Patents

Literature

32results about How to "Promote bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

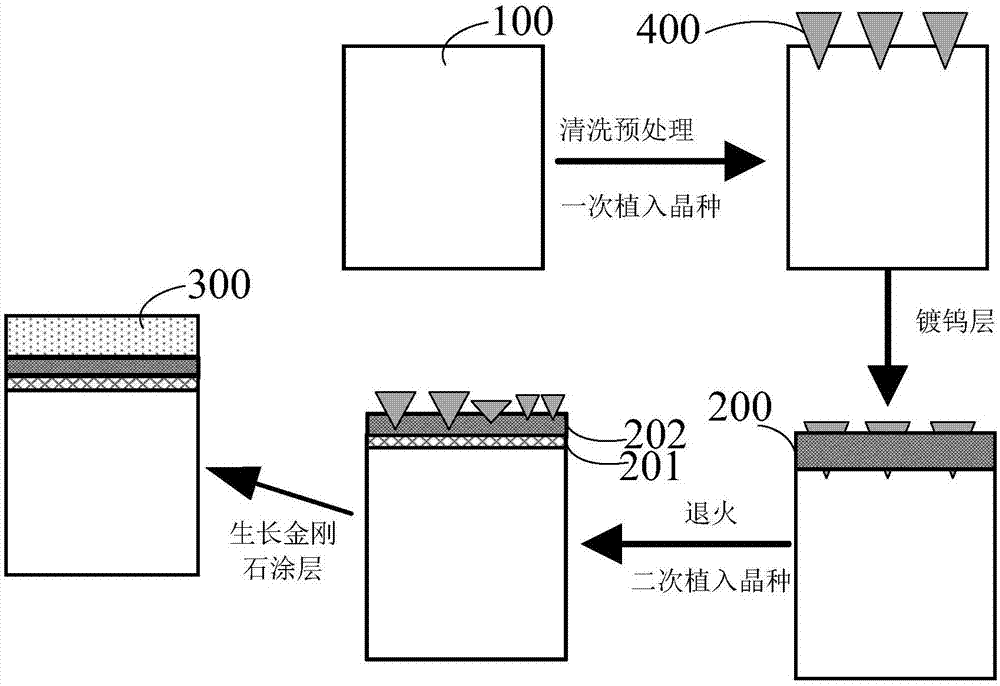

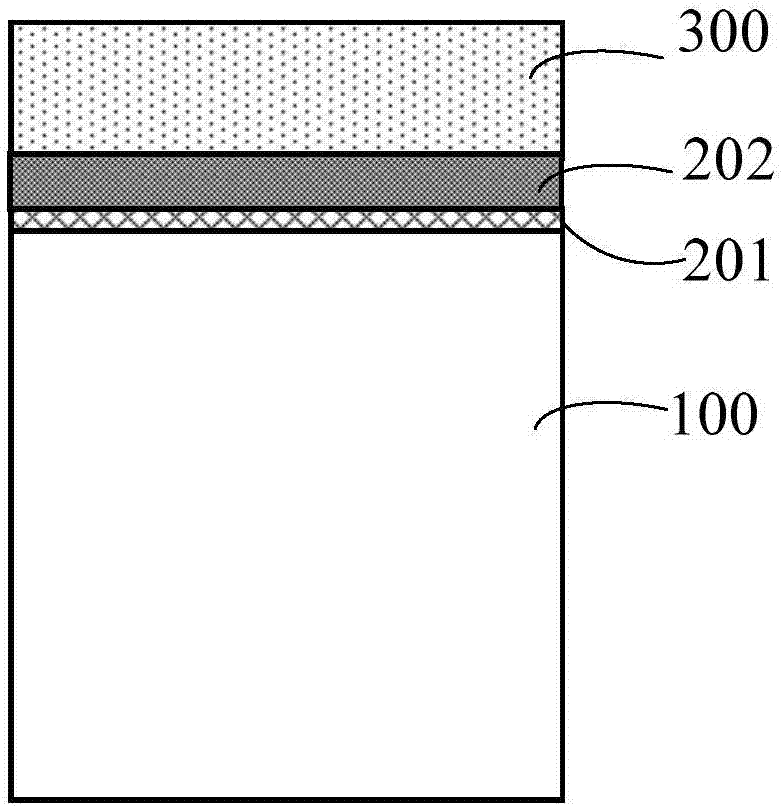

Hard alloy part with diamond coating and preparation method of hard alloy part

ActiveCN107034467APromote bondingImprove adhesionVacuum evaporation coatingSputtering coatingCemented carbidePre treatment

The invention provides a preparation method of a hard alloy part with a diamond coating. The preparation method comprises the steps that a hard alloy matrix is obtained, cleaned and pretreated, and then is placed into diamond powder suspension liquid, and diamond seed crystals are implanted into the matrix; an initial tungsten layer is deposited on the surface of the matrix where the diamond seed crystals are implanted, and the initial tungsten layer partially covers the implanted diamond seed crystals; the matrix with the tungsten layer is annealed in the reducing atmosphere; the diamond coating is deposited on the annealed tungsten layer, and the hard alloy part with the diamond coating is obtained. By means of the method, the graphitization effect produced by cobalt when a diamond film layer is deposited can be eliminated, the diamond coating and the matrix have high adhesive force under the combined effect of a Co-W-C transition layer and the tungsten layer which are formed through annealing, and the film-matrix combination strength is high. The invention further provides the prepared hard alloy part with the diamond coating.

Owner:SHENZHEN INST OF ADVANCED TECH

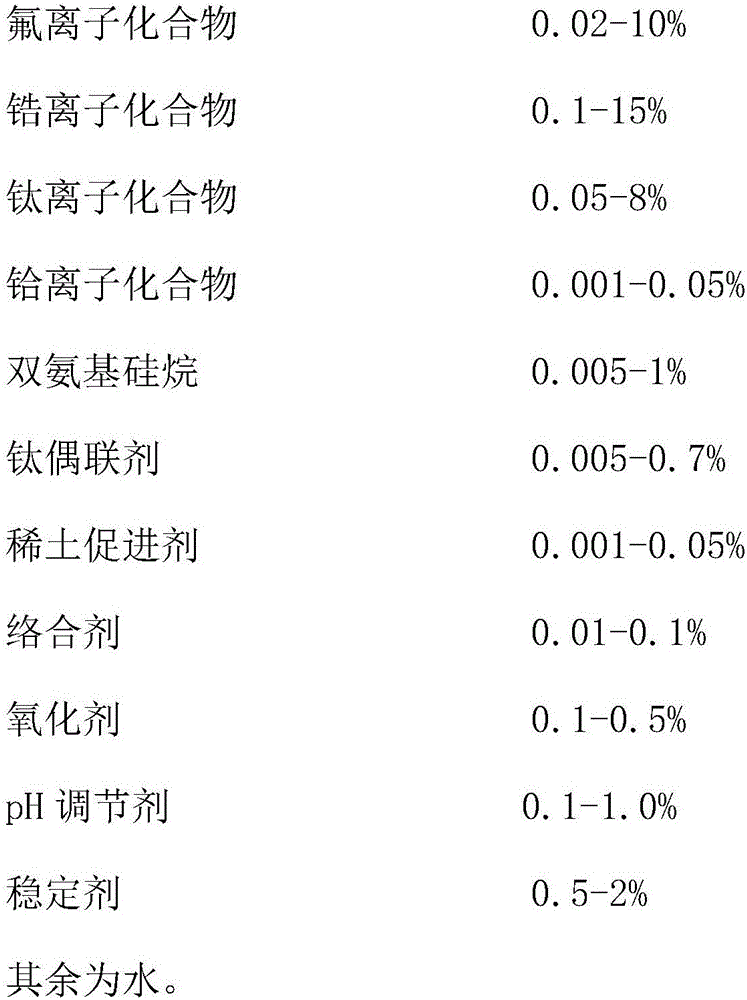

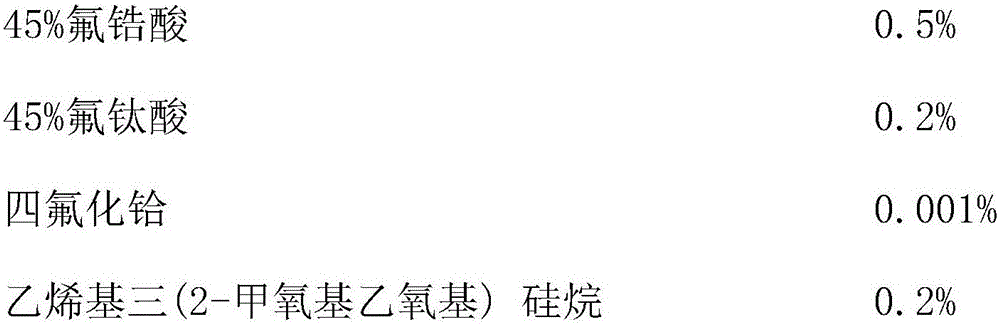

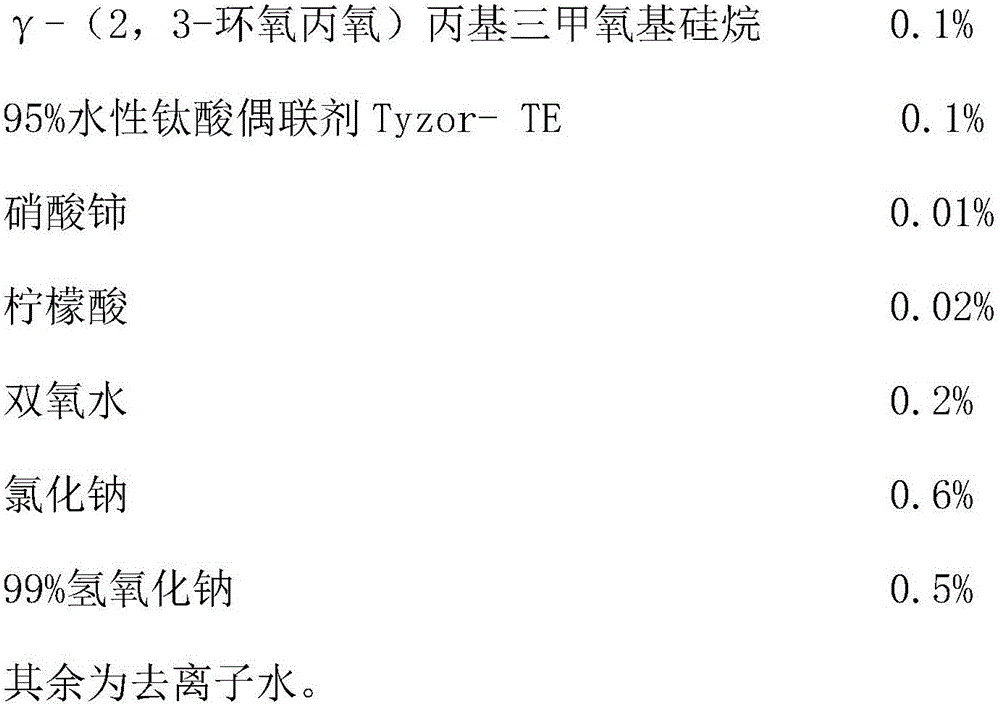

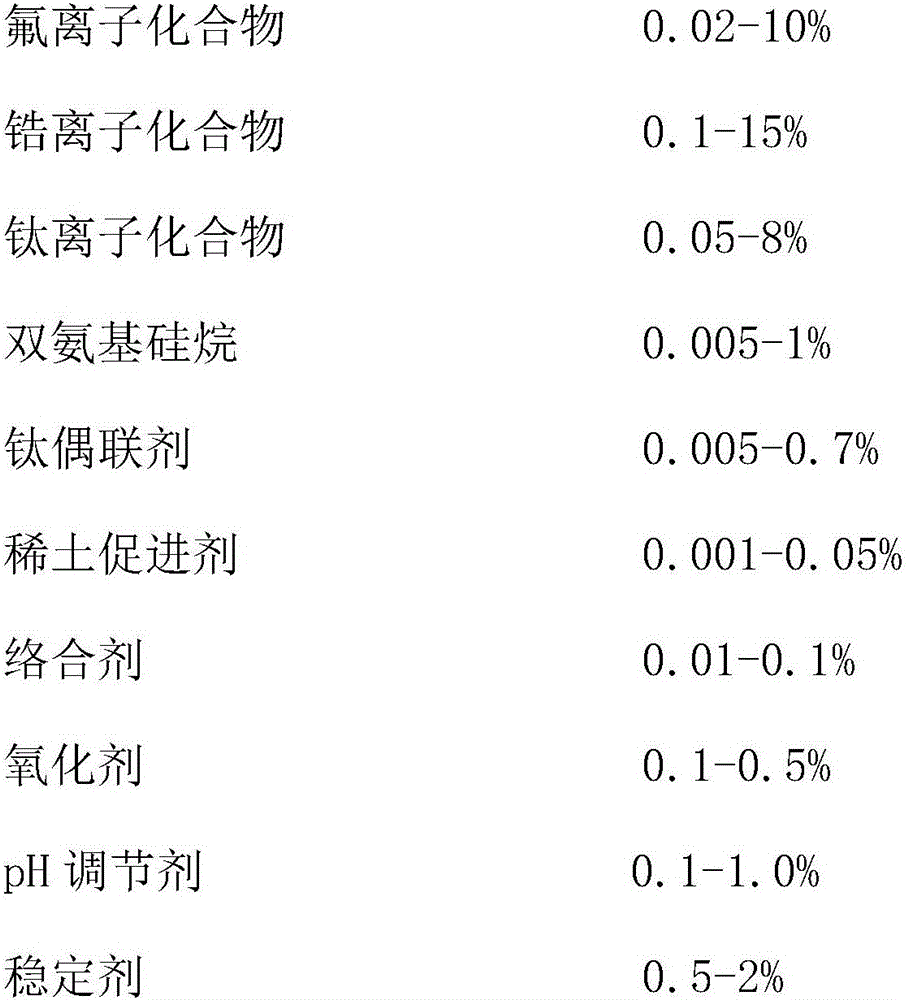

Ceramic transforming agent capable of improving corrosion resistance of metal, preparation method and using method thereof

ActiveCN106756935APromote bondingGood electrical conductivityMetallic material coating processesIonCorrosion

The invention provides a ceramic transforming agent capable of improving the corrosion resistance of a metal, a preparation method and a using method thereof. Compared with the prior art, the fluorine ions are firstly slightly dissolved on the surface of steel and a zinc substrate and form a compact conversion film layer on the dissolved metal surface with zirconium / titanium / hafnium ions under a certain acidity condition; and an silane coupling agent and a cross-linking agent in a colloid synergistically take effect, and meanwhile, a rare earth promoter in a solution further plays a role. An organic-inorganic hybrid membrane is formed on the metal surface, and the corrosion resistance of the conversion film and the adhesion of electrophoretic paint are superior to those of a ternary phosphating film and an ordinary ceramic transforming film.

Owner:芜湖市瑞杰环保材料科技有限公司

Chrome-free tanning method of alligator skin

The invention provides a chrome-free tanning method of alligator skin. The chrome-free tanning method comprises the following steps of (1) adding water and sodium chloride to a rotary drum or a paddle vat, adding a pickling alligator skin blank after the sodium chloride is dissolved, rotating the rotary drum or paddling a paddle plate for 5-10 minutes, and regulating the pH value of a mixed solution inside the rotary drum or the paddle vat to 3.4-3.7; (2) adding an organic phosphonium salt tanning agent, an alcamines compound and fatty aldehyde to the rotary drum or the paddle vat, then rotating the rotary drum or paddling the paddle plate for 10-20 minutes, standing for 30-60 minutes, and repeating the operation of rotating the rotary drum or paddling the paddle plate and standing till the alligator skin blank is fully impregnated; (3) regulating the pH value of the mixed solution inside the rotary drum or the paddle vat to 5.8-6.2, then rotating the rotary drum or paddling the paddle plate for 5-10 minutes, standing for 30-60 minutes, and repeating the operation of rotating the rotary drum or paddling the paddle plate and standing for 3-5 times, then standing for 6-12 hours, and then completely discharging the mixed solution; (4) adding the water and an oxidizing agent to the rotary drum or the paddle vat, then rotating the rotary drum or paddling the paddle plate for 5-10 minutes, standing for 30-60 minutes, and repeating the operation of rotating the rotary drum or paddling the paddle plate and standing for 3-5 times.

Owner:广西盟展鳄鱼科技开发有限公司

Metalized ceramic leading edge nozzle kiels for high-temperature turbine applications

ActiveUS20140090457A1Promote bondingGas-turbine engine testingRapid change measurementMetallurgyNozzle

Owner:GENERAL ELECTRIC CO

Ceramization agent for electrophoretic coating pretreatment, preparation method and usage method for ceramization agent

ActiveCN106702363AGood effectPromote bondingMetallic material coating processesCorrosionOrganic inorganic

The invention method provides a ceramization agent for electrophoretic coating pretreatment, a preparation method and a usage method for the ceramization agent. Compared with the prior art, fluorine ions slightly dissolve the surfaces of steel and a zinc substrate first, and meanwhile, the fluorine ions and zirconium / titanium ions form a compact conversion film layer on the dissolved metal surface; and a silane coupling agent and a cross-linking agent in colloid achieve the synergistic effect, and meanwhile, a rare earth promoter in a solution also plays a role. An organic-inorganic hybrid film is formed on the metal surface, and the corrosion resistance of the conversion film as well as the adhesive force of the conversion film and electrophoretic paint are far superior to that of ternary phosphating films and common ceramization films.

Owner:芜湖市瑞杰环保材料科技有限公司

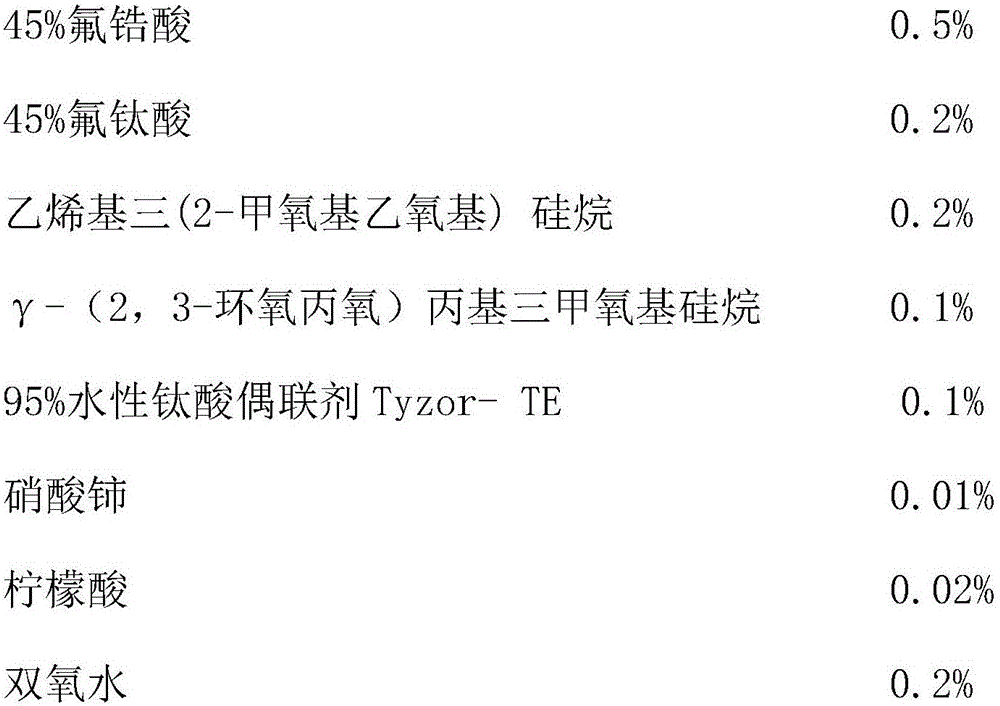

Edible and biodegradable package materials

The invention relates to an edible and biodegradable package material composition and uses thereof. Specifically, the invention relates to a package material composition comprising a polysaccharide component, a protein component, or a combination thereof, in order to produce a transformational package that is both edible and naturally biodegradable. The package material composition of the invention provides a structural integrity to serve a full range of uses for packaging and shipping of both wet and dry products.

