Patents

Literature

61results about How to "Thickness can be adjusted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

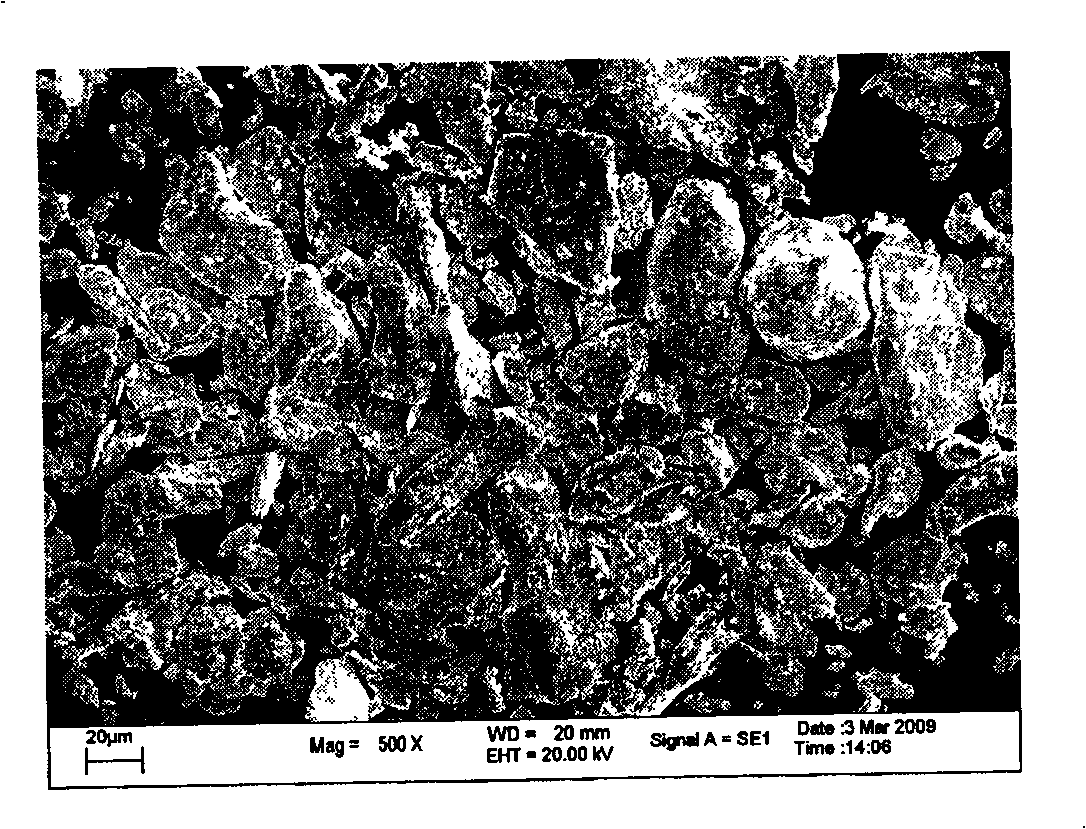

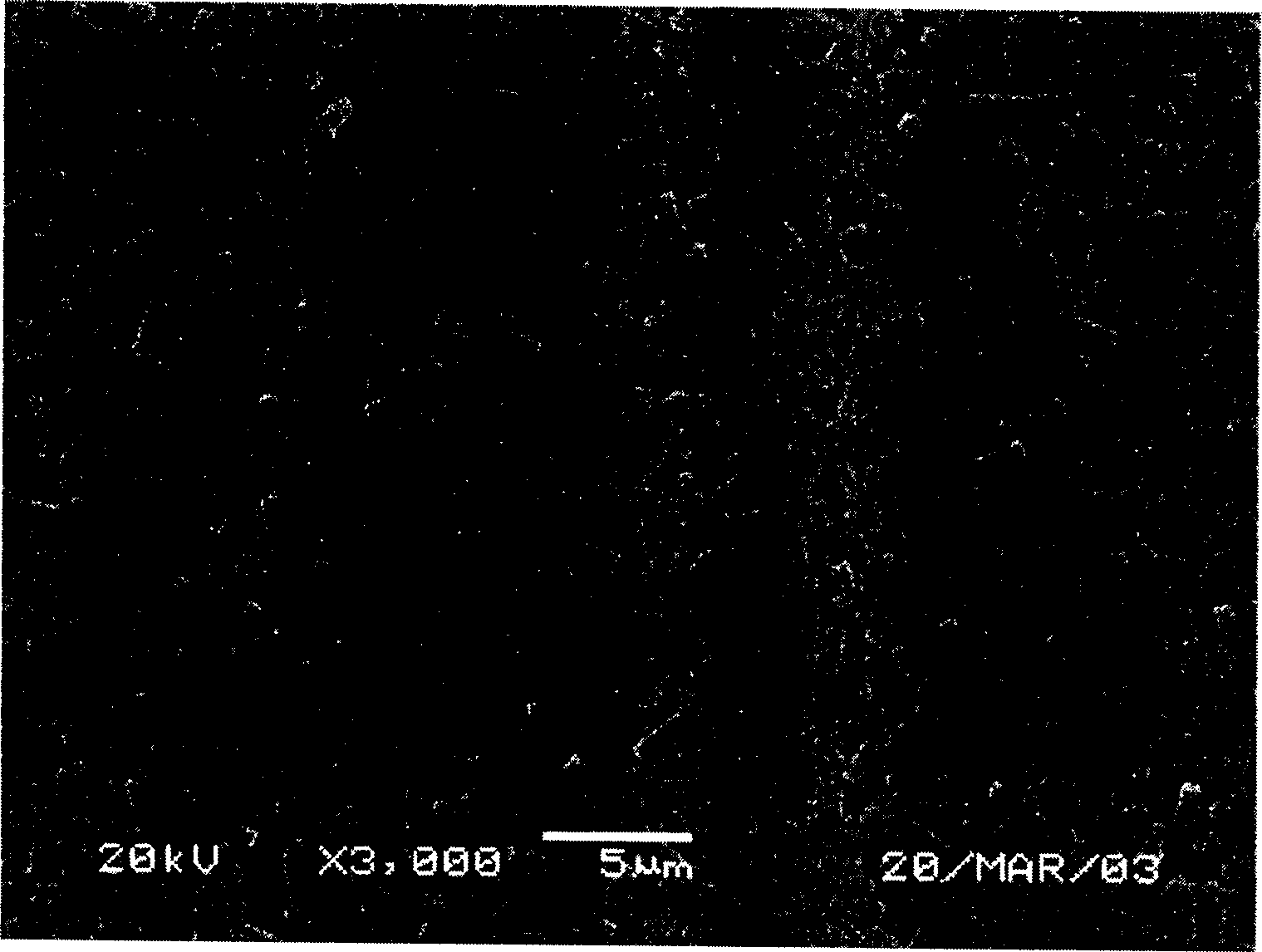

Preparation method of copper-coated tungsten composite powder

InactiveCN101537491AHigh sintering activityUniform thicknessLiquid/solution decomposition chemical coatingWater bathsBipyridine

The invention discloses a preparation method of copper-coated tungsten composite powder, belonging to the technical field of powder metallurgy. Corresponding tungsten powder and blue vitriod are employed according to the weight ratio of composite powder to be prepared and the tungsten powder is pre-treated; copper sulphate and seignette sol are dissolved into solution; bipyridine is added and NaOH is used to adjust pH value to 12-14; an appropriate amount of formaldehyde solution and the tungsten powder are added; the mixture is heated and then stirred continuously in constant-temperature bathing at 30-60 DEG C until the tungsten powder is red; the tungsten powder is washed, dried, reduced and annealed, thereby obtaining copper-coated tungsten composite powder. The preparation method of copper-coated tungsten composite powder has wide application range and is applicable to tungsten-powder coating coppers with different finenesses and shapes. The preparation method of copper-coated tungsten composite powder prepares copper-coated tungsten composite powder in different content ratios according to different requirements. The copper-coated tungsten composite powder obtained by the method of the invention has excellent sintering activity, thereby improving the combination property of tungsten copper alloy.

Owner:UNIV OF SCI & TECH BEIJING

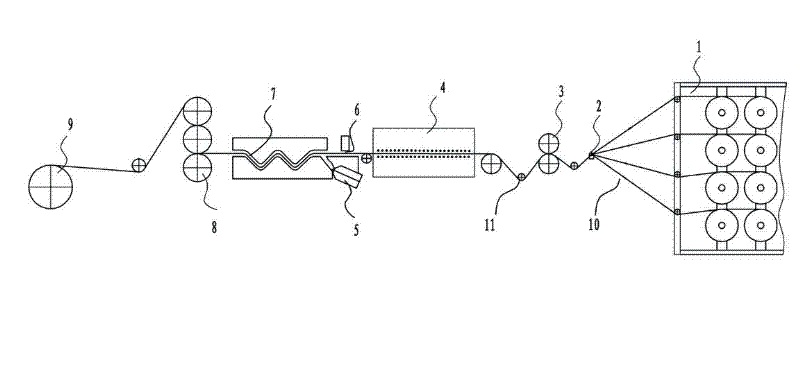

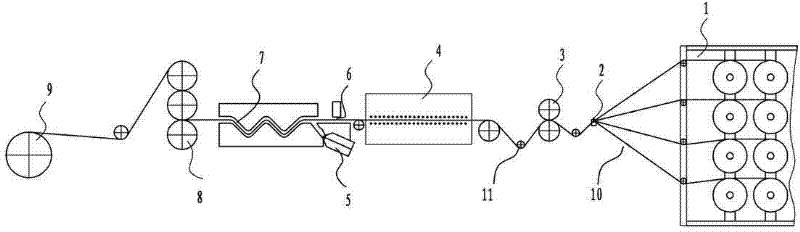

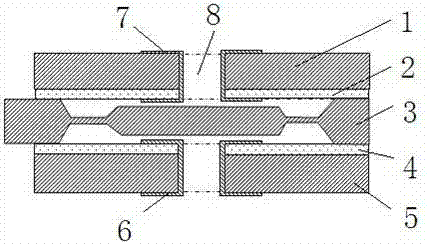

Method and equipment for producing continuous fiber-reinforced thermoplastic composite material prepreg tape

InactiveCN102328443AImproved impregnation and workabilityEvenly dispersed fibersDischarge pressureFibre reinforcement

The invention discloses a method and equipment for producing a continuous fiber-reinforced thermoplastic composite material prepreg tape. In the method, an extrusion die head is used for extruding fused resin, preheated continuous fibers are guided into a primary tank for preliminary impregnation, and then discharge pressure is controlled to enable pre-impregnated continuous fibers to pass through a secondary impregnating tank filled with fused resin to realize a full impregnation process. Therefore, the problems of how to enable the prepreg tape to be fully impregnated and threaded and how to enable joint cleaning to become easy can be solved.

Owner:TAIZHOU JIADEBAO TECH

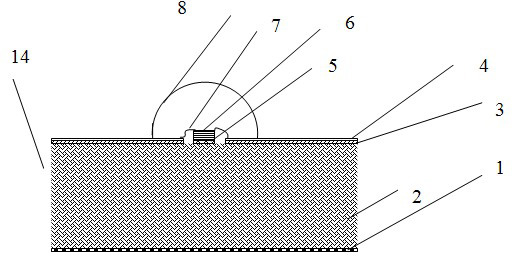

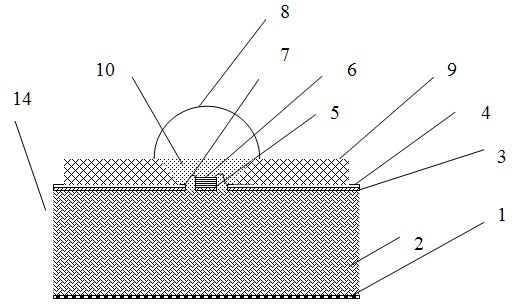

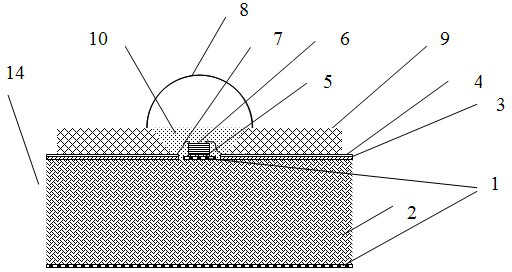

High-power light emitting diode with radiating substrate made of diamond-like film-copper composite material

InactiveCN102354725ABoth have cooling effectIncrease contact areaSolid-state devicesSemiconductor devicesJunction temperatureEngineering

The invention discloses a high-power light emitting diode with a radiating substrate made of a diamond-like film-copper composite material. The diode comprises an LED (Light Emitting Diode) chip, a lens, a reflection cup and the radiating substrate made of the diamond-like film-copper composite material, wherein the LED chip is positioned in the reflection cup; the lens is positioned above the reflection cup; the lower surface of the cooling substrate directly contacts with air; and the LED chip is directly placed on the upper surface of the cooling substrate by die attaching resin or metal eutectic welding. The composite material disclosed by the invention extracts heat from high-power LED via a shortest path, and directly emits heat to the air so as to effectively lower the junction temperature of the LED. Because the composite material can lower the thermal resistance of the whole LED packaging structure, the composite material can be used for cooling single high-power LED and an LED module by combining with an optimized structural design, thereby realizing high-luminance shining for a long term.

Owner:SOUTH CHINA NORMAL UNIVERSITY

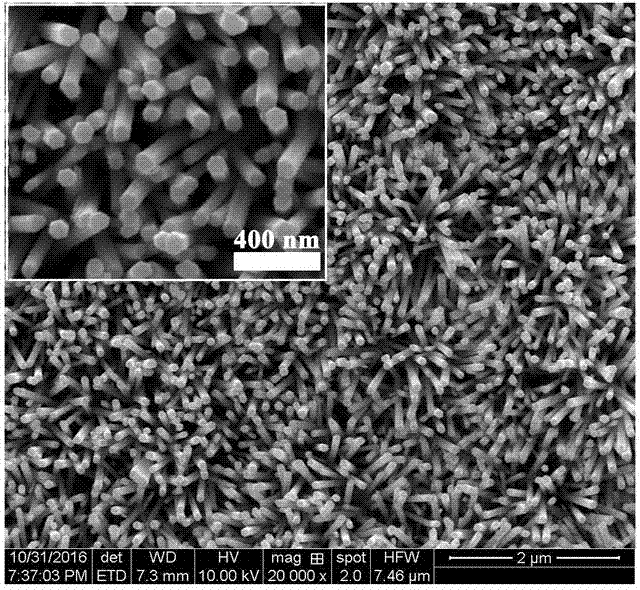

Preparation of rod-like ZnO/ZIF-8 and low temperature H2 sensitive effect of rod-like ZnO/ZIF-8

