Patents

Literature

60results about How to "Less drug consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flocculating agent for waste water treatment, and preparation method thereof

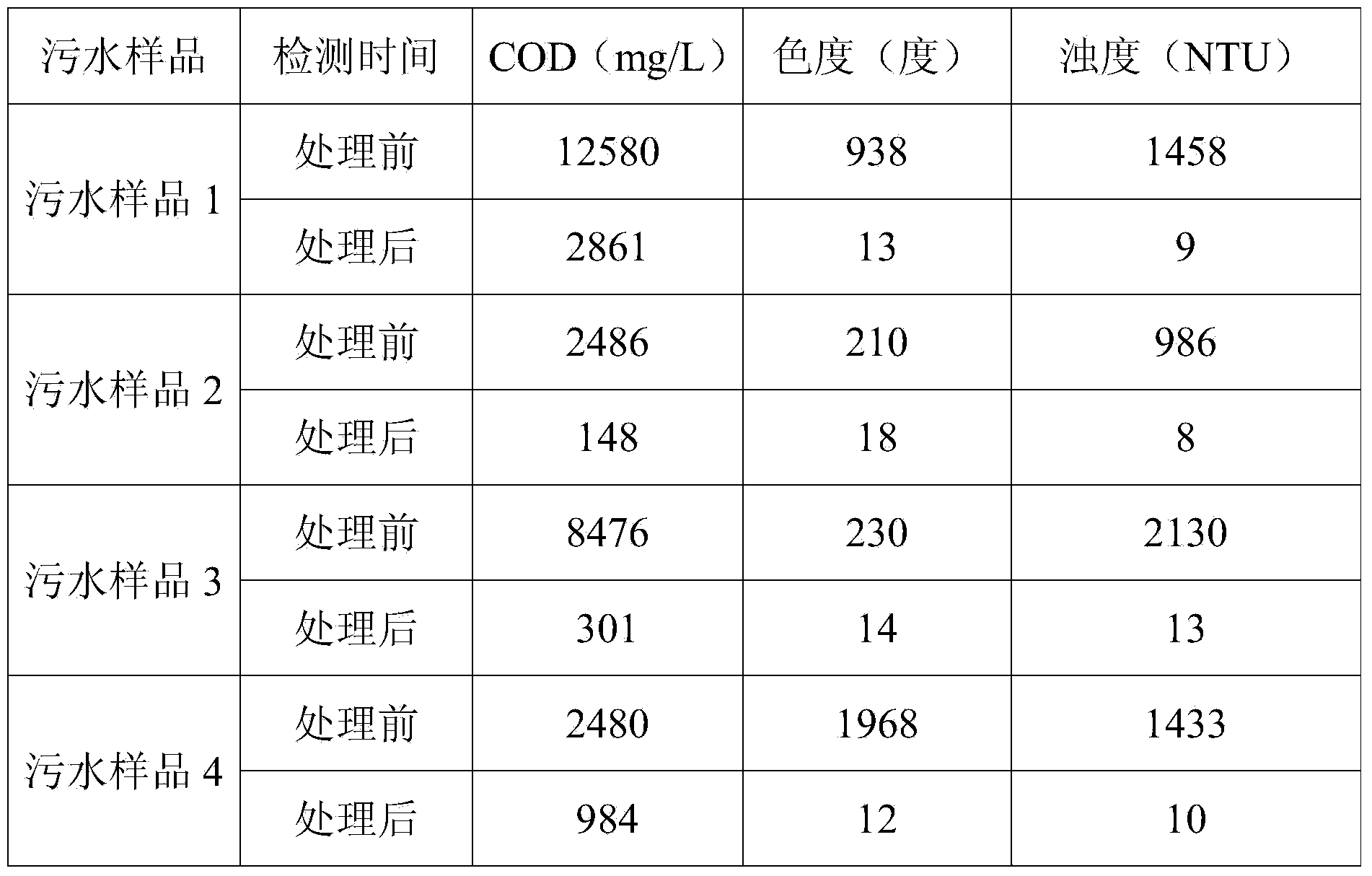

InactiveCN104071881AReduce CODReduce chromaWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAluminum IonTurbidity

The invention discloses a flocculating agent for waste water treatment. The flocculating agent comprises components of calcium sulfate, aluminum ion salt, sodium carbonate, polyacrylamide, sodium thiosulfate, chitosan, chitosan quaternary ammonium salt, diatomite, cement and a pH adjusting agent, can be used for treating waste water discharged from food processing plants, metal manufacturing plants, chemical plants and the like, can also be used for treating waste water discharged from farms and slaughter plants, can also be used for purification of water quality in river channels and lakes, and can effectively reduce COD, color and turbidity of waste water.

Owner:廉勇

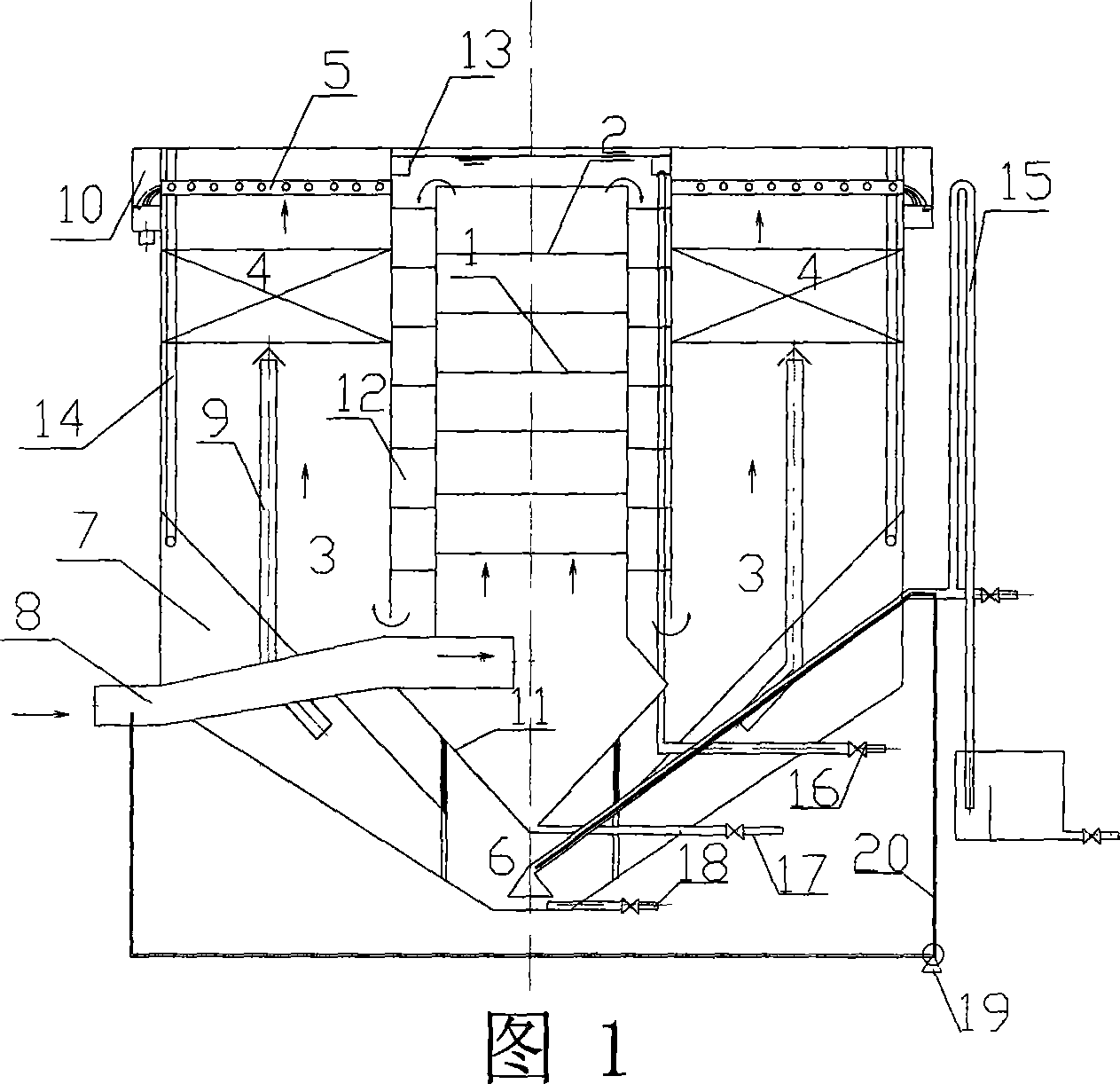

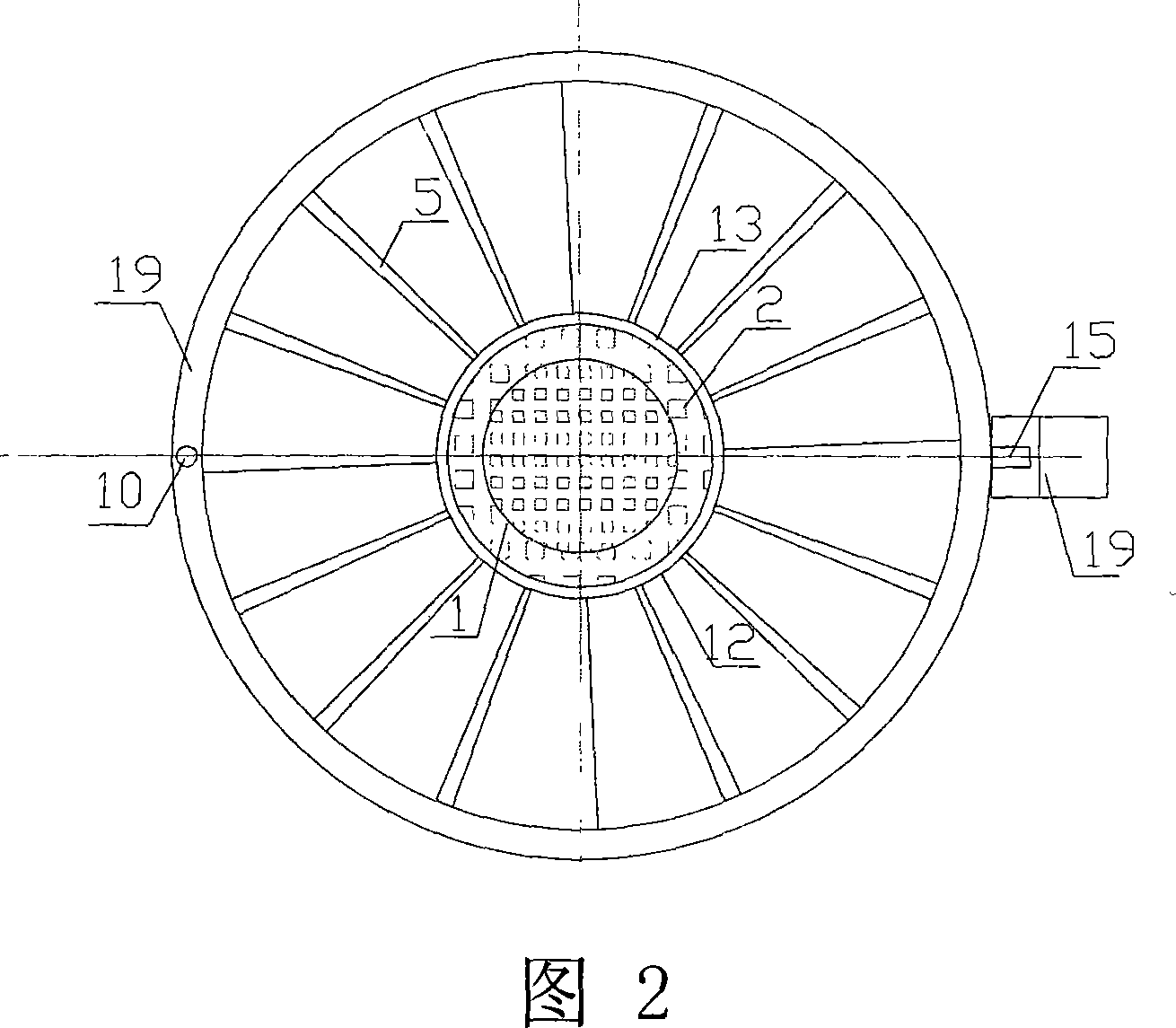

Apparatus and process for clarifying water efficiently

The invention is concerned with a kind of high efficiency water treatment equipment and technology belonging to water treatment field. The middle parts of the equipment are two flocculating rooms having mesh setting with disturbing flow, and the bottom of the flocculating room is precipitation tank. The suspending layer of active mud residue is out of the flocculating room and there is slanting pipe on top of it and concentrate room under it. The pipe excluding residue sets in the suspending layer of active mud residue, and the bottom of clean tank is filler to exclude residue, and there is siphon pipe connecting with the filler. There are grooves excluding residue at top of the flocculating room connecting with the pipe excluding residue and the siphon pipe connects with the residue reuse tank. The filler to exclude residue connects with a pump of reused residue. The equipment gathers the small air flotation, flocculating, active mud residue layer flocculating, and reused technology. Compared with traditional mixed and coagulate deposition technology, it saves 40 percent of field, reduces 10 percent of drug and enhances 15 percent disposal efficiency.

