Patents

Literature

246 results about "Fatty aldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fatty aldehydes are aliphatic, long-chain aldehydes which may be mono- or polyunsaturated. The fatty aldehydes include compounds such as octanal, nonanal, decanal or dodecanal. The nomenclature is derived from the nomenclature of the alkanes, the ending -al is added to indicate the aldehyde group.

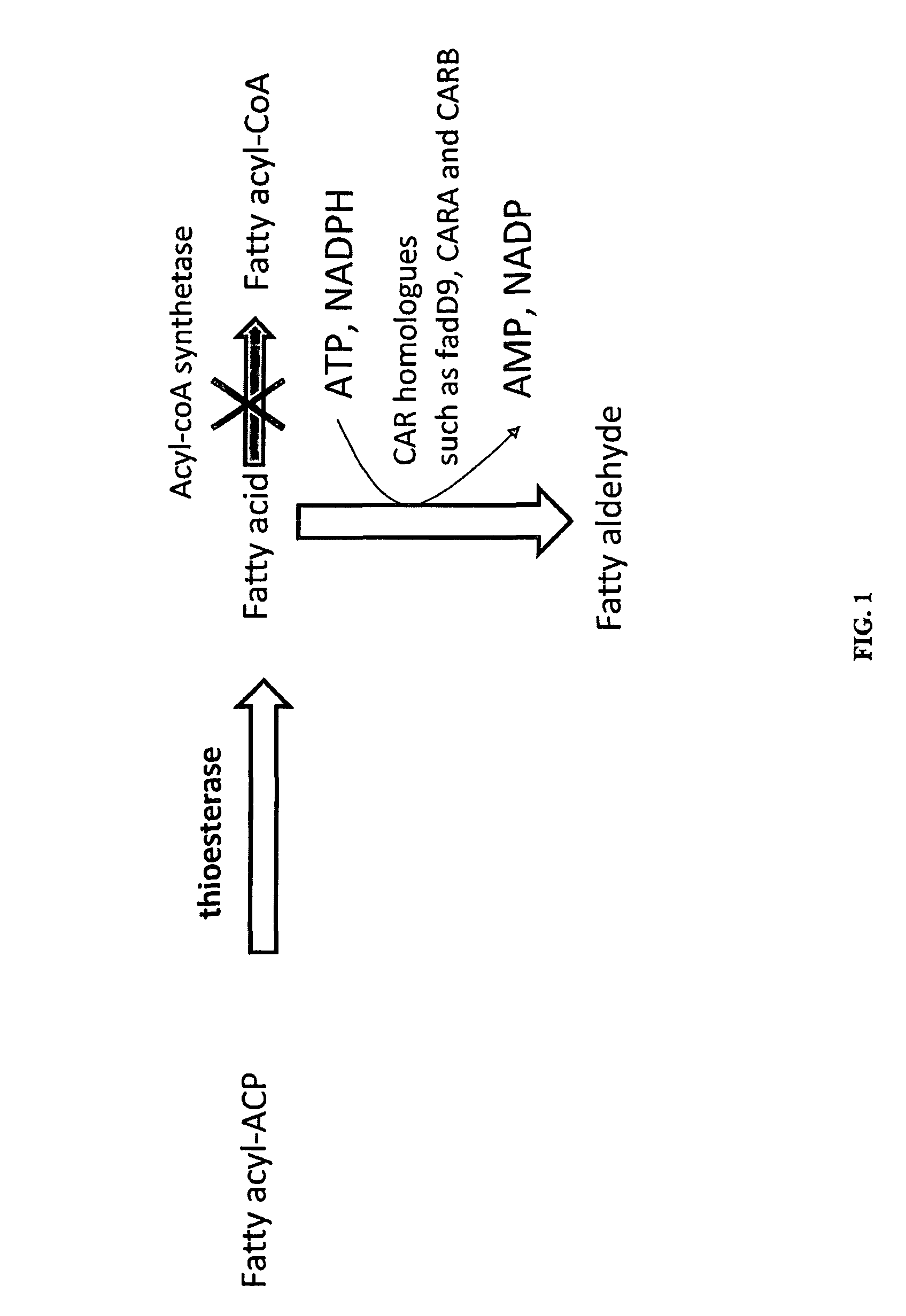

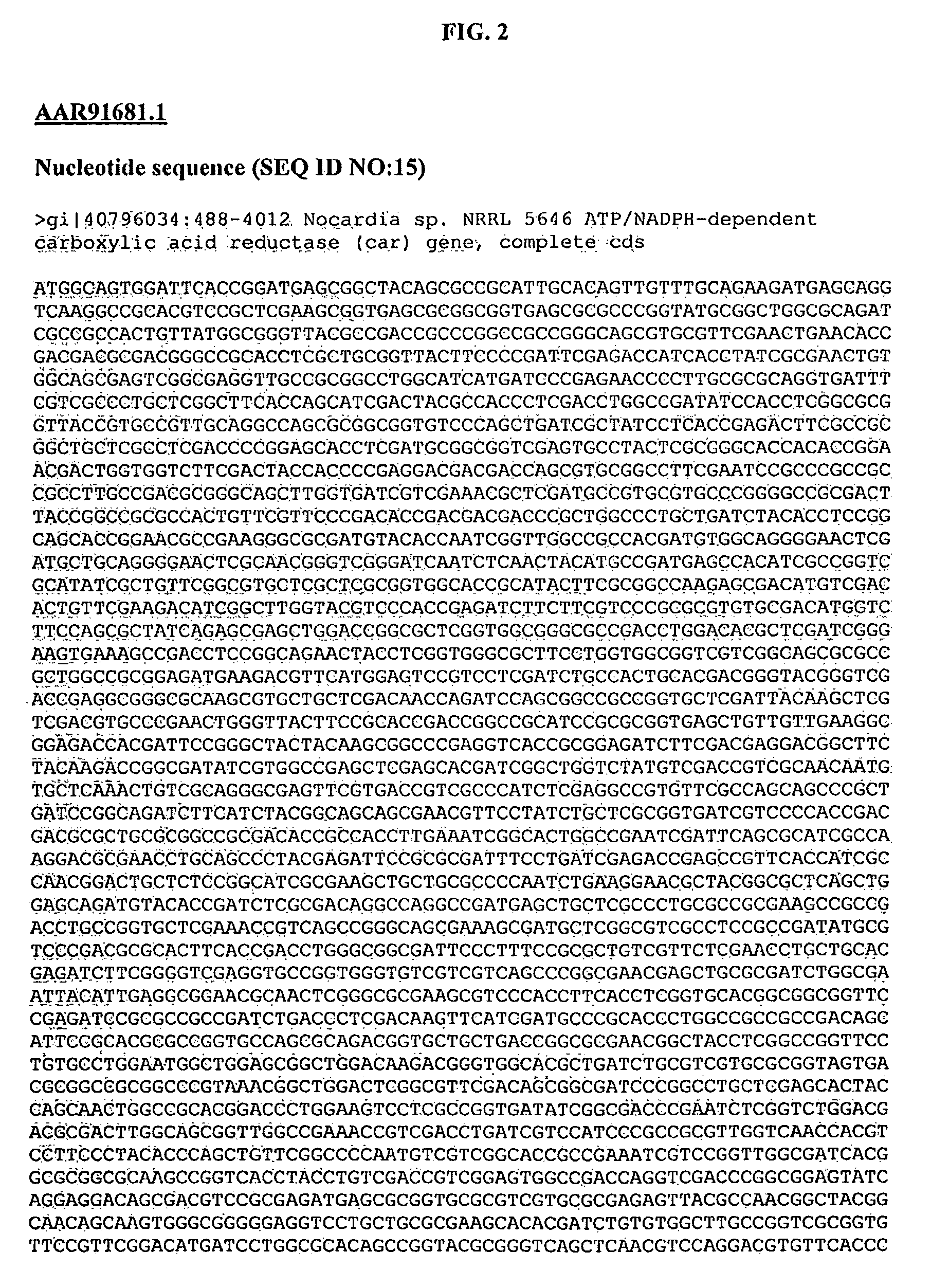

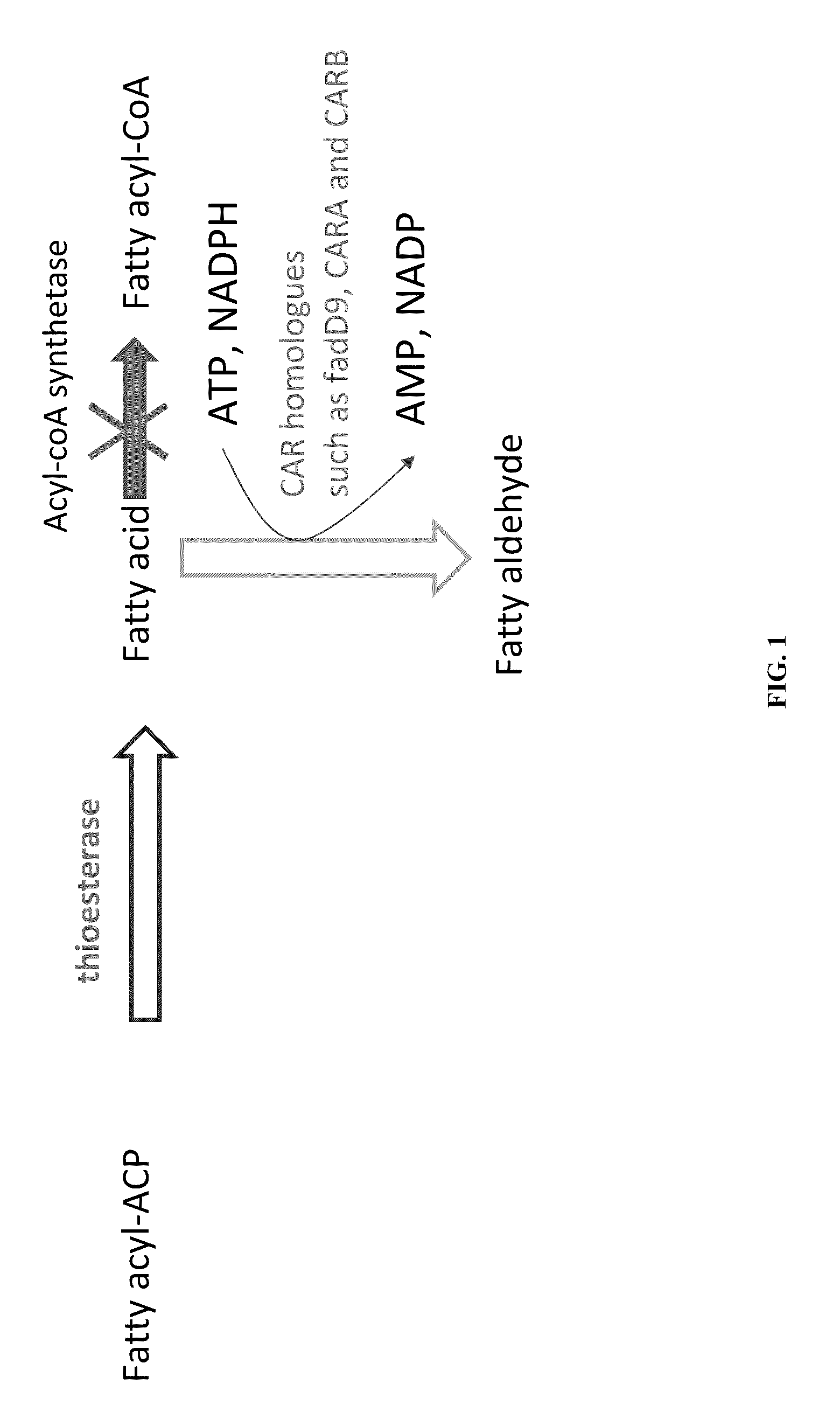

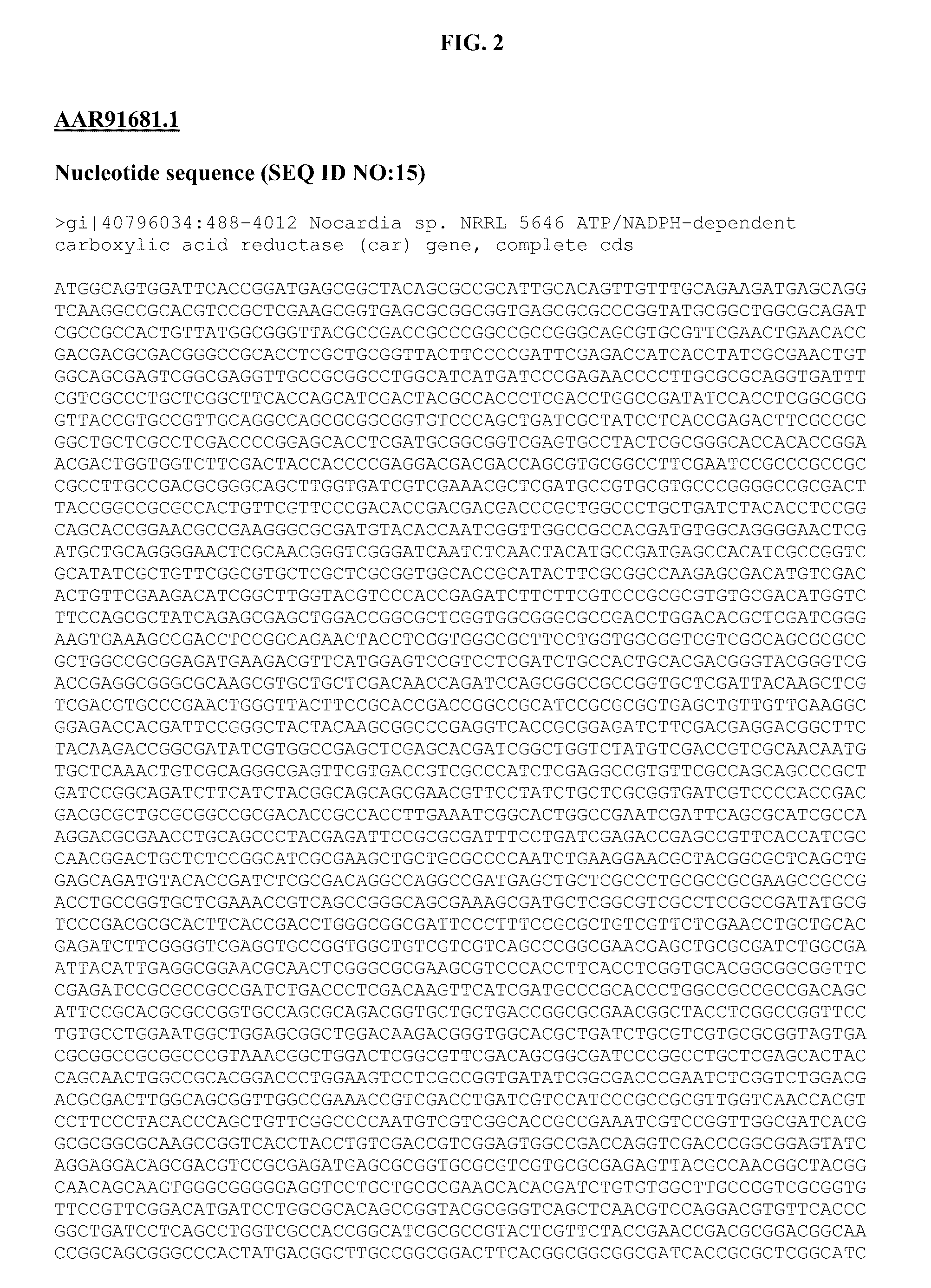

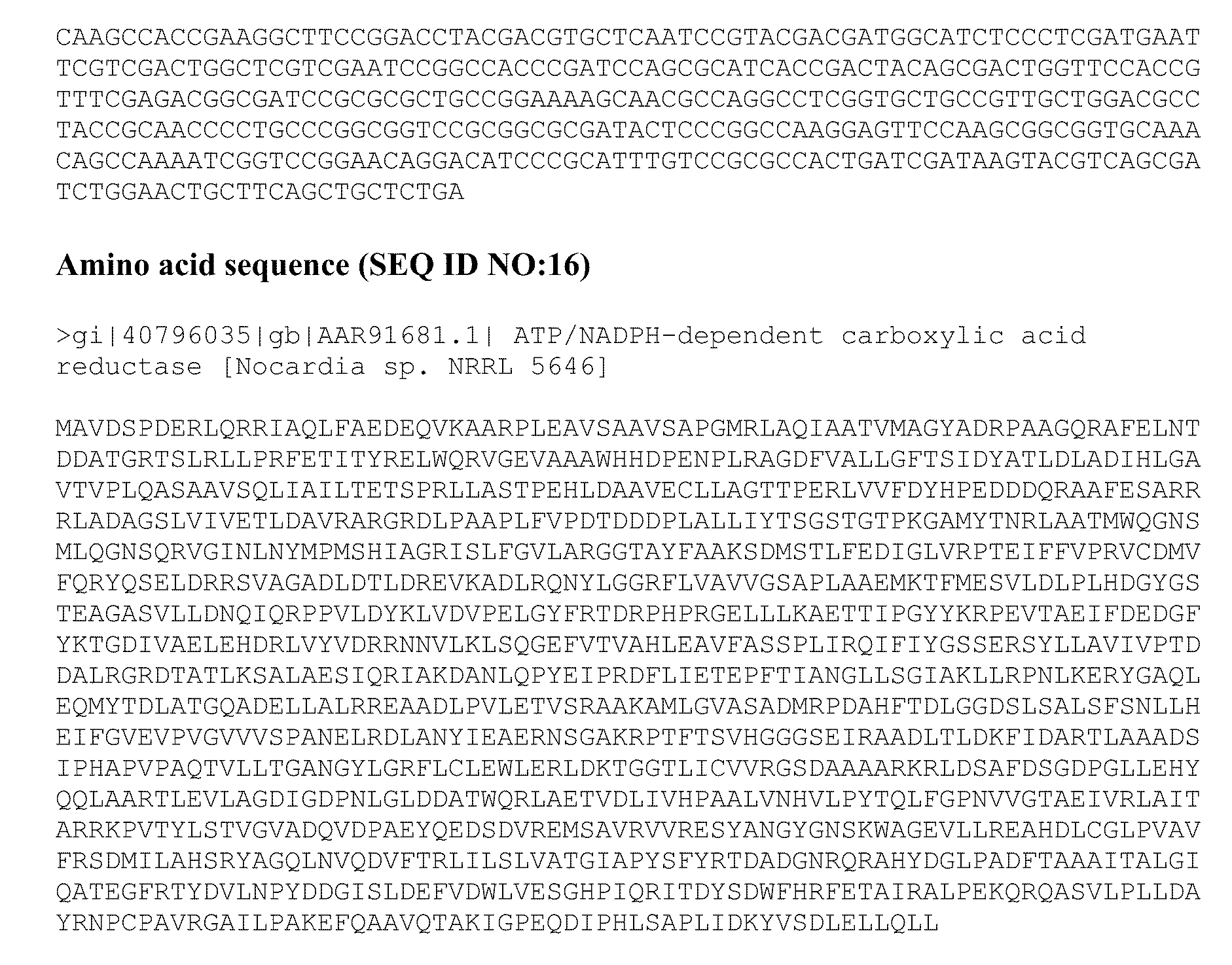

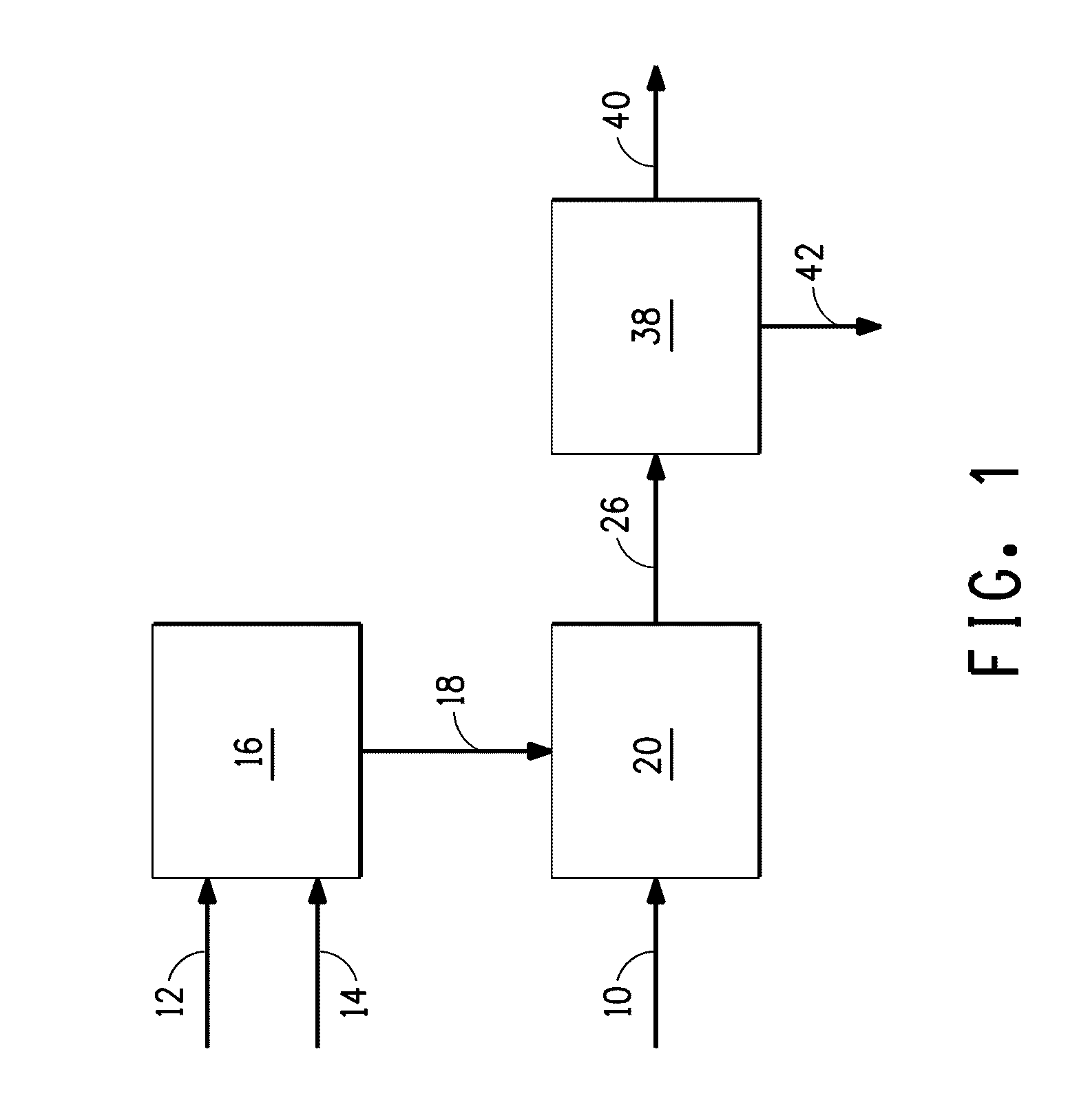

Methods and compositions for producing fatty aldehydes

Methods and compositions, including nucleotide sequences, amino acid sequences, and host cells, for producing fatty aldehydes are described.

Owner:GENOMATICA INC +1

Methods and compositions for producing fatty aldehydes

Methods and compositions, including nucleotide sequences, amino acid sequences, and host cells, for producing fatty aldehydes are described.

Owner:GENOMATICA INC +1

Method for producing butanol using extractive fermentation

InactiveUS20110097773A1Less corrosiveOrganic compound preparationMicroorganismsAlcoholCarboxylic acid

A method for producing butanol through microbial fermentation, in which the butanol product is removed by extraction into a water-immiscible extractant composition comprising a first solvent and a second solvent, is provided. The first solvent is selected from the group consisting of C12 to C22 fatty alcohols, C12 to C22 fatty acids, esters of C12 to C22 fatty acids, C12 to C22 fatty aldehydes, C12 to C22 fatty amides and mixtures thereof. The second solvent is selected from the group consisting of C7 to C11 alcohols, C7 to C11carboxylic acids, esters of C7 to C11 carboxylic acids, C7 to C11 aldehydes, and mixtures thereof. Also provided is a method for recovering butanol from a fermentation medium.

Owner:BUTAMAXTM ADVANCED BIOFUELS

Process for preparing alcohols from olefins by hydroformylation and hydrogenation

InactiveUS20060129004A1Downtime costEasy to preparePreparation by oxo-reaction and reductionOrganic compound preparationCobalt saltOxygen

A process for preparing aliphatic alcohols that includes cobalt-catalyzed hydroformylation of olefins, treatment of a hydroformylation mixture with oxygen-containing gases in the presence of acidic, aqueous cobalt(II) salt solutions, separation of a mixture into an aqueous phase comprising cobalt salts and an organic phase comprising the aliphatic aldehydes, and hydrogenation of an aldehyde-containing organic phase wherein the organic phase and treatment with an adsorbent to separate off cobalt compounds prior to hydrogenation.

