN102208503AExcellent ElectricalGood optical performanceSemiconductor devicesQuantum efficiencyOptical property

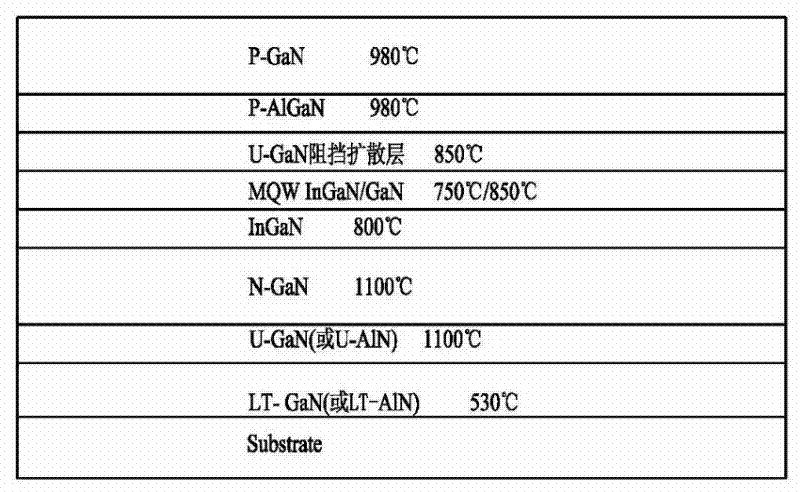

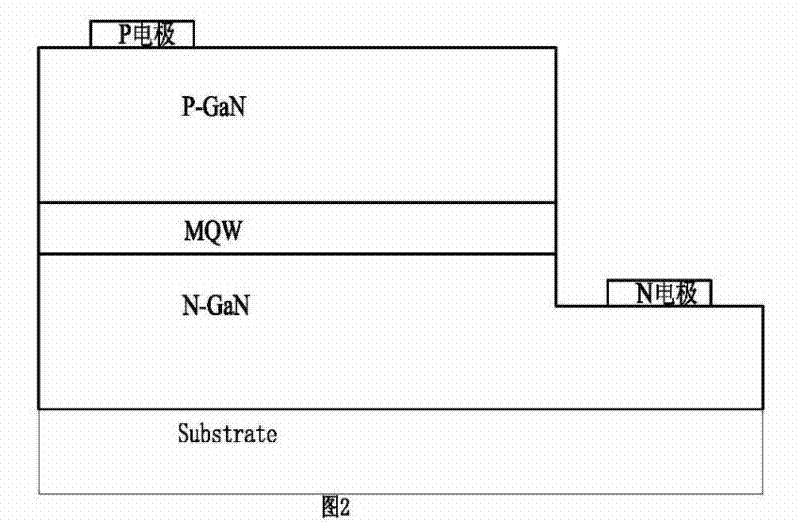

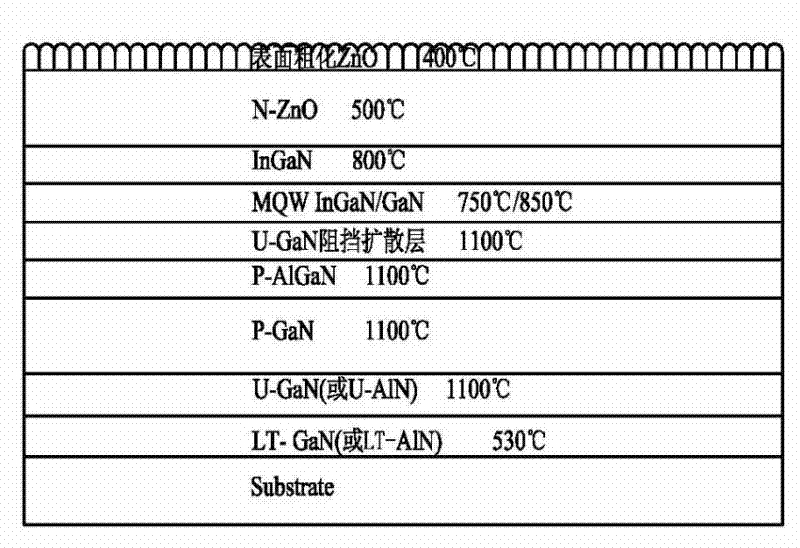

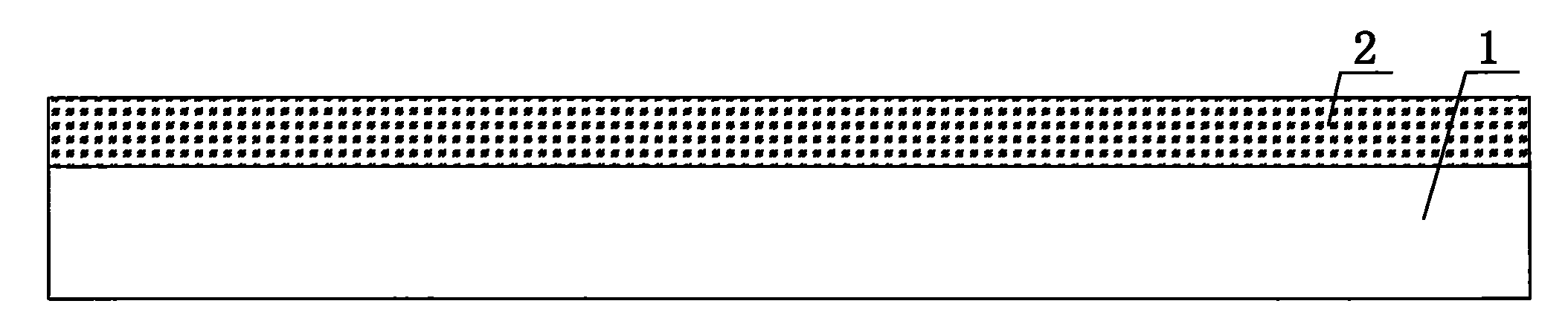

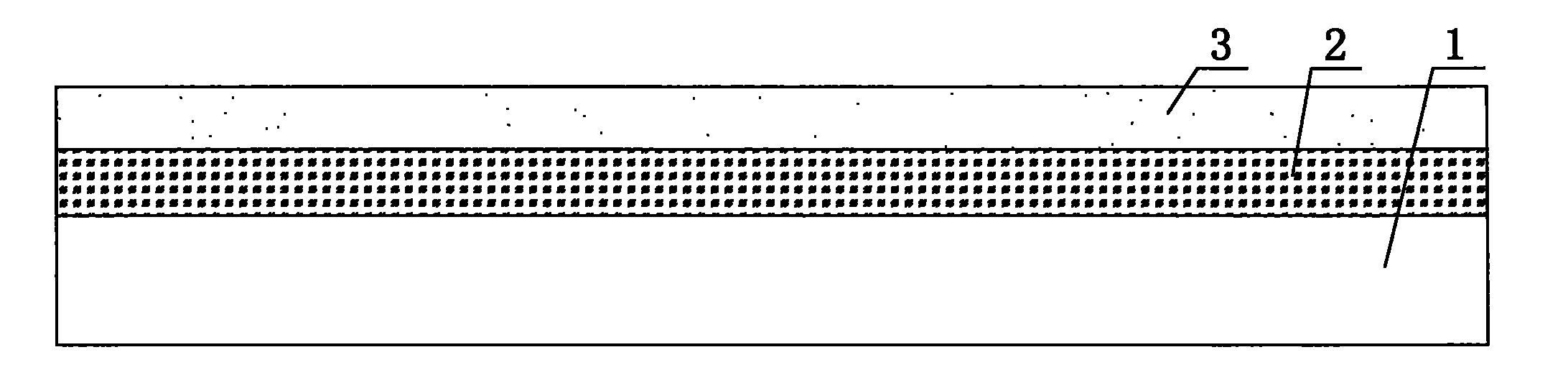

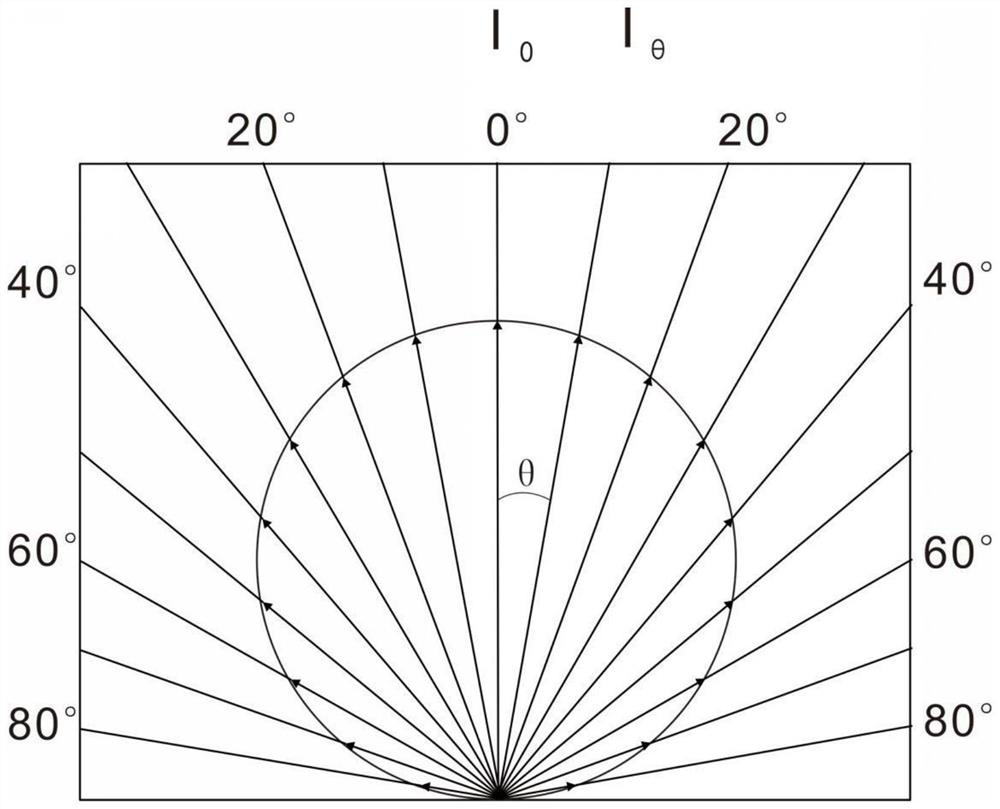

The invention discloses a light-emitting diode (LED) epitaxial structure and a manufacturing method thereof. The LED epitaxial structure successively comprises an epitaxial substrate, a leukotriene (LT)-GaN nucleating layer, a high-temperature non-doped buffer layer, a P-GaN layer, a P-AlGaN layer, a diffusion barrier layer, a multiple quantum well (MQW) luminous layer, an InGaN current expansion layer, an N-ZnO layer and a surface-coarsened ZnO layer. The manufacturing method comprises the following steps: pre-treating the epitaxial substrate; growing the nucleating layer; growing the buffer layer; growing the P-GaN layer; growing the P-AlGaN layer; growing the diffusion barrier layer; growing the MQW luminous layer; growing the InGaN current expansion layer; growing the N-ZnO layer; and growing the surface-coarsened ZnO layer. By using the LED epitaxial structure obtained by virtue of the manufacturing method provided by the invention, an excellent electrical property and a good optical property are obtained, the internal quantum efficiency and the electronic static discharge (ESD) resistance capability are improved, the lost light caused by total reflection is lowered, the external quantum efficiency is greatly improved, a high-brightness LED is obtained, and the purposes of development and sustainable development of the LED industry are greatly promoted.

Owner:中山大学佛山研究院 +1

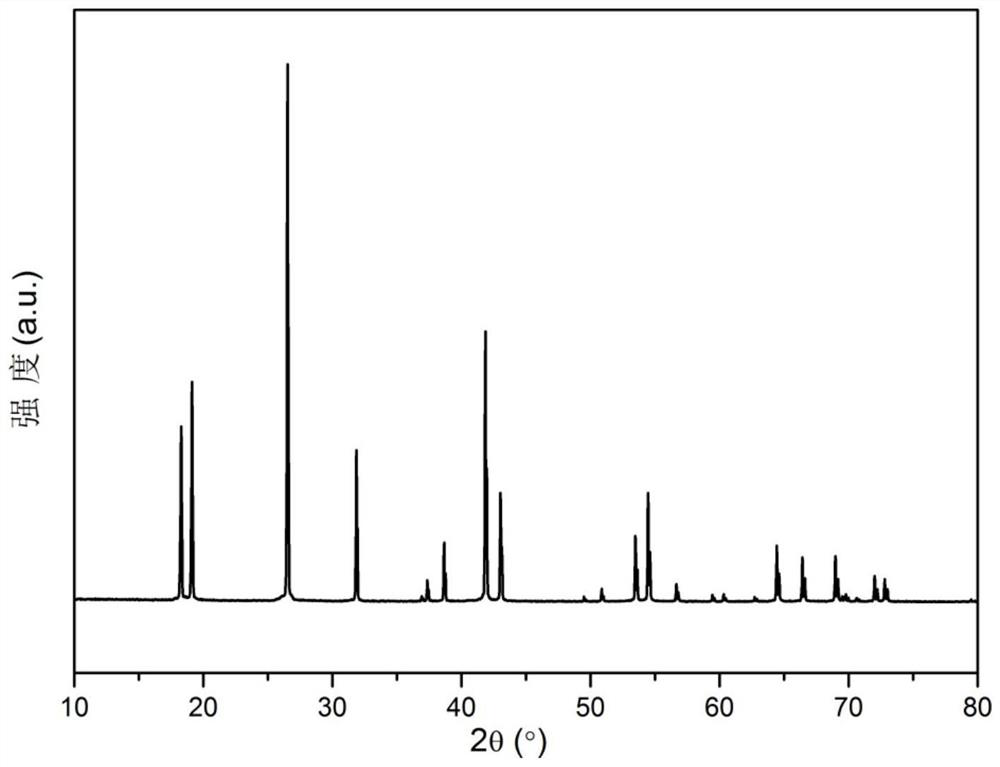

Rare-earth ligand intercalated hydrotalcite with fluorescent property and its preparing method

InactiveCN1715365AProcess stabilityFull layer structureLuminescent compositionsAnion intercalationFluorescence

The present invention provides a kind of RE complex anion intercalated hydrotalcite with fluorescent property and its preparation process. Through ion exchange, the RE complex anion enters to interlamination of the hydrotalcite to constitute laminated material with RE complex anion accounting 40-100 % of the total interlamination anion mole number; and after the RE complex intercalation enter the interlamination of the hydrotalcite, the fluorescent performance may be maintained. The present invention utilizes the intercalating and assembling performance and the laminate controlling and locating effect of laminated hydrotalcite material to assemble RE ion with excellent optical performance into interlamination of the hydrotalcite and to realize the molecule level hybridization of RE ion in interlamination of the hydrotalcite. Through regulating the laminate metal, the present invention prepares organic and inorganic hybridized luminous material with homogeneously distributed RE element and adjustable material grain size.

Owner:BEIJING UNIV OF CHEM TECH

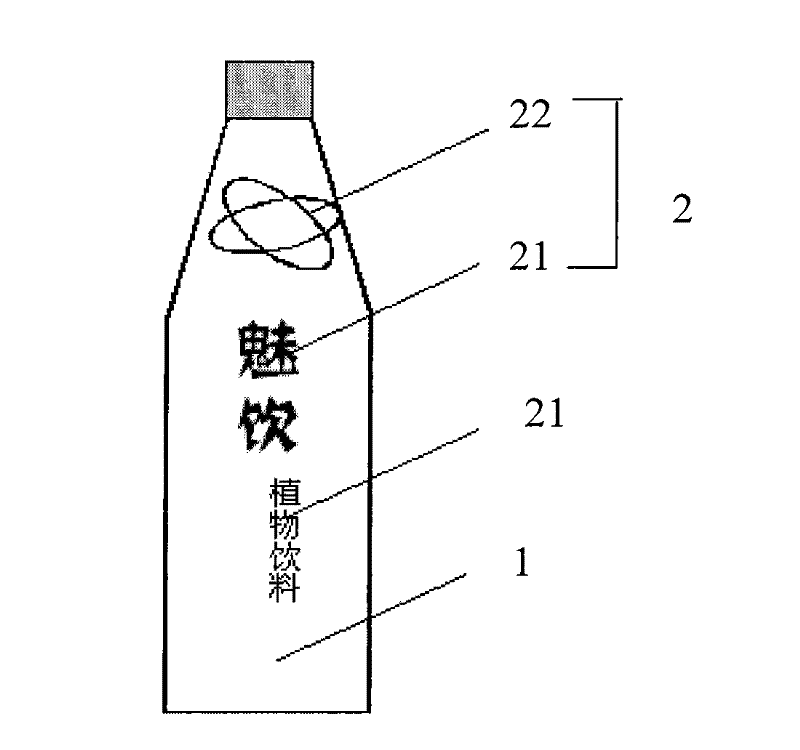

Food and beverage outer package printed with luminescent patterns

InactiveCN102133977AImprove visibilityAdd funInksCoverings/external coatingsEngineeringDefoaming Agents

The invention discloses a food and beverage outer package printed with luminescent patterns. The food and beverage outer package comprises a container for accommodating foods and beverages, wherein the outer wall of the container is provided with a luminescent ink coating for displaying the luminescent patterns; the luminescent ink coating is formed by printing luminescent ink on the outer wall of the container, and the luminescent ink is prepared from the following raw materials in part by weight: 30 to 80 parts of long afterglow fluorescent powder, 10 to 50 parts of light-transmitting glass pigment, 15 to 35 parts of suspension, 5 to 10 parts of solid dispersant and 2 to 5 parts of defoaming agent; and the fusion temperature of the suspension is not higher than 200 DEG C. Aiming at the problems that the conventional food and beverage outer packages do not have luminescent performance and striking highlighting, and the conventional luminescent ink does not have high temperature resistance and cannot be used for printing on the food and beverage outer packages, the invention provides the food and beverage outer package printed with the luminescent patterns, which can luminesce and is extremely striking in a dim environment and can resist high temperatures in the process of printing the luminescent ink coating.

Owner:郯城县瑞丰米业有限公司

Night-gloss glass printing ink, preparation method and printing method on glass product

ActiveCN101974264AGood luminous effectMaintain luminous performanceInksOther printing apparatusPrinting inkDefoaming Agents

The invention discloses night-gloss glass printing ink, a preparation method and a printing method on a glass product. The night-gloss glass printing ink is prepared from long afterglow fluorescent powder, light-transmitting glass pigment, a suspensoid agent, a solid dispersion agent and a defoaming agent. The night-gloss glass printing ink is prepared by uniformly mixing the long afterglow fluorescent powder with the light-transmitting glass pigment, adding the mixture in the fused supensoid agent, solid dispersion agent and defoaming agent, and stirring and cooling. The printing method is realized by the following steps of: silk printing night-gloss patterns on the glass product with the night-gloss ink; raising the temperature of the glass product to 520-650DEG C; and maintaining the temperature for 20-30 minutes and then cooling to obtain the finished product. The night-gloss glass printing ink is roasted silk printing ink for resisting the high temperature of 520-650DEG C and being applied to the glass product and is ink which can be quickly cured and has remarkable night-gloss effect, strong adhesive force and friction resistance; and the preparation method has simple process, and is convenient to operate and suitable for industrial production.