Owner:1 MIGHTY MOGUL

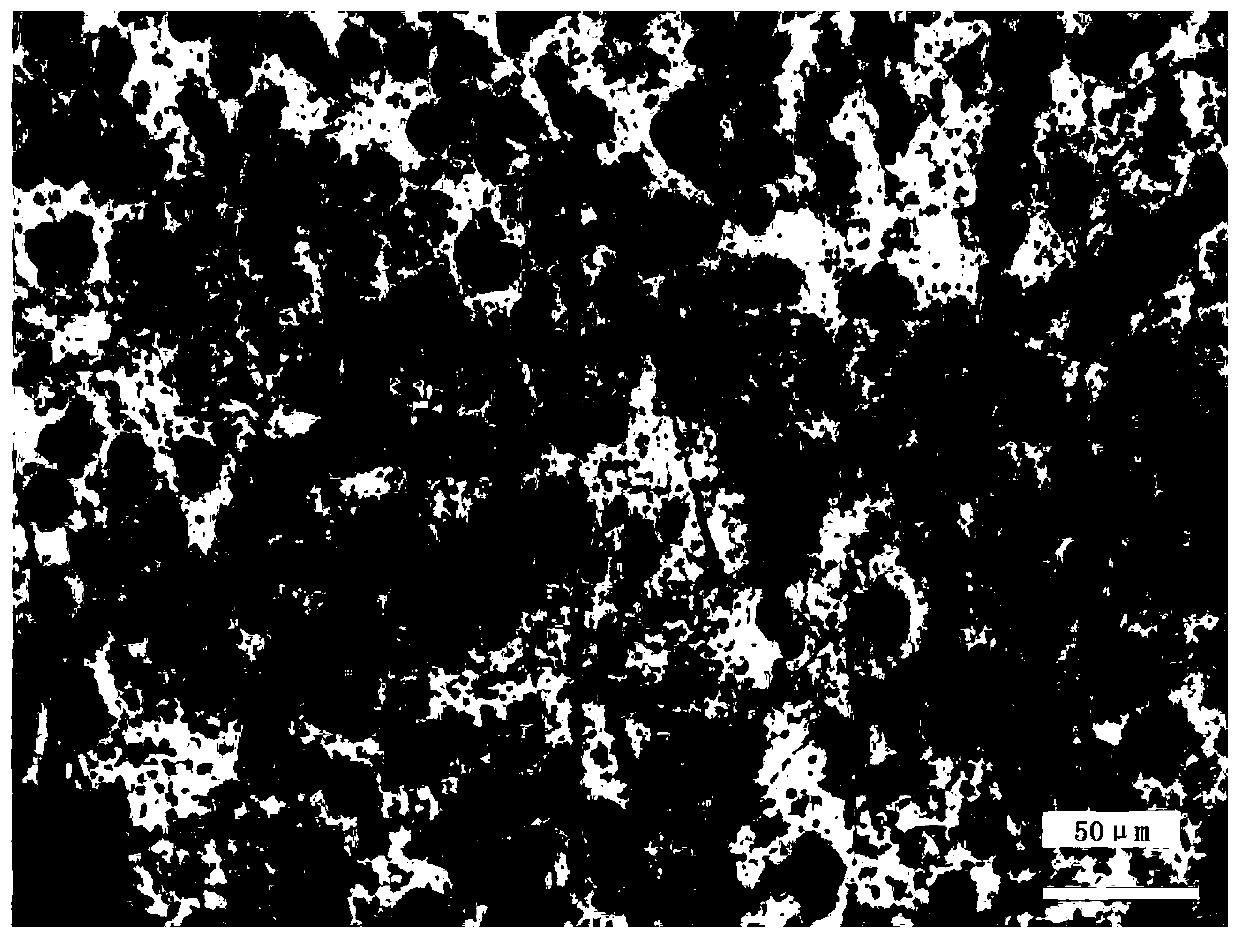

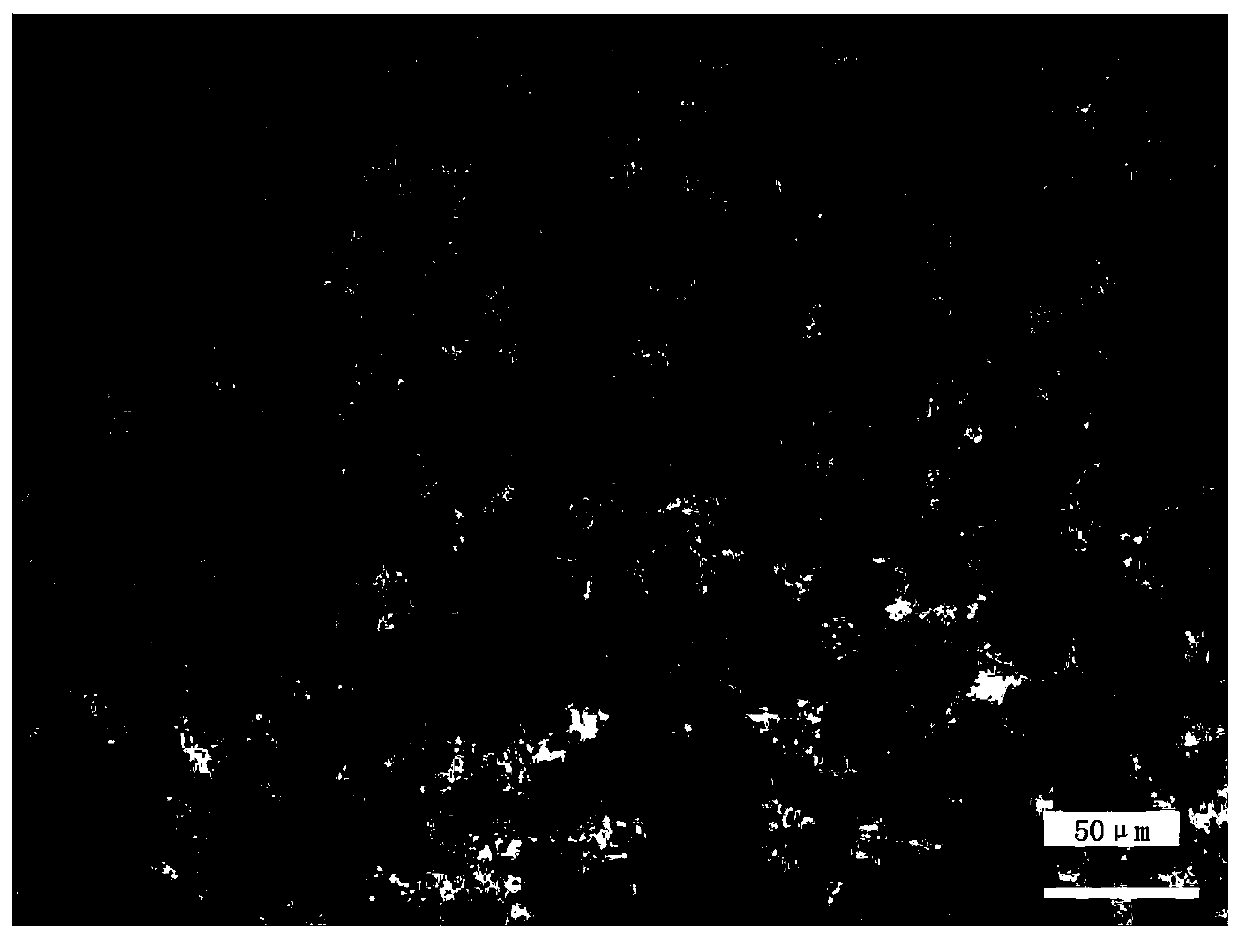

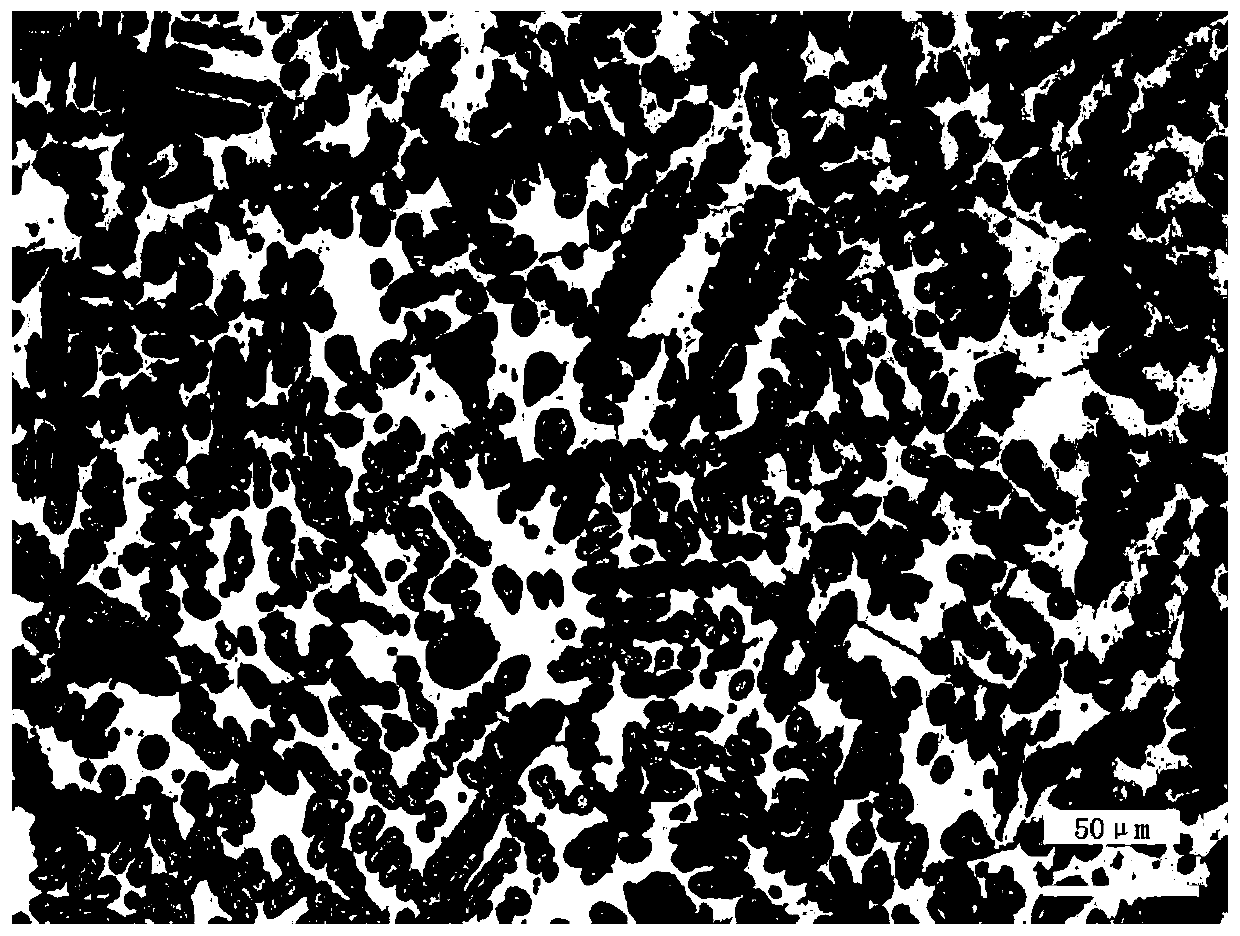

Copper-iron intermediate alloy and preparing method thereof

The invention discloses copper-iron intermediate alloy and a preparing method thereof. The copper-iron intermediate alloy is prepared from, by mass percentage, 20-50% of Fe, 0.01-1.0% of Ni, 0.01-1.0%of Cr, 0.01-0.5% of Mg, 0.01-0.5% of Y, 0.01-0.05% of S, 0.005-0.03% of P and the balance copper and other inevitable trace impurities. The invention further provides a preparing method of the copper-iron intermediate alloy. Ni, Cr, Mg, Y, S, P and other various metal elements are added, and a technology of combining smelting with compressed air blowing and quick cooling is adopted under a non-vacuum condition. According to the copper-iron intermediate alloy prepared by means of the method, segregation and beneficiation of iron in ingot casting are avoided, the component homogeneity is greatly improved, and can reach the range of + / -2%, and the average size of the iron-rich phase is smaller than or equal to 50 micrometers.

Owner:JINTIAN COPPER GROUP CORP NINGBO

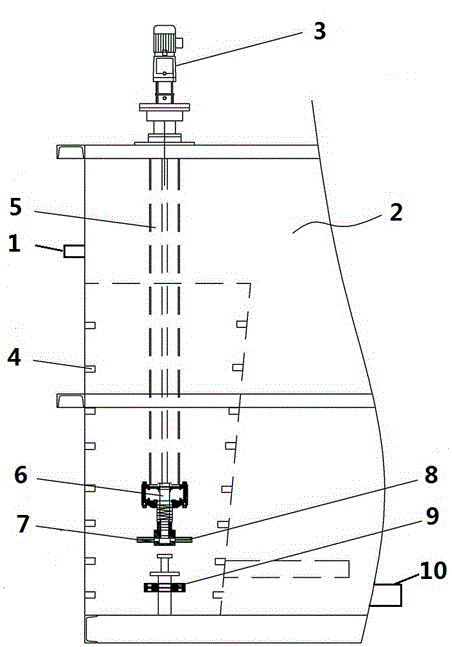

Method using coagulation air floatation machine to treat sewage

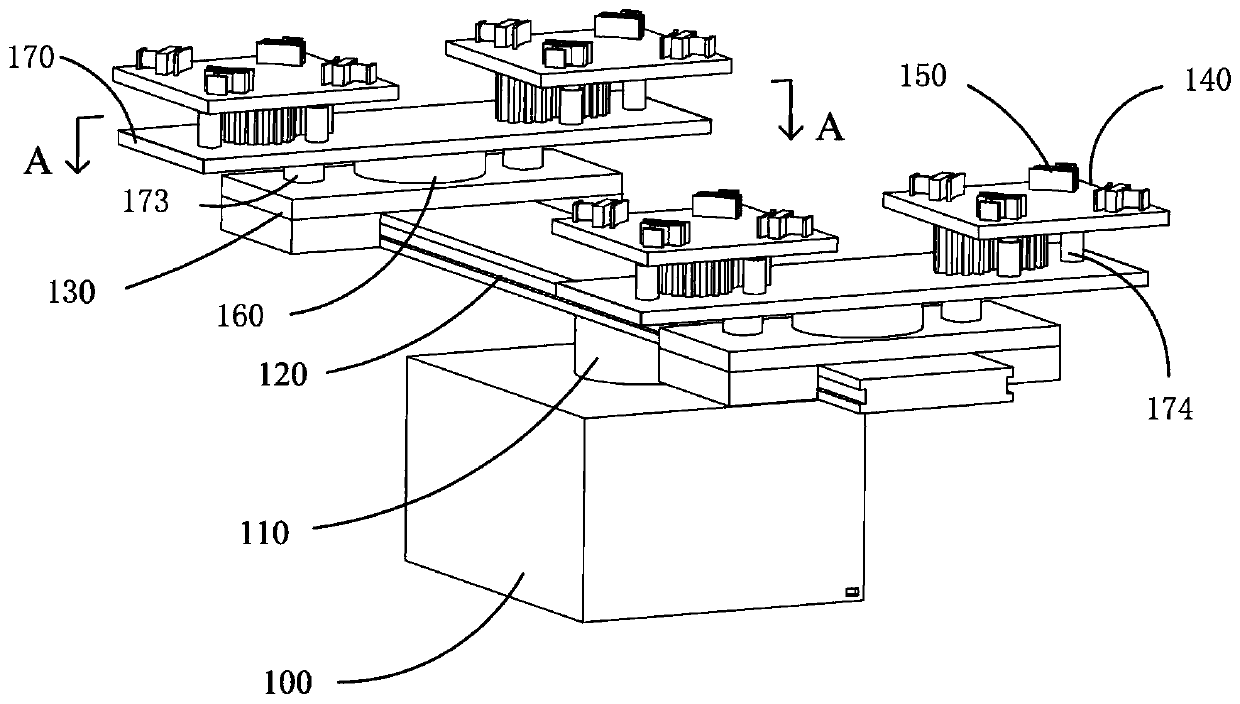

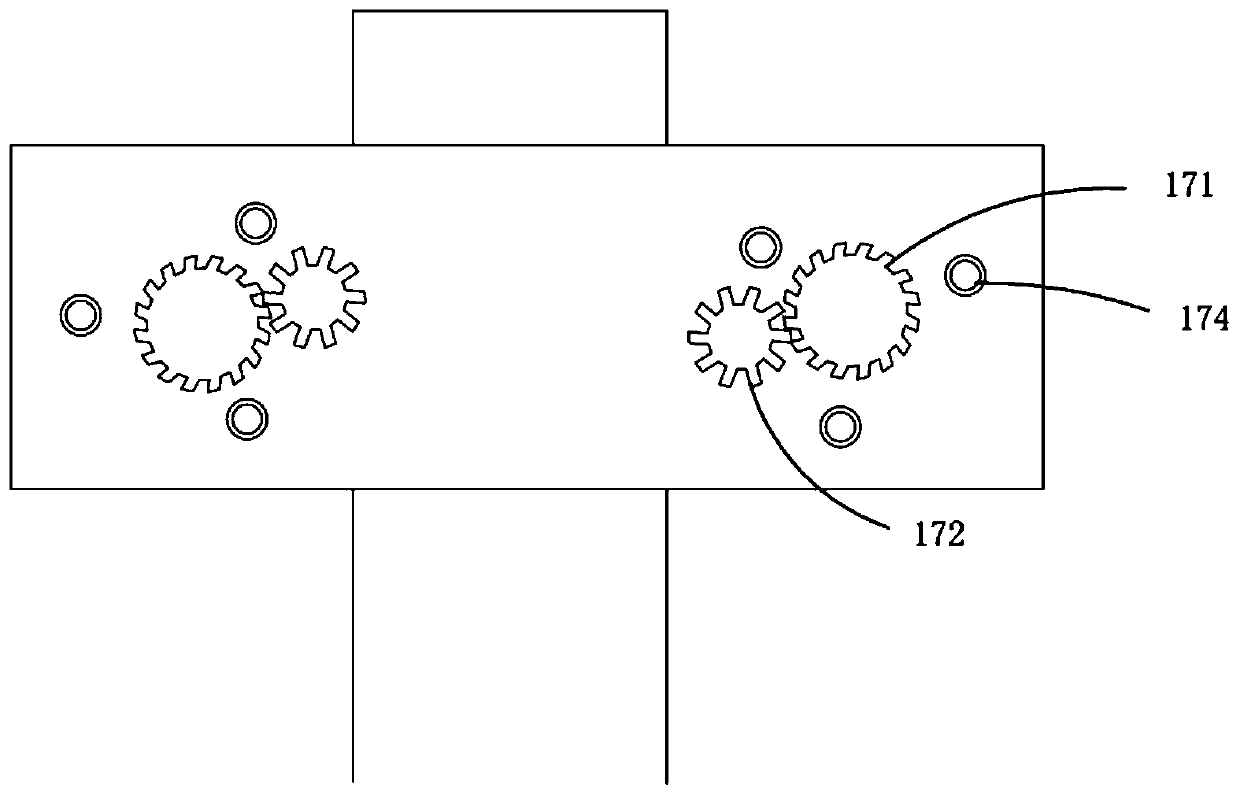

ActiveCN105884087APromote bondingImprove air flotation effectTreatment involving filtrationMultistage water/sewage treatmentElectric machineryEnvironmentally friendly

The invention provides a method using a coagulation air floatation machine to treat sewage. The method includes: the filtered and flocculently precipitated sewage is guided into the coagulation air floatation machine, and coagulant is added; the motor of the coagulation air floatation machine drives blades to rotate through a rotary shaft so as to allow the coagulant to have mixed reaction with the impurities in the sewage to form floc; an ultrasonic transmitter cavitates air entering the coagulation air floatation machine through an air inlet pipe to generate fine bubbles; the fine bubbles floats and adheres and carries away the floc during floatation; the floc floats to the water surface along with the fine bubbles and forms floating residues, the floating residues are removed, and the water treated by the fine bubbles is discharged from the water outlet in the bottom of the coagulation air floatation machine. The method has the advantages that the water treatment method is simple, low in cost and capable of effectively removing the impurities such as suspended particles, emulsified oil, fibers and heavy metal in the sewage, environmentally friendly, free of pollution and high in market application value.

