Coating fixation process suitable for textile fibers

A textile fiber and coating technology, which is applied in the field of coating color fixing technology, can solve the problems that it is difficult to strictly ensure the color fixing effect of spinning, and achieve the effects of improving dyeing effect, improving fixability, and promoting combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

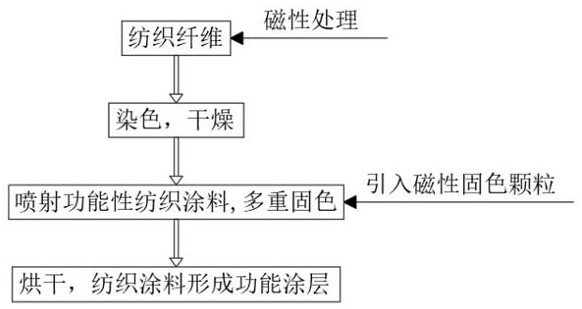

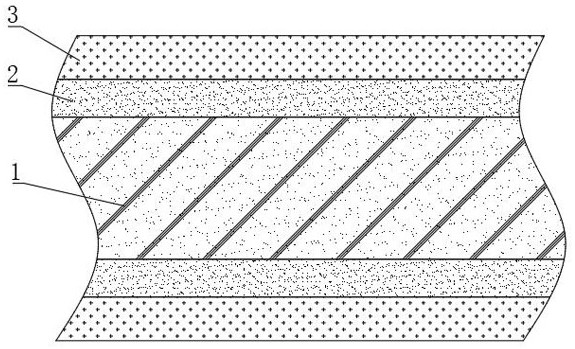

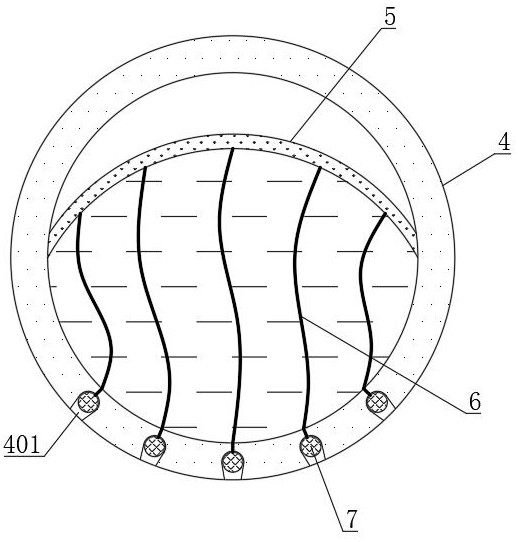

[0042] see figure 1 and figure 2 , a coating fixation process applicable to textile fibers, comprising the following steps:

[0043] S1. Put the magnetically treated textile fiber 1 into a dye for dyeing, and the dye is adsorbed on the surface and inside of the textile fiber 1 to form a dyed layer 2;

[0044] S2, drying the dyed textile fiber 1, so that the dyed layer 2 is in a semi-solidified state;

[0045] S3. According to the textile needs, select a suitable functional textile coating, add magnetic color-fixing particles into it, mix it well and spray it evenly on the surface of the textile fiber 1, completely cover the dyeing layer 2, and the magnetic color-fixing particles promote the textile fiber 1 The dye on the surface diffuses deeply into the interior, and at the same time releases the color-fixing agent to the interior of the dyed layer 2;

[0046] S4, drying the textile fiber 1 obtained in S3, the textile coating is solidified to form a functional coating 3, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com