Owner:SHENZHEN HUAXI BIO TECH LTD

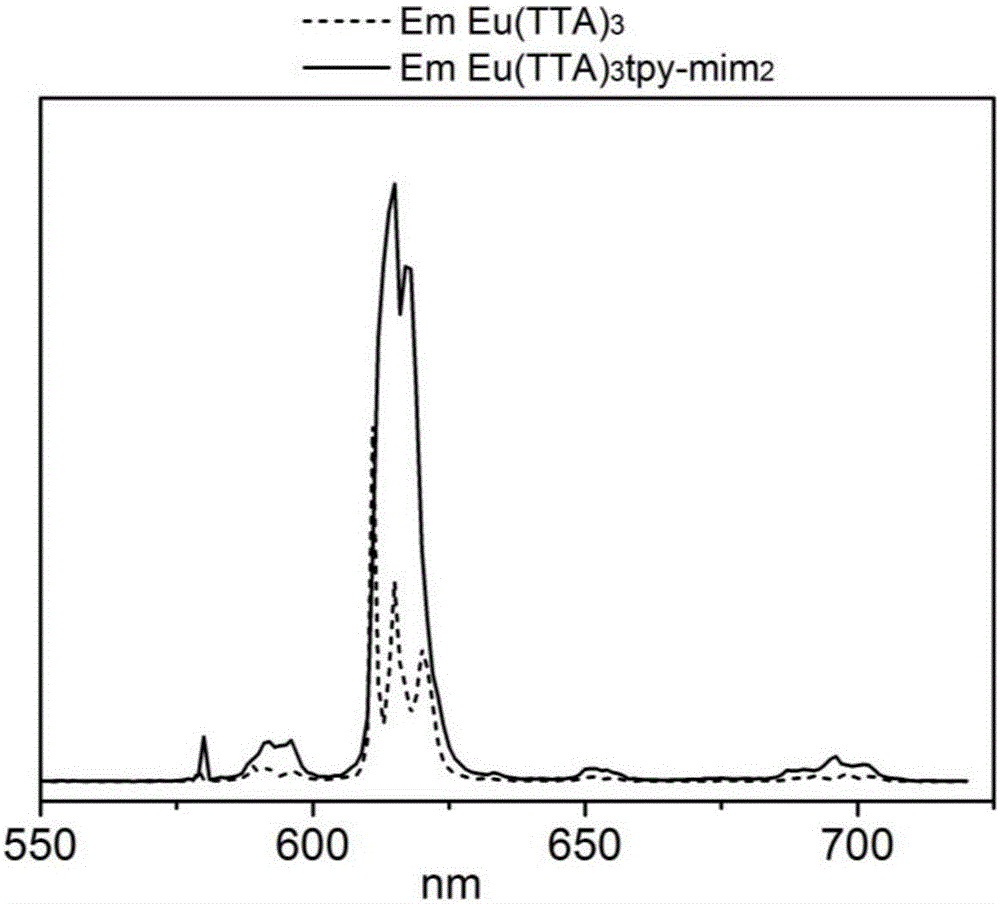

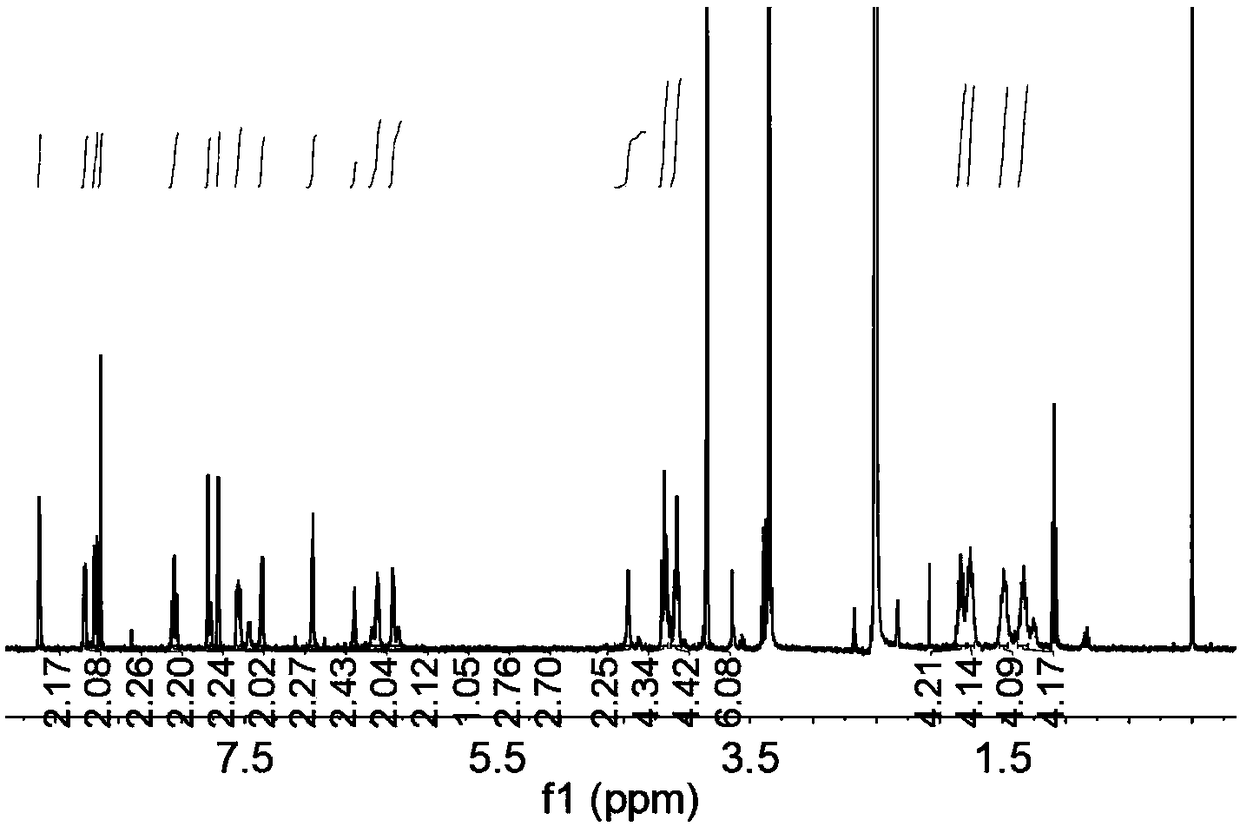

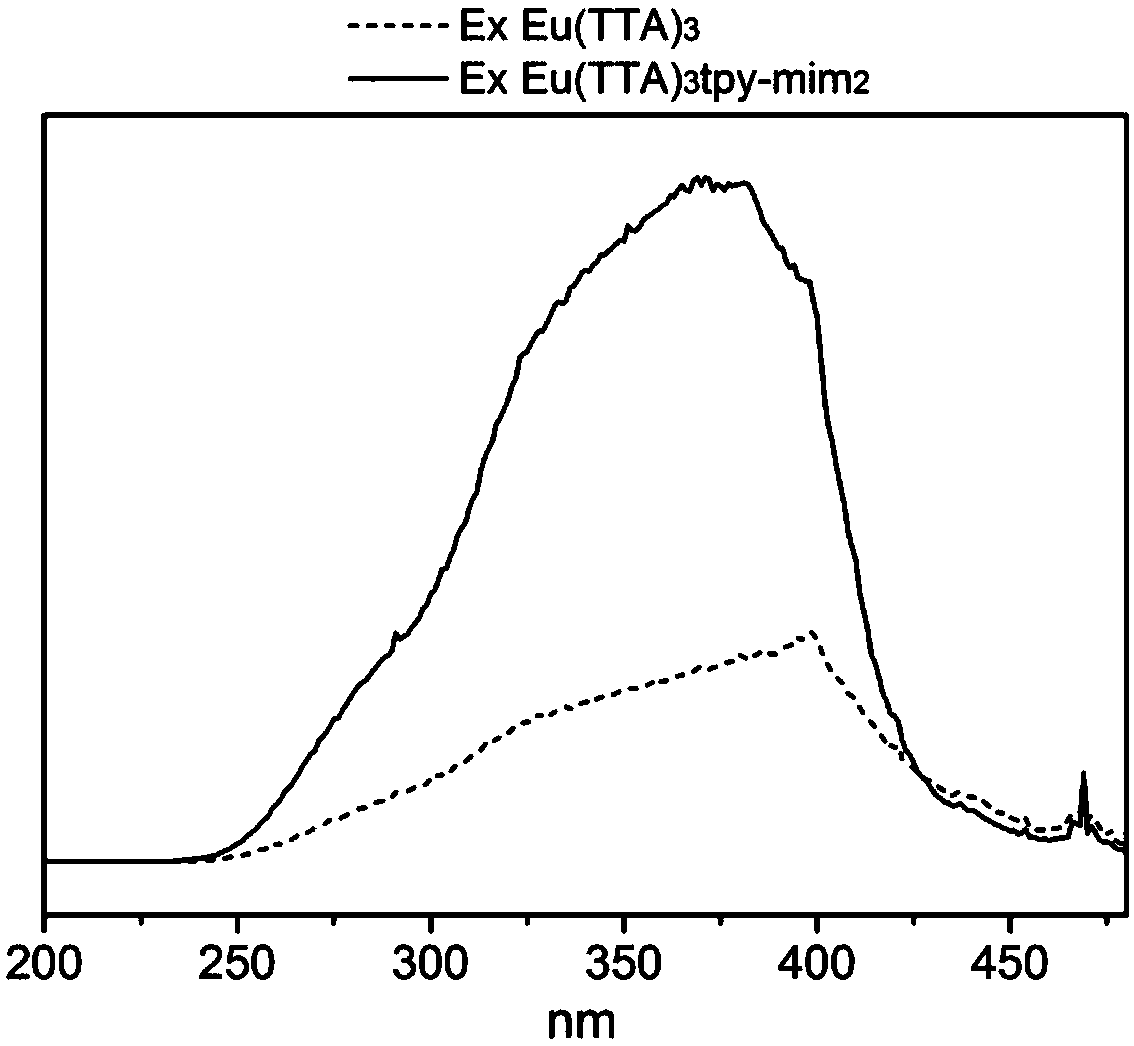

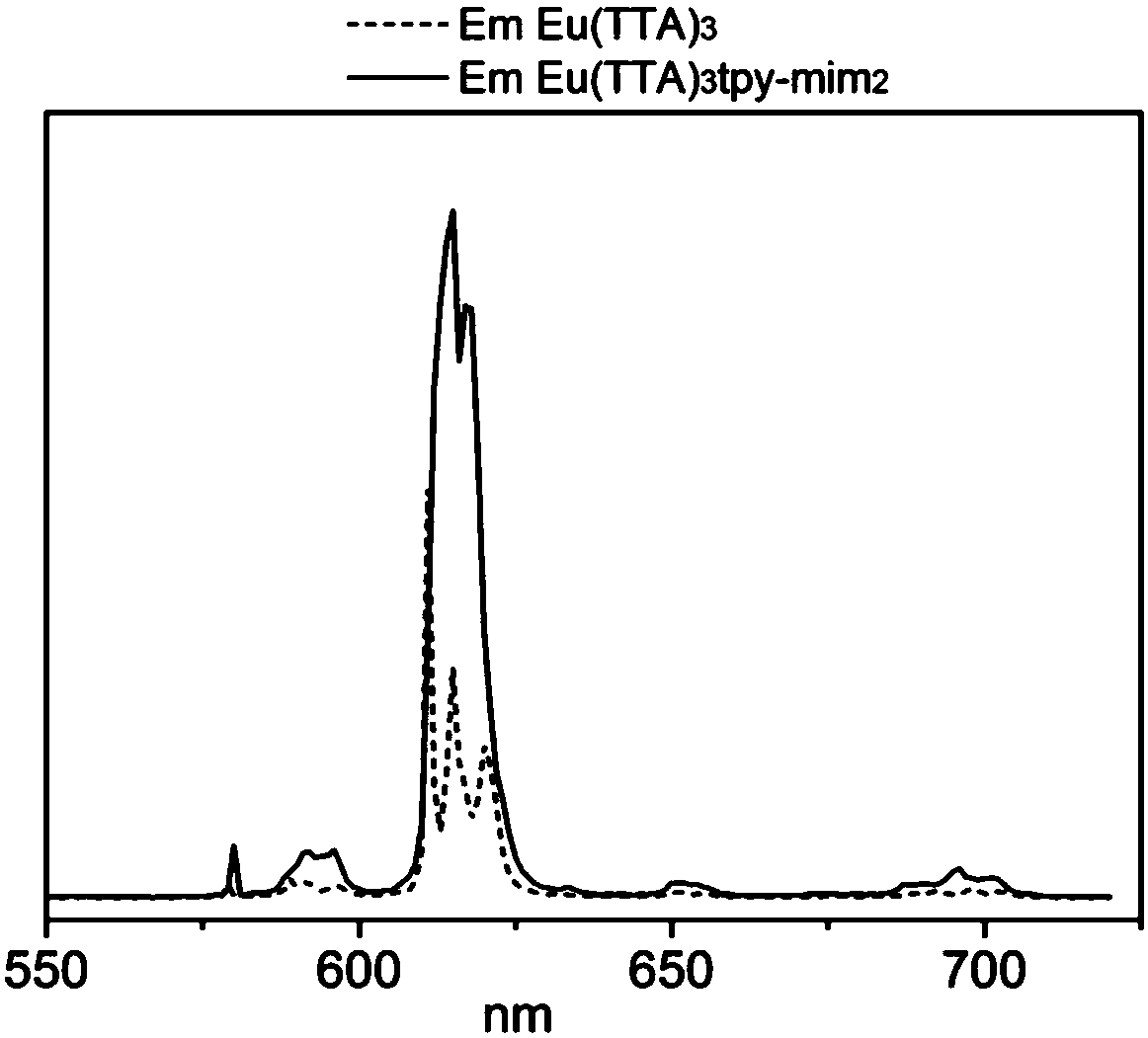

Ternary rare earth complex and application of complex in preparing high-strength hybrid luminous hydrogel

ActiveCN106432297AHigh transparencyHigh mechanical strengthGroup 3/13 organic compounds without C-metal linkagesLuminescent compositionsEnvironmental resistanceStructural formula

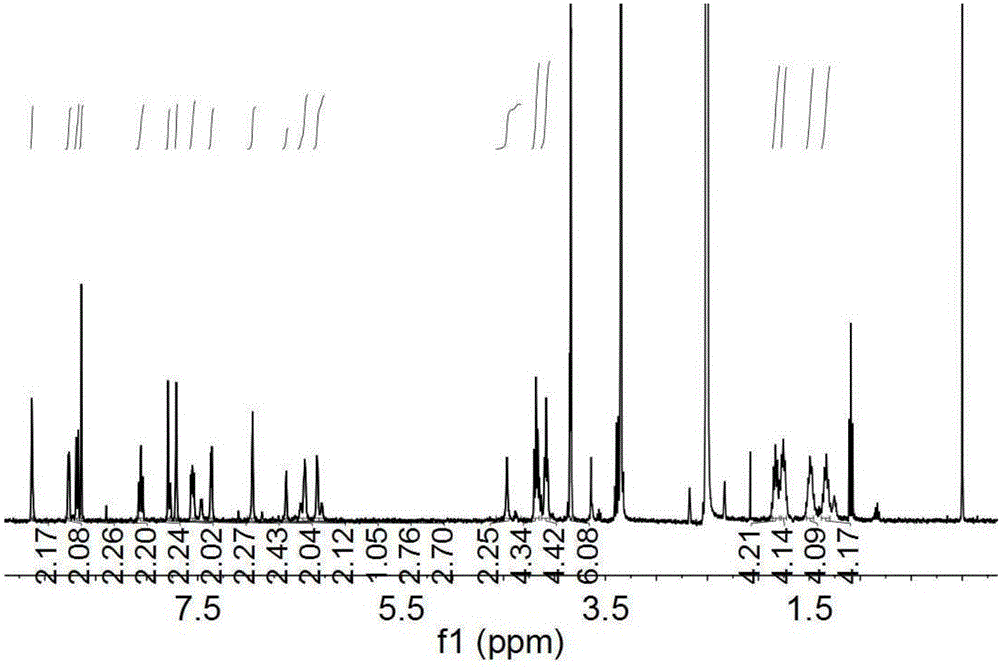

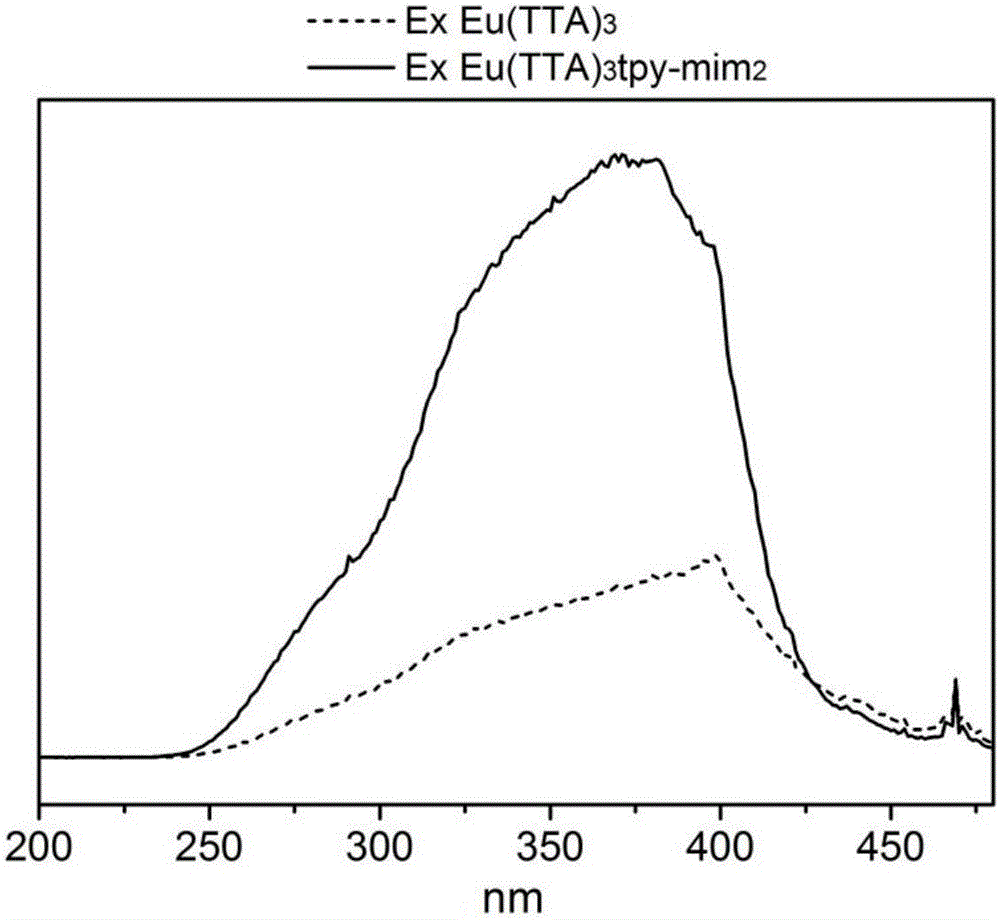

The invention provides a ternary rare earth complex and application of the complex in preparing high-strength hybrid luminous hydrogel. The chemical structural formula of the ternary rare earth complex is shown as follows. First terpyridyl bridged imidazolium salt is used for being combined with a rare earth beta-diketone complex to form a ternary complex, the ternary complex can be self-assembled in water to form a micellar structure, and then rare earth ions and ASPA are isolated through the collaborative protection on the rare earth ions by the ternary complex and the micellar structure, so that the aim of preparing a hydrogel which is good in luminescence property and high in mechanical strength is achieved. The hydrogel uses water as a medium, the preparation method is simple, easy and environmentally friendly, and a volatile organic solvent is avoided from being used. Please see the formula in the description.

Owner:HEBEI UNIV OF TECH

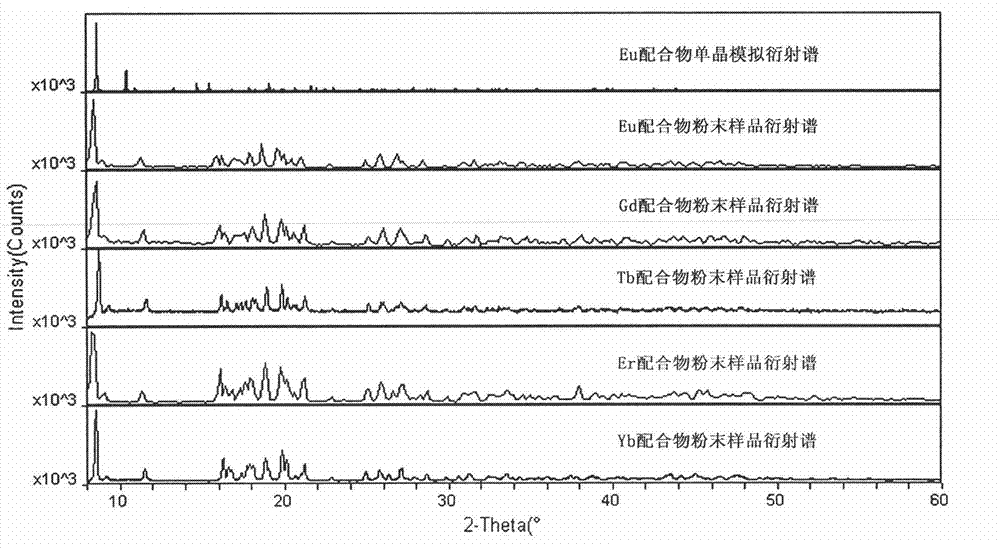

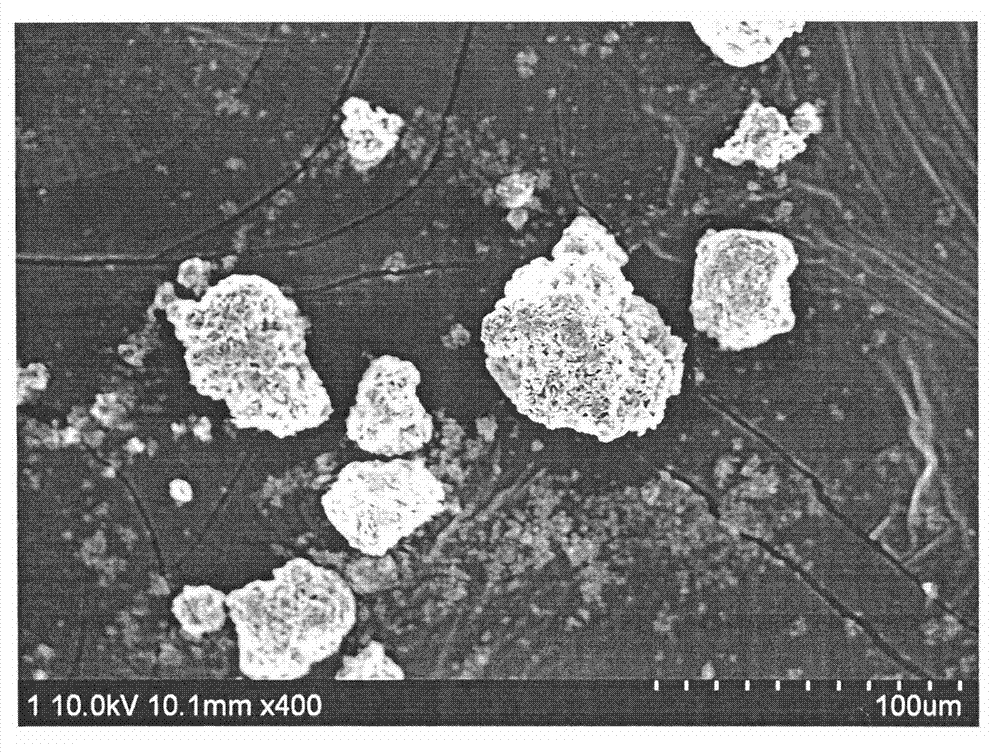

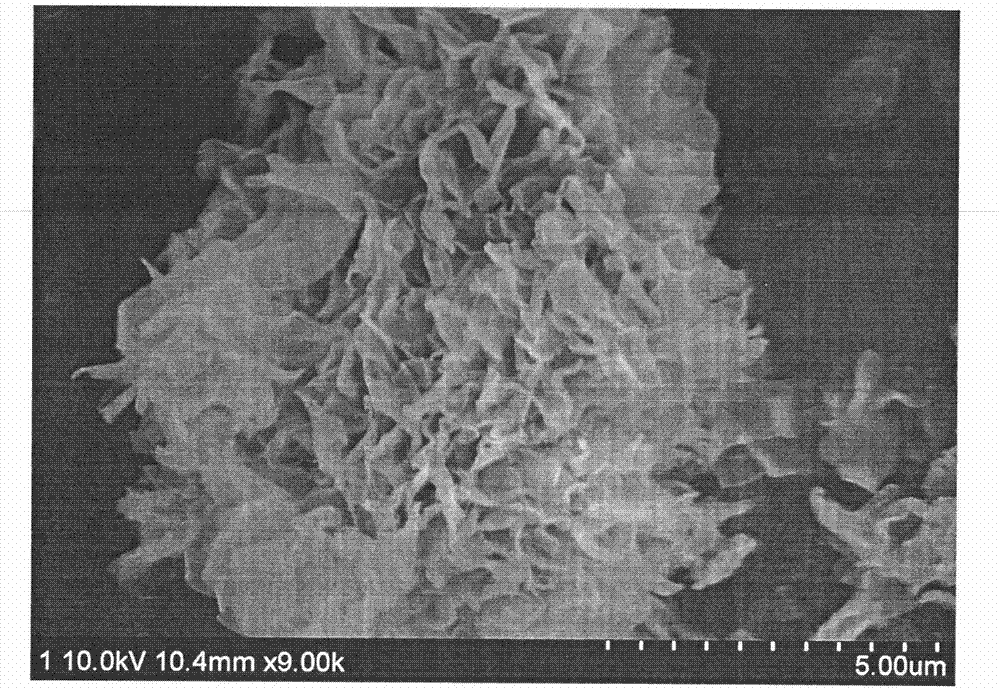

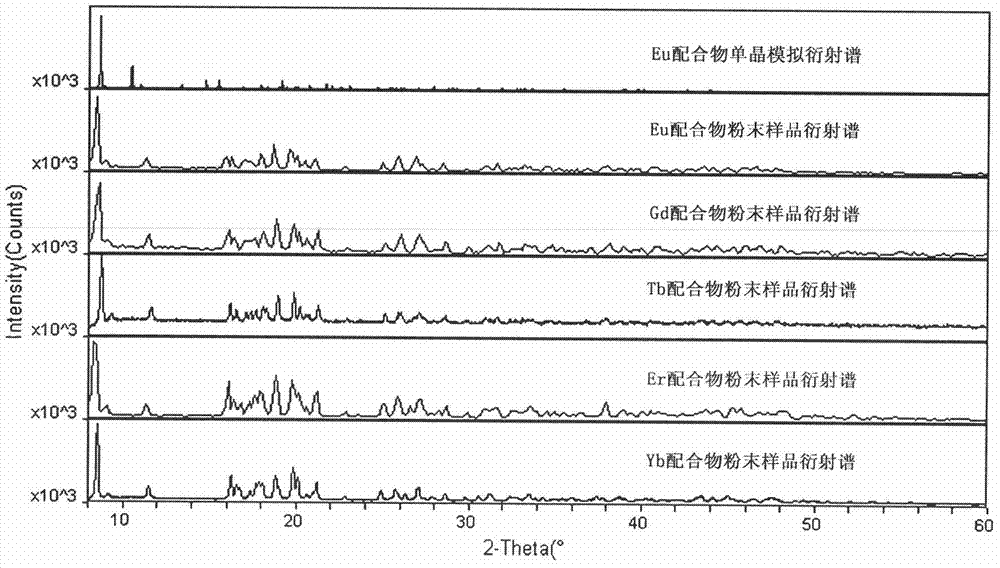

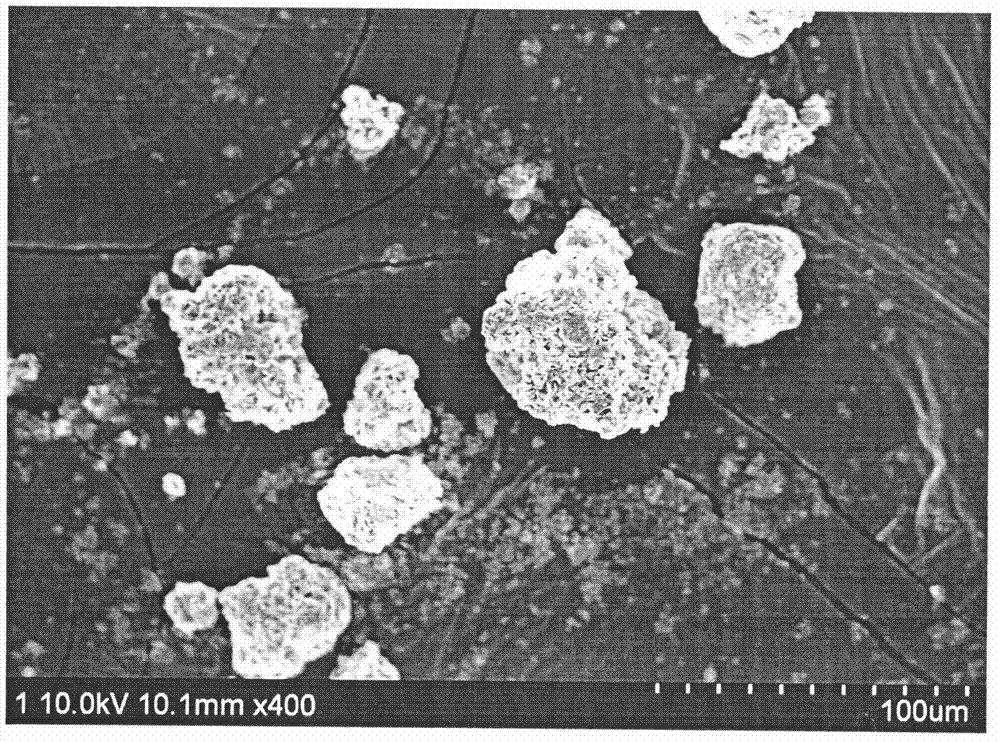

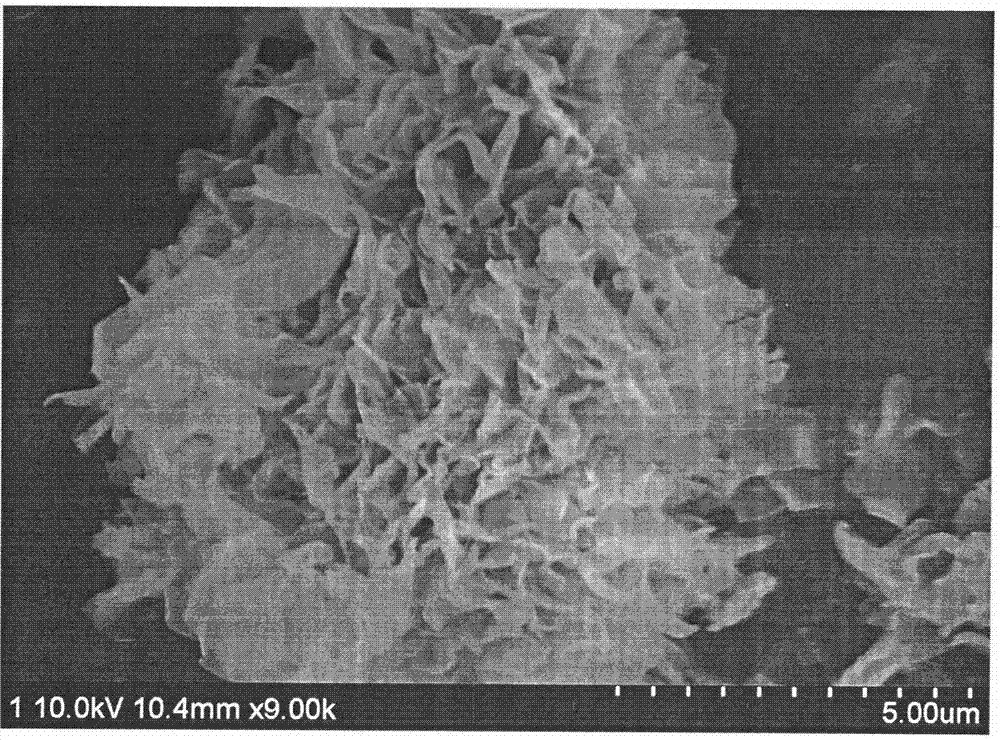

Rare-earth complex nano luminescent material

InactiveCN102827193AMaintain luminous performanceLow costGroup 3/13 element organic compoundsLuminescent compositionsRare-earth elementChemistry

The invention discloses a rare-earth complex nano luminescent material. The rare-earth complex nano luminescent material is obtained by performing controlled coordination reaction on rare-earth nitrate aqueous solution and mixed aqueous solution of ligand; the formula structure of the rare-earth complex nano luminescent material is [Ln(ad)0.5(phth)(H2O)2], wherein in the formula, Ln is single rare-earth element Eu, Tb or double rare-earth element of combination of Eu and Yb, or combination of Tb and Gd; in the formula, ad and phth are respectively organic ligand adipic acid and phthalic acid; the nano luminescent material is in nano sheet appearance; and the nano sheets can be mutually gathered to form flower-shaped appearance. The single rare-earth material and the double rare-earth doping material are strong fluorescent material; particularly, when the Gd-Tb double rare-earth material contains only 10% of Tb, the luminescent strength is nearly same as that of the pure Tb material. Therefore, the luminescent material has the advantages of nano materials; and moreover, the cost can be reduced through doping, thus, the rare-earth complex nano luminescent material has wide application prospect.