Owner:EVONIK DEGUSSA GMBH

Process for extracting multiple active components from residual dregs of monordica grosvenori

InactiveCN1397539AImprove efficiencyFermentationFatty-oils/fats productionActive componentGlycoside formation

A process for extracting the active components (farnesol, fatty aldehyde and edible fibres) from the momordica grosvenori dregs generated after extracting glycoside includes extracting seed oil, extracting farnesol by fraction, extracting fatty aldehyde from the water phase, and preparing edible fibres from the dregs by chemical or enzyme method. Its advantages are simple process and high output rate.

Owner:王恒山 +2

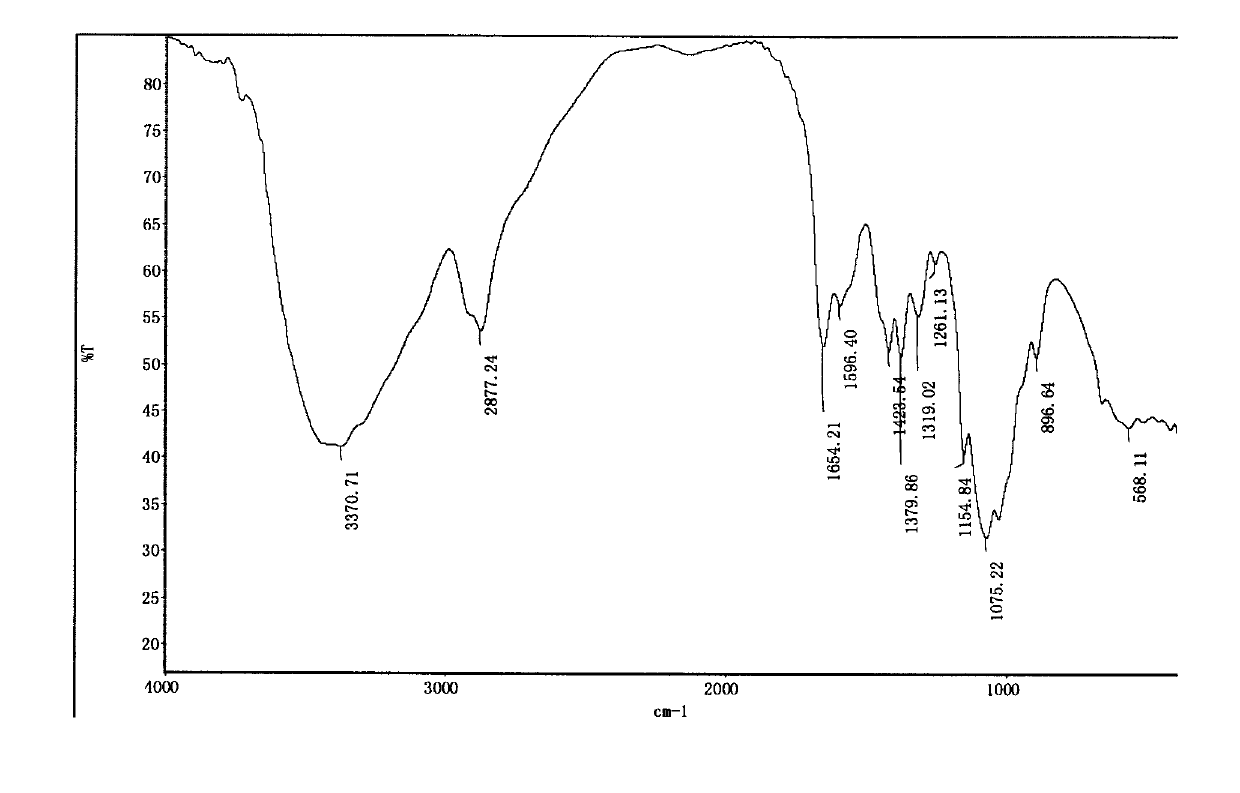

Chitosan aminoethyl quaternary ammonium salt derivative and preparation method thereof

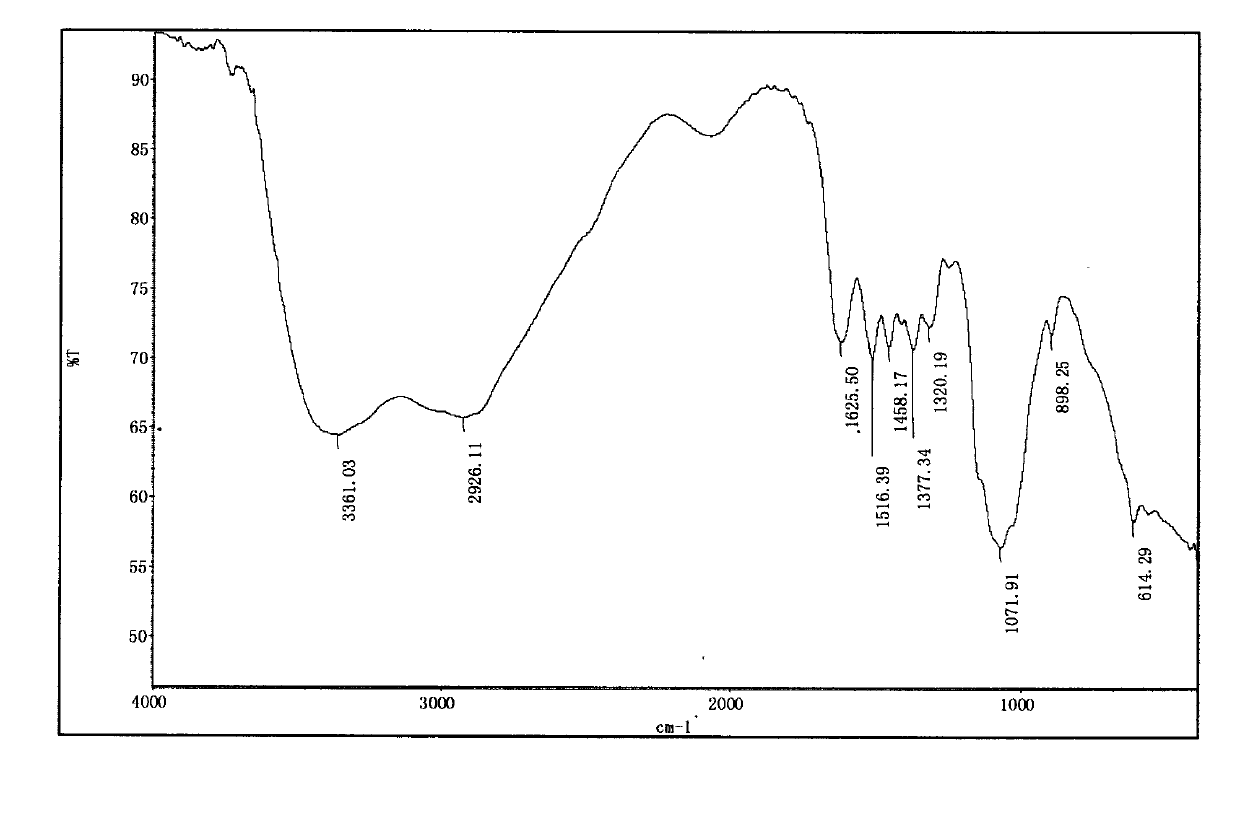

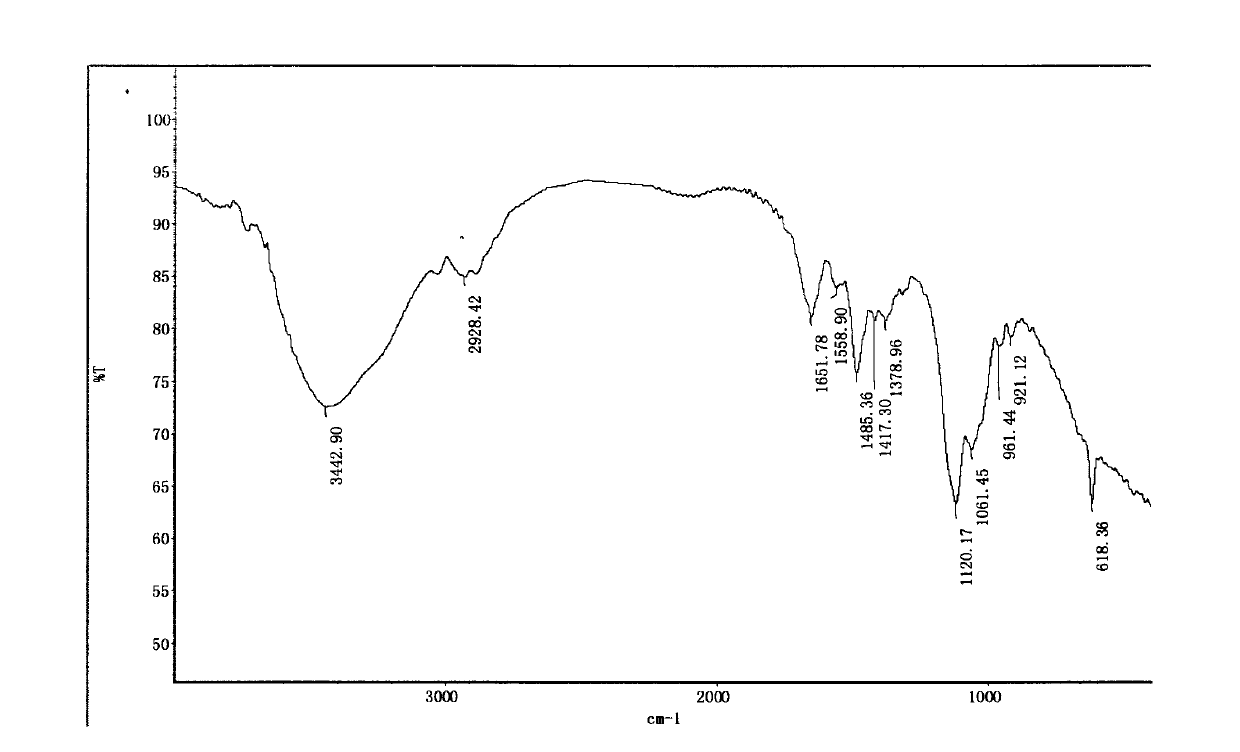

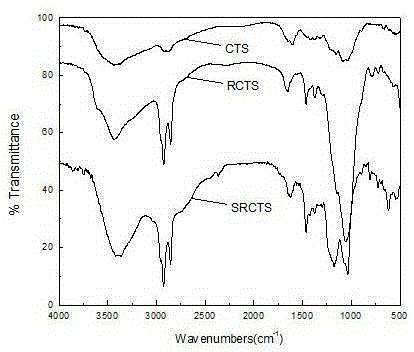

The invention belongs to ocean chemical engineering technology, and specifically relates to a chitosan aminoethyl quaternary ammonium salt derivative and a preparation method thereof. The chitosan aminoethyl quaternary ammonium salt derivative is shown as a formula (I), wherein R1 represents methyl or -H, and R2 represents -CH3, linear alkyl, branched alkyl or -Ar, and n equals to 4-4000. According to the invention, 2-chloroethylamine is subjected to an electrophilic substitution reaction with -NH2 on C2 and -OH on C6 of the chitosan to generate aminoethyl chitosan, amino on which reacts directly with iodomethane to generate N-trimethyl quaternary ammonium salt derivative, or which is subjected to a condensation reaction with aromatic aldehyde or fatty aldehyde to generate Schiff base which is reduced by sodium borohydride and quaternized under effect of iodomethane to obtain chitosan aminoethyl quaternary ammonium salt derivative. According to infrared spectroscopic analysis on the obtained derivative, chitosan and the grafted groups are effectively combined to generate aminoethyl quaternary ammonium salt. According to the invention, aminoethyl quaternary ammonium salt group is introduced into the chitosan structure to increase positive charge level of the chitosan, substantially enhance biological activity of the chitosan, such as antibiosis and sterilization, etc.

