Preparation of near-infrared quantum dot assembly structure

A quantum dot and near-infrared technology, applied in the field of medicine, can solve the problems of loss of fluorescence performance of quantum dots, poor stability, difficult purification, etc., and achieve the effects of easy repetition and promotion, stable performance and good biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Preparation of PbS quantum dots (PbS) in the second near-infrared region:

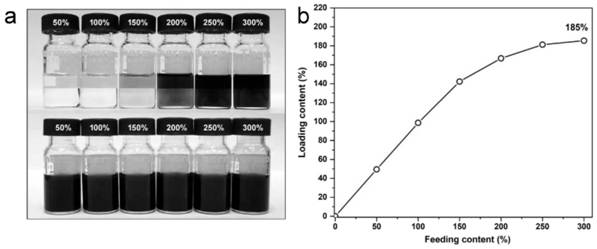

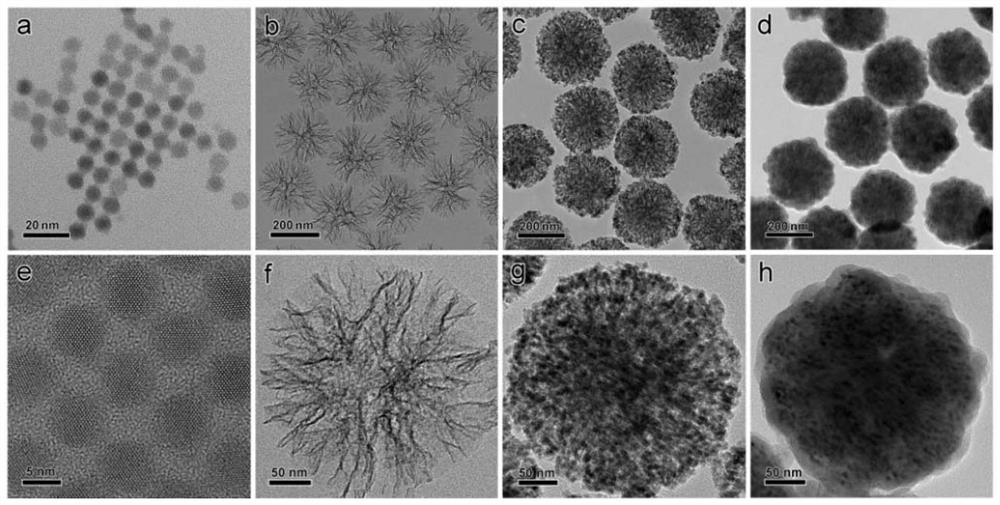

[0018] Weigh 0.04g S and dissolve in 7.5mL oleylamine, 2 The temperature was raised to 120 ° C under the condition of magnetic stirring for 20 min, then cooled to room temperature, and continued to keep flowing N 2 . Preparation of Pb precursor: weigh 2g PbCl 2 and 7.5mL oleylamine in a three-necked bottle, vacuumed to remove oxygen, and 2 The temperature was raised to 150 °C under the condition of magnetic stirring for 40 min. The reaction temperature was lowered to 70°C. Under vigorous stirring, the S precursor solution was quickly injected into the Pb precursor, and the solution in the three-neck flask quickly changed from white to black. After maintaining the reaction temperature at 70 °C for 6 minutes, pour 20 mL of n-hexane solution to stop the growth of PbS quantum dots. The prepared PbS quantum dot solution is centrifuged to remove impurities and then left to stand and purified....

Embodiment 2

[0026] (1) Preparation of PbS quantum dots (PbS) in the second near-infrared region:

[0027] Weigh 0.04g S and dissolve in 7.5mL oleylamine, 2 The temperature was raised to 120 ° C under the condition of magnetic stirring for 20 min, then cooled to room temperature, and continued to keep flowing N 2 . Preparation of Pb precursor: weigh 2g PbCl 2 and 7.5mL oleylamine in a three-necked bottle, vacuumed to remove oxygen, and 2 The temperature was raised to 150 °C under the condition of magnetic stirring for 40 min. The reaction temperature was lowered to 70°C. Under vigorous stirring, the S precursor solution was quickly injected into the Pb precursor, and the solution in the three-neck flask quickly changed from white to black. After maintaining the reaction temperature at 70 °C for 6 minutes, pour 20 mL of n-hexane solution to stop the growth of PbS quantum dots. The prepared PbS quantum dot solution is centrifuged to remove impurities and then left to stand and purified....

Embodiment 3

[0035] (1) Preparation of PbS quantum dots (PbS) in the second near-infrared region:

[0036] Weigh 0.04g S and dissolve in 7.5mL oleylamine, 2 The temperature was raised to 120 ° C under the condition of magnetic stirring for 20 min, then cooled to room temperature, and continued to keep flowing N 2 . Preparation of Pb precursor: weigh 2g PbCl 2 and 7.5mL oleylamine in a three-necked bottle, vacuumed to remove oxygen, and 2 The temperature was raised to 150 °C under the condition of magnetic stirring for 40 min. The reaction temperature was lowered to 70°C. Under vigorous stirring, the S precursor solution was quickly injected into the Pb precursor, and the solution in the three-neck flask quickly changed from white to black. After maintaining the reaction temperature at 70 °C for 6 minutes, pour 20 mL of n-hexane solution to stop the growth of PbS quantum dots. The prepared PbS quantum dot solution is centrifuged to remove impurities and then left to stand and purified....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com