Owner:CHINA JILIANG UNIV

Outdoor fluorescent wood-plastic floorboard and preparation method thereof

The invention discloses an outdoor fluorescent wood-plastic floorboard. The preparation method comprises the following steps: adding a luminous pigment into the wood-plastic floorboard raw materials, wherein the luminous pigment is an organic modified fluorescent material; mixing, treating by a melt plasticizing facility, and carrying out molding formation to obtain the integrally-luminous fluorescent wood-plastic floorboard; or mixing the organic modified fluorescent material used as the luminous pigment with a wood-plastic floorboard coextrusion material, adding the mixture into a side extrusion hopper of a coextruder, coextruding with the raw materials of the main extruder wood-plastic floorboard, and carrying out mold extrusion formation to obtain a surface coextruded wood-plastic floorboard, thereby obtaining the surface-luminous fluorescent wood-plastic floorboard. The invention also discloses a preparation method of the outdoor fluorescent wood-plastic floorboard. The method disclosed by the invention can be used for preparing the fluorescent wood-plastic product with uniform color, favorable durability and favorable luminescence, and the fluorescent wood-plastic product has the effects of dim light indication and decoration.

Owner:SHANDONG XIAGUANG INDAL

Fabrication method of LED device

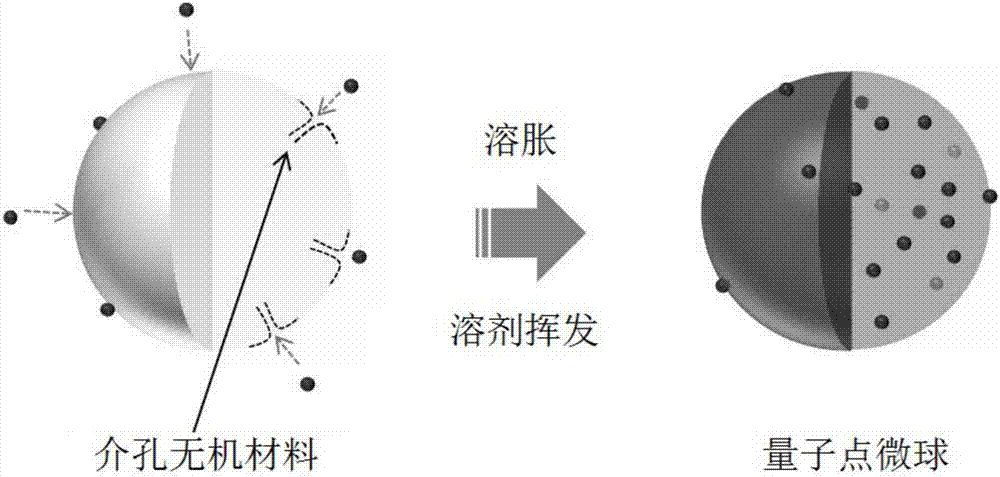

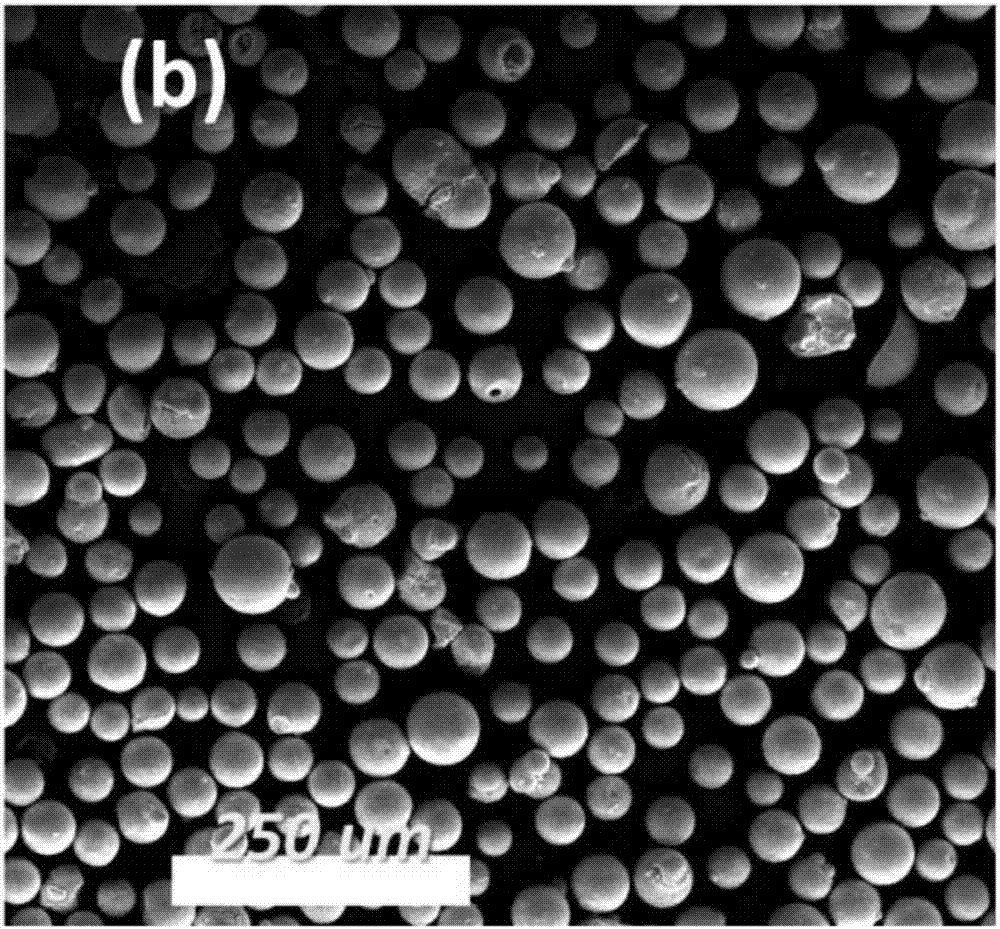

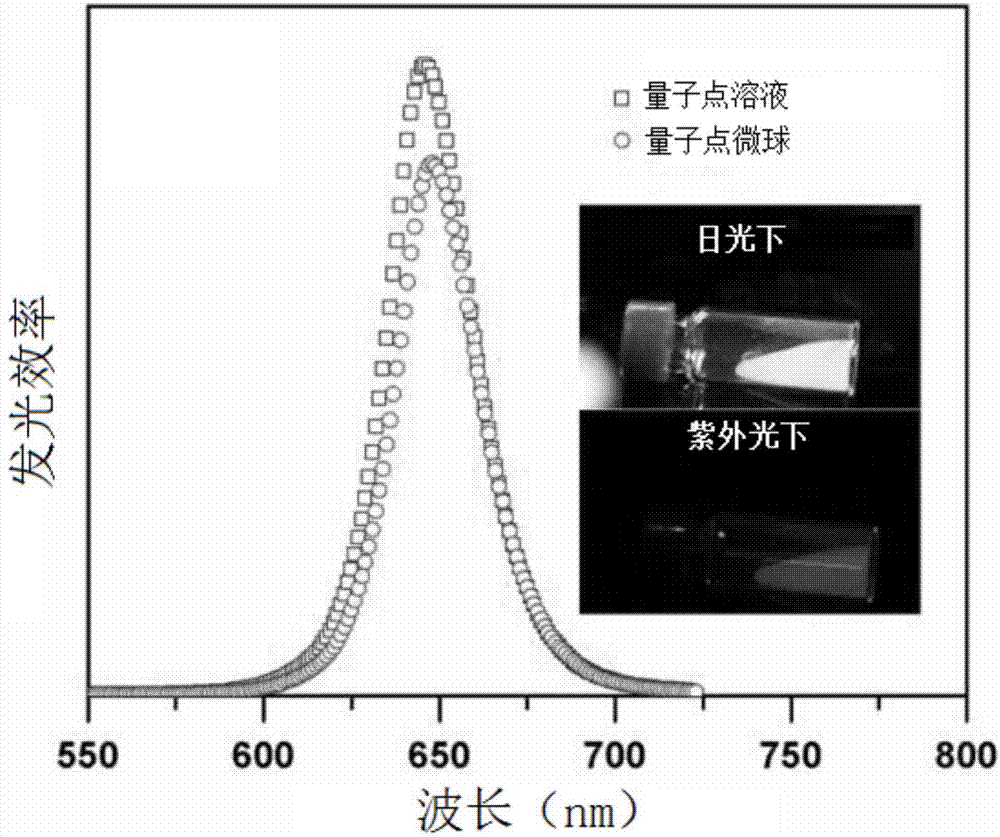

ActiveCN107342348AHigh light transmittanceGood thermal conductivitySemiconductor devicesMicrosphereQuantum dot

The invention discloses a fabrication method of an LED device. Graphene is introduced to a quantum dot-LED package system, while the graphene can be directly combined with a quantum dot to cause the quantum dot to be quenched when the graphene and a quantum dot are directly mixed for a quantum dot-LED device. According to the fabrication method, a quantum-dot microsphere is used for substituting quantum-dot powder in a traditional LED device, the quantum-dot microsphere is employed to be mixed with the graphene, the quantum dot can be prevented from being quenched, the luminous performance of the quantum dot can be effectively maintained, and high light conversion efficiency and high luminous efficiency of the LED device are ensured.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

Method for implementing transfer of up-conversion nanocrystals from oil phase to aqueous phase

InactiveCN102241968AMaintain luminous performanceGood experimental repeatabilityLuminescent compositionsBiocompatibility TestingOil phase

The invention belongs to the technical field of functional inorganic nanocrystal surface modification, and relates to a method for transferring oil-soluble up-conversion nanocrystals to an aqueous phase so as to improve the biocompatibility of the up-conversion nanocrystals. The method comprises the following steps of: dissolving 0.02 to 0.2g of small molecular surfactant in 10 to 20ml of water in a room temperature open system; and adding 1 to 4 ml of up-conversion nanocrystal solution prepared by dissolving up-conversion nanocrystals in a low boiling point organic solvent, and heating to the temperature of between 55 and 80DEG C to volatilize the organic solvent so as to obtain the water-soluble up-conversion nanocrystals. By lyophobic-lyophobic interaction of the small molecular surfactant and ligands on the surfaces of the up-conversion nanocrystals, stable coating layers are formed, and the hydrophobicity of the surfaces of the nanocrystals is changed to hydrophilcity. The method is easy and convenient to implement; different surfactants can be introduced according to requirements; a problem that the up-conversion nanocrystals are hardly transferred from the oil phase to the aqueous phase is solved; and the method provides a reaction platform for coupling the up-conversion nanocrystals with biomolecules and other materials.