Owner:FUDAN UNIV +1

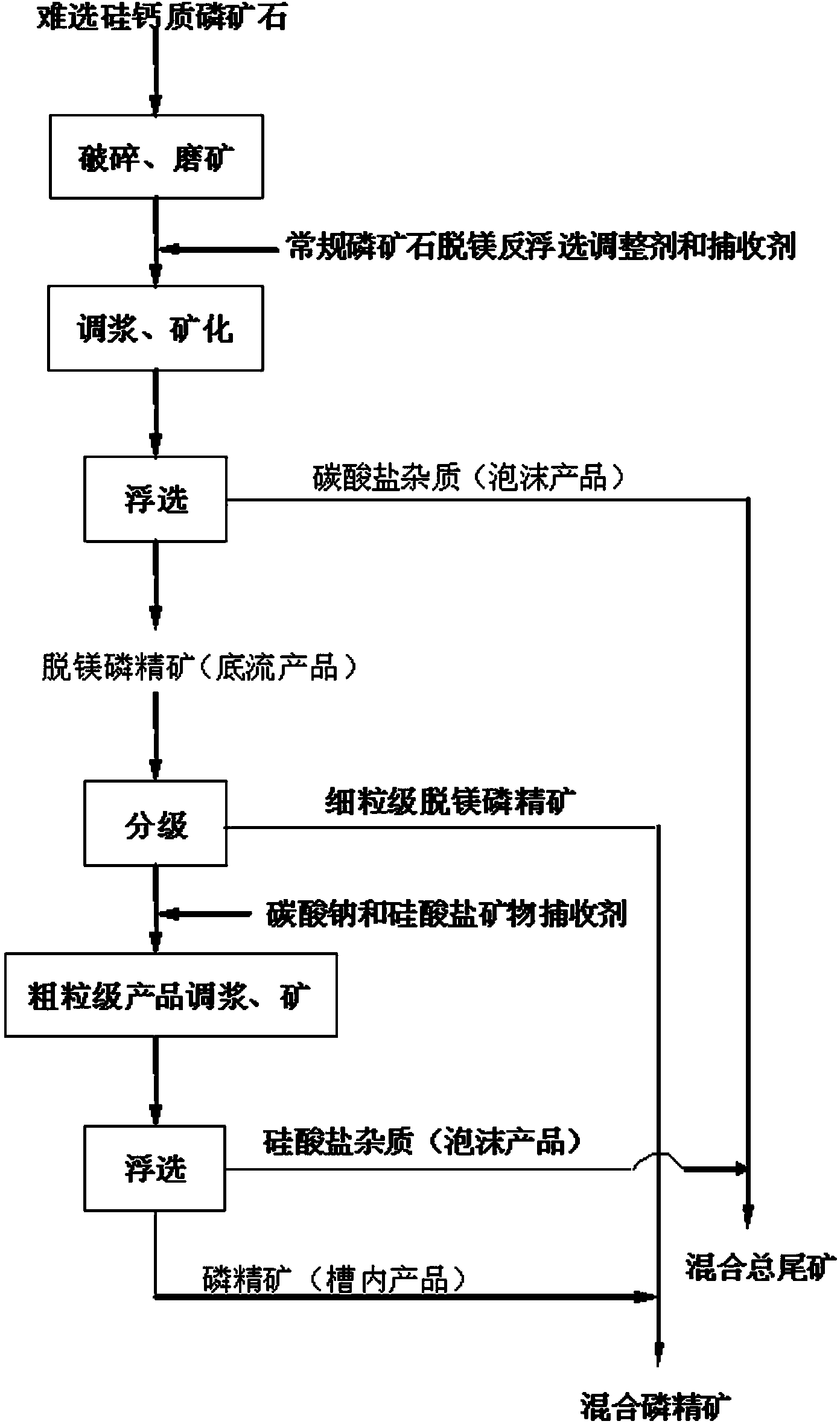

Double-medium decoupling fracture damage blasting control method and auget

InactiveCN101363701AHighlight substantive featuresHigh static pressure resultant forceBlasting cartridgesBlastingEngineeringExplosive power

The invention relates to a method for controlling blasting by double-medium decoupling fracture and damage and a blasting cartridge thereof. The method adopts cylindrical explosive, detonator or primacord to explode a hole on a blasted rock body. The method is characterized in that water and air are simultaneously used in the hole to separate explosive, wherein, the water medium is aligned to the side of a free surface, while the air medium is aligned to the side of a reserved surface; the uniform distributing state of explosive energy can be changed by using the characteristics that the two media have different efficiencies of transmitting energy, thereby achieving the function of completely destroying one side and protecting the reserved surface during blasting, and forming a flat fracture surface. The blasting cartridge consists of an outer tube, an inner tube and a separating wall, wherein, the separating wall separates a cavity formed between the outer tube and the inner tube into a medium chamber for containing the water medium and a medium chamber for containing the air medium; and an explosive chamber for placing the cylindrical explosive is arranged in the inner tube. The invention has the advantages of easily operating, improving explosive power and agglomerating rate, protecting stability of wall rock, reducing harm of dust and noise, and the like, and can be widely applied to smooth blasting projects such as tunnels, side slopes, water conservancies, mining, and the like.

Owner:TAIYUAN UNIV OF TECH

Organic polymer flocculant and its prepn. and application in water treatment

InactiveCN1336391ALess drug consumptionGood processing effectWater/sewage treatment by flocculation/precipitationWater chlorinationPhosphorus trichloride

The present invention relates to preparation of organic polymer coagulant and its application in water treatment. Said method incldues condensation polymerization, inorganic ammonium salt is dissolved in a reactor containing aliphatic aldehyde and water, reaction temp. is 60-95 deg.C, reaction time is controlled at 0.5-3 hr., proceed hydrolysis and esterification, reduce the temp. of reaction liquid to 20-70 deg.C., and phosphorus trichloride, raise temp. to 90-120 deg.C, react for 2-9 hr., then reduce temp. of 45-85 deg.C, and additive, continue reaction 1-3 hr. cool to room temp. to obtain product. The invented product is ideal in waste water treatment, good in stability, non-toxic etc..

Owner:FUZHOU UNIV

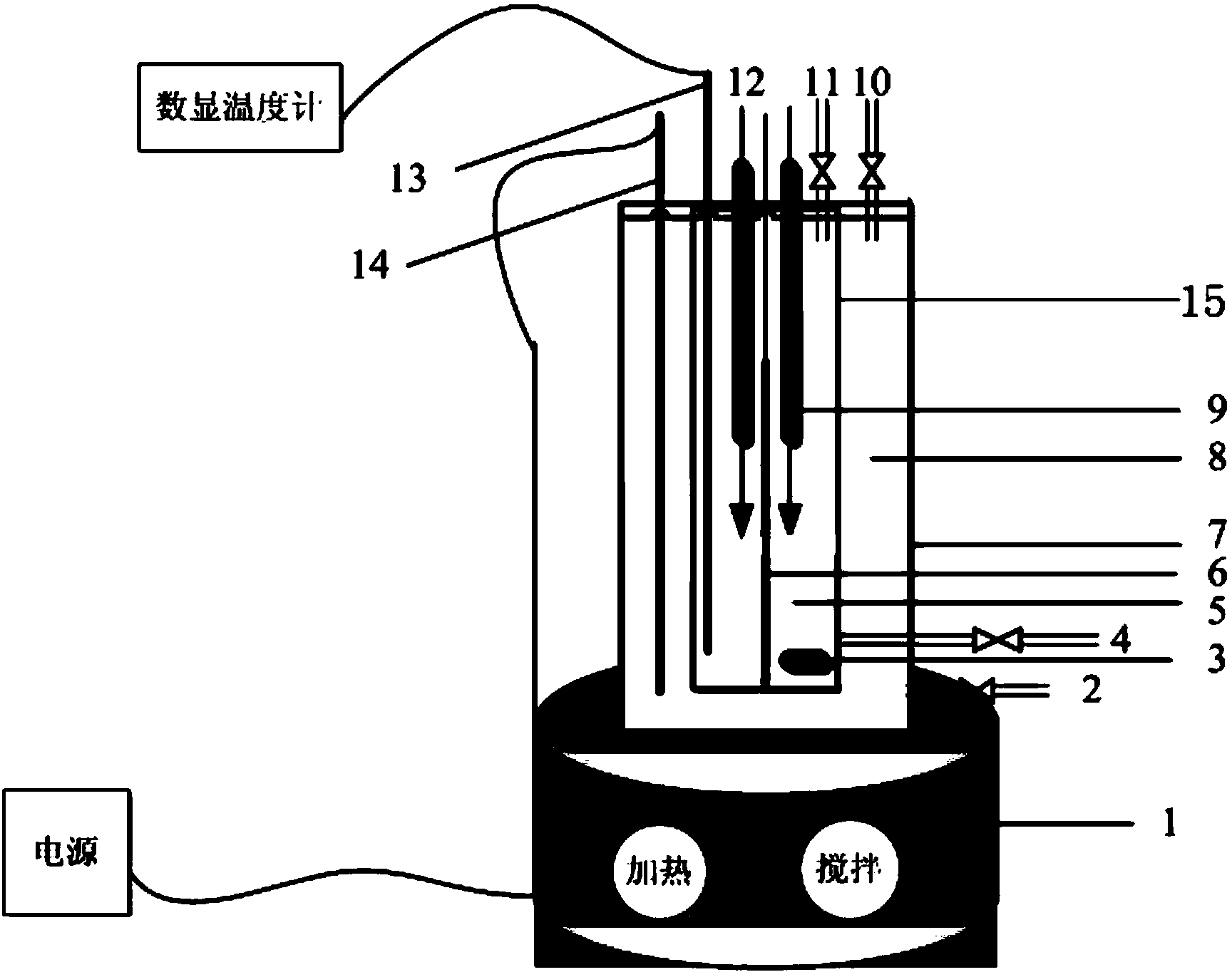

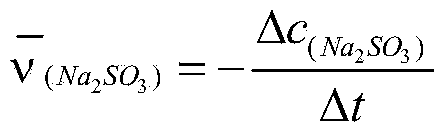

Experimental device for measuring chemical reaction rate and activation energy

InactiveCN103926378AEasy to useReduce usageEducational modelsMaterial analysisWater bathsChemical reaction

The invention discloses an experimental device for measuring chemical reaction rate and activation energy. The experimental device comprises a reaction container with a cover plate, wherein the reaction container is positioned on a magnetic stirrer; a reaction tube with a bottom is arranged in the reaction container; the upper end of the reaction tube is arranged on the cover plate, and the bottom of the reaction tube is suspended; a lifting movable separator is arranged in the reaction tube, so that the reaction tube is divided into a left reaction area and a right reaction area; a water bath area is formed in an area between the reaction container and the reaction tube; a water bath area water outlet is formed in the lower part of the water bath area; a reaction area water outlet is formed in the lower part of the reaction tube; two charging openings which correspond to the two reaction areas, a gas collection port which corresponds to any reaction area, and a water bath area water inlet are respectively formed in the cover plate; chargers are respectively arranged on the two charging openings; the gas collection port is connected with a gas collection device. The experimental device can accurately measure the chemical reaction rate and activation energy and is low in medicine consumption, simple in structure, convenient to operate and low in manufacturing cost.

