Inorganic perovskite solar cell and preparation method thereof

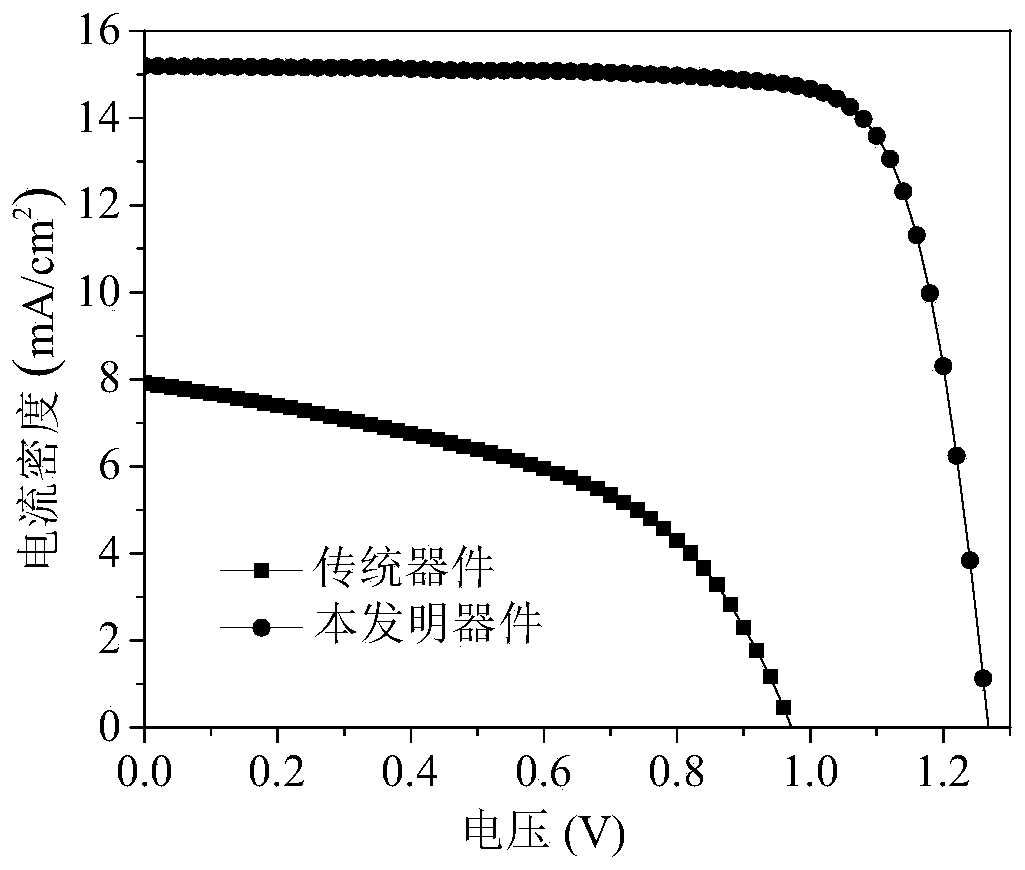

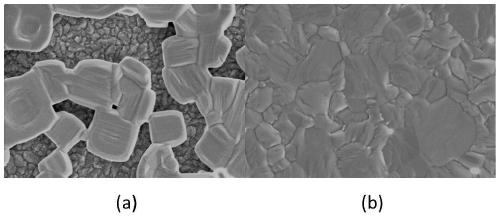

A technology of solar cells and inorganic calcium, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of excessive crystallization speed of inorganic perovskite solar cells and the influence of perovskite thin films, and achieve the goal of increasing thickness and increasing current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

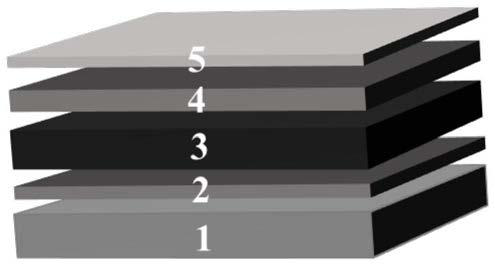

[0036] The invention discloses an inorganic perovskite solar cell prepared in a high-humidity environment and a preparation method thereof. The method can reduce the crystallization rate of the perovskite film and overcome the influence of high humidity on the perovskite precursor film, thereby ensuring the quality of the perovskite film and the performance of the perovskite device. The entire preparation process of the perovskite battery has no special requirements on the environment, except that the final gold electrode is evaporated in a vacuum environment, and the rest of the steps have no special requirements for the environment, especially for high-humidity air environments. This method is also applicable. The preparation includes the following step:

[0037] Step 1, cleaning the conductive glass substrate 1;

[0038] The conductive glass substrate 1 is fluorine-doped tin oxide conductive glass, and the cleaning process is sequentially cleaning with ethanol, isopropanol...

Embodiment 1

[0054] Step 1, cleaning of the conductive glass substrate 1: ultrasonically clean the cut FTO conductive glass substrate in ethanol, isopropanol, and acetone for 30 minutes each, and then blow dry with a dry air flow.

[0055] Step 2, preparation of the electron transport layer; preparation of the electron transport layer 2: the FTO substrate was treated with ultraviolet ozone for 10 minutes, and a layer of TiO was deposited on the cleaned FTO surface by the hydrothermal insulation deposition method. 2 As the electron transport layer 2, the hydrothermal insulation temperature is 70°C, and the precursor is TiCl 4 .

[0056] Step 3, prepare all-inorganic perovskite light-absorbing layer 4; The HPbI of 0.393g 3 , 0.150g HPbBr 3 and 0.178g of CHCsO 2 Dissolve in 1mL of DMSO solution to form a perovskite precursor solution with a concentration of 1mol / mL, and then spin-coat the perovskite precursor solution on TiO 2 Surface, the specific spin-coating process is when the conduct...

Embodiment 2

[0061] In this embodiment, in step 3, the solute concentration of the perovskite precursor solution is 1.1mol / L, the low-speed spin-coating speed of the perovskite absorbing layer is 800rpm, and the time is 20s; the high-speed spin-coating speed is 3500rpm, and the time is 40s; the heating temperature of the conductive glass substrate in the spin-coating process is 60°C; the annealing temperature of the perovskite film prepared after spin-coating is 280°C, and the annealing time is 8min; the thickness of the metal electrode is 60nm.

[0062] All the other unrelated parts are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com