Owner:JILIN UNIV

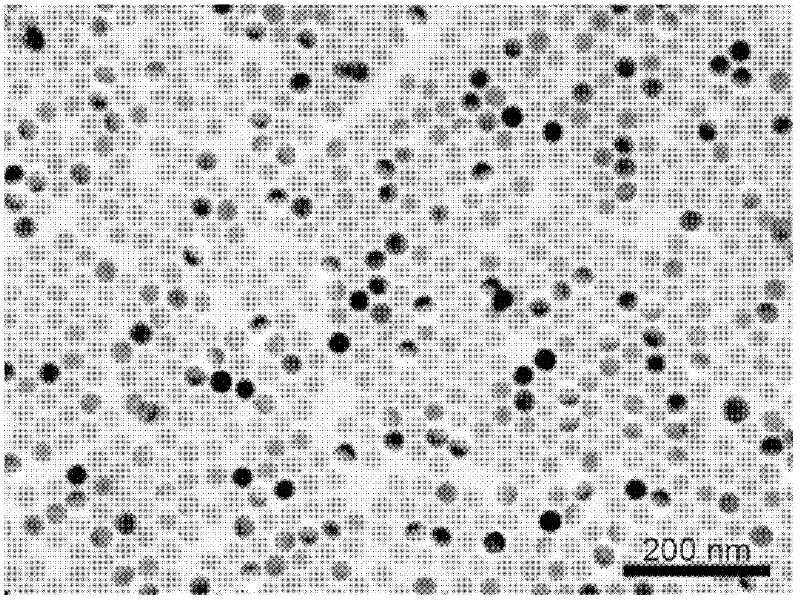

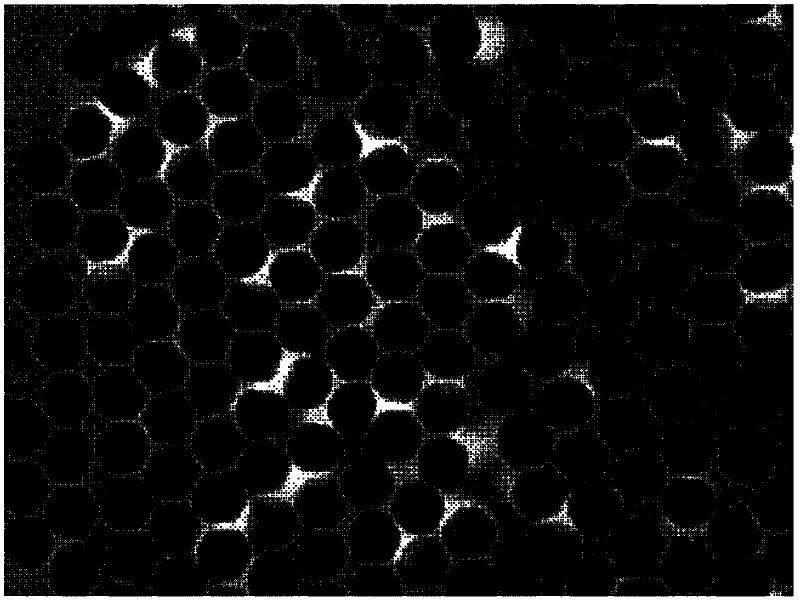

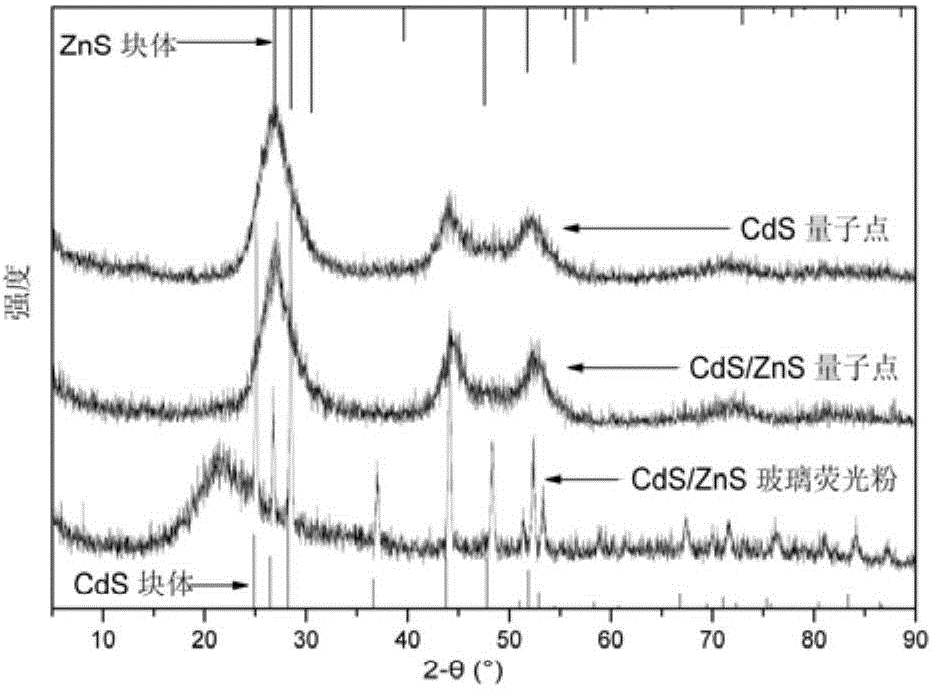

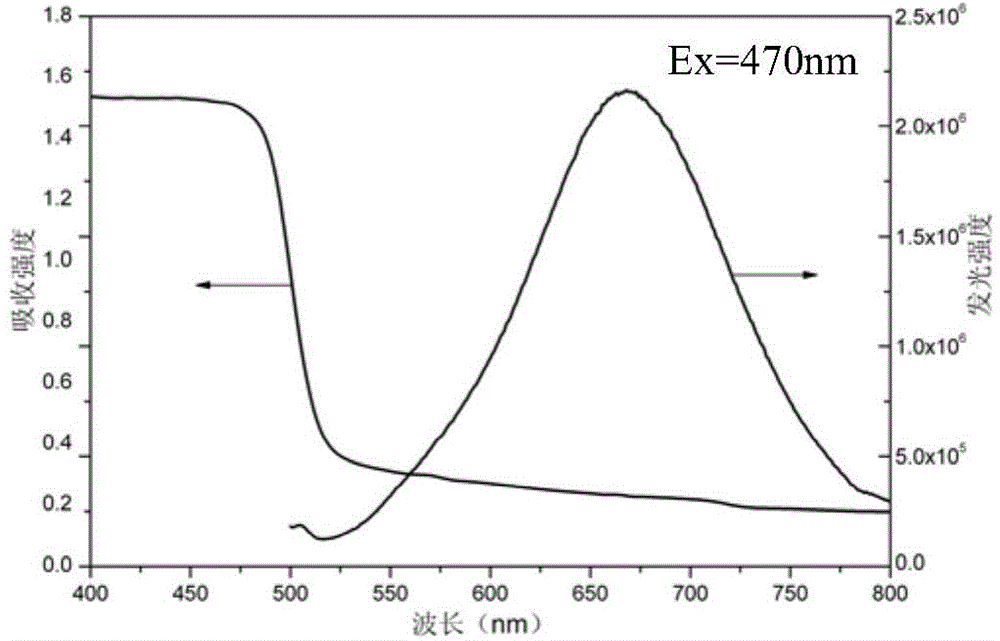

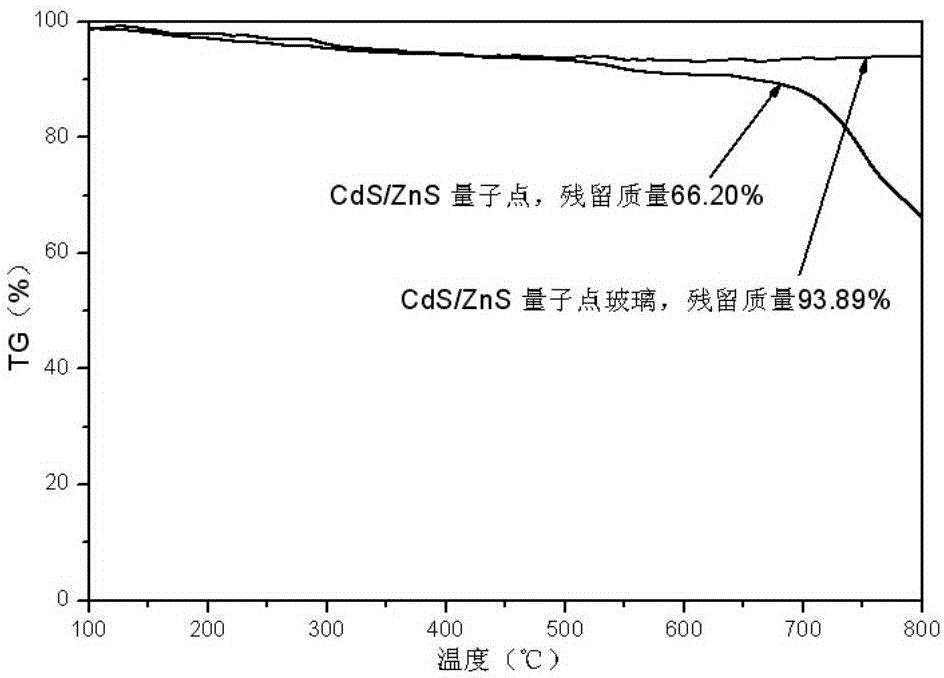

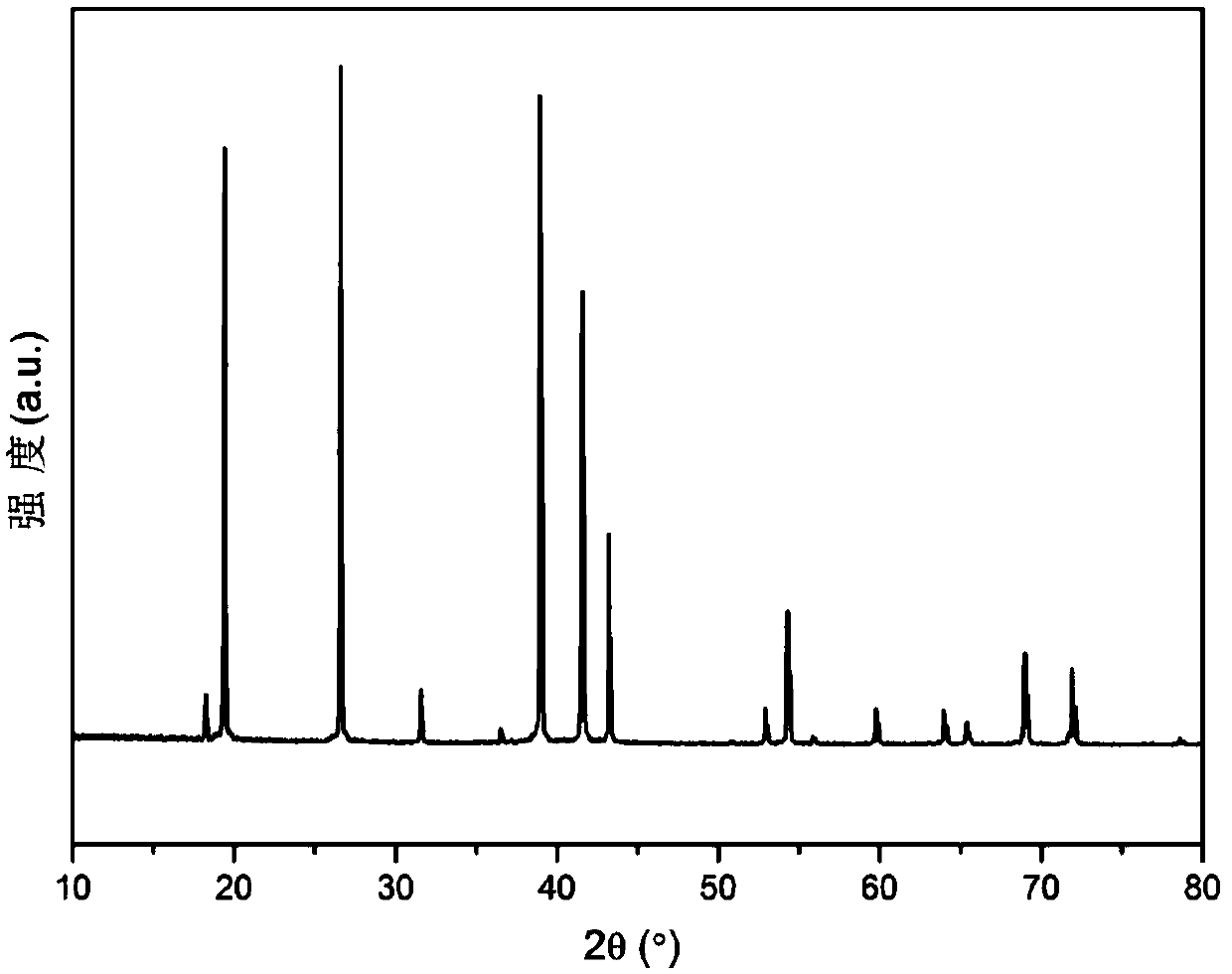

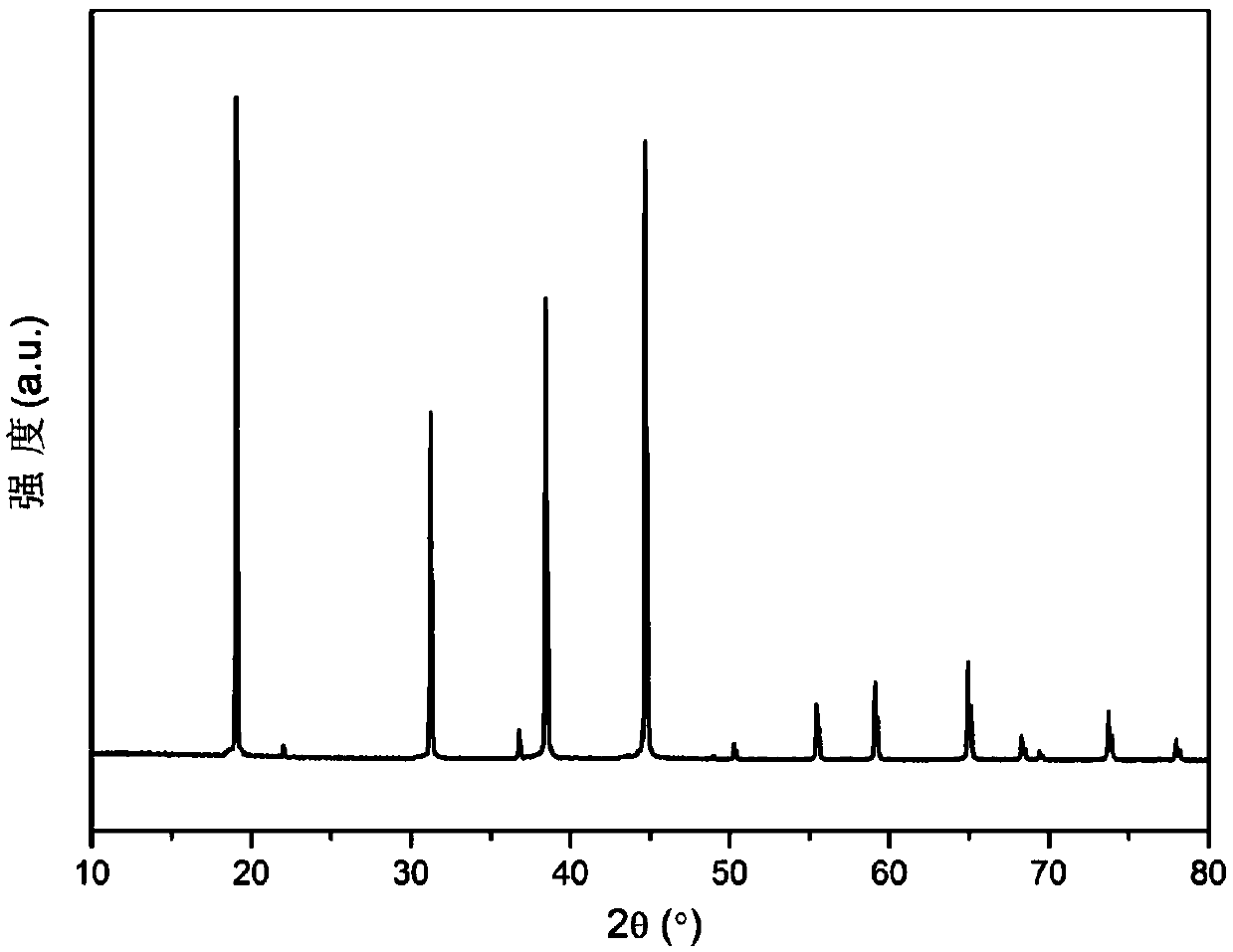

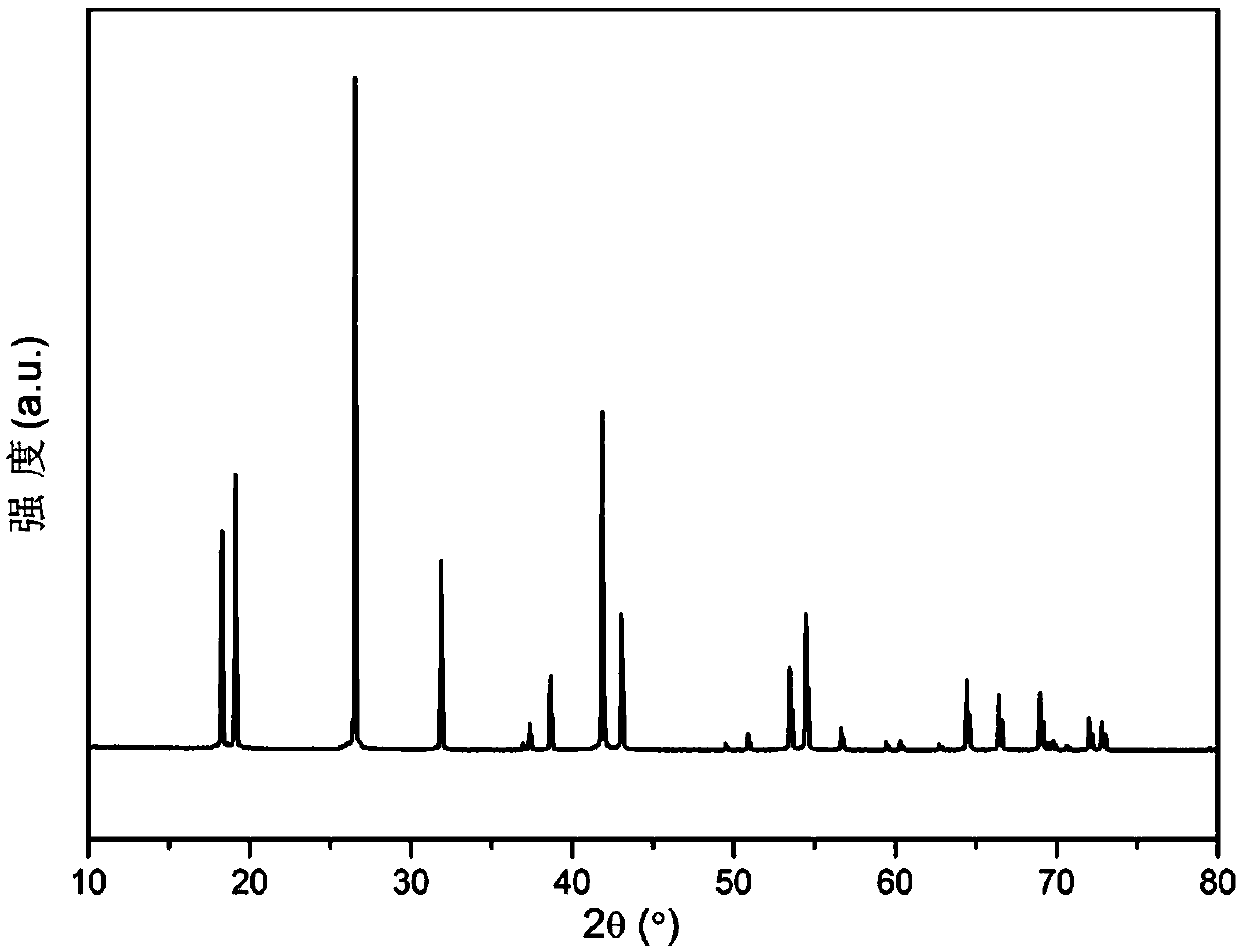

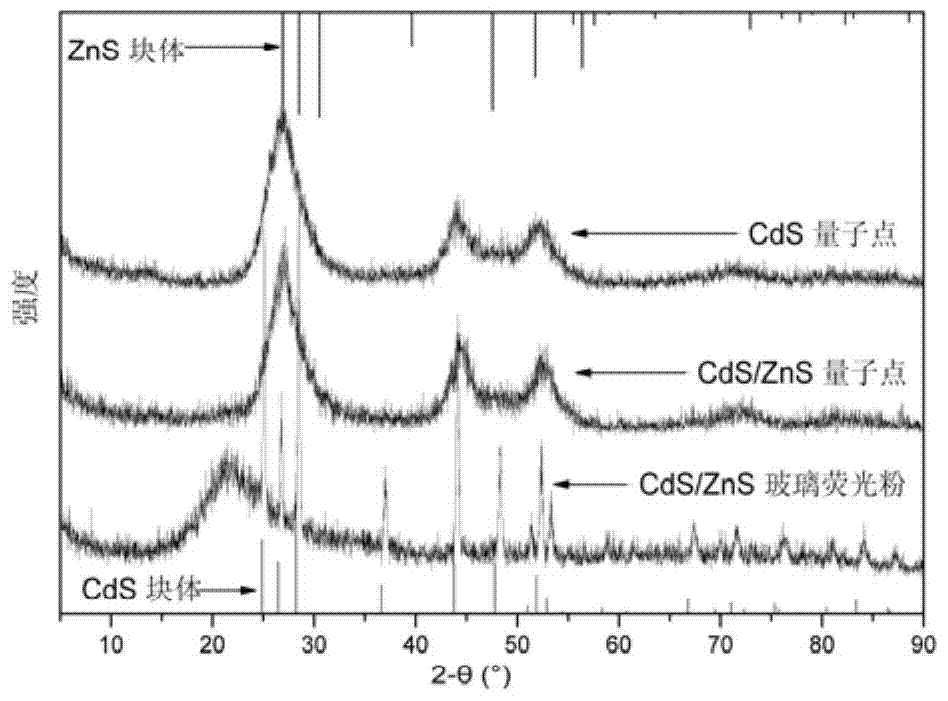

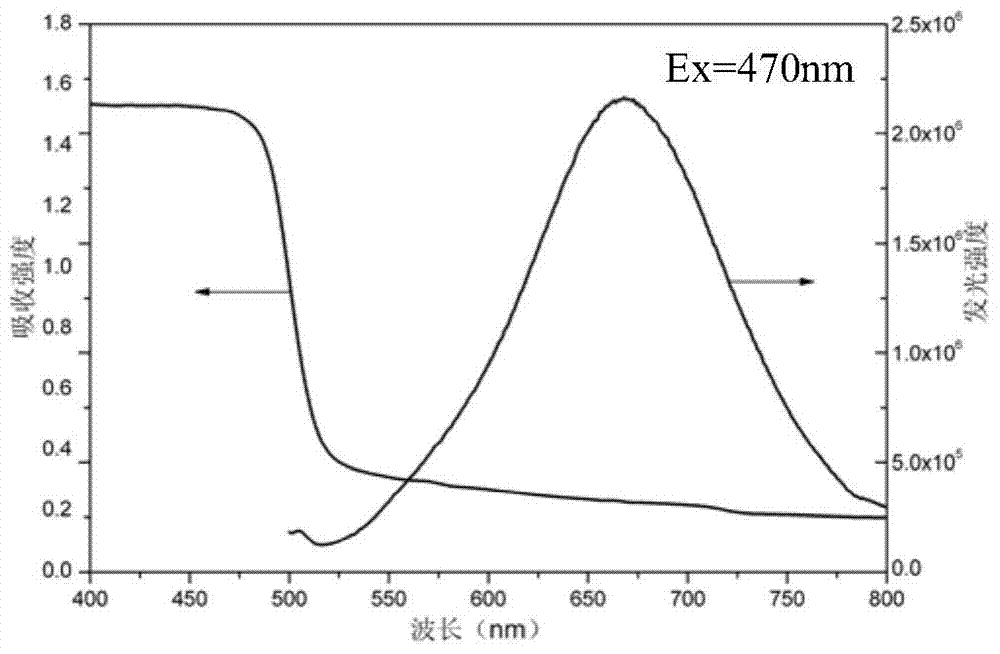

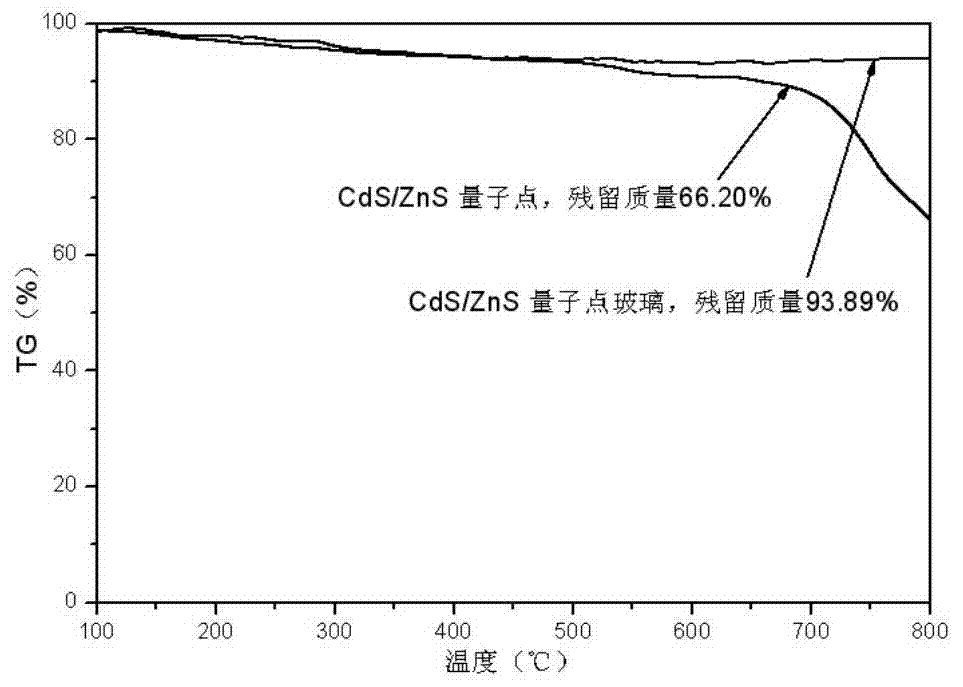

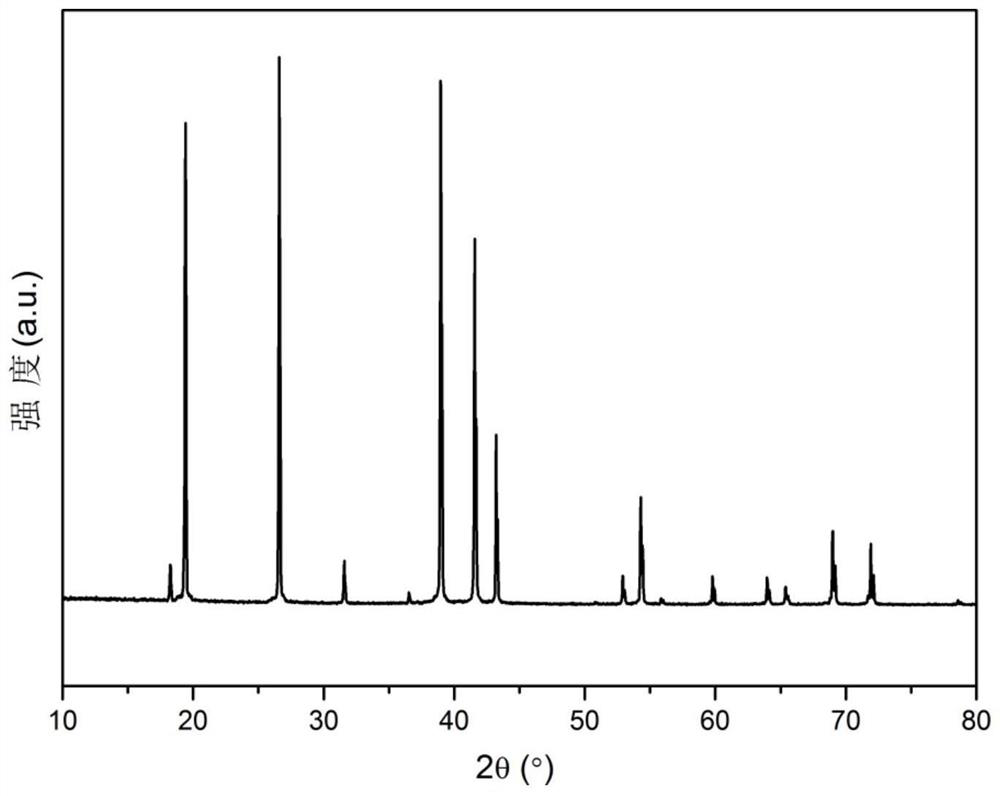

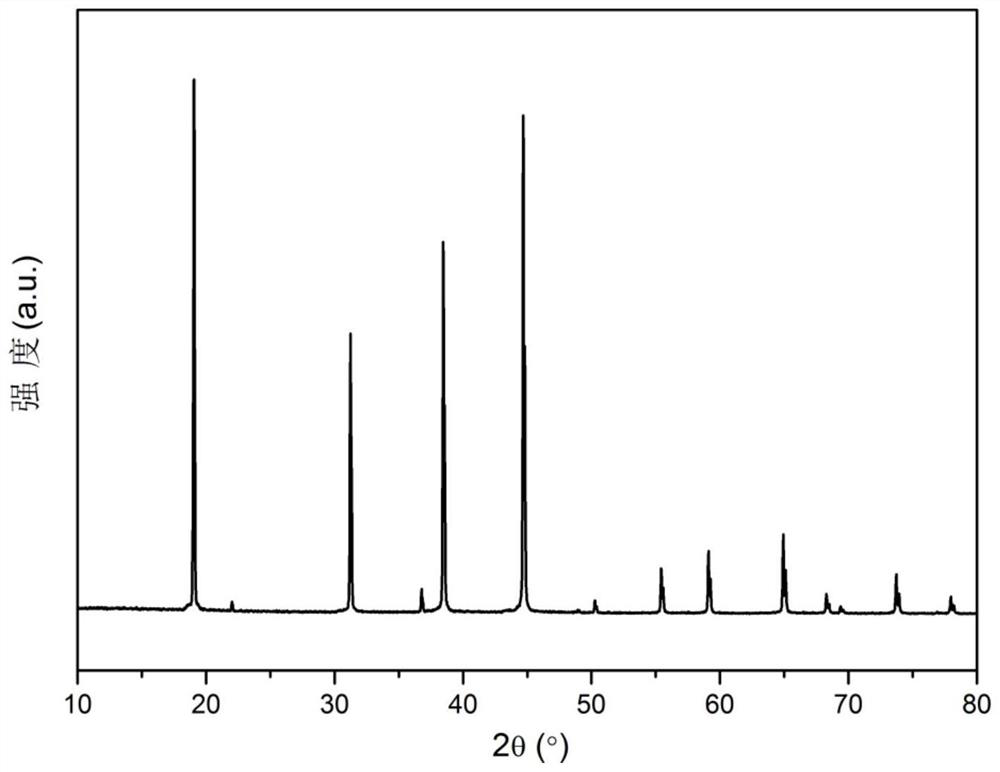

Quantum dot glass phosphor powder as well as preparation method and application thereof

ActiveCN104876441AGood luminous stability at high temperatureSimple preparation processTransmittanceQuantum dot

The invention relates to quantum dot glass phosphor powder as well as a preparation method and application thereof. The quantum dot glass phosphor powder is prepared from the following raw materials in percentage by weight: 1%-15% of a quantum dot material and 85%-99% of a silicon-based mesoporous material. The preparation method is as follows: sintering the quantum dot material and the silicon-based mesoporous material. The quantum dot glass phosphor powder is applied to a white-light LED (light-emitting diode) apparatus, an LED display, an LED backlight source, a signal indicator and an indicator for illumination. The quantum dot glass phosphor powder with different luminous intensities and transmittance is obtained by adjusting the quantum dot doping concentration; and the quantum dot glass phosphor powder with different luminous positions is obtained by adjusting the reaction conditions and selecting different single-quantum dot or core-shell quantum dot materials. The matrix material provided by the invention is quartz glass, and has good heat stability; the luminescence property of the quantum dot can be well kept; the high-temperature luminous efficiency of the quantum dot can be ensured; and meanwhile, the quantum dot glass phosphor powder is simple in preparation technology, energy-saving and environmentally friendly, so that the quantum dot glass phosphor powder has a good application prospect.

Owner:DONGHUA UNIV

Surface modification method of fluoride luminescent material, and fluoride luminescent material prepared by method

ActiveCN111171815AImprove corrosion resistanceReduce surface defectsEnergy efficient lightingLuminescent compositionsQuantum yieldQuantum efficiency

The invention relates to a surface modification method of a fluoride luminescent material, and the fluoride luminescent material prepared by the method. According to the invention, a matrix material AxMFy:Mn<4+> coated with an inorganic coating layer AxMFy, and an organic solution containing metal phosphate or alkoxy silane or an organic carboxylic acid substance or organic amine, and the obtainedmixed solution is subjected to evaporation drying to obtain the surface-modified fluoride luminescent material co-coated with the organic coating layer-inorganic coating layer; according to the coating method, the corrosion resistance of the fluoride fluorescent powder is remarkably improved, the luminous intensity retention rate and the quantum efficiency retention rate of the modified fluorescent powder reaches 85-95% in a high-temperature and high-humidity environment, and the fluoride fluorescent powder can be widely applied to the field of white light LED backlight source display; afterinorganic coating, the surface defects of the fluorescent powder are reduced, and the luminous intensity and the quantum yield of the fluorescent powder are improved by 5%-15%; after coating with theorganic coating layer, the luminous intensity reducing of the fluorescent powder is less than 3%; and the surface modification method provided by the invention has the advantages that the preparationtemperature is low, the time is short, the process is easy to control, and the surface modification method is suitable for industrial large-scale preparation.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

Fluorescence wood plastic decorative board and preparation method

This invention discloses a kind of fluorescence wood plastic decorative board and preparing method thereof, the key technical point is adopting organic modification treated fluorescence material as luminous pigment, and adding it to wood plastic compound material, then plasticize and mix and fix pattern by mold, then the fluorescence wood plastic decorative board is got. This preparing method can solve the compatibility of inorganic luminous pigment and wood plastic, and the blackening problem of luminous pigment during wood plasticized material process, the prepared fluorescence wood plastic decorative board has even tint, good mechanical performance and luminous performance, and can be widely applied to building indoor and outdoor decoration for weak light indication and beautification.