Owner:SICHUAN GERUISI ENVIRONMENT TECH CO LTD

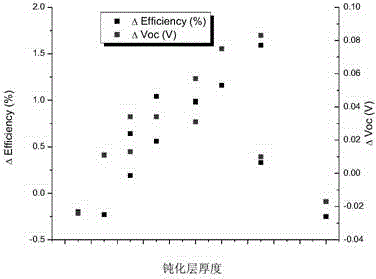

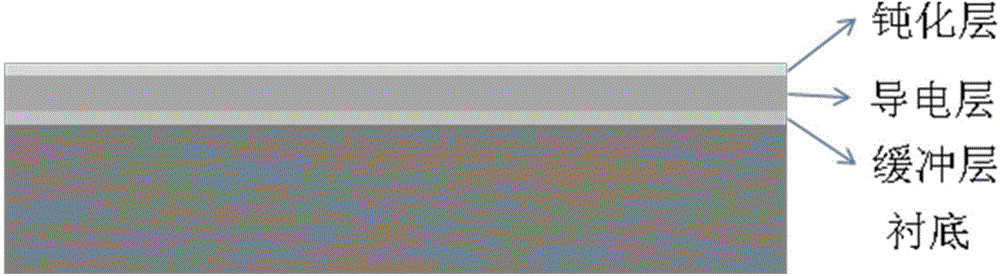

Solar cell back electrode passivation layer preparation technology based on surface oxidation method

InactiveCN104576780APromote bondingImprove bindingFinal product manufacturePhotovoltaic energy generationSurface oxidationThin layer

The invention relates to a solar cell back electrode passivation layer preparation technology through adopting a surface oxidation method. A back electrode is characterized in that the back electrode is composed of two compositions. The back electrode comprises a buffer layer, a conducting layer and a passivation layer, wherein the buffer layer is an Mo thin film with a loose structure, so that the back electrode can make good contact with a substrate; the conducting layer is another Mo thin film which is with different structure of the buffer layer and with good electrical conductivity, and the conducting layer is used for collecting electrons generated by a conduction absorbing layer; the passivation layer is formed by adding an Mo thin layer which is mixed up with MoO2 on the Mo conducting layer surface through utilizing a surface oxidation technology, so that the passivation layer can make good contact with the absorbing layer, good electrical conductivity is maintained, and the efficiency of solar cell devices is improved. A solar cell back electrode passivation layer prepared through the surface oxidation method has the advantages that the machining is easy, the technology is continuous, the controllability is strong, and the solar cell back electrode passivation layer has an extensive prospect in the field of the future solar photovoltaic industry.

Owner:SUZHOU RUISHENG SOLAR ENERGY TECH

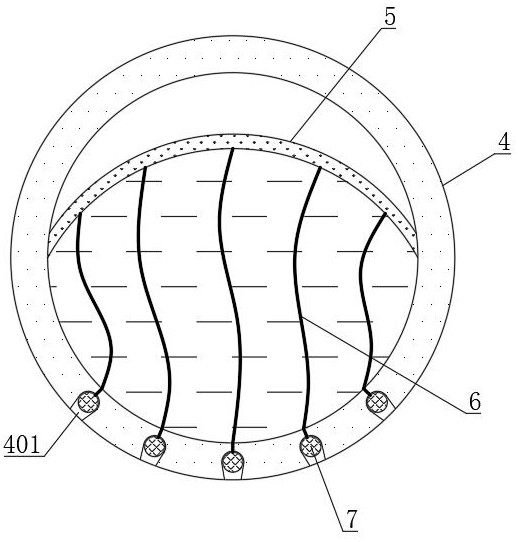

High-strength bearing processing frosting wheel

InactiveCN109159036APromote bondingImproves strength and hardnessAbrasion apparatusGraphiteSilicon carbide

The invention discloses a high-strength bearing processing frosting wheel comprising a frosting wheel base body and an abrasive layer. The abrasive layer comprises a bonding agent and a mixed abrasive; the bonding agent is a ceramic bonding agent; a mixed abrasive layer comprises the following components including, by mass, 12-16 parts of graphite, 22-26 parts of diamond, 30-33 parts of pigment filler, 10-14 parts of silicon dioxide, 14-18 parts of black silicon carbide and 8-14 parts of an auxiliary abrasive; the pigment filler is a mixture of titanium dioxide and zinc chloride, the mass ratio of the titanium dioxide to the zinc chloride is 2:1; the auxiliary abrasive is white corundum; and the frosting wheel base body is made of a high-strength alloy material and comprises components including, by weight, 1.23%-1.78% of Zr, 0.02%-0.09% of Re, 0.58%-1.14% of Bi, 0.05%-0.13% of Cs, 0.78%-1.45% of Pb, 0.02%-0.06% of Al, 2.45%- 3.15% of Ru, 1.19%-1.25% of Zn, 20%- 28% of rare earth and the balance Fe and trace impurities.

Owner:扬中市飞宇磨具有限公司

Preparation method of whole-bean bean curd

InactiveCN107616237AImprove hydrophilicityPromote bondingCheese manufactureFood scienceFiber layerMechanical force

The invention belongs to the technical field of food processing, and particularly relates to a preparation method of whole-bean bean curd. The method comprises the following steps of material preparation, soaking, soup heating, milk grinding, homogenizing, heating and solidification. The prepared bean curd is detected; a purpose-made solution 1 is used for performing soup heating on the soybeans;the proper time is controlled; the proper material to water ratio is controlled; the homogenizing treatment is performed; under the mechanical force effect, large particle bean dreg fiber layers are separated till fracture; the fracture fiber has high hydrophilia; colloid can be formed in the water; the blocking effect of the bean dreg in the gel forming process is overcome; the gel intensity is as high as 180g, so that the bean curd block is complete and does not have air holes; no normally visible particles or impurities exist; the texture is soft and tender; the texture is tight and compact; the profile is bright; the bean fragrance is intense.

Owner:田松

Method for cladding bimetal

The invention relates to a method for cladding a bimetal, which comprises the following steps of: a, heating a cleaned copper strip at the temperature of between 500 and 900 DEG C; b, cleaning the external surface of a steel core through a cleaning device, and preheating the cleaned steel core in protective atmosphere by an induction heating mode at the temperature of between 700 and 1,100 DEG C; c, putting the preheated steel core and the copper strip together into a gas protection chamber which is filled with the protective atmosphere for inhibiting surface oxidation of a steel wire and the copper strip, and then extruding the steel wire and the copper strip to generate solid-phase binding through a binding roller and allowing the copper strip to surround the steel core to finish cladding molding; and d, finally, winding up a copper clad steel wire after cladding through a winding roller. The method for cladding the bimetal can control the uniformity of a clad layer, and can make the bimetal bound after being clad at the same time and overcome the defects of other cladding methods.

Owner:FUSHI INT DALIAN BIMETALLIC CABLE

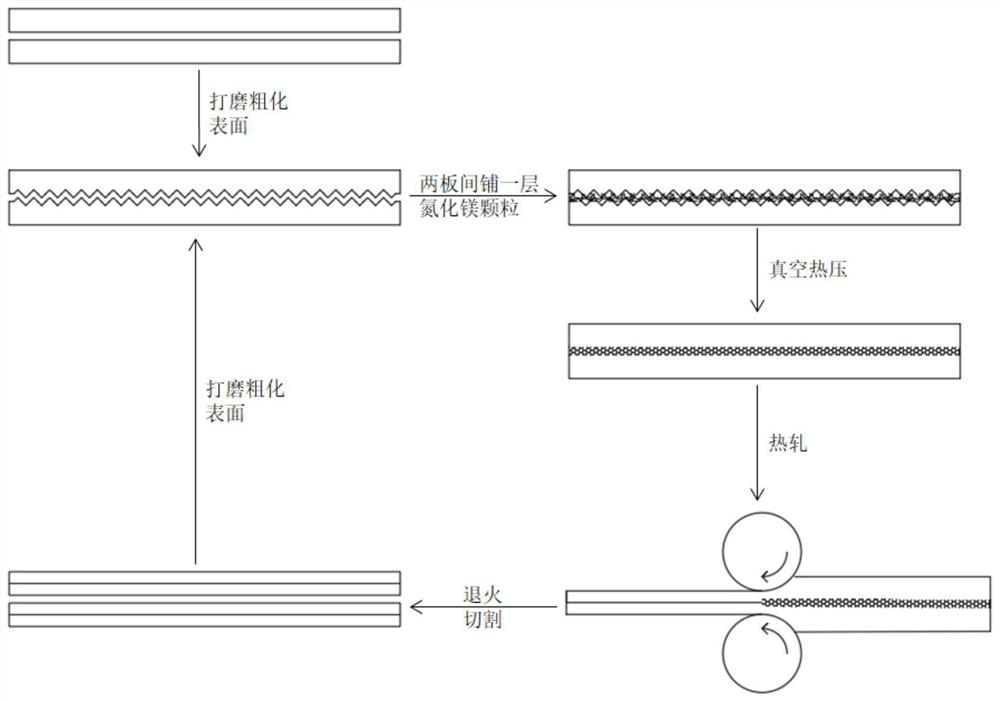

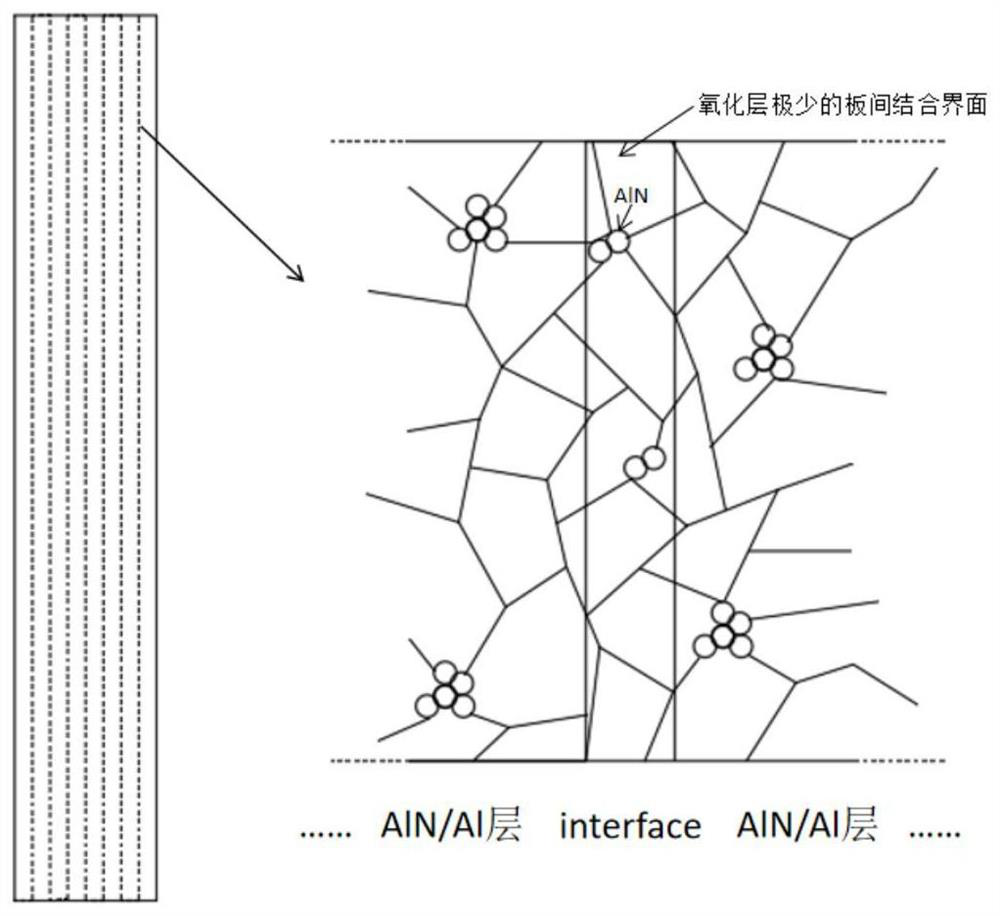

Layered aluminum alloy/aluminum-based composite board and preparation method thereof

PendingCN113385534AAvoid contact surface oxidationPromote bondingFurnace typesAuxillary arrangementsAluminum matrix compositesBonding strength

The invention belongs to the field of metal material preparation, and particularly relates to a layered aluminum alloy / aluminum-based composite board and a preparation method thereof. The preparation method specifically comprises the following steps that magnesium nitride powder is uniformly dispersed between aluminum alloy plates subjected to surface roughening treatment, the stacked plates are subjected to vacuum hot pressing to generate AlN in situ through a replacement reaction, the bonding strength and the bonding quality between the plates are improved, the plates are rolled to refine grains, the dislocation density and the grain boundary number in the materials are improved, the effect of improving the mechanical property of the material is achieved, and then low-temperature annealing is carried out to remove residual stress, so that the material has better comprehensive mechanical properties; and then the obtained plate is cut into two pieces with the same size. The prepared layered aluminum-based composite material plate is good in interface bonding, internal defects introduced in the rolling process are reduced to the maximum extent, and the material has good strength and plasticity.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of nano-phase reinforced aluminum-based composite board

ActiveCN111451514APromote bondingImprove plate yieldMetal rolling arrangementsAluminum matrix compositesPowder metallurgy

The invention provides a nano-phase reinforced aluminum-based composite board and a preparation method thereof, and belongs to the technical field of metal-based composite material preparation and processing. The method combines sheet powder metallurgy and asynchronous rolling, and comprises the following steps of: firstly, carrying out variable-speed ball milling to obtain sheet composite powderwith nano-phase dispersed distribution; then, carrying out powder metallurgy sintering to obtain a powder metallurgy ingot blank; and finally, adopting asynchronous rolling, and strictly controlling technological parameters such as the asynchronous rolling ratio and the pass reduction to obtain the nano-phase reinforced aluminum-based composite board. The aluminum-based composite board prepared bythe method has the advantages of being high in modulus, high in strength, good in plasticity and the like, the material preparation process is simple, the yield is high, and the preparation and production of the nano-phase reinforced aluminum-based composite board with the thickness of 1-5 mm can be met.