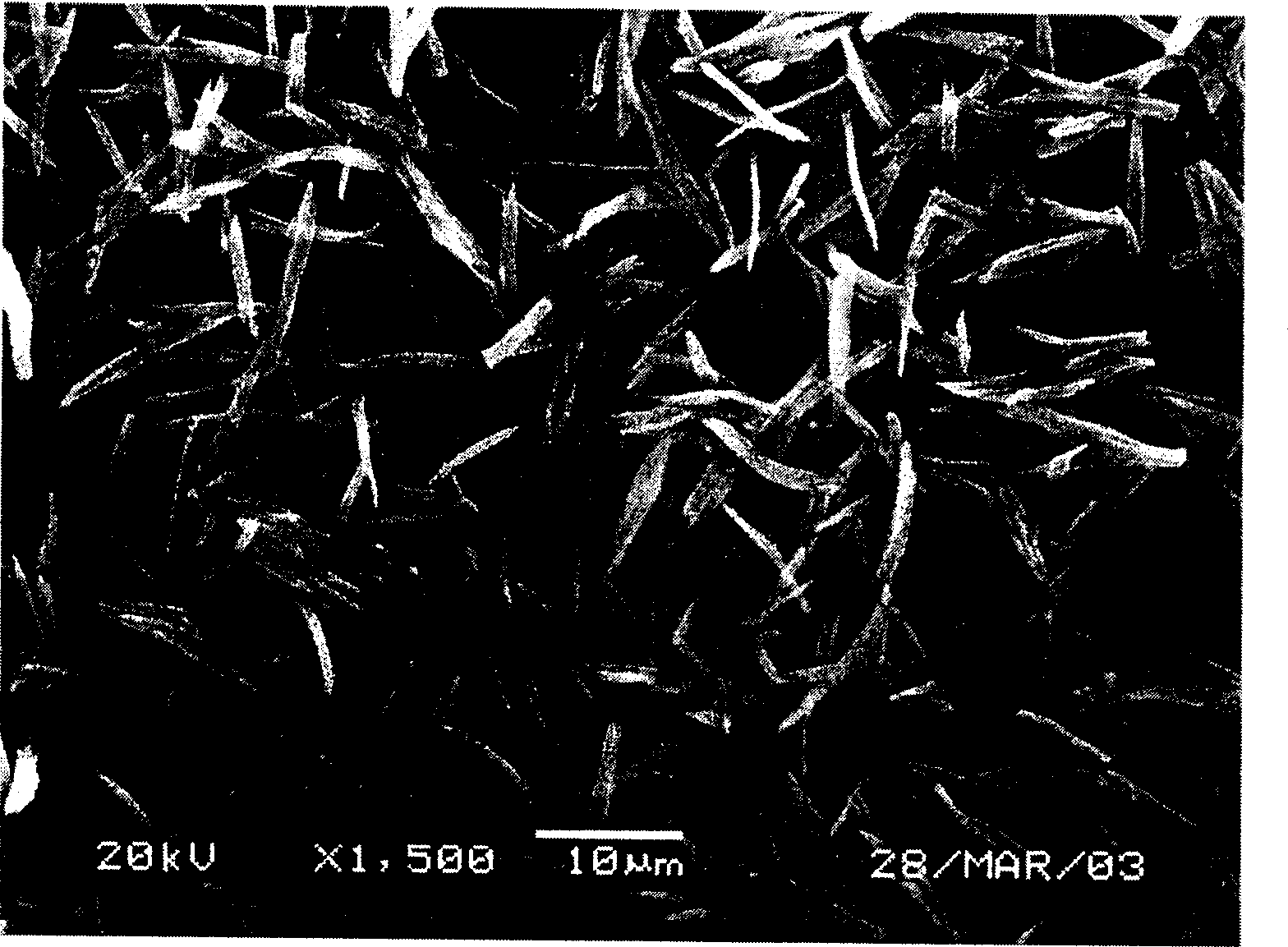

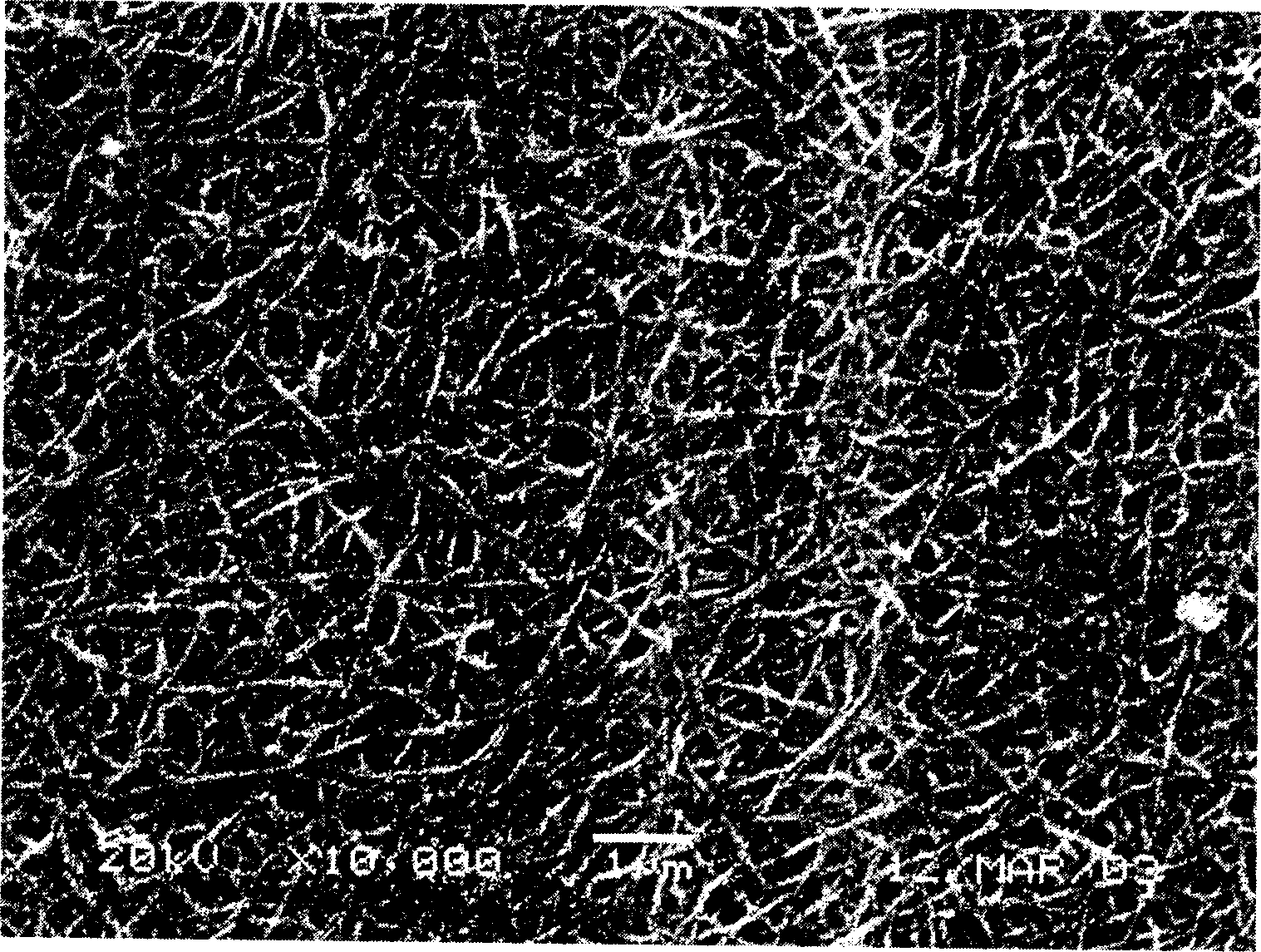

InactiveCN107991350AGreat application potentialGood choiceMaterial nanotechnologyZinc oxides/hydroxidesGas detectorZinc Acetate Dihydrate

The invention comprises the following steps: utilizing an alumina plate electrode as a substrate, preparing a ZnO crystal layer on the alumina plate electrode by utilizing a spin-coating method, and then growing ZnO nano rods at the ZnO crystal layer by a hydrothermal method, finally, putting in a mixed solution of 2-methylimidazole and zinc acetate, growing at room temperature to obtain a rod-like ZnO / ZIF-8. The preparation of the rod-like ZnO / ZIF-8 and low temperature H2 sensitive effect of rod-like ZnO / ZIF-8 disclosed by the invention have the advantages that a composite material is prepared at room temperature, so that power consumption is significantly decreased; the prepared rod-like ZnO / ZIF-8 with porous structure forms regular array; extreme high selectivity is provided when a gassensor detects small molecule gases such as H2; the application potentiality is larger.

Owner:UNIV OF JINAN

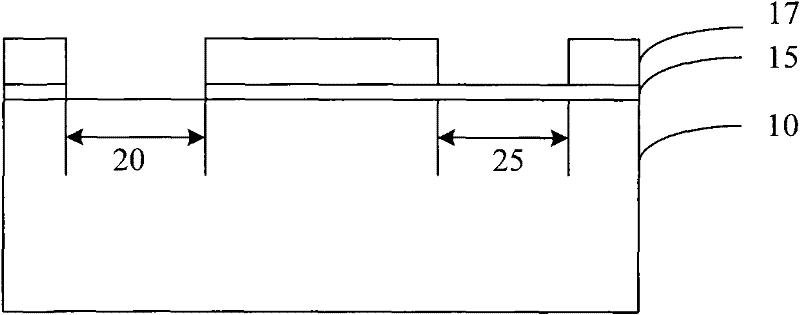

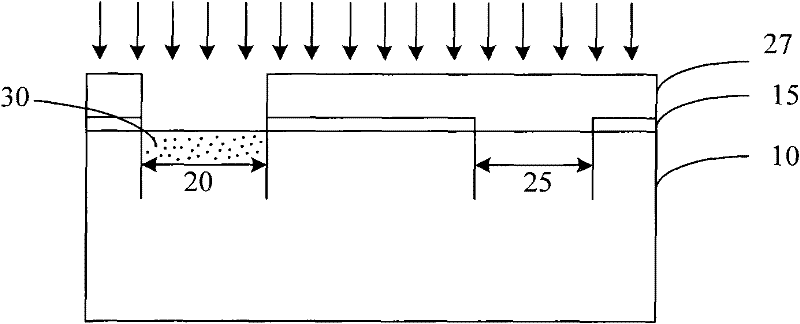

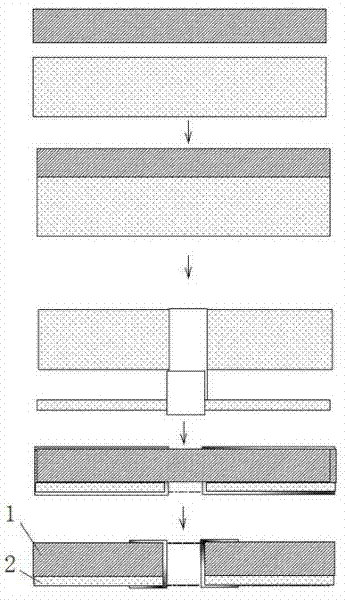

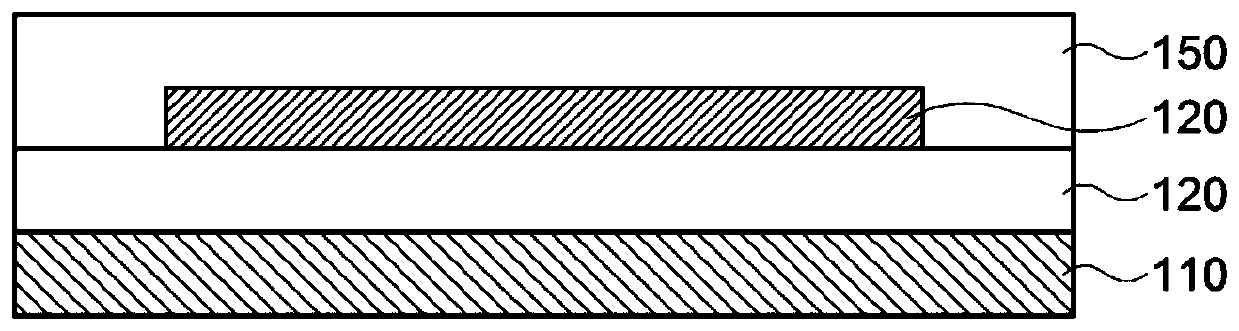

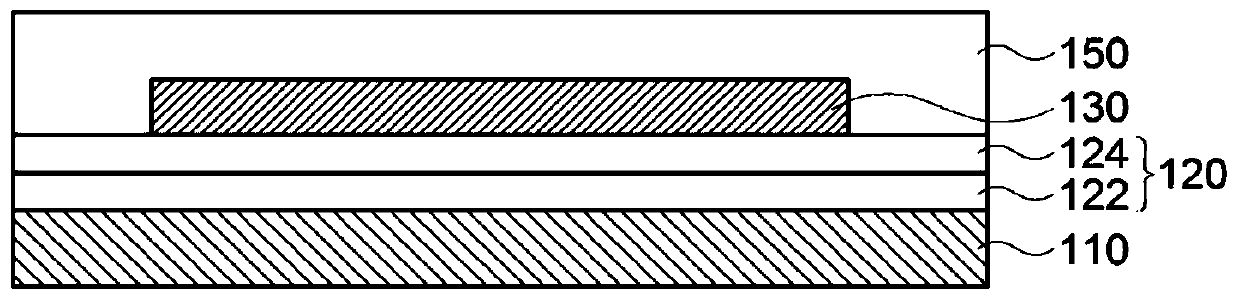

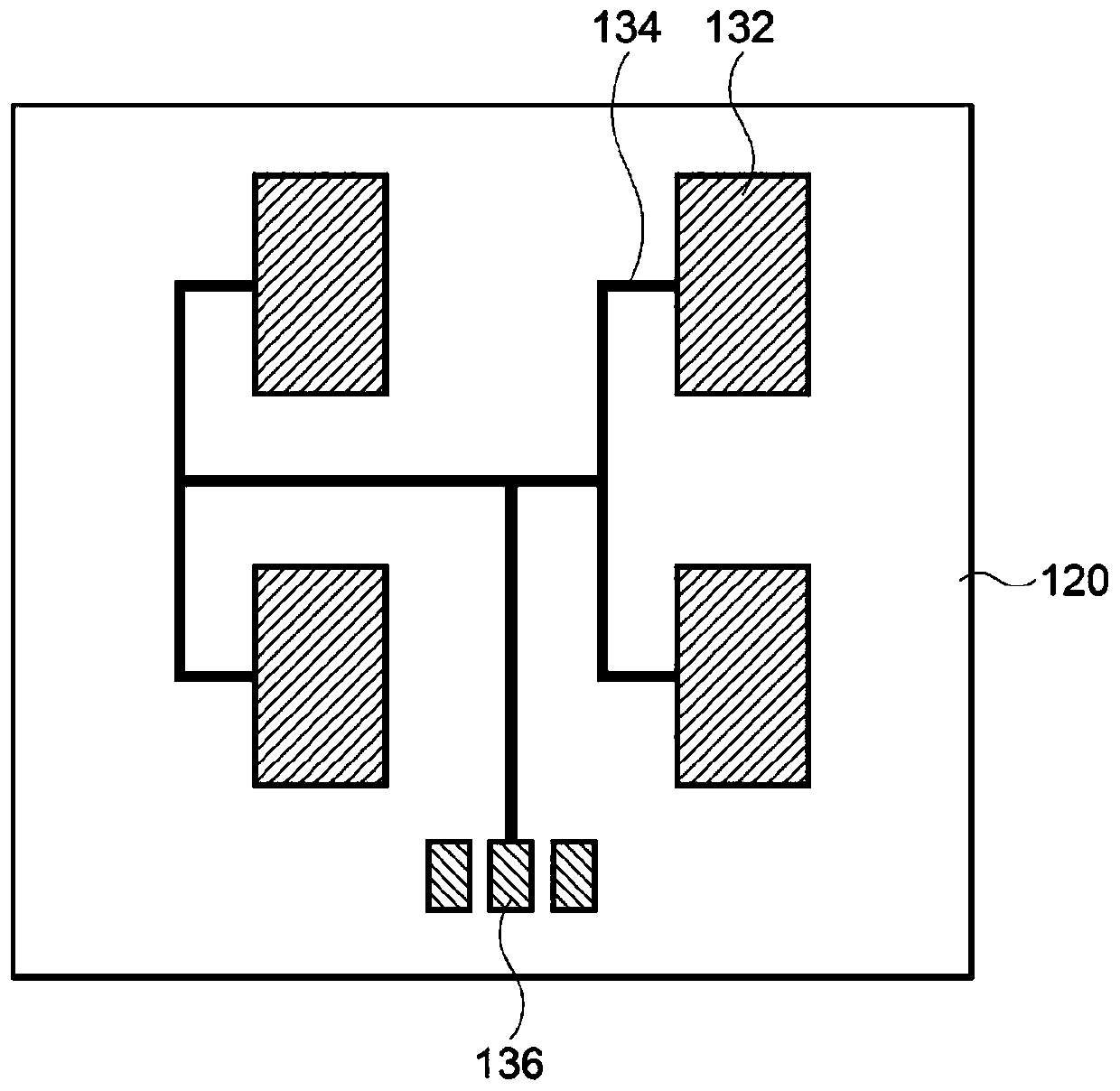

Semiconductor device and manufacturing method thereof

InactiveCN102237293AThickness can be adjustedAdjustable thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesImpurity ionsSilicon oxide

The invention provides a semiconductor device and a manufacturing method thereof, wherein the manufacturing method comprises the following steps: providing a semiconductor substrate, wherein the semiconductor substrate comprises a hard mask layer which is arranged on the surface of the semiconductor substrate and the semiconductor substrate comprises a first region and a second region; removing the hard mask layer from the surface of the semiconductor substrate in the first region; implanting impurity ions in the first region; growing a first silicon oxide layer on the semiconductor substrate in the first region; removing the hard mask layer from the surface of the semiconductor substrate in the second region; growing a second silicon oxide layer respectively in the first region with the first silicon oxide layer and on the semiconductor substrate in the second region, thus improving the withstand voltage effect of a high voltage device.