Owner:SHANDONG XIAGUANG INDAL

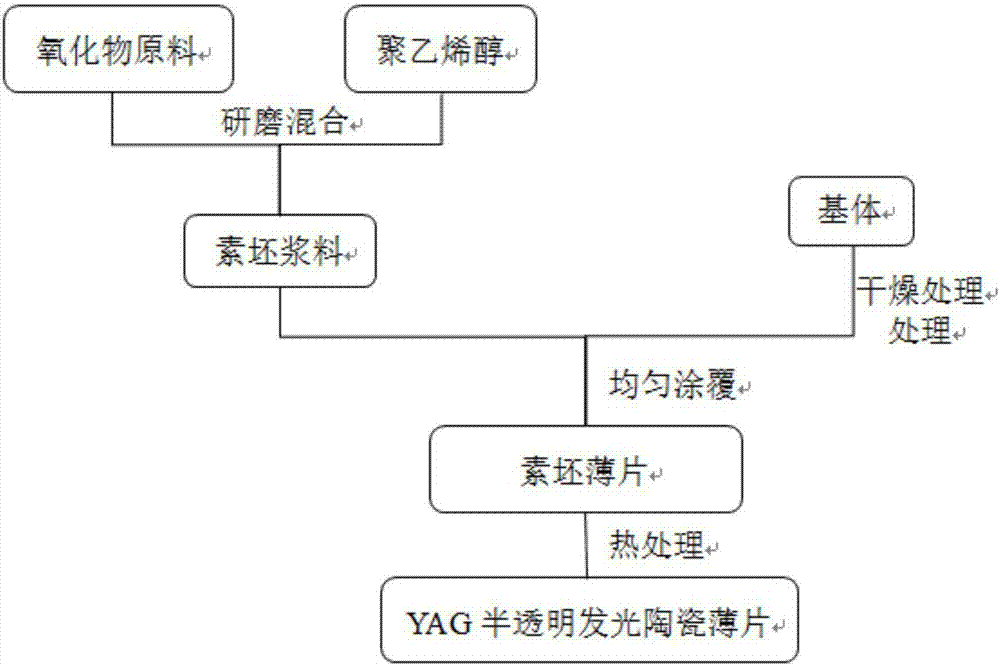

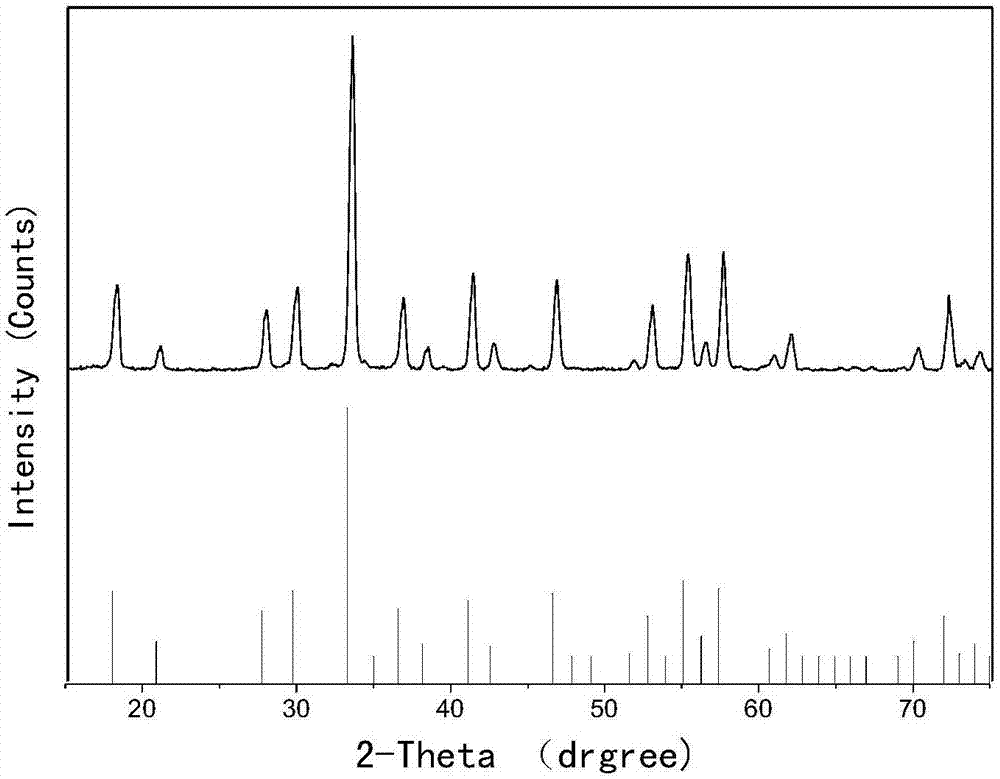

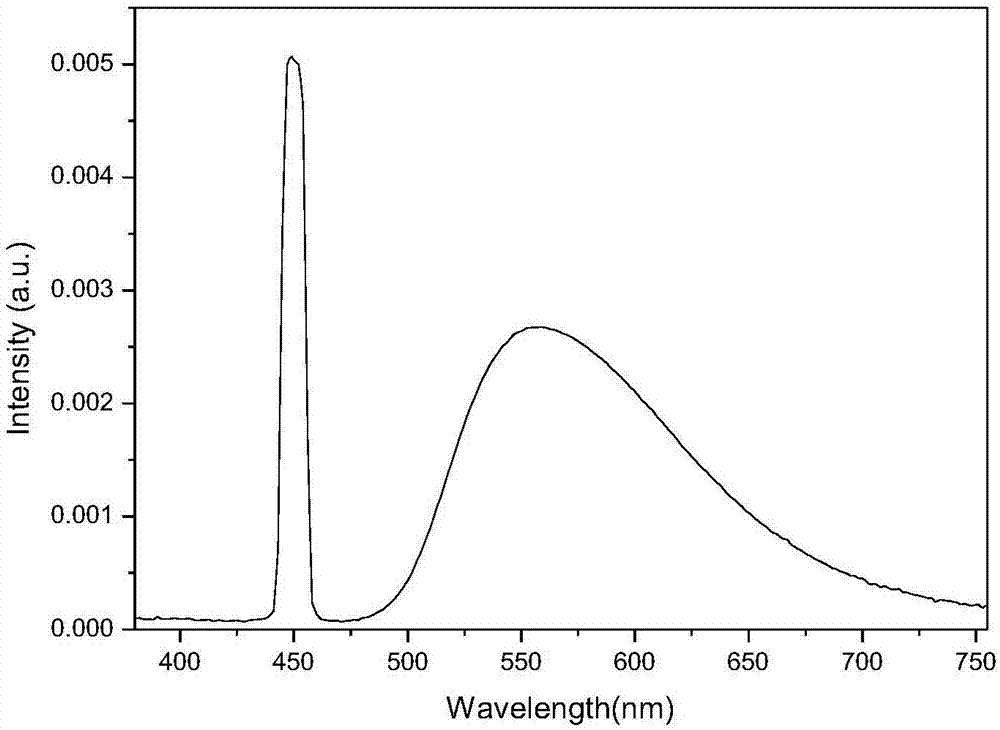

Preparation method for semitransparent YAG fluorescent ceramic sheet

The invention belongs to the technical field of an illuminating material and especially relates to a preparation method for a semitransparent YAG fluorescent ceramic sheet. The method comprises the following steps: uniformly mixing oxides, such as, yttria and aluminum oxide; mixing adhesive, dispersing agent and precursor and preparing into a biscuit sizing agent; in-situ curing and drying the biscuit sizing agent and then acquiring a biscuit sheet; uniformly coating the biscuit sheet on a mould utilizing a coating tool; standing, airing and then taking off; placing the biscuit sheet into a reducing atmosphere furnace for calcining for 4-7 hours under the calcining temperature at 1300-1800 DEG C, thereby acquiring the required ceramic sheet. According to the invention, the ceramic biscuit is compounded under normal temperature and normal pressure; a high temperature solid phase method is adopted for compounding the ceramic sheet; the fluorescent ceramic sheet is capable of emitting bright white light under the stimulation of 435-450nm blue light and is capable of meeting the illuminating requirement; the prepared ceramic sheet has light, thin and semitransparent characteristics.

Owner:CHONGQING UNIV OF ARTS & SCI

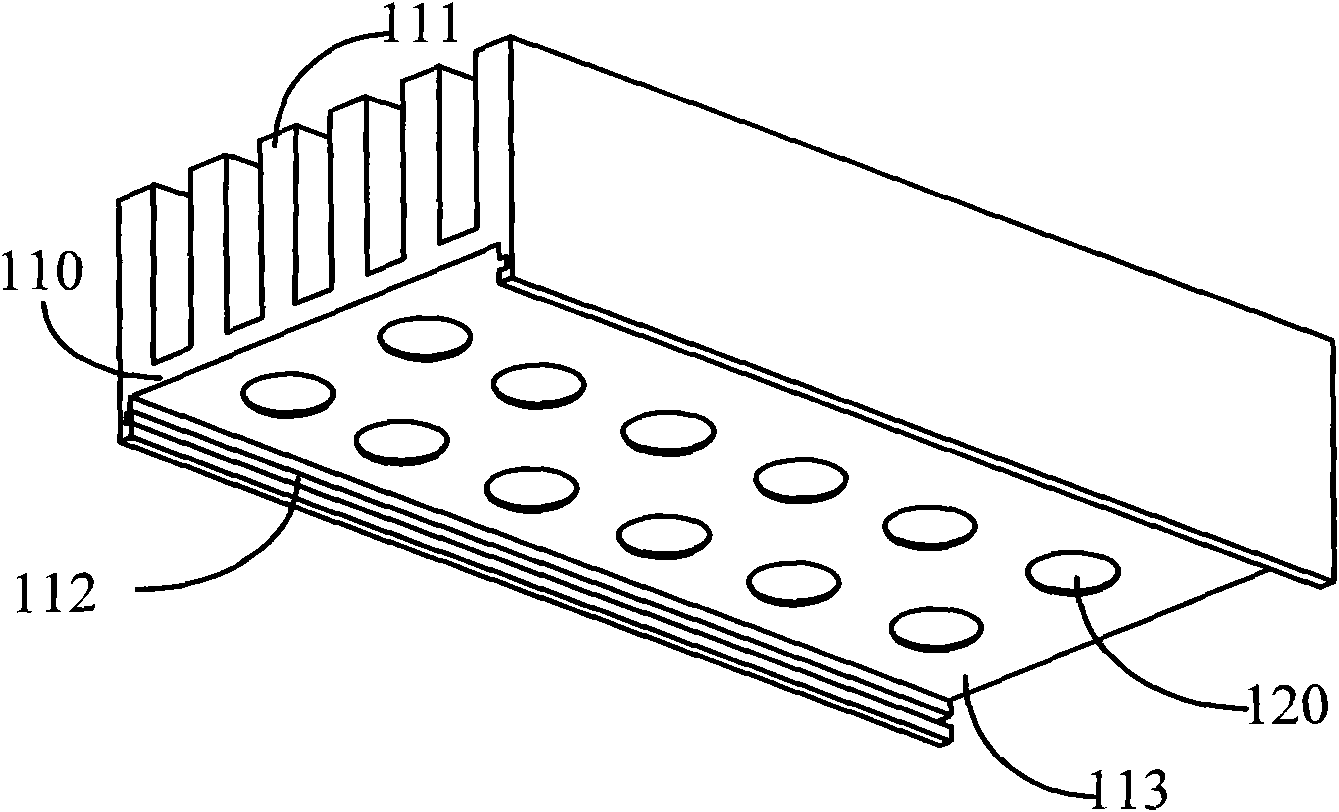

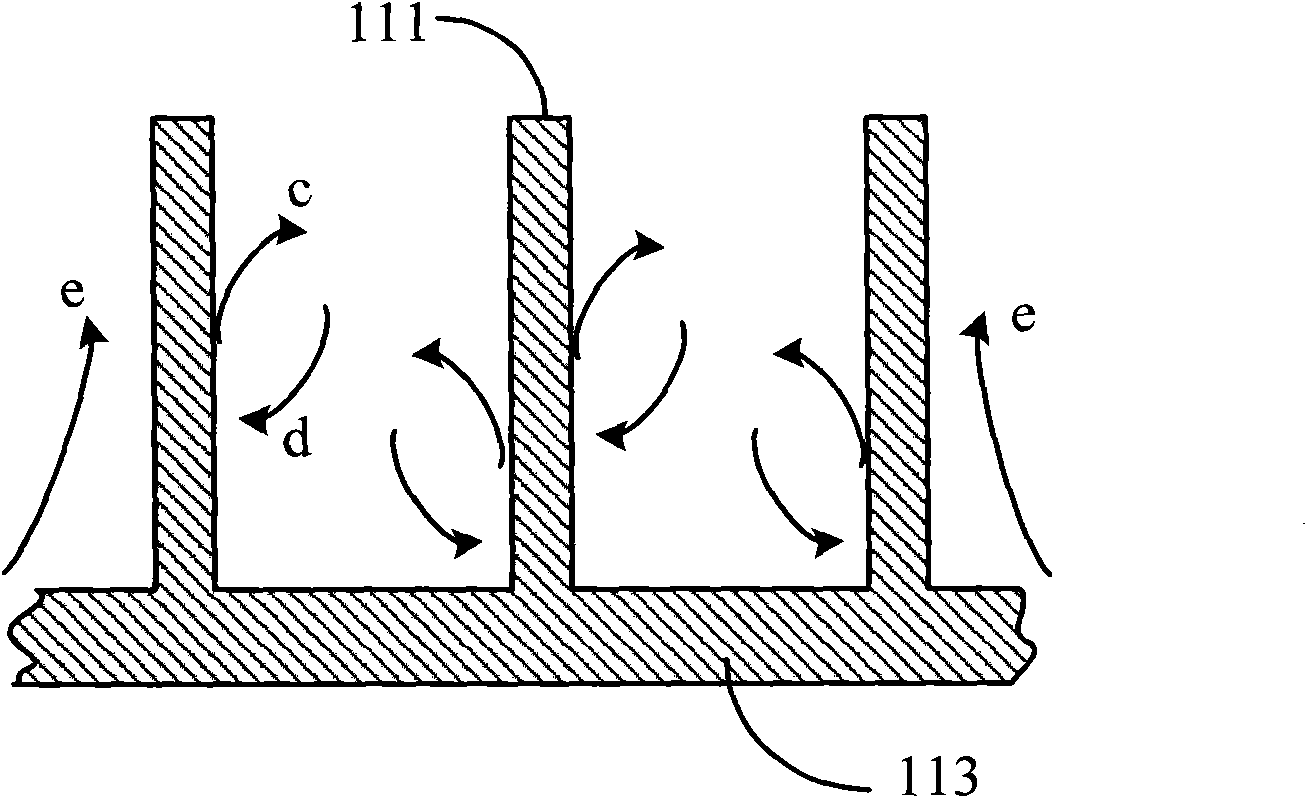

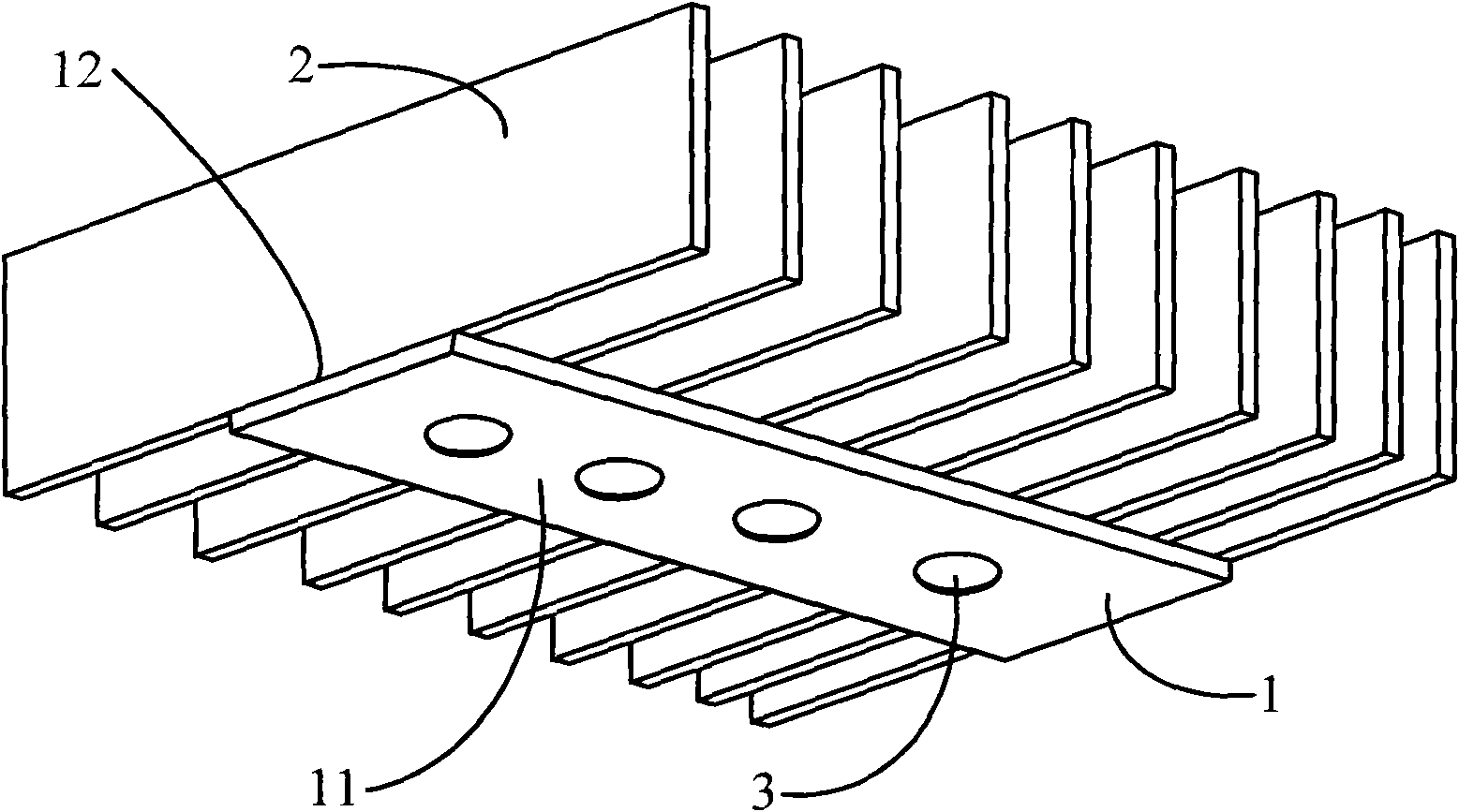

Modular LED lamp and manufacture method thereof

InactiveCN101666432AExtended service lifeMaintain luminous performancePoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention provides a modular LED lamp and a manufacture method thereof. The lamp comprises a strip-shaped base, a plurality of radiating fins and LED components, wherein the strip-shaped base comprises an installing surface and a radiating surface which are back to each other, the LED components are distributed and arranged on the installing surface; bottom edges of the radiating fins are connected to the radiating surface, wherein the width of each radiating fin is larger than that of the radiating surface, and two sides of the radiating fins extend to exceed the margin of the radiating surface. The technical scheme of the embodiment of the invention can ensure that heat produced by the LED components can smoothly and successfully radiated by the radiating fins so as to further prolong the service life of the LED components and keep better luminescence performance.

