Quantum dot purification method

A purification method and technology of quantum dots, which are applied in the field of quantum dot technology, can solve the problems of quantum dot impurities and easy shedding of ligands, and achieve the effects of improving dispersibility, maintaining luminous efficiency and excellent monodispersity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

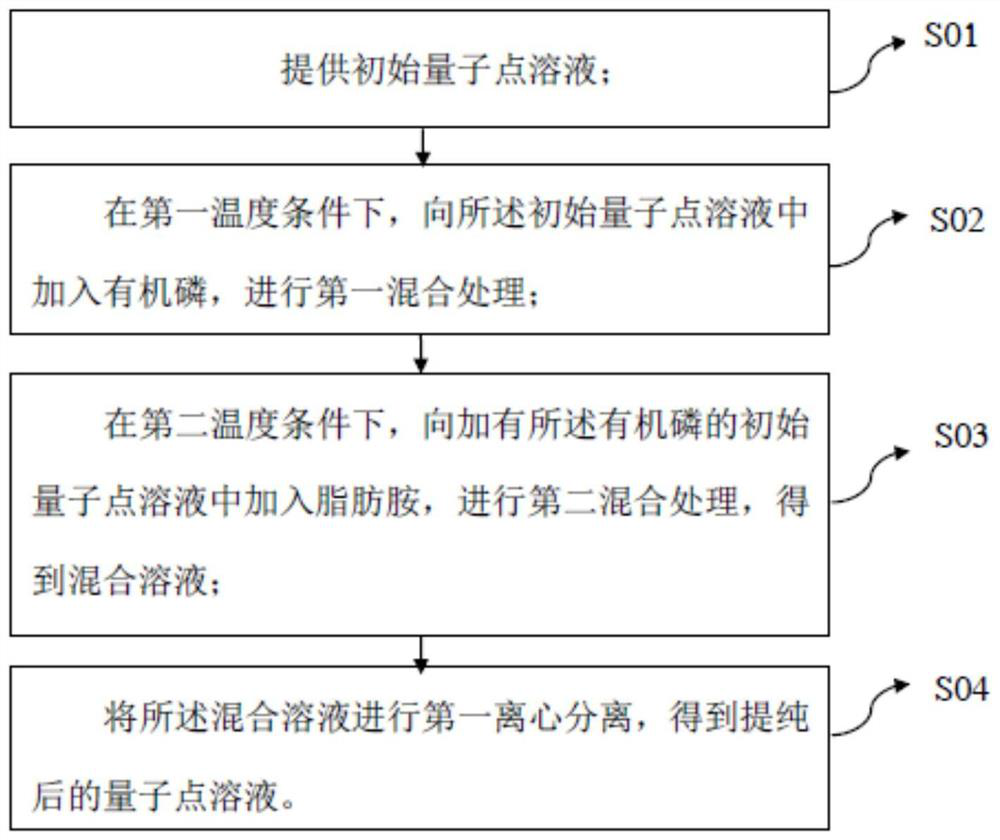

[0045] The quantum dot purification method provided in this embodiment comprises the steps:

[0046] (1) At 120°C, under an argon atmosphere, add 60ml of quantum dot stock solution (Cd x Zn 1-x S / Cd y Zn 1-y S / ZnS) was added 6ml trioctylphosphine (wherein, the volume ratio of organophosphorus trioctylphosphine and quantum dot stock solution was 1:10), and reacted at this temperature for 20min to obtain the first quantum dot solution;

[0047] (2) At 100°C under an argon atmosphere, continue to add 4ml of oleylamine to the above-mentioned first quantum dot solution (the volume ratio of fatty amine oleylamine to quantum dot stock solution is 1:15), and react at this temperature 10min, obtain the second quantum dot solution;

[0048] (3) Centrifuge the above-mentioned second quantum dot solution at a rotation speed of 7000 rpm for 10 min. The lower precipitate was removed, and 60 ml of ethanol was added to the supernatant for precipitation. Next, dissolve 10 ml of n-hexane ...

Embodiment 2

[0053] The quantum dot purification method provided in this embodiment comprises the steps:

[0054] (1) At 120°C, under an argon atmosphere, add 60ml of quantum dot stock solution (Cd x Zn 1-x S / Cd y Zn 1-y S / ZnS) was added 6ml tributylphosphine (wherein, the volume ratio of organophosphorus tributylphosphine and quantum dot stock solution was 1:10), and reacted at this temperature for 20min to obtain the first quantum dot solution;

[0055] (2) At 100°C under an argon atmosphere, continue to add 4ml of oleylamine to the above-mentioned first quantum dot solution (the volume ratio of fatty amine oleylamine to quantum dot stock solution is 1:15), and react at this temperature 10min, obtain the second quantum dot solution;

[0056] (3) Centrifuge the above-mentioned second quantum dot solution at a rotation speed of 7000 rpm for 10 min. The lower precipitate was removed, and 60 ml of ethanol was added to the supernatant for precipitation. Next, dissolve 10 ml of n-hexane ...

Embodiment 3

[0061] The quantum dot purification method provided in this embodiment comprises the following steps:

[0062] (1) At 120°C, under an argon atmosphere, add 60ml of quantum dot stock solution (Cd x Zn 1-x S / Cd y Zn 1-y S / ZnS) was added with 6ml of diphenylphosphine (wherein the volume ratio of organophosphorus diphenylphosphine to quantum dot stock solution was 1:10), and reacted at this temperature for 20min to obtain the first quantum dot solution;

[0063](2) At 100°C under an argon atmosphere, continue to add 4ml of oleylamine to the above-mentioned first quantum dot solution (the volume ratio of fatty amine oleylamine to quantum dot stock solution is 1:15), and react at this temperature 10min, obtain the second quantum dot solution;

[0064] (3) Centrifuge the above-mentioned second quantum dot solution at a rotation speed of 7000 rpm for 10 min. The lower precipitate was removed, and 60 ml of ethanol was added to the supernatant for precipitation. Next, dissolve 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com