Owner:SHANGHAI JIAO TONG UNIV +1

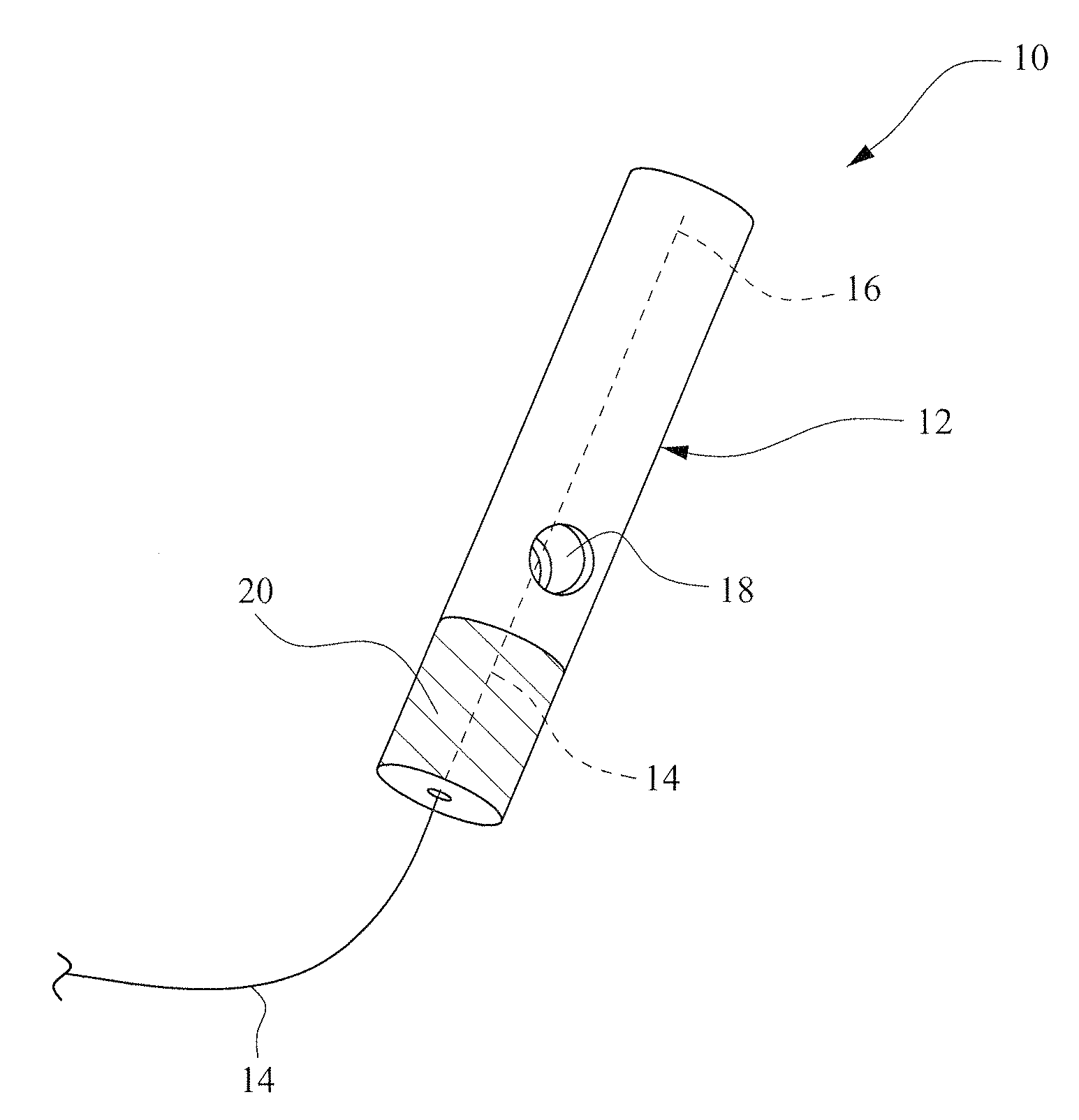

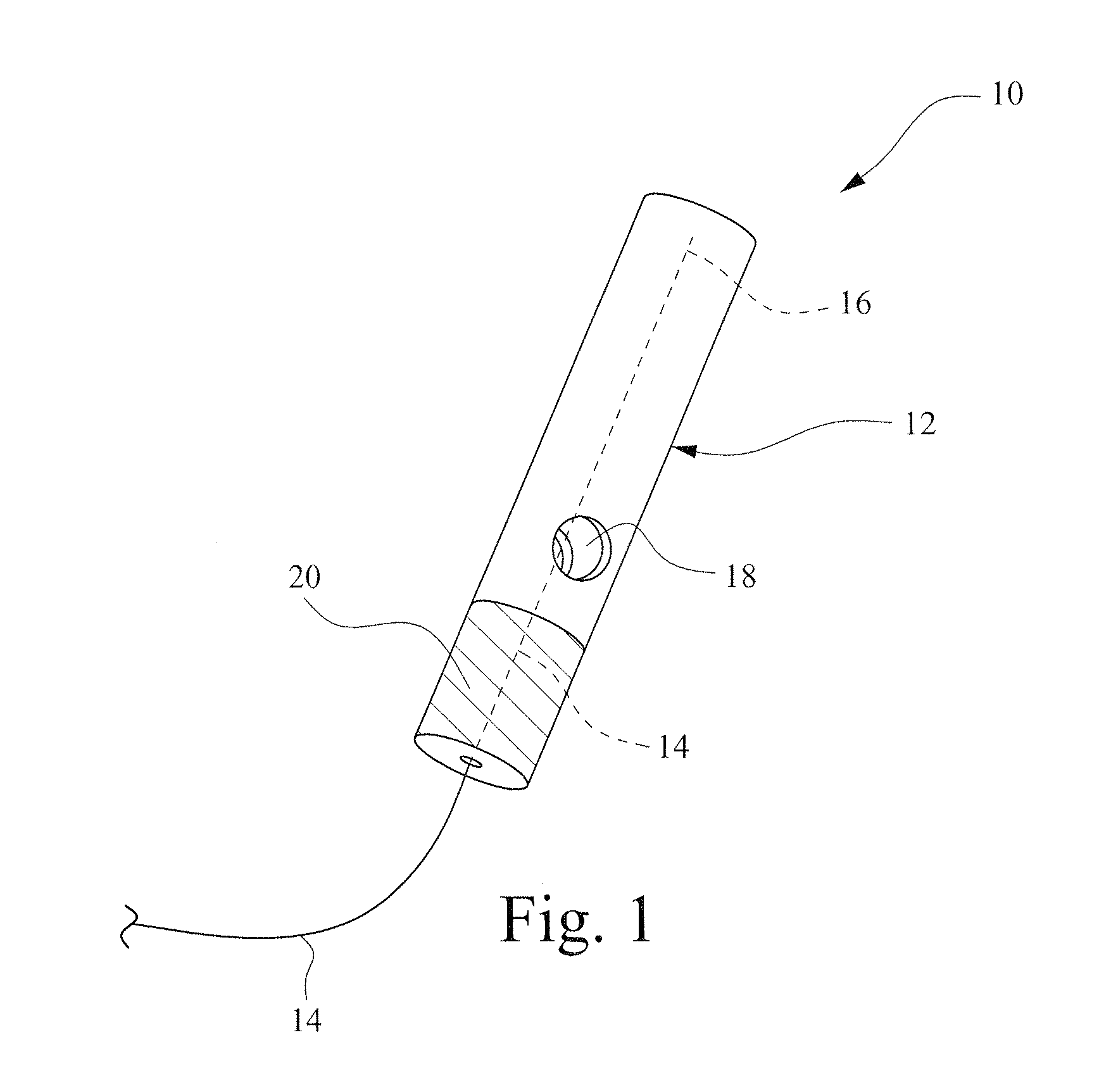

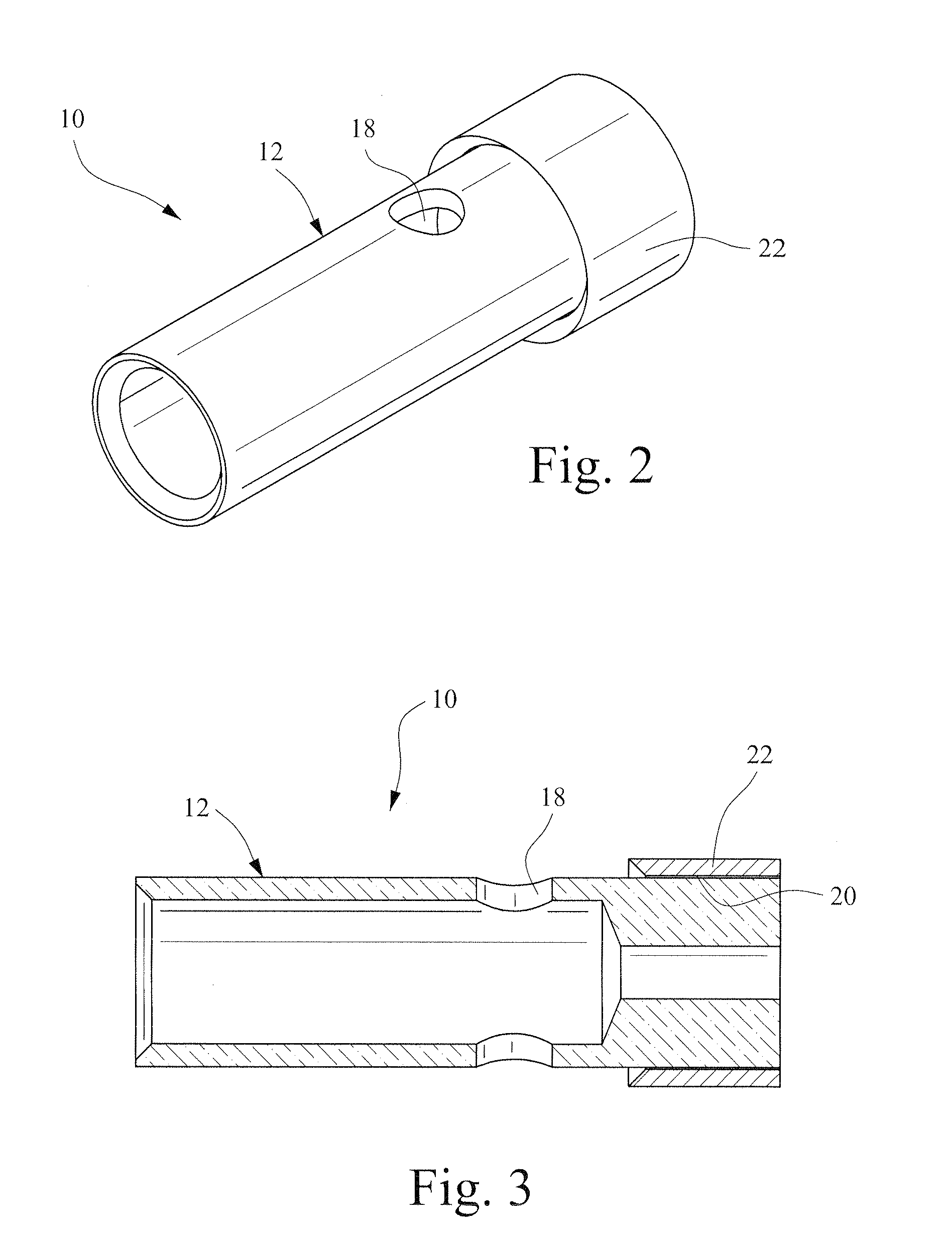

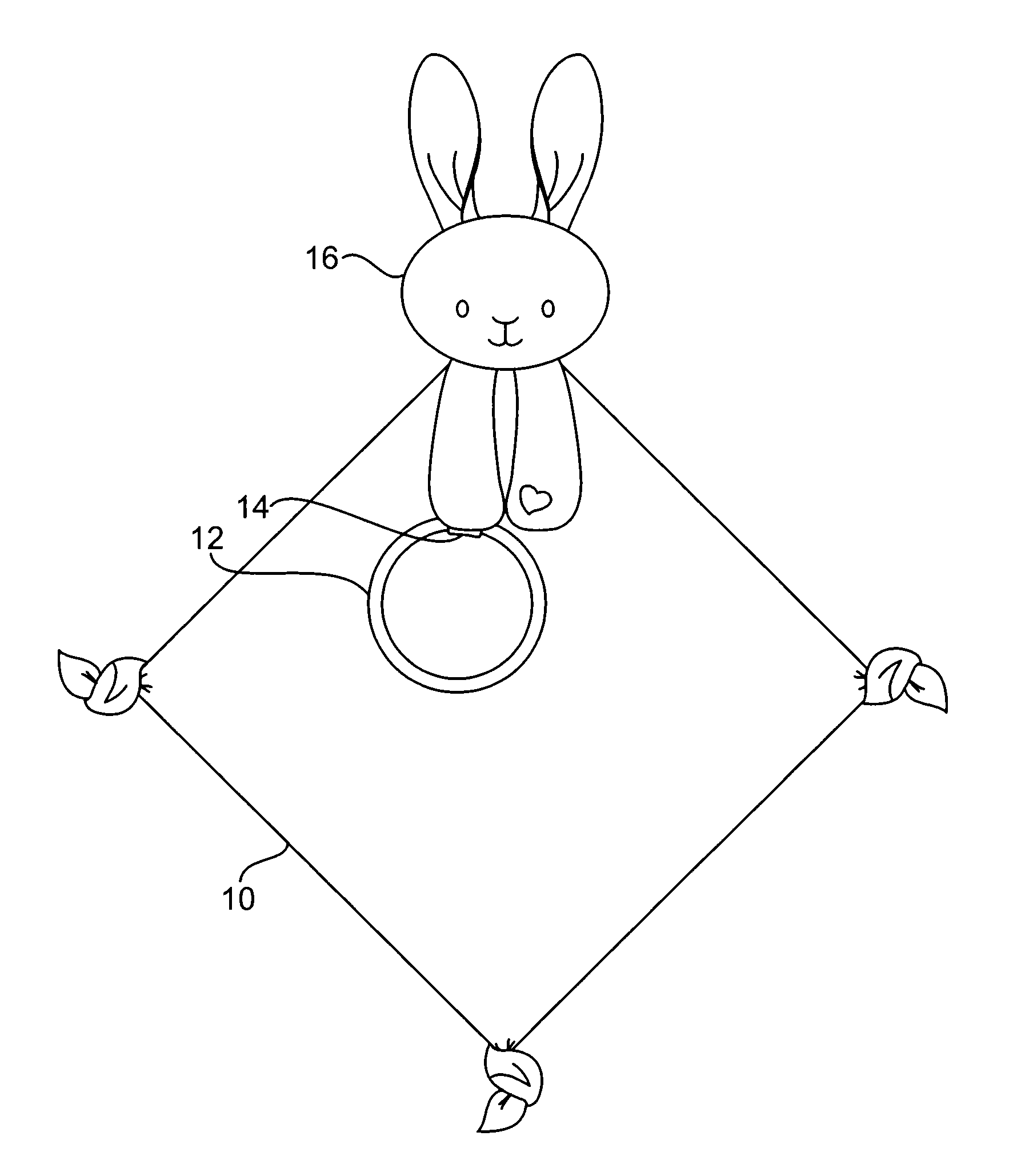

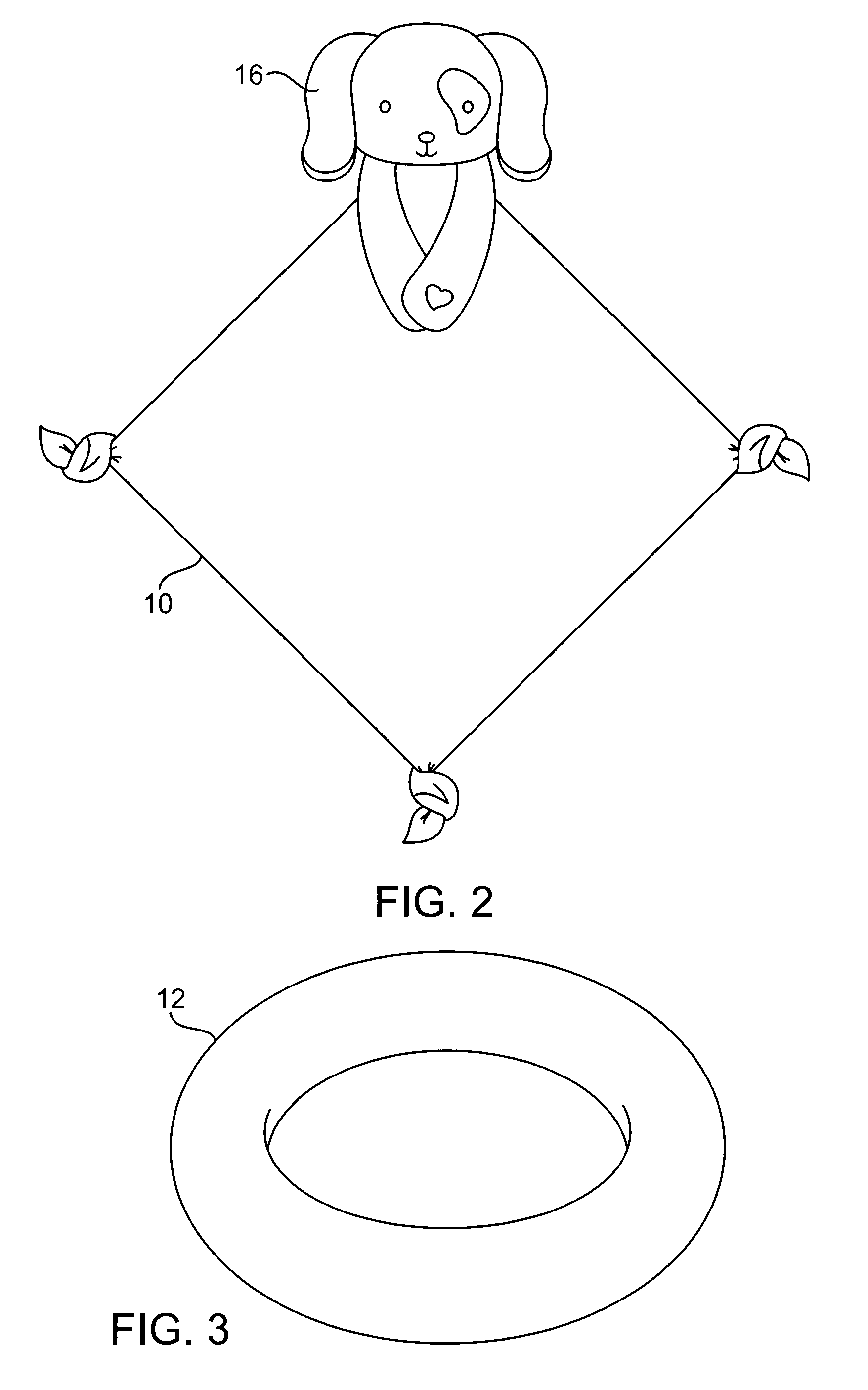

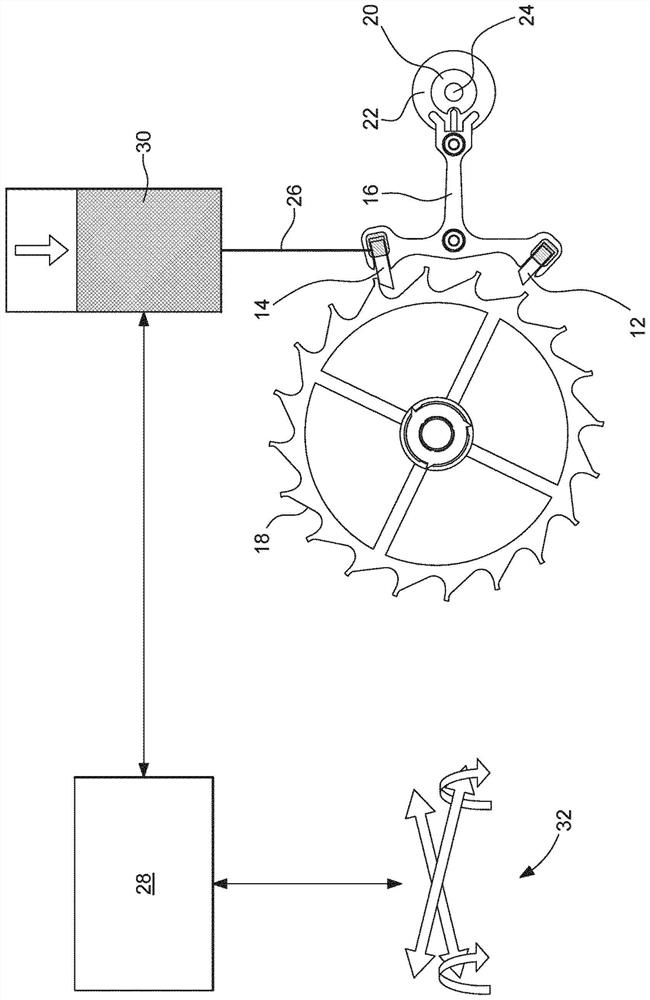

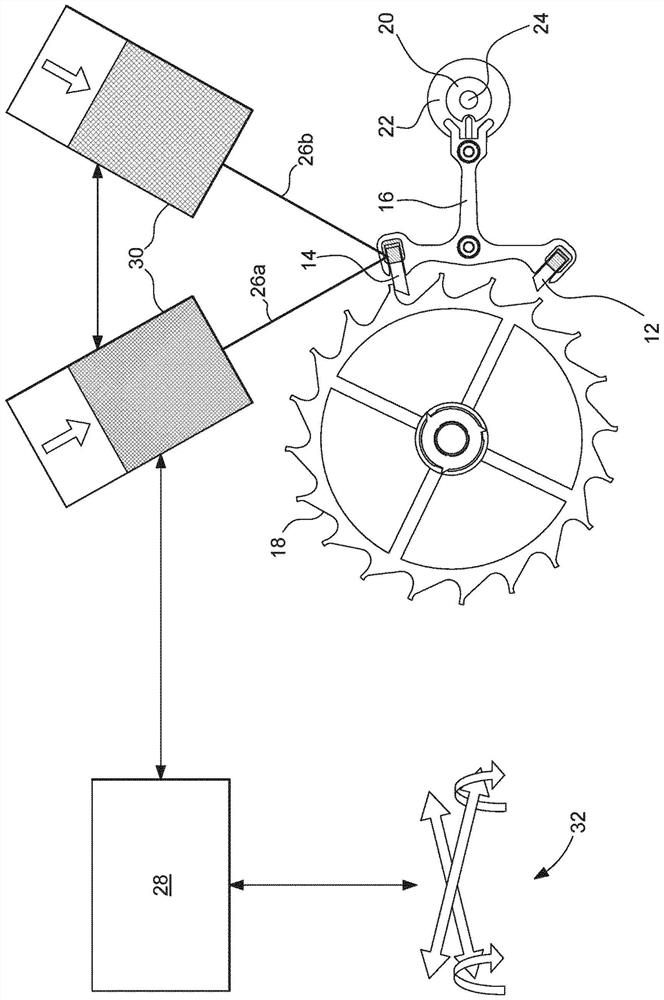

System for promoting a secure parent/child attachment bond

InactiveUS20170011650A1Promote bondingEasy to carryDollsTeaching apparatusHuman–computer interaction

A system with a transitional object to promote the bond between children and adults by exchanging that object when in the absence or presence of the adult. Preferably the system is used between children and parents. The system has a first three-dimensional object, a second three-dimensional object that may be easily carried by an adult, wherein the first three-dimensional object receives the second three-dimensional object which is removably enclosed by the first three-dimensional object. When the parent and child are together the second three-dimensional object is enclosed by the first three-dimensional object, and when the parent leaves the child, the second three-dimensional object is removed and kept with the parent. Upon returning to the child the parent re-disposes the second three-dimensional object in association with the first three-dimensional object. This ritual and routine promotes bonding between an adult and child.