Owner:DALIAN GOLDEN THERMALWAY TECH

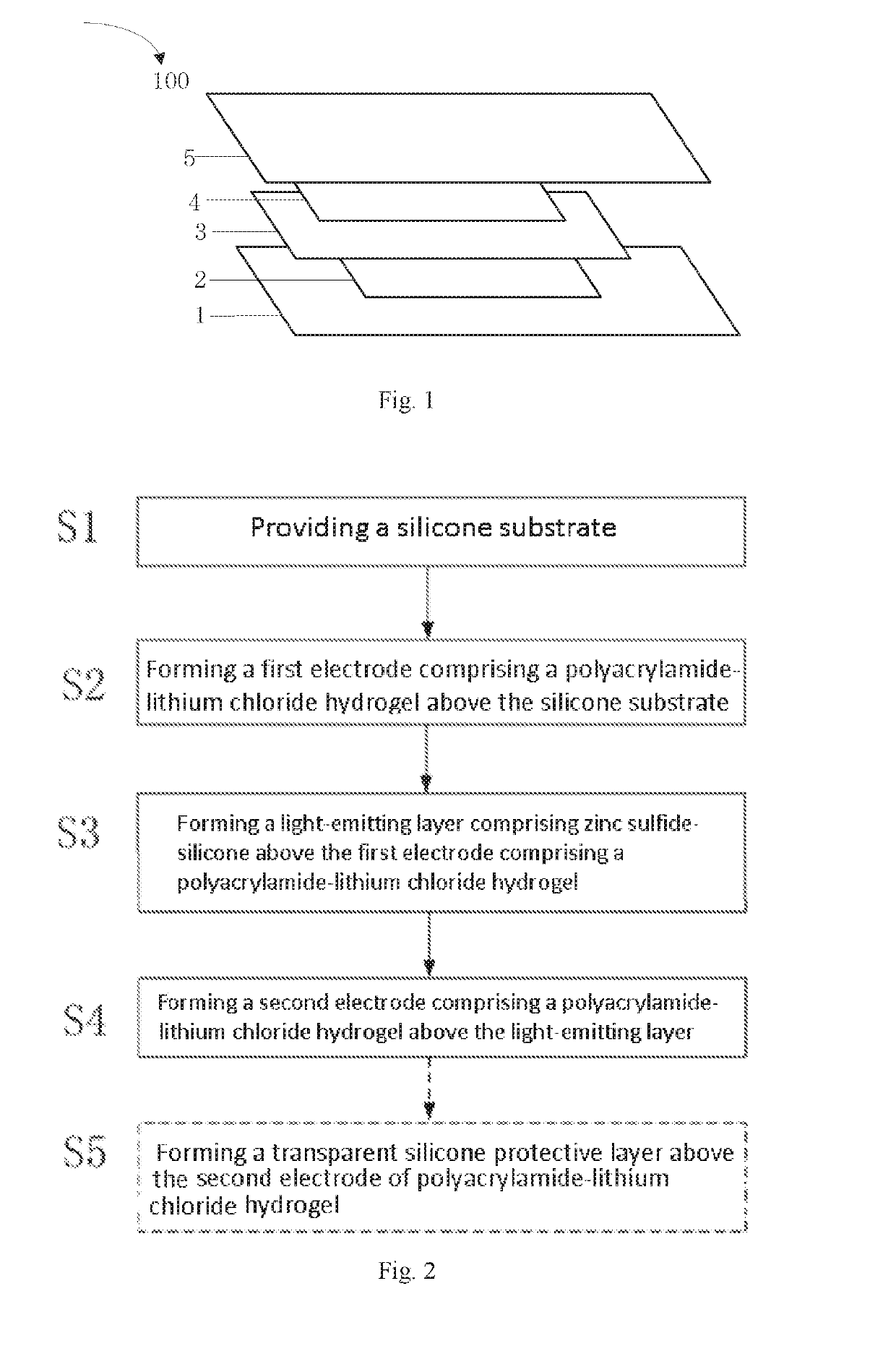

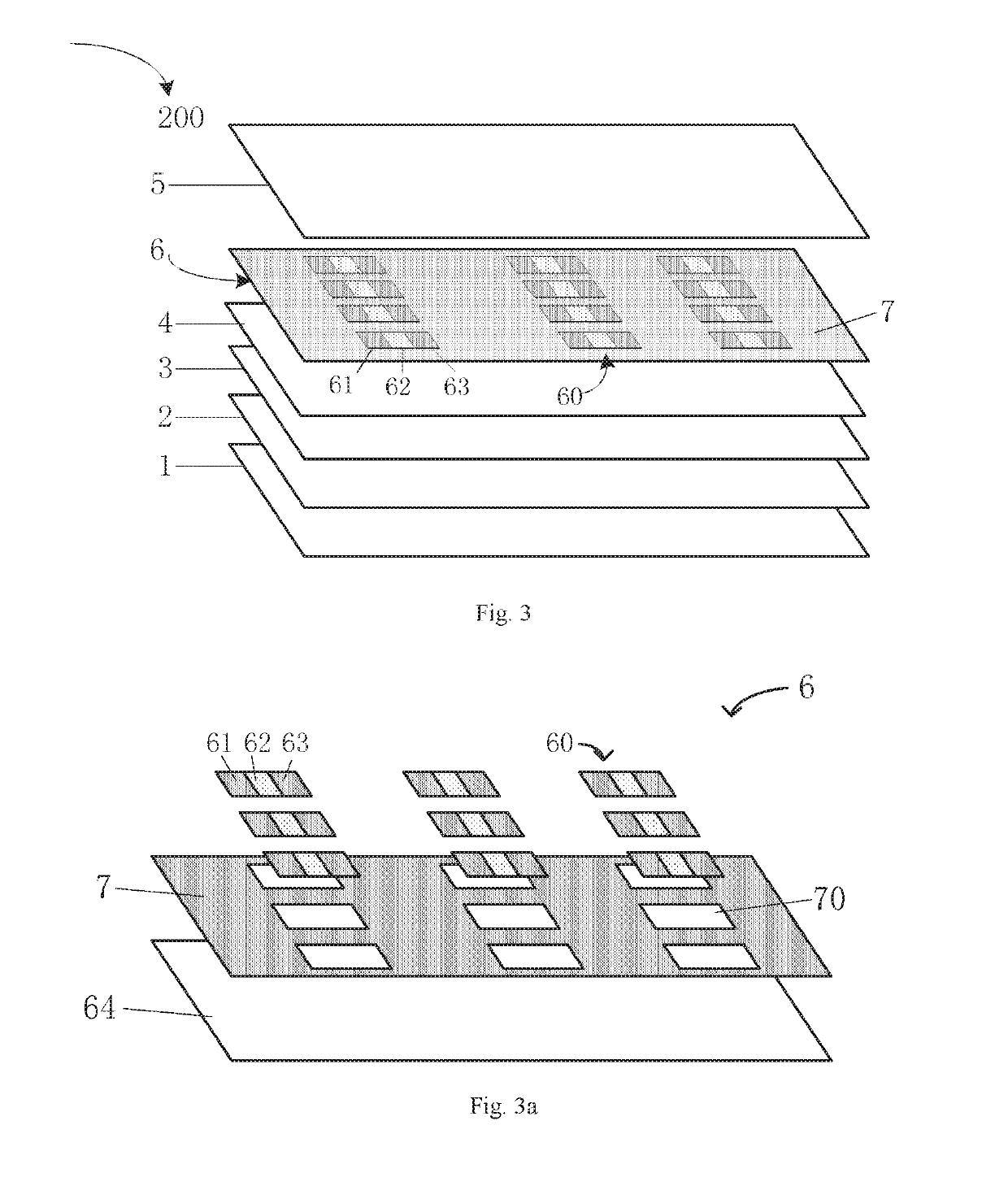

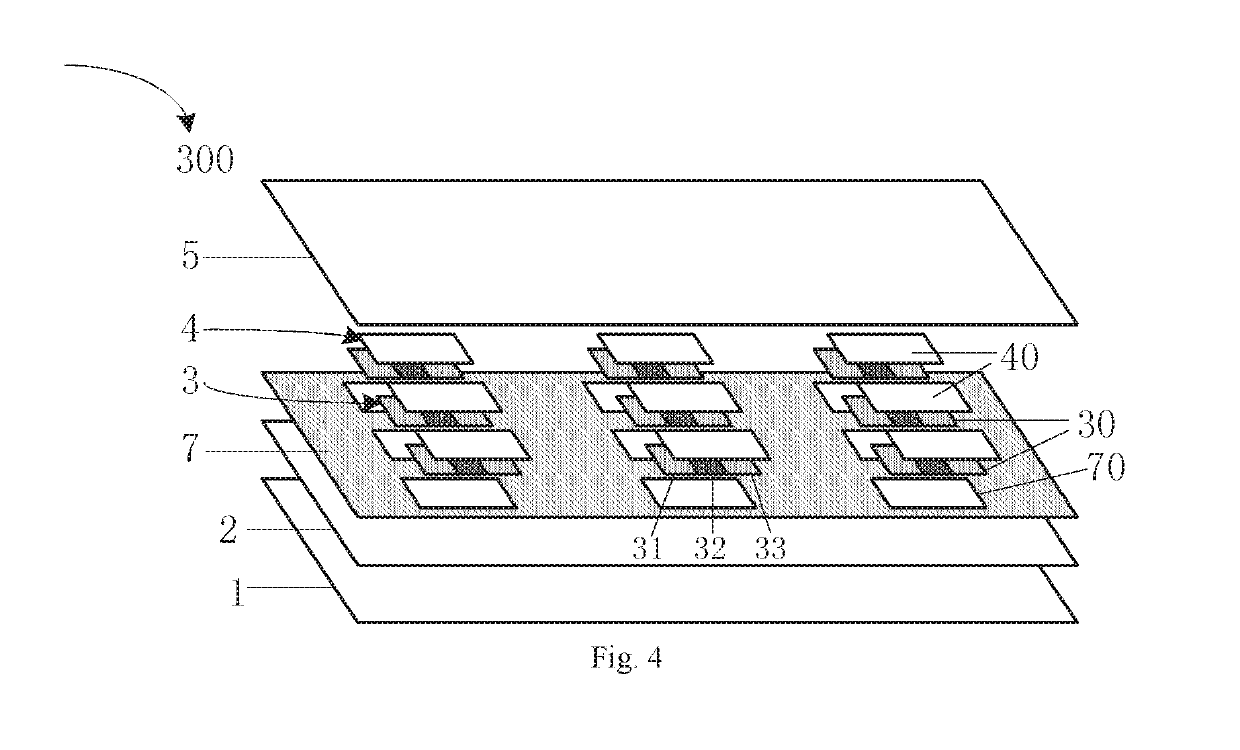

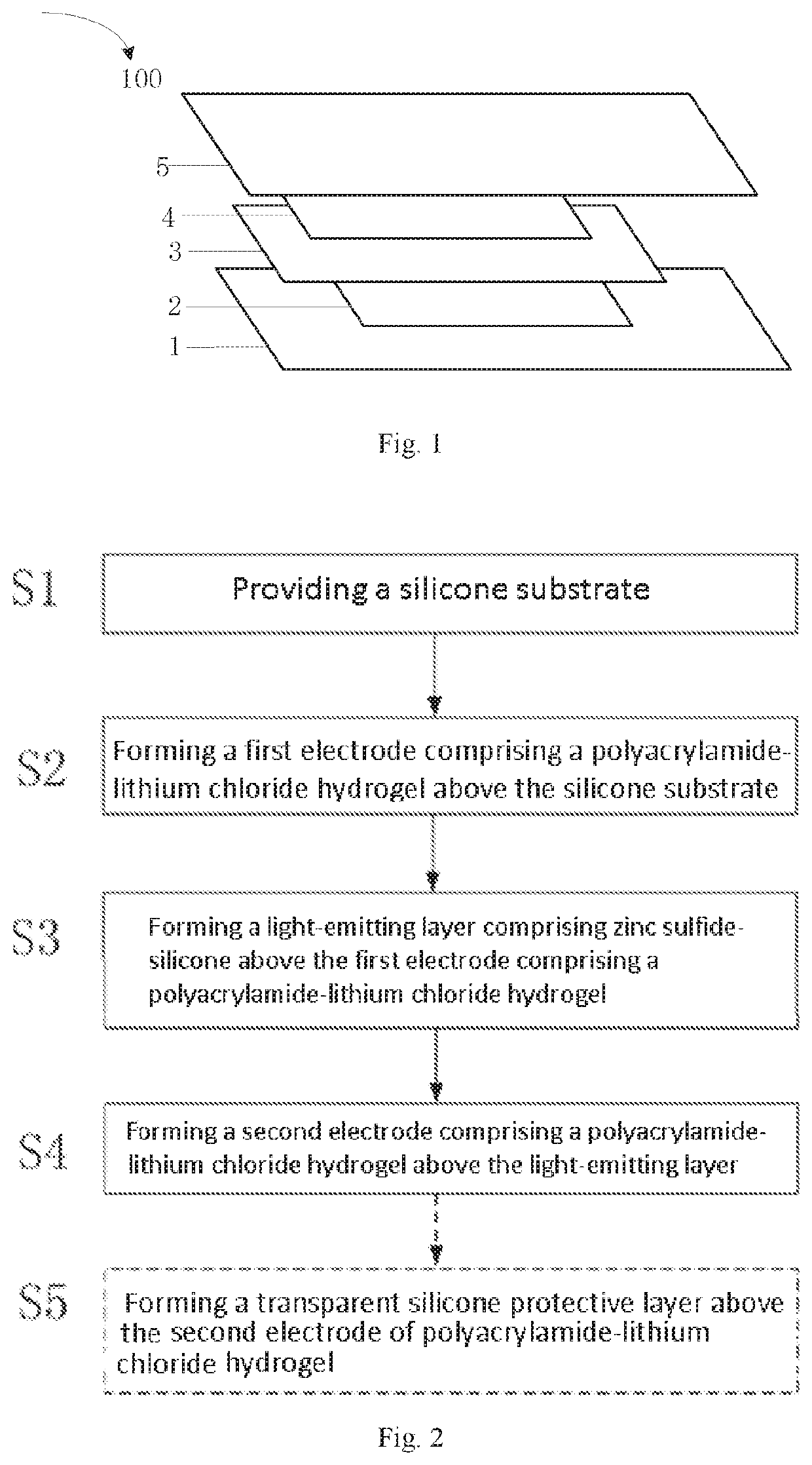

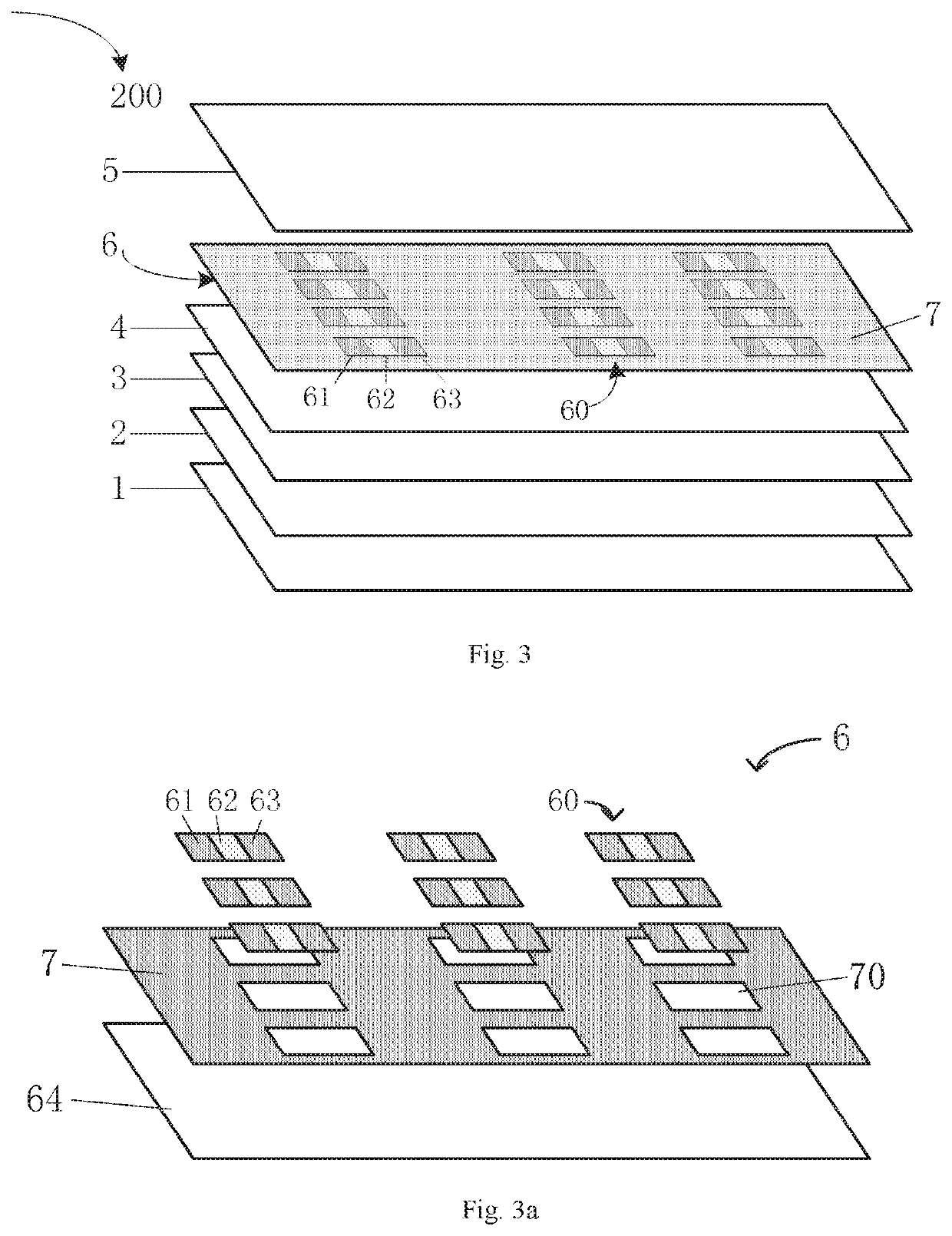

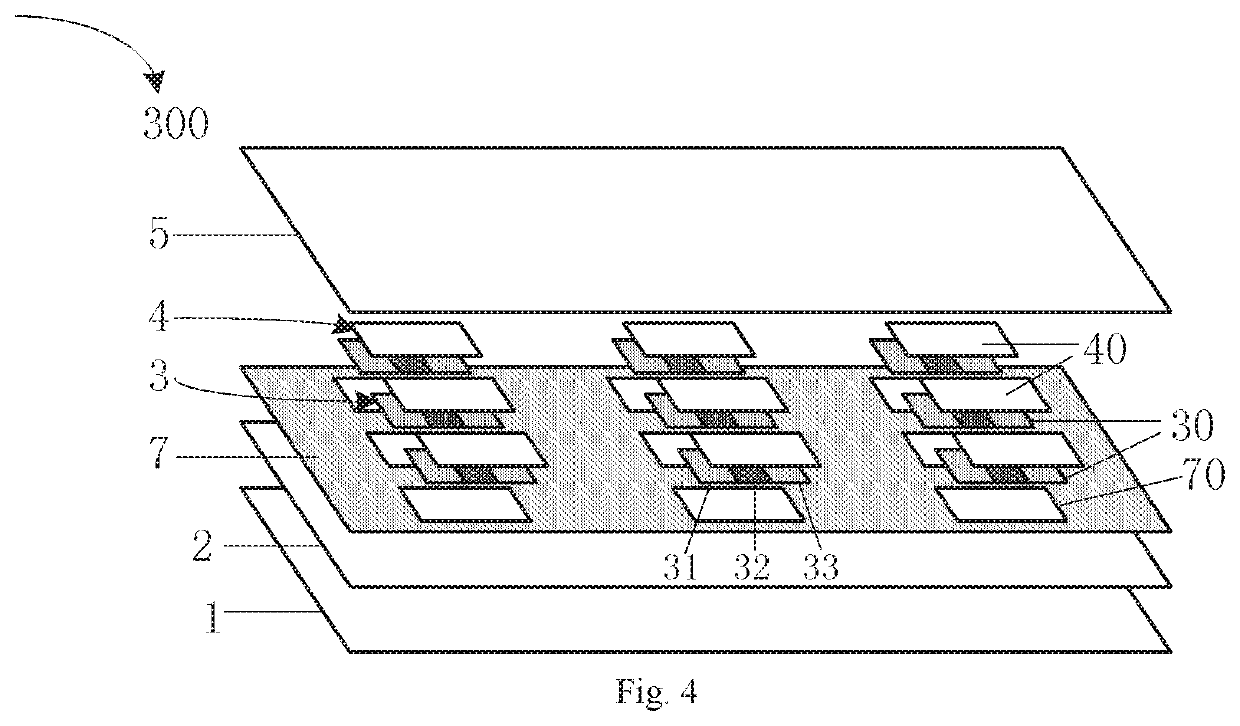

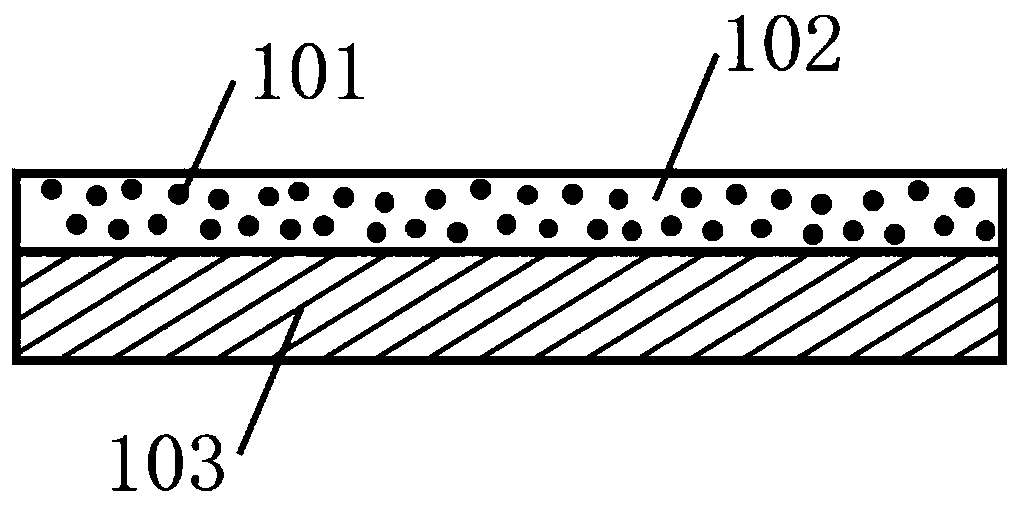

Flexible display screen, method of producing the same, and display apparatus

ActiveUS20190123282A1Maintain luminous performanceIncrease flexibilityFinal product manufactureSolid-state devicesSiloxanePolyacrylamide

This application relates to a flexible display screen, comprising: a silicone substrate; a first electrode of polyacrylamide-lithium chloride hydrogel above the silicone substrate; a zinc sulfide-silicone light-emitting layer above the first electrode of polyacrylamide-lithium chloride hydrogel; and a second electrode of polyacrylamide-lithium chloride hydrogel above the zinc sulfide-silicone light-emitting layer.

Owner:BOE TECH GRP CO LTD +1

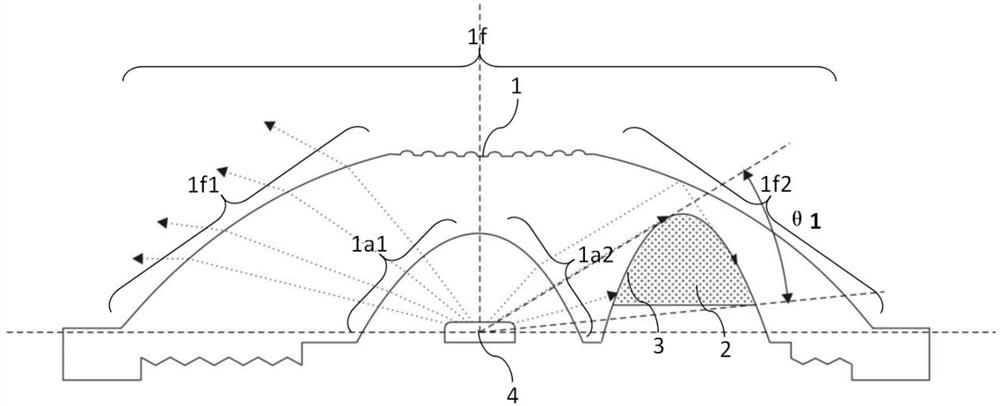

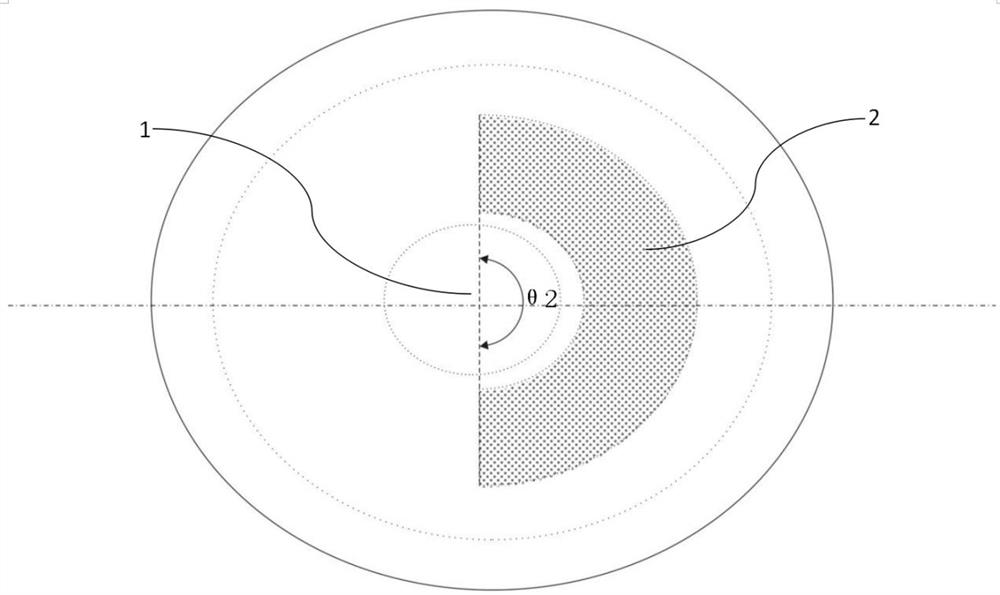

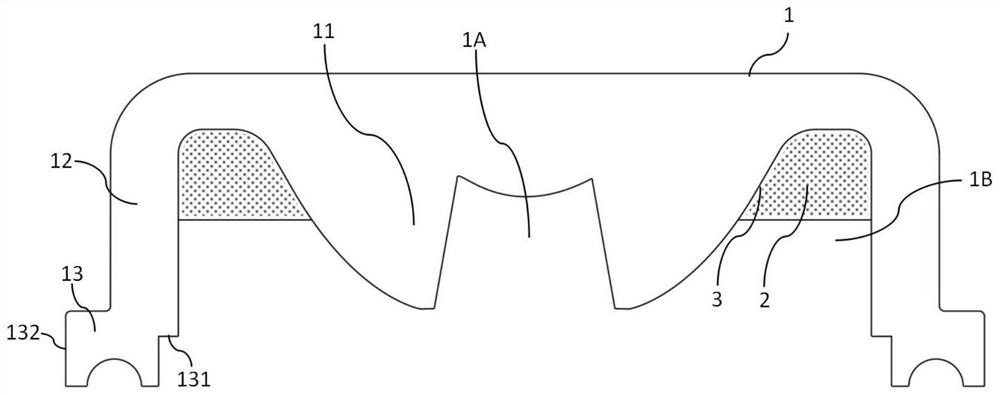

LED (light-emitting diode) long-afterglow composite light-emitting spreadlight lens and light-emitting device with LED long-afterglow composite light-emitting spreadlight lens structure

PendingCN112944281AWith long afterglow glow effectMaintain luminous performanceSpectral modifiersSemiconductor devices for light sourcesDriver/operatorLight guide

The invention discloses an LED (light-emitting diode) long-afterglow composite light-emitting spreadlight lens. The LED long-afterglow composite light-emitting spreadlight lens comprises a lens body structure (1) and a long-afterglow light-emitting forming body (2), the lens body structure (1) is of a big-end-down convex body structure and comprises a light emitting main body part (11) on one side and an auxiliary optical part (12) on the other side, the bottom of the lens body structure (1) is concaved inwards to form a containing cavity (1A), and an accommodating groove (1B) or a wedging structure (1D) is formed in the lens body structure (1). The long-afterglow light-emitting forming body (2) is combined on the auxiliary optical part (12) through the accommodating groove (1B) or the wedging structure (1D), a transparent light guide medium (3) is arranged on the combined surface to form a light guide coupling surface (1e), and the light guide coupling surface can be combined with an LED to manufacture various light-emitting devices. One side focuses on the LED emergent light-emitting effect, so that emergent light meets the requirements of fixed-point projection or directional projection and the like of a main light beam, and the whole body has a long-afterglow light-emitting effect; and during installation, the emergent surface of the LED faces the vehicle facing surface or the road surface and the ground, so that the light guide coupling surface serves motor vehicle drivers and can further serve pedestrians and non-motor vehicle drivers.

Owner:方显峰

Fluorescent wood-plastic external wall board and preparation method thereof

InactiveCN106366497AUniform colorImprove luminous performanceLuminescent compositionsSurface layerFluorescence

The invention relates to a fluorescent wood-plastic external wall board. Raw materials of the fluorescent wood-plastic external wall board further include a luminous pigment, the luminous pigment is prepared by directly and physically mixing a fluorescent material subjected to organic modification treatment and then performing forming through a fusing-plasticizing device and a mouth mold or is prepared by adopting the fluorescent material subjected to organic modification treatment as a fluorescent pigment, co-extruding and mixing the fluorescent pigment and a wood-plastic wall board, adding the mixture to a lateral extrusion machine of a coextrusion machine for coextrusion with the coextrusion machine and performing plasticizing, mixing and mouth mold forming. The invention further discloses a preparation method. By the adoption of the preparation method, a surface-layer luminous wood-plastic product uniform in color and luster, good in durability and having good luminous property can be prepared, and the effects of weak light indication, decoration and beautifying are played.

Owner:SHANDONG XIAGUANG INDAL

Flexible display screen, method of producing the same, and display apparatus

ActiveUS10580991B2Maintain luminous performanceIncrease flexibilityFinal product manufactureSolid-state devicesLithium chloridePhysical chemistry

This application relates to a flexible display screen, comprising: a silicone substrate; a first electrode of polyacrylamide-lithium chloride hydrogel above the silicone substrate; a zinc sulfide-silicone light-emitting layer above the first electrode of polyacrylamide-lithium chloride hydrogel; and a second electrode of polyacrylamide-lithium chloride hydrogel above the zinc sulfide-silicone light-emitting layer.

