Patents

Literature

115results about How to "Fully destroyed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

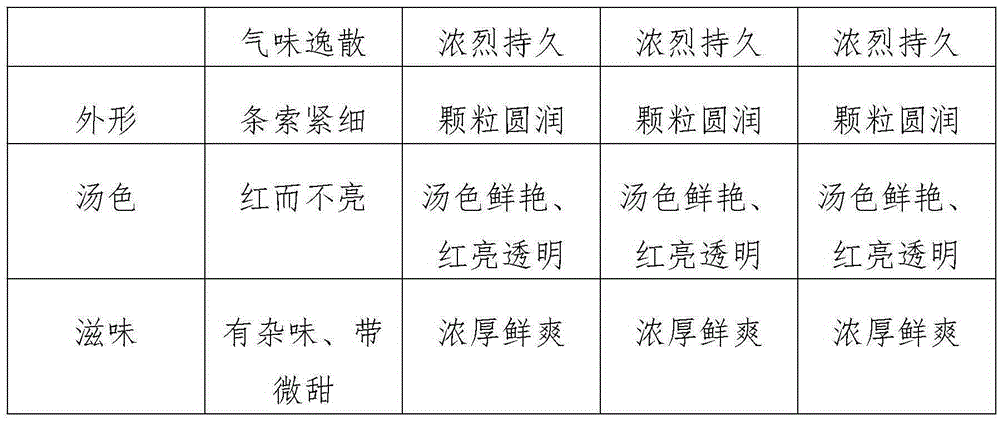

Honey-aroma type congou black tea processing method

ActiveCN104886288AConducive to mutual frictionEasy to convertPre-extraction tea treatmentBlack teaFermentation

The invention discloses a honey-aroma type congou black tea processing method and belongs to the technical field of tea processing. The method includes: firstly, picking fresh leaves of large-leaf tea, and placing the fresh leaves of a tea tree in a withering trough for green leaf cooling; repeatedly subjecting the fresh leaves of the tea tree to rocking process and green leaf cooling for twice, and spreading the obtained rocked leaves in the withering trough for withering processing; twisting the obtained withered leaves heavily and slightly alternatively; sending the obtained twisted leaves to a fermentation chamber for fermentation; subjecting the fermented leaves to drying processing, taking out the fermented leaves for sizing and sending to a dryer for drying process after spreading for cooling; spreading and cooling the dried leaves to obtain the spread and cooled leaves which are sent to a baking machine for aroma extraction to obtain the honey-aroma type congou black tea. Compared with the prior art, the honey-aroma type congou black tea processing method has the advantages that the processed tea leaves are tightly knotted and black, even, fragrant, remarkable in honey aroma, red and bright in soup, rich in taste and bright red in infused leaves.

Owner:贵州怡壶春生态茶业有限公司

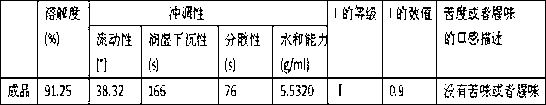

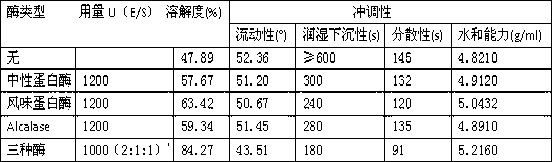

Preparation method of egg albumen powder with great instant property and no bitter and fishy smells

ActiveCN103263036AGood instant solubilityImprove solubilityFood shapingFood preparationBiotechnologyAnimal science

The invention discloses a preparation method of egg albumen powder with a great instant property and no bitter or fishy smells, which solves the problems of bad instant property, bitter smell or fishy smell, and bad organoleptic quality of egg albumen powder in the market at present. According to the preparation method, enzymolysis treatment is performed on egg albumen protein by a compound protease (including Alcalase, neutral protease and flavourzyme) and cooperates with a two-stage enzymolysis method, the use amount of the compound protease is less than the use amount of any one protease in the compound protease during independent use, the physicochemical indexes of instant property, taste and the like of the egg albumen powder obtained via the enzymolysis are greatly improved, and unexpected technical effects are obtained; the proportioning ratio of Alcalase to neutral protease to flavourzyme in the compound protease is determined to be 1: 2: 1, and via the proportioning, the instant property and dissolution stability of the egg albumen powder are remarkably improved; and high-speed short-time superfine treatment is combined, so that the effects are better.

