Method and equipment for producing continuous fiber-reinforced thermoplastic composite material prepreg tape

A technology of reinforced thermoplastic and continuous fiber, which is applied in the field of prepreg preparation to achieve the effects of low cost, complete fiber dispersion and impregnation, and uniform fiber dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

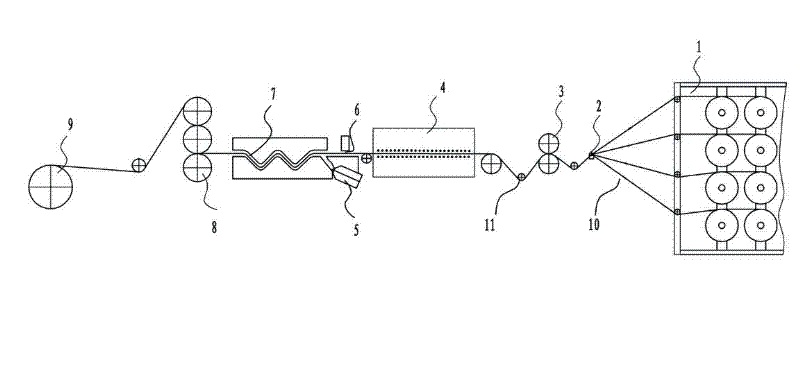

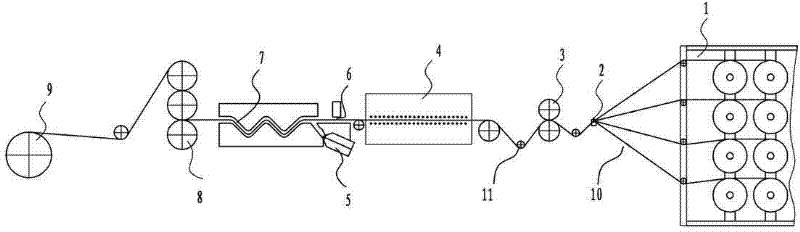

[0028] Please refer to figure 1 , the equipment of the present invention includes a creel 1, a yarn guide device 2, a traction and dispersion device 3, a far-infrared heating box 4, an extrusion die head 5, a primary dipping tank 6, a secondary dipping tank 7, a dipping calender roll group 8, Traction winding device 9.

[0029] First, the continuous fiber 10 is installed on the spindle of the creel 1, and then the continuous fiber 10 is drawn into the yarn guide device 2, so that the continuous fiber 10 can be in the same plane and evenly distributed. The continuous fiber 10 drawn into the same plane is sent into the far-infrared heating box 4 through the pulling roller 11 to be preheated at 250 degrees, so that the preheated continuous fiber 10 enters the initial dipping tank 6 . At this time, the extrusion die head 5 extrudes the molten resin and impregnates the continuous fiber 10 in the initial impregnation tank 6 through the first molten resin channel, which is not descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com