Concave-convex felt roll for special-shaped felt production

A special-shaped felt and roll technology, applied in the field of rolls, can solve the problems of increasing production costs, reducing production efficiency, energy waste, etc., and achieving the effects of saving costs, saving resources and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

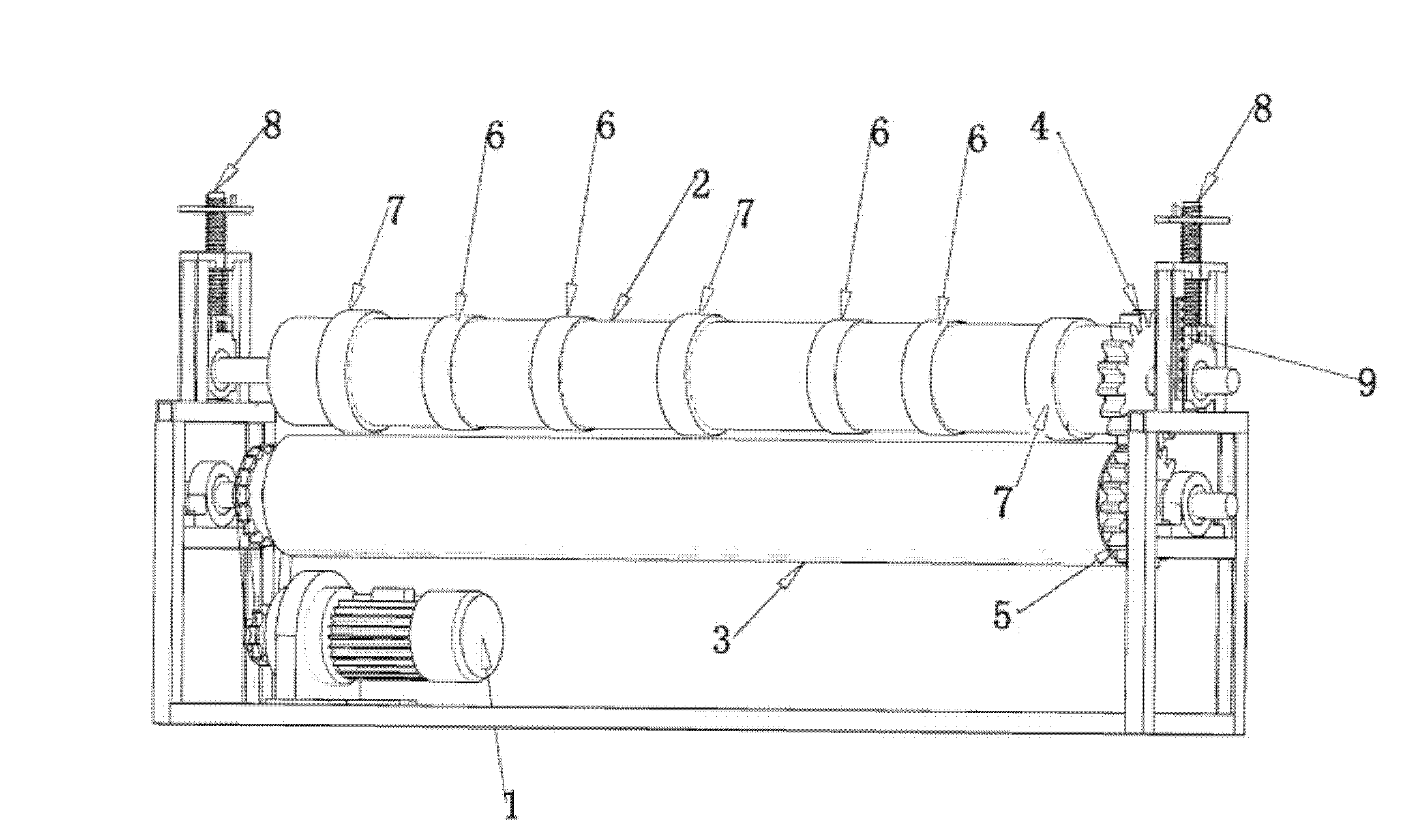

[0034] A concave-convex felt roll for special-shaped felt production, its structure is as follows figure 1 As shown, it includes a frequency modulation motor 1, an upper cylinder 2, a lower cylinder 3, a driving gear 5, a driven gear 4, a hoop, an upper cylinder spacing adjustment device 8, and a scale 9. Wherein, the frequency modulation motor 1 is arranged at the lower part to provide power for frequency modulation. The lower cylinder 3 is located on the top 1 of the frequency modulation motor, and is a smooth cylinder with a diameter of 300mm, which is connected with the driving gear 5 as a whole. The upper cylinder 2 is set above the lower cylinder 3 and is integrated with the driven gear 4. Several detachable hoops are embedded on the upper cylinder 2. The distance between the hoops can be adjusted according to different product sizes. , in this embodiment, including the first hoop 6 and the second hoop 7, the diameter of the first hoop 6 is 280 mm, the width is 80 mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com