Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of weakening the depletion effect of the drift region, failing to achieve the withstand voltage effect, etc., so as to enhance the withstand voltage effect and reduce costs. , The effect of saving process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

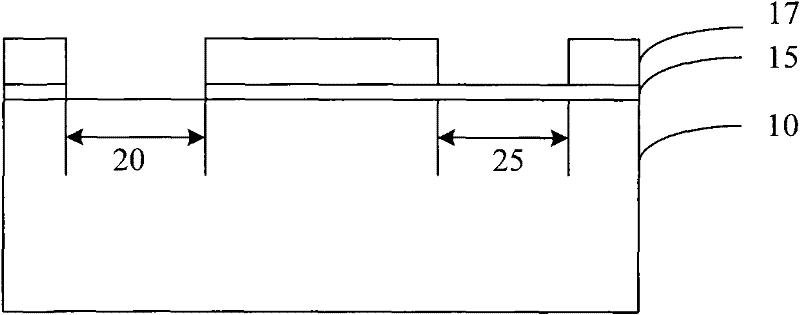

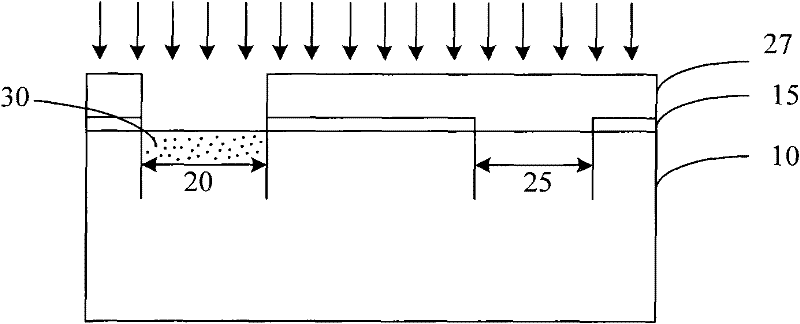

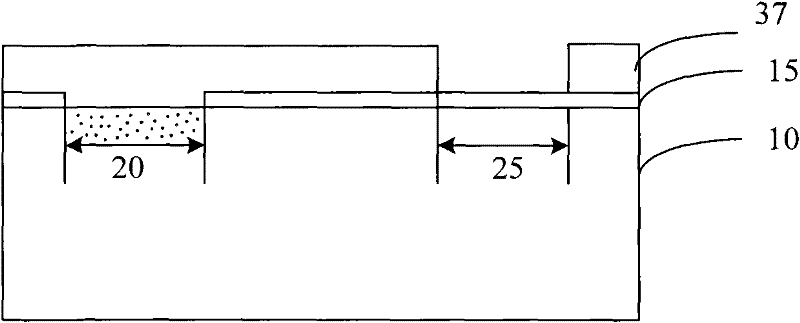

[0038] It can be seen from the background technology that in the prior art, since the field oxygen in the isolation region and the thermal oxide layer in the drift region are formed in the same process, the thickness of the thermal oxide layer in the drift region can only be the same as the thickness of the field oxygen, so that the drift region The thickness of the thermal oxide layer is uncontrollable, and in order to ensure the effect of isolation, the field oxygen usually needs to be thicker. Too thick thermal oxide layer in the drift region will weaken the depletion effect of the drift region, and cannot achieve the best withstand voltage effect. In addition, the implantation of the field region and the implantation of the drift region need to be defined twice by lithography, and one more lithography process increases the cost.

[0039] After a lot of experiments, the inventor of the present invention has obtained a manufacturing method of a semiconductor device by first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com