Double-medium decoupling fracture damage blasting control method and auget

A technology of controlled blasting and dual media, used in blasting, blasting cylinders, weapon accessories, etc., can solve the problems of ineffective protection of the reserved surface, complex charge structure, difficult operation, etc. The effect of reducing the consumption of medicine and increasing the power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

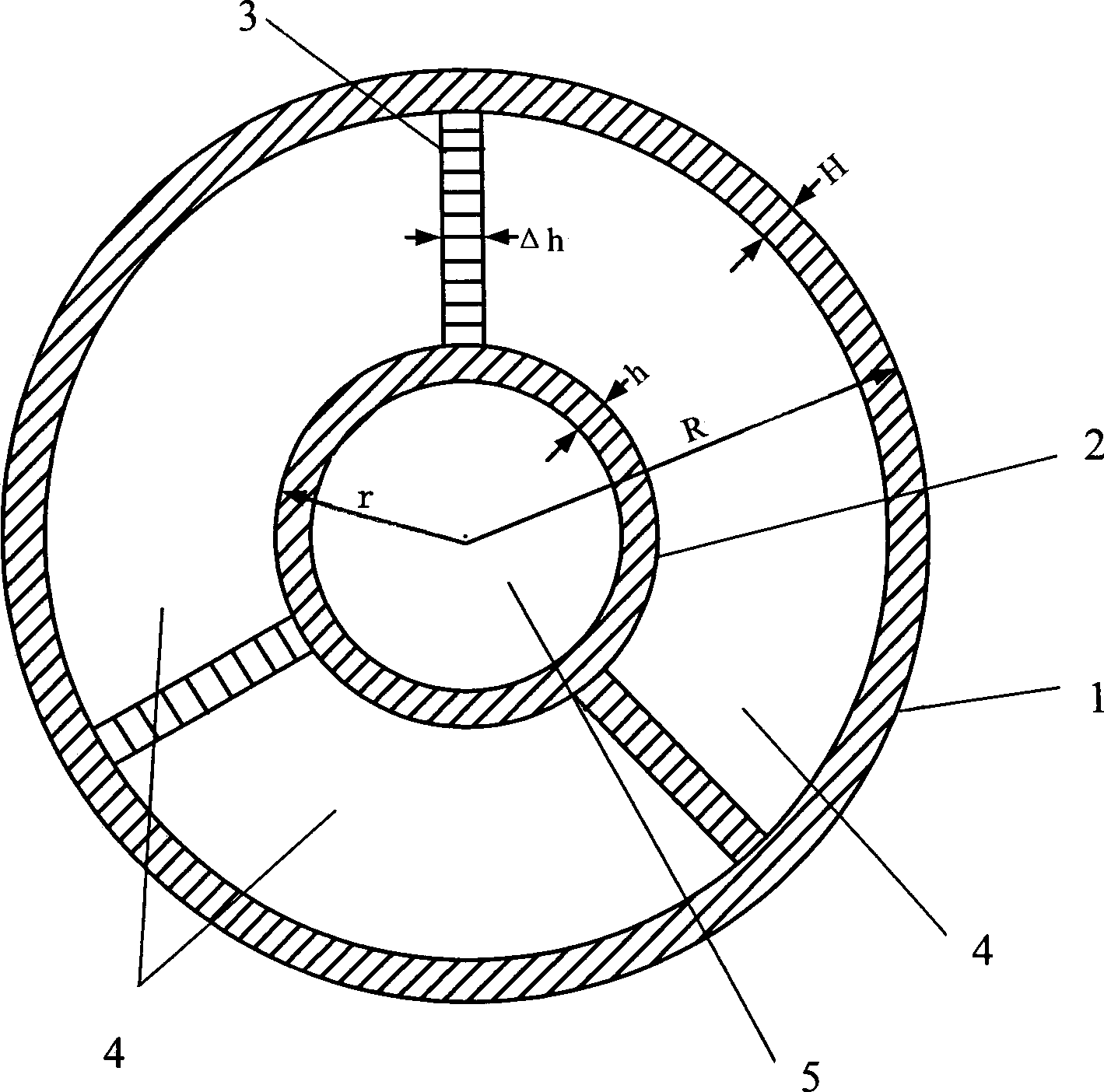

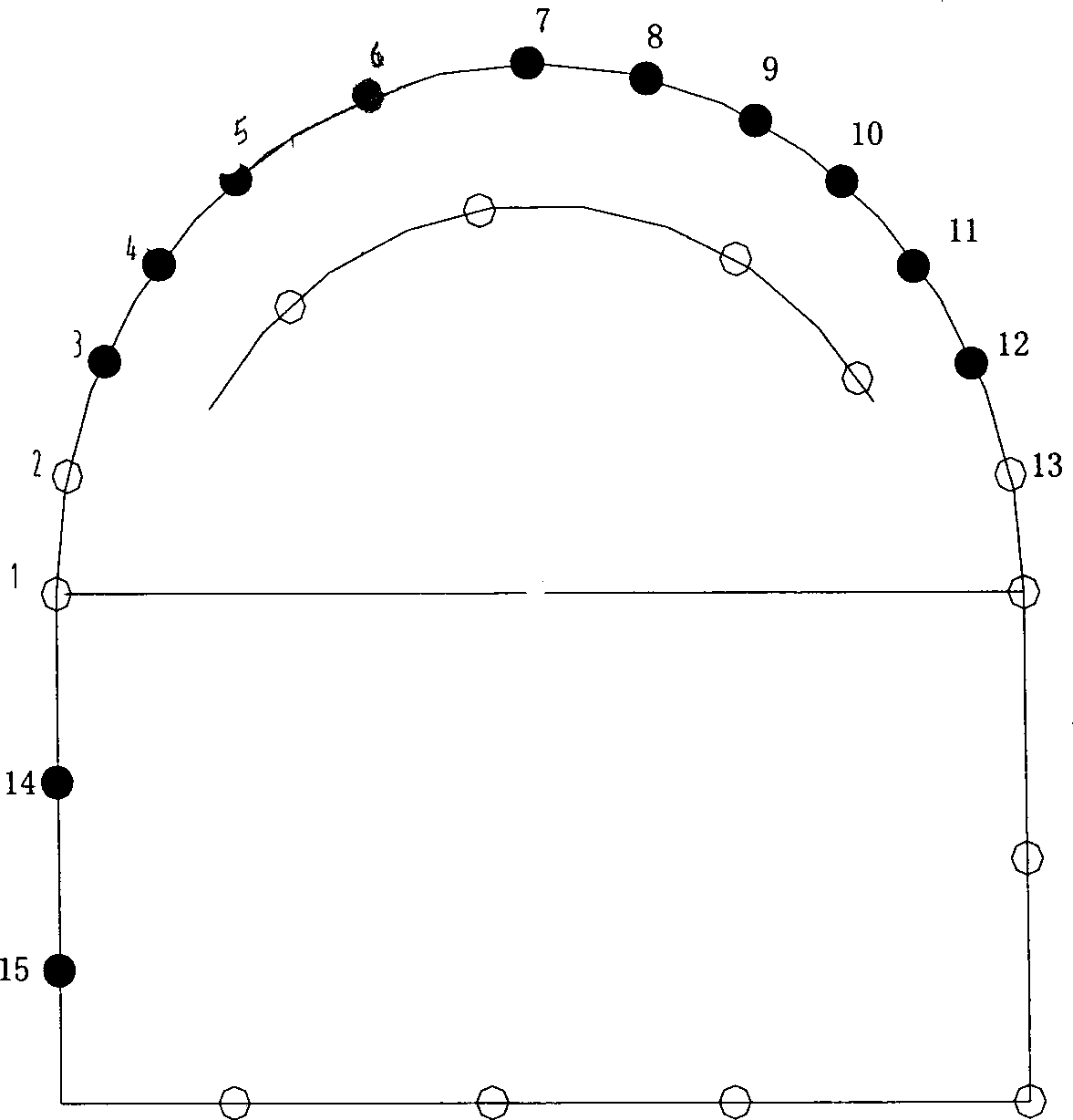

[0018] The dual-medium non-coupling fracture damage control blasting method of the present invention adopts columnar explosives, detonators or detonating cords, and drills blast holes on the rock to be blasted. When the columnar explosives are loaded, the explosive structure adopts radial non-coupling charge, which can be When loading columnar explosives, two mediums of water and air are used to isolate the explosives in the blast hole, the water medium is aligned with the side of the free surface, and the air medium is aligned with the side of the reserved surface; the characteristics of the different energy transfer efficiency of the two media are used To change the uniform distribution of explosive energy, the side of the water medium that is aligned with the free surface is fully destroyed during blasting, while the side of the air medium that is aligned with the reserved surface can effectively protect the reserved surface and form a flat fracture surface.

[0019] figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com