Owner:CHONGQING UNIV

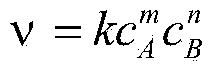

Floatation method for silica-calcium collophane with difficult separation

The invention discloses a floatation method for a silica-calcium collophane with difficult separation. According to the detailed technology, the floatation method includes the steps that (1) breaking and grinding are performed on the silica-calcium collophane; (2), a sulfate mineral negative ion collecting agent, a phosphate mineral negative ion collecting agent and a carbonate mineral negative ion collecting agent are respectively added into ore pulp for mixing and mineralizing, and air inflation is performed for reverse floatation; (3), magnesium removal phosphate ore concentrate is graded; (4), the ore pulp concentration of a coarsely graded phosphate ore concentrate is controlled, then sodium carbonate mineral positive ions and silicate mineral positive ions are respectively added for pulp mixing and mineralizing, and air inflation is performed for reverse floatation; (5), a finely graded phosphate ore concentrate and a desilication phosphate ore concentrate are mixed, and carbonate impurities and silicate impurities are mixed. The problems that because the carbonate impurities are removed only through single reverse floatation, the phosphate ore concentrate is not high in content and high in silicate impurity content, the requirement for the phosphate ore concentrate used for wet-process phosphoric acid can not be met, and then in the process that the silicate impurities are removed through reverse floatation, floatation froth is sticky, not prone to breaking and poor in ore pulp flowability due to the existence of a great deal of slurry are solved, and the floatation method is adaptive to the silica-calcium collophane and efficient in impurity removal.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Tunnel excavation water pressure blasting construction method

The invention discloses a tunnel excavation water pressure blasting construction method. The method comprises following steps that firstly, according to the surrounding rock classification, the drilling depth is determined, a cutting hole is drilled in the center of the excavation face, an auxiliary hole is drilled outwards in the excavation face along the cutting hole, a bottom side hole is drilled in the bottom of the excavation face, and periphery holes are drilled in the periphery of the excavation face; secondly, the interiors of the drilled holes are cleaned; thirdly, explosives, water bags and stemming are arranged in the drilled holes; and fourthly, a detonating tube or detonating cord is ignited for blasting. According to the method, the water bag is added, during blasting, the water wedge effect is generated, the energy use rate is improved, surrounding rock breaking is facilitated, and the explosive consumption amount is reduced; after blasting, water in blat holes can carryout atomizing so as to achieve dust falling, the ventilation dust falling time after blasting can be shortened, and the one-time excavation depth is improved.

Owner:中建桥梁有限公司 +1

Little-chlorine and little-pollution bleaching process for paper pulp biomimetic pretreatment

The invention relates to a little-chlorine and little-pollution bleaching process for paper pulp biomimetic pretreatment, in particular to a little-chlorine element chlorine-free bleaching (ECF) process for the paper pulp biomimetic pretreatment. The process is a novel little-pollution bleaching technology in the paper pulp biomimetic pretreatment and belongs to the technical field of paper making. The process mainly comprises the following steps of: (1) carrying out metal salen biomimetic pretreatment to paper pulp bleaching, wherein metal salen, pyridine, H2O2 and O2 are used for carrying out bleaching pretreatment to oxygen-removal kraft pulp in alkaline condition; and (2) carrying out subsequent little-chlorine and little-pollution bleaching, wherein paper pulp after the biomimetic pretreatment undergoes three-section bleaching treatment, i.e., a chlorine dioxide bleaching section, a chelation treating section and a hydrogen peroxide bleaching section. The process is simple and easy to implement, has remarkable effect and can improve the whiteness and the property of the paper pulp. Compared with the conventional little-chlorine bleaching procedures, the bleaching process uses less chlorine. Compared with the conventional CEH bleaching, the bleaching process can reduce the time for pulping.

Owner:KUNMING UNIV OF SCI & TECH

Waste water treatment, recovery and utilization for power plant

InactiveCN1778700AExtend your lifeSimple processWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by neutralisationWater qualityFresh water

A waste-water treatment and recovery for power plant is carried out by classification treating for waste water, gathering it into water-collecting pool, adding into medicine, adjusting pH value, entering the waste water into micro-filter membrane filtering system from micro-coagulator, flowing micro-filtered water into medium water tank, delivering it into safety filter by lifting pump, inverse penetration treating by high-pressure pump, flowing concentrated water into chemical neutralization pool and flowing fresh water into recovering pipe net of factory. Its advantages include low cost, better water quality, safety and stability and high recovery efficiency.

Owner:张宝泉 +2

Traditional Chinese medicine preparation for treating scanty menstruation

InactiveCN104383433ALow costLess menstruationUnknown materialsSexual disorderSide effectLicorice roots

The invention discloses a traditional Chinese medicine preparation for treating scanty menstruation. The traditional Chinese medicine preparation is prepared from the following traditional Chinese raw medicines by weight: 10g of semen cuscutae, 11g of herba cistanche, 12g of the fruit of Chinese wolfberry, 14g of glossy privet fruit, 14g of the bark of eucommia, 12g of angelica sinensis, 13g of root of common peony, 14g of radix paeoniae alba, 10g of fructus aurantii, 14g of rhizoma cyperi, 16g of rhizoma corydalis, 14g of radix curcumae, 15g of trogopterus dung, 9g of dandelion, 10g of honey-fried licorice root, 12g of ligusticum wallichii, 14g of cattail pollen, 7g of rhizoma atractylodis, 12g of yam, 11g of polygonum multiflorum, 12g of tuber fleeceflower stem, 10g of astragalus membranaceus, 9g of rhizoma cyperi, 11g of dogwood, 12g of licorice root, 12g of radix bupleuri, 14g of codonopsis pilosula, 16g of prepared rhizome of rehmannia, 15g of caulis spatholobi, 9g of poria cocos, 8g of flowers carthami, 6g of dogwood and 7g of cassia twig. The traditional Chinese medicine preparation is remarkable in curative effect, low in medicine cost, short in treatment cycle, low in amount of used medicines and free of any side effects.

Owner:宿州学院

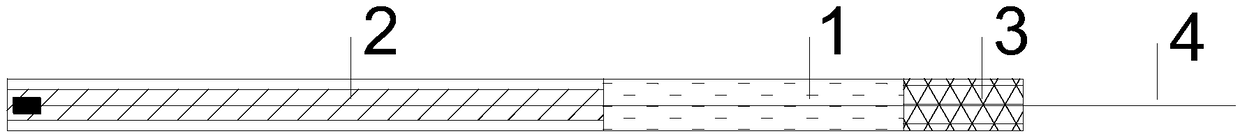

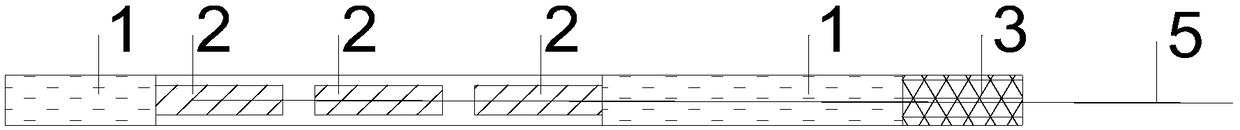

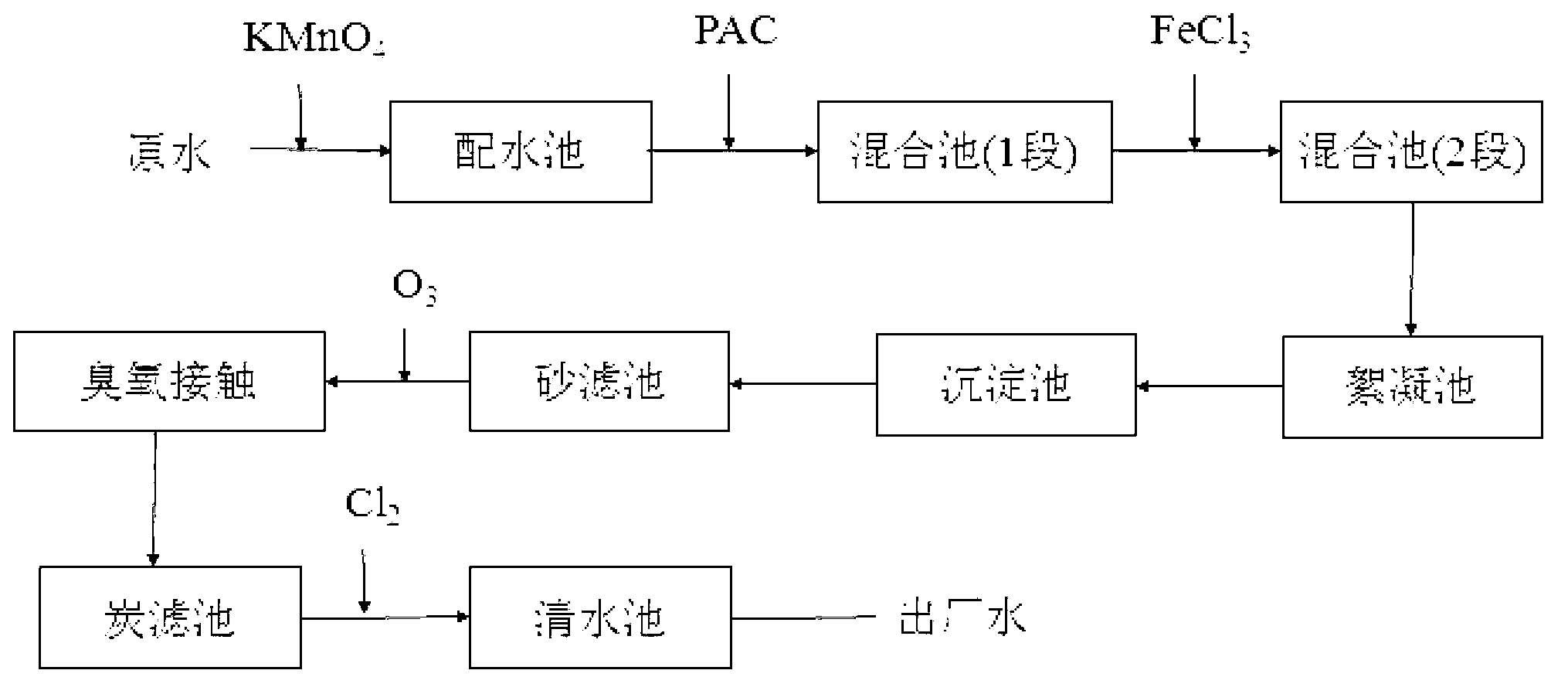

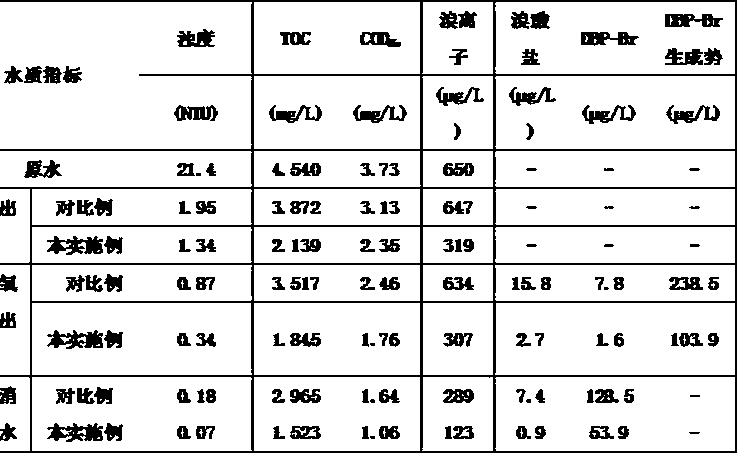

Method for removing bromide ion out of bromide ion-containing drinking water

ActiveCN103214119AGood removal effectImprove adsorption capacityWater contaminantsMultistage water/sewage treatmentBiological activated carbonDisinfection by-product

The invention relates to a method for removing bromide ions out of bromide ion-containing drinking water. The method is characterized by comprises the following steps of: before the bromide ion-containing drinking water is treated by using an ozone-biologic activated carbon process, adding 0.5-1mg / L potassium permanganate into raw water, preoxidizing for 3-5 minutes, and then sequentially adding 12-18mg / L polymeric aluminum by Al and 8-12mg / L ferric trichloride by Fe for coagulating, wherein the mass concentration ratio of polymeric aluminum to ferric trichloride is 3:2. The method is simple to operate and safe and reliable, the bromide ion content (100-100mu g / L) of the raw water is reduced by 45-70%, and the purpose of controlling the bromine disinfection by-product generation in the later ozonation bromate and disinfection period is reached; therefore, the method has wide application prospects.