Owner:SIMMS MANN INST FOR EDUCATION & COMMUNITY DEVEMENT

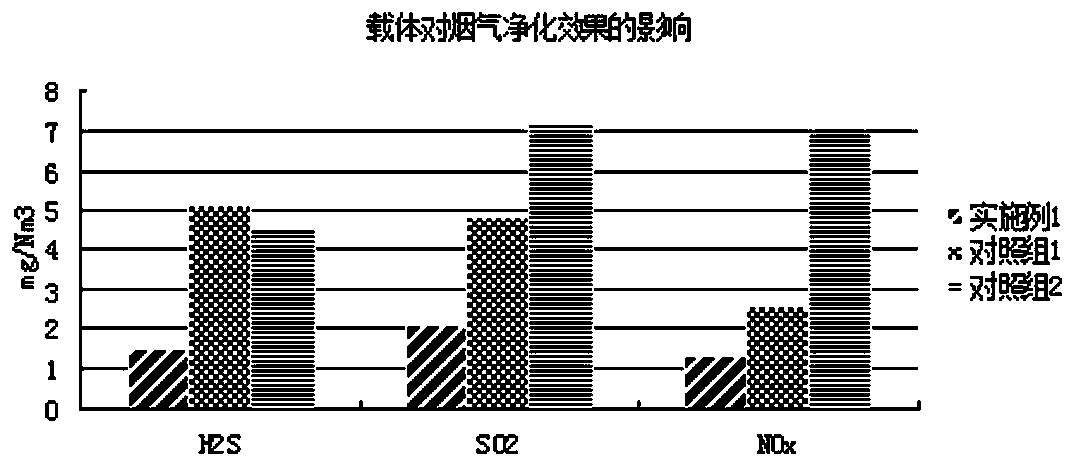

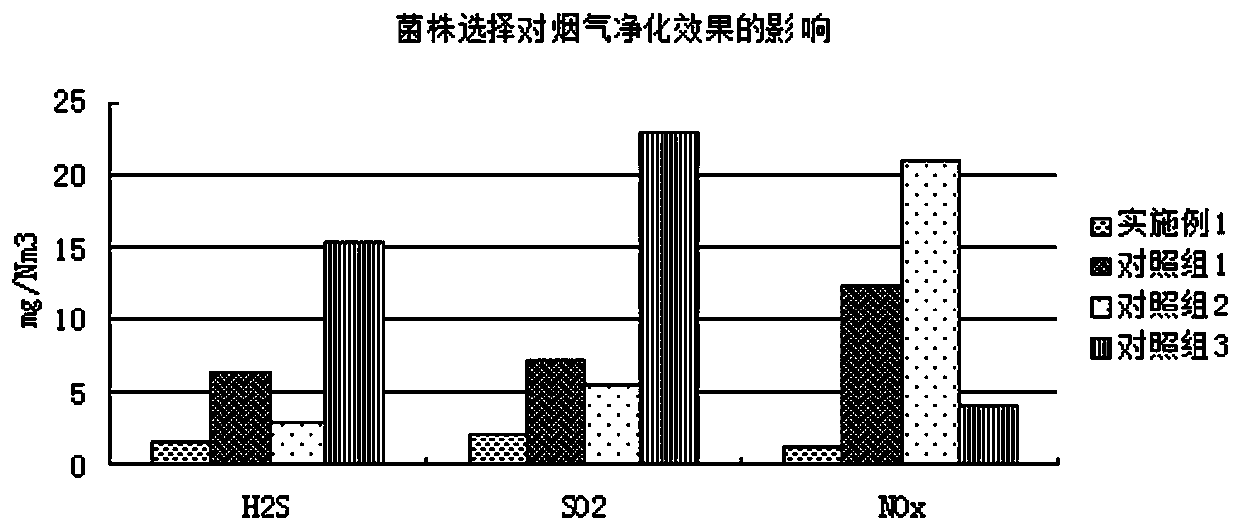

Method for purifying and absorbing spraying granulation flue gas by utilizing resin complex

PendingCN110496526APromote bondingImprove compatibilityDispersed particle separationAir quality improvementPollutantChemistry

The invention belongs to the technical field of environmental protection, and discloses a method for purifying and absorbing spraying granulation flue gas by utilizing a resin complex. The method comprises the following steps: firstly performing spray washing on the spraying granulation flue gas through a spray washing tower, performing cooling to 33 DEG C or less, performing purification absorption in a reaction chamber containing the resin complex, and performing discharge. The method provided by the invention adopts the resin complex to purify and absorb the spraying granulation flue gas, is simple and feasible, and can effectively remove main pollutants such as H2S, SO2 and NOx in the flue gas.

Owner:卢松

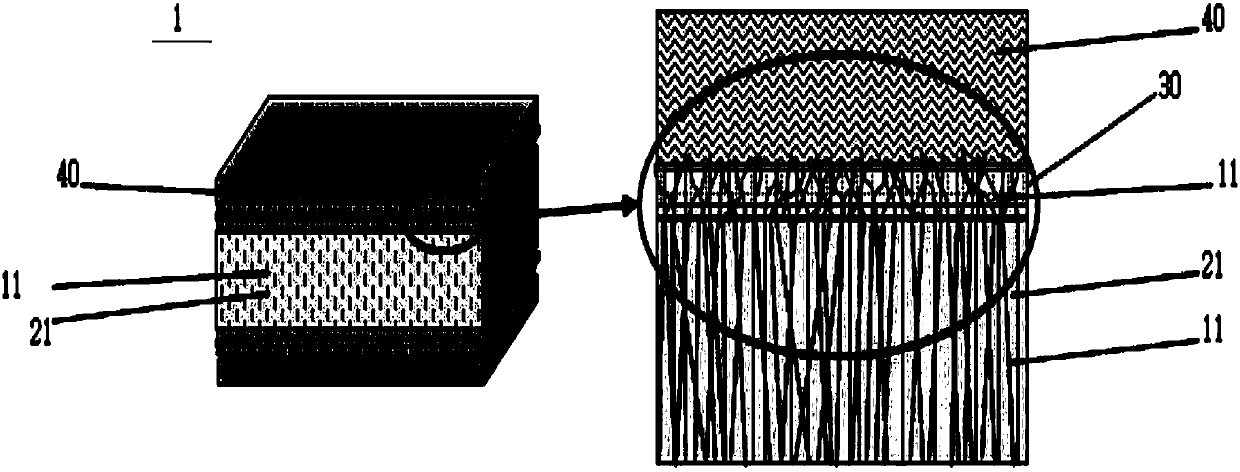

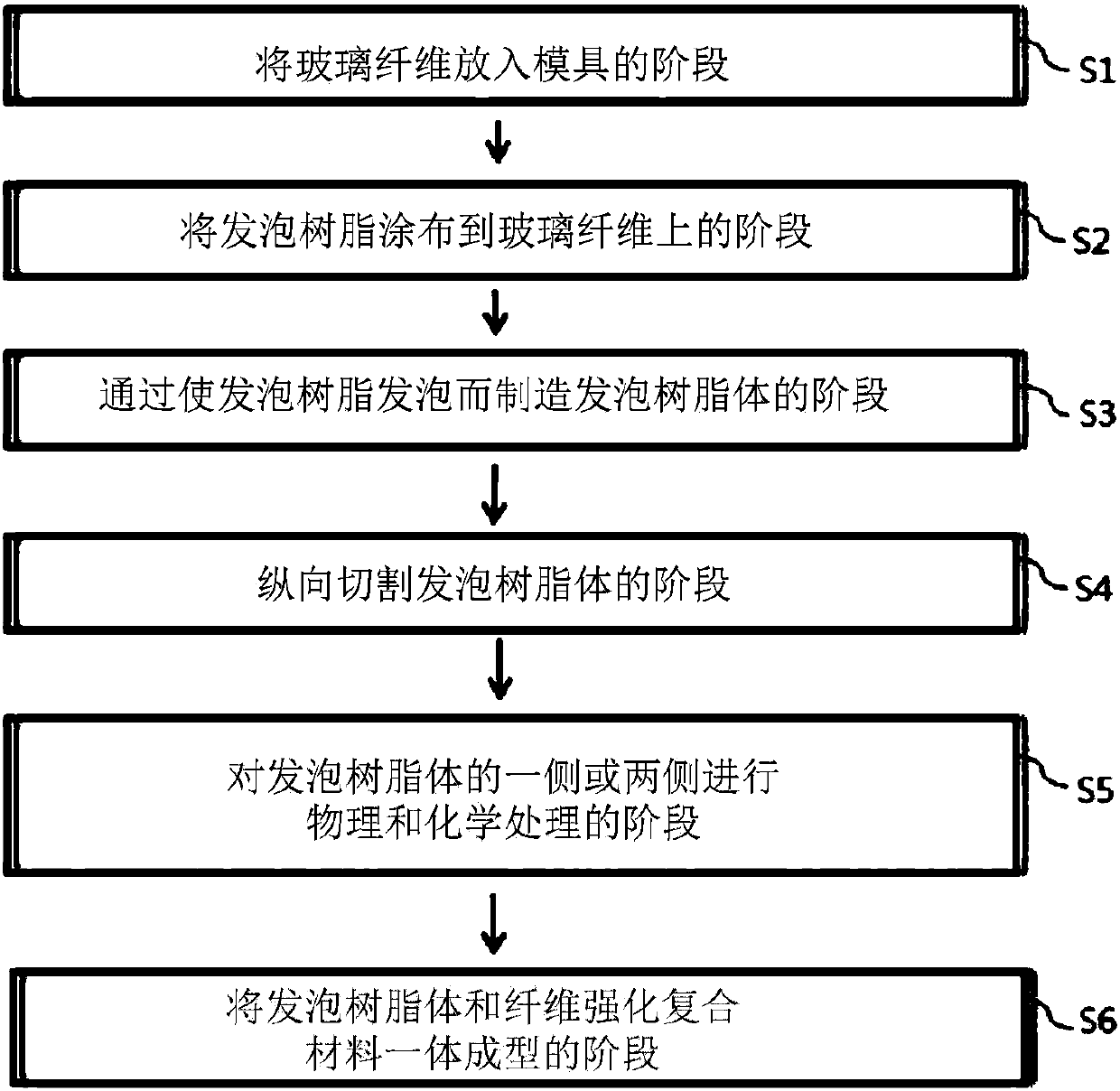

Structure applying the glass fiber-reinforced resin foam and manufacturing method therefor

ActiveCN107303748APromote bondingHigh bending fatigue resistanceSynthetic resin layered productsVehicle componentsFiber-reinforced compositeGlass fiber

The invention relates to a vehicle sandwich structure and a manufacturing method thereof. The vehicle sandwich structure according to the present invention is characterized as follows: being composed of a foamed resin article in sheet form forming the core, a fiber-reinforced composite layer forming a surface material that is located on one or both sides of the foamed resin article in thickness direction; forming a binding layer of core and surface materials between the foamed resin article and the fiber-reinforced composite layer; a large number of glass fibers being inserted within said foamed resin article; more than 70% of total glass fibers being the glass fibers which form an angle between the longitudinal direction of each glass fiber and said foamed resin article, the angle of which satisfying a range from 45 DEG to 90 DEG; more than 70% of total glass fibers being a glass fiber that satisfies a range of smaller than or equal to 90 degrees; the exposed glass fiber being impregnated and bound to the binding layer and the fiber-reinforced composite layer, wherein one or both ends of the glass fiber are exposed on the entire foamed resin article. Also, it is characterized by the height of the glass fiber which is exposed above the foamed resin article being 0.5 to 10 mm.

Owner:HANKUK CARBON CO LTD

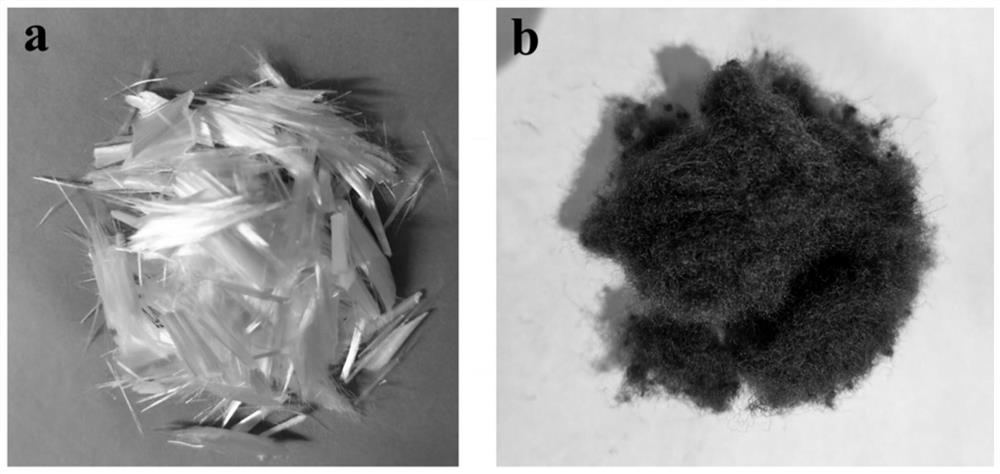

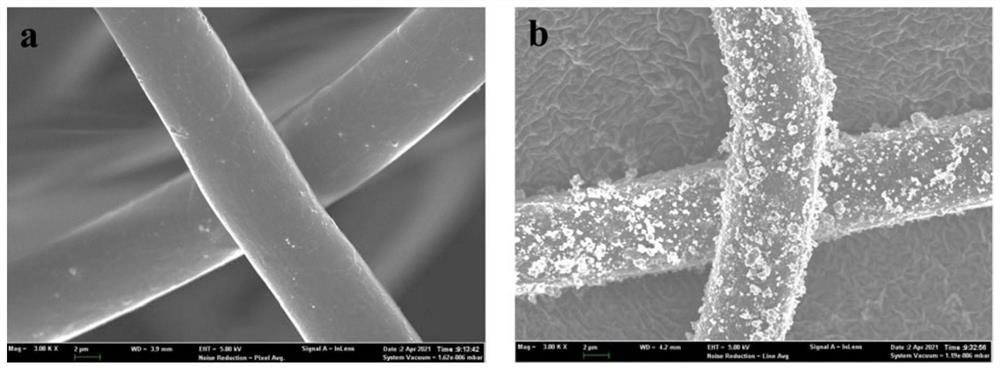

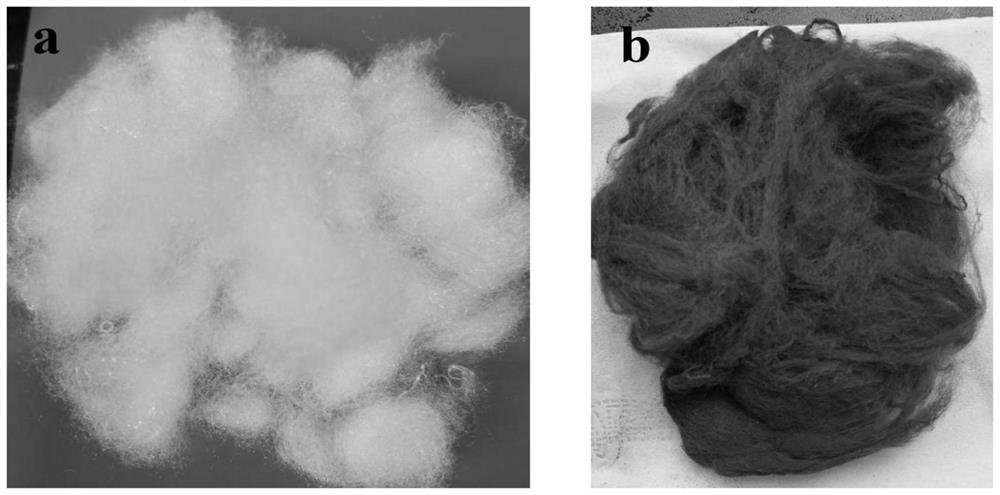

Supported catalyst based on fiber carrier, preparation method thereof and indoor air purification device

PendingCN113289597APromote bondingStrong combinationGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsIndoor airFiber

The invention relates to a preparation method of a supported catalyst based on a fiber carrier, which comprises the following steps of placing the fiber carrier in a stirring device, adding active ingredients by several times, and carrying out mechanical stirring once after each time of adding so as to load the active ingredients on the fiber carrier. The single mechanical stirring process is as follows: the stirring rotating speed is 500 rad / min-1500 rad / min, the stirring power is 0.5 kW-2. 5kW, in the stirring process, the stirring is paused for each 5 s-12 s, the pause time is 3 s-15 s, the total stirring time is 20 s-50 s, the temperature in a stirring device is kept at 25 DEG C-80 DEG C, and the active component is metal nanoparticles or metal oxide nanoparticles. The invention also relates to the supported catalyst prepared by the preparation method. The invention further relates to an indoor air purification device.

Owner:TSINGHUA UNIV +1

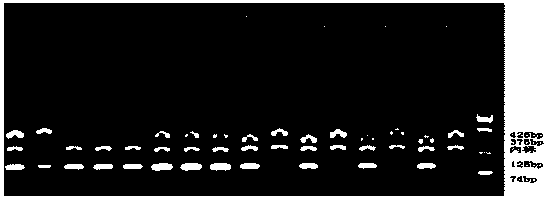

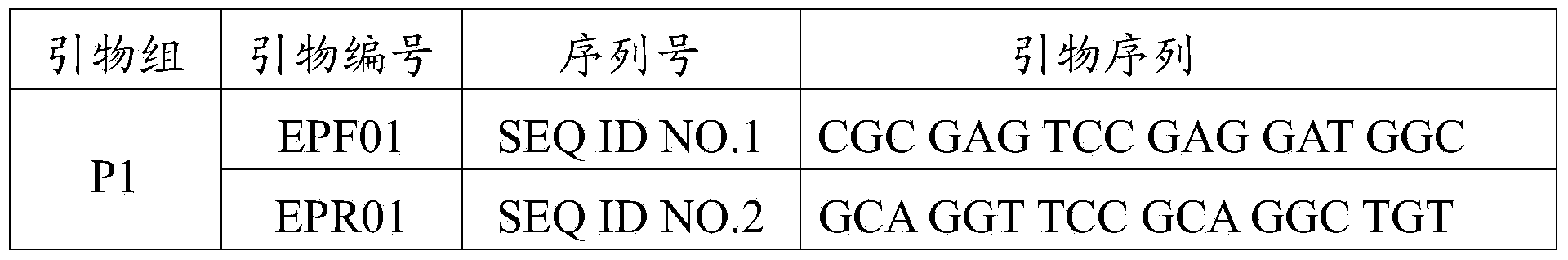

Primer for rapidly detecting HLA-B*1502 allele, kit and detection method

ActiveCN104046696APromote bondingPrevent false positivesMicrobiological testing/measurementDNA/RNA fragmentationGenetic engineeringGene specific primer

The invention belongs to the technical field of genetic engineering and discloses a primer for rapidly detecting an HLA-B*1502 gene, a kit comprising the primer and a method for rapidly detecting the HLA-B*1502 gene by the primer and kit. According to the invention, by virtue of the HLA-B*1502 gene-specific primer and the combinational design of multiplex primers, an SNP site of the HLA-B*1502 gene is completely covered, the specific binding is enhanced and the false positive generation is more effectively prevented. In addition, by pre-mixing the specific primer, dNTPs, PCR buffer and dyes, the operating time and workload are significantly saved, the method is fast, simple, accurate and intuitive, the entire gene screening and classification experiment can be completed within three hours and the problem of safe medication instruction of the HLA-B*1502 gene in antiepileptic drugs is solved.