Owner:BOE TECH GRP CO LTD +1

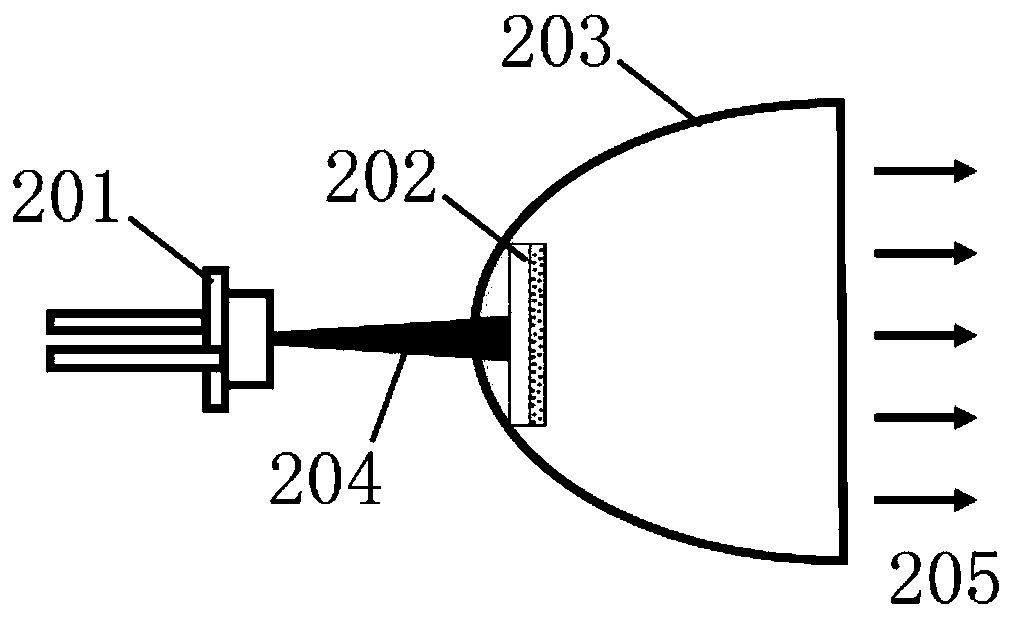

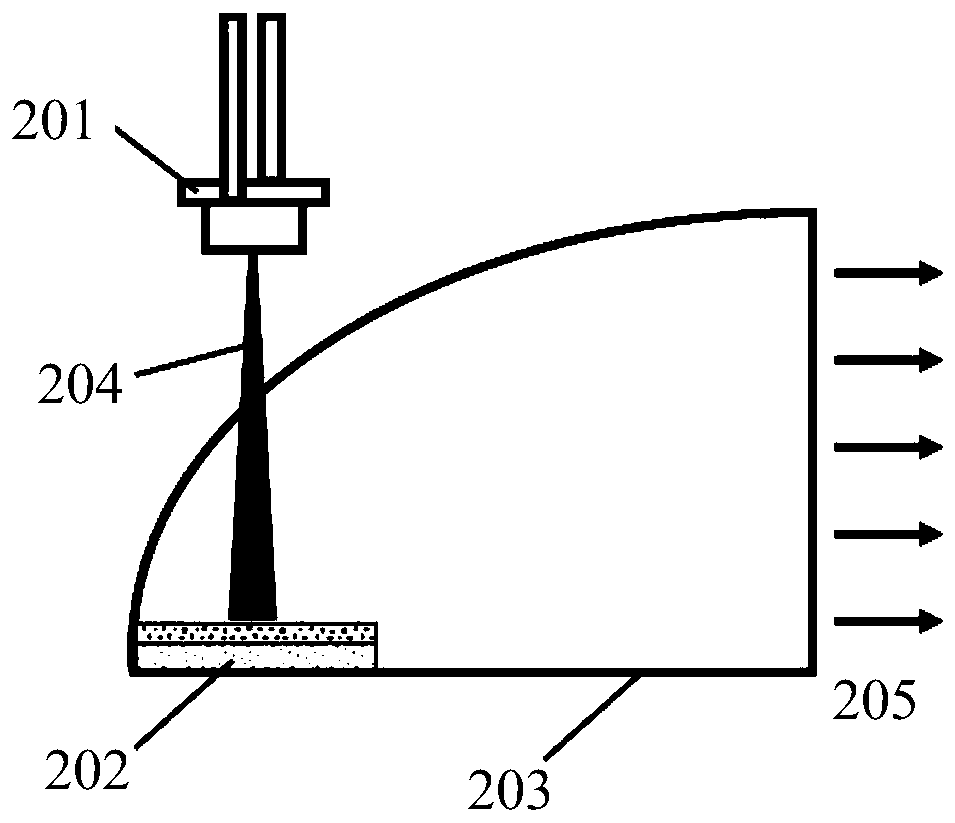

Nitride phosphor/glass composite light conversion component for laser lighting and its preparation

InactiveCN108895314BImprove quantum efficiencyExcellent thermal quenching performanceSemiconductor devices for light sourcesGlass compositesPhysical chemistry

The invention relates to a nitride phosphor / glass composite optical conversion kit for laser illumination and a preparation thereof, which relates to light conversion components. Nitride phosphor / glass composite optical conversion kit for laser illumination comprises a nitride phosphor / glass composite coating and a high thermal conductivity ceramic substrate, the nitride phosphor / glass composite coating is closely grown on the high thermal conductivity ceramic substrate. The preparation of phosphor slurry: the nitride phosphor / glass composite optical conversion kit is prepared for laser illumination. The nitride phosphor / glass composite optical conversion kit can be used in laser illumination. The luminous efficiency above 280 lm / W can be obtained by coupling the provided nitride phosphor / glass composite optical conversion kit for laser illumination with a laser source with emission wavelength about 450 nanometers.

Owner:XIAMEN UNIV

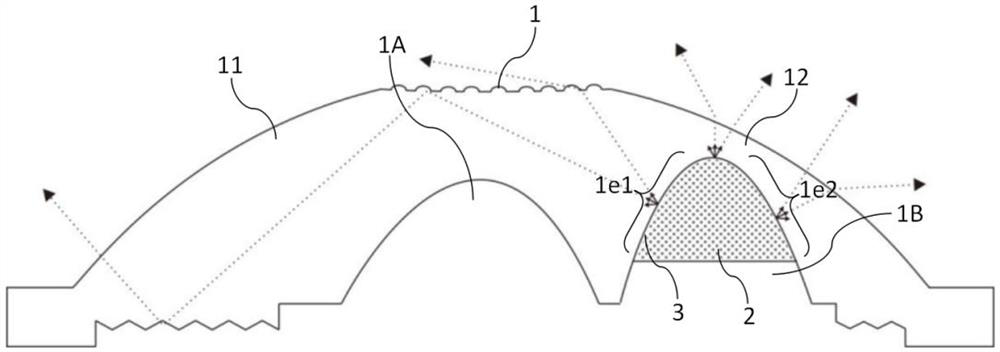

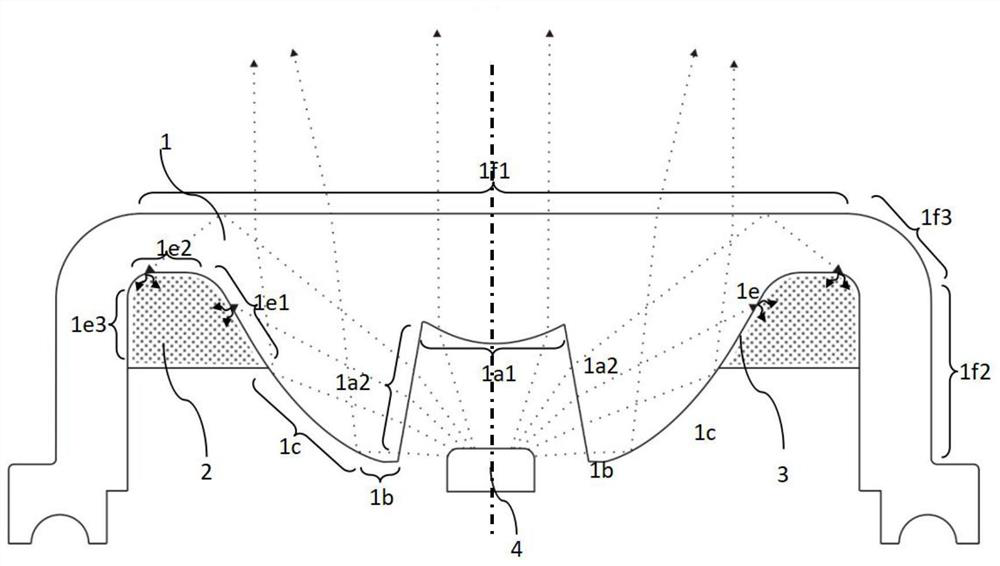

LED long-afterglow composite light-emitting lens and light-emitting device comprising LED long-afterglow composite light-emitting lens structure

PendingCN112923326AAvoid oversaturationReduce wasteSpectral modifiersSemiconductor devices for light sourcesLight guideLight energy

An LED long-afterglow composite light-emitting lens comprises a lens body structure (1) and a long-afterglow light-emitting forming body (2), the lens body structure (1) at least comprises a light distribution optical main body part (11), and the lens body structure (1) is provided with a containing groove (1B) or a wedging structure (1D); the center of the bottom of the lens body structure (1) is recessed inwards to form a center containing cavity (1A), the long-afterglow light-emitting forming body (2) is combined on the lens body structure (1) through the containing groove (1B) or the wedging structure (1D), and a transparent light guide medium (3) is arranged on the combination face of the long-afterglow light-emitting forming body (2) and the lens body structure (1) to form a light guide coupling face (1e); the universal light-emitting lens structure can be suitable for LED long-afterglow light-emitting forming bodies of various types and specifications and can be combined with LEDs to be manufactured into various light-emitting devices; the light energy distribution proportion can be adjusted, light distribution is conducted on an emergent light field, the light coupling effect with the long-afterglow light-emitting forming body (2) is achieved, and at least part of emergent light of an LED light-emitting body can be emitted according to the light path design while the advantages of afterglow light emitting are reserved.

Owner:方显峰

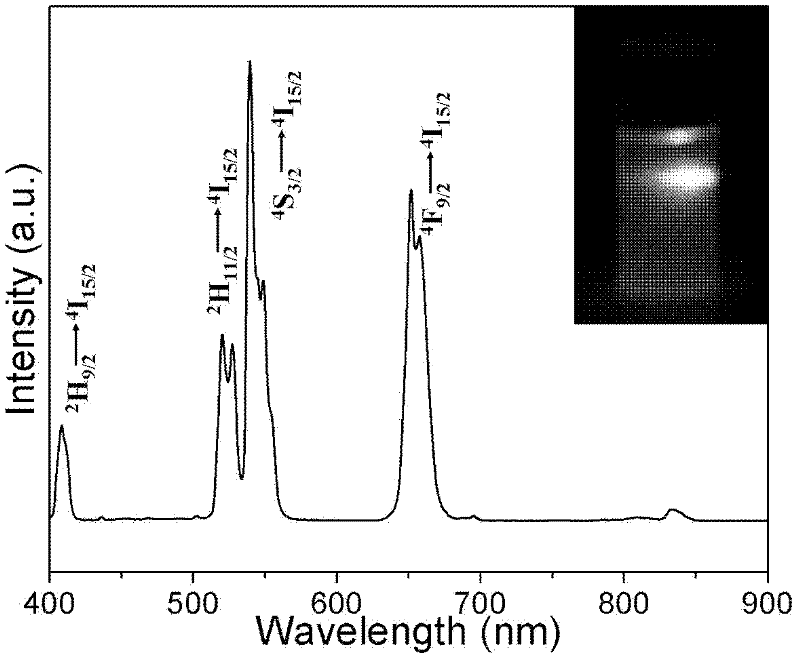

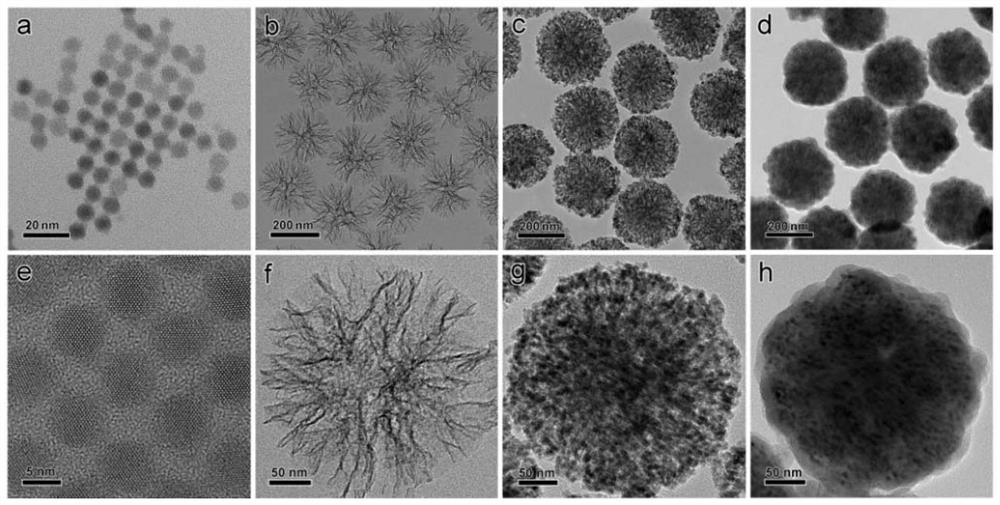

Preparation of near-infrared quantum dot assembly structure

PendingCN114214058AGood biocompatibilityStable performanceFluorescence/phosphorescenceLuminescent compositionsActive agentSurface-active agents

The invention discloses a near-infrared quantum dot assembly structure, which is characterized in that high-light-emitting microspheres with adjustable assembly density and excellent water solubility are obtained by efficiently filling a tree-shaped silicon pore channel with near-infrared two-region PbS quantum dots. Firstly, lead chloride is used as a lead source, oleylamine is added to serve as a surface stabilizer and a solvent, and a lead precursor is obtained under inert gas and high temperature; dissolving elemental sulfur in oleylamine to obtain a sulfur precursor; and rapidly injecting the sulfur precursor into the lead precursor at a certain lead precursor temperature to obtain the oil-soluble PbS quantum dot. Secondly, preparing a central radial macroporous dendritic silicon (dSi) template by adopting a dual-surfactant method; and then, by utilizing the affinity of sulfydryl on the surface of the dSi nanosphere pore channel and the PbS quantum dots and taking dSi as an affinity template, realizing efficient assembly of the silicon pore channel from inside to outside. N-octyltrimethoxysilane / methanol / ammonia water is used as a hydrolysis system, so that silanization modification of the hydrophobic assembly is realized.

Owner:SHENZHEN PEOPLES HOSPITAL

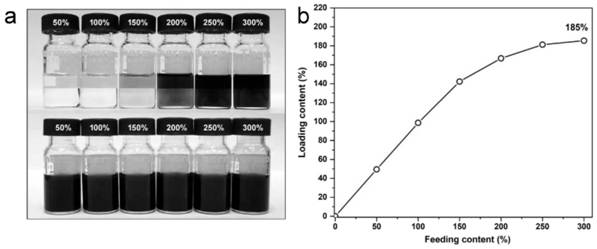

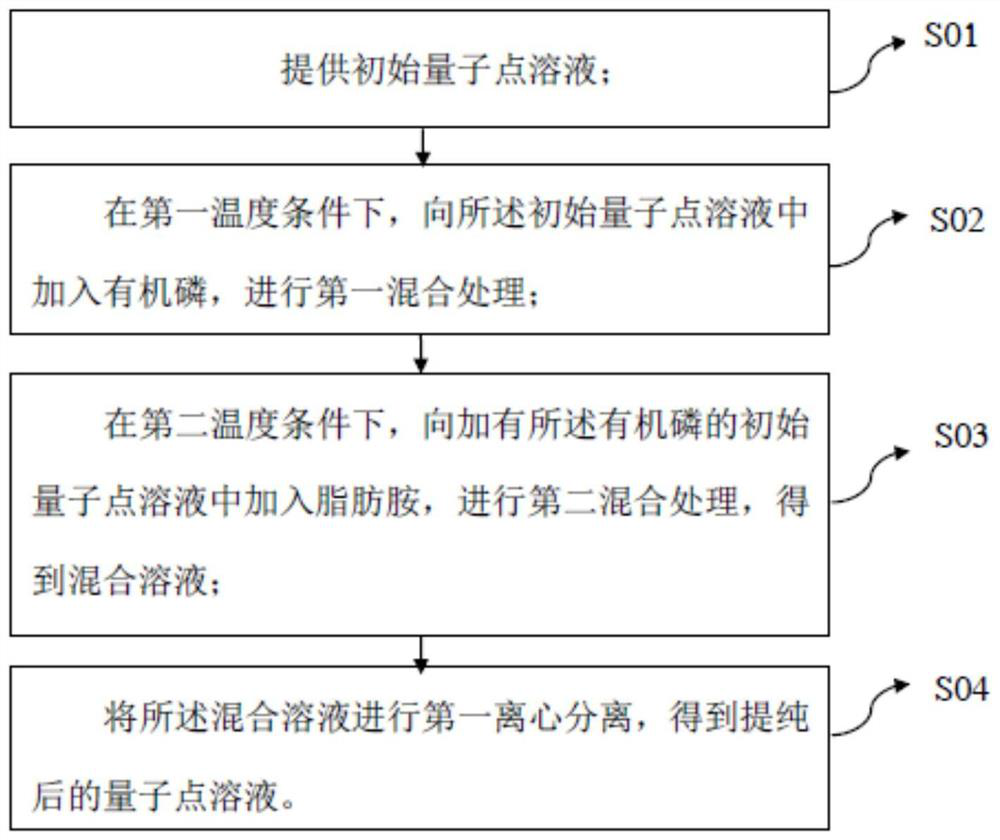

Quantum dot purification method

InactiveCN112410022AImprove solubilityMaintain luminous performanceMaterial nanotechnologyNanoopticsChemical physicsPurification methods

The invention belongs to the technical field of quantum dot processes, and particularly relates to a quantum dots purification method. The quantum dots purification method comprises the following steps: providing an initial quantum dot solution; under a first temperature condition, adding organic phosphorus into the initial quantum dot solution, and carrying out first mixing treatment; under a second temperature condition, adding fatty amine into the initial quantum dot solution added with the organic phosphorus, and carrying out second mixing treatment to obtain a mixed solution; and carryingout first centrifugal separation on the mixed solution to obtain a purified quantum dot solution. After the purification method is adopted to purify the initial quantum dot solution, high-purity quantum dots with original luminous efficiency can be obtained, and the quantum dots have excellent monodispersity in a non-polar solvent.

Owner:TCL CORPORATION

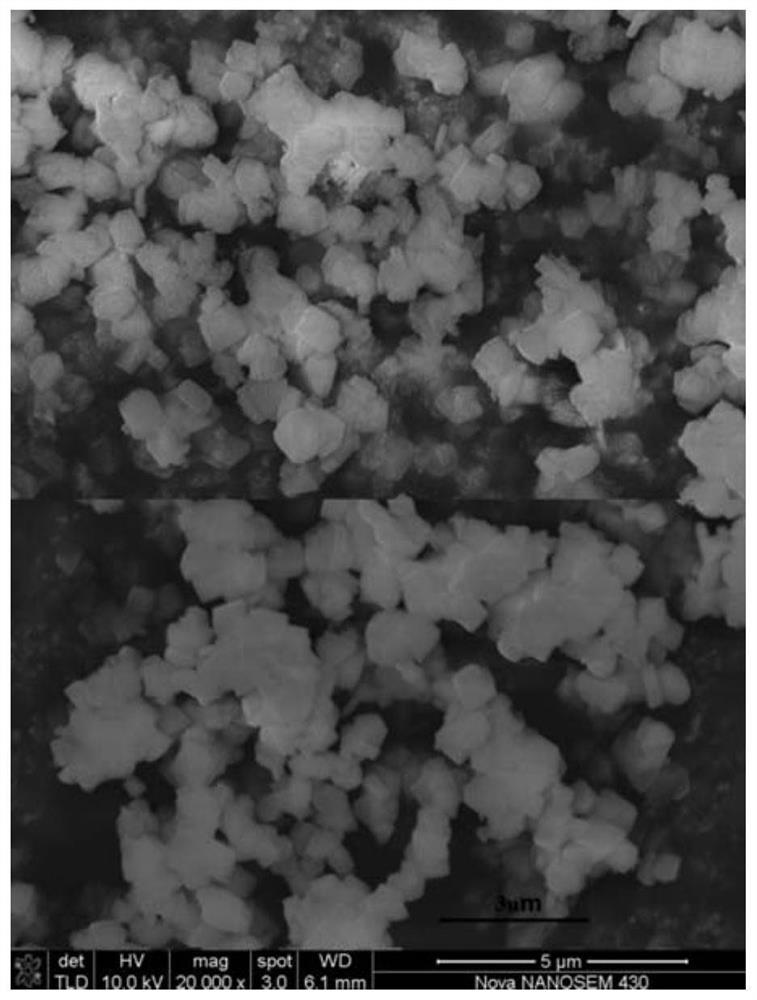

Rare-earth complex nano luminescent material

InactiveCN102827193BMaintain luminous performanceLow costGroup 3/13 element organic compoundsLuminescent compositionsRare-earth elementFluorescence

The invention discloses a rare-earth complex nano luminescent material. The rare-earth complex nano luminescent material is obtained by performing controlled coordination reaction on rare-earth nitrate aqueous solution and mixed aqueous solution of ligand; the formula structure of the rare-earth complex nano luminescent material is [Ln(ad)0.5(phth)(H2O)2], wherein in the formula, Ln is single rare-earth element Eu, Tb or double rare-earth element of combination of Eu and Yb, or combination of Tb and Gd; in the formula, ad and phth are respectively organic ligand adipic acid and phthalic acid; the nano luminescent material is in nano sheet appearance; and the nano sheets can be mutually gathered to form flower-shaped appearance. The single rare-earth material and the double rare-earth doping material are strong fluorescent material; particularly, when the Gd-Tb double rare-earth material contains only 10% of Tb, the luminescent strength is nearly same as that of the pure Tb material. Therefore, the luminescent material has the advantages of nano materials; and moreover, the cost can be reduced through doping, thus, the rare-earth complex nano luminescent material has wide application prospect.

Owner:CHINA JILIANG UNIV

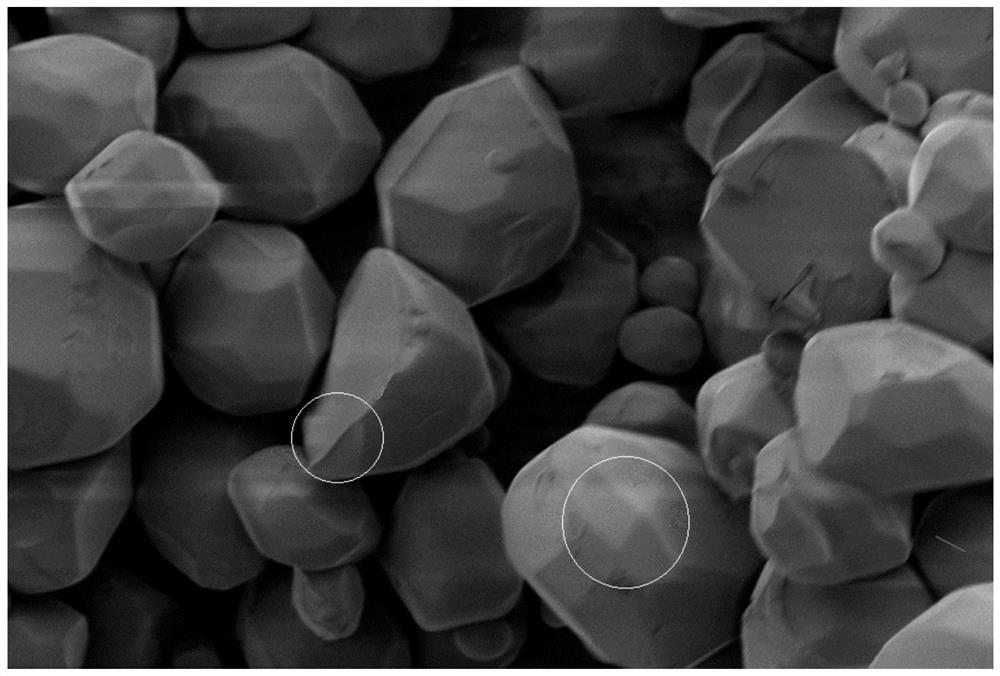

A fluorescent ceramic and its preparation method, light source device and projection device

ActiveCN111039660BImprove structural strengthLarge particle size coverageProjectorsLuminescent compositionsFluorescenceSingle crystal

The invention provides a fluorescent ceramic and its preparation method, a light-emitting device and a projection device. The fluorescent ceramic includes an alumina matrix phase and a luminescence center uniformly dispersed in the alumina matrix phase. It is characterized in that the luminescence center is The spherical fluorescent single crystal particle has a smooth spherical outer surface. The spherical fluorescent single crystal particles have a regular spherical shape and a smooth outer surface, so that they can maintain their original appearance after sintering, which is beneficial to the improvement of the structural strength of the fluorescent ceramics after sintering. In addition, the present invention has a larger particle size range The spherical fluorescent single crystal particles can further improve the luminous efficiency of fluorescent ceramics.