Owner:常州通用自来水有限公司

Special corrosion and scale inhibitor for surface evaporation air cooling

InactiveCN1459424AExcellent corrosion and scale inhibitionLittle effect of turbidityScale removal and water softeningTurbidityWater quality

A retarding-corrosion antiscaling compound for the surface-evaporating air cooler used in high-hardness and high-basicity circulating water system is prepared from zinc sulfate 15-25 wt. portions, acrylic acid-acrylate copolymer 30-36 portions, hydroxy-1-1-ethylene diphosphonic acid 34-46 portions, and benzotriazole 4-6 portions. It still exhibits good performance under the condition of relatively bad quality of circulating water. Its advantages are its effect little affected by turbidity, adapting to wide pH range, high effect, and low dosage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Coagulant for industrial wastewater treatment and manufacturing method thereof

InactiveCN106477699AChemically stableGood value for moneyWater/sewage treatment by flocculation/precipitationPhosphoric acidPolyacrylamide

The invention discloses coagulant for industrial wastewater treatment and a manufacturing method thereof. The coagulant for industrial wastewater treatment is prepared from, by weight, aluminum hydroxide, ferric hydroxide, ferric sulfate, magnesium sulfate, calcium sulfate, poly dimethyl diallyl ammonium chloride, hydrochloric acid, phosphoric acid, polymethylacrylamide, polyethylacrylamide, cationic-type polyacrylamide, starch, sodium carboxymethylcellulose, modified activated carbon and water. The coagulant has the advantages of being efficient, rapid in precipitation, high in adaptability, convenient to operate, low in consumption and the like; raw materials are easy to obtain, the cost performance is high, the coagulant can be industrially produced in a large scale, has the strong condensation effect, and is wide in application range and capable of treating raw water and industrial wastewater of various types; the water treated by the coagulant is stable in chemical property, and normal use is not affected.

Owner:张伟荃

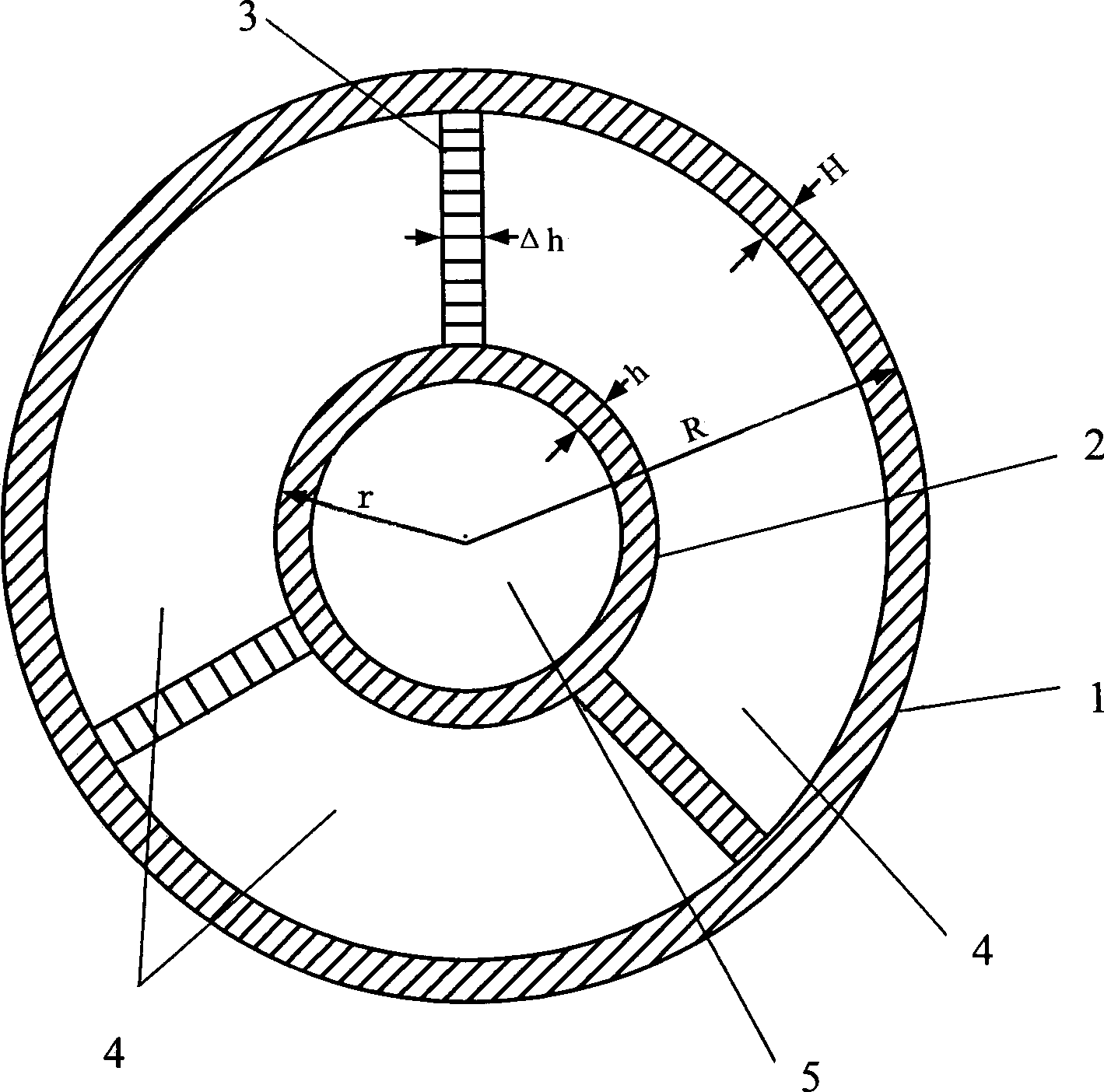

Pneumatic flotation machine with mechanical stirring

The invention discloses a pneumatic flotation machine with mechanical stirring, which comprises a cylindrical tank body flotation chamber, wherein a foam product collecting chute is closely fastened on the outer side of the upper end of the flotation chamber, and the outer side of the foam product collecting chute is connected with a concentrate pipe; a hollow shaft connected with a driving device is arranged in the flotation chamber, and the hollow shaft is fixed on the support through a bearing and bearing blocks, a bearing housing is arranged between the bearing blocks, an air inlet formedon the bearing housing is connected with an air inlet pipe, and an air inlet is formed on a hollow shaft corresponding to the bearing housing; the lower end of the hollow shaft is connected with a rotor which has an air outlet, and a stator is arranged on the outer side of the rotor; a feed tank is hoisted on the upper part of the flotation chamber, the feed tank is a tank body with an annular cavity, the annular tank body surrounds the outside of the hollow shaft, a feed inlet is formed on the upper part of the feed tank, and discharging nozzles are uniformly arranged on the lower part of the feed tank; and a tailing chamber is formed at the bottom part of the flotation chamber, and the tailing chamber is communicated with a tailing tank through a pipe. The machine is efficient, energy-saving and very adaptable and is long in service life and low in production cost.

Owner:张玮

Traditional Chinese medicine mixture for treating arrhythmia

InactiveCN103961677ALow costEasy to useInanimate material medical ingredientsCardiovascular disorderMonkshoodsSide effect

The invention discloses a traditional Chinese medicine mixture for treating arrhythmia. The traditional Chinese medicine mixture for treating arrhythmia is characterized by being prepared ftrom the following traditional Chinese medicine raw materials in parts by weight: 30 parts of cinnamon, 12 parts of cassia twig, 30 parts of oyster, 10 parts of radix paeoniae rubra, 30 parts of astragalus membranaceus, 20 parts of jujube, 30 parts of fossil fragments, 6 parts of ginger, 15 parts of monkshood, 6 parts of liquorice, 20 parts of poria cocos and 18 parts of rhizoma pinelliae preparata. The traditional Chinese medicine mixture for treating arrhythmia has the advantages of quick drug release, quick effect, less toxic and side effects, convenience in taking and the like.

Owner:蚌埠易益商贸有限公司

Traditional Chinese medicine pill for tonifying kidney, invigorating blood circulation and stimulating menstrual flow

InactiveCN101757259ALow costEasy to useAnthropod material medical ingredientsSexual disorderSide effectCurative effect

The invention relates to a traditional Chinese medicine pill for tonifying kidney, invigorating blood circulation and stimulating menstrual flow which is a Chinese patent drug for curing amenorrhea, deficiency of the kidney and blood stagnation by using Chinese herbal medicine as the raw materials. The raw materials comprise dogwood, polygonum, prepared rehmannia root, medlar, Chinese dodder seed, black ants, teasel root, Angelica, Caulis Spatholobi, medicinal cyathula, Ligusticum wallichii, Eupolyphaga, herba lycopi, platycladi seed, leech, and Radix Glycyrrhizae Preparata. The invention can efficiently cure amenorrhea, deficiency of the kidney and blood stagnation and has obvious curing effect and no side effect.

Owner:唐超

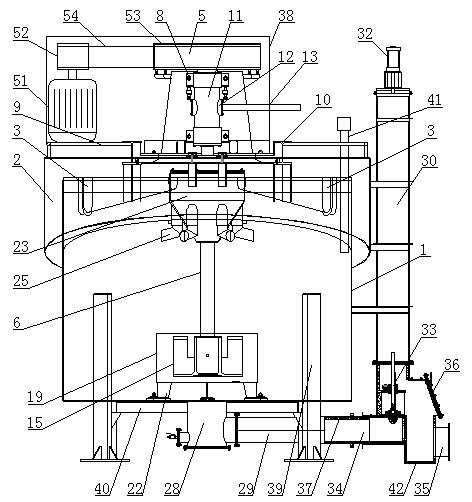

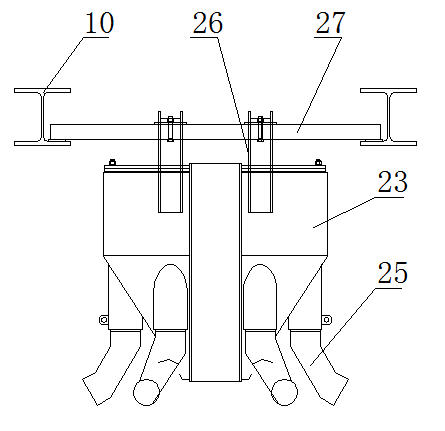

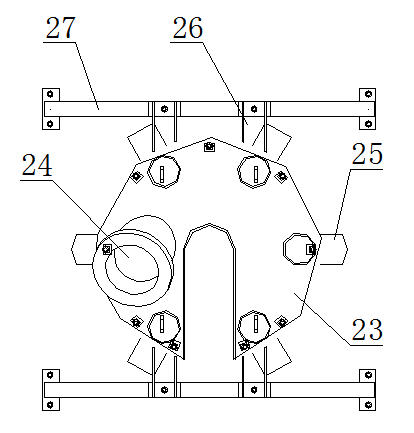

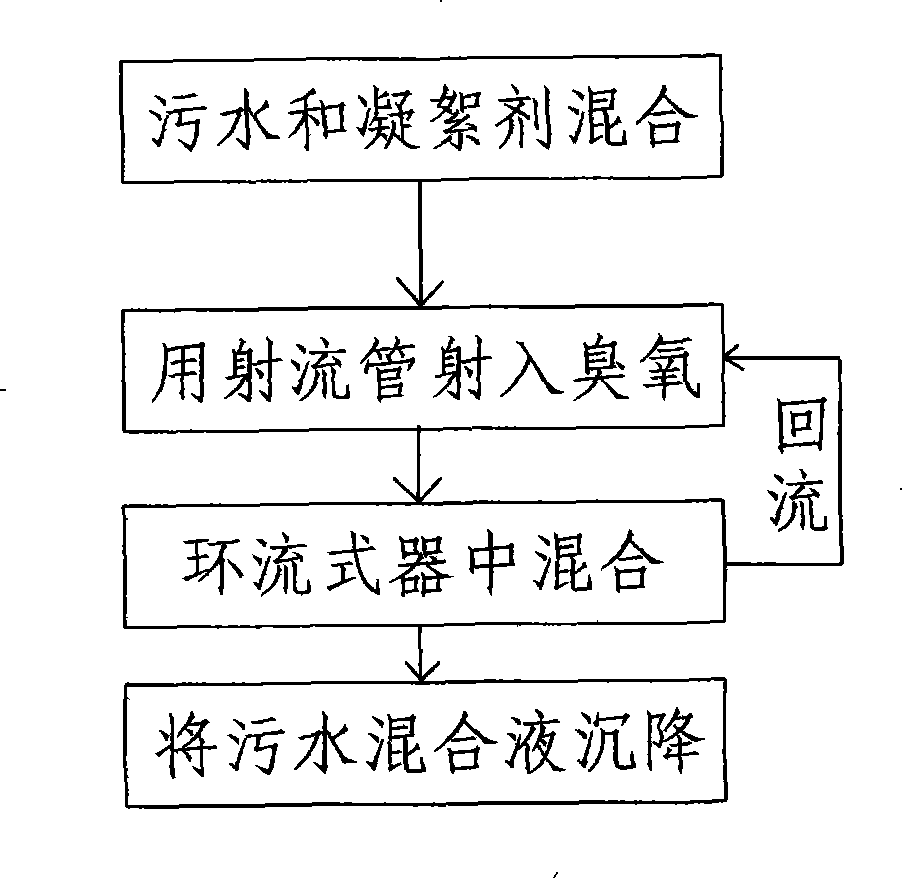

Method and device for processing sewage water by annular contact oxidation

ActiveCN101250010AEasy to operateSmall footprintMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationRefluxElectricity

A method for sewage disposal with ring-shaped contact oxidation reaction firstly mixes sewage with a flocculating agent, then ejects ozone air into the sewage for mixing by a jet pipe with pressure more than 0.15 MPa, mixes the mixture in a circulating mixer under a pressure more than standard atmosphere pressure, controls certain quantity of reflux to the mixing fluid with a reflux device, increases the reaction efficiency, and finally the sewage mixing fluid settles to finish the disposal process, and the flocculating agent is diatomite. The method and device for sewage disposal with ring-shaped contact oxidation reaction are simple, and the device has small covering area, small amount of electricity and medicaments consumption, small amount of investment, short construction time, low operation cost, and small amount of treated residual water, sludge and residue.