Owner:水母娘娘海洋生物科技有限公司

Catalyzer for synthesizing pyridine base

InactiveCN1565736AHigh yieldImprove technical effectOrganic chemistryMolecular sieve catalystsGas phaseKetone

The invention relates to a catalyst for synthesizing pyridine base for improving the yield of pyridine base. The technology is characterized in that the catalyst with cobalt, lead or metal oxide of their mixture -supported on ZSM-5 zeolite can promoting the reaction of fatty aldehyde, fatty ketone or their mixtures and ammonia.

Owner:CHINA PETROLEUM & CHEM CORP +1

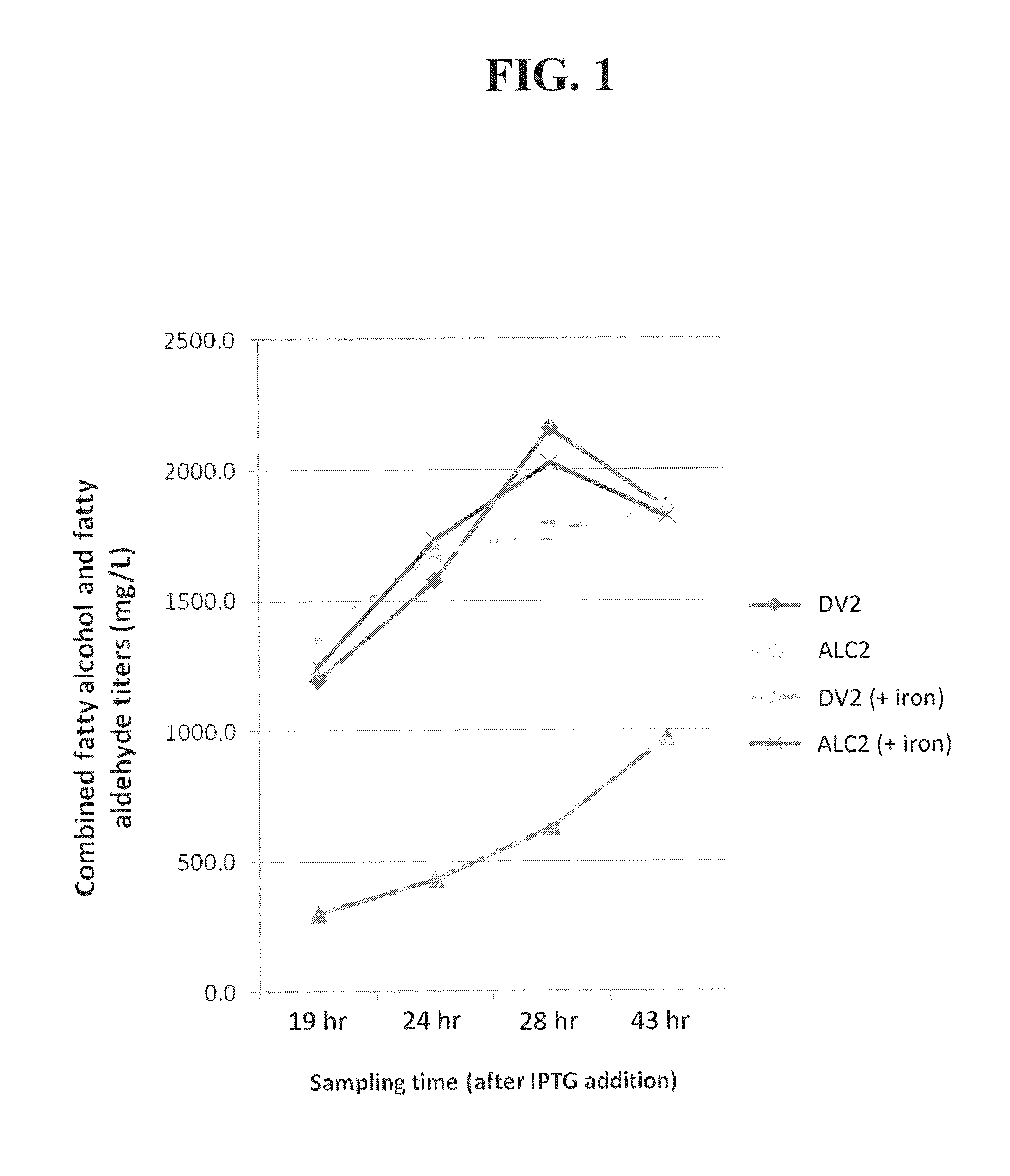

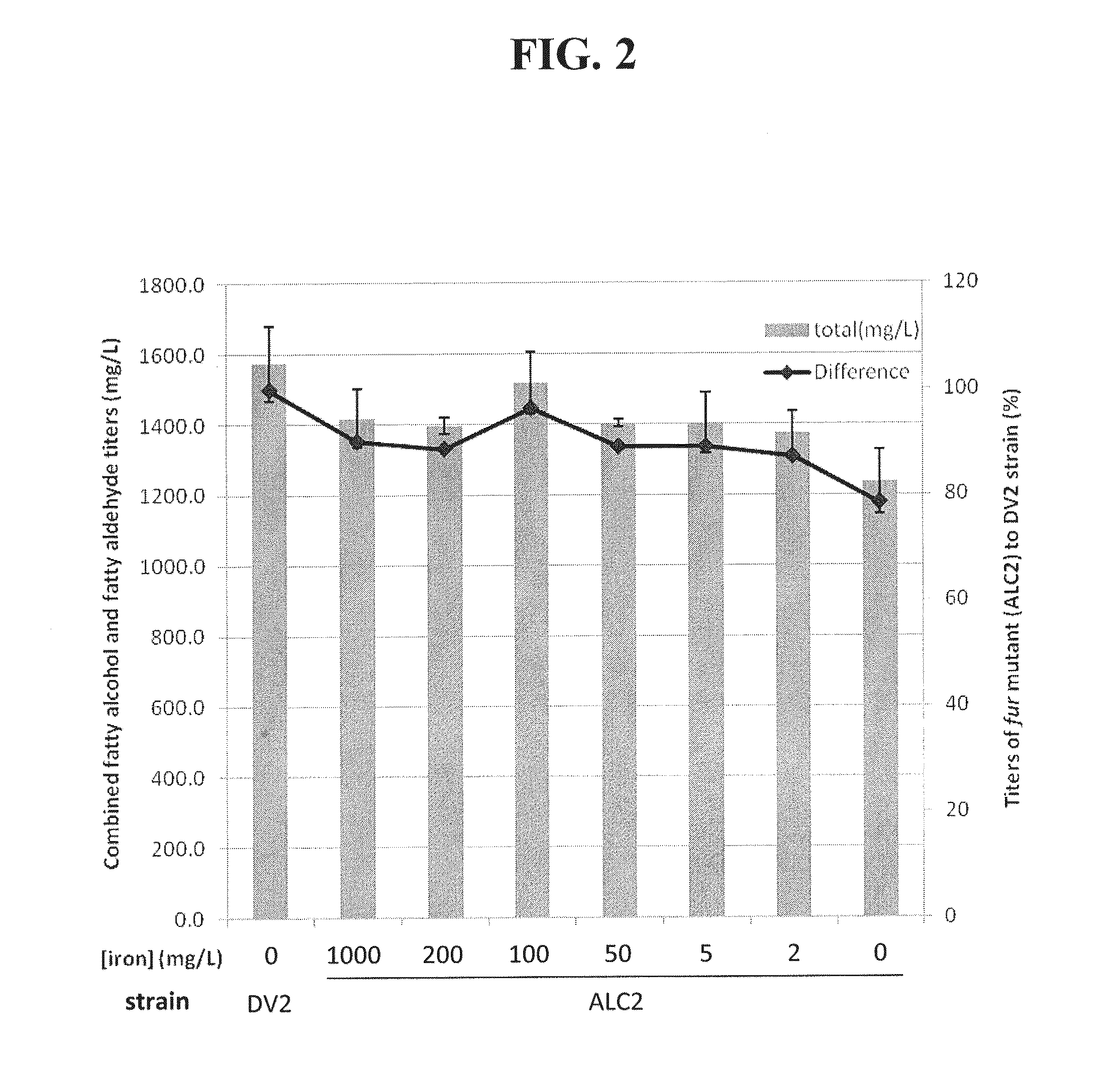

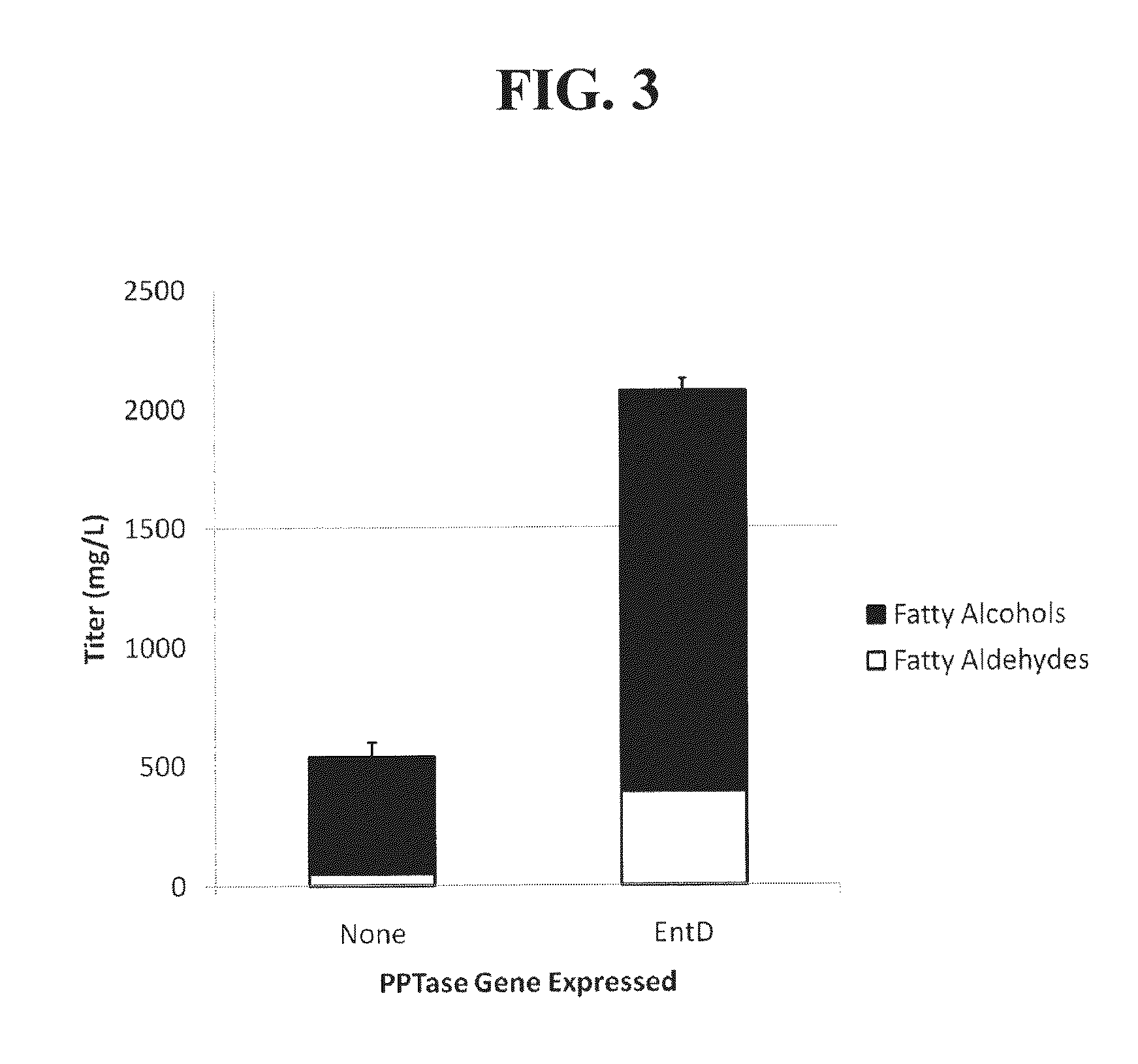

Methods and compositions for enhanced production of fatty aldehydes and fatty alcohols

InactiveUS20130035513A1Increase productionIncrease in reductase activityFungiBacteriaNucleotideFatty alcohol

The invention relates to the use of EntD polypeptides, polynucleotides encoding the same, and homologues thereof to enhance the production of fatty aldehydes and fatty alcohols in a host cell.

Owner:LS9 INC +1

Process for preparing cationic polyvinyl acetals

InactiveUS20060264572A1Improve adhesionAvoid thixotropic effect in solutionInksHemiacetalCarboxylic acid

Cationic polyvinyl acetals are prepared by copolymerizing one or more cationic N-alkyldiallylammonium salt monomers with one or more vinyl esters of branched or unbranched carboxylic acids having 1 to 15 carbon atoms, hydrolyzing the resulting copolymers to copolymers containing >50 mol % vinyl alcohol units, and acetalizating the vinyl alcohol units with one or more aliphatic aldehydes having 1 to 15 carbon atoms, their acetals, and / or hemiacetals, wherein the copolymerization takes place in a mixture of water and monovalent aliphatic alcohol having a water content of 2% to 35% by weight.