Owner:CSMC TECH FAB1 +1

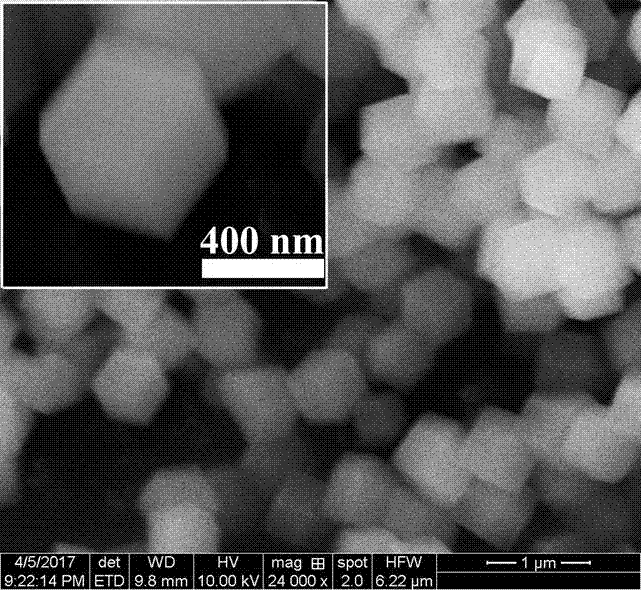

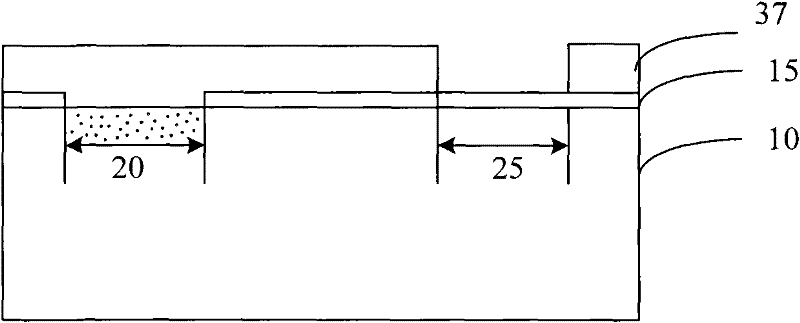

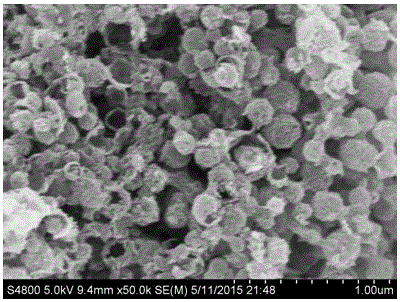

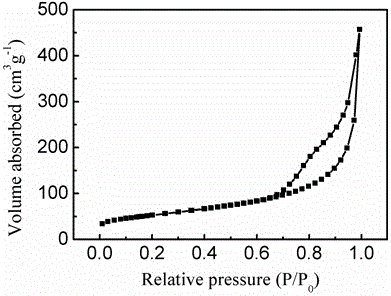

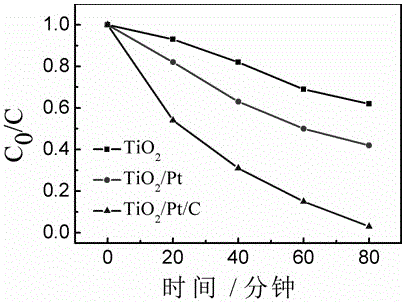

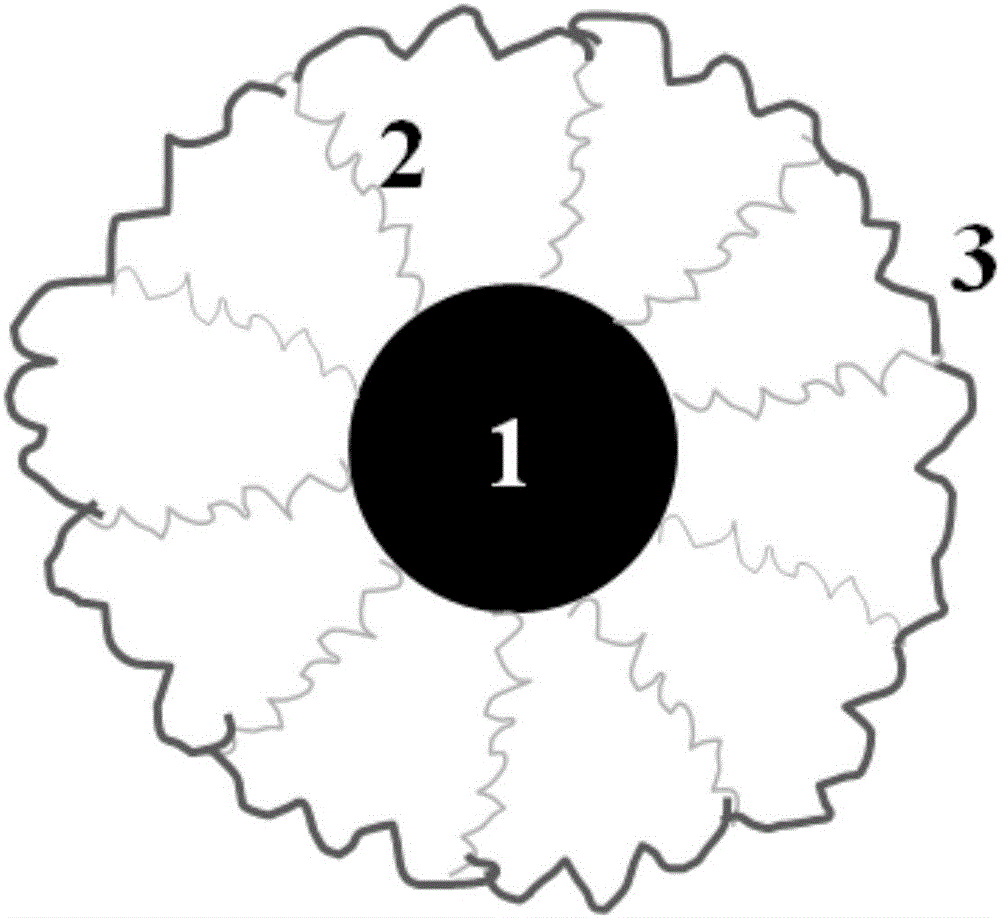

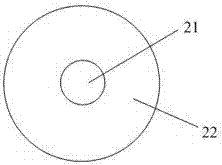

Hollow sphere adopting metal oxide/Pt/C three-layer nano structure and preparation method of hollow sphere

InactiveCN105056849ASimple methodLow costMicroballoon preparationMicrocapsule preparationPhoto catalysisLithium electrode

The invention discloses a hollow sphere adopting a metal oxide / Pt / C three-layer nano structure. A spherical shell of the hollow sphere sequentially comprises a metal oxide layer, a Pt layer and an amorphous carbon layer from inside to outside. A template adsorption method is used, a hollow metal oxide sphere is prepared firstly, Pt particles are prepared on the surface of metal oxide with an impregnation method, finally, the surface of the hollow metal oxide sphere coated with the Pt particles is coated with amorphous carbon through hydro-thermal treatment, and then the hollow sphere adopting the metal oxide / Pt / C three-layer nano structure is prepared. The prepared hollow sphere with the metal oxide / Pt / C three-layer nano structure has a regular core-shell structure, the thickness is adjustable, and the specific surface area is larger than 200 m <2> / g. A method is simple, the cost is lower, industrial production can be easily realized, and the hollow sphere can be well applied to fields such as photocatalytic decomposition of water for hydrogen production, gas sensing, super capacitors, lithium ion batteries and the like.

Owner:ZHEJIANG UNIV

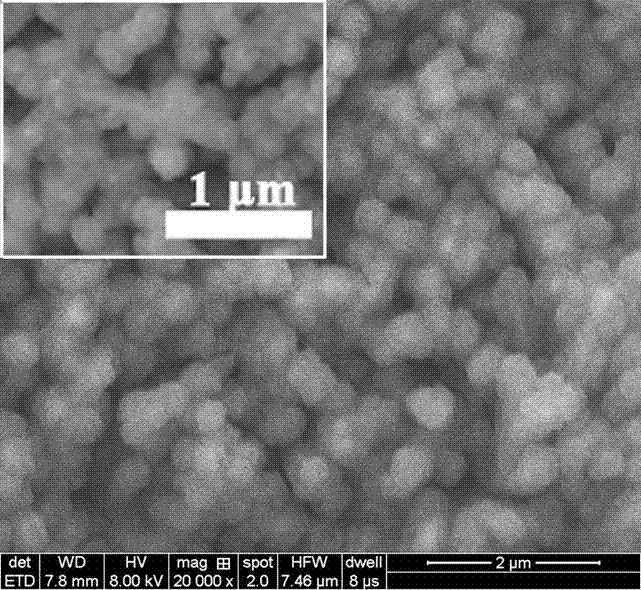

Anode material for lithium ion battery as well as preparation method and application of anode material

ActiveCN106803574AThickness can be adjustedEasy to prepareCell electrodesSecondary cellsPolymer electrolytesConductive polymer

The invention relates to an anode material for a lithium ion battery as well as a preparation method and application of the anode material. The anode material is an LMP / PEG-PTh composite material, wherein the mass percentage of PTh in the LMP / PEG-PTh composite material is 1%-15%. The preparation method of the anode material comprises the following steps: with an LMP material as a kernel, attaching PEG to the surface of the LMP kernel, so as to obtain an LMP / PEG composite material; and depositing a conductive polymer PTh on the surface of the LMP / PEG composite material, so as to obtain the LMP / PEG-PTh composite material. According to the invention, the PEG can form a cladding layer on the surface of the LMP so as to restrain the dissolving of manganese and is a good solid polymer electrolyte matrix capable of promoting the transmission of lithium ions; and by utilizing a PTh cladding layer with relatively high conductivity, the load transfer resistance among LMP interfaces can be reduced, the surface migration rates of the lithium ions and electrons can be increased, and therefore, the rate capability of an electrode is improved.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

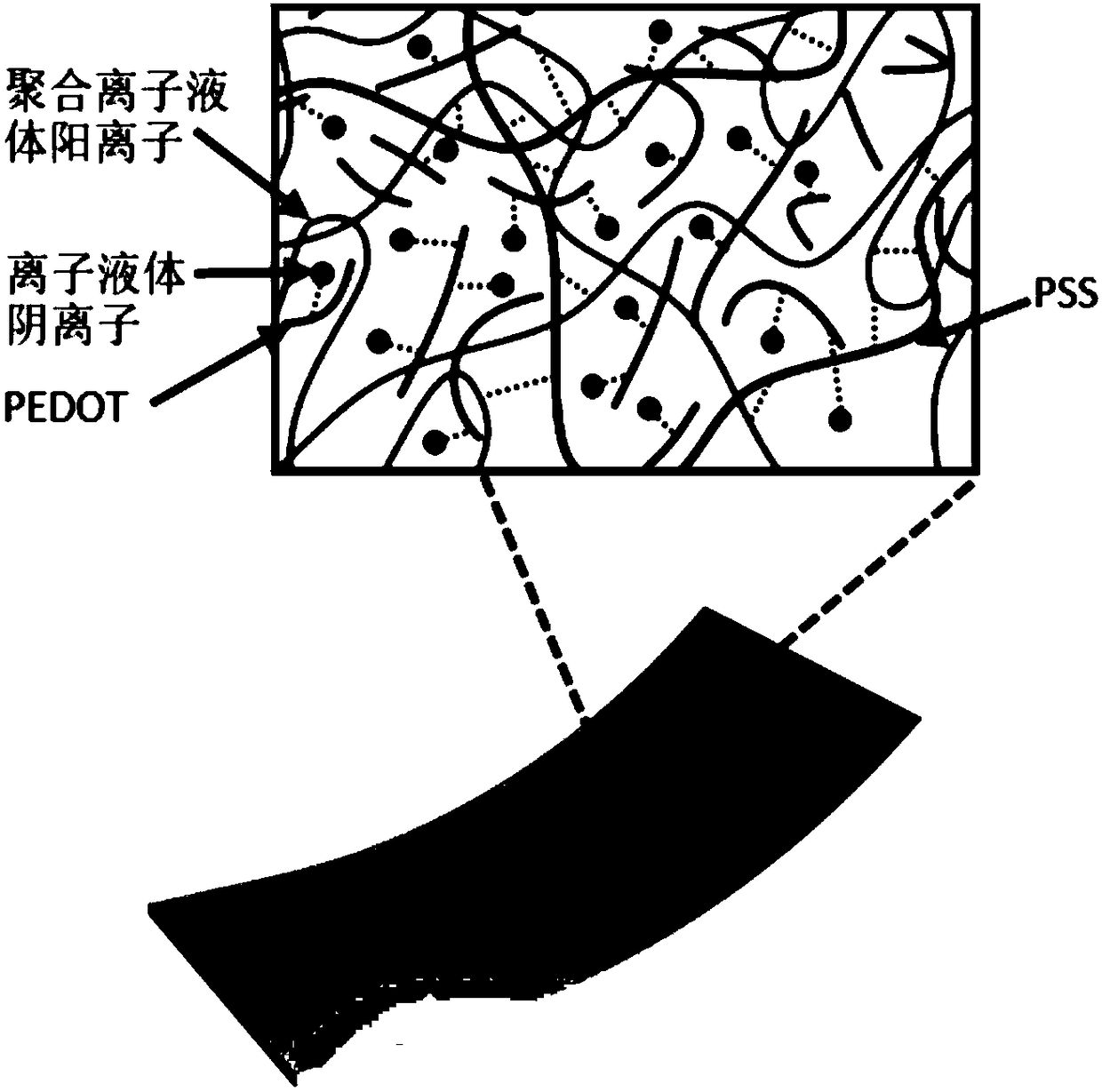

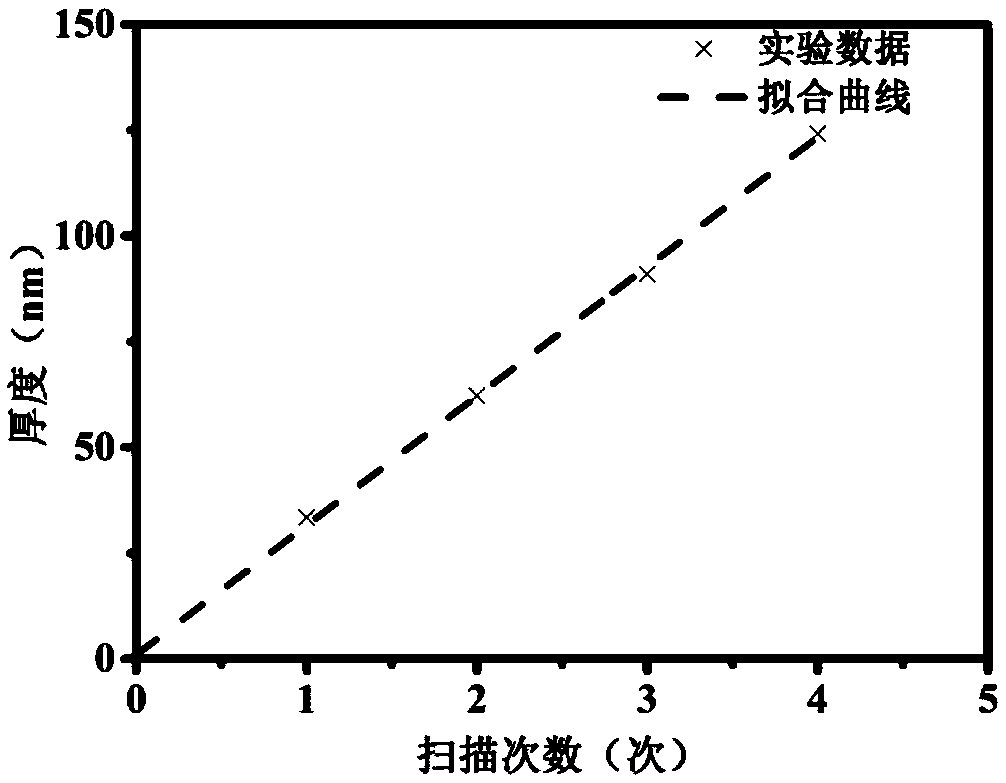

Manufacturing method of PEDOT:PSS@ ionic liquid gel composite self-supporting flexible transparent electrode

ActiveCN108630340AThickness can be adjustedAdjustable resistanceConductive layers on insulating-supportsCable/conductor manufactureConductive polymerSolar cell

The invention relates to the manufacturing method of a PEDOT:PSS@ ionic liquid gel composite self-supporting flexible transparent electrode. The manufacturing method comprises the following steps of compositing a conductive polymer PEDOT:PSS and an ionic liquid monomer through an electrostatic interaction; and under light and heat conditions, carrying out polymerization crosslinking and acquiringthe PEDOT:PSS@ ionic liquid gel composite self-supporting flexible transparent electrode. The composite flexible transparent electrode has good stability and an excellent mechanical property. Shedding, fracture and other problems between the flexible transparent electrode and a substrate are overcome. The electrode has characteristics that a manufacturing process is simple; cost is low; and the electrode is stable and has good flexibility. The transparent electrode is suitable for manufacturing wearable electronic equipment, a flexible touch screen, a flexible solar cell and a flexible organicEL panel.

Owner:BEIJING SCITECH NANOTECH CO LTD

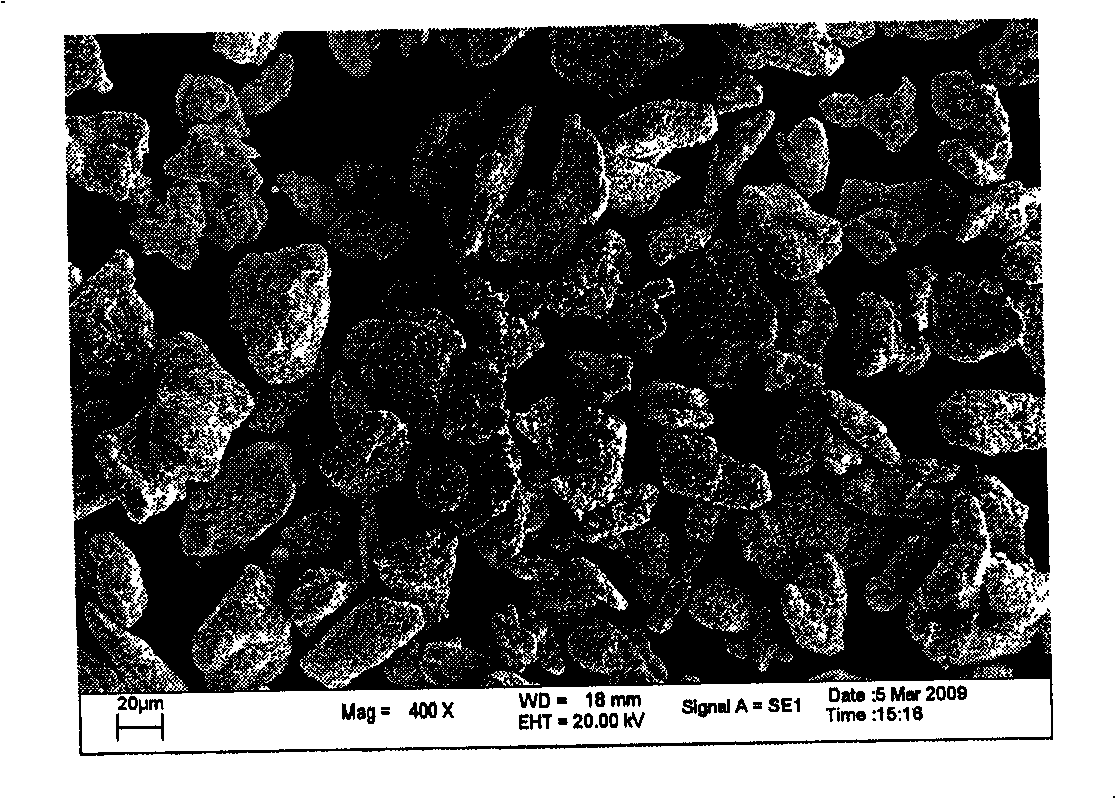

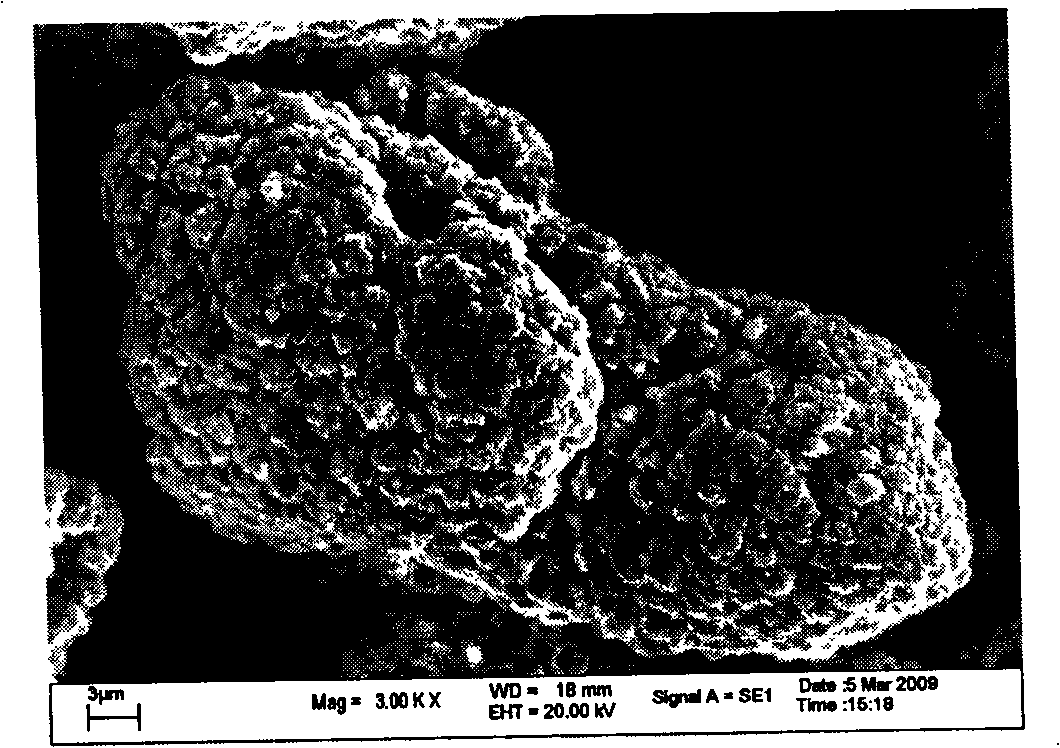

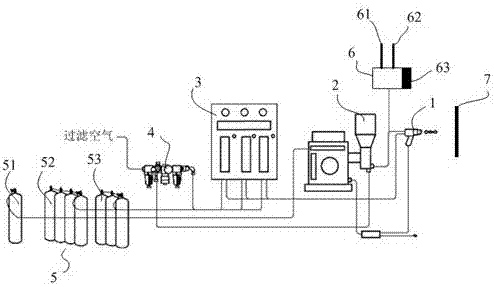

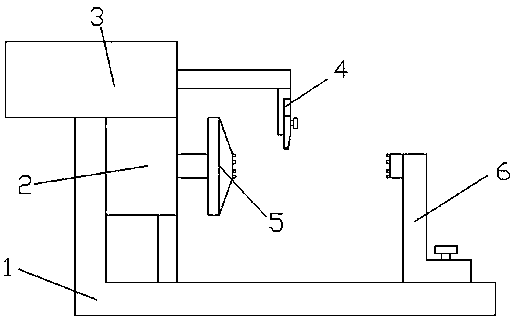

Plasma thermal spraying device

InactiveCN106958002AImproved coefficient of thermal expansionHigh thermal conductivityMolten spray coatingMicron scaleAir filtration