Owner:黎斌

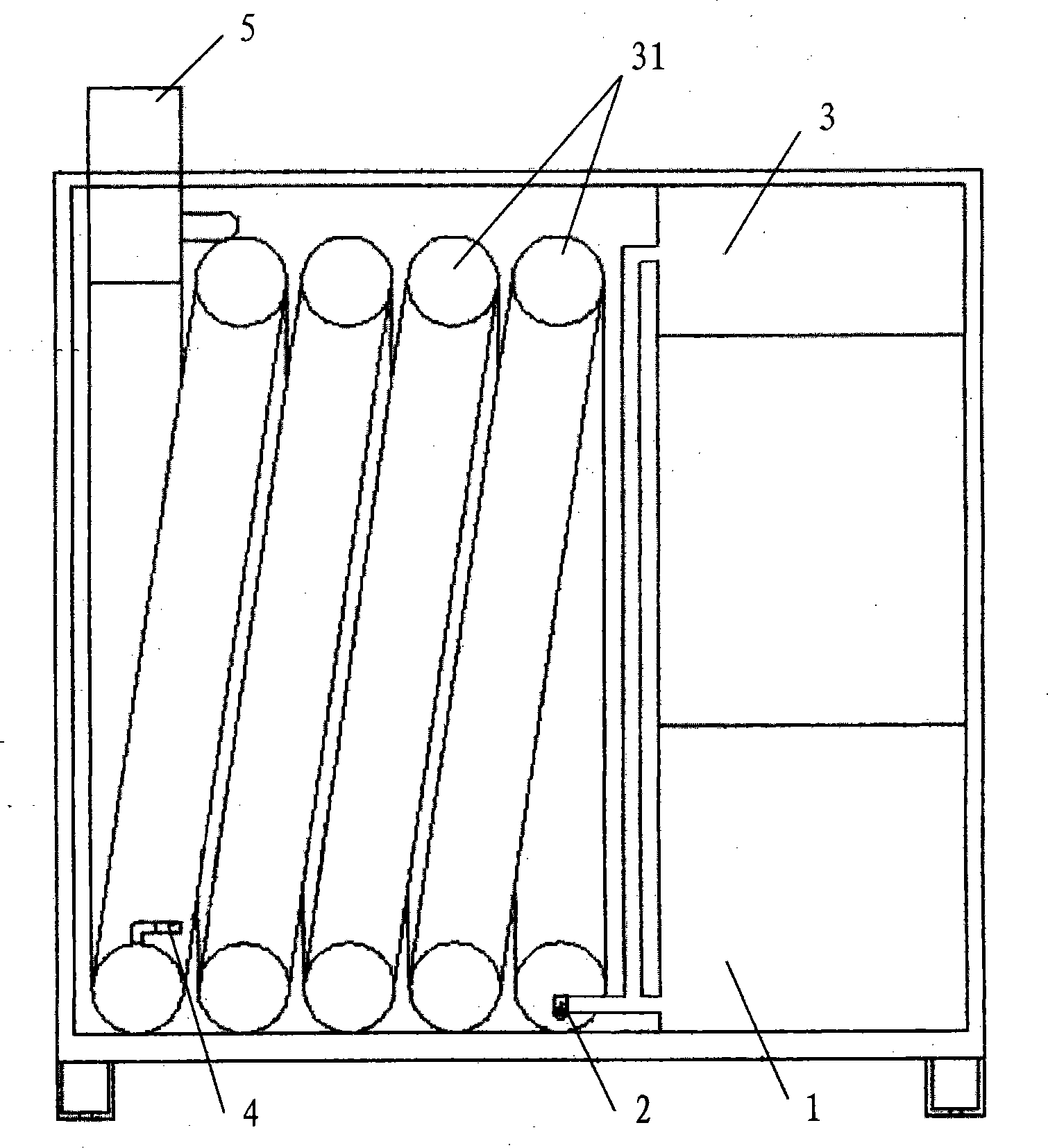

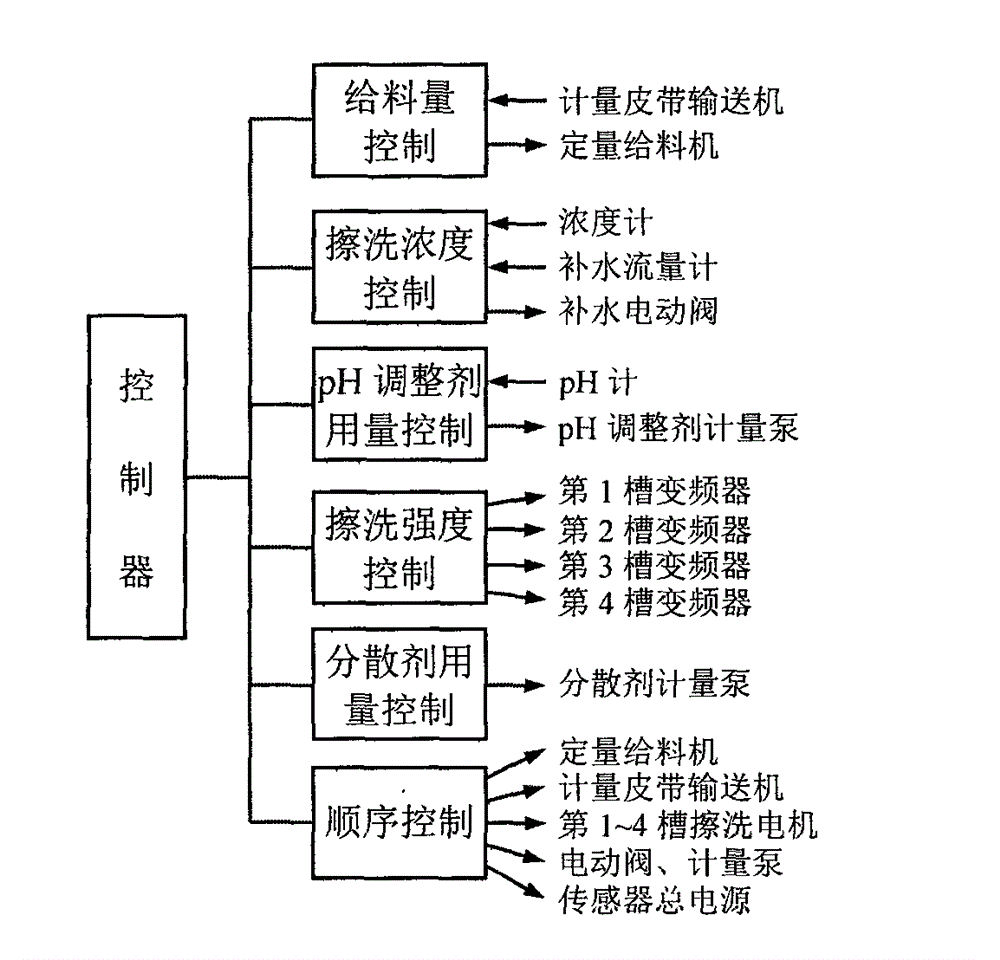

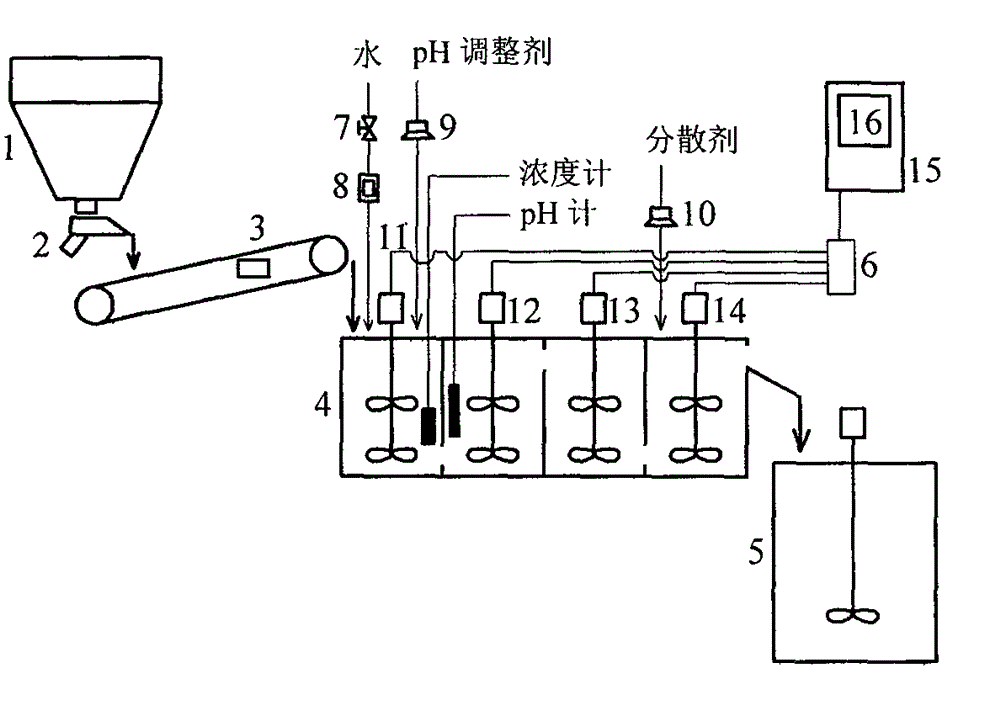

Control method of diatomite ore scrubbing process

InactiveCN102716802AEfficient productionRapid productionSolid separationSequence controlClay minerals

The invention discloses a control method of a diatomite ore scrubbing process and belongs to the technical field of mineral separation process control. The control method is characterized by including feeding quantity control, scrubbing density control, pH adjusting agent dosage control, scrubbing strength control, dispersing agent dosage control, sequence control and a controller. The method includes determining feeding quantity according to diatom content of diatomite ores, adjusting a water compensation motor-driven valve according to the feeding quantity, controlling the scrubbing density to be 30%-40%, adjusting a pH adjusting agent metering pump to enable the pH value of ore pulp to be 9-10, changing working efficiency of a first-slot scrubbing motor, a second-slot scrubbing motor, a third-slot scrubbing motor and a fourth-slot scrubbing motor of a scrubbing machine to control scrubbing strength, adding proper dispersing agent according to the scrubbing density to enable clay minerals to be in the suspension dispersing state which is favorable for the following centrifugal sedimentation and separation. The control method enables clay removing rate of the diatomite ores to be high, obviously improves hole plugging, remarkably improves specific surface area, is not large in breakage rate increase, and is especially suitable for scrubbing of clay minerals.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