Owner:SHANGHAI TISSUEBANK BIOTECH +3

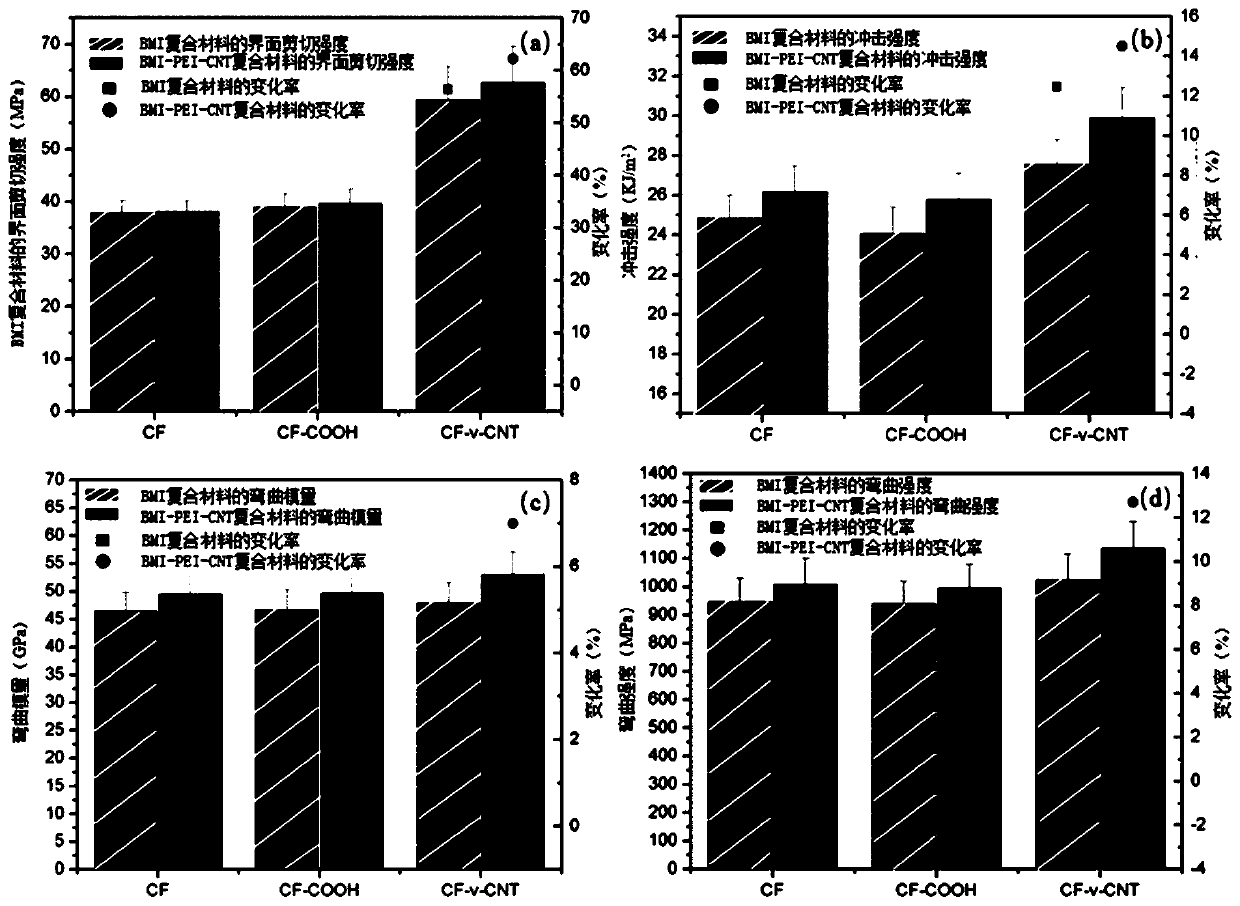

Method for preparing bismaleimide resin-based composite material by chemical vapor deposition method, and application of composite material

ActiveCN110819107AImprove mechanical propertiesPromote bondingCarbon fibresMechanical properties of carbon nanotubesCompositermes

The invention relates to a method for preparing a bismaleimide resin-based composite material with a carbon fiber-carbon nanotube reinforcement phase by a chemical vapor deposition method. The chemical vapor deposition method is used to prepare a carbon fiber-carbon nanotube micro-nano reinforcement phase, NiNO3 particles with Ni ions are preloaded on the surface of carbon fibers, then high-temperature reduction is performed to obtain nano Ni particles with pure surfaces, ethanol is used as a carbon source, catalytic cracking is performed on the surface of the catalyst particles, and carbon nanotubes are grown through the deposition of carbon atoms. Then the prepared carbon fiber-carbon nanotube micro-nano reinforcement phase is used to compound with a BMI-PEI-CNT matrix resin to prepare the bismaleimide resin-based composite material with high strength and high modulus. Compared with the prior art, the method can relatively conveniently control the length, diameter, distribution, anddensity of the carbon nanotubes on the surface of the carbon fibers, so that the synergistic effect of the carbon fibers and the carbon nanotubes is realized, expansion paths of horizontal and vertical stresses at interfaces are changed, stress concentration is dispersed, and thereby mechanical properties of the composite material are improved.

Owner:TONGJI UNIV

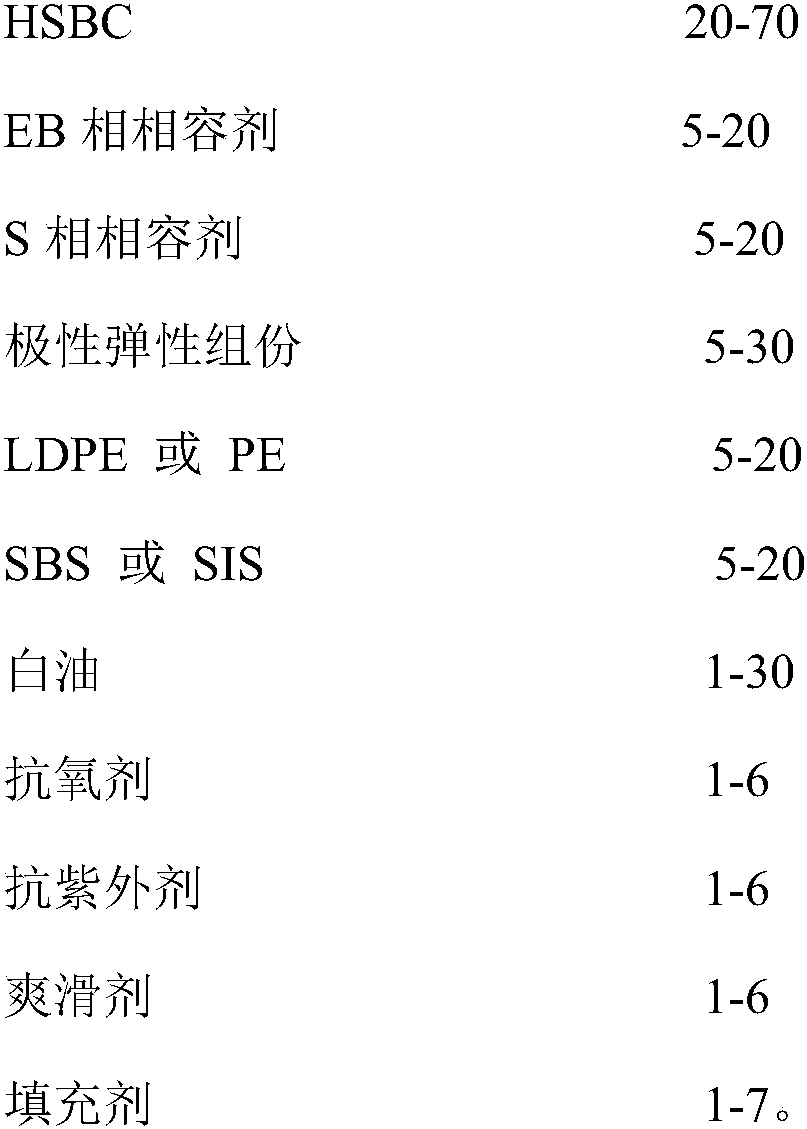

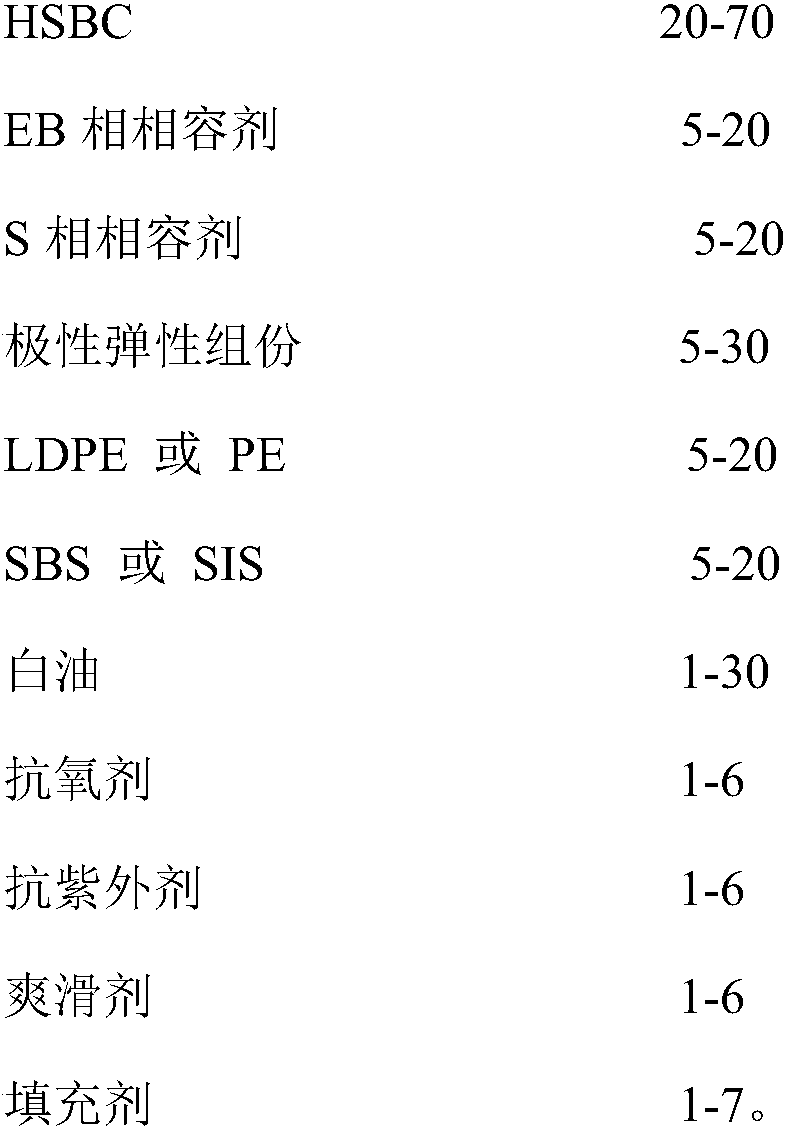

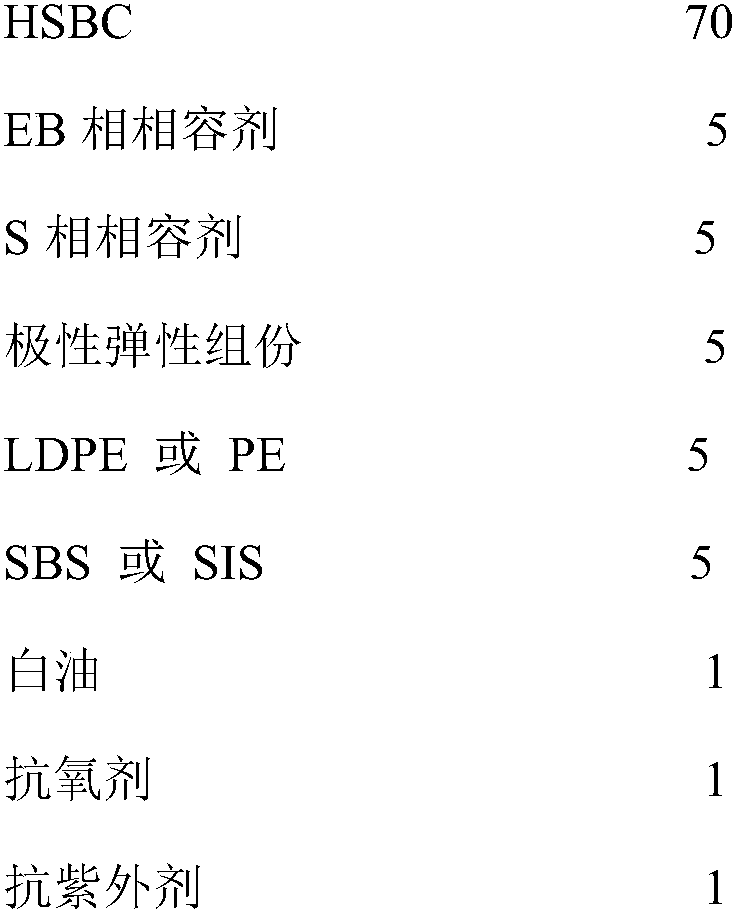

Thermoplastic elastomer for encapsulating PC/ABS, and preparation method thereof

The invention discloses a thermoplastic elastomer for encapsulating PC / ABS, and a preparation method thereof, wherein the thermoplastic elastomer is prepared from the following components by weight: 20-70 parts of HSBC, 5-30 parts of a compatibilizer, 5-30 parts of a polar elastic component, 5-20 parts of LDPE or PE, 5-20 parts of SBS or SIS, 1-30 parts of white oil, 1-6 parts of an antioxidant, 1-6 parts of an anti-ultraviolet agent, 1-6 parts of a slipping agent, and 1-7 parts of a filler. According to the invention, by adding MAH-PE / PP / POE and MAH-PS as the compatilizers, the phase separation between the non-polar phase and the polar phase in TPE is reduced so as to achieve the effect of mutual dissolution; the polarity-polarity interaction with the PC / ABS base material can be generatedby utilizing the polarity; and by adding the unhydrogenated SBS or SIS, the adhesive force of the TPE is increased to improve the bonding between the soft rubber and the hard rubber.