Owner:迟玉杰

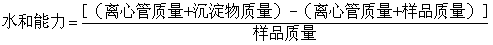

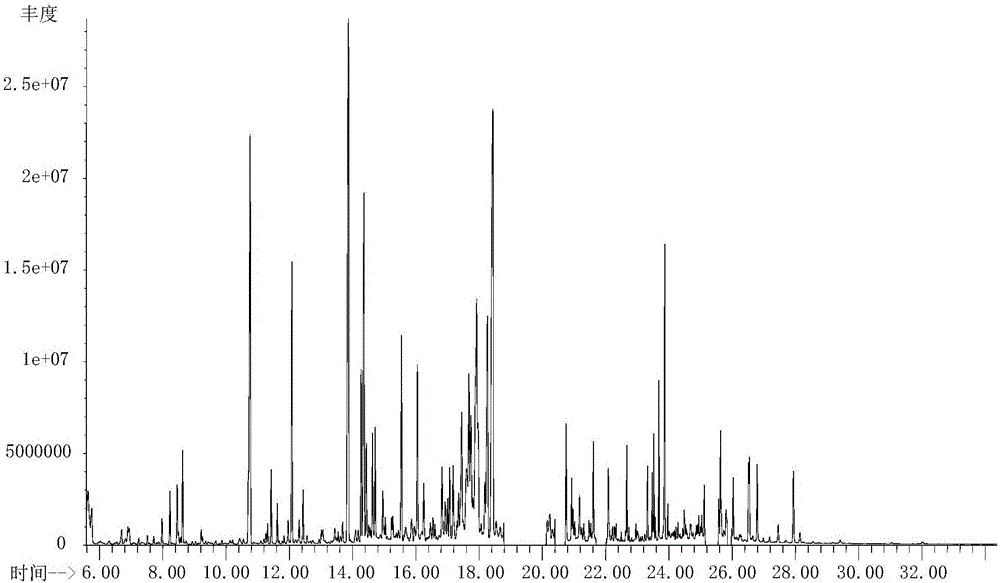

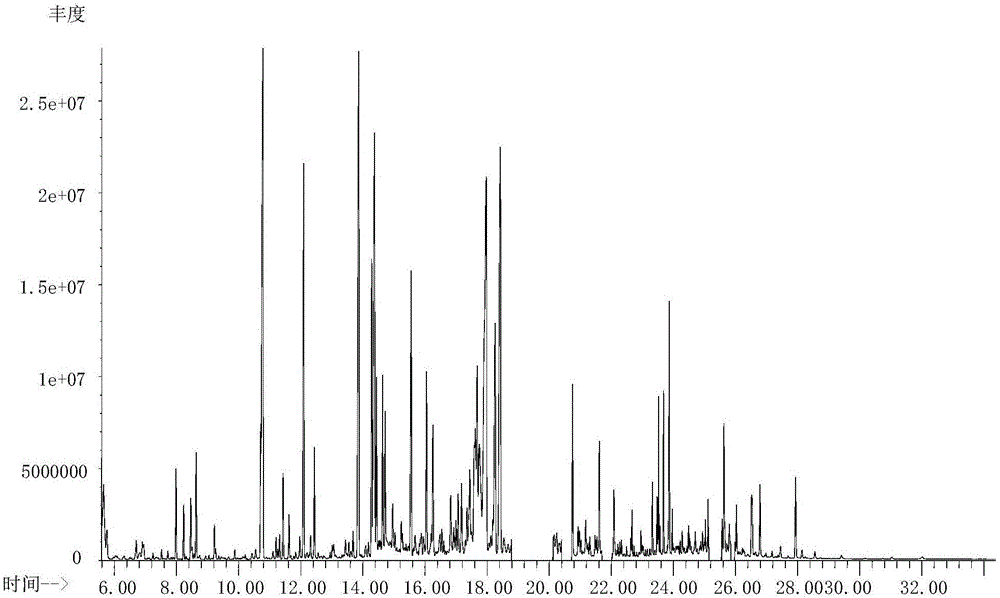

GC-MS-based plant non-targeted metabolomics sample pretreatment method

The invention discloses a GC-MS-based plant non-targeted metabolomics sample pretreatment method. The method comprises the steps of 1) mixing up a plant sample, an internal standard substance and a hydrophilic organic solvent, wherein the hydrophilic organic solvent is pre-cooled to be -20 to 4 DEG C; cooling the obtained mixture to be -80 to -10 DEG C, grinding, crushing and conducting the supersonic extraction in the ice-water bath; 2) then respectively adding a lipophilic organic solvent and water, uniformly mixing up, conducting the supersonic extraction in the ice-water bath, conducting the high-speed centrifugation at the temperature of 0 to 16 DEG C, obtaining the aqueous phase and evaporating; 3) adding an oximation reagent, and conducting the oximation reaction at the temperature of 30 to 45 DEG C; 4) finally adding a derivatization reagent and n-hexane, and conducting the derivatization reaction at the temperature of 60 to 80 DEG C. According to the technical scheme of the invention, based on the above pretreatment method, the primary metabolites of a plant sample can be fully extracted, so that the abundant metabolite spectrum data information can be obtained. Meanwhile, both the change of metabolites during the extraction process, and the pollution of liposoluble substances to a gas chromatographic column can be avoided as much as possible. Therefore, the better sample reproducibility is realized.