Owner:KURARAY EURO GMBH

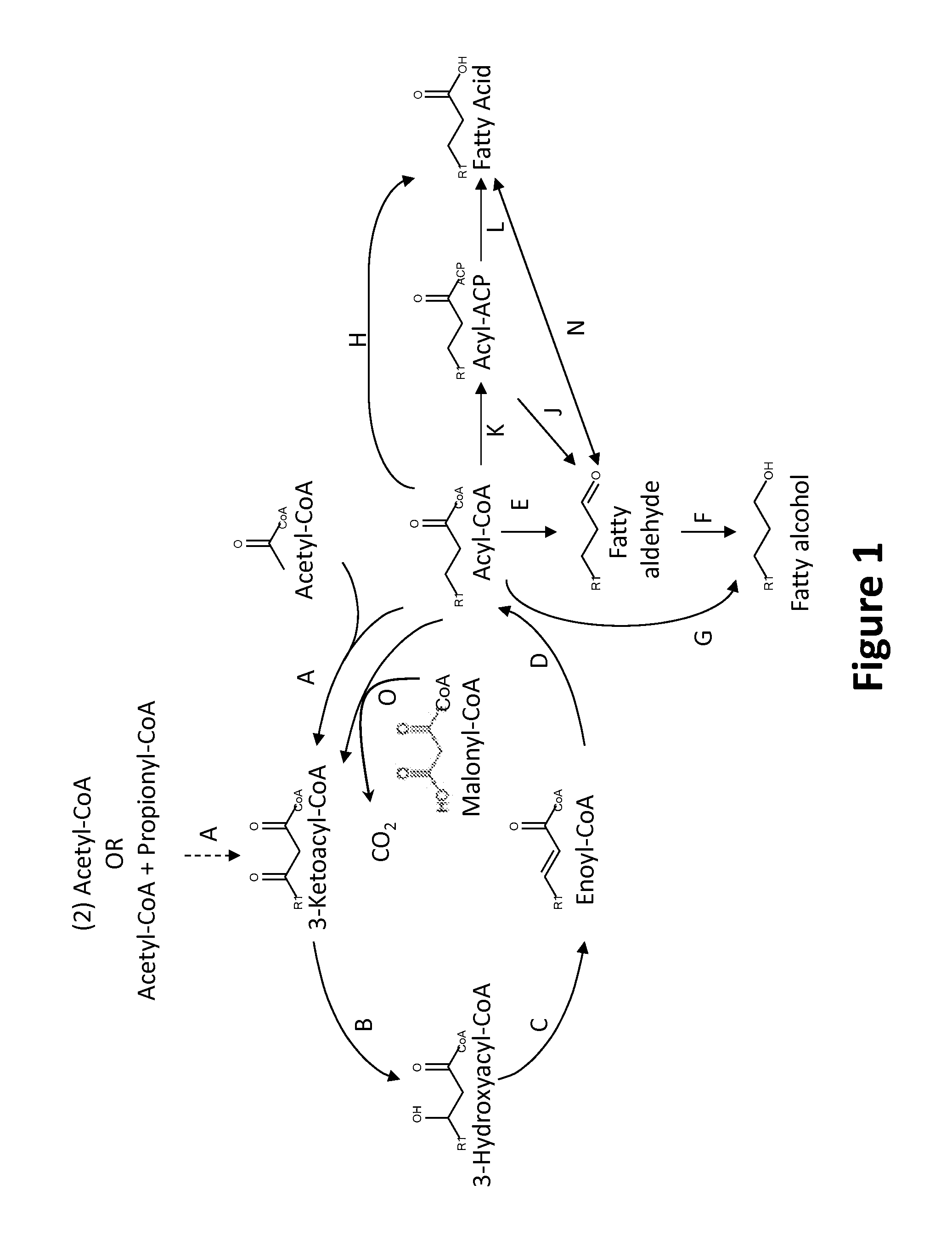

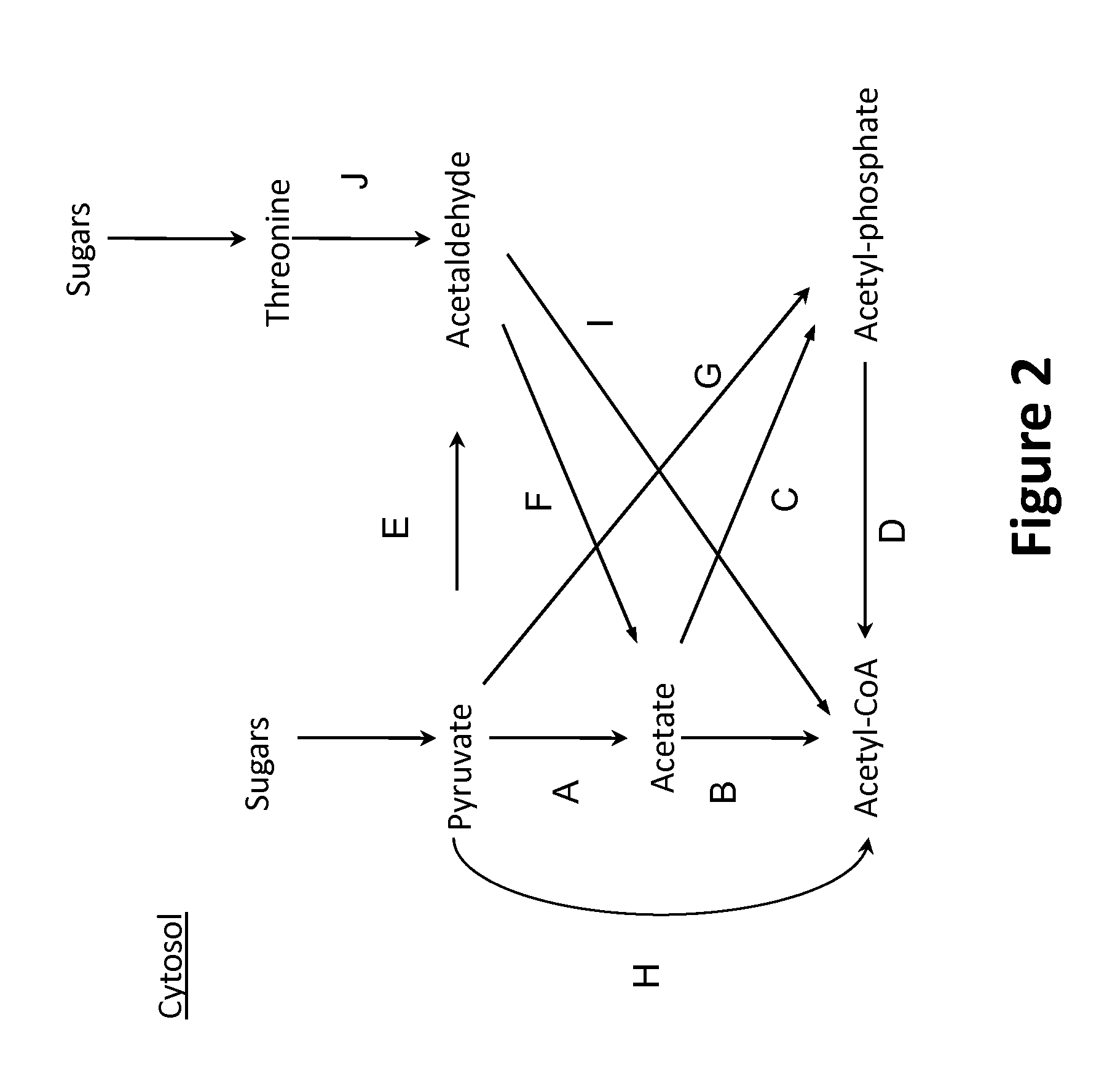

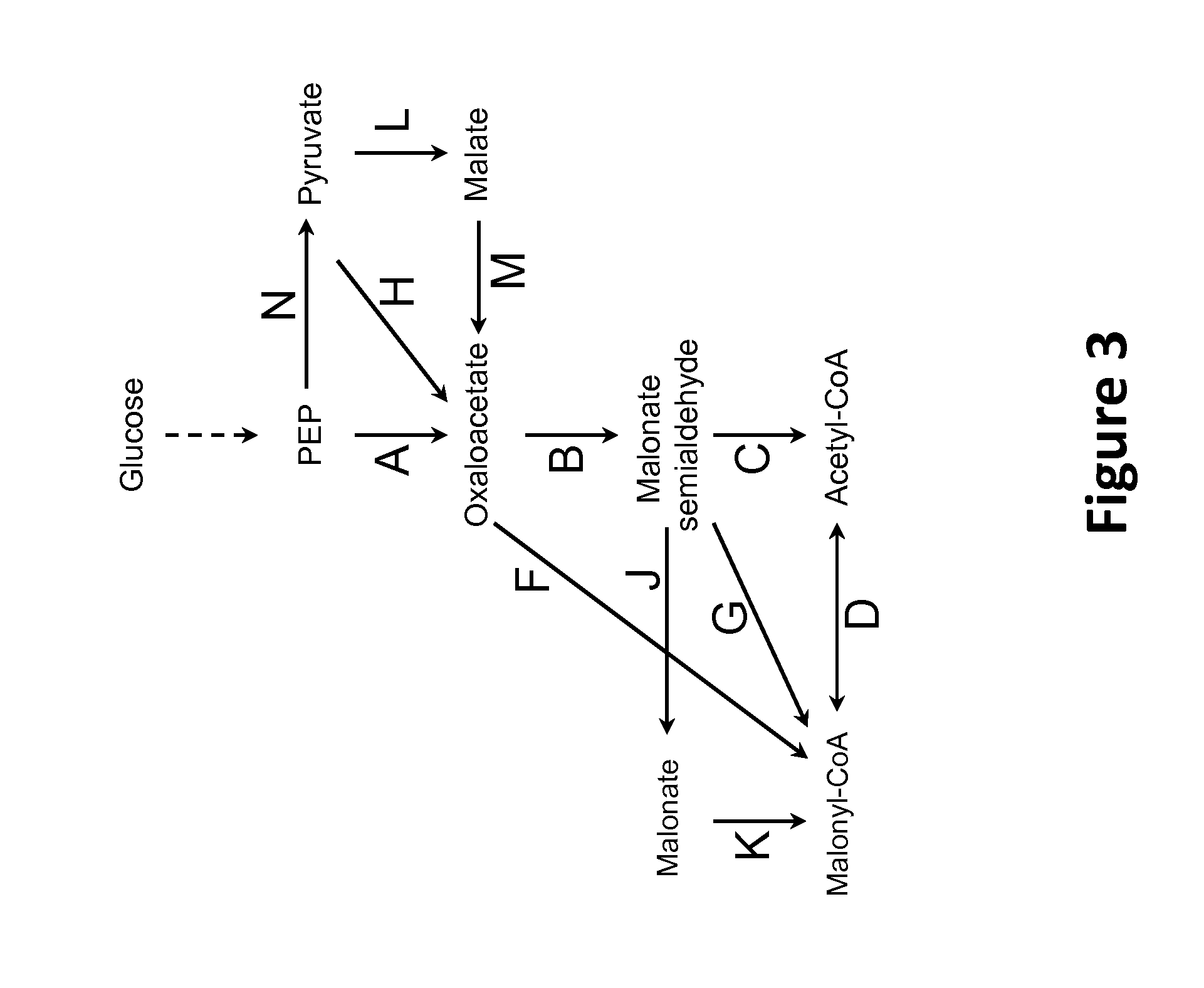

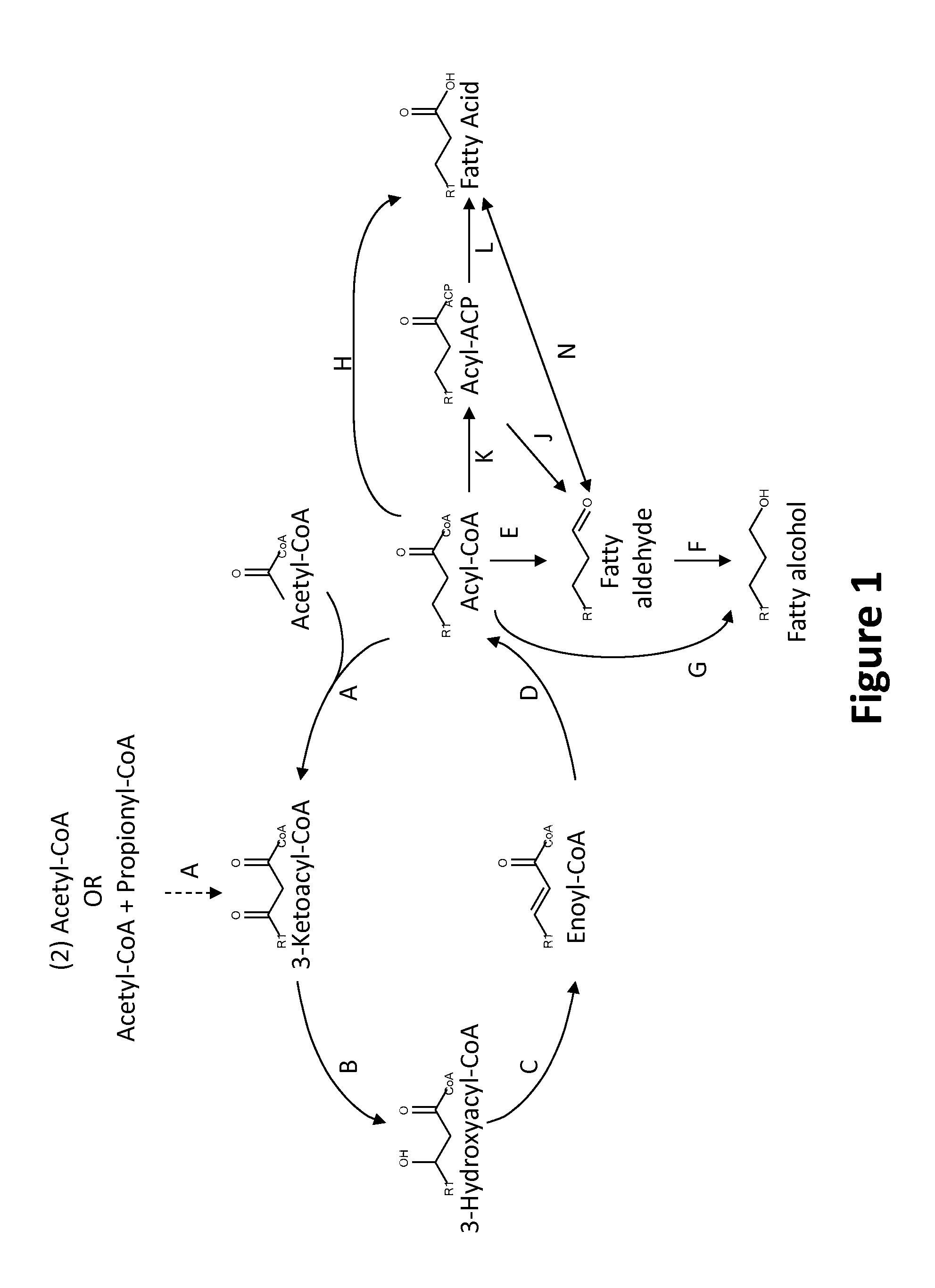

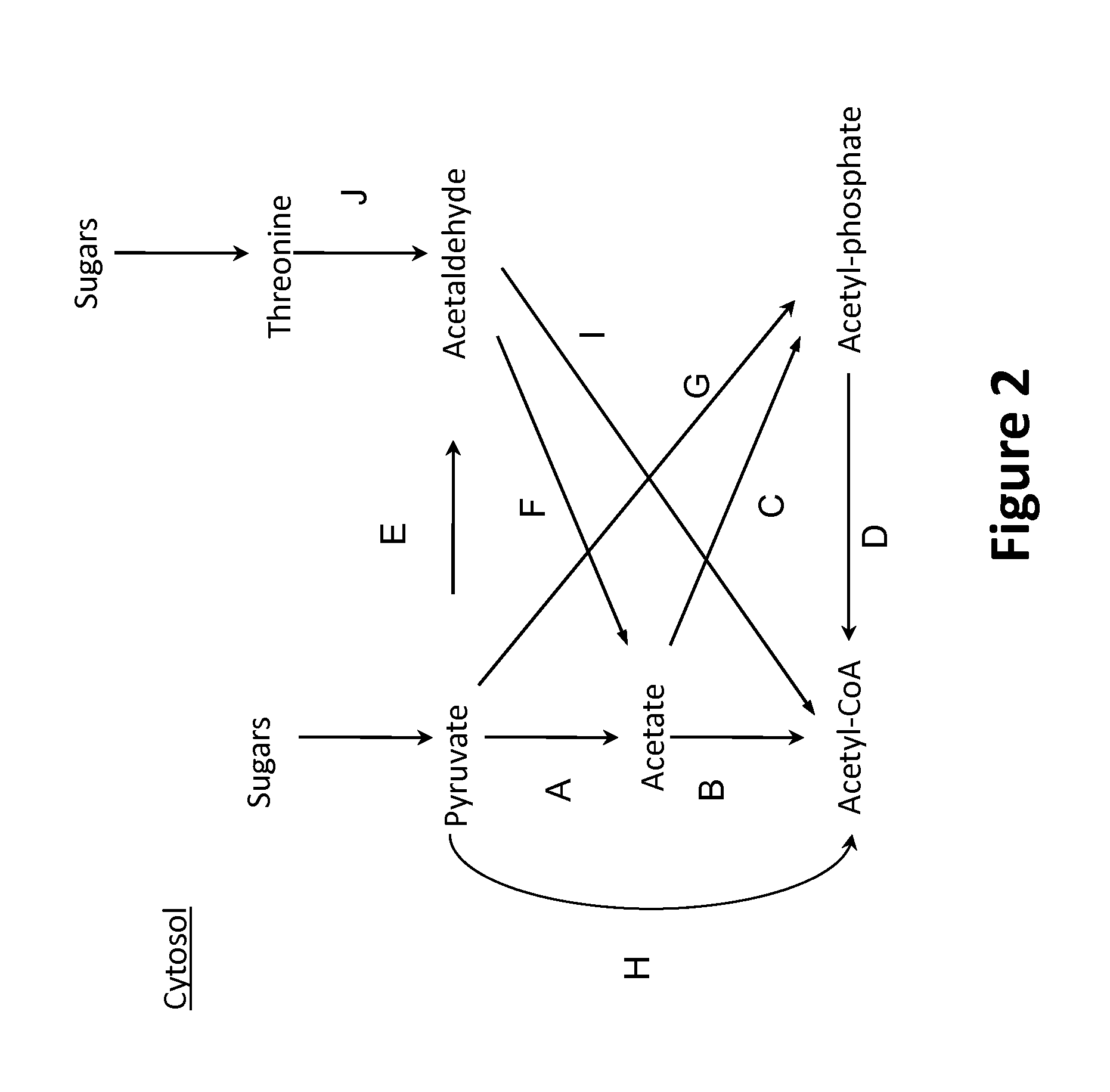

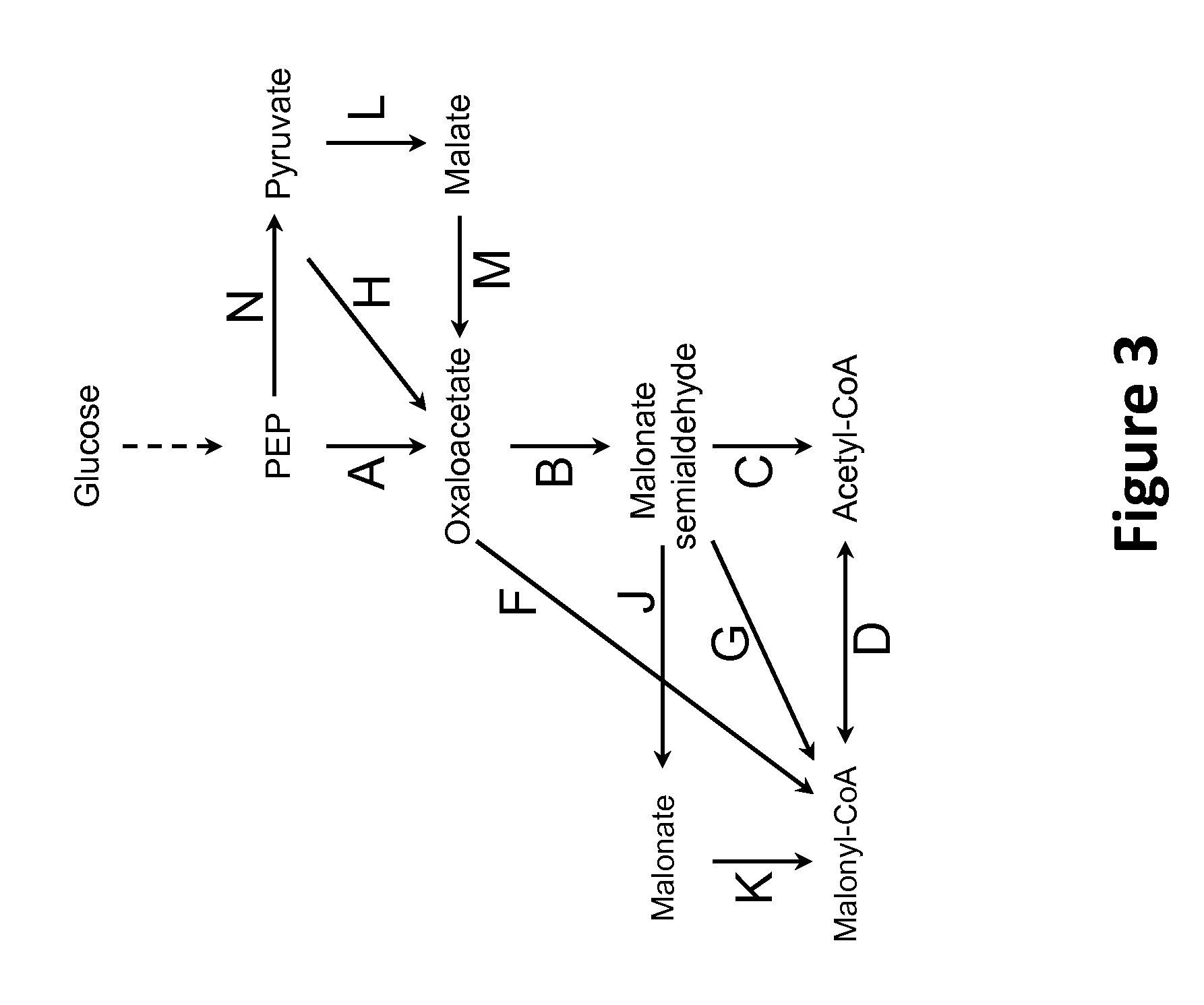

Microorganisms and methods for production of specific length fatty alcohols and related compounds

The invention provides non-naturally occurring microbial organisms containing a fatty alcohol, fatty aldehyde or fatty acid pathway, wherein the microbial organisms selectively produce a fatty alcohol, fatty aldehyde or fatty acid of a specified length. Also provided are non-naturally occurring microbial organisms having a fatty alcohol, fatty aldehyde or fatty acid pathway, wherein the microbial organisms further include an acetyl-CoA pathway. In some aspects, the microbial organisms of the invention have select gene disruptions or enzyme attenuations that increase production of fatty alcohols, fatty aldehydes or fatty acids. The invention additionally provides methods of using the above microbial organisms to produce a fatty alcohol, a fatty aldehyde or a fatty acid.