Owner:苏州长振新材料科技有限公司

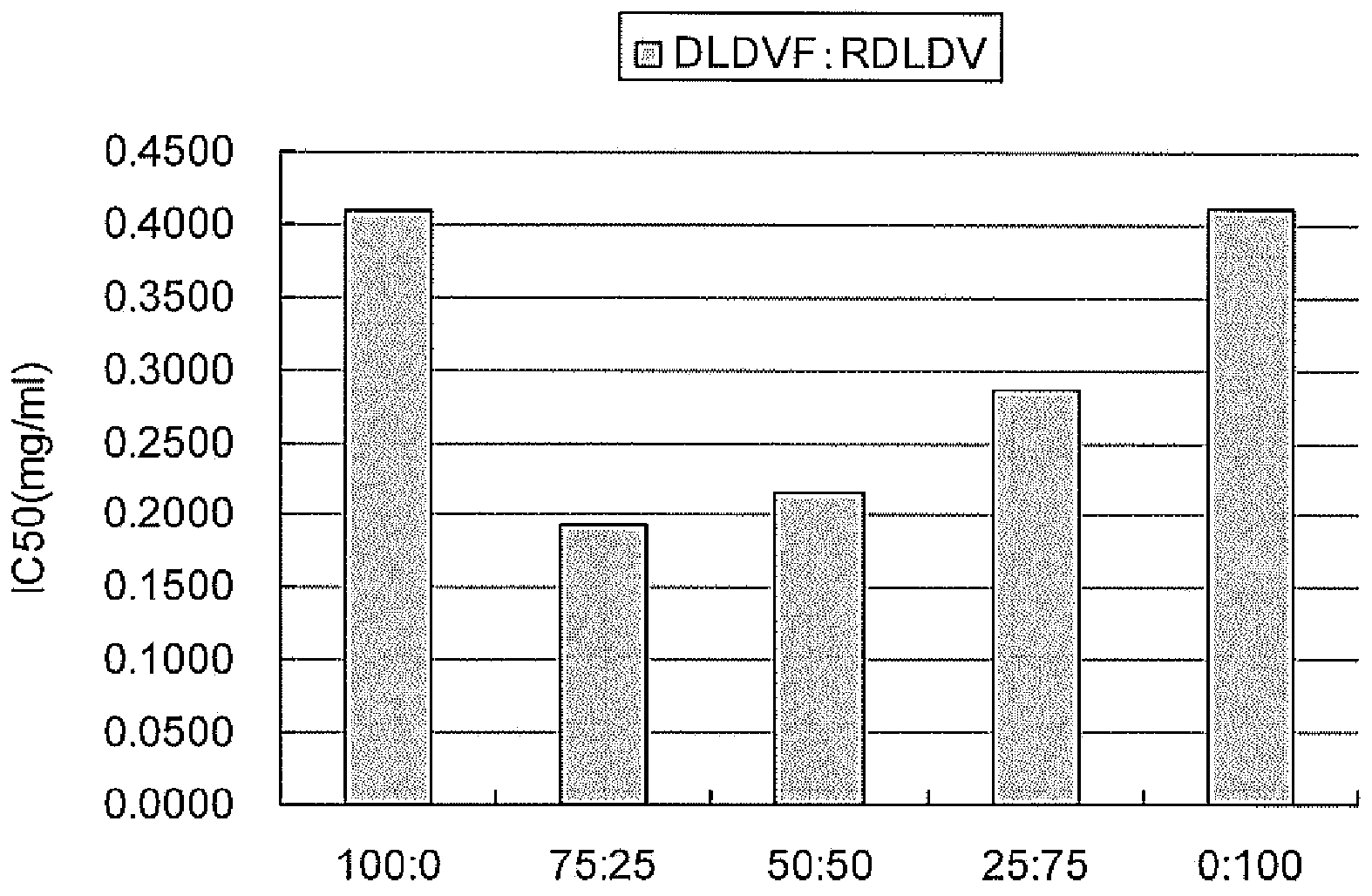

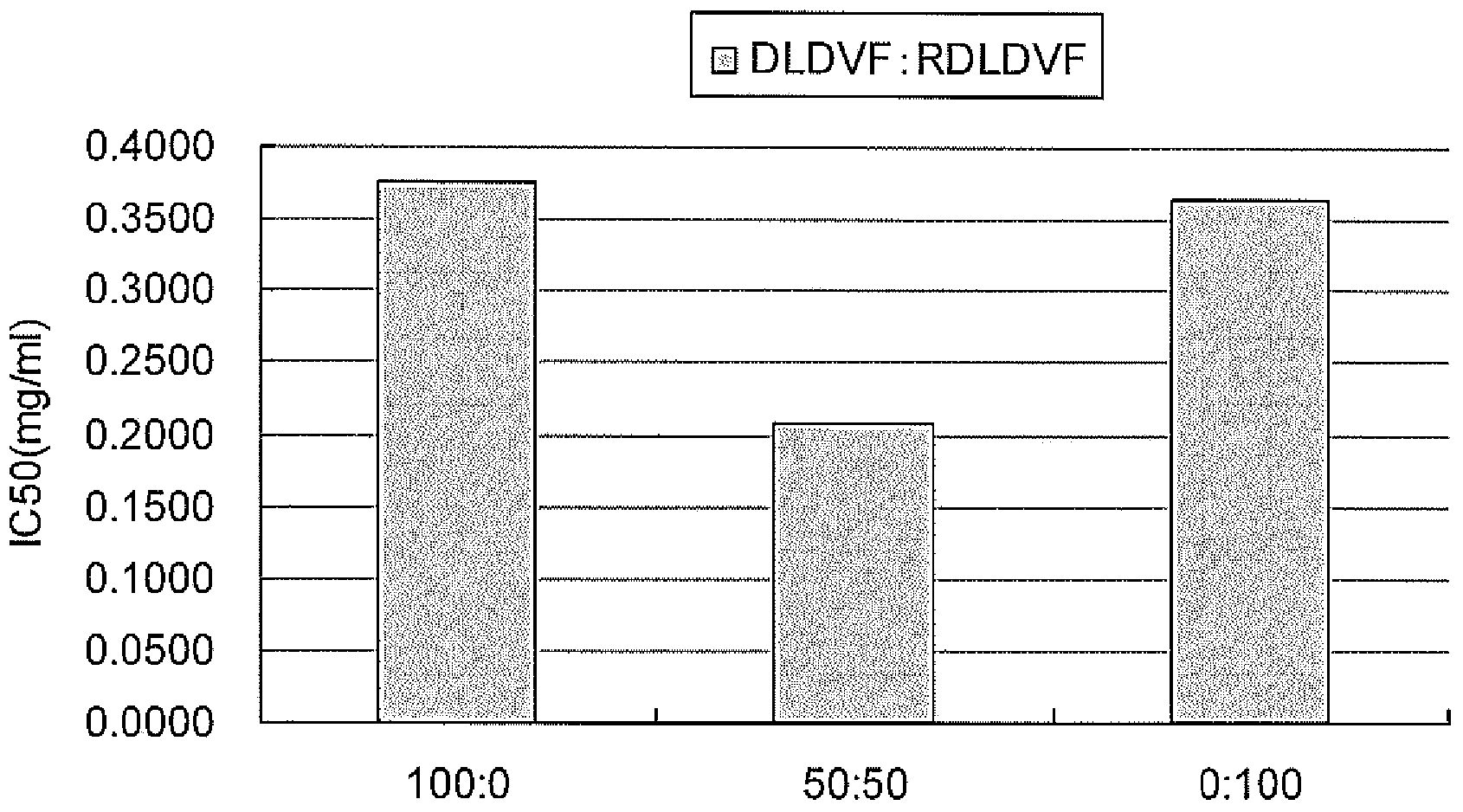

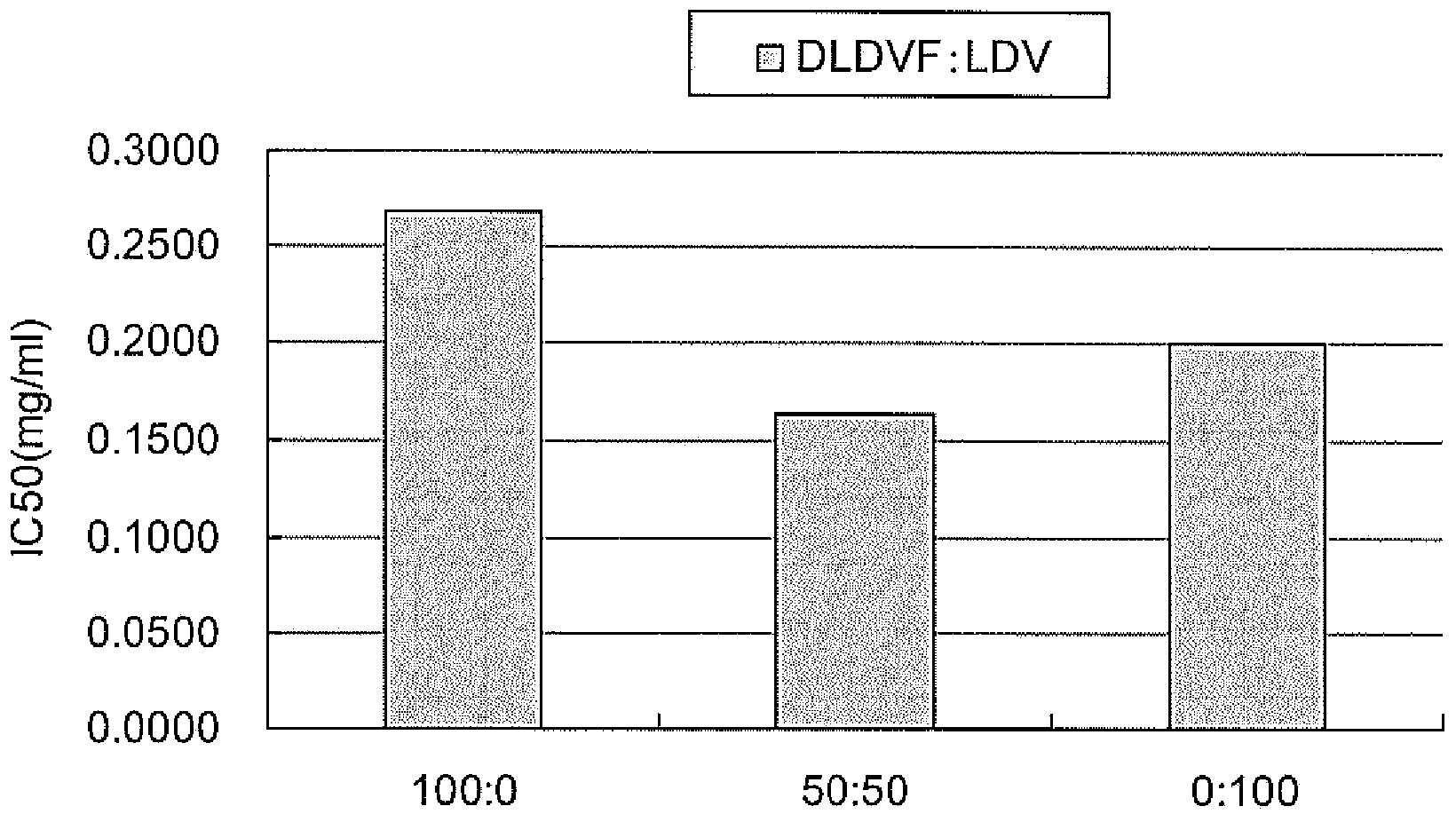

Novel peptide

InactiveCN103443118APrevents reduction in bonding abilityPromote bondingCosmetic preparationsAngiotensinsAngiotensin-converting enzymePeptide

The purpose of the present invention is to provide a novel substance which has an activity of inhibiting an angiotensin-converting enzyme and / or an activity of promoting the adhesion between a fibroblast and collagen. A peptide comprising an amino acid sequence represented by formula (I): Xaa1-Asp-Leu-Asp-Val-Xaa2 (SEQ ID NO:1) [wherein Xaa1 and Xaa2 may be present or absent and, if present, independently represent an arbitrary amino acid residue], a derivative of the peptide, or a salt of the peptide or the derivative.

Owner:ROHTO PHARM CO LTD

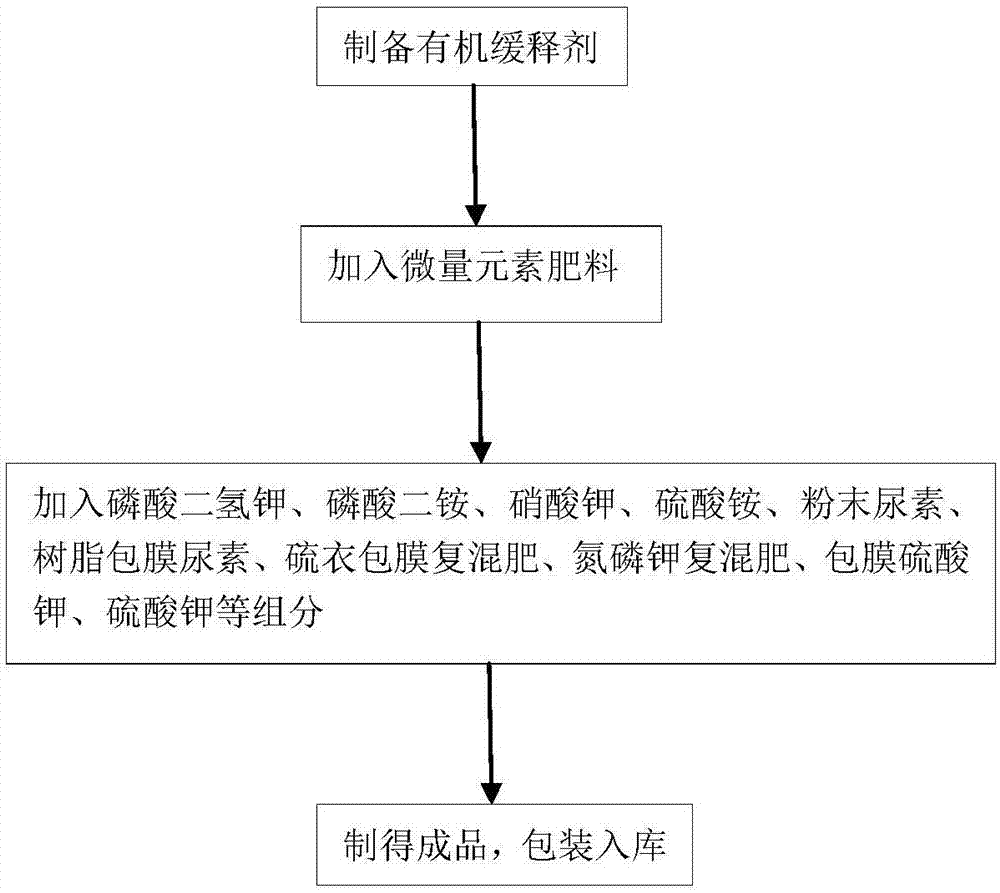

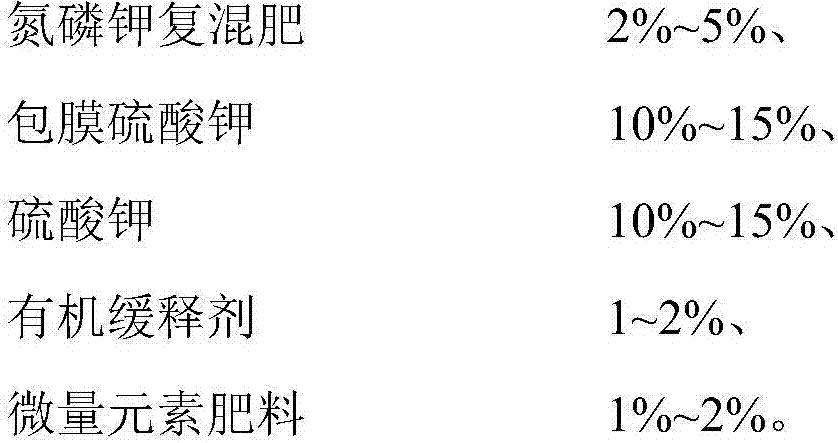

Special fertilizer for grapes as well as preparation method and application method thereof

PendingCN107382560AReduce nitrogen lossPromote bondingAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAmmonium sulfateCoated urea

The invention provides special fertilizer for grapes. The special fertilizer is prepared from the following components in percentage by weight: 1 percent to 2 percent of potassium dihydrogen phosphate, 15 percent to 20 percent of monoammonium phosphate, 8 percent to 15 percent of potassium nitrate, 25 percent to 30 percent of ammonium sulfate, 1 percent to 2 percent of resin-coated urea, 10 percent to 15 percent of sulfur-coated compound fertilizer, 2 percent to 5 percent of nitrogen phosphorus potassium compound fertilizer, 10 percent to 15 percent of film-coated potassium sulfate, 10 percent to 15 percent potassium sulfate, 1 percent to 2 percent of an organic sustained-release agent and 1 percent to 2 percent of microelement fertilizer. The special fertilizer for the grapes, provided by the invention, has diversified and comprehensive nutrients, and rapid effect is combined with sustained release, so that nutrient elements needed by normal growth of the grapes can be provided and stable production and high yield of the grapes can be ensured; the invention further provides a preparation method and an application method of the special fertilizer for the grapes; when the special fertilizer for the grapes is applied, the aims of saving cost and increasing the effect can be realized and nutrient loss caused by excessive fertilization or accustomed fertilization and influences on the environment are alleviated.

Owner:HUNAN AGRICULTURAL UNIV

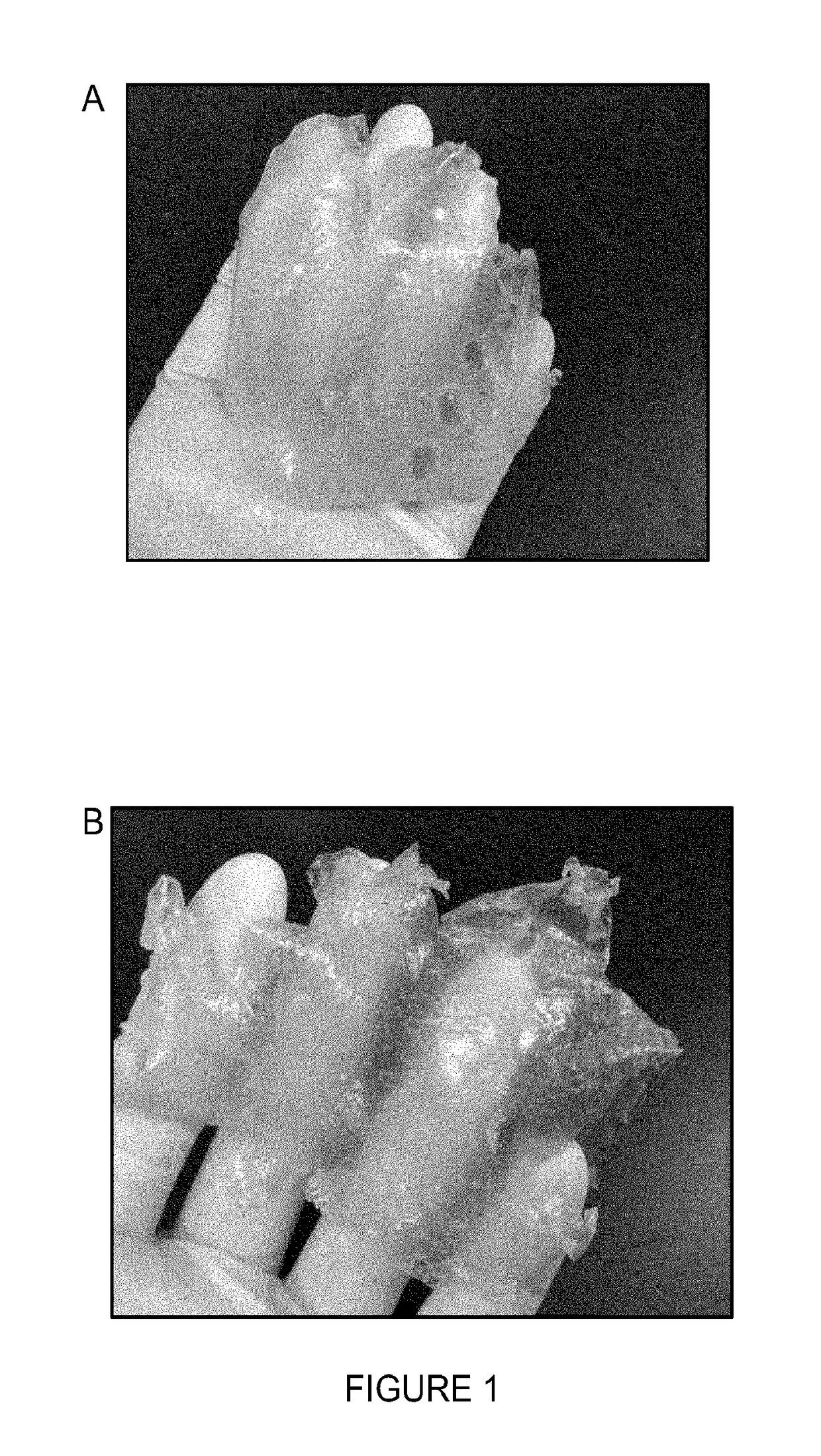

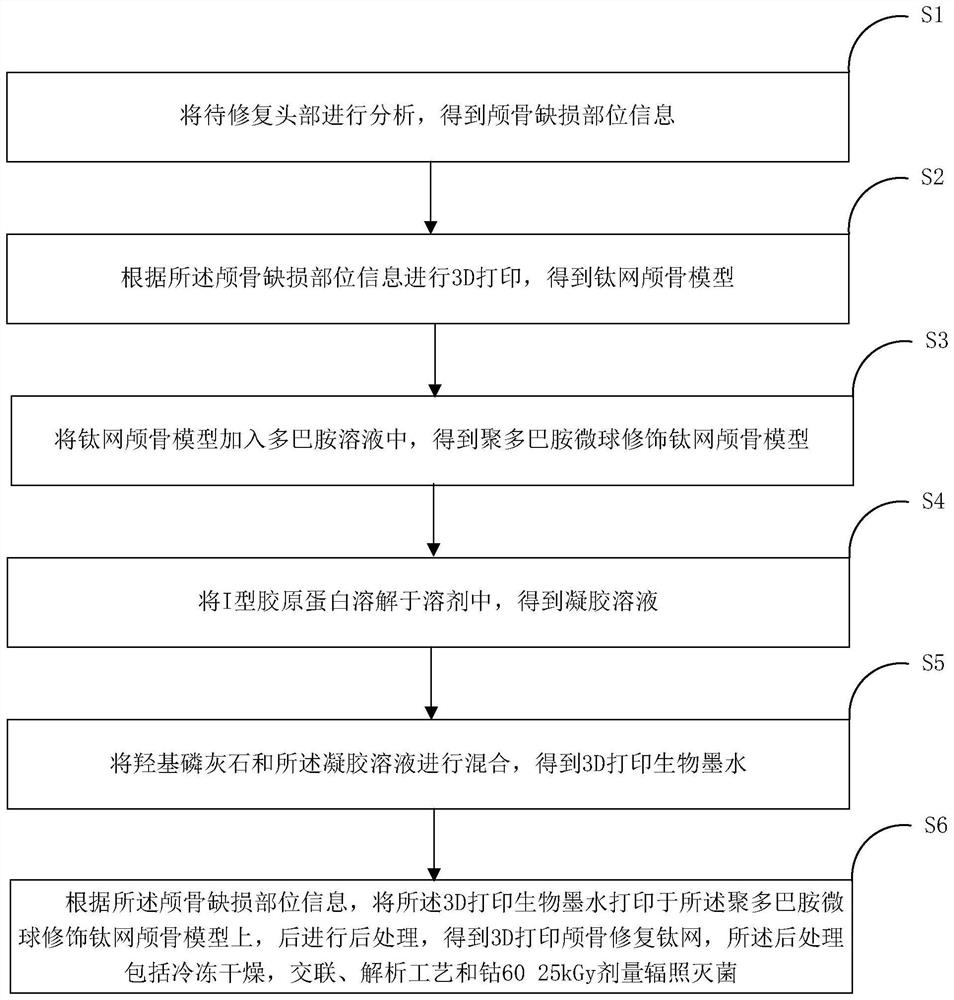

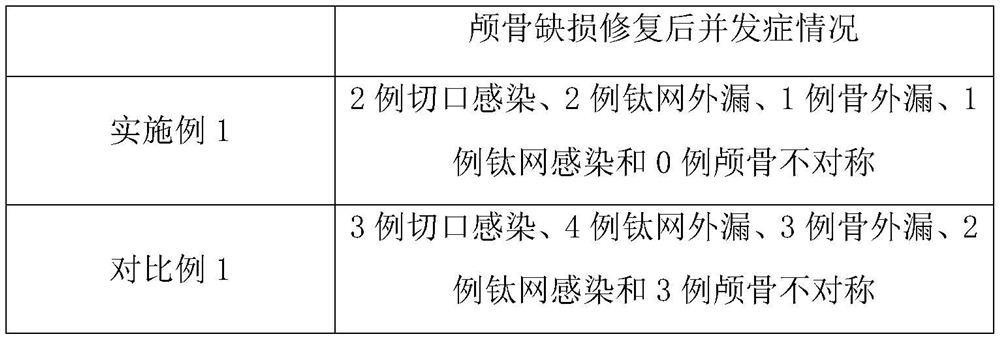

3D printing skull repair titanium mesh and preparation method thereof

ActiveCN114504677AIncreased surface roughness and bioactivityPromote bondingAdditive manufacturing apparatusIncreasing energy efficiencyBiomedical engineeringCollagenan