The invention discloses a plasma thermal spraying device which is used for spraying tungsten-copper mixed powder to a red copper substrate. The plasma thermal spraying device comprises a spray gun, a powder feeder, an air flow meter, an air controller and an air supply system, wherein the spray gun is connected with the powder feeder, the air controller is used for controlling air filtration, the air controller is connected with the air flow meter, the air supply system is connected with the air flow meter, and the air flow meter is connected with the spray gun; the powder feeder is used for providing the tungsten-copper mixed powder, the tungsten-copper mixed powder is spherical powder grains with the grain size ranging from 2 micrometers to 15 micrometers, the spherical powder grains comprise tungsten grains and a copper layer which covers the tungsten grains, the tungsten grains are nano-scale grains, and the copper layer is a micron-scale layer; and the distance from the spray gun to the red copper substrate ranges from 8 mm to 12 mm. The plasma thermal spraying device is simple in structure, convenient to operate and low in cost, thermal conductivity of a tungsten-copper flange cooling fin made through the device reaches up to 380 W / m*K, and the cooling fin is stable and reliable.

Owner:FOSHAN SENHE YEFENG PAPER PROD CO LTD

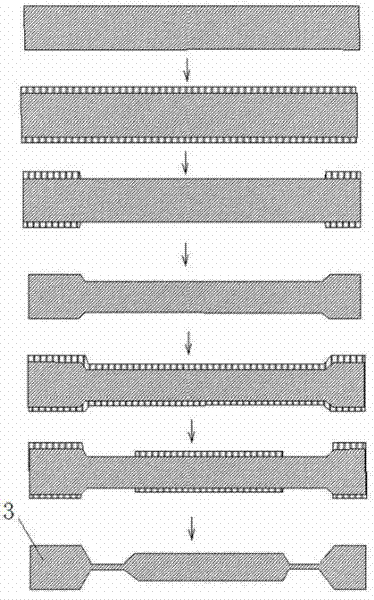

Silicon capacitance pressure sensor

InactiveCN102654426AAchieve performanceThickness can be adjustedFluid pressure measurement using capacitance variationCentral pressureParasitic capacitance

The invention relates to a silicon capacitance pressure sensor, comprising a silicon wafer layer and a glass layer. The silicon capacitance pressure sensor is characterized in that: a silicon fixed polar plate is respectively connected with the upper side and the lower side of a movable polar plate at the silicon center of an island film structure, and the silicon fixed polar plate comprises the silicon wafer layer and the glass layer, both of which are statically sealed in vacuum, and the thickness of the glass layer is 50-200 microns; a central pressure leading hole is formed at the middle part of the silicon fixed polar plate, and an aluminum film layer is arranged on the outer surface of the silicon fixed polar plate in the central pressure leading plate and close to the central pressure leading hole. The invention provides a new design realization scheme aiming at a core component of a present silicon capacitance pressure sensor. Even through silicon polar plates are connected through thin-layer glass through a static seal process without a high-temperature bonding furnace and an ultraclean environment, the process condition is simple and is directly compatible with the present processes, especially the thickness of the glass thin layer can be regulated, and interlayer parasitic capacitors are controlled in a certain range. Through the performance of the silicon capacitance pressure sensor disclosed by the invention, an effect approximating a silicon-silicon-silicon scheme is realized.

Owner:SHENYANG ACAD OF INSTR SCI

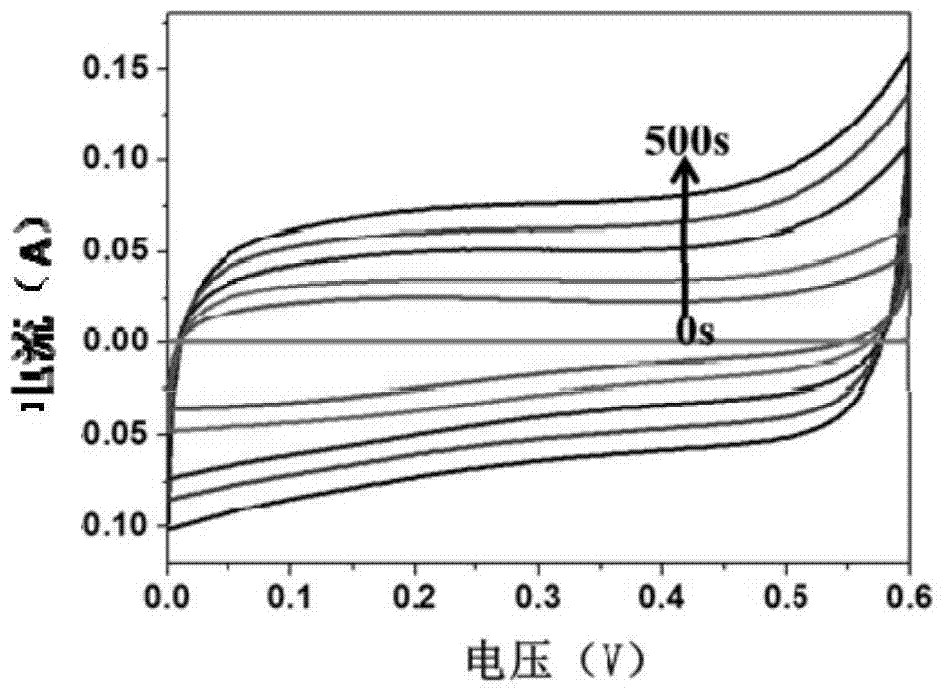

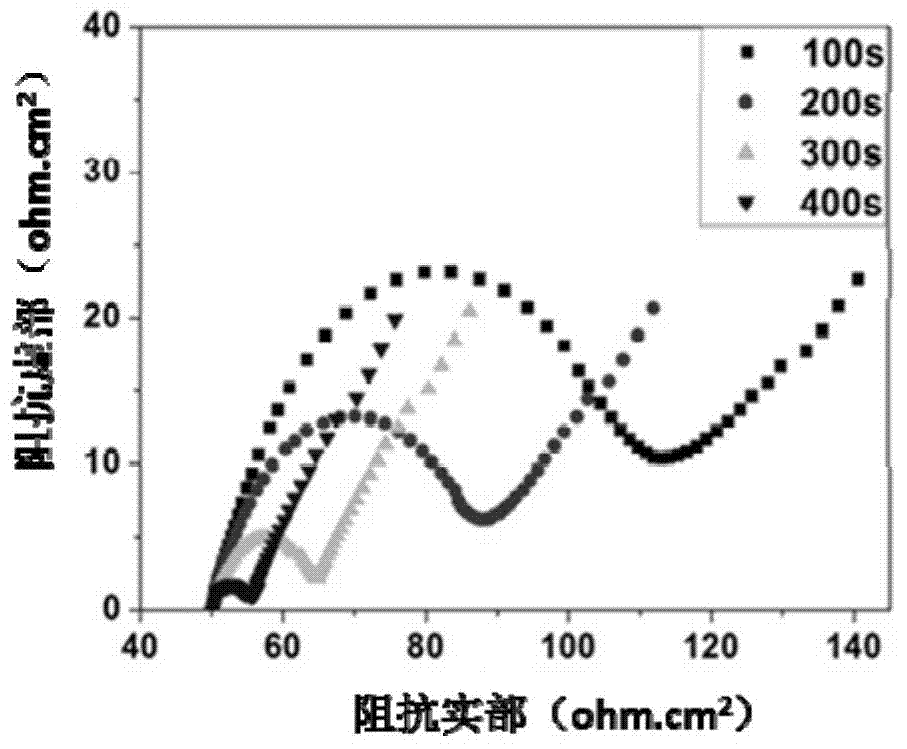

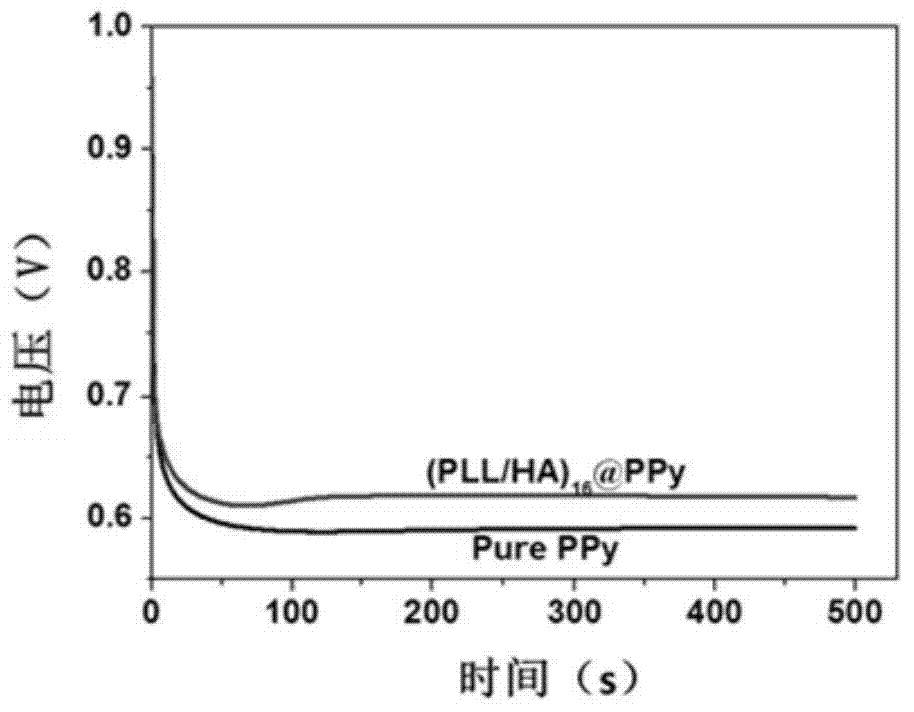

Method and product for establishing conductive hydrogel ultrathin membrane by using layered assembly and electrochemical technology

ActiveCN103545050AGood biocompatibilityUniform distribution and content controllable adjustmentConductive layers on insulating-supportsCable/conductor manufactureSolventPyrrole

The invention discloses a method for establishing a controllable conductive hydrogel ultrathin membrane by using layered assembly and an electrochemical technology. The method comprises the following steps of alternately performing layer-by-layer self-assembly on a conductive substrate in polycation and polyanion electrolyte solution to obtain a conductive substrate with a hydrogel ultrathin membrane; mixing pyrrole, sodium p-tolue and solvent E to obtain solvent G, placing the conductive substrate with the hydrogel ultrathin membrane in the solvent G, and soaking the conductive substrate until the concentrations of the pyrrole and the sodium p-tolue on the inside and the outside of the hydrogel ultrathin membrane are balanced; and performing electrical oxidation polymerization on the pyrrole in the environment of the solution G by using a chronopotentiometry after soaking to obtain the conductive hydrogel ultrathin membrane. The invention also discloses a conductive hydrogel ultrathin membrane prepared by the method for establishing the controllable conductive hydrogel ultrathin membrane by using the layered assembly and the electrochemical technology. The layered assembly and the electrochemical technology used together, and the electrical performance of the conductive hydrogel ultrathin membrane can be accurately regulated and controlled by changing the time of electrochemical reaction.

Owner:ZHEJIANG UNIV

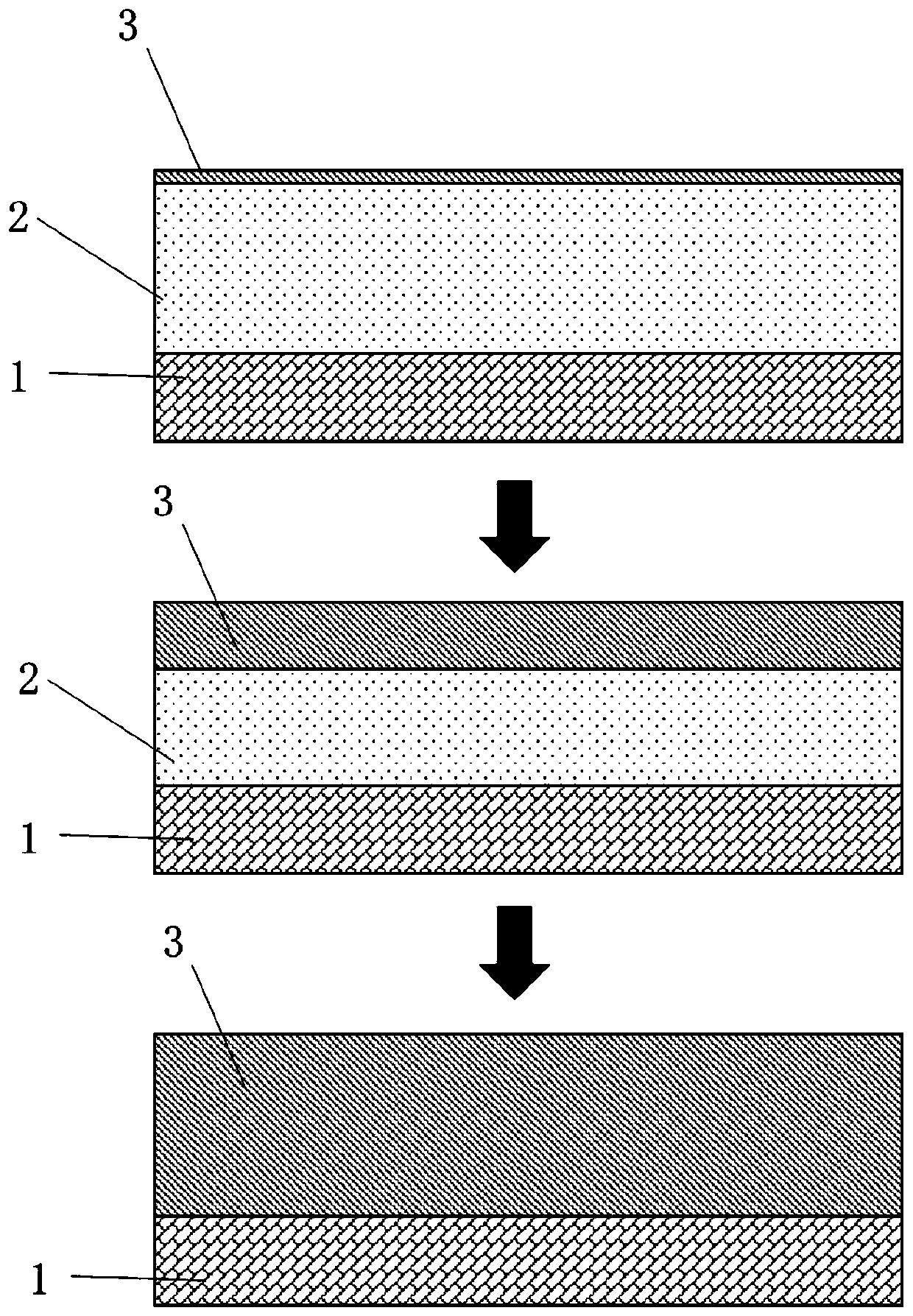

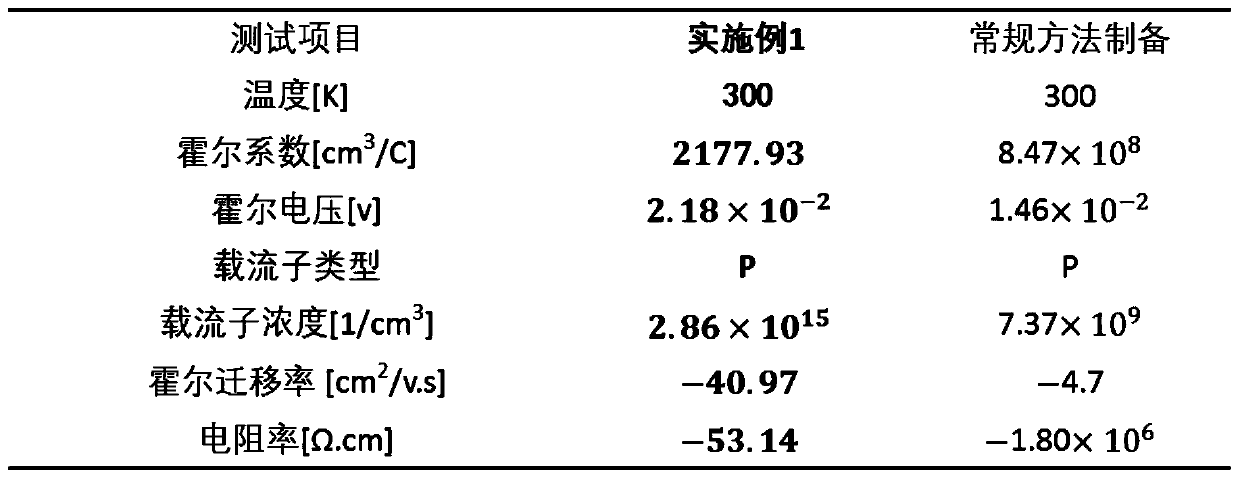

P-type nitrogen-doped gallium oxide film and preparation method thereof

ActiveCN111341839AHigh doping rateHigh repetition rateTransistorFinal product manufactureThin membraneHigh resistivity

The invention discloses a p-type nitrogen-doped gallium oxide film and a preparation method thereof. Through thermal oxidation growth, tahe p-type gallium oxide film grows from the upper surface of agallium nitride film to the lower surface of the gallium nitride film in a diffusion mode, and the carrier concentration of the prepared p-type gallium oxide film is 1.0 * 10 <11> / cm <3>-1.0 * 10 <20> / cm < 3 >, the surface roughness of the film is 1 nm-100 nm, and the resistivity of the film is smaller than or equal to 100 ohm.cm. The invention provides the method which is simple in process and can repeatedly and stably prepare the p-type gallium oxide film; the prepared p-type gallium oxide film is high in nitrogen doping content, high in carrier concentration, high in mobility and low in resistivity; the quality of the p-type gallium oxide material is improved, and the industrialization process of the gallium oxide material is promoted.