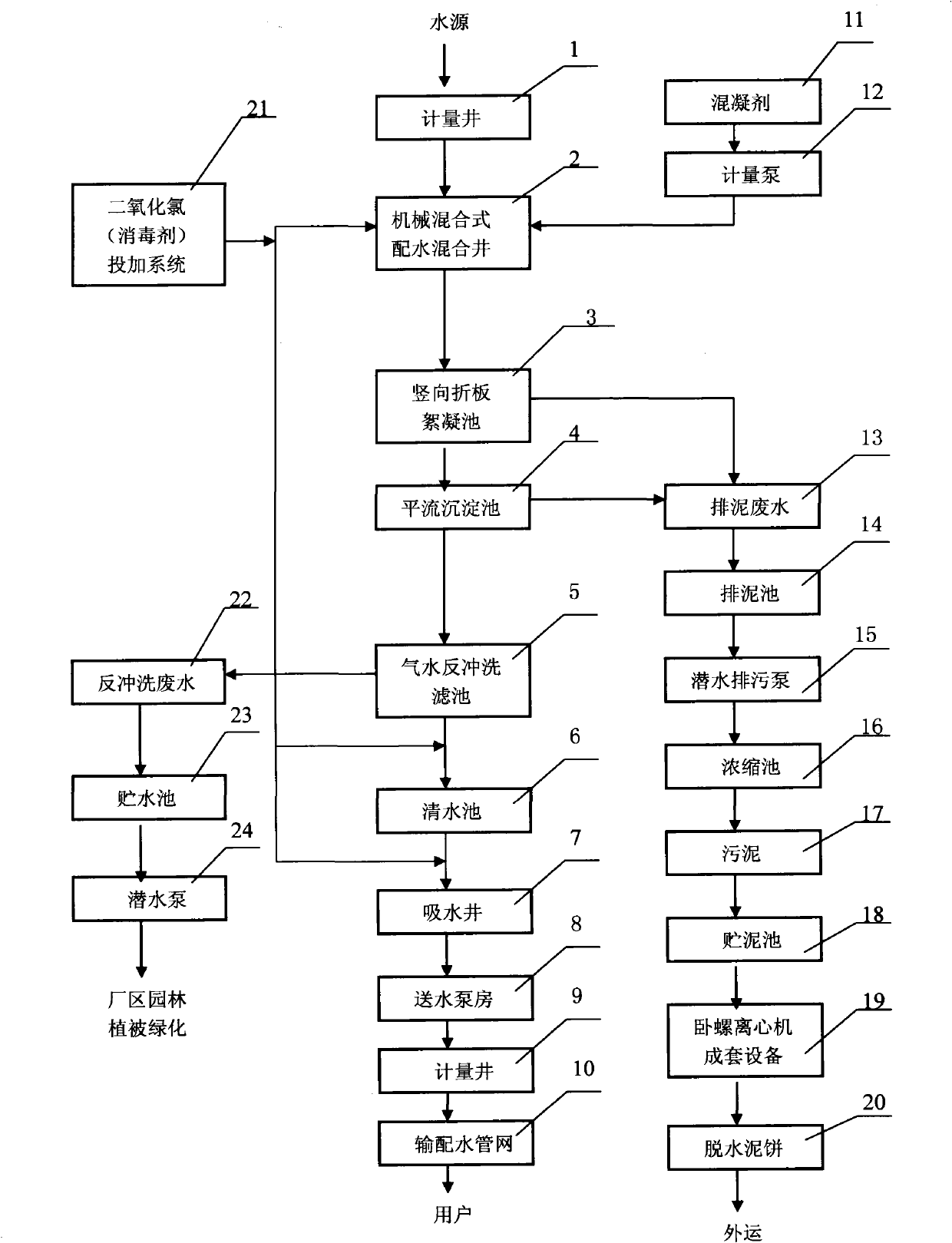

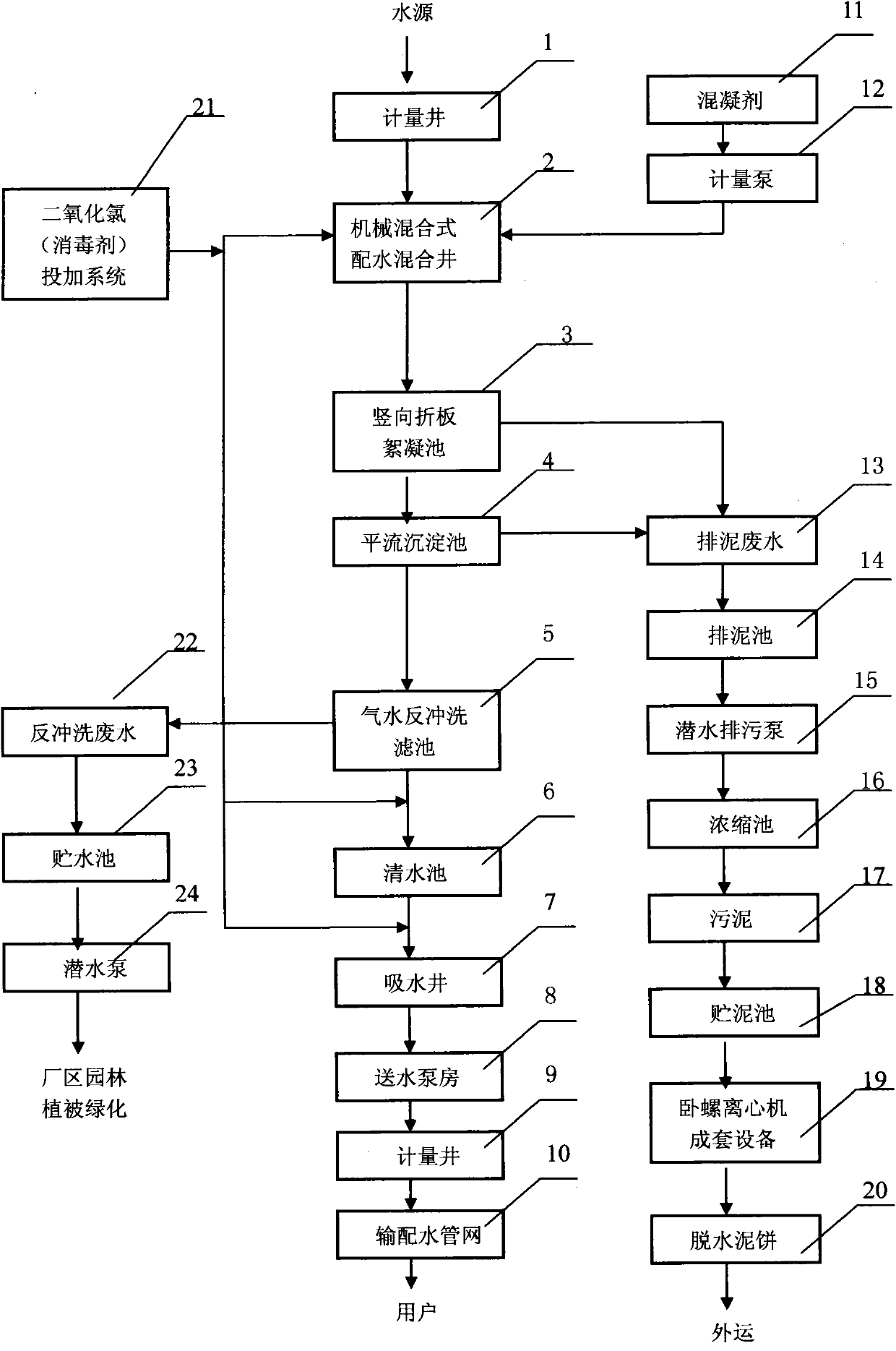

Low-carbon, environment-friendly, economical and reasonable water treatment process flow and method for water treatment plant

InactiveCN102167456AReduce volumeIncrease solid contentSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWastewaterWater resources

The invention discloses a low-carbon, environment-friendly, economical and reasonable water treatment process flow and method for a water treatment plant, and belongs to the fields of water resource reasonable utilization technology and environmental protection. The water treatment process flow and method comprises the following steps of: adding a coagulant; adding a disinfectant; purifying water; and utilizing and treating wastewater. The invention has the advantages that: problems of the conventional process are solved; and the water treatment process and method for the water treatment plant is low-carbon, environment-friendly, economical, reasonable, stable and reliable in operation and convenient to manage and maintain, ensures water treatment effect to reduce project investment and daily operating cost.

