LED (light-emitting diode) long-afterglow composite light-emitting spreadlight lens and light-emitting device with LED long-afterglow composite light-emitting spreadlight lens structure

A technology of long afterglow luminescence and polarizing lens, which is applied to semiconductor devices of light-emitting elements, optical elements used to change the spectral characteristics of emitted light, light sources, etc. Chromaticity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

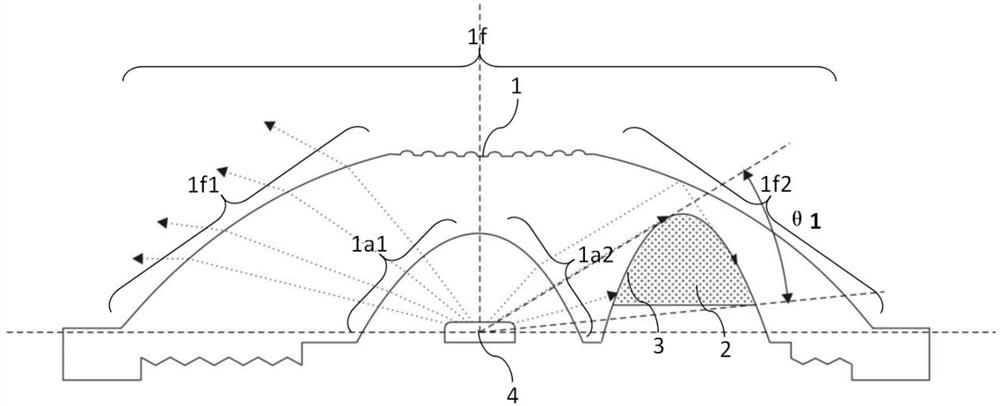

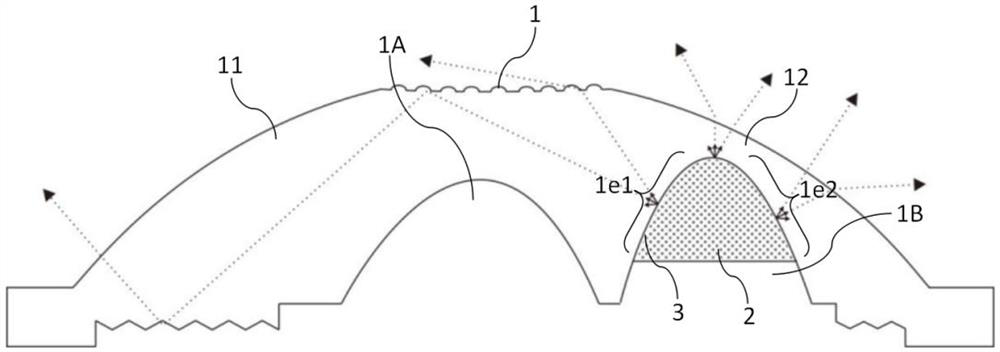

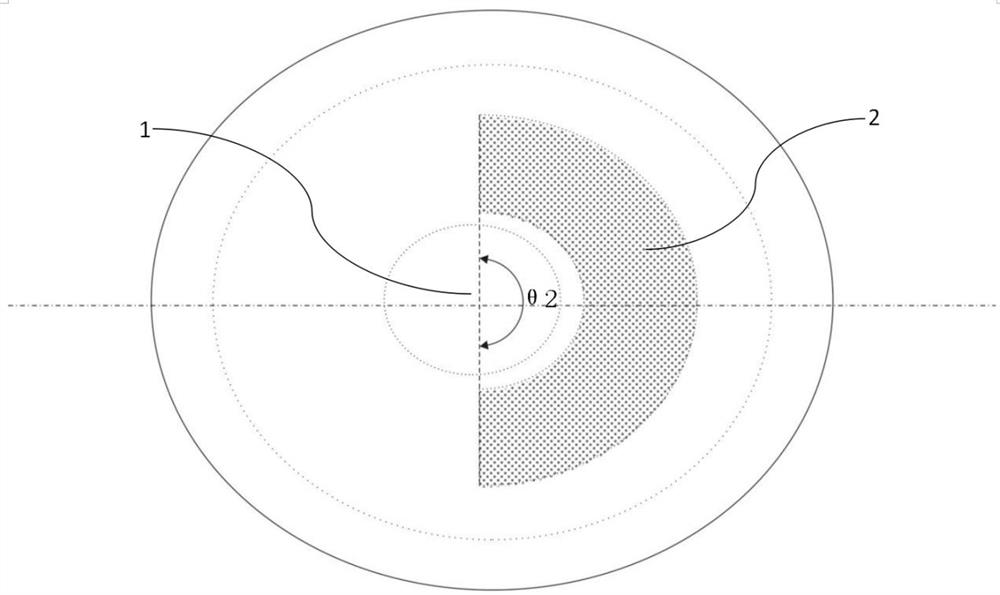

[0139] Embodiment 1 of the present invention provides a waterproof point light source (or luminescent lamp) with LED long afterglow composite luminous polarizing lens, such as Figure 7-10 As shown, the lens body structure (110) is raised as a whole, and the top surface is a plane or a convex or convex free-form surface with a small curvature. The light exits the first light incident surface (110a1) on the side of the main body (1110) ) and the first light-emitting surface (110f1) [the first light-emitting surface (110f1) can be convex arc surface, such as Figure 7 , 9 As shown, or the first light-emitting surface (110f1) can be inclined, such as Figure 11 , 13 As shown, the side wall between ] is in the shape of a narrow top and a wide bottom (similar to the refraction of an arc prism), forming a shape that can make at least part of the light of the LED in the accommodating cavity go to the side where the light exits the main body (1110) to the optical structure that def...

Embodiment 2

[0150] Embodiment 2 of the present invention provides a modeling luminous lamp with LED long afterglow composite luminous polarizing lens multi-unit module, such as Figure 17-26 As shown, the units of the lens body structure (210) can be arranged according to certain rules, and can be arranged into characters, symbols, numbers, etc. as required, or arranged in a determinant or array, or two connected rows or two columns are dislocated. Or form a circular or polygonal form, etc.; the bottom of each lens body structure (210) unit is recessed inwardly to form a single, opening downward accommodating cavity; the top or side of each lens body structure (210) unit is connected to each other or each The top or side of the unit of the lens body structure (210) extends outward and connects with each other to form a panel (lamp board or lamp housing), and the same side of the housing cavity of the adjacent lens body structure (210) is provided with an arc according to the first embodime...

Embodiment 3

[0158]Embodiment 3 of the present invention provides a strip light with LED long afterglow composite light strip polarized lens structure, such as Figure 27-29 As shown, the lens structure is PC or PMA extruded hard light bar or transparent silicone, PU, PVC extruded soft light bar or light strip or injection molded light board cover, and its lens body structure (310) It is strip-shaped and extends in a straight line, and the side wall between the first light-incident surface (310a1) and the first light-emitting surface (310f1) on the side where the light exits the main body (3110) is in the shape of a narrow top and a wide bottom ( Similar to arc-shaped prism refraction), forming an optical structure that can make at least part of the light of the LED in the accommodating cavity laterally deflect and exit to this side, and one side of the auxiliary optical part (3120) is provided with a lens body structure (310) Parallel linear accommodation grooves, long afterglow luminou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com