Owner:上海鹿明生物科技有限公司

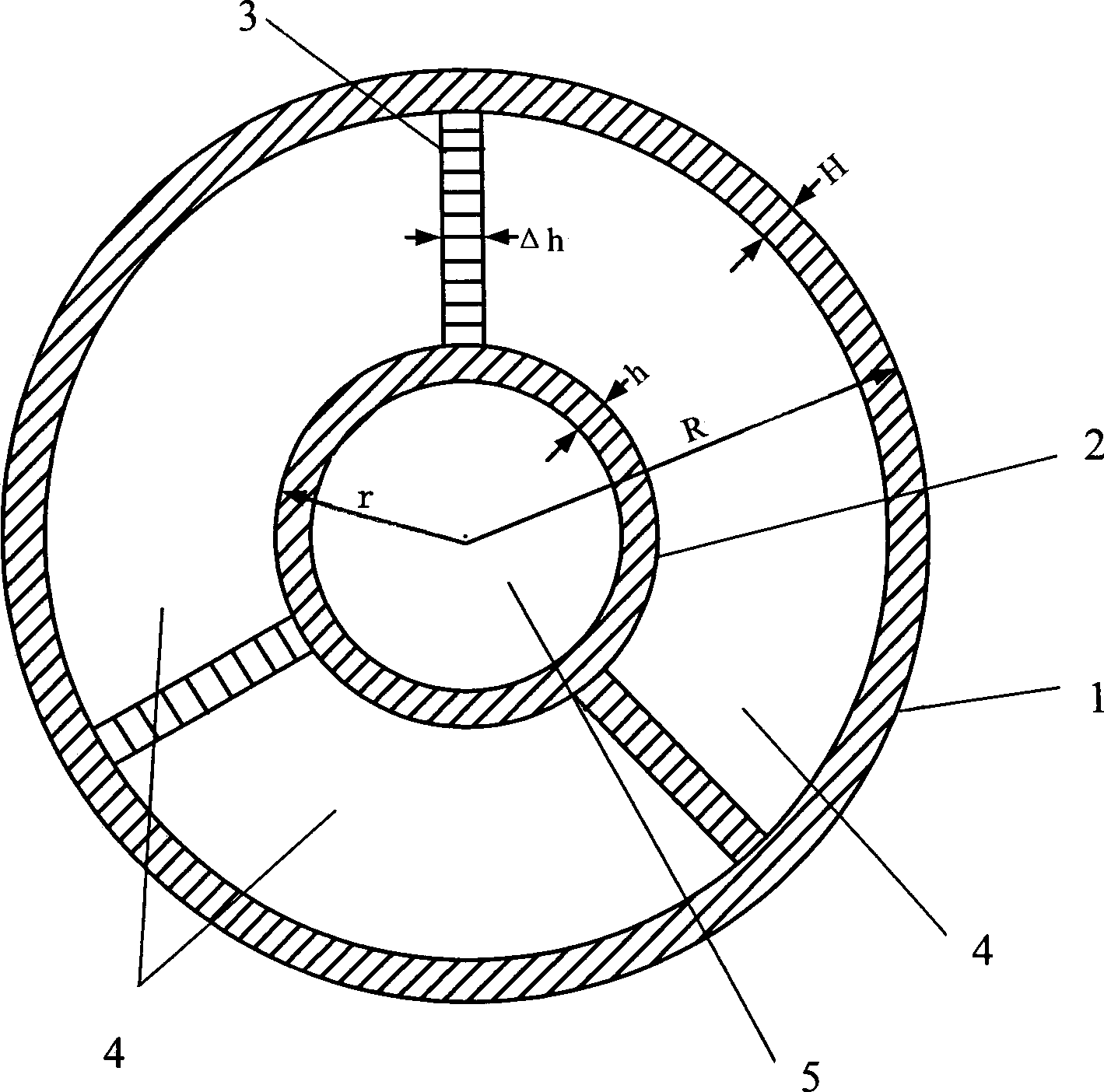

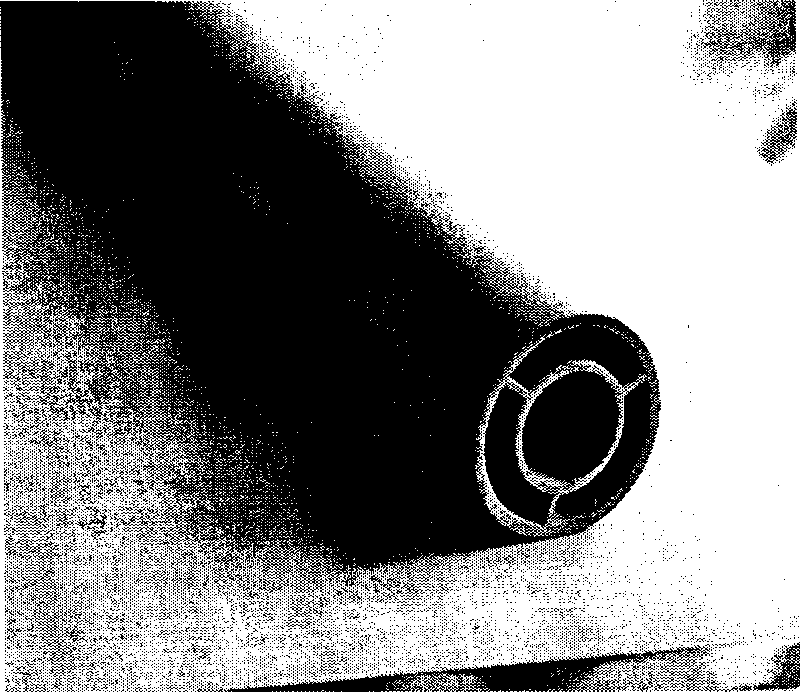

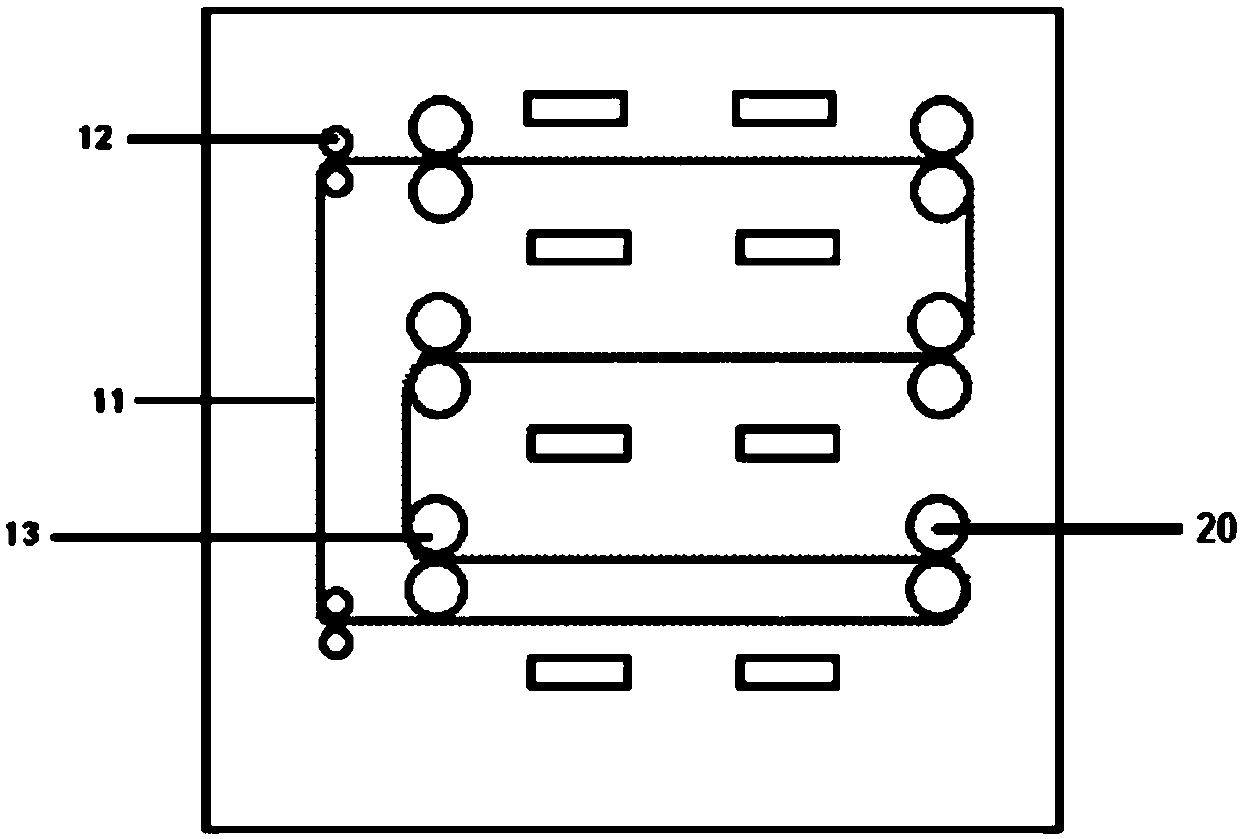

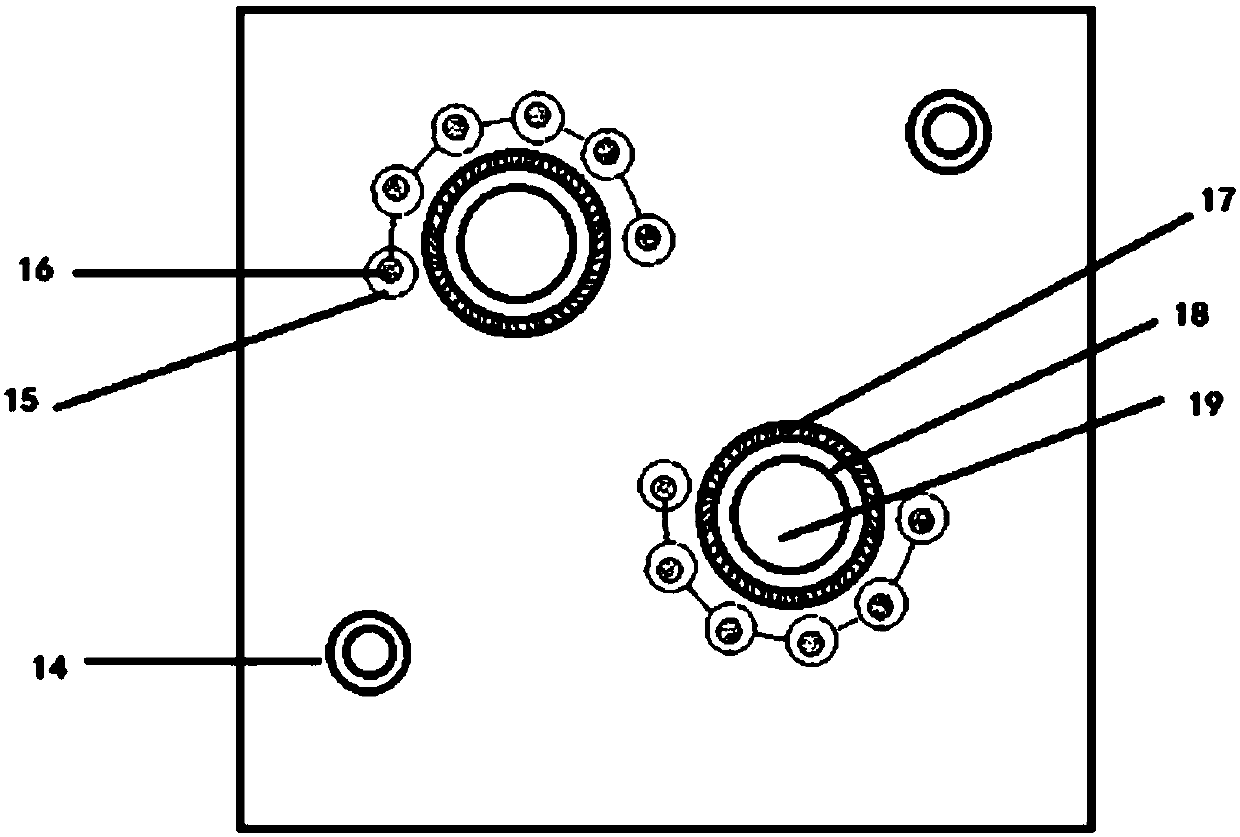

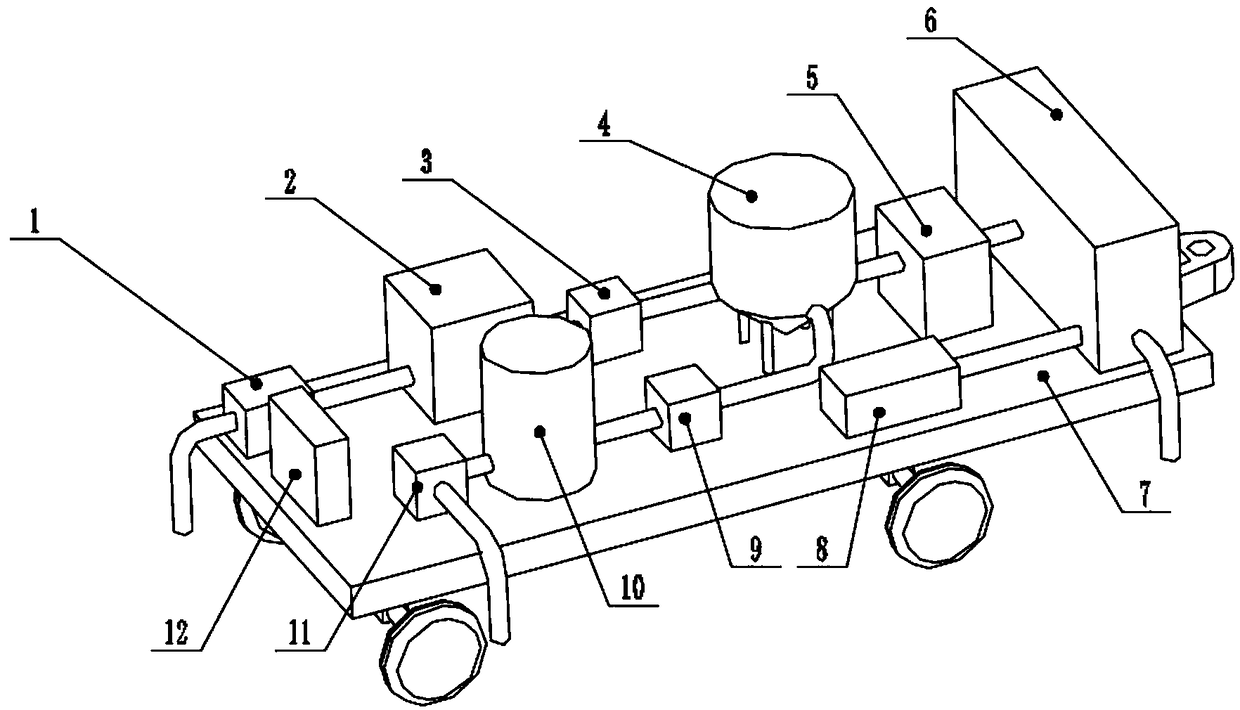

Double-medium decoupling fracture damage blasting control method and auget

InactiveCN101363701AHighlight substantive featuresHigh static pressure resultant forceBlasting cartridgesBlastingEngineeringExplosive power

The invention relates to a method for controlling blasting by double-medium decoupling fracture and damage and a blasting cartridge thereof. The method adopts cylindrical explosive, detonator or primacord to explode a hole on a blasted rock body. The method is characterized in that water and air are simultaneously used in the hole to separate explosive, wherein, the water medium is aligned to the side of a free surface, while the air medium is aligned to the side of a reserved surface; the uniform distributing state of explosive energy can be changed by using the characteristics that the two media have different efficiencies of transmitting energy, thereby achieving the function of completely destroying one side and protecting the reserved surface during blasting, and forming a flat fracture surface. The blasting cartridge consists of an outer tube, an inner tube and a separating wall, wherein, the separating wall separates a cavity formed between the outer tube and the inner tube into a medium chamber for containing the water medium and a medium chamber for containing the air medium; and an explosive chamber for placing the cylindrical explosive is arranged in the inner tube. The invention has the advantages of easily operating, improving explosive power and agglomerating rate, protecting stability of wall rock, reducing harm of dust and noise, and the like, and can be widely applied to smooth blasting projects such as tunnels, side slopes, water conservancies, mining, and the like.