Owner:姚家泰

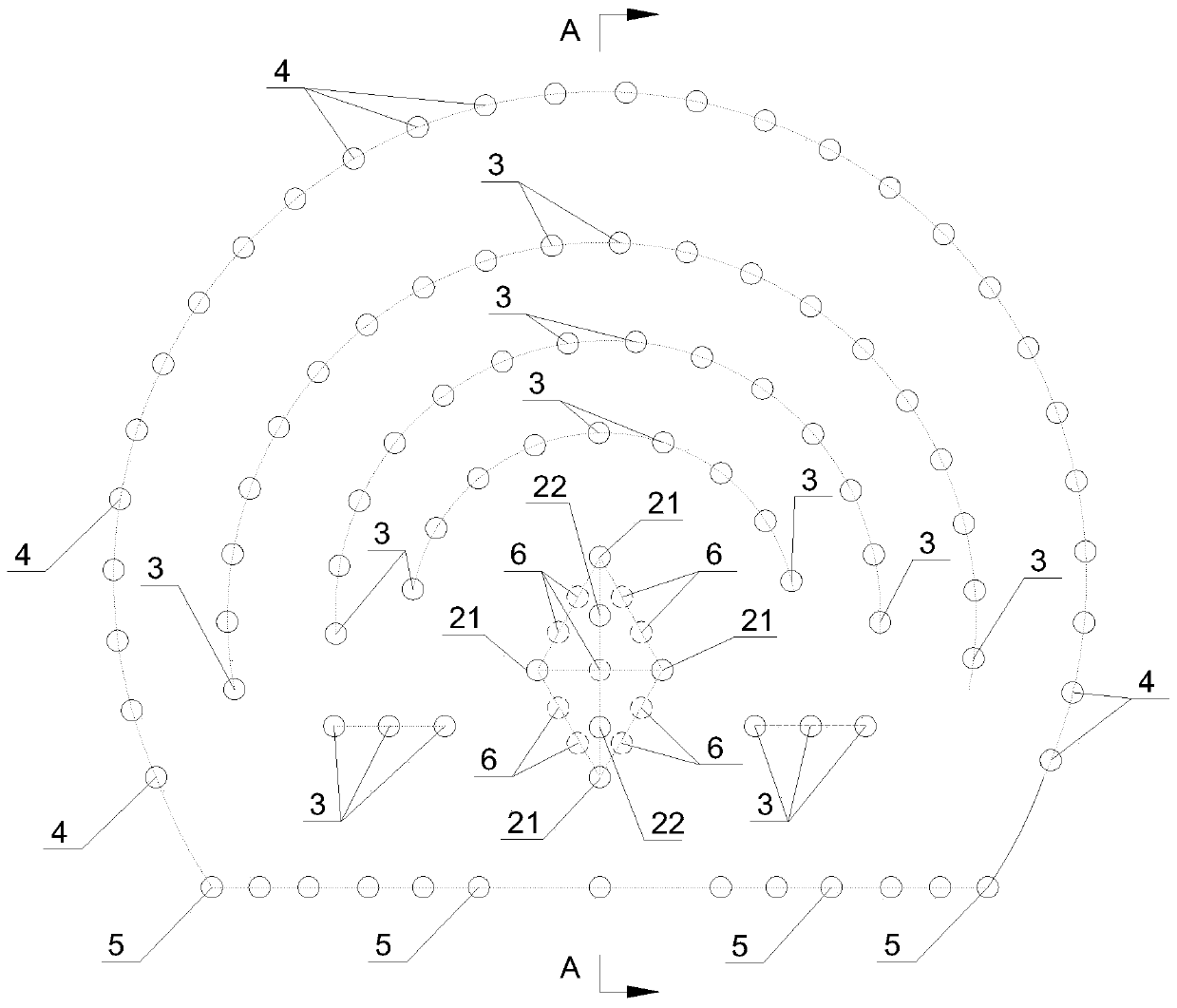

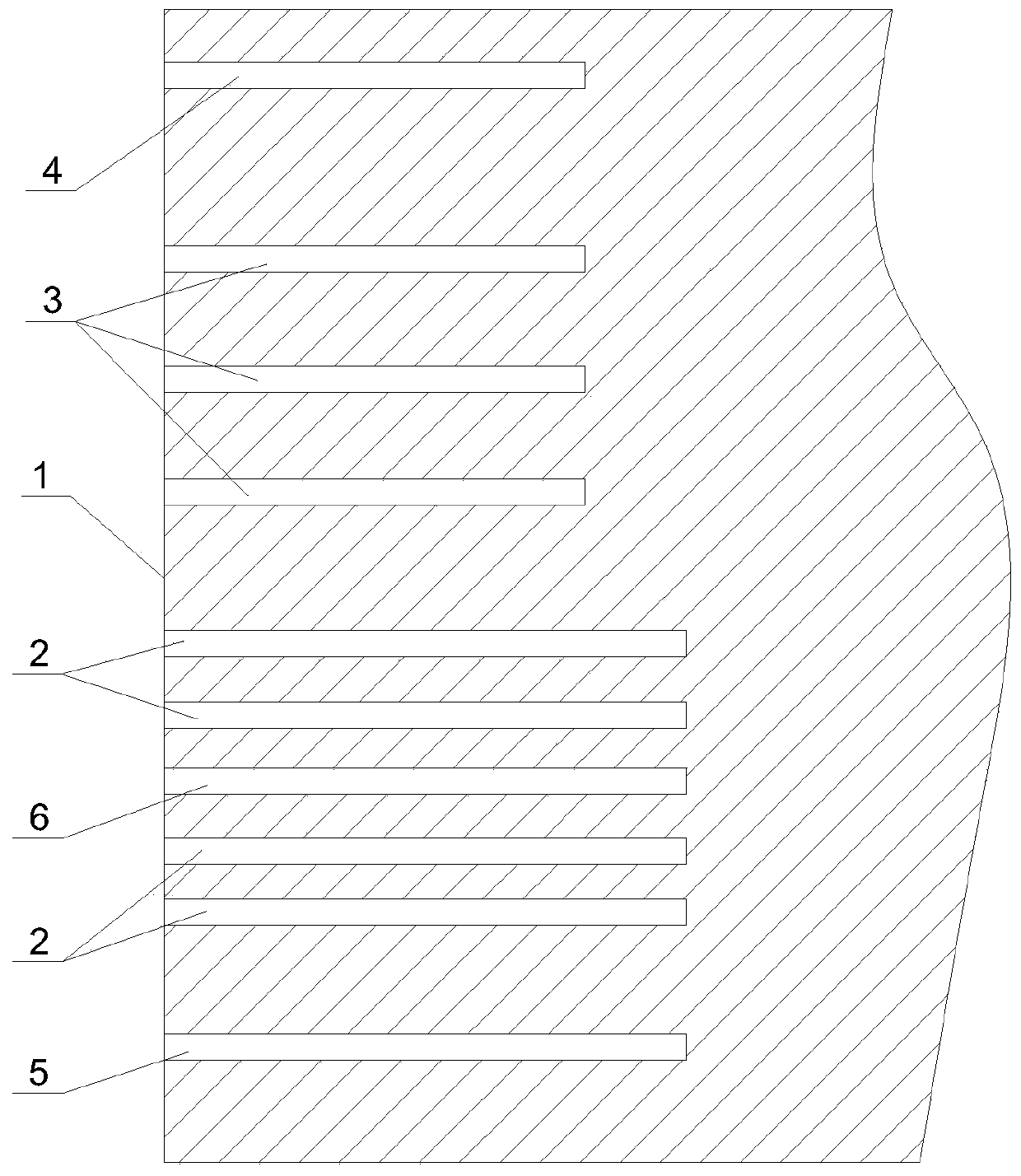

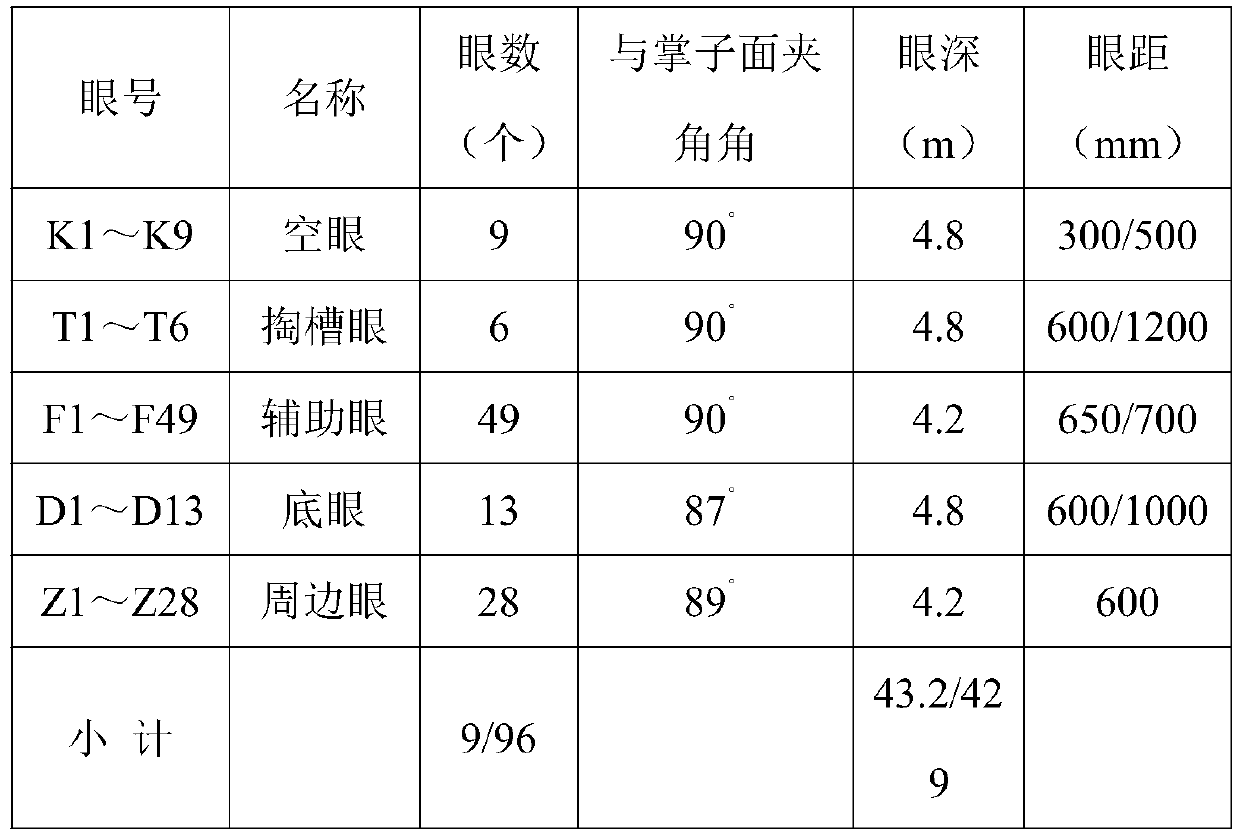

Hard rock tunnel blasting excavation method

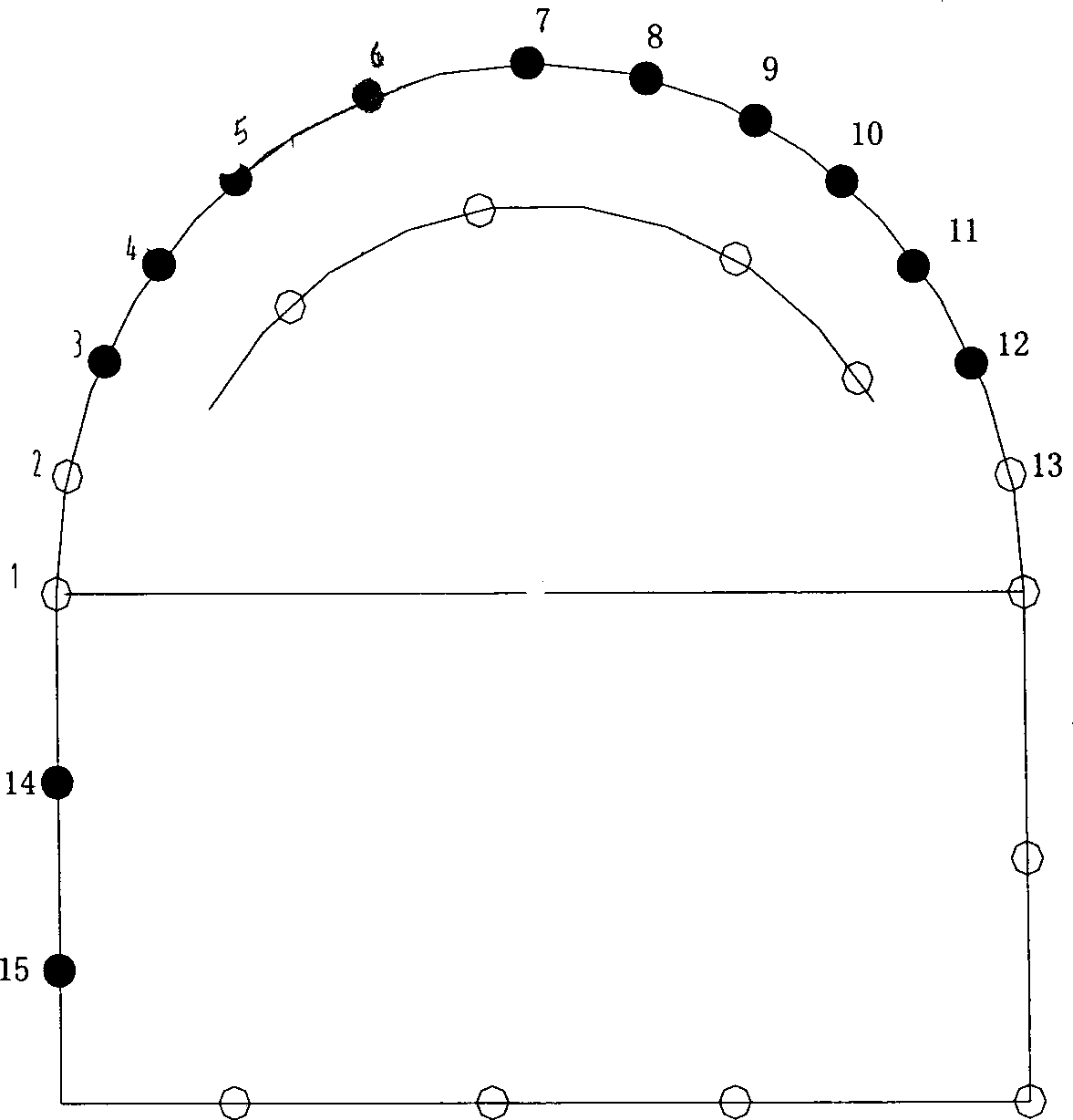

ActiveCN109813189AIncrease the speed of excavationImprove blasting cycle footageBlastingTunnelsRock tunnelPetrology

The invention discloses a hard rock tunnel blasting excavation method. The hard rock tunnel blasting excavation method comprises the steps that blasting holes are drilled in the rock of a tunnel faceand include cut holes, auxiliary holes, peripheral holes, bottom holes and empty holes, and at least one empty hole is formed in the periphery of each cut hole; the blasting holes are cleaned; explosives are put into the cut holes, the auxiliary holes, the peripheral holes and the bottom holes; a front stemming section, a resisting part and a rear stemming section are put into the remaining part of each cut hole in sequence, the hole opening of each cut hole is tightly wedged by a wedge, branches are arranged on each resisting part, each resisting part is pushed into the corresponding cut holein the forward direction, and the interiors of the remaining parts of the auxiliary holes, the peripheral holes and the bottom holes are plugged by stemming sections; blasting cap leg wires of the explosives are connected, and ignition and blasting are conducted; after the blasting is accomplished, and residue removal is conducted on the blasted tunnel face; and the operation is repeated until hard rock tunnel blasting excavation is accomplished. The tunnel blasting cyclical footage can be increased, and the tunnel excavation speed can be increased.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

Traditional Chinese medicine powder for treating dental ulcer

InactiveCN101757212AEffective treatmentSignificant effectAnthropod material medical ingredientsDigestive systemDental plaque induced gingivitisTherapeutic effect

The invention relates to a traditional Chinese medicine powder for treating dental ulcer, which is a Chinese patent medicine for treating dental ulcer, angular stomatitis and gingivitis. The traditional Chinese medicine powder is prepared by using indigo naturalis, alum, Chinese gall and golden cypress as raw materials. The invention has simple preparation mehtod and remarkable treatment effect.