Owner:SHENZHEN INST OF WIDE BANDGAP SEMICON

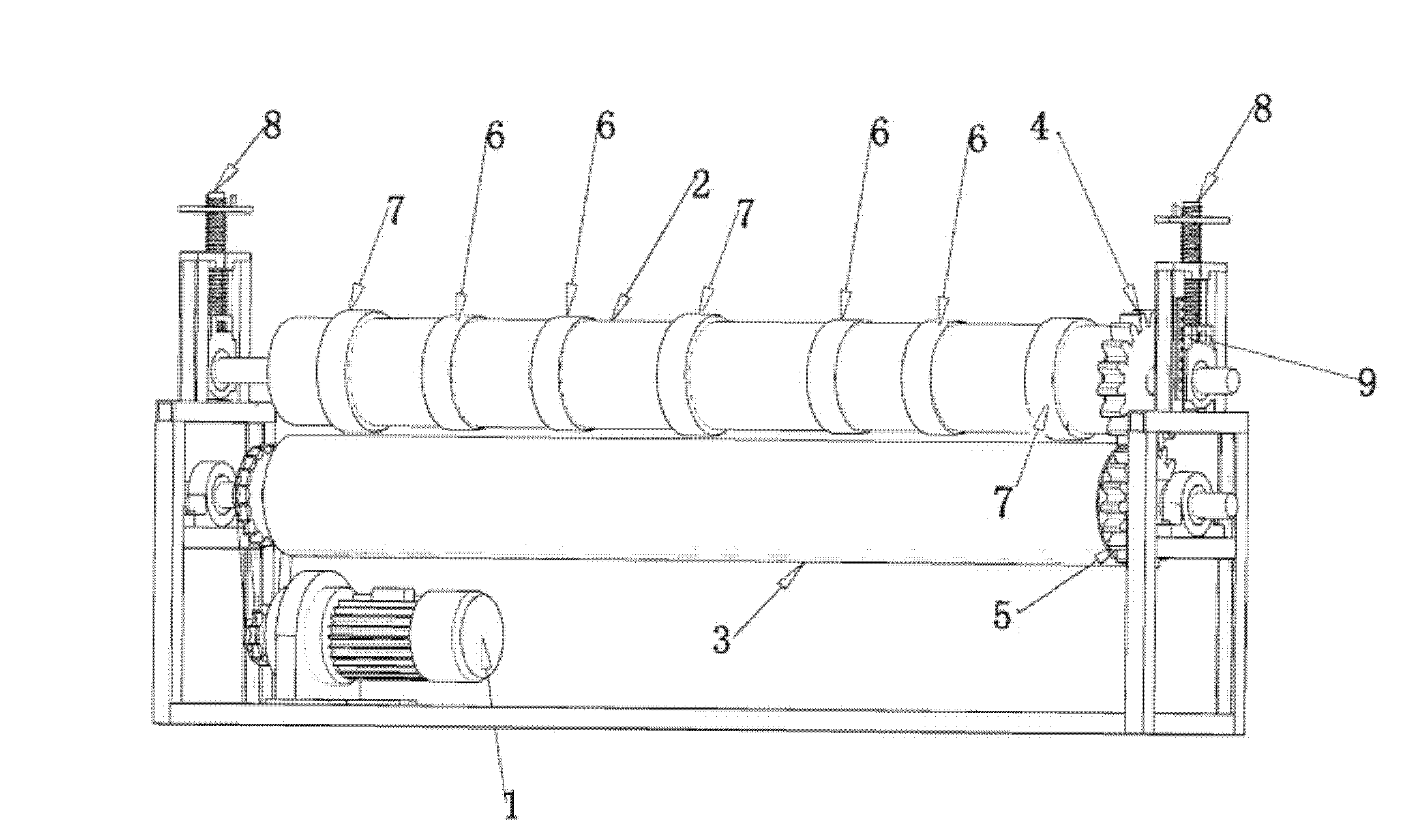

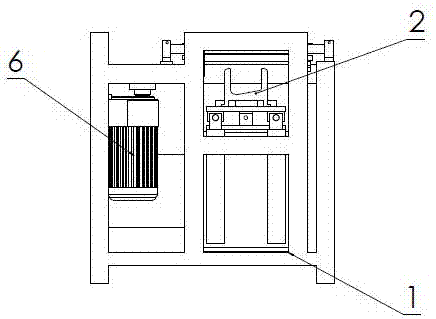

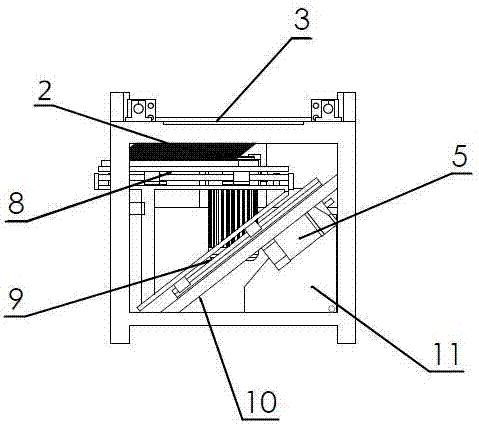

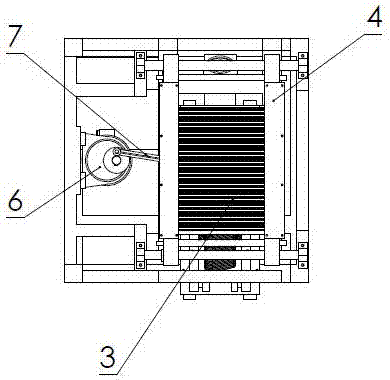

Concave-convex felt roll for special-shaped felt production

The invention relates to a concave-convex felt roll for special-shaped felt production. The concave-convex felt roll for the special-shaped felt production comprises a frequency modulation motor, a lower drum, an upper drum, and distance adjusting devices, wherein the frequency modulation motor is arranged on the lower part and provides frequency modulation power, the lower drum is arranged on the upper portion of the frequency modulation motor and a driving gear is arranged on one side of the lower drum, the upper drum is arranged above the lower drum and a driven gear is arranged on one side of the upper drum, and the distance adjusting devices are arranged on two sides of the upper drum and used for adjusting distance between the upper drum and the lower drum. Compared with the prior art, the concave-convex felt roll for the special-shaped felt production can continuously produce and has the advantages that cost is saved, work efficiency is improved, work intensity is reduced and the like.

Owner:SHANGHAI XINAN CAR DEADENING FELT

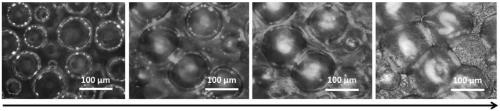

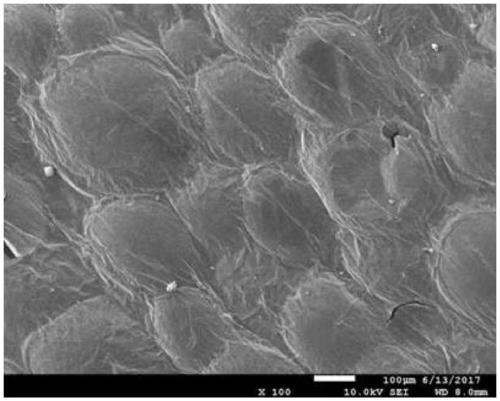

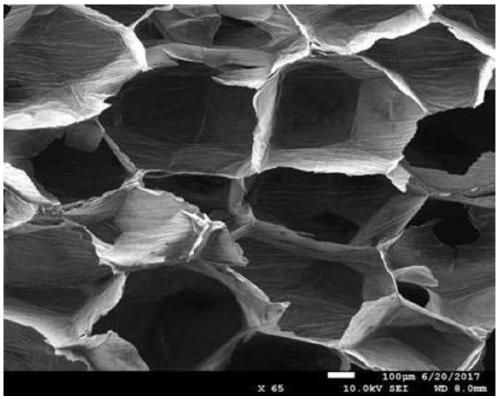

Three dimensional graphene oxide foamed material preparation method through natural drying of solution

The invention relates to a three dimensional graphene oxide foamed material preparation method through natural drying of a solution, and belongs to the technical field of graphene based three dimensional material preparation. According to the method, a high concentration graphene oxide solution containing a surfactant is stirred and foamed, and then the solution is painted on a substrate and naturally dried in the air to obtain a three dimensional graphene oxide foamed material. The method has the advantages of simple operation, low cost, environmental friendliness, and in-situ preparation, and is suitable for industrial large scale continuous production of the three dimensional graphene oxide foamed material. The prepared three dimensional graphene oxide foamed material is composed of a large amount of irregular hollow graphene oxide micro spheres that are connected to each other; has an enclosed pore structure and small density, and can be used as a precursor for the preparation of agraphene based three dimensional foamed material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

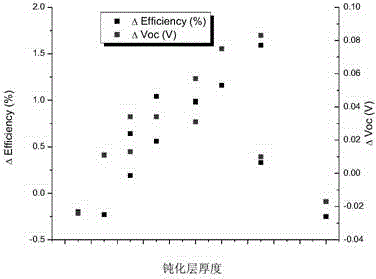

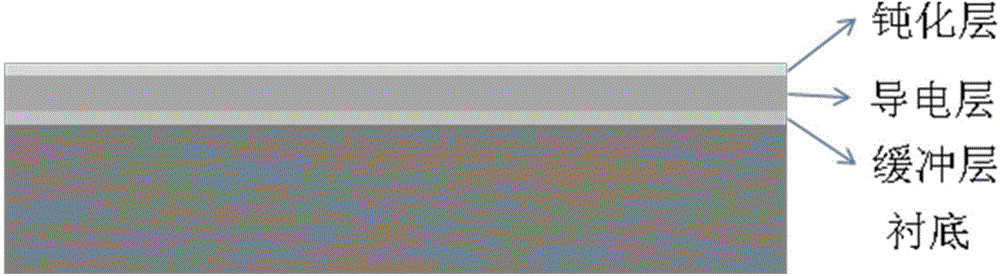

Solar cell back electrode passivation layer preparation technology based on surface oxidation method

InactiveCN104576780APromote bondingImprove bindingFinal product manufacturePhotovoltaic energy generationSurface oxidationThin layer

The invention relates to a solar cell back electrode passivation layer preparation technology through adopting a surface oxidation method. A back electrode is characterized in that the back electrode is composed of two compositions. The back electrode comprises a buffer layer, a conducting layer and a passivation layer, wherein the buffer layer is an Mo thin film with a loose structure, so that the back electrode can make good contact with a substrate; the conducting layer is another Mo thin film which is with different structure of the buffer layer and with good electrical conductivity, and the conducting layer is used for collecting electrons generated by a conduction absorbing layer; the passivation layer is formed by adding an Mo thin layer which is mixed up with MoO2 on the Mo conducting layer surface through utilizing a surface oxidation technology, so that the passivation layer can make good contact with the absorbing layer, good electrical conductivity is maintained, and the efficiency of solar cell devices is improved. A solar cell back electrode passivation layer prepared through the surface oxidation method has the advantages that the machining is easy, the technology is continuous, the controllability is strong, and the solar cell back electrode passivation layer has an extensive prospect in the field of the future solar photovoltaic industry.