The invention particularly relates to a 3D printing skull repair titanium mesh and a preparation method thereof, and belongs to the technical field of biomedical materials.The method comprises the steps that a to-be-repaired head is analyzed, and skull defect part information is obtained; 3D printing is conducted according to the skull defect part information, and a titanium mesh skull model is obtained; adding the titanium mesh skull model into a dopamine solution to obtain a polydopamine microsphere modified titanium mesh skull model; the method comprises the following steps: dissolving type I collagen in a solvent to obtain a gel solution; mixing hydroxyapatite with the gel solution to obtain the 3D printing bio-ink, 3D printing bio-ink is printed on the poly-dopamine microsphere modified titanium mesh skull model, post-treatment is conducted, and the repaired titanium mesh is obtained. The 3D printing titanium mesh is combined with the hydroxyapatite / collagen guided tissue regeneration layer, so that the surface roughness and biological activity of the titanium mesh material can be improved, the combination of the material and bones is promoted, the adhesion and proliferation of cells are promoted, osteogenesis is induced, and the repair and healing of skull tissues are accelerated.

Owner:ASIA BIOMATERIALS WUHAN CO LTD

Preparation method of flame-retardant shaving board based on double-layer coated ammonium polyphosphate microcapsule modification

ActiveCN114315225ASynergistic flame retardant propertiesPromote bondingFlame resistanceAmmonium orthophosphate

The invention relates to the technical field of flame-retardant shaving board preparation, in particular to a flame-retardant shaving board preparation method based on double-layer coated ammonium polyphosphate microcapsule modification, which comprises the following steps: S1, aluminum hydroxide coated ammonium polyphosphate modification: ammonium polyphosphate is added into absolute ethyl alcohol and fully stirred to form a suspension, an aluminum chloride solution is added and fully stirred, and filtration is performed to obtain an aluminum hydroxide coated ammonium polyphosphate suspension; washing and drying to obtain aluminum hydroxide coated ammonium polyphosphate; s2, dopamine secondary coating modification: dopamine is added into deionized water, and a dopamine solution is prepared; then adding the aluminum hydroxide coated ammonium polyphosphate prepared in the step S1; s3, preparing a metal ion salt solution; s4, wood shaving modification; and S5, wood shaving sizing and paving. The preparation method is simple, easy to implement and capable of quickly adapting to the production process and technology of existing shaving boards, secondary processing equipment is avoided, cost is saved, and the prepared shaving boards have excellent mechanical property and flame retardant property.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

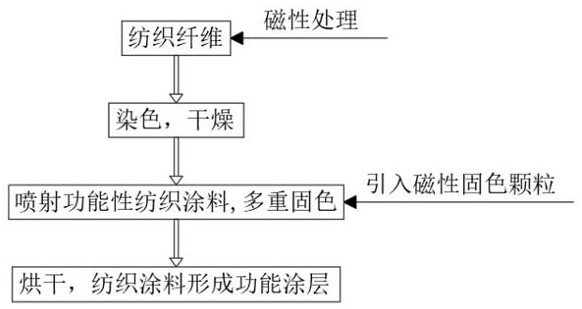

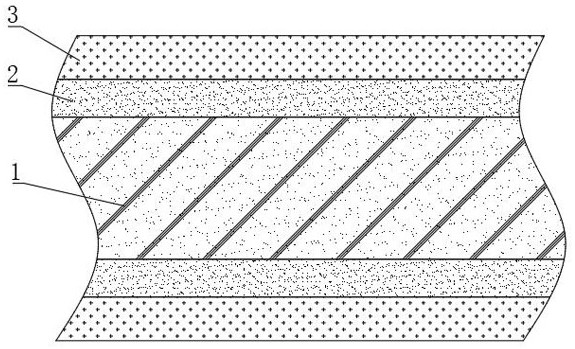

Coating fixation process suitable for textile fibers

The invention discloses a coating fixation process suitable for textile fibers, and belongs to the field of textile technology. After the textile fibers subjected to magnetic treatment are dyed, the surfaces of the textile fibers are coated with a functional textile coating introduced with magnetic fixation particles, and a functional coating is formed; and the effects of wrapping, deep diffusion and color fixation on the dye on the textile fibers are achieved, and the multiple color fixation effect on the textile fibers is achieved; compared with the existing color fixation process, the coating fixation process has a more efficient color fixation effect, and due to the functional coating on the textile fibers, no additional coating treatment is needed on the textile made of the textile fibres; and compared with the existing means of directly carrying out coating treatment on the surface of the textile fabric, the textile fabric prepared from the textile fibers disclosed by the invention has a more uniform and comprehensive coating function.

Owner:南通隆彩纺织科技有限公司

Method for joining timepiece parts

The present invention relates to a method for bonding timepiece components, comprising applying an adhesive to first and / or second timepiece components to be bonded to each other, and depositing an adhesive layer on at least one of the first and second components to be bonded by spraying a primer composition in a localized bonding area, the primer composition is then cured. If an adhesive is applied to the same one or more components as the adhesion layer, the adhesion layer is deposited prior to application of the adhesive.

Owner:ETA SA MFG HORLOGERE SUISSE

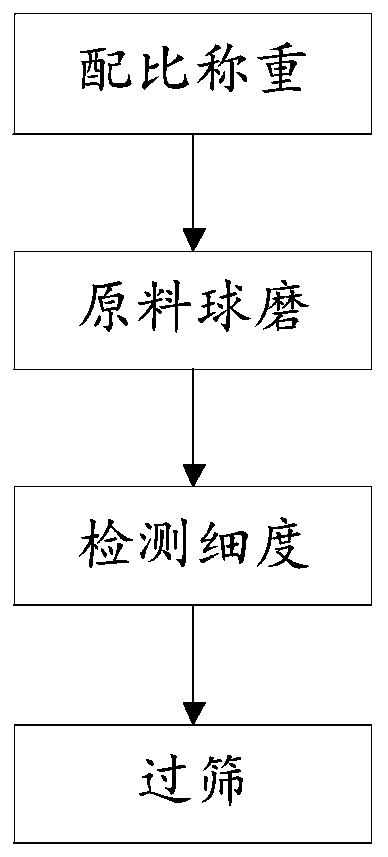

Transmutation glaze ground coat, preparation method thereof and porcelain

The invention discloses a transmutation glaze ground coat which comprises the following components in percentage by mass: 70%-75% of frit, 5%-8% of kaolin, 4%-7% of zinc oxide, 1%-2% of barium carbonate and 10%-13% of ferric oxide. The invention further discloses a preparation method of the transmutation glaze ground coat and porcelain. According to the transmutation glaze ground coat, the preparation method thereof and the porcelain, a unique ground coat formula is adopted, good application of the transmutation glaze ground coat to the porcelain is achieved through mutual cooperation and combined action of all the components and the content of all the components, the porcelain rich in hue and variable in texture is obtained, and the glaze is resistant to abrasion, not prone to falling offand little in environmental pollution. The transmutation glaze ground coat is applicable to the technical field of ceramics.

Owner:潮州市荣嘉陶瓷有限公司

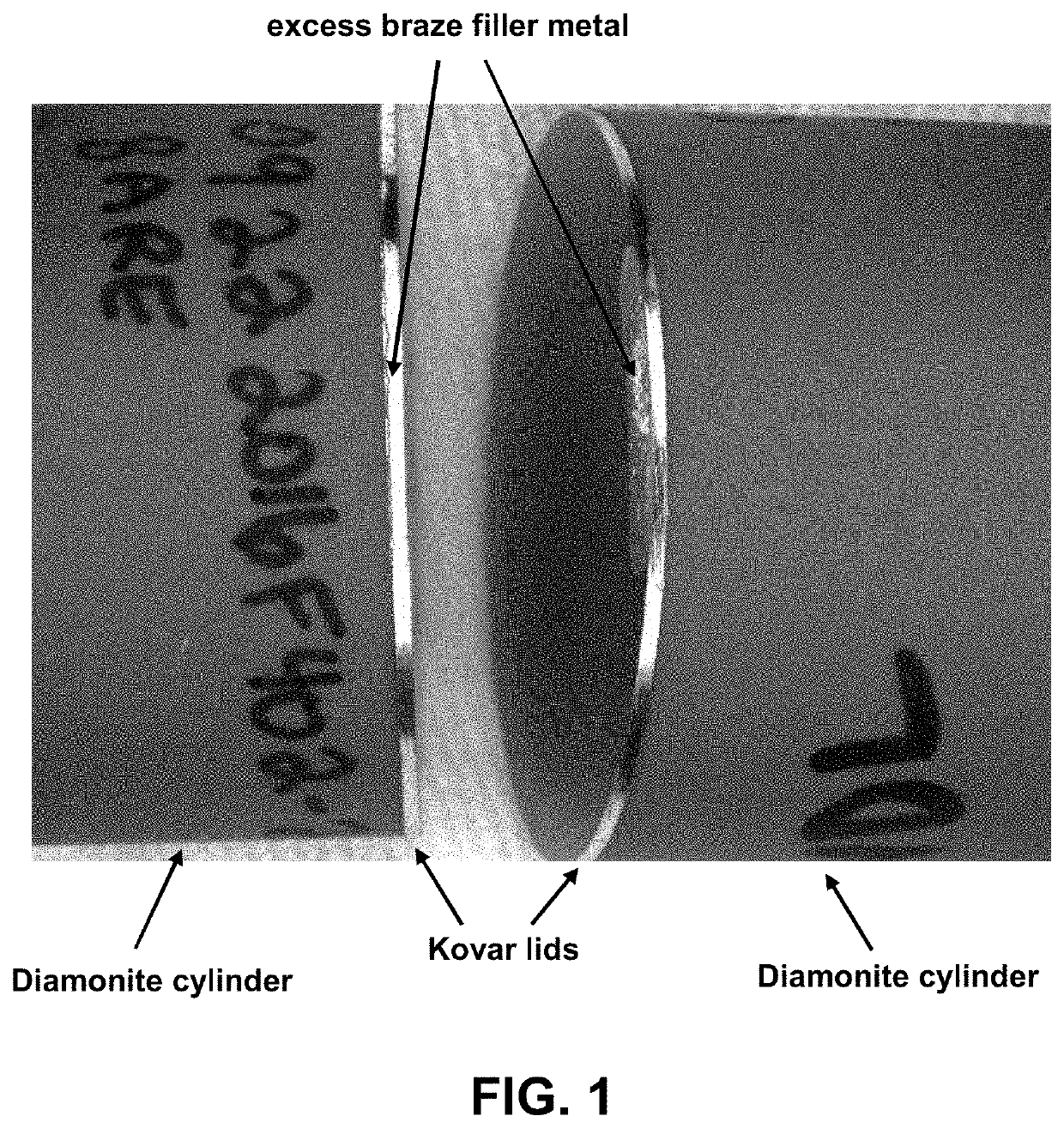

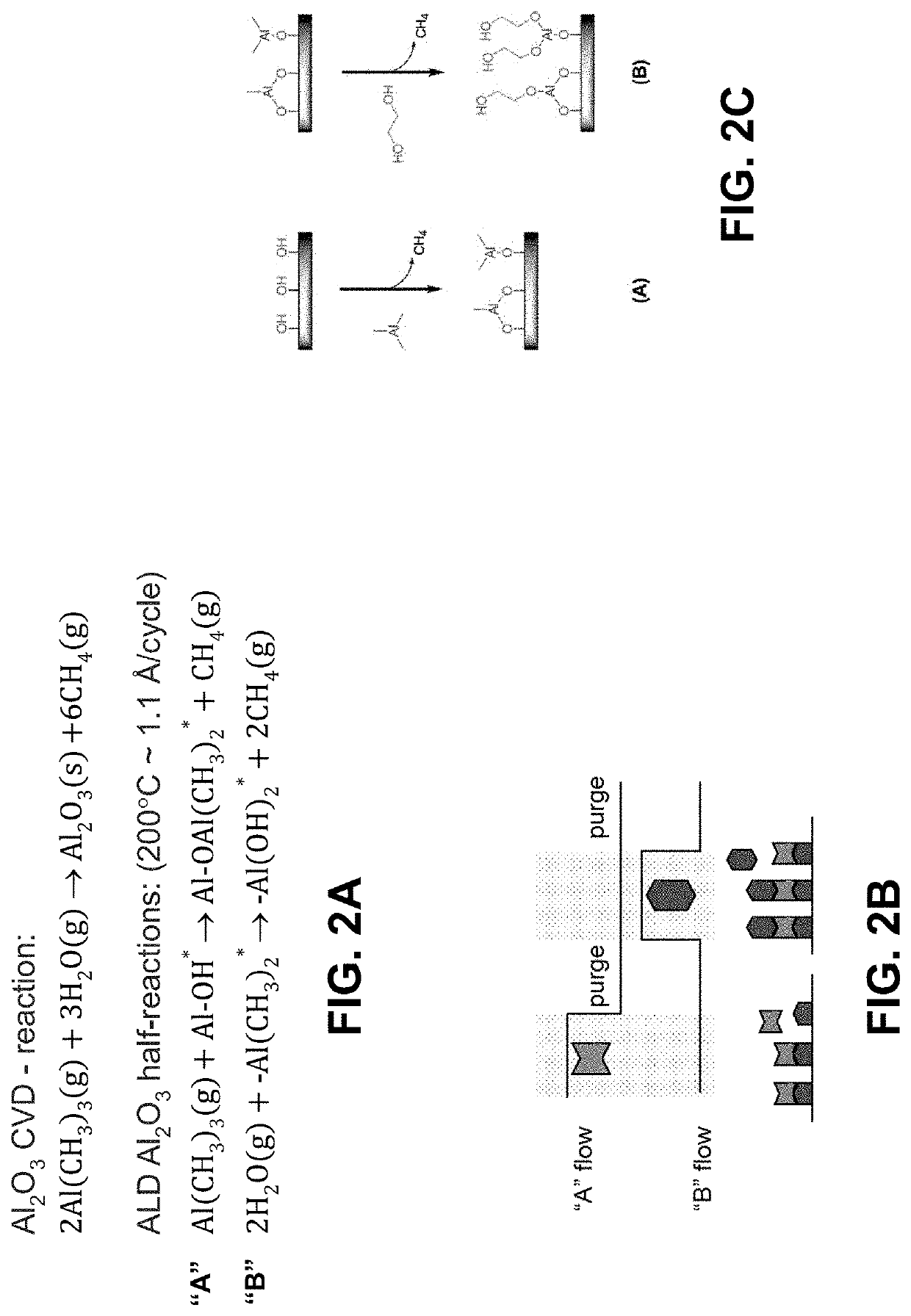

Method for eliminating runout of braze filler metal during active brazing

ActiveUS20200023454A1Promote bondingEliminate jumpingSoldering apparatusWelding/soldering/cutting articlesFiller metalConformal coating

Nanometers thick conformal coatings deposited by atomic-layer deposition (ALD) onto the metal surface of an active braze joint modifies the surface chemistry to eliminate excess braze filler metal flow. Unlike other means used to prevent braze filler metal runout, the thin ALD coating does not hinder next assembly processes, does not require post-braze cleaning, and does not alter the base material mechanical properties.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

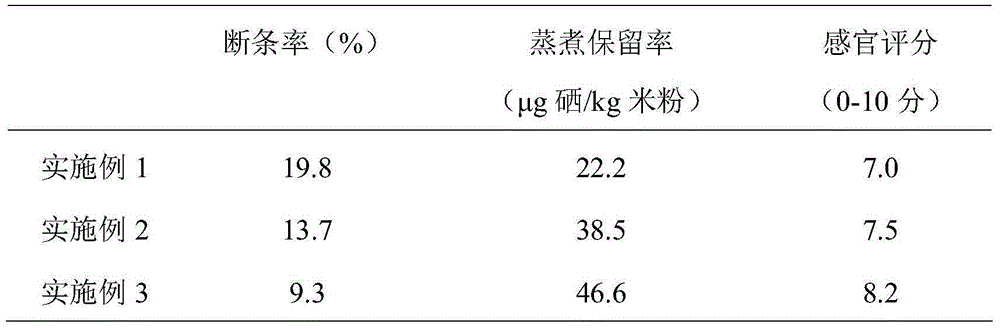

Selenium and vitamin C synergistically strengthened straight rice noodles

InactiveCN105104957APromote bondingImprove toughnessFood ingredientsFood preparationMicrowaveMoisture

The invention provides selenium and vitamin C synergistically strengthened straight rice noodles. The straight rice noodles are obtained by using rice as a main raw material, adding sodium selenite and vitamin C in the flour stirring process after soaking and grinding the rice, adjusting the moisture content, carrying out the procedures of twin-screw extrusion, aging, re-steaming, microwave and ultrasonic treatment, combing and washing, and the like, and finally carrying out drying, cutting and packaging procedures. The strengthened straight rice noodles have the unique features that ultrasonic catalytic treatment is carried out on the rice noodles in the aging process, and microwaves and ultrasonic waves have additive effects on the rice noodles after re-steaming; the ultrasonic waves intensify rearrangement of starch molecules in the rice noodles in the continuous vibration and beating processes, and combination of vitamin C, selenium ions and the starch molecules is promoted via synergistic effects of the microwaves and ultrasonic waves; the prepared rice noodles are chewy; and the nutritional factors are tightly combined with the starch molecules, so that the rice noodles are easy to absorb by human bodies and have a high retention rate after cooking.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com