Owner:贠钦亮

Plaster for treating habitual abortion

InactiveCN101757232ALow costSignificant effectHeavy metal active ingredientsSexual disorderChinese herbsSide effect

The invention relates to a plaster for treating habitual abortion, which is a traditional Chinese medicine preparation prepared by decocting traditional Chinese herbs of sesame oil, angelica, root of rehmannia, white atractylodes rhizome, teasel, astragalus mongholicus, and yellow lead in a certain proportion. The plaster has obvious treatment effect and no side effect.

Owner:贠钦亮

Chinese medicinal paste for treating diabetes

InactiveCN101732418AEasy to makeSignificant effectMetabolism disorderMammal material medical ingredientsMedicinal herbsSide effect

The invention relates to a paste for treating diabetes. The paste is the Chinese medicinal paste which reduces blood sugar and uses Chinese medicinal herbs as raw materials. The paste is prepared from the following raw materials: morning glory, white pepper, cochinchina momordica seed and eggs. The paste can effectively reduce the blood sugar, has obvious curative effect and does not generate any toxic or side effects.

Owner:邹元华

Preparation method of sewage corrosion and scale inhibitor

InactiveCN107857375AReduce volumeLow costBiocideScale removal and water softeningReverse osmosisStrontium sulfate

The invention relates to a preparation method of a sewage corrosion and scale inhibitor. The raw materials include: reverse osmosis water, ammonium persulfate, an oxidizing agent, phosphorus trichloride, sodium sulfonate, methylbenzotriazole, expanded graphite, disodium hydroxyethylidene diphosphonate, dimethylamine, acrylic acid, acrylamide, zinc chloride, zinc chloride, sodium lignin sulfonate and isopropyl alcohol. The heavy metal ion elution rate is up to 92-99%, the BOD removal rate is 88-92%, the penicillium fermentation broth and streptomyces griseus fermentation broth have a flocculation rate of 88-90%, the calcium carbonate scale inhibition rate is 98-99%, the corrosion rate of carbon steel is 0.0014-0.002mm / a, the COD removal rate is 84-94%, the SS removal rate is 99.7-99.9%, thecalcium carbonate scale inhibition rate is up to 99-99.6%, the strontium sulfate scale inhibition rate is 99.2-99.6%, the carbon steel slow release rate is 89-97%, and the sustained release rate of galvanized material is 93-97%.

Owner:江苏悠谷未来科技有限公司

Traditional Chinese medicine powder for treating galls

InactiveCN102309680AEasy to useShort course of treatmentAntibacterial agentsPowder deliverySide effectTherapeutic effect

The invention relates to traditional Chinese medicine powder for treating galls, in particular to the traditional Chinese medicine powder taking Chinese herbal medicine as raw materials. The traditional Chinese medicine powder is made from edible tulip, alisphaera, fritillary, kelp and oyster, and can be used for effectively treating the galls, with remarkable treatment effect and without any side effect.

Owner:贠钦亮

Pills for treating cough

The invention discloses a pill for treating cough which is prepared from schisandra chinensis, angelica sinensis, white peony root, bulbus fritilariae, balloonflower, aster, asparagus, liriope, poria cocos, peucedanum root, cortex mori, donkey hide gelatin and lily. The pill is prepared from raw material by weight of as follows: 20-40g schisandra chinensis, 20-40g angelica sinensis, 36-56g white peony root, 20-40g bulbus fritilariae, 36-56g balloonflower, 36-56g aster, 56-76g asparagus, 52-72g poria cocos, 56-76g peucedanum root, 52-72g cortex mori, 20-40g donkey hide gelatin and 85-105g lily. The pill has better treatment effect for eliminating the pathogenic factors without harming healthy qi, strengthening healthy qi without remaining evil qi, also can be used for treating other respiratory disease.

Owner:陈海生

Traditional Chinese medicine decoction for preventing influenza

InactiveCN101897759AEasy to useSignificant preventive effectAntiviralsPlant ingredientsSide effectForsythia

The invention relates to traditional Chinese medicine decoction for preventing influenza, which is prepared from Chinese herbal medicines and is used for preventing and controlling the influenza. The raw materials of cyrtomium fortune, weeping forsythia, liquoric root and cabbage root are decocted in water. The traditional Chinese medicine decoction can effectively prevent multiple kinds of influenza, and has obvious effect and no toxic or side effect.

Owner:唐超

Preparation method of composite flocculant for water treatment

InactiveCN107827217AWide variety of sourcesLow costWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionEpoxyPolyethylene glycol

The invention discloses a preparation method of a composite flocculant for water treatment. The preparation method includes following steps: mixing zeolite powder, nano medical stone powder, coconut shell charcoal, polyethylene glycol and dimethyl sulfoxide, heating, stirring well, adding epoxy resin, continuing stirring, adding a formaldehyde solution, stirring well, cooling, filtering, washing,drying, grinding, adding polydimethyl diallyl ammonium chloride, and mixing well to obtain a material A; well mixing polysulfate ferric aluminum chloride, polyferric sulfate, polyphosphate ferric chloride and hydrogen peroxide to obtain a material B; well mixing the material a, the material B, calcium lignosulfonate and triethanolamine to obtain the composite flocculant. The preparation method isextremely simple in process, the composite flocculant is extensive in raw material source, low in cost, convenient to produce and use, small in feeding amount and good in flocculation effect, gel flocculation and deposition can be generated effectively, quick settling can be realized, water treatment efficiency and utilization rate of the flocculant are improved, and lowering cost of water treatment is facilitated.

Owner:芜湖上水源环保科技有限公司

Traditional Chinese medicine decoction for preventing influenza

InactiveCN103768155AEasy to useSignificant preventive effectAntiviralsPlant ingredientsSide effectCyrtomium fortunei

The invention relates to a traditional Chinese medicine decoction for preventing influenza, and the decoction is used for preventing and controlling influenza spread and employs Chinese herbal medicines as raw materials. The traditional Chinese medicine decoction is prepared by taking cyrtomium fortunei, fructus forsythiae, licorice and Chinese cabbage root as raw materials and adding water and decocting. The traditional Chinese medicine decoction can effectively prevent various kinds of influenza, and has obvious effect and no toxic or side effect.

Owner:杨永江

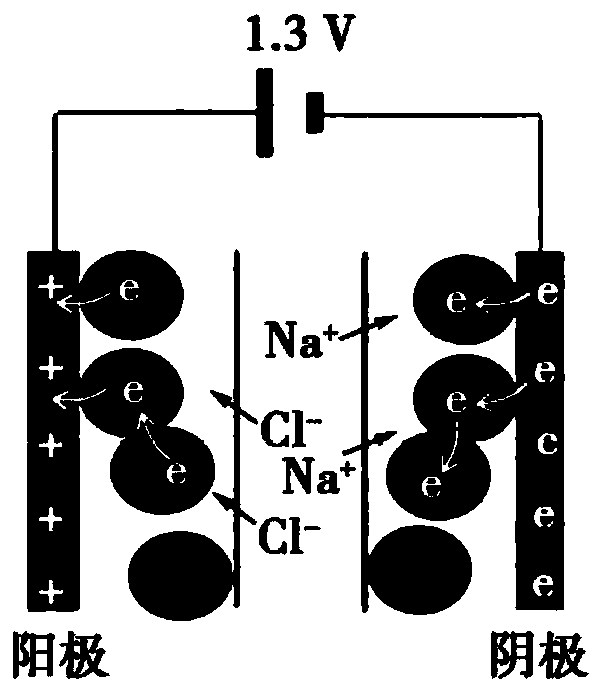

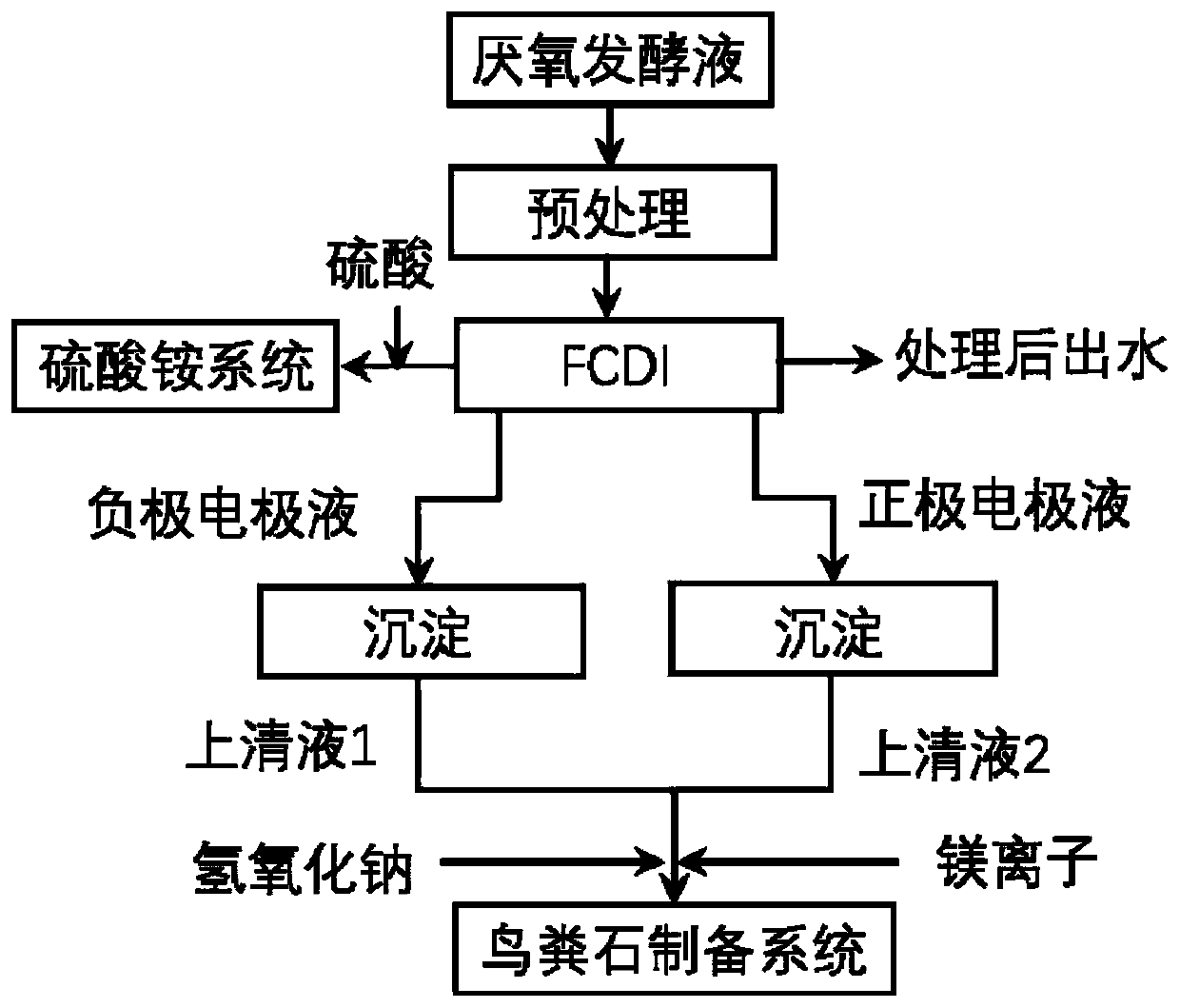

Method for recycling anaerobic fermentation liquor

ActiveCN111253005AHigh recovery rateReduce dosageWater contaminantsDispersed particle separationBiotechnologyPulp and paper industry

The invention relates to the technical field of wastewater recycling, which relates to the technical field of biotechnology, in particular to a method for recycling anaerobic fermentation liquor, theanaerobic fermentation liquor comprises NH4<+>, PO4<3-> and organic matters, and the method comprises the following steps: (1) anion-cation separation is performed on the anaerobic fermentation liquorthrough an anion electrodialysis membrane and a cation electrodialysis membrane of FCDI to obtain a FCDI effluent; (2) the negative electrode chamber of the FCDI adsorbs NH4 < + > to form ammonia gas, and sulfuric acid is introduced to generate ammonium sulfate; and (3) precipitating is carried out in the negative electrode chamber and the positive electrode chamber of the FCDI, a supernatant isrespectively taken, the materials are mixed, and Mg<2+> and alkali are added to prepare struvite, so that the product has the advantages of high nitrogen and phosphorus yield, high struvite purity andgood benefit.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com