Owner:SUZHOU RUISHENG SOLAR ENERGY TECH

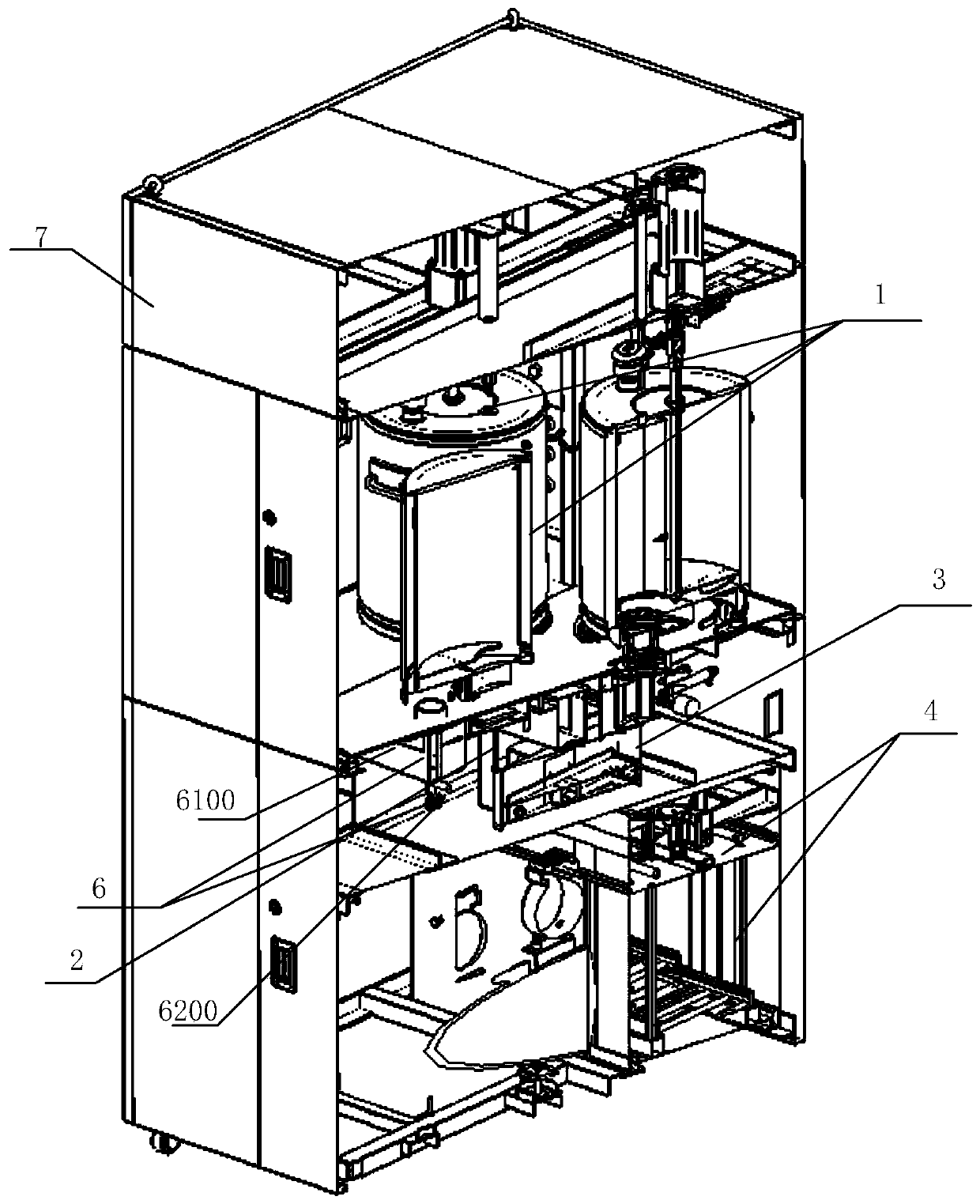

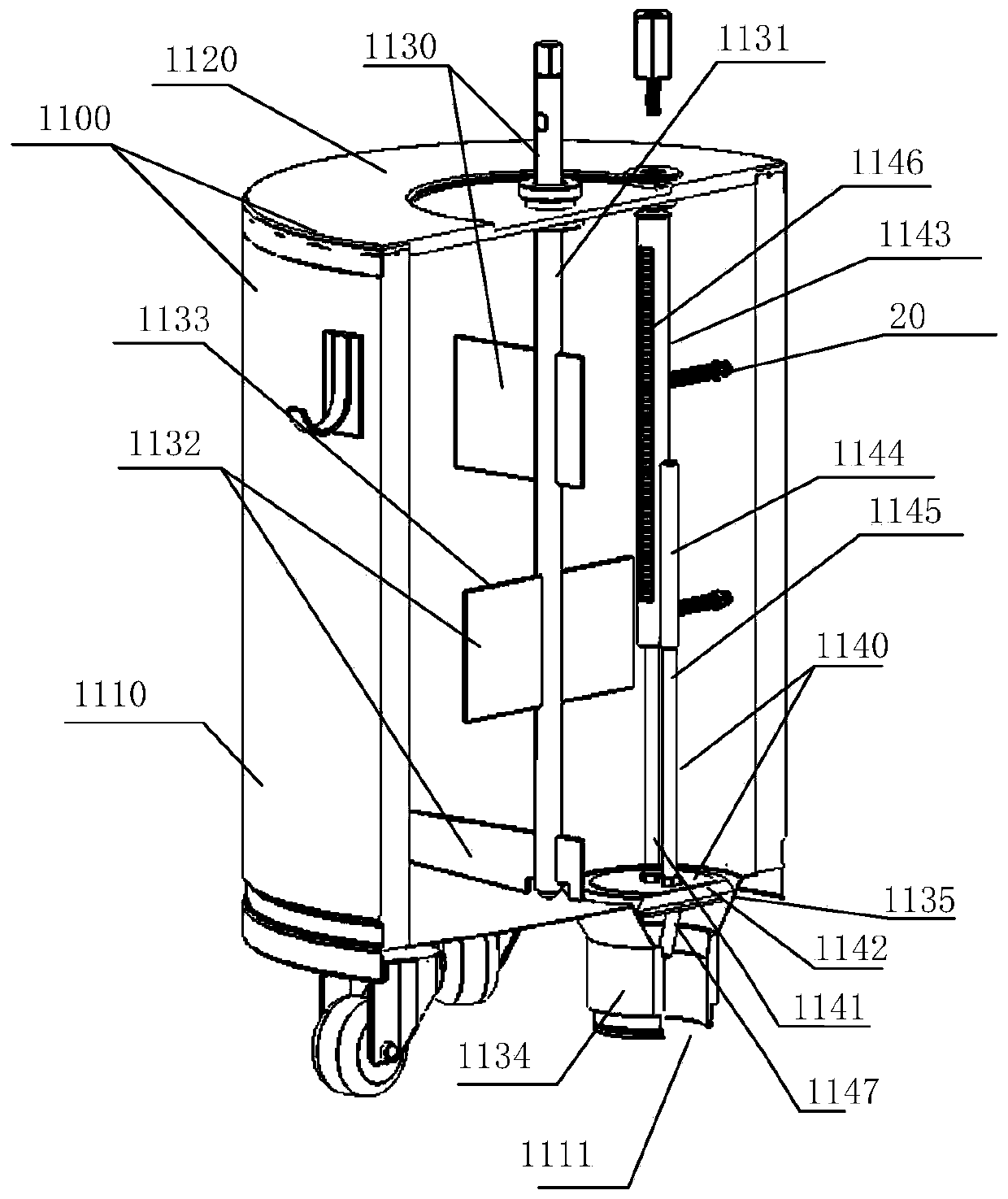

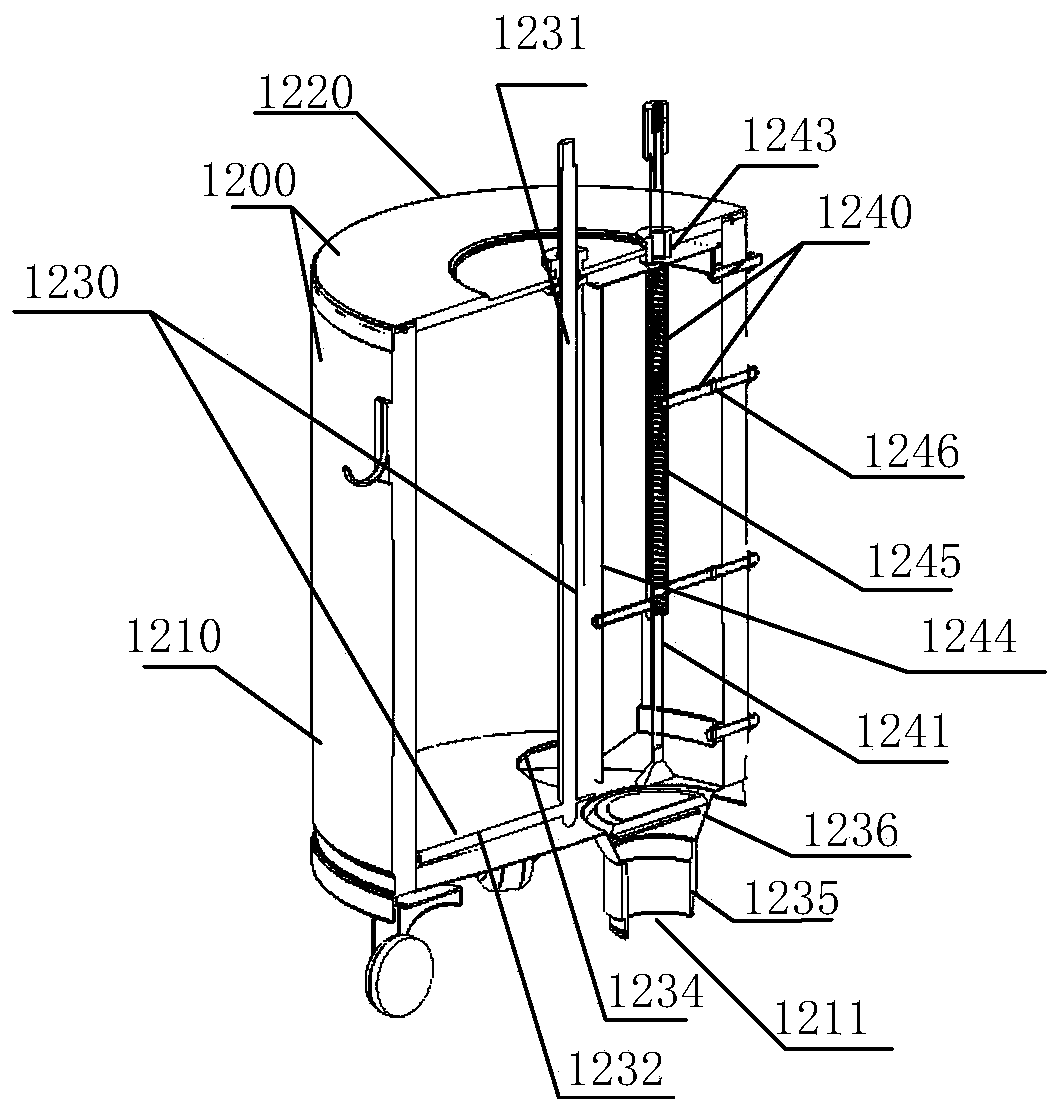

Automatic dish selling machine

PendingCN110613315AAchieve diversificationRealize automatic vendingCoin-freed apparatus detailsCooking vesselsChinese charactersPower output

The invention discloses an automatic dish selling machine which comprises a dish storage barrel set which is used for storing dishes, is shaped like a Chinese character 'pin' and provided with a matched power assembly and comprises a porridge barrel, a cooked dish barrel and a fried dish barrel which are respectively matched with porridge to be sold, cooked dishes to be sold and fried dishes to besold. Each of the porridge barrel, the cooked dish barrel and the fried dish barrel comprises a barrel body, wherein a dish outlet or a rice outlet is formed in the bottom of the barrel body; a coverbody which is matched with the barrel body; a stirring assembly which is arranged in the barrel body, wherein one end of the stirring assembly penetrates through the cover body so as to be in transmission connection with a first power output shaft of the power assembly, and therefore objects contained in the barrel body can fall into the dish outlet or the rice outlet along with rotation; and a plugging assembly, wherein the plugging assembly which penetrates through the cover body and is connected with a second power output shaft of the power assembly so as to switch the working state of thedish outlet or the rice outlet is arranged at the position, corresponding to the dish outlet or the rice outlet, in the barrel body.

Owner:四川奥德瑞斯智能科技发展有限公司

Method for preparing phthalocyanine film

InactiveCN1445873ANo impuritiesThickness can be adjustedLiquid surface applicatorsFinal product manufacturePhthalocyanineOrganic semiconductor

A preparing method for phthalocyanine film includes such steps as: 1) putting phthalocyanine into solvent as mass ratio of 1:1000 to 100000 for mixing to obtain phthalocyanine solution with solid content of 0.001%-0.1% by mass and 2) immersing baseplate into the above-mentioned phthalocyanine solution and carrying on the external field action for one minute to one hour for obtaining the phthalocyanine film on the baseplate, furthremore obtaining the dried phthalocyanine film in thickness of 10nm to 1 mum by removing the solvent.

Owner:ZHEJIANG UNIV

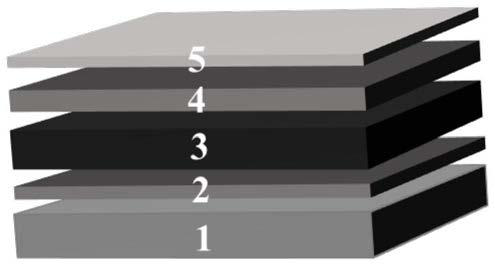

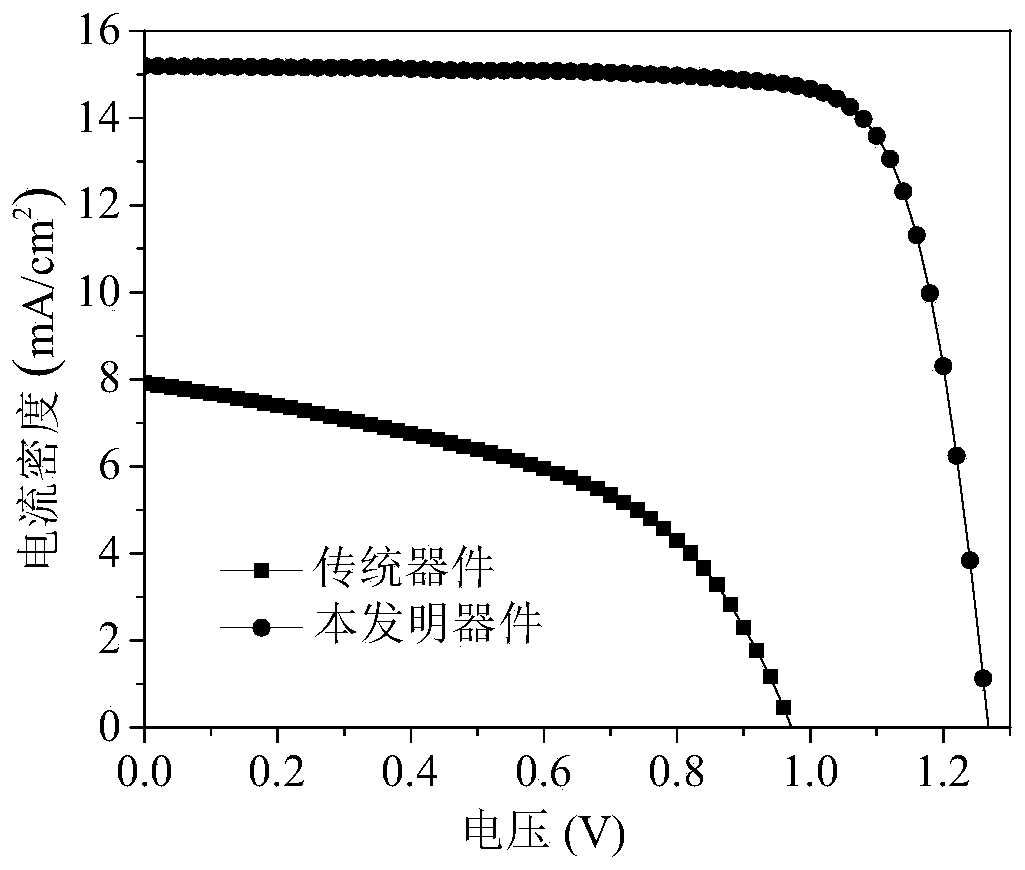

Inorganic perovskite solar cell and preparation method thereof

ActiveCN111312906ASlow crystallization rateImprove performanceFinal product manufactureSolid-state devicesPerovskite solar cellElectrical battery

The invention discloses an inorganic perovskite solar cell and a preparation method thereof. Compared with a traditional perovskite solar cell, the traditional precursor solution components are changed, formate ions and hydrogen ions in the optimized components can spontaneously form acting force in the preparation process, so that the components are prevented from forming a perovskite phase alongwith volatilization of a solvent, the crystallization speed is reduced, and the influence of moisture on the light absorption layer thin film before annealing is greatly reduced. The perovskite thinfilm prepared by the method ensures the photoelectric conversion efficiency of an assembled device, and solves the problem of poor stability of a light absorption layer thin film in a high-humidity environment.