Owner:TAIYUAN UNIV OF TECH

Dried tangerine peel extract preparation method and prepared dried tangerine peel extract thereof, and applications of dried tangerine peel extract

InactiveCN107435059AHigh in hesperidinStrong specificityNatural extract food ingredientsFermentationPectinaseCellulase

The invention discloses a dried tangerine peel extract preparation method, wherein the dried tangerine peel extract is prepared by using dried tangerine peel as a raw material through cellulase and pectinase combined enzymolysis. The invention further discloses the dried tangerine peel extract prepared by using the method and applications of the dried tangerine peel extract. According to the present invention, by using the cellulase and pectinase combined enzymolysis method, the characteristics of high efficiency, simple and convenient operation, mild reaction condition and the like can be provided; after the enzymolysis reaction, ethanol is used as a solvent to extract; and the method has advantages of high yield, safety, effectiveness and solvent recovery, and is suitable for industrial production.

Owner:SHENZHEN WEICKY BIOLOGICAL TECH

Method for extracting lentinan from foot of lentinus edodes

A method for extracting lentinan from the foot of lentinus edodes belongs to the technical field of polyose and derivatives processing and is used for solving the problem of improving the extraction rate of lentinan in the foot of lentinus edodes. The technical proposal is as follows: the foot of lentinus edodes is taken as raw material to prepare the lentinan through the steps of pretreatment, extraction, concentration, alcohol sedimentation and separation, drying and the like. After improvement, the extraction step is as follows: pretreated degreased lentinus edodes foot powder is extracted under decompressed hot reflux at the temperature of 40-70 DEG C; leaching liquor is 0.1-0.4mol / L diluted acid solution; the mass ratio of the diluted acid solution and the lentinus edodes foot powder is 30-50:1 when leaching; the leaching time is 40-90min; the pressure adopted in leaching is 2.5-15MPa; and the diluted acid solution is volatile acid solutions of hydrochloric acid, acetic acid and the like. The method increases the rate of extracting the lentinan from the foot of the lentinus edodes to a great degree, effectively improves the utilization rate of the raw material, reduces production cost, has simple and direct process route and little equipment investment, and is easy for industrialization and an effective method for comprehensively processing and using the foot of the lentinus edodes.

Owner:何颖娜

Method for multiphase catalytic ozone treatment of residual activated sludge

ActiveCN106277660AImprove activity stabilityImprove the stability of useSludge treatmentActivated sludgeRare earth

The invention discloses a method for multiphase catalytic ozone treatment of residual activated sludge, wherein the method comprises the steps: (1) adding an ozone catalyst into a sludge concentration tank, wherein the ozone catalyst comprises a carrier and active metal components loaded on the carrier, a transition metal and a rare earth metal are used as the active metal components, the transition metal is selected from non-noble metals of fourth and fifth periods of the periodic table of elements, the carrier takes 150-300 mesh activated carbon as a core and amorphous alumina as a shell, the amount of the activated carbon accounts for 10%-70% of the weight of the carrier, and the amount of alumina accounts for 30%-90% of the weight of the carrier; (2) introducing ozone into the sludge concentration tank of the step (1), and making the sludge decomposed; and (3) carrying out solid-liquid separation of the sludge after treatment in the step (2), and removing water. By adding the ozone catalyst into the conventional sludge concentration tank, uniform mixing is performed, then ozone is introduced, organic matters in the sludge can be quickly destroyed and decomposed, and the sludge quality and volume are effectively reduced; and the method is economical and practical, and easy to operate and manage, and has no secondary pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