Owner:APPOTRONICS CORP LTD

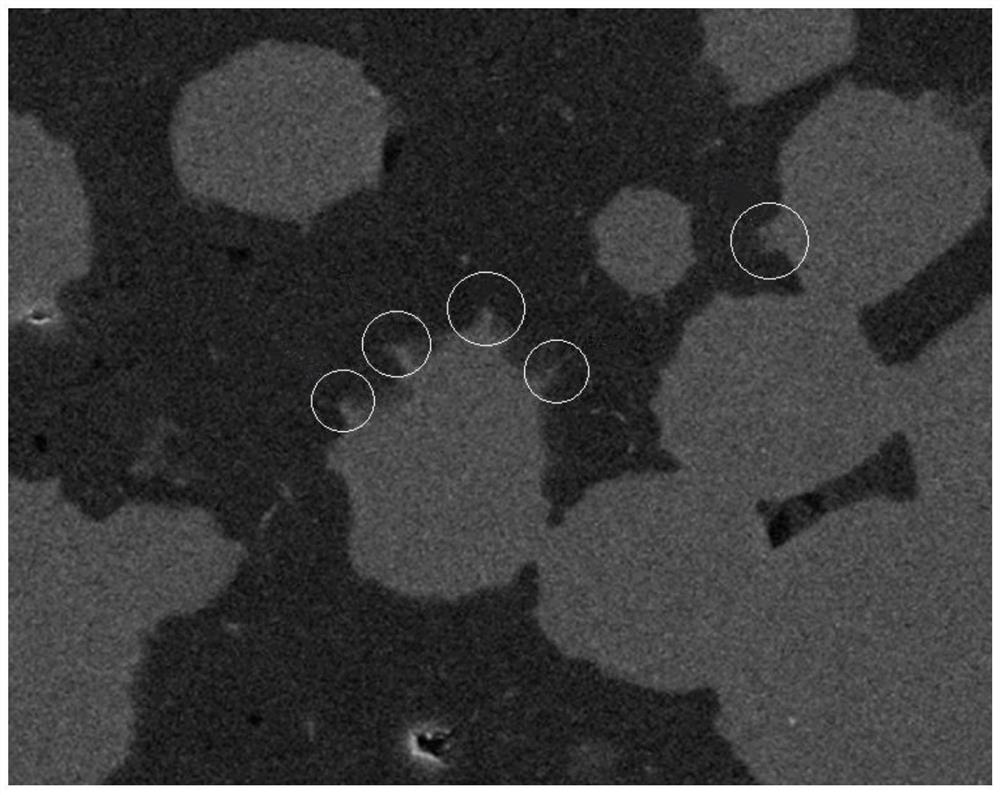

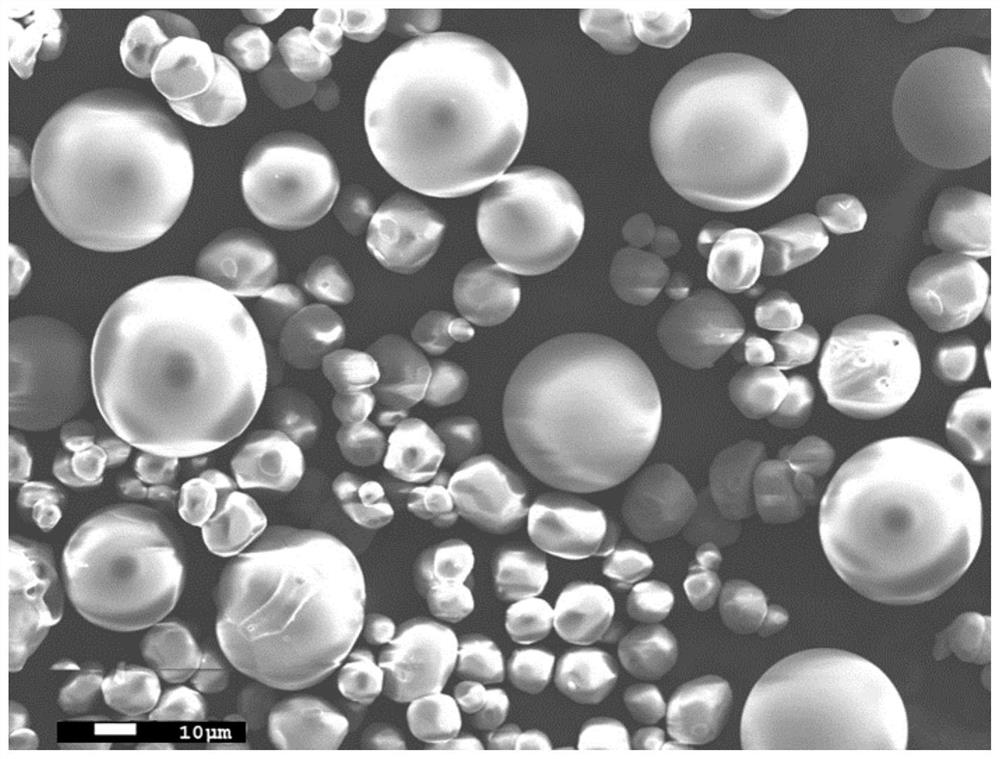

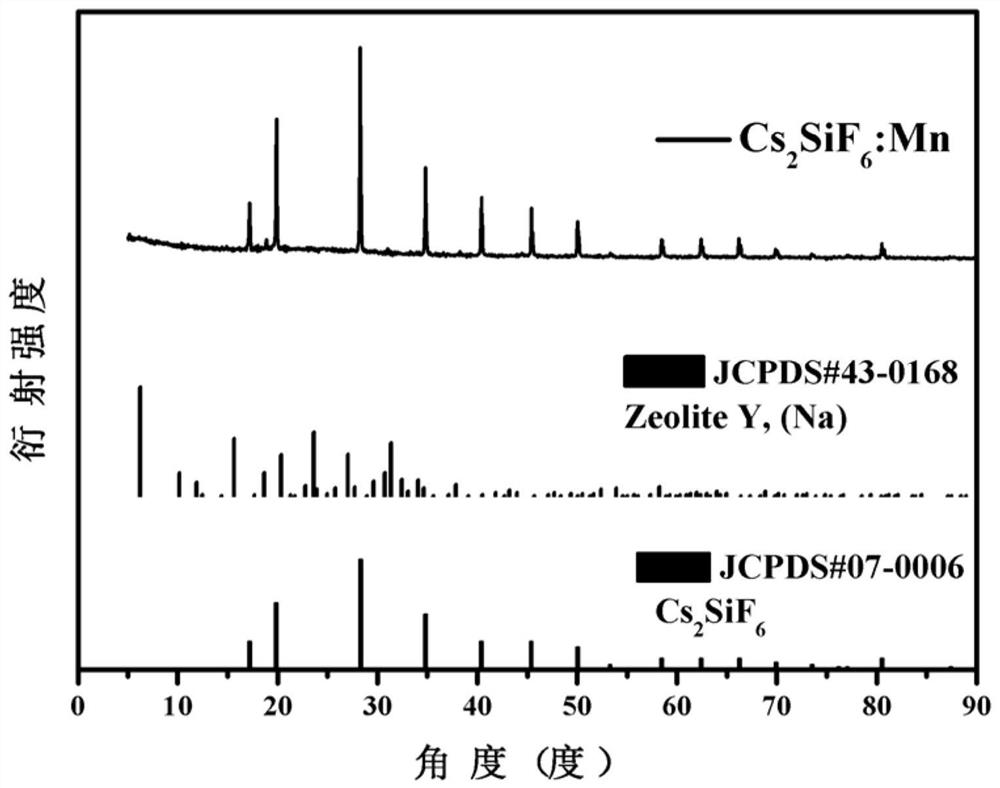

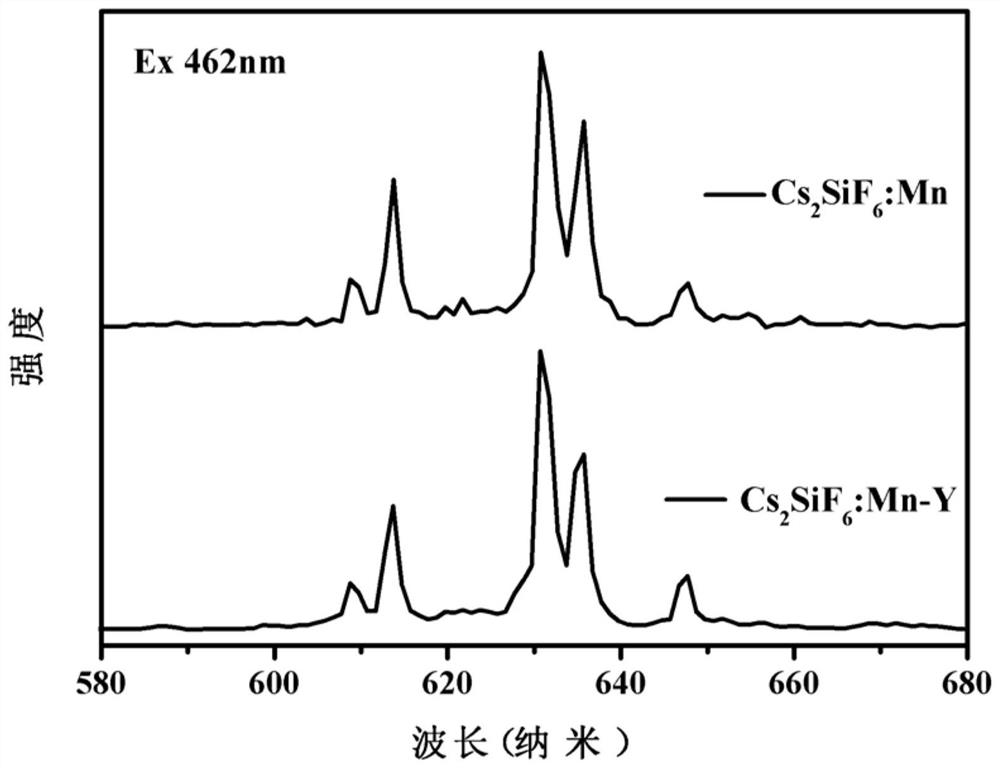

A kind of red fluorescent powder and molecular sieve composite luminescent material and its preparation method and application

ActiveCN108865121BMaintain luminous performanceImprove stabilityLuminescent compositionsSemiconductor devicesMolecular sieveIon exchange

The invention discloses a preparation method of a compound luminescent material with red fluorescent powder and molecular sieves. The method comprises the following steps: (1) exchanging molecular sieves through ions by adding the molecular sieves into a halogenated cesium solution, stirring, centrifuging, washing, drying and repeating the above steps to obtain Cs<+> exchanged molecular sieves; (2) preparing a precursor solution with Si<4+> and Mn<4+> by taking H2SiF6 as a reaction solution system, adding K2MnF6 powder and dissolving to prepare the precursor solution with Si<4+> and Mn<4+>; and (3) adding the Cs-Y molecular sieves prepared in the step (1) into the precursor solution with Si<4+> and Mn<4+> obtained in the step (2), stirring and fully reacting, then collecting precipitate, centrifuging, washing and drying. The compound material is capable of effectively increasing the display index in lighting indexes and reducing the color temperature, has excellent heat stability and moisture resistance, and can be applied to the field of white LED.

Owner:SOUTH CHINA UNIV OF TECH

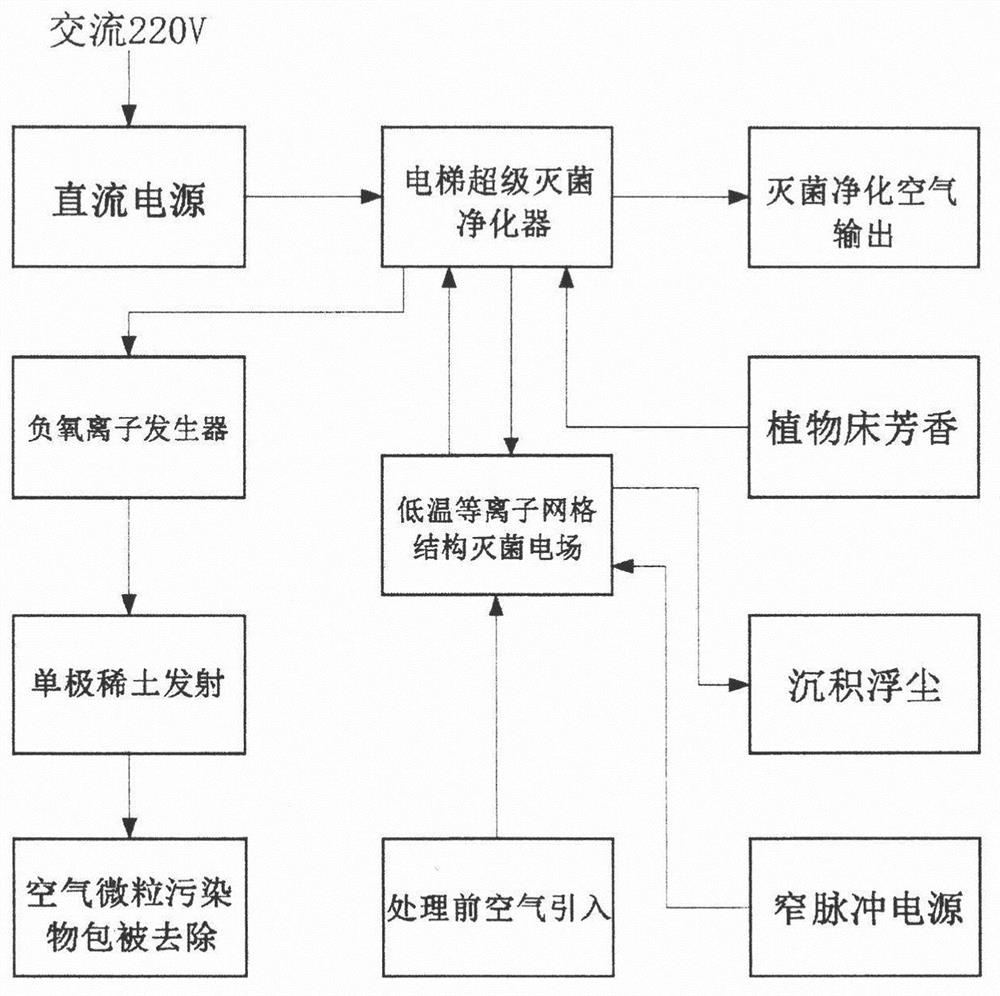

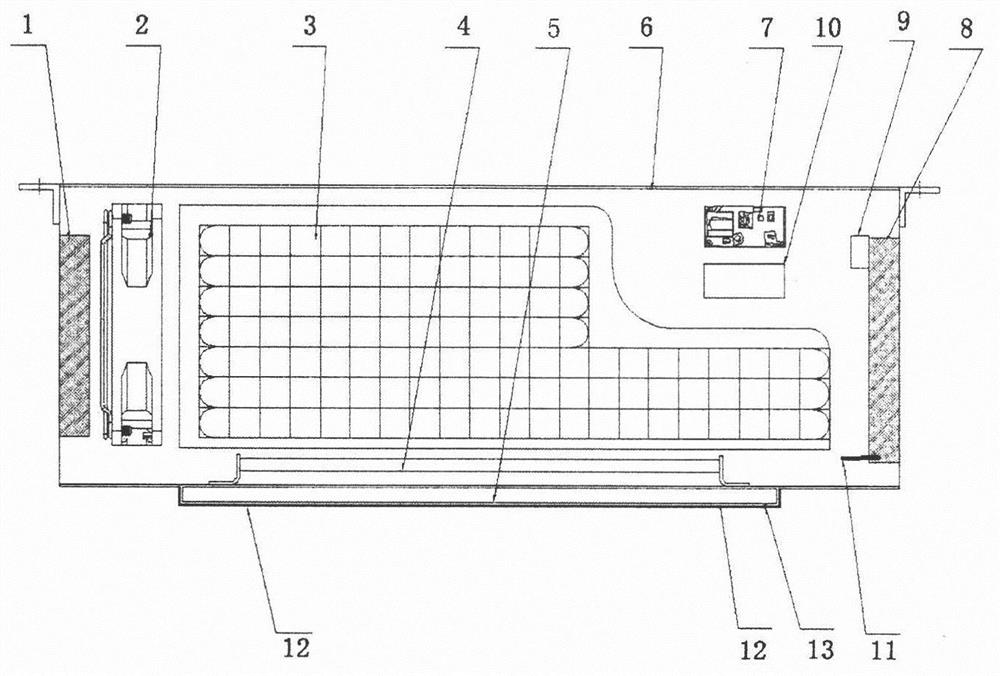

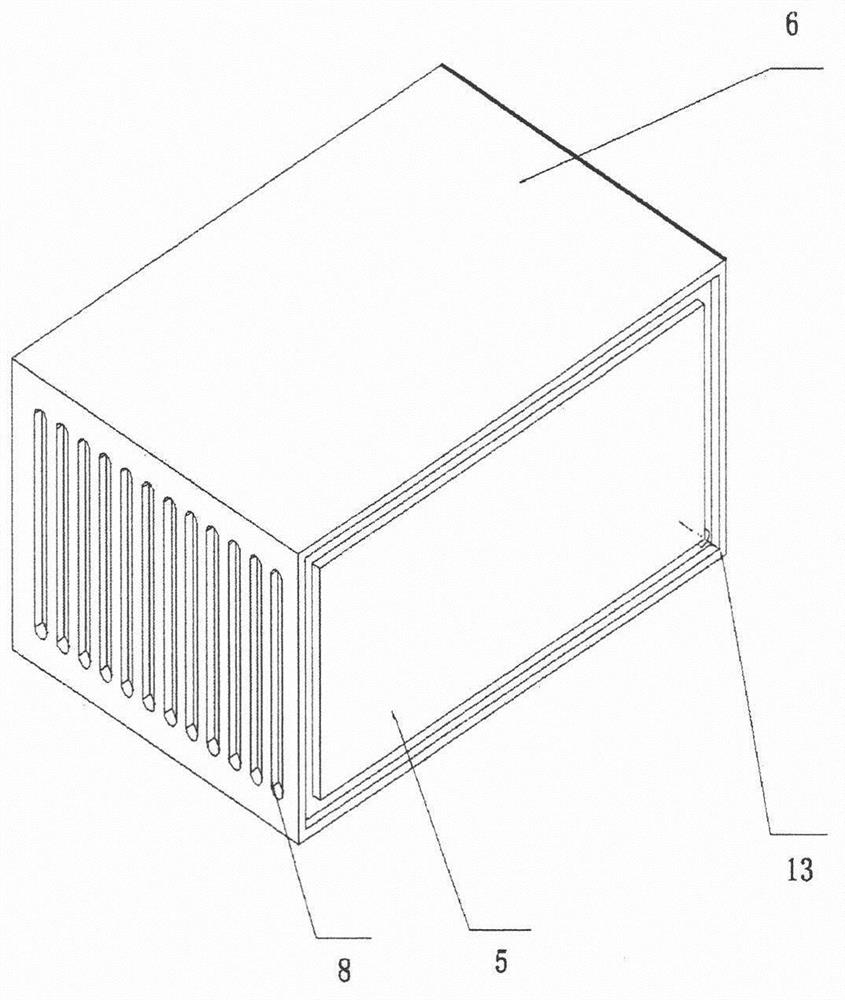

Super sterilization and purification device based on monopole rare earth material

PendingCN112325434ARelaxSame hot and cold resistanceTelevision system detailsMechanical apparatusHigh concentrationOxygen ions

The invention relates to a sterilization, ventilation and purification technology special for elevators, in particular to a super sterilization and purification device based on a monopole rare earth material. A sterilization technology that a special electric field generates a high temperature of 10,000 DEG C within 70 ns is adopted, temperature rise of equipment is only 5 DEG C, and droplet pollution in public places is solved. Meanwhile, a monopole rare earth emission technology of an ion cloud is designed for haze coating removing and positioning, fixed-point and regular cleaning is conducted in an elevator car within the range of 70 cm, consumable-free air purification and peculiar smell treatment are achieved, and the electric field power only needs to be about 6 watts; and through natural plant resin (sandalwood), air is fragrant, and an aromatic and beautiful artistic conception is provided. The high-concentration negative oxygen ion cloud is emitted through a rare earth material electrode, and 7 million negative oxygen ions are emitted per cubic centimeter. The equipment is also provided with a new light source (the illuminance is larger than 100 lm and the color temperature is 3,800-4,200 k) which is most suitable for the illuminance and the color temperature of the elevator. The sterilization and purification device has a huge application market and can be applied toclosed indoor space and mobile space (airplanes, steamships, automobiles, elevators and the like).

Owner:上海达奥斯电梯装潢有限公司

A ternary rare earth complex and its application in the preparation of high-intensity hybrid luminescent hydrogel

ActiveCN106432297BHigh transparencyHigh mechanical strengthGroup 3/13 organic compounds without C-metal linkagesLuminescent compositionsStructural formulaCoordination complex

The invention provides a ternary rare earth complex and application of the complex in preparing high-strength hybrid luminous hydrogel. The chemical structural formula of the ternary rare earth complex is shown as follows. First terpyridyl bridged imidazolium salt is used for being combined with a rare earth beta-diketone complex to form a ternary complex, the ternary complex can be self-assembled in water to form a micellar structure, and then rare earth ions and ASPA are isolated through the collaborative protection on the rare earth ions by the ternary complex and the micellar structure, so that the aim of preparing a hydrogel which is good in luminescence property and high in mechanical strength is achieved. The hydrogel uses water as a medium, the preparation method is simple, easy and environmentally friendly, and a volatile organic solvent is avoided from being used. Please see the formula in the description.

Owner:HEBEI UNIV OF TECH

A kind of quantum dot glass phosphor and its preparation method and application

ActiveCN104876441BImprove luminosityBoth high temperature and aging resistanceLuminous intensityHeat stability

The invention relates to quantum dot glass phosphor powder as well as a preparation method and application thereof. The quantum dot glass phosphor powder is prepared from the following raw materials in percentage by weight: 1%-15% of a quantum dot material and 85%-99% of a silicon-based mesoporous material. The preparation method is as follows: sintering the quantum dot material and the silicon-based mesoporous material. The quantum dot glass phosphor powder is applied to a white-light LED (light-emitting diode) apparatus, an LED display, an LED backlight source, a signal indicator and an indicator for illumination. The quantum dot glass phosphor powder with different luminous intensities and transmittance is obtained by adjusting the quantum dot doping concentration; and the quantum dot glass phosphor powder with different luminous positions is obtained by adjusting the reaction conditions and selecting different single-quantum dot or core-shell quantum dot materials. The matrix material provided by the invention is quartz glass, and has good heat stability; the luminescence property of the quantum dot can be well kept; the high-temperature luminous efficiency of the quantum dot can be ensured; and meanwhile, the quantum dot glass phosphor powder is simple in preparation technology, energy-saving and environmentally friendly, so that the quantum dot glass phosphor powder has a good application prospect.

Owner:DONGHUA UNIV

Surface modification method of fluoride luminescent material and fluoride luminescent material prepared therefrom

ActiveCN111171815BImprove corrosion resistanceReduce surface defectsEnergy efficient lightingLuminescent compositionsQuantum yieldPhosphoric Acid Esters

Owner:XIAMEN INST OF RARE EARTH MATERIALS

Food and beverage outer package printed with luminescent patterns

InactiveCN102133977BWell mixedReduce generationInksCoverings/external coatingsEngineeringDefoaming Agents

The invention discloses a food and beverage outer package printed with luminescent patterns. The food and beverage outer package comprises a container for accommodating foods and beverages, wherein the outer wall of the container is provided with a luminescent ink coating for displaying the luminescent patterns; the luminescent ink coating is formed by printing luminescent ink on the outer wall of the container, and the luminescent ink is prepared from the following raw materials in part by weight: 30 to 80 parts of long afterglow fluorescent powder, 10 to 50 parts of light-transmitting glasspigment, 15 to 35 parts of suspension, 5 to 10 parts of solid dispersant and 2 to 5 parts of defoaming agent; and the fusion temperature of the suspension is not higher than 200 DEG C. Aiming at the problems that the conventional food and beverage outer packages do not have luminescent performance and striking highlighting, and the conventional luminescent ink does not have high temperature resistance and cannot be used for printing on the food and beverage outer packages, the invention provides the food and beverage outer package printed with the luminescent patterns, which can luminesce andis extremely striking in a dim environment and can resist high temperatures in the process of printing the luminescent ink coating.

Owner:郯城县瑞丰米业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com