Owner:SHAANXI NORMAL UNIV

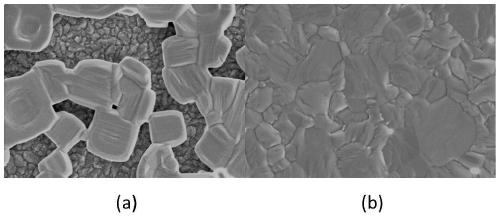

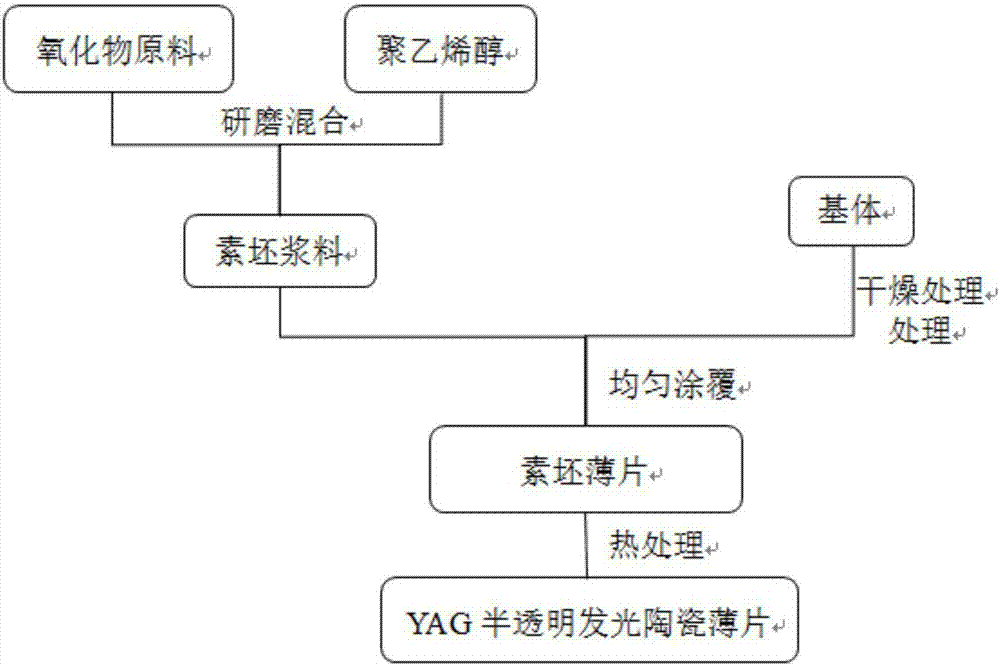

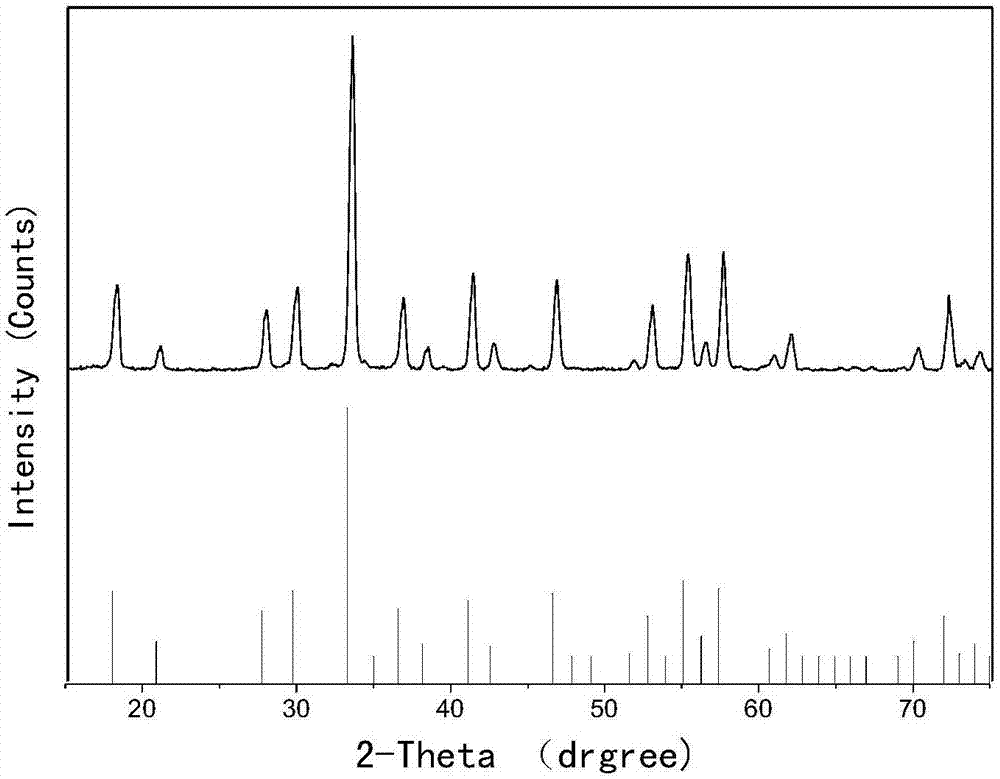

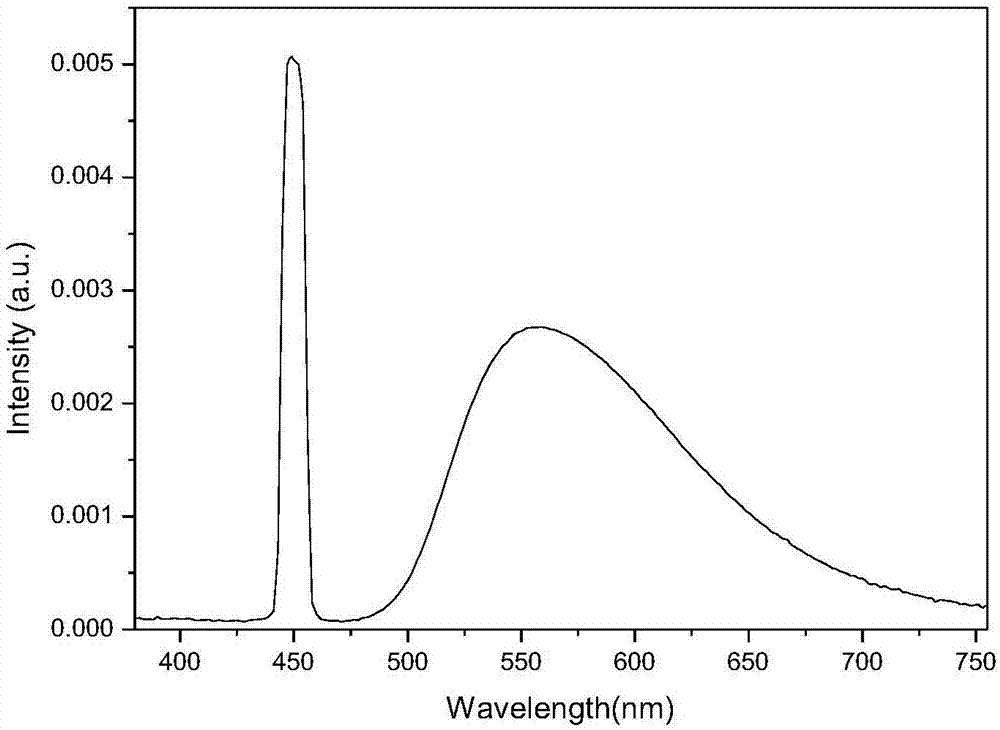

Preparation method for semitransparent YAG fluorescent ceramic sheet

The invention belongs to the technical field of an illuminating material and especially relates to a preparation method for a semitransparent YAG fluorescent ceramic sheet. The method comprises the following steps: uniformly mixing oxides, such as, yttria and aluminum oxide; mixing adhesive, dispersing agent and precursor and preparing into a biscuit sizing agent; in-situ curing and drying the biscuit sizing agent and then acquiring a biscuit sheet; uniformly coating the biscuit sheet on a mould utilizing a coating tool; standing, airing and then taking off; placing the biscuit sheet into a reducing atmosphere furnace for calcining for 4-7 hours under the calcining temperature at 1300-1800 DEG C, thereby acquiring the required ceramic sheet. According to the invention, the ceramic biscuit is compounded under normal temperature and normal pressure; a high temperature solid phase method is adopted for compounding the ceramic sheet; the fluorescent ceramic sheet is capable of emitting bright white light under the stimulation of 435-450nm blue light and is capable of meeting the illuminating requirement; the prepared ceramic sheet has light, thin and semitransparent characteristics.

Owner:CHONGQING UNIV OF ARTS & SCI

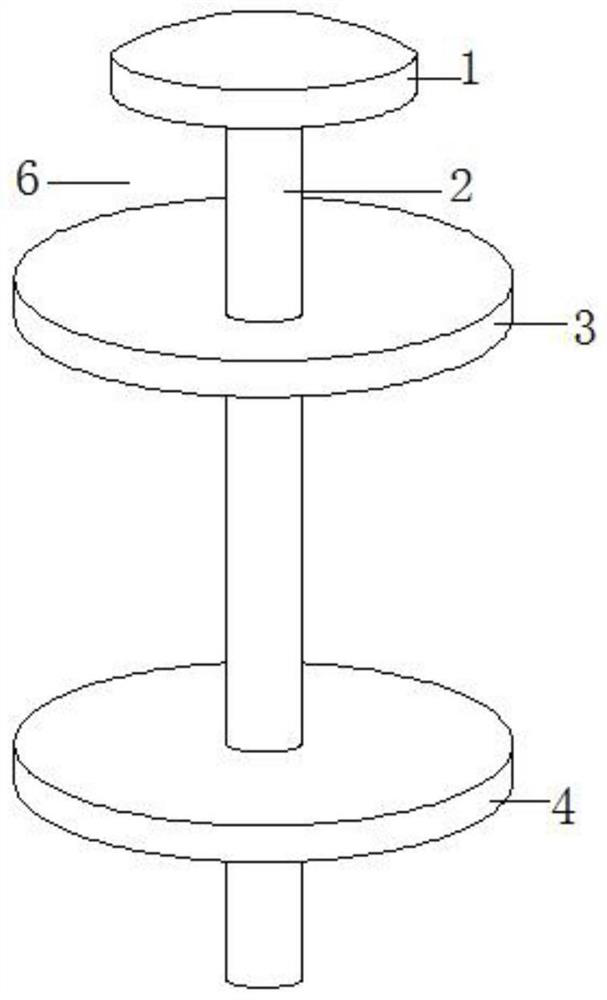

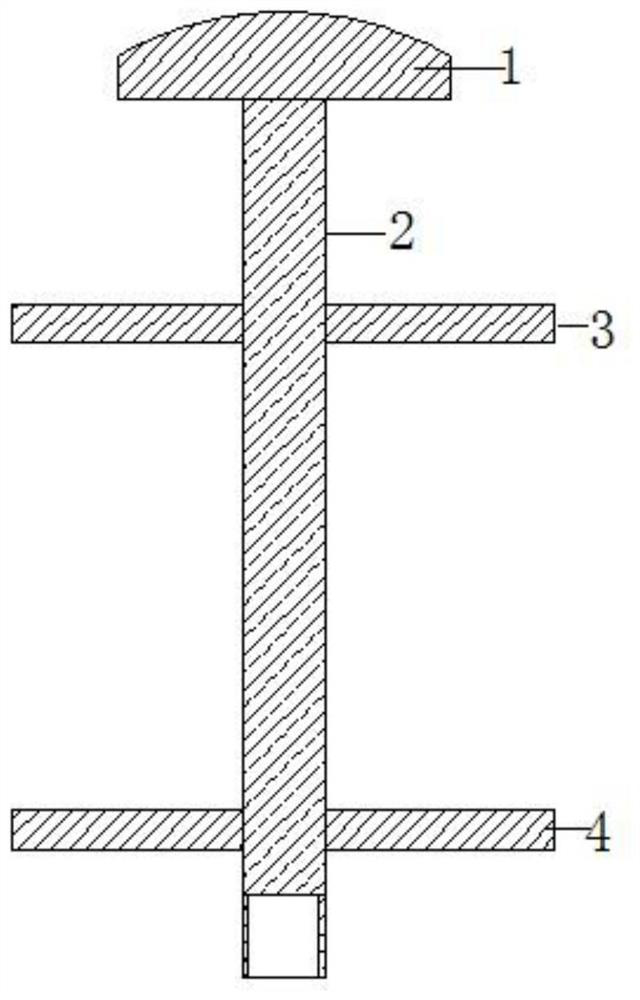

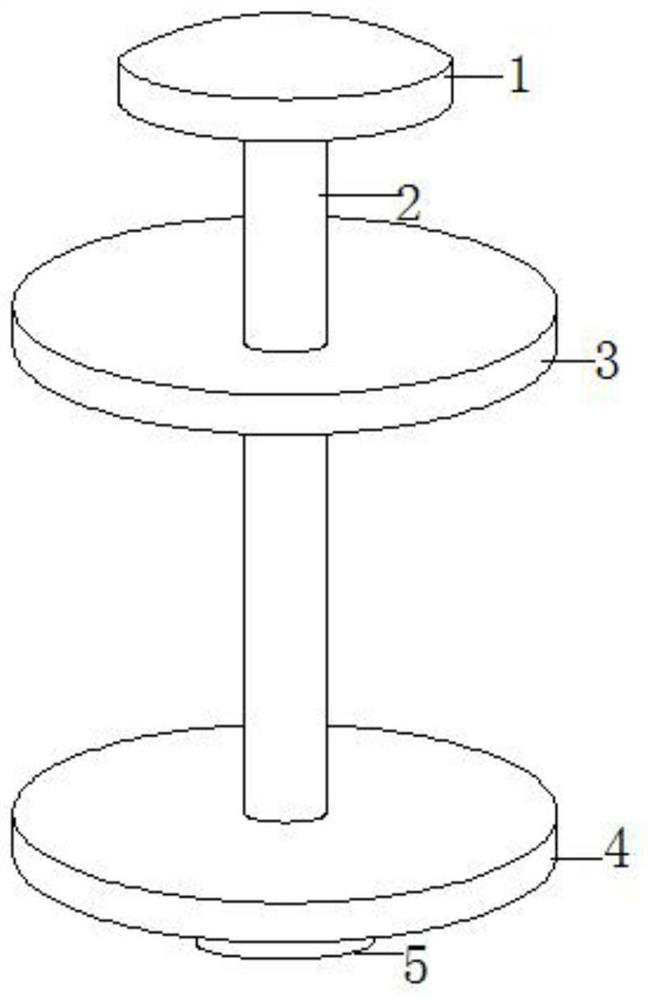

Double-layer self-locking pin

PendingCN111911508AShorten the timeThickness can be adjustedWashersStaplesEngineeringStructural engineering

The invention discloses a double-layer self-locking pin. The double-layer self-locking pin comprises an umbrella cap, the middle of the umbrella cap is connected with a pin rod, an upper gasket is arranged below the umbrella cap, the pin rod penetrates through the middle of the upper gasket and is fixedly connected with the upper gasket, and a lower gasket is arranged below the upper gasket. According to the double-layer self-locking pin, holes do not need to be punched, materials can be punched directly through cooperation of pins and a matched nailing machine, direct one-time forming is achieved, and long time can be saved; the thickness of a product can be adjusted without customizing pins with various lengths; the circular-arc-shaped umbrella cap is of a double-layer design and is attractive, elegant, firm and durable; and when a customer installs the umbrella, due to the fact that the 360-degree circular opening is formed between the umbrella cap and the lower gasket, the customercan sleeve the connected stainless steel wire or spring without seeing the umbrella with eyes, installation and operation are easy, and the umbrella is very convenient to use and practical especiallyin narrow space.

Owner:上海赫鹏新材料科技有限公司

Film antenna and display device comprising same

ActiveCN111033893ARealize the antenna structureThickness can be adjustedAntenna arraysAntenna supports/mountingsDisplay deviceThin membrane

Owner:DONGWOO FINE CHEM CO LTD +1

Automatic peeling device

InactiveCN104106970AAvoid scratchesThickness can be adjustedPeelersHigh volume manufacturingEngineering

The invention discloses an automatic peeling device which comprises a fixing base, a rotary motor, an electromagnetic telescopic rod, an adjustable knife rest and a movable tailstock. The rotary motor is arranged at the left end of the fixing base, the electromagnetic telescopic rod is arranged on the upper portion of the rotary motor, the adjustable knife rest is disposed at the end of the electromagnetic telescopic rod, the movable tailstock is arranged on the fixing base, the fixing base is provided with a sliding groove, and the movable tailstock is fixed to the sliding groove through bolts. By means of the mode, the automatic peeling device can be used for peeling straight food materials such as Chinese yam, the peeling thickness can be adjusted, and the automatic peeling device is flexible and convenient to use, high in safety, capable of preventing hands from being hurt and suitable for large-scale production.

Owner:CHANGZHOU ZHANHUA ROBOT

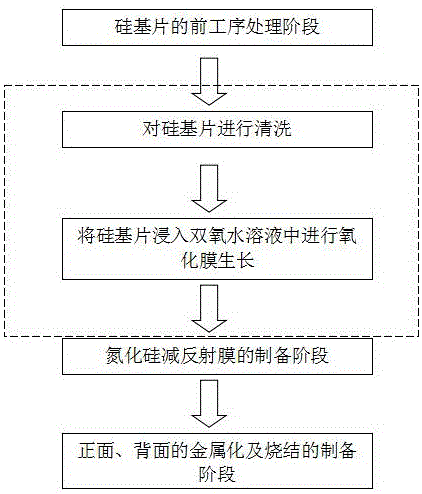

Manufacturing method of crystalline silicon solar cell resistant to PID effect

InactiveCN106611807AAnti-reflection effectsThickness can be adjustedFinal product manufacturePhotovoltaic energy generationEtchingSilicon oxide

The invention discloses a manufacturing method of a crystalline silicon solar cell resistant to a PID effect. In the crystalline silicon solar cell resistant to the PID effect, a silicon dioxide layer is formed between a silicon substrate layer and a silicon nitride film. The manufacturing method comprises the following specific steps: carrying out front process treatment on the silicon substrate, wherein the treatment comprises the steps of affected layer removal and cleaning, texturing, diffusion and etching; carrying out phosphorosilicate glass removal and cleaning on the treated silicon substrate; soaking the cleaned silicon substrate into a hydrogen peroxide solution with certain concentration and temperature for oxidation treatment, taking out the silicon substrate after a certain period of time, drying after rinsing with deionized water to obtain the silicon dioxide layer; depositing a silicon nitride layer on the surface of a silicon oxide layer; and carrying out metallization and sintering on the front face and the back face of the silicon substrate. A silicon oxide film obtained by adopting a hydrogen peroxide oxidation technology is compact and has a relatively low surface state density, and the passivation effect for surface defects of base silicon is improved, so that the photoelectric conversion efficiency of the solar cell is improved.

Owner:JIANGSU FOCUS NEW ENERGY TECH

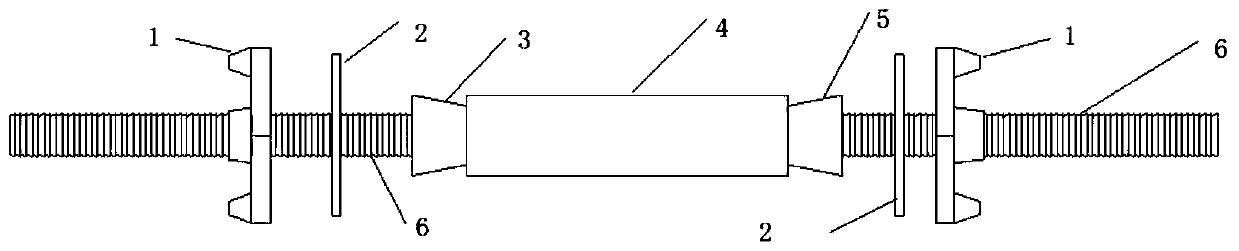

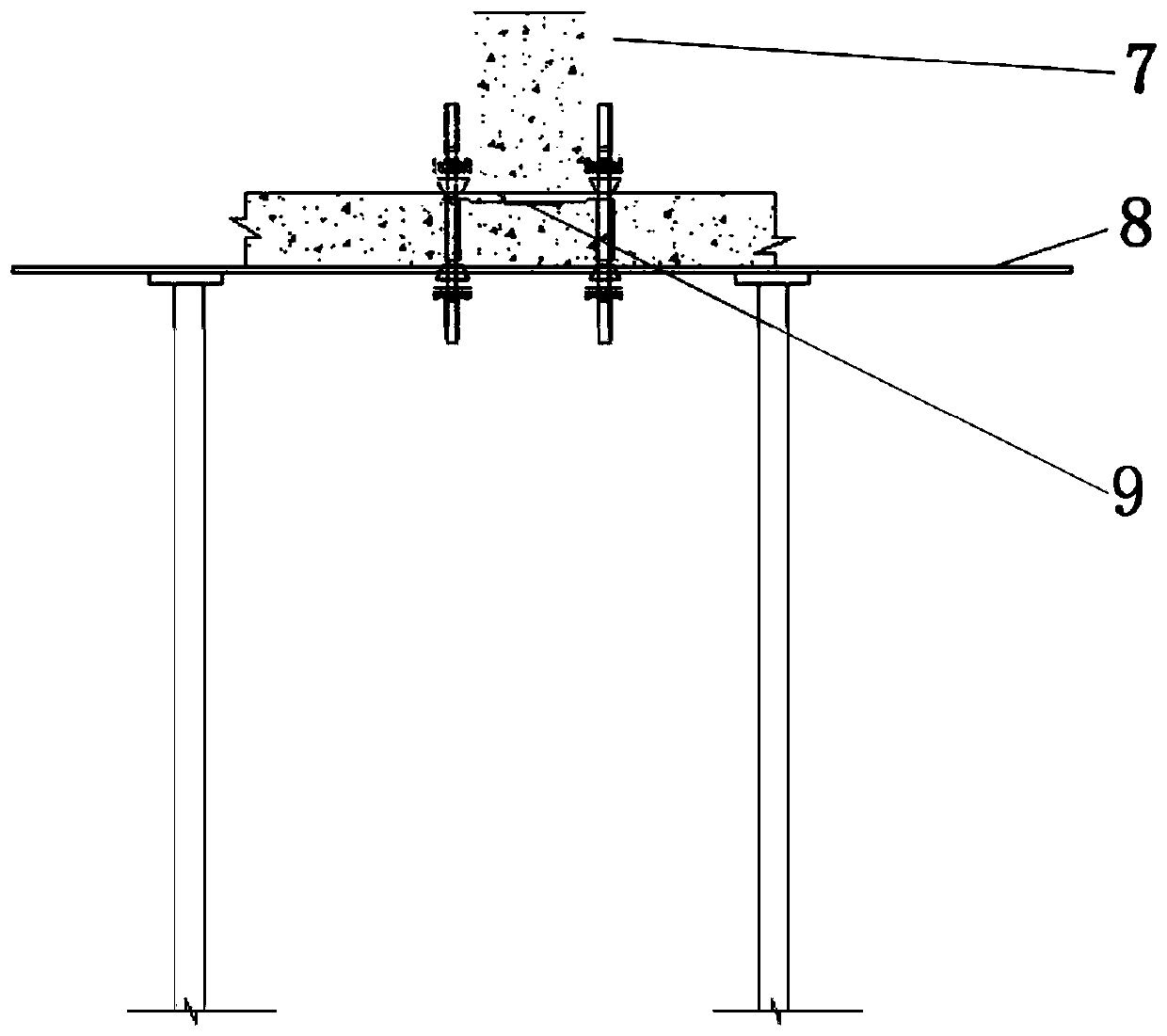

Supporting and positioning component of counter-ridge hanging formwork system of kitchen and a bathroom and framework supporting mode

PendingCN110984570AThickness can be adjustedSolve the leakForms/shuttering/falseworksEngineeringStructural engineering

The invention provides a supporting and positioning component of a counter-ridge hanging formwork system of a kitchen and a bathroom. The supporting and positioning component comprises fastening clamps, gaskets, fixing nuts, plastic sleeves, adjustable nuts and a screw, wherein the fixing nuts are mounted on one side of the screw, and the adjustable nuts are mounted on the other side of the screw;the plastic sleeves are arranged on the screw in a sleeving manner; the gaskets and the fastening clamps are arranged at two ends of the screw. The invention further provides a formwork supporting mode of the supporting and positioning component of the counter-ridge hanging formwork system of the kitchen and the bathroom. The thickness of a floor can be adjusted, the problems that the root of a counter-ridge of the kitchen and the bathroom leaks and the plane position and the elevation of a counter-ridge formwork of the kitchen and the bathroom cannot be positioned along with construction ofa main body top plate in a traditional method can be solved effectively, and the pouring quality of the counter-ridge of concrete of the kitchen and the bathroom is improved.