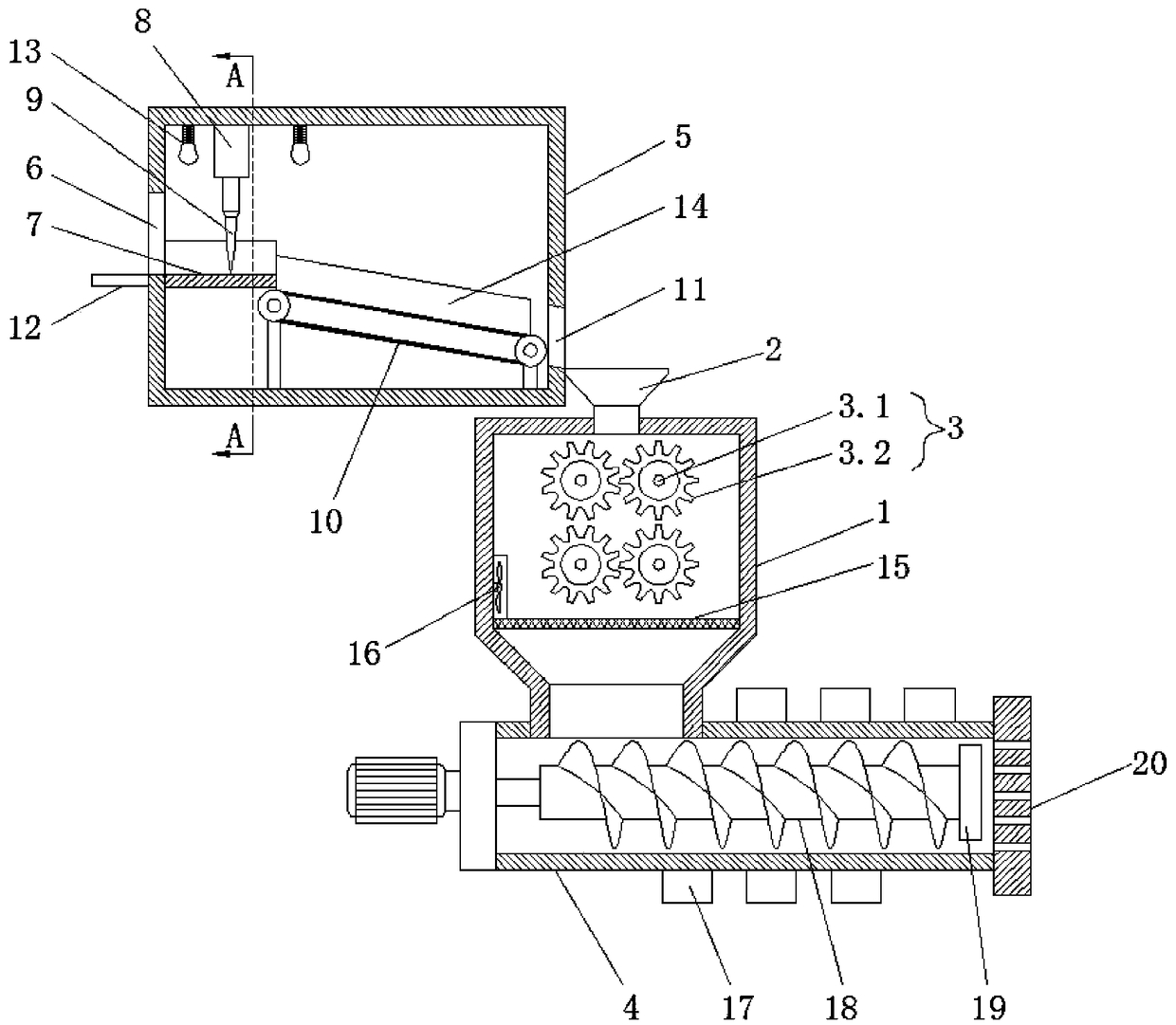

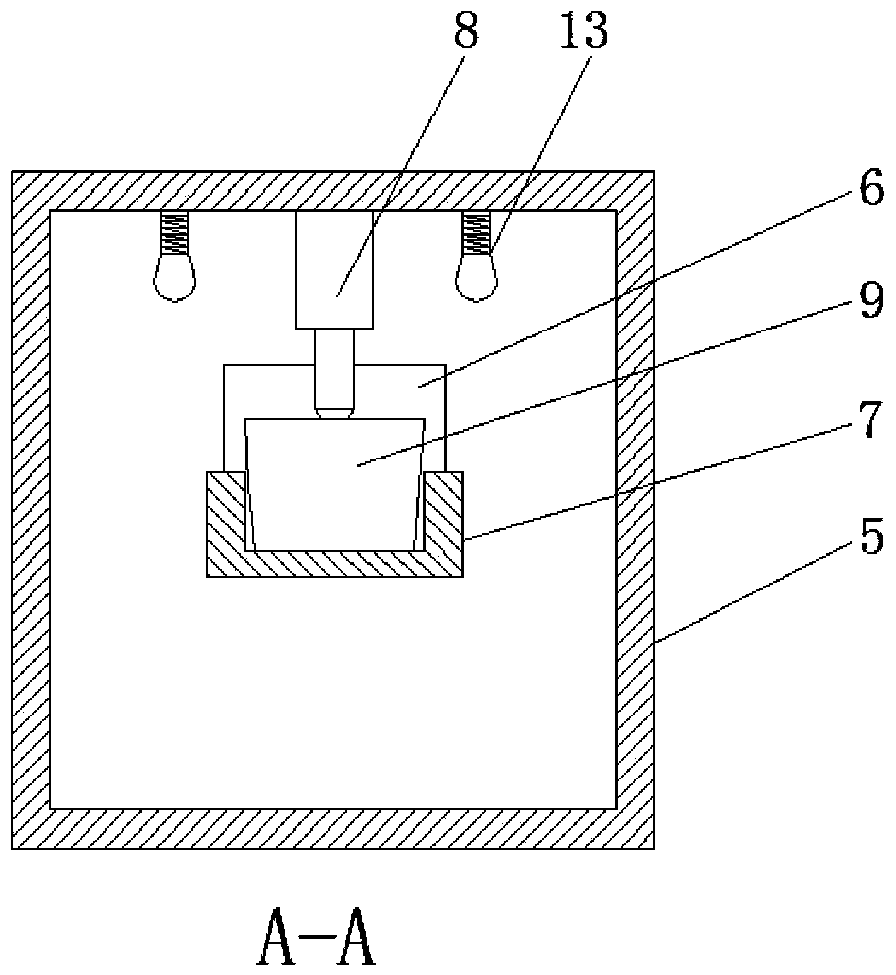

Multi-stage processing system for crop straw and operation method thereof

The invention discloses a multi-stage processing system for crop straw and an operation method thereof, and relates to the technical field of straw processing. The multi-stage processing system for the crop straw comprises a pretreatment machine for cutting straw raw materials into strips, a crusher is arranged below the pretreatment machine, a feeding hopper close to the discharging end of the pretreatment machine is arranged at the top of the crusher, the crusher is internally provided with at least two groups of crushing mechanisms arranged from top to bottom, and the crushing mechanisms are arranged under the feeding hopper. The bottom of the crusher is connected with an extrusion processing machine, the pretreatment machine is used for cutting, the crusher is used for crushing, and the extrusion processing machine is used for extruding. The multi-stage processing system for the crop straw has the advantages that the functions are complete, use safety of equipment is high, and thequality of produced fuel is high.