Owner:GENOMATICA INC

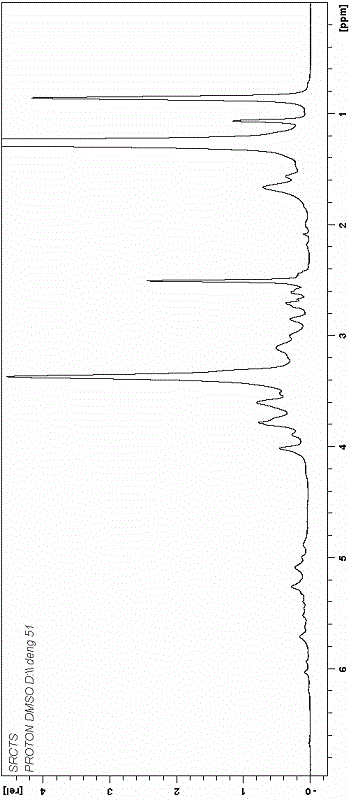

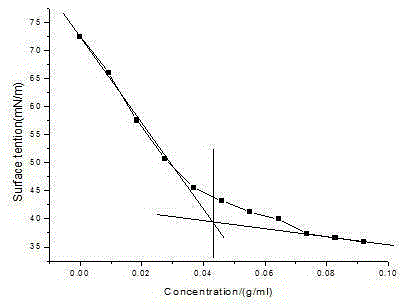

Chitosan amphiphilic polymer surfactant, and synthetic method thereof

The invention relates to a chitosan amphiphilic polymer surfactant, and a synthetic method thereof. The general structure of the chitosan amphiphilic polymer surfactant is represented by a formula in the invention, wherein n=1-2000. According to the synthesis method, natural high molecular chitosan is taken as a base raw material; -NH2 in chitosan and a fatty aldehyde are subjected to condensation reaction so as to obtain Schiff base; NaBH3CN is used for reduction reaction so as to introduce hydrophobic groups and obtain N-alkylated chitosan; a halide containing hydrophilic group -SO3H and N-alkylated chitosan are subjected to substitution reaction to introduce hydrophilic groups, and the novel degradable chitosan amphiphilic polymer surfactant with obvious amphipathy is obtained. Critical micelle concentration of the chitosan amphiphilic polymer surfactant is 0.043g / ml, surface tension at the critical micelle concentration is 39.5mN.m<-1>. The synthetic method is simple; yield is high; surface properties of the obtained product are excellent; the green safe chitosan amphiphilic polymer surfactant can be prepared with high efficiency and low energy consumption via the environmental-friendly synthesis method; and the synthesis method possesses significant importance on environment protection and resource regeneration.

Owner:SHANGHAI UNIV

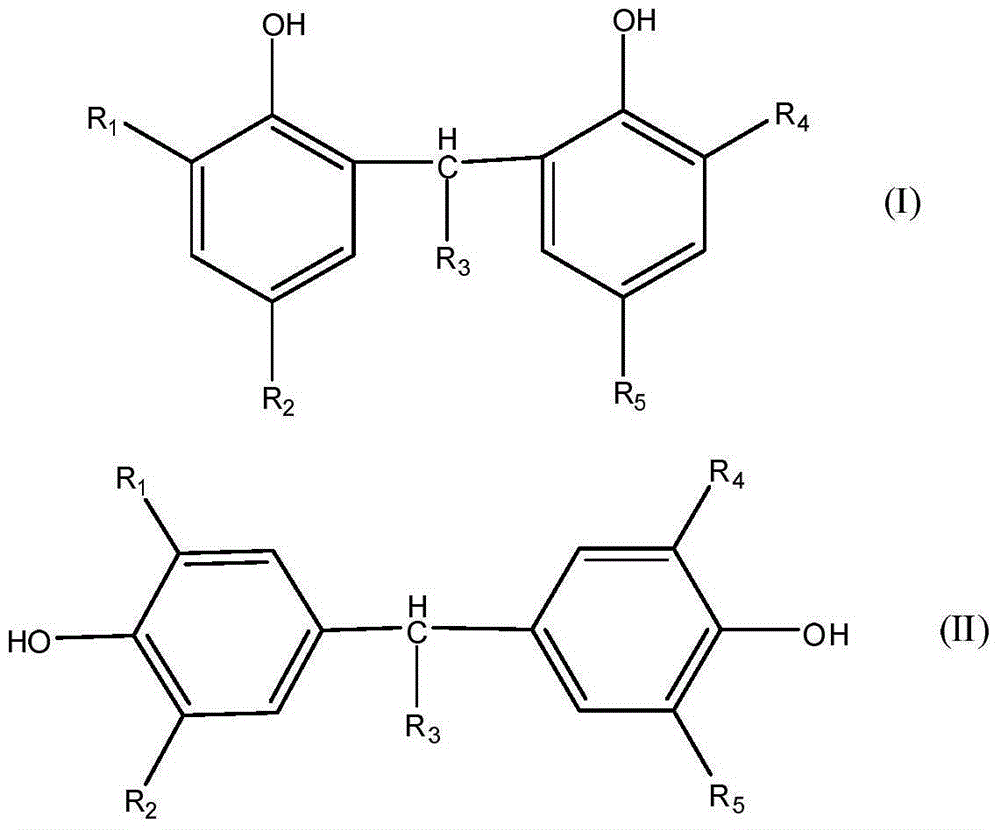

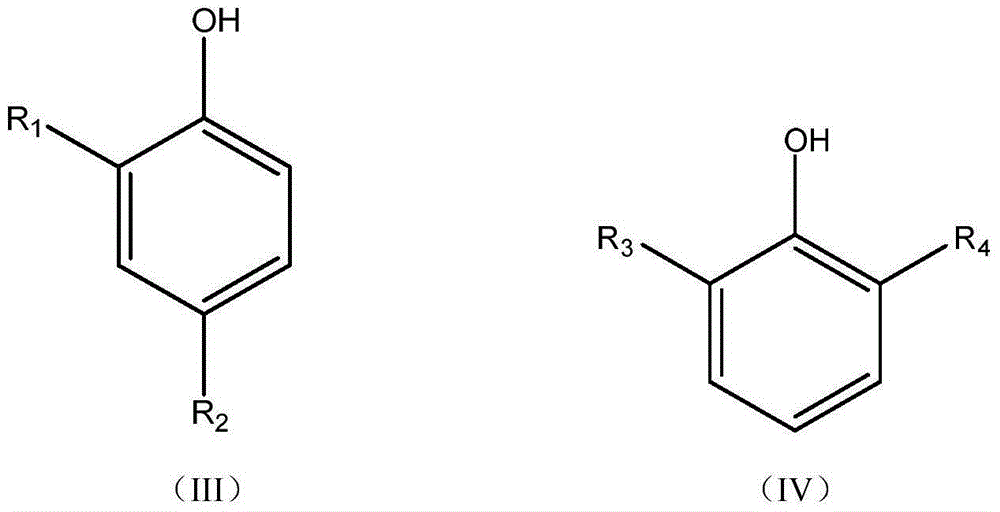

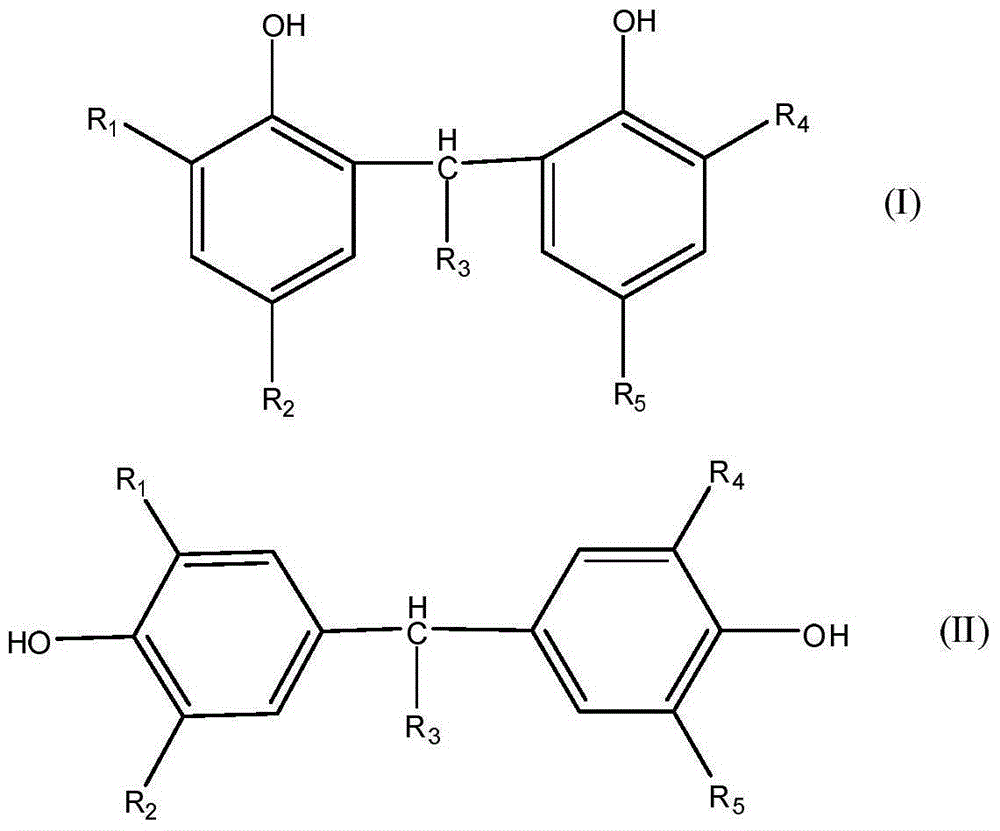

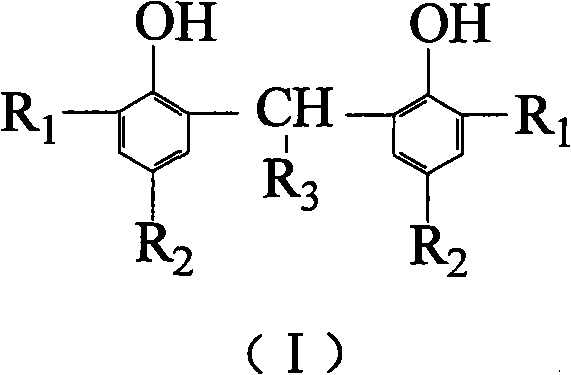

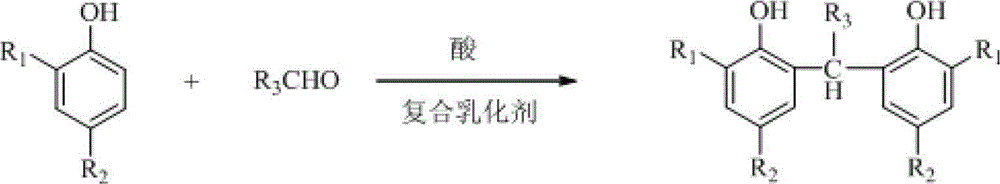

Cleaner production method and use of bisphenol compound anti-oxidant

ActiveCN105523899AScientific and reasonable route designMild process conditionsOrganic chemistryOrganic compound preparationFiltrationSolid acid

The invention discloses a cleaner production method and a use of a bisphenol compound anti-oxidant. The cleaner production method comprises that fatty aldehyde and dialkyl-substituted phenol as raw materials undergo a reaction in the presence of a solid acid as a catalyst in an enclosed environment and the reaction product is subjected to hot filtration so that a desired product is obtained. The desired product can be used for preparation of a lubricating oil composition or can be used as an antiager of plastic and rubber. The production method of the bisphenol compound anti-oxidant has the advantages of simple processes, mild conditions, use of a catalyst and raw materials with a wide source, a cheap price and easy availability, short reaction period, control convenience, high process safety, low energy consumption in production, high yield, high product purity, no use of moisture, an organic solvent and a surfactant in the reaction, no use of a water washing product in the later period, no production of waste water and control and reduction of pollutant discharge. The production method is a safe, energy saving and eco-friendly novel technology.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

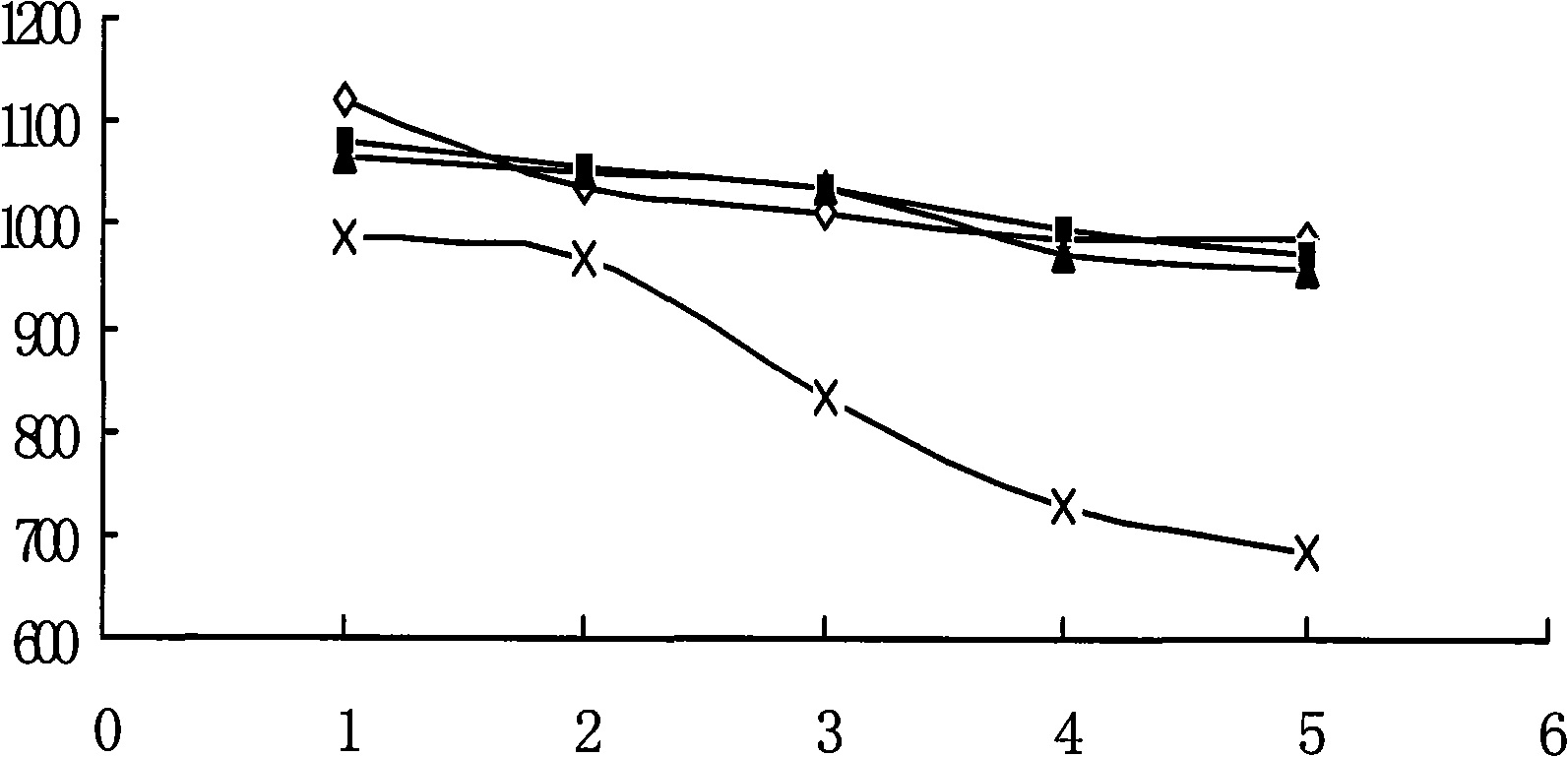

Method for preparing bisphenol compound antioxidant product by using organic acid catalyst

ActiveCN101704728AReduce consumptionControl and reduce emissionsOrganic chemistryOrganic compound preparationReaction temperatureSolvent

The invention discloses a method for preparing a bisphenol compound antioxidant product by using an organic acid catalyst. A closed reactor is adopted, water is used as reaction solvent, a liquid organic acid catalyst is selected as a catalyst, and the bisphenol compound antioxidant product is generated through the condensation reaction of dialkyl phenol and aliphatic aldehyde. The liquid organicacid catalyst is one or a mixture of more of long-chain alkyl benzene sulfonic acid, long-chain dialkyl benzene sulfonic acid, long-chain alkyl diphenyl ether disulfonic acid and long-chain dialkyl diphenyl ether disulfonic acid and aliphatic hydrocarbon of C6 to C10 or aromatic hydrocarbon of C6 to C8 in a mass ratio of 1: 0.1-1.0. The dosage of the liquid organic acid catalyst is 7 to 30 percent by mass of dialkyl phenol; the mass ratio of the water to the dialkyl phenol is 2-5:1; and the molar ratio of the aliphatic aldehyde to the dialkyl phenol is 0.45-0.60: 1. The reaction pressure is 0to 0.1MPa, the reaction temperature is 60 to 95 DEG C, and the reaction time is 4 to 7 hours. The raw material variety used by the method is reduced, and the production efficiency is improved; and the method avoids using sulfuric acid and hydrochloric acid with stronger corrosion on the equipment.

Owner:溧阳常大技术转移中心有限公司

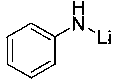

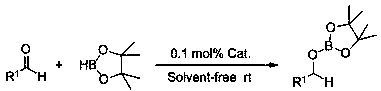

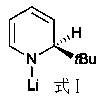

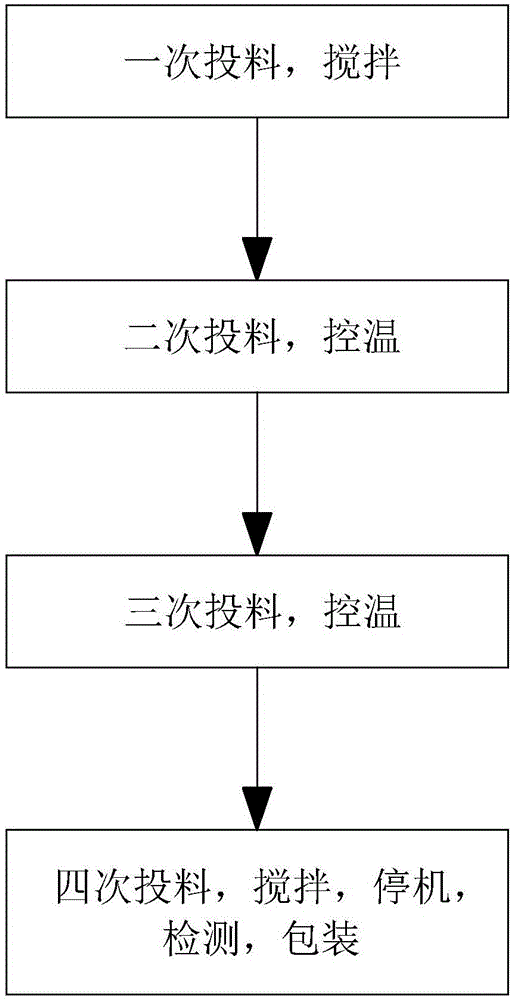

Method of preparing borate ester based on aldehyde

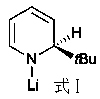

InactiveCN108409772AEfficient hydroboration reactionReduce pollutionOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsLithiumBottle

The invention relates to application of anilino lithium, in particular to a method of preparing borate ester based on hydroboration reaction of aldehyde and borane. The method comprises the followingsteps of under the conditions without water and oxygen, in an inert gas atmosphere, adding the borane in a reaction bottle subjected to dehydration and deoxygenation treatment, then adding the anilinolithium as a catalyst, performing uniform mixing, then adding the aldehyde for hydroboration reaction, and performing exposure in the air for reaction termination to obtain the borate ester as a product, wherein the aldehyde is selected from fatty aldehydes. By adopting the method provided by the invention, the condition that the anilino lithium can extremely efficiently catalyze cyclohexanecarboxaldehyde, propionaldehyde and heptanal to generate hydroboration reaction with the borane is discovered for the first time, and a new scheme is provided to prepare the borate ester by adopting a carbonyl compound and the borane to generate the hydroboration reaction.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Organic polymer flocculant and its prepn. and application in water treatment

InactiveCN1336391ALess drug consumptionGood processing effectWater/sewage treatment by flocculation/precipitationWater chlorinationPhosphorus trichloride

The present invention relates to preparation of organic polymer coagulant and its application in water treatment. Said method incldues condensation polymerization, inorganic ammonium salt is dissolved in a reactor containing aliphatic aldehyde and water, reaction temp. is 60-95 deg.C, reaction time is controlled at 0.5-3 hr., proceed hydrolysis and esterification, reduce the temp. of reaction liquid to 20-70 deg.C., and phosphorus trichloride, raise temp. to 90-120 deg.C, react for 2-9 hr., then reduce temp. of 45-85 deg.C, and additive, continue reaction 1-3 hr. cool to room temp. to obtain product. The invented product is ideal in waste water treatment, good in stability, non-toxic etc..

Owner:FUZHOU UNIV

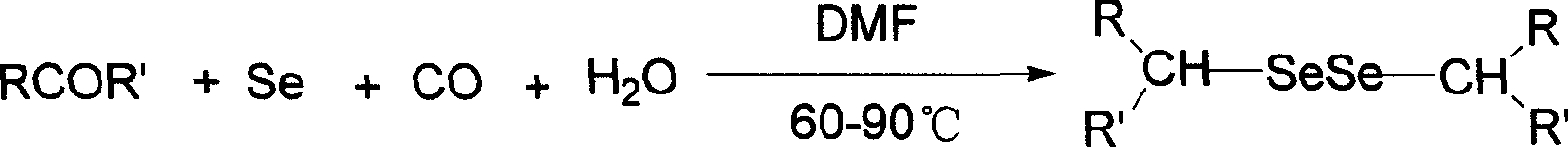

White leather tanning agent and production method thereof

ActiveCN101435003AImprove storage conditionsAdd lessTanning treatmentChromium freeAlkaline earth metal

The invention discloses a chromium-free tanning agent in the tanning industry and a synthetic production process thereof; the formula (weight ratio) comprises: 60-150 parts of amide containing hydroxymethyl, 30-100 parts of aliphatic aldehydes, and 1-5 parts of anti-yellowing agent. The production method comprises the following steps: in the first step, 60-150 parts of amide containing hydroxymethyl are added into a reaction kettle with a stirring function, a thermometer, a reflux condenser and a vacuum distillation unit; in the second step, temperature is raised to 30 to 40 DEG C; in the third step, 30-100 parts of aliphatic aldehydes are dripped; in the fourth step, 1-5 parts of anti-yellowing agent are added with 2-4 hours of heat insulation; and in the fifth step, decompression distillation is carried out for 4-6h at the temperature of 50-90 DEG C and the pressure of -0.3bar-0.95bar for removing the water. The third step and the fourth step can be exchanged. The invention solves the color changing problem in the production and storage processes of the products, adds a small amount of anti-yellowing material alkali metal and the borate solution of alkaline earth metal, greatly improves the storage conditions of the 'oxazolidine' type tanning agent, and prolongs the quality guaranteeing time; as the anti-yellowing material has low price, is easy for acquisition, and has small adding amount, the invention does not affect the application characteristics of the products and can be widely promoted.

Owner:德瑞(常州)特种材料有限公司

Environment-friendly synthesis method for 4(3H)-quinazolinone

InactiveCN103613550ARaw materials are cheap and easy to getEasy to operateOrganic chemistryPtru catalystMedicinal chemistry

The invention provides a method for synthesizing 2-substituted 4(3H)-quinazolinone by directly heating aldehyde and anthranilamide in air without using a catalyst. According to the synthesis method, air is taken as an oxidizing agent, aldehyde comprises compounds such as aromatic aldehyde, cinnamyl aldehyde and fatty aldehyde, recyclable dimethylsulfoxide is taken as a solvent, or excess recyclable aldehyde is taken as both a reactant and the solvent, due to heating, the aldehyde and anthranilamide react so as to obtain 2-substituted 4(3H)-quinazolinone compounds. The raw materials used by the synthesis method are easy to obtain; and the method is environment-friendly, is very simple to operate, and is applicable to industrial production.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

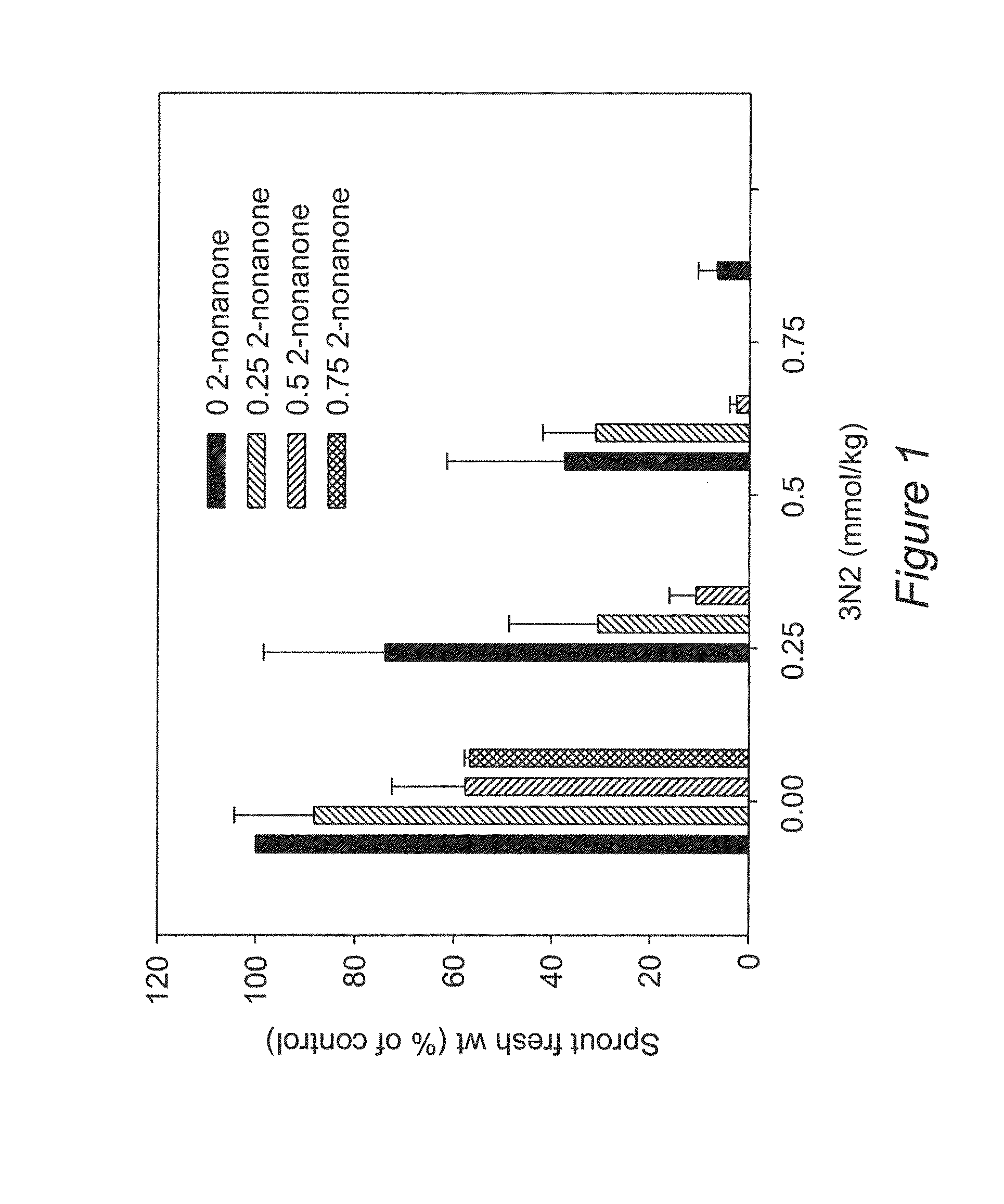

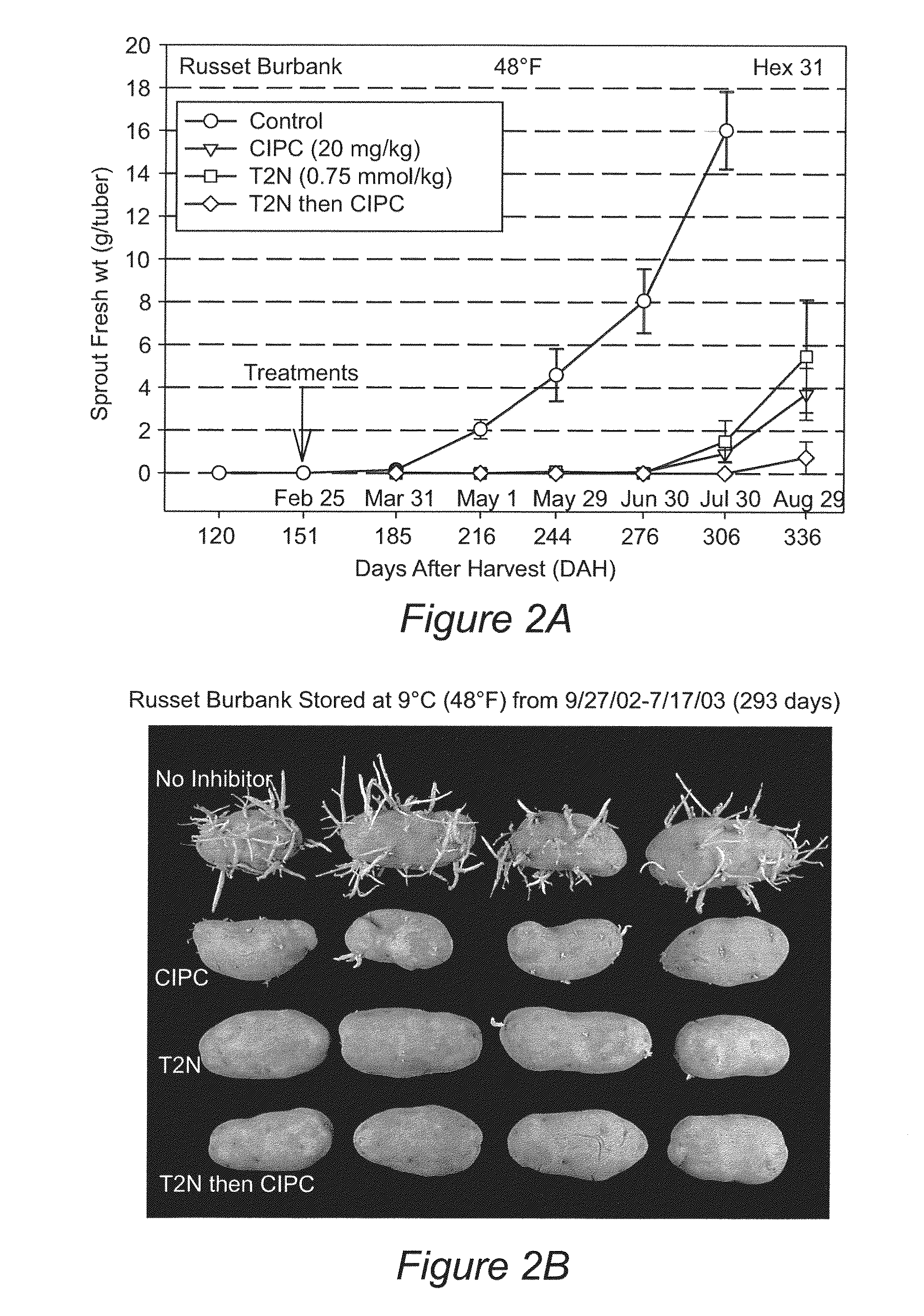

Enhancement of Potato Tuber Sprouting Inhibitors Using Various Combinations of Agents

ActiveUS20130183419A1Reduce application rateLong-term potato sprout controlBiocideMilk preservationKetoneSolanum tuberosum

Compositions and methods for inhibiting the sprouting of potato tubers are provided. The compositions comprise combinations of i) α,β-unsaturated aliphatic aldehydes, and ketones,C3 to. C14 aliphatic aldehydes and ketones, and / or C3 to C7 saturated or unsaturated primary and secondary aliphatic alcohols; and 2) conventional sprout Inhibitors, The effect of the combinations is additive and / or synergistic, and less of the conventional inhibitor is required to achieve the same or improved levels of sprout inhibition.

Owner:WASHINGTON STATE UNIVERSITY

Dyeing and retanning tanning process

ActiveCN102051419AReduce usageEmission reductionTanning treatmentPre-tanning chemical treatmentManufacturing cost reductionSodium bicarbonate

The invention relates to a dyeing and retanning tanning process, which comprises a softening and through-dyeing process and a color fixing and fixing process. The dyeing and retanning tanning process is characterized in that: the softening and through-dyeing process comprises the steps of adding normal-temperature water, wet blue leather, MND1717, MND3009, MND2031, MND2010, MND7010, sodium formate or sodium acetate, sodium bicarbonate, ammonium bicarbonate and dye by weight into a revolving drum, revolving for more than 2 hours, checking that the center of the obtained product is penetrated, stopping the drum, and keeping stand the obtained product overnight; and the color-fixing and fixing process comprises the steps of adding methanoic acid and MND1717 into a drum provided with a leather blank subjected to softening and through-dyeing treatments in the softening and through-dyeing process, in the same bath, adjusting the pH value, adding a chrome tanning agent, MND3009, MND2031, MND2010, glutaraldehyde or fatty aldehyde, and a mildew inhibitor into the drum, revolving for more than 4 hours, rinsing, taking the obtained product out of the drum, coating and finishing according to the conventional process. Compared with the prior art, the dyeing and retanning tanning process has the advantages of simple process, wide scope of application, capability of improving the quality of finished leather, raw material and labor saving, reduction of labor intensity, energy saving, effective reduction of wastewater discharge, and lower manufacturing cost.

Owner:禾瑞(漳州)助剂有限公司

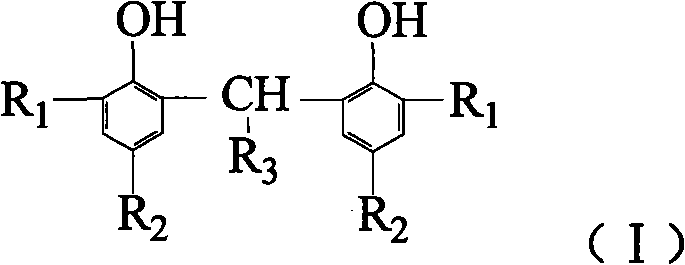

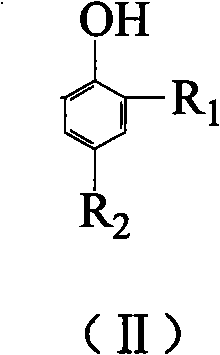

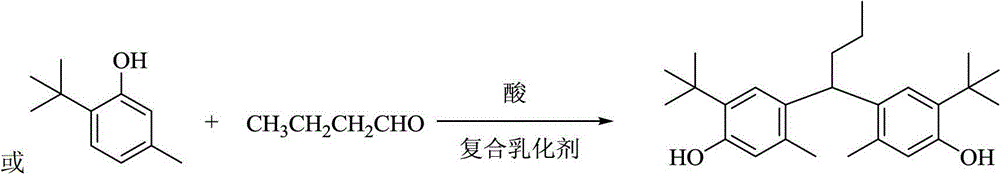

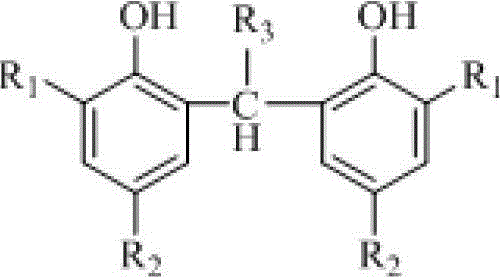

Alkylene bialkylphenol compound and preparation method thereof

ActiveCN102718634AEvenly dispersedGood emulsifying effectOrganic chemistryOrganic compound preparationPolyvinyl alcoholAqueous solution

The invention relates to alkylene bialkylphenol compound and a preparation method of the alkylene bialkylphenol compound. Bialkylphenol and fatty aldehyde are used as raw materials, and compound emulsifying agent is added under the catalysis of vitriol, namely the alkylene bialkylphenol compound is synthesized under a composite emulsifying agent system consisting of polyvinyl alcohol and an anionic surface agent; according to the reaction conditions, based on 100g of bialkylphenol, the polyvinyl alcohol is 1.5 to 2.5g, the anionic surface agent is 0.5 to 2g, and 2 to 10% sulphuric acid solution is 200 to 400g, and the mole ratio of bialkylphenol to fatty aldehyde is of 1: 0.5-0.8; and the reaction lasts for 5 to 10 hours at temperature of 70 to 100 DEG C. Compared with existing synthesis route, the preparation method provided by the invention has the advantages that the composite emulsifying agent system comprising the polyvinyl alcohol and the anionic surface is adopted, and therefore various materials in the reaction system can be dispersed more uniformly, and the emulsifying effect is greater, and the reaction can be better carried out as well; and moreover, the operation process is simple, convenient and reliable; the conditions are easy to control; the product has high purity; and the yield and the purity are both higher than 98%.

Owner:RIANLON

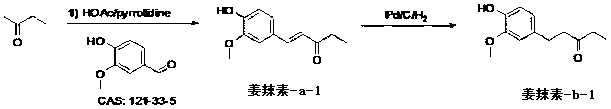

Synthesis process of gingerol derivative

InactiveCN103159599AAvoid multi-step reactionsShort synthetic routeOrganic compound preparationCarbonyl compound preparationShogaolCombinatorial chemistry

The invention relates to a synthesis process of a gingerol derivative. A shogaol derivative is obtained by condensation of vanillin, aliphatic aldehyde and ketone in acid and base solvents in an appropriate ratio. The novel gingerol derivative is obtained by catalytic hydrogenation reduction of shogaol. The synthesis process disclosed by the invention is simple, and the gingerol derivative can be obtained through the reaction with one step-two steps and through a simple and convenient purification method.

Owner:朱志成

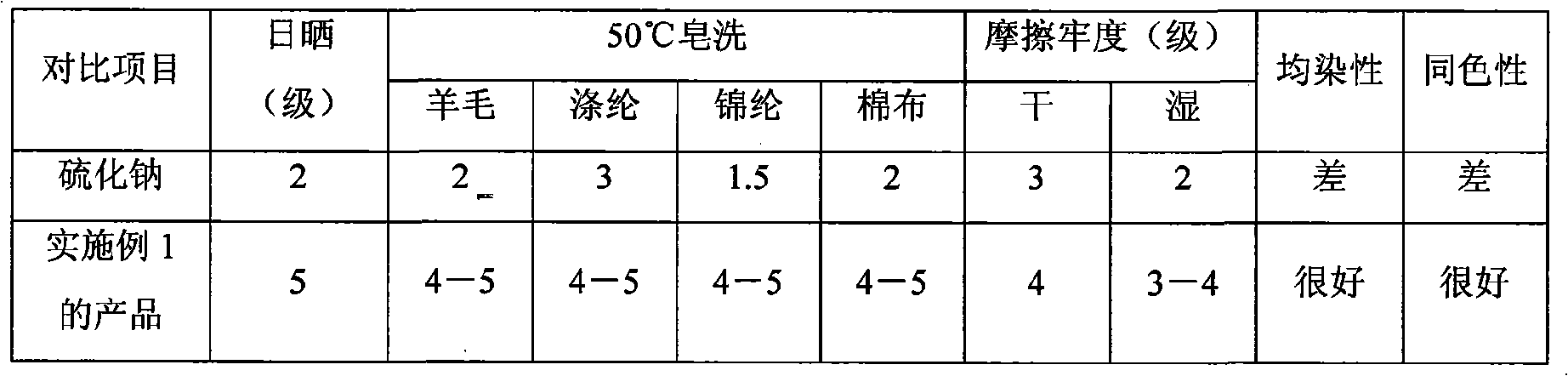

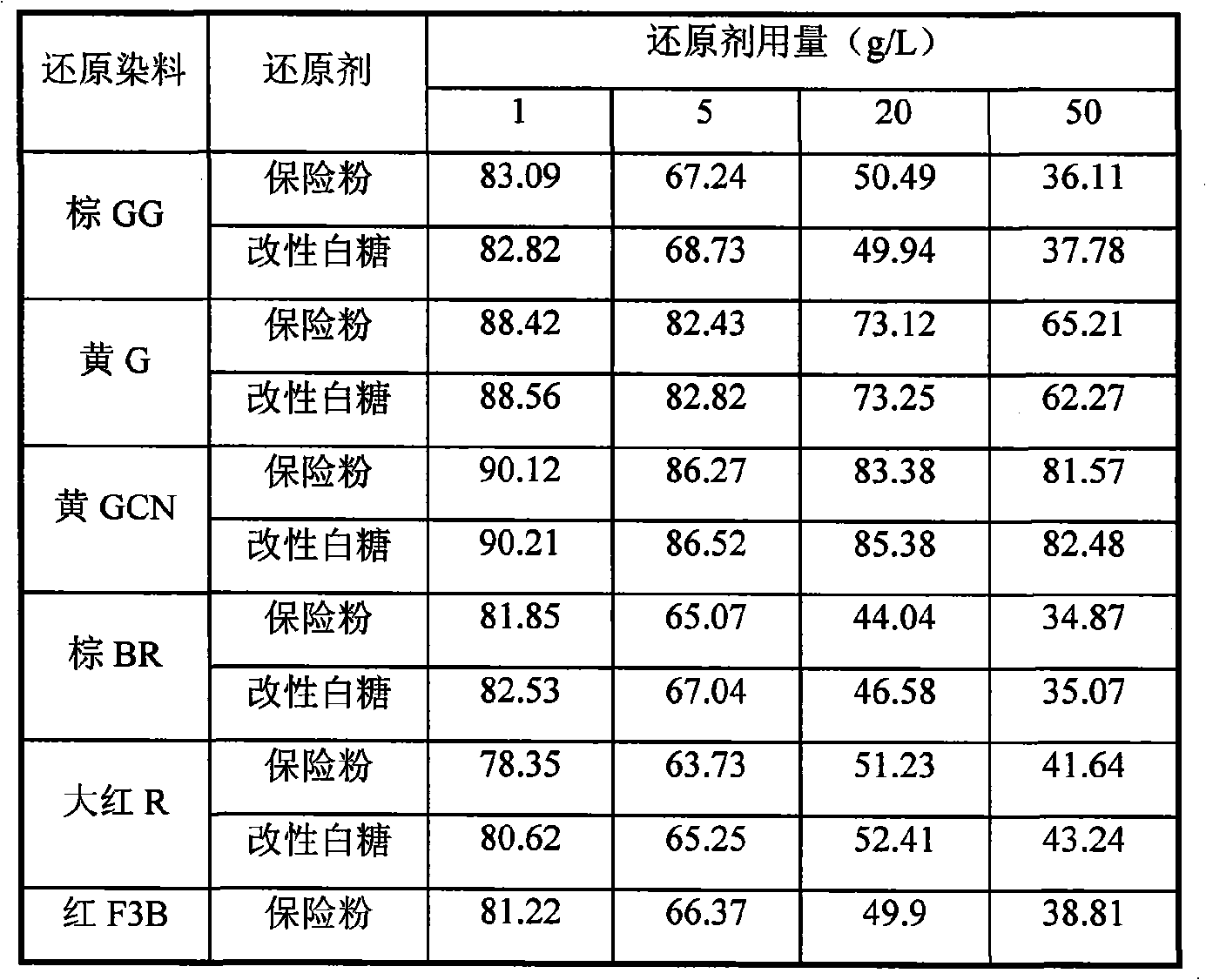

Modified white sugar reducer and preparation method thereof and application thereof in printing and dyeing industry

InactiveCN101575812AGood chemical stabilityReduce manufacturing costDyeing processSulfite saltSuccinic acid

The invention provides a modified white sugar reducer and a preparation method thereof and application thereof in printing and dyeing industry. The preparation method thereof includes the following steps: acetaldehyde (concentration of 40%) is slowly added into a reactor containing white sugar, monosodium orthophosphate and water, the temperature of mixing reaction is controlled to be below 15 DEG C, stirring is carried out at the speed of 75r / min, the temperature of the mixing reaction is heated up to 60 DEG C at the speed of 3 DEG C per minute after fatty aldehyde is added, the mixing reaction is carried out for 65 minutes and then sodium sulfite is added at the temperature of 65 DEG C, the temperature of the mixing reaction is heated up to 120 DEG C at the speed of 2 DEG C per minute after sulfonating agent is added, after the mixing reaction is carried out for 150 minutes the temperature is reduced to 85 DEG C, sodium arabo-ascorbate and succinic acid are added and the mixing reaction is carried out for 45 minutes, and white or straw yellow powdery product is obtained by drying. The product is easy to be dissolved in water, has high chemical durability and low manufacturing cost with environmentally friendly production environment, and has the characteristic of efficient and environmentally friendly application in the printing and dyeing industry.

Owner:FUZHOU UNIV +1

Microorganisms and methods for production of specific length fatty alcohols and related compounds

The invention provides non-naturally occurring microbial organisms containing a fatty alcohol, fatty aldehyde or fatty acid pathway, wherein the microbial organisms selectively produce a fatty alcohol, fatty aldehyde or fatty acid of a specified length. Also provided are non-naturally occurring microbial organisms having a fatty alcohol, fatty aldehyde or fatty acid pathway, wherein the microbial organisms further include an acetyl-CoA pathway. In some aspects, the microbial organisms of the invention have select gene disruptions or enzyme attenuations that increase production of fatty alcohols, fatty aldehydes or fatty acids. The invention additionally provides methods of using the above microbial organisms to produce a fatty alcohol, a fatty aldehyde or a fatty acid.

Owner:GENOMATICA INC

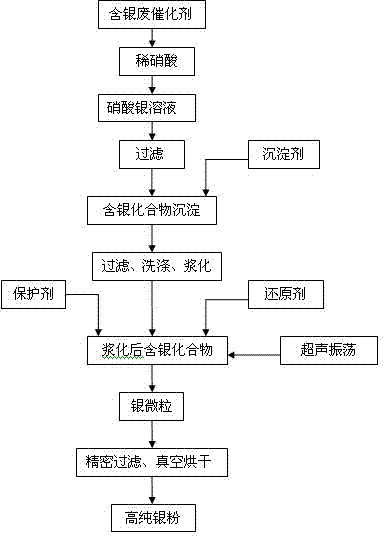

Method for producing high-purity silver powder by using silver-containing dead catalyst

InactiveCN103074500AHas a variety of characteristicsSolve the problem of energy consumptionProcess efficiency improvementDispersityPolyethylene glycol

The invention discloses a method for producing high-purity silver powder by using a silver-containing dead catalyst, and belongs to the technical field of noble metal refining. The method comprises the following steps: the silver-containing dead catalyst is used as a raw material, silver is dissolved and converted to silver nitrate solution by dilute nitric acid; a precipitant is added in the silver nitrate solution after the filtration; a silver-containing compound precipitate is pulped after being filtered and washed; one or two reagents are randomly chosen from hydrazine hydrate, hydrogen peroxide, sodium borohydride, formic acid, ascorbic acid, glucose, fatty aldehyde, fatty amine and formaldehyde as reducing agent; any one reagent is chosen from polyvinylpyrrolidone, cetyl trimethyl ammonium bromide, lauryl sodium sulfate, polyethylene glycol and between as a protective agent; silver ions are reduced to silver particles under the condition of ultrasonic oscillation; and the silver particles are precisely filtered, and are dried in vacuum to obtain the high-purity silver powder product. The method has the benefit that the high-purity silver powder product with high purity, high dispersity and high activity can be obtained, and has the advantages of stable product performance, high recovery rate and environmental friendliness.

Owner:HOOTECH

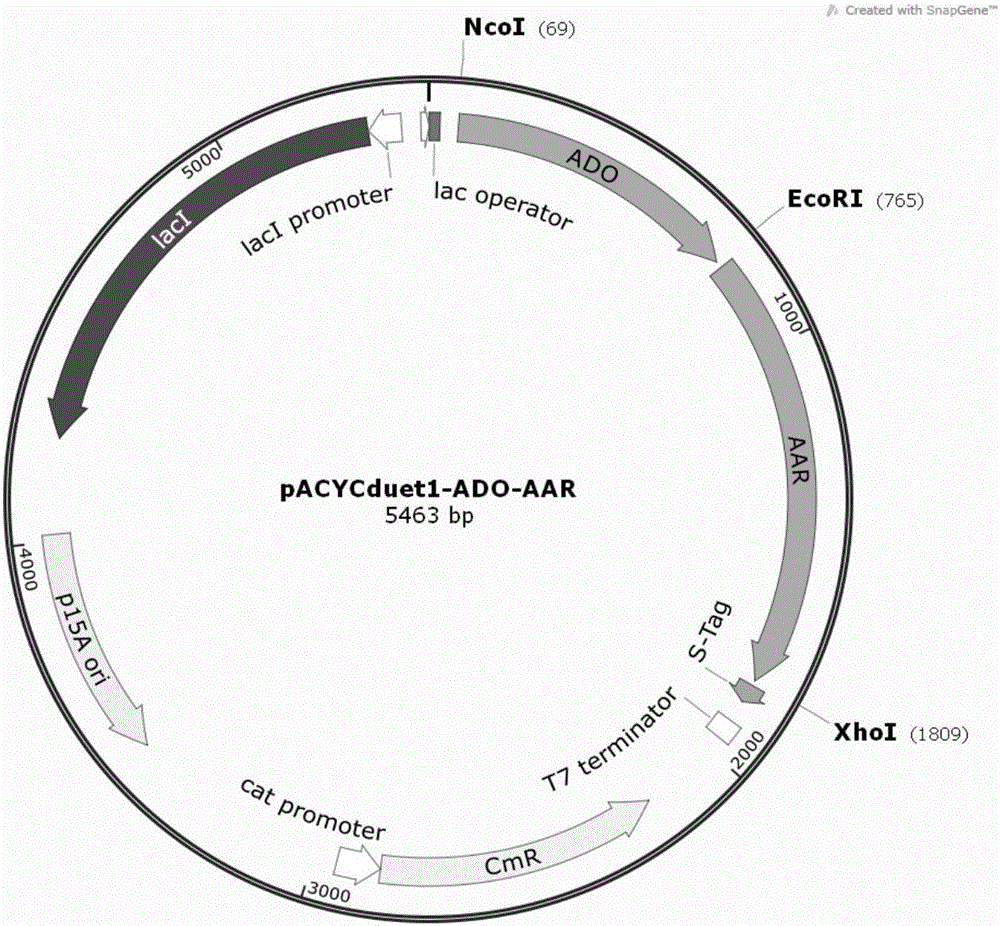

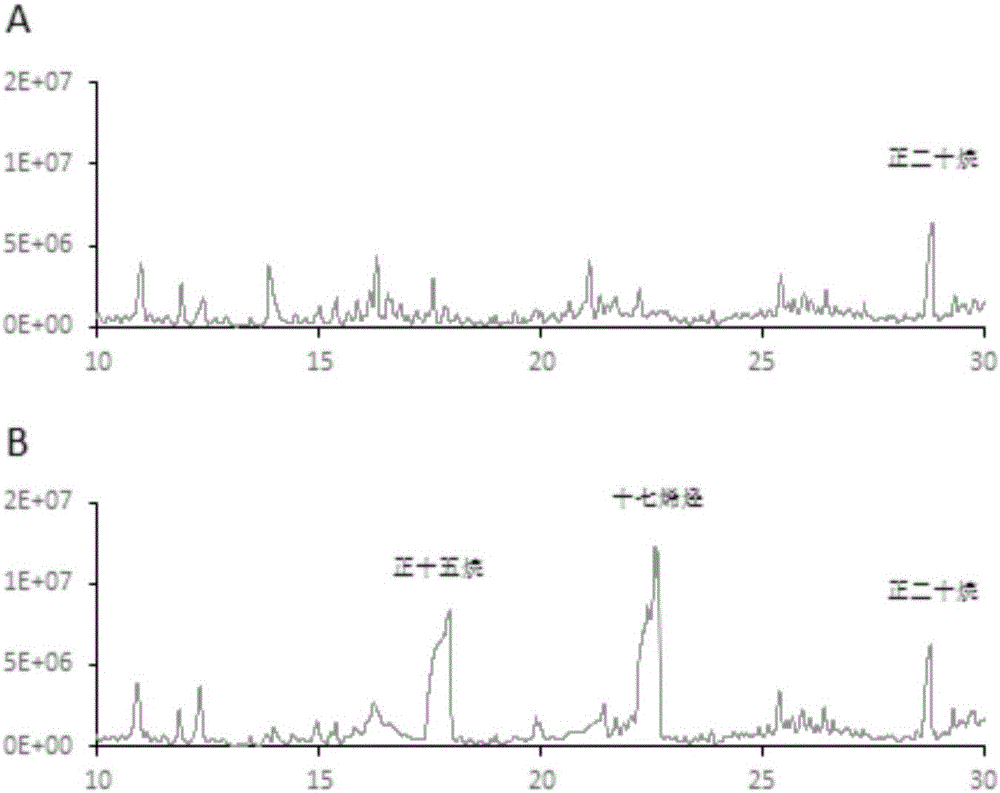

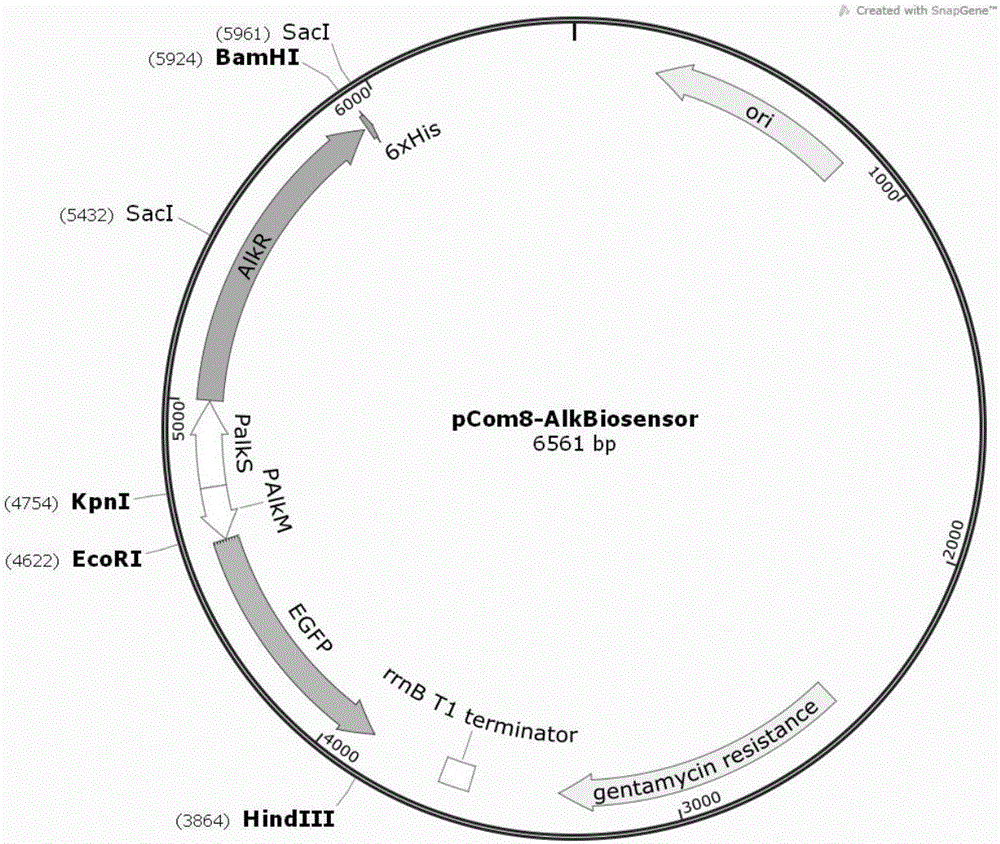

High-flux screening method of aliphatic hydrocarbon generation gene, obtained mutant and application

ActiveCN105802983AHigh synthesis efficiencyStrong hydrocarbon production capacityFungiBacteriaOxygenaseHigh flux

The invention discloses a high-flux screening method of an aliphatic hydrocarbon generation gene, an obtained mutant and application, and belongs to the technical field of biological engineering.By means of the method, a carrier carrying a potential aliphatic hydrocarbon generation gene is introduced into a host cell carrying a detection element, the host cell is cultured, the expression situation of the target gene is authenticated by responding to a signal of the detection element, and the mutant with high aliphatic hydrocarbon yield is separated out.Meanwhile, the invention further provides the aldehyde deformylating oxygenase mutant obtained through the screening method.The aldehyde deformylating oxygenase mutant has higher aliphatic hydrocarbon synthesis efficiency compared with an enzyme wild type.By means of the method, the specific gene or mutant with higher aliphatic hydrocarbon yield can be easily and rapidly screened from candidate genes with potential aliphatic hydrocarbon generation capacity and a mutant library of the candidate genes.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

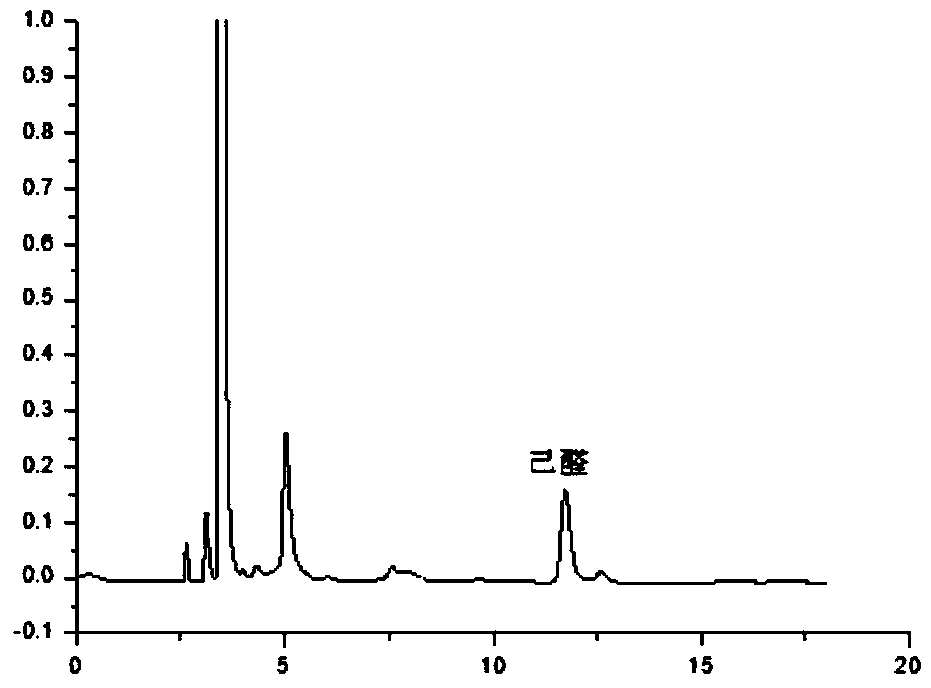

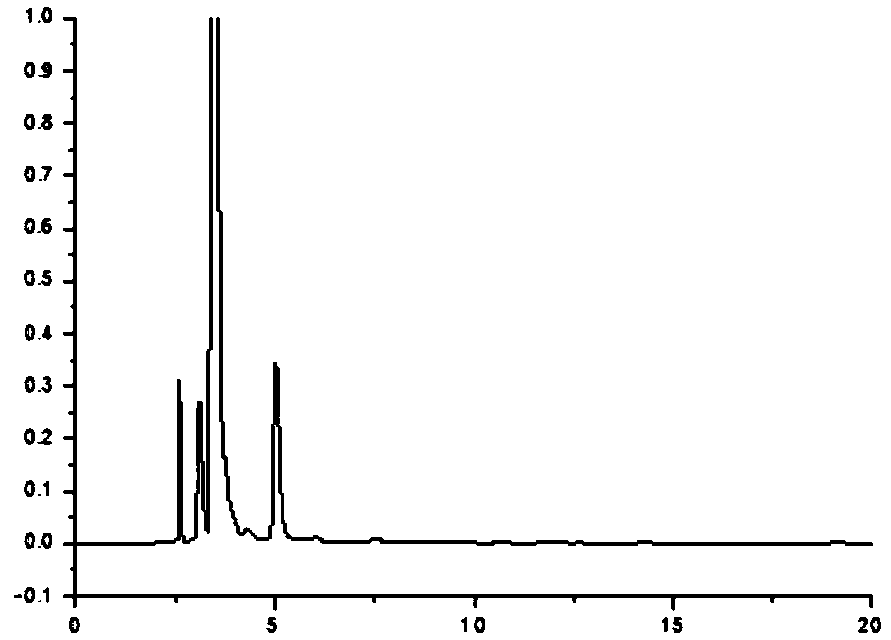

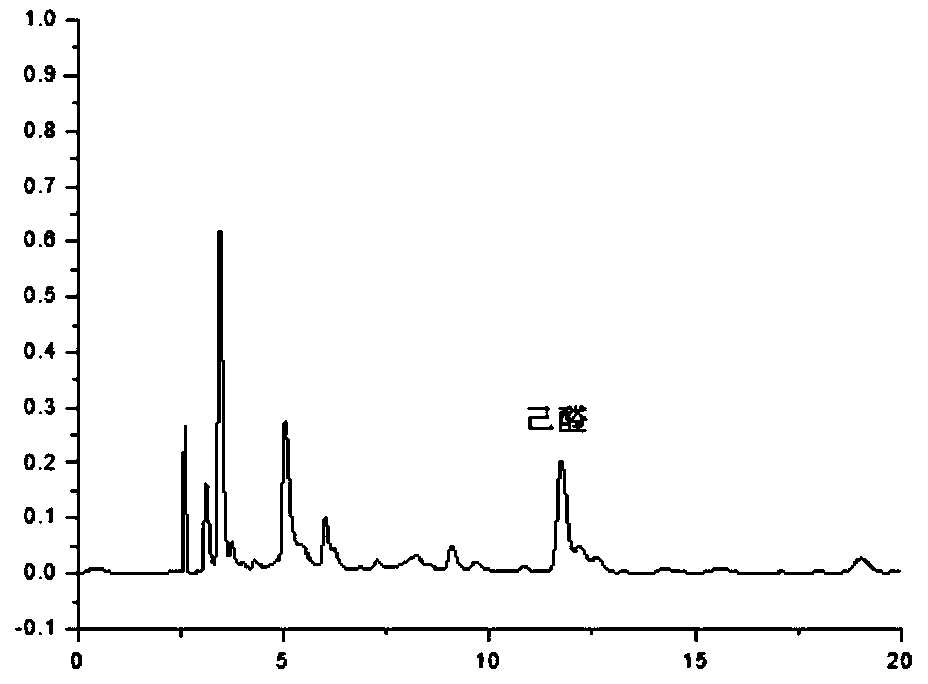

Method for measuring doped gutter oil in edible vegetable oil

The invention relates to a method for measuring doped gutter oil in edible vegetable oil. The method comprises the following steps of (1) deriving of a vegetable oil sample: deriving the vegetable oilsample by a 2,4-dinitrophenylhydrazine deriving solution; (2) drawing of an external standard working curve; (3) detection of the sample. The invention also relates to application of a reaction product (aldehyde phenylhydrazone) of fatty aldehyde and 2,4-dinitrophenylhydrazine to detect the doped gutter oil in the edible vegetable oil.

Owner:XINJIANG UYGUR AUTONOMOUS REGION PROD QUALITY SUPERVISION & INSPECTION RES INST

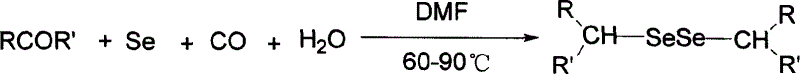

Method of preparing alkyl diselenide

The invention provides a process for preparing alkyl diselenide, which comprises venting and bubbling CO, using fat aldehydes or fat ketones, selenium and water as raw material, and preparing alkyl diselenide through one-step reaction. The invention has the advantages of mild reaction condition, simple operation, no by-product, no need of any adjuvant.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Manufacturing method for high-strength calfskin for special purpose

ActiveCN105154594AHigh fullnessGood flexibilityTanning treatmentPre-tanning chemical treatmentTanninAldehyde formation

The invention provides a manufacturing method for high-strength calfskin for a special purpose. Calf wet blue which is evenly shaved through a conventional process is used as a raw material, the raw material is weighed, returned to water, degreased, retanned, neutralized, filled with grease and top-dyed, and then the raw material is sorted and coated according to the conventional process. In the retanning working procedure, tannin extract is used and combined with phthalidyl / peptide bonds on a polypeptide chain of skin collagen through hydrogen bonds, and therefore raw hide is changed into leather; fatty aldehyde is added in the retanning working procedure, carbonyl in the fatty aldehyde reacts with amidogen in skin collagen fiber, the skin collagen fiber is further fixed, and the defects existing in tannin extract tanning are overcome; and non-chrome retanning is performed, the fatty aldehyde is used for replacing a chrome tanning agent, and therefore chrome pollution is greatly reduced. The fatty aldehyde is added in the greasing working procedure, so that the fullness and the softness of the leather are improved, the alkali resistance and the laundering durability of the leather are improved, and the shrinkage temperature of the leather is increased. The tensile strength of the calfskin manufactured through the method is 19 N / mm<2> and the tearing strength is increased to 72 N / mm and the tensile strength and the tearing strength of the calfskin are increased by 26.7% and 10.77% compared with those of calfskin produced through an existing process.

Owner:JIHUA 3512 LEATHER & GARMENT

Environment-friendly efficient ferrous sulfide passivant and preparation method thereof

ActiveCN106221806APollutionStrong scale resistanceTreatment apparatus corrosion/fouling inhibitionSpontaneous combustionManganese

The invention relates to an environment-friendly efficient ferrous sulfide passivant and a preparation method thereof. The passivant comprises the following components in parts by weight: 4 parts of fatty aldehyde, 3.5 parts of disodium edetate dehydrate, 1.3 parts of sodium carbonate, 3.5 parts of amine oxide, 1.6 parts of fatty alcohol polyoxyethylene ether sodium sulphate, 1.4 parts of sodium dodecyl benzene sulfonate, 1.5 parts of an edible essence, 2.6 parts of an itaconic acid copolymer, 1.6 parts of polyquaternium, 1.4 parts of a corrosion inhibitor and 83 parts of water. The environment-friendly efficient ferrous sulfide passivant has relatively high and thorough ferrous sulfide removal efficiency and is capable of simultaneously removing malignant stinks such as hydrogen sulfide and ammonia nitrogen; besides, the passivant does not contain chloride ion, heavy metal ions such as manganese and chromium and other toxic and harmful components, has strong biodegradability and does not pollute the environment, and toxic and harmful gases such as hydrogen sulfide are not produced during the construction, so that the personal injury and the environmental pollution are avoided, the damage of equipment is avoided, the spontaneous combustion of ferrous sulfide can be effectively prevented, and hydrogen sulfide can be eliminated.

Owner:南京南炼宏泰技术开发有限公司

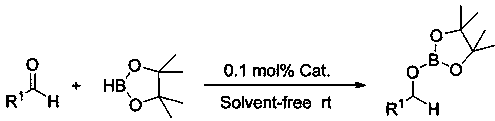

Application of n-butyllithium in catalyzing hydroboration of aldehyde and borane

InactiveCN108404984AReduce electropositivityWeakened nucleophilic addition activityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsN-ButyllithiumOxygen

The invention discloses application of n-butyllithium in catalyzing hydroboration of aldehyde and borane, a method of hydroboration comprises the following steps of in a water-free and oxygen-free environment, under the inert gas atmosphere, adding borane into a reaction bulb subjected to dehydration and deoxidization treatment, then adding a catalyst n-butyllithium, uniformly mixing, then addingaldehyde to perform hydroboration. Exposing to the air to stop the reaction after the reaction is finished, so as to obtain a product. The catalyst disclosed by the invention has better universality to aromatic aldehyde with different replace positions and different electronic effects as well as to heterocyclic aldehydes and fatty aldehyde, and more choice can be provided for obtaining boric acidester compounds with different substituent group structures.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com