Owner:MCC TIANGONG GROUP

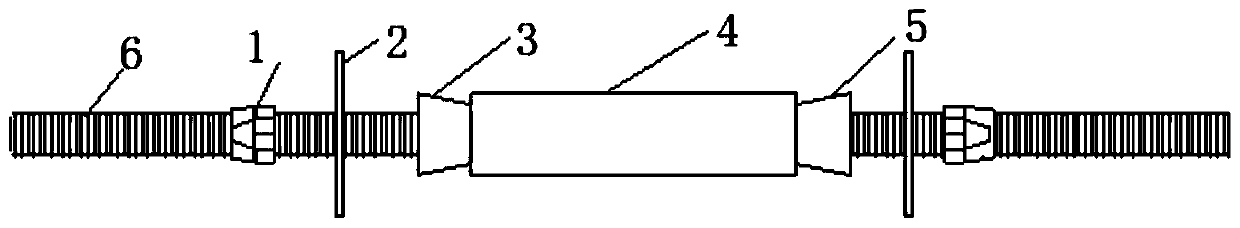

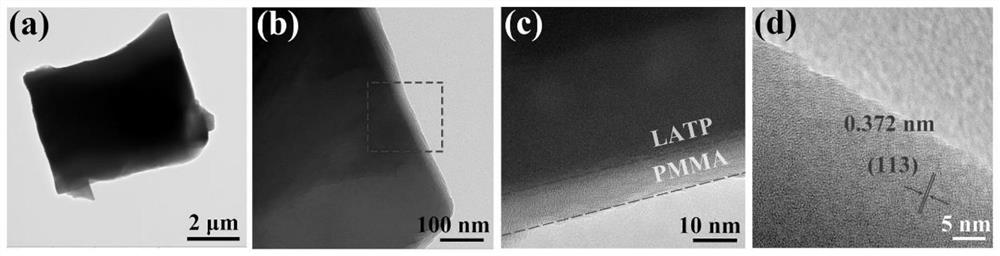

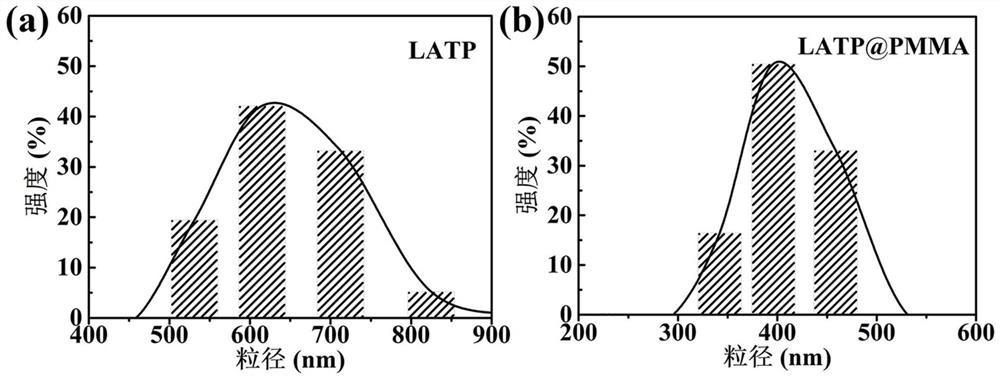

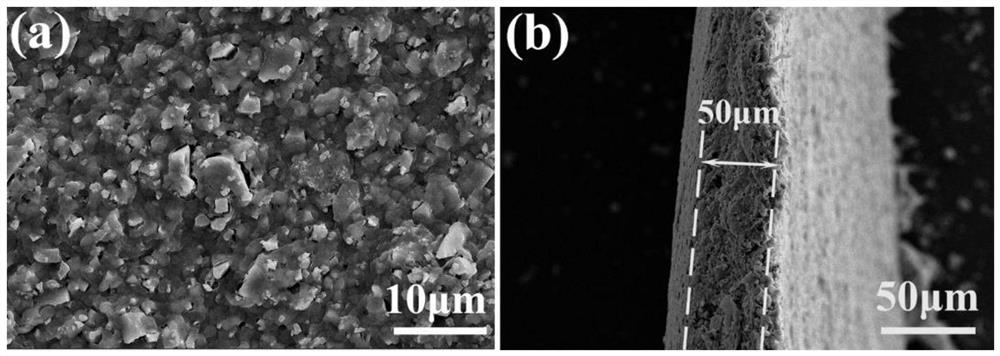

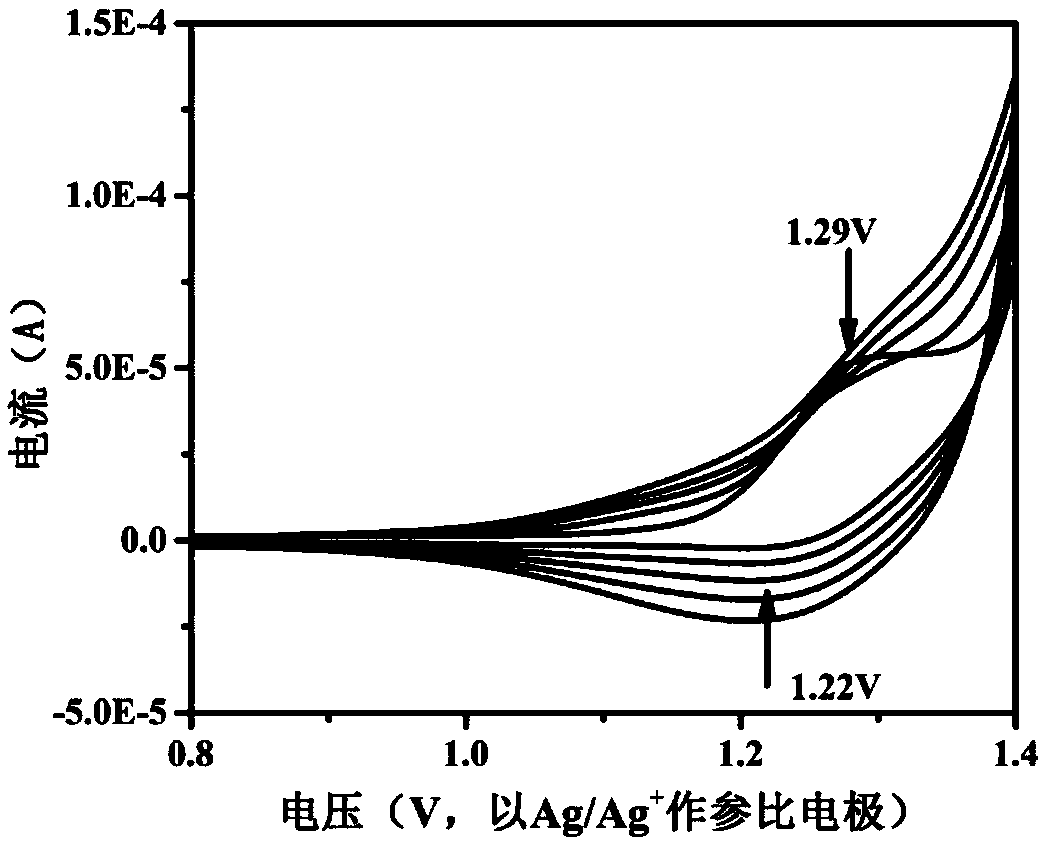

A kind of double-layer solid electrolyte film for lithium battery and preparation method thereof

ActiveCN112599847BAvoid reunionGood dispersionSolid electrolytesLi-accumulatorsSolid state electrolyteAll solid state

Owner:HARBIN INST OF TECH

Lithium-ion battery positive electrode material and its preparation method and application

ActiveCN106803574BInhibition of dissolutionEasy transferCell electrodesSecondary cellsPolymer electrolytesConductive polymer

The invention relates to an anode material for a lithium ion battery as well as a preparation method and application of the anode material. The anode material is an LMP / PEG-PTh composite material, wherein the mass percentage of PTh in the LMP / PEG-PTh composite material is 1%-15%. The preparation method of the anode material comprises the following steps: with an LMP material as a kernel, attaching PEG to the surface of the LMP kernel, so as to obtain an LMP / PEG composite material; and depositing a conductive polymer PTh on the surface of the LMP / PEG composite material, so as to obtain the LMP / PEG-PTh composite material. According to the invention, the PEG can form a cladding layer on the surface of the LMP so as to restrain the dissolving of manganese and is a good solid polymer electrolyte matrix capable of promoting the transmission of lithium ions; and by utilizing a PTh cladding layer with relatively high conductivity, the load transfer resistance among LMP interfaces can be reduced, the surface migration rates of the lithium ions and electrons can be increased, and therefore, the rate capability of an electrode is improved.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

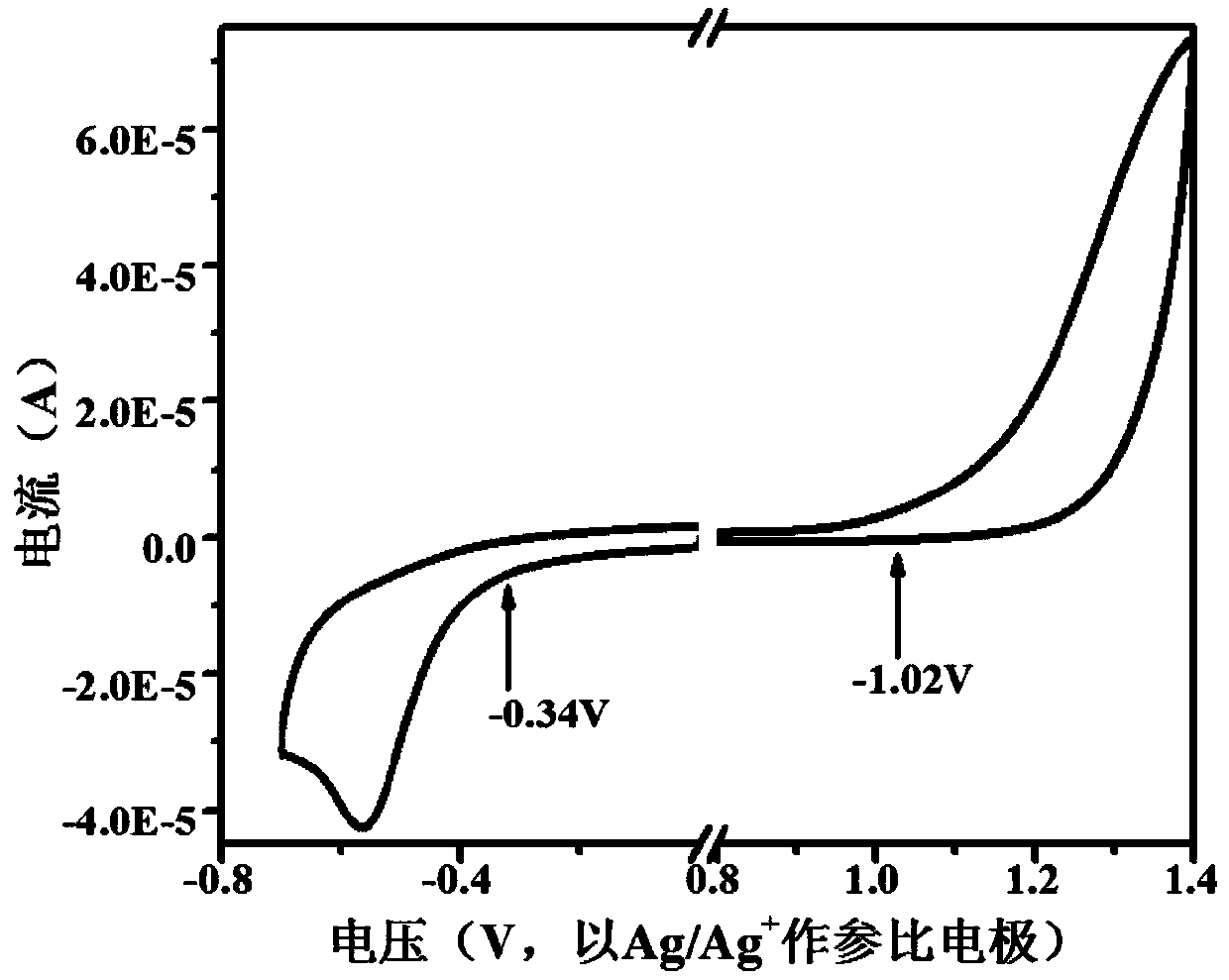

Organic solar cell and preparation method thereof

ActiveCN110452363AReduce corrosionIncrease currentSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellInterface layer

The invention belongs to the field of organic solar cells, and in particular relates to an organic solar cell and a preparation method thereof. The invention provides an application of spirobifluorenepolymers, and the spirobifluorene polymers can be used as an organic solar cell anode interface material; the material can be subjected to in-situ film formation on electroconductive glass by using apolymer monomer through a CV process; and in the film formation process, the thickness of the formed film can be regulated and controlled. The polymers provided by the invention are applied to the organic solar cell as an anode interface layer, and compared with PEDOT:PSS, the polymers provided by the invention can obtain a higher current and exhibit more dominant bimolecular recombination; afterthe polymer monomer is subjected to film formation through an electrochemical process, the neutral polymer film is formed; compared with the acidic PEDOT:PSS, the neutral interfacial layer has the following two advantages: 1, corrosion of an electrode by acidity is reduced; and 2, if an active layer material contains a basic group, an interfacial acid-base reaction of the neutral interfacial layer and the basic group can be avoided; and the preparation method provided by the invention is simple and easy to implement.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Full-automatic fresh meat inclined slicing machine

InactiveCN107053269AUniform thicknessThickness can be adjustedMetal working apparatusEngineeringMechanical engineering

The invention discloses a fully automatic oblique slicer for fresh meat, comprising: a frame, a lower knife blade set and an upper knife blade set arranged in the frame; a lower knife horizontal slide rail and a lower knife blade set are arranged below the lower knife blade set The lower knife lifting slide rail; the lower knife lifting slide rail is arranged on the lower knife lifting bracket; the lower knife lifting motor is arranged under the lower knife lifting bracket; the upper knife blade group is arranged on the upper knife rest; the upper knife The knife rest is connected with the upper knife swing motor through a connecting rod. Using the lower knife blade set and the upper knife blade set to cut meat, the speed is fast, the efficiency is high, the thickness is uniform and the thickness can be adjusted; it can not only cut fresh meat of common meat, but also can be used for cutting sashimi, etc., and can be used for multiple purposes. ; The bottom of the lower knife lifting bracket is also provided with a cleaning water tank, and the water in the cleaning water tank can be used to clean the upper and lower blades.

Owner:余青松

Process for preparing electronic ink by using light complex functional ball of optical subwavelength

InactiveCN101333352AHigh refractive indexImprove mechanical propertiesInksNon-linear opticsEngineeringMechanical property

The invention relates to a method for preparing electronic ink from light composite function ball at sub-optical wavelength. Mixing dispersant and organic solvent, oscillating with ultrasonic wave, adding light composite function ball at sub-optical wavelength and blending, thus obtaining light composite function ball suspension at sub-optical wavelength with bistability; then adding background dye and mixing, thus obtaining electrophoretic display liquid, namely the electronic ink; or dispersing the light composite function ball at sub-optical wavelength in organic solvent, oscillating with ultrasonic wave, heating to 105-120 DEG C, adding Tissuemat E gradually and blending, thus obtaining light composite function ball suspension at sub-optical wavelength with bistability; then adding background dye and dispersant and mixing, thus obtaining electrophoretic display liquid, namely the electronic ink. Electronic paper display units made from the electronic ink are of good mechanical property, wear resistance, pressure resistance, impact resistance and quick response, and the images produced have clear boundaries, high contrast grade and high resolution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of coating paint film containing modified silica sol

InactiveCN106811094AIncreasing the thicknessThickness can be adjustedAnti-corrosive paintsPolyurea/polyurethane coatingsDistilled waterSilica gel

The invention discloses a preparation method of a coating paint film containing modified silica sol. The preparation method comprises the following procedures: (1) adding toluene diisocynate and the like into a first reaction kettle, so as to obtain a primary product; (2) adding dimethylolpropionic acid and the like into the primary product, so as to obtain an aromatic waterborne polyurethane emulsion; (3) preparing modified silica sol; (4) adding the modified silica sol and the aromatic waterborne polyurethane emulsion into a third reaction kettle, so as to obtain a mixed emulsion; (5) adding a proper amount of acrylic copolymer sylvite and the like into the fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; (6) adding the mixed emulsion into the mixed base solution, so as to obtain a coating containing the modified silica gel; (7) carrying out air-drying on a plastic film, and diluting the coating containing the modified silica gel; and (8) spraying the coating containing the modified silica gel to the plastic film, so as to obtain the coating paint film containing the modified silica sol. The paint film prepared by virtue of the preparation method can be used for conveniently testing the properties such as tensile property, corrosion resistance, vapor permeability and peel strength of the coating containing the modified silica sol.

Owner:重庆市共赢包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com