Owner:河南博顿生物科技有限公司

Preparation method of vacuum freeze dried fresh white fungus soup product

The invention discloses a preparation method of a vacuum freeze dried fresh white fungus soup product. The preparation method comprises the following steps of cooking fresh white fungus raw materials at steam pressure being 0.1-0.25MPa and steam temperature being 100-125 DEG C for 85-125s; then taking 36-50 parts of the cooked white fungus raw materials, and uniformly mixing the taken cooked white fungus raw materials with 14-22 parts of a 0.3-0.9% KGM solution, 10-18 parts of white granulated sugar or crystal sugar, 12-22 parts of first ingredients and 1-5 parts of second ingredients to obtain a mixture, wherein the first ingredients are mixed materials of purple sweet potatoes, apples, pineapples, papayas, mangoes and snow pears, and the second ingredients are mixed materials of honey, red jujubes, Chinese wolfberry fruits, lily bulbs, lotus seeds, blood nests and Chinese forest frogs; and performing vacuum freeze drying on the mixture so as to obtain finished products. According to the preparation method disclosed by the invention, technique bottlenecks that conventional cooking time is long, hot air dried white fungus products are not liable to rehydrate, white funguses are dry and crisp in mouth feel and are not soft and glutinous enough and cooking liquor is light and bad in color and flavor are broken through, the obtained white fungus soup products can be eaten after being brewed with ice water or warm boiled water, the white funguses are soft, glutinous and good in consistency, ingredients are natural and safe, and the products are rich in nutrition.

Owner:福建立兴食品股份有限公司

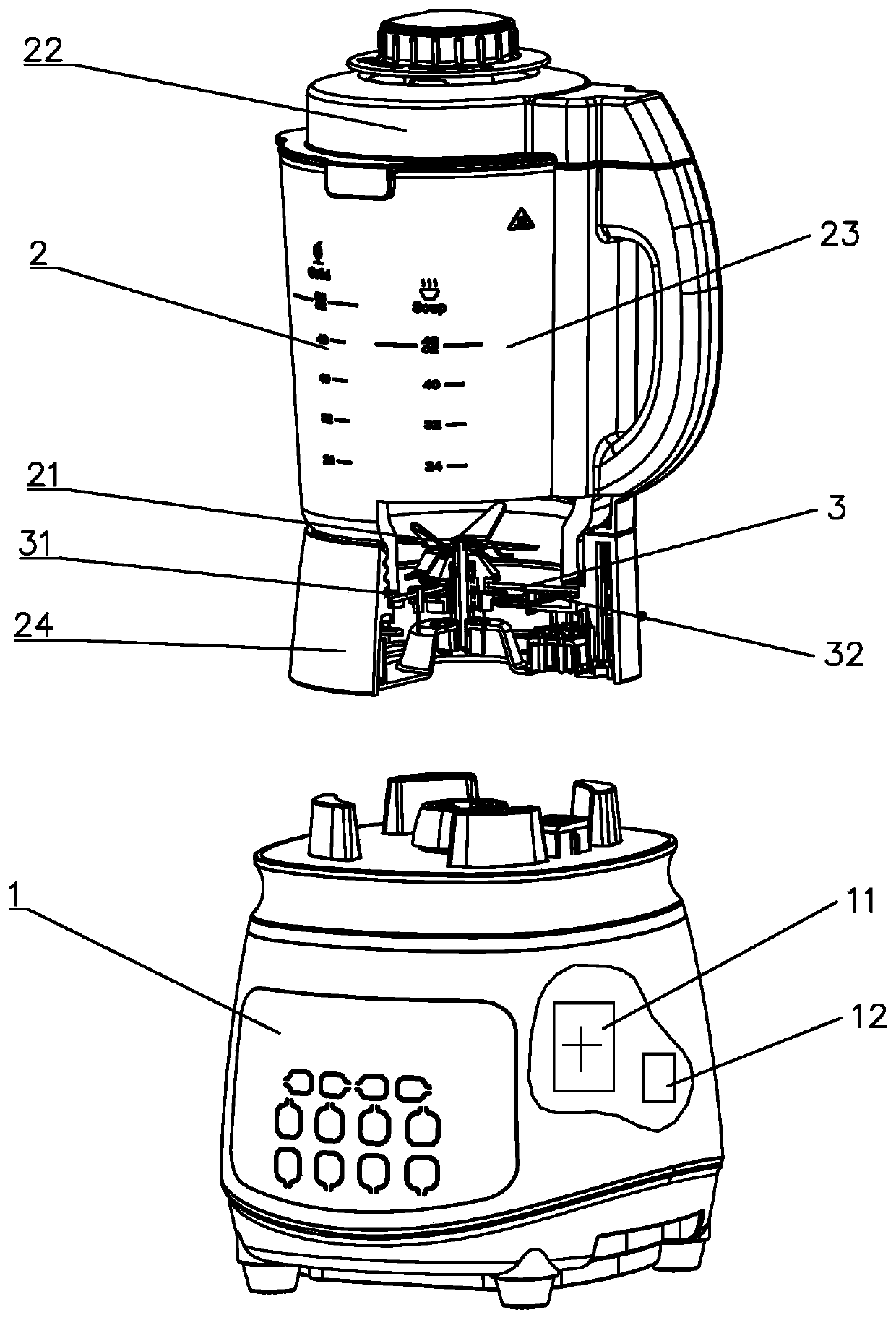

