Method for joining timepiece parts

A component and watch technology, applied in the field of integrated components, can solve the problems that the pallet cannot be combined, shellac escapes, surface tension is incompatible with shellac wetting, etc., to improve the combination, reduce dirt, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

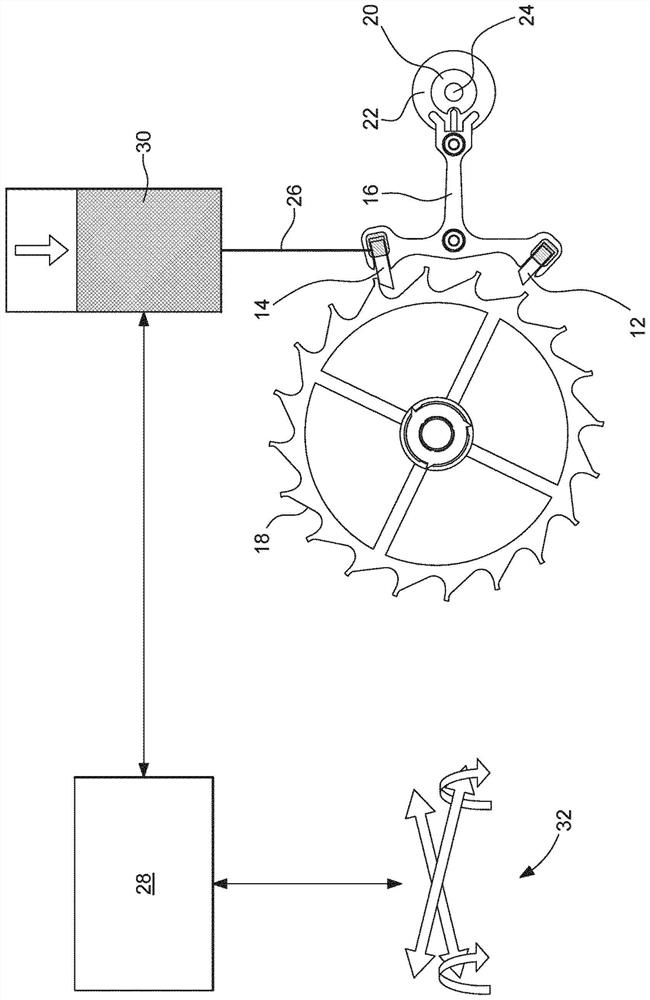

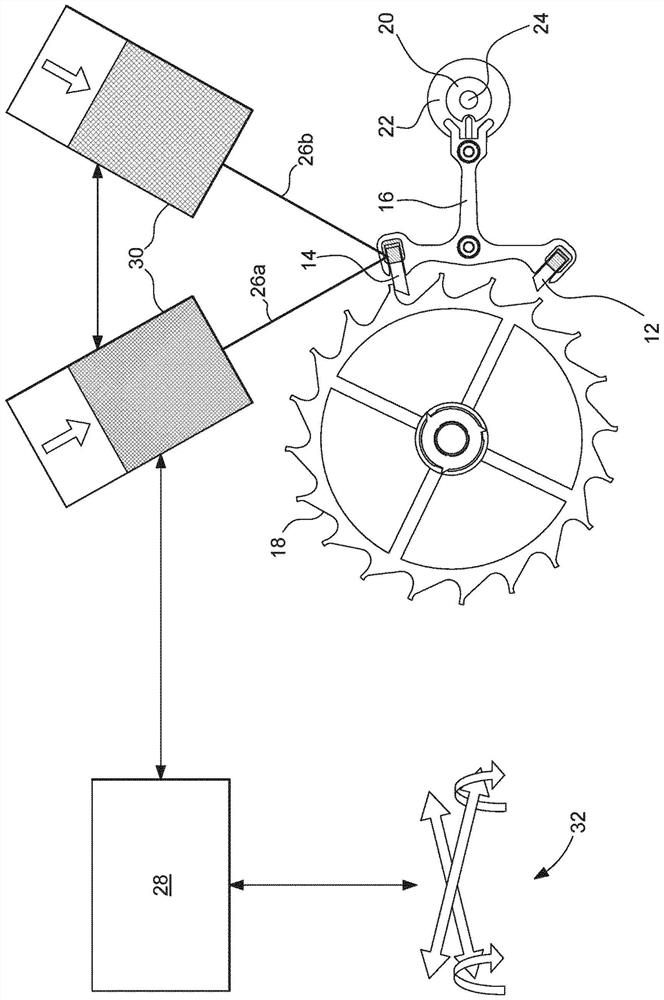

[0041] figure 1 with 2An embodiment of the bonding method according to the invention is shown schematically. As mentioned above, the method according to the invention can be used to join pallet stones 12 , 14 to pallet lever 16 of escapement mechanism 10 of a mechanical watch. The figures show a Swiss lever escapement 10 . It includes the escape wheel 18, usually made of hardened and polished steel. Pallet lever 16 connects the escape wheel to the balance wheel (small disc 20, large disc 22 and balance shaft 24 are shown) and can be applied between two positions in a balance-hairspring assembly. rate switching. Every half cycle, the escape wheel 18 provides an impact to the pallet lever 16, which transmits this impact to the balance wheel to maintain the oscillation of the balance wheel. The pallet stones 12, 14 are usually made of ruby due to its hardness and low coefficient of friction, and are bonded to the pallet rod 16 by means of a shellac-based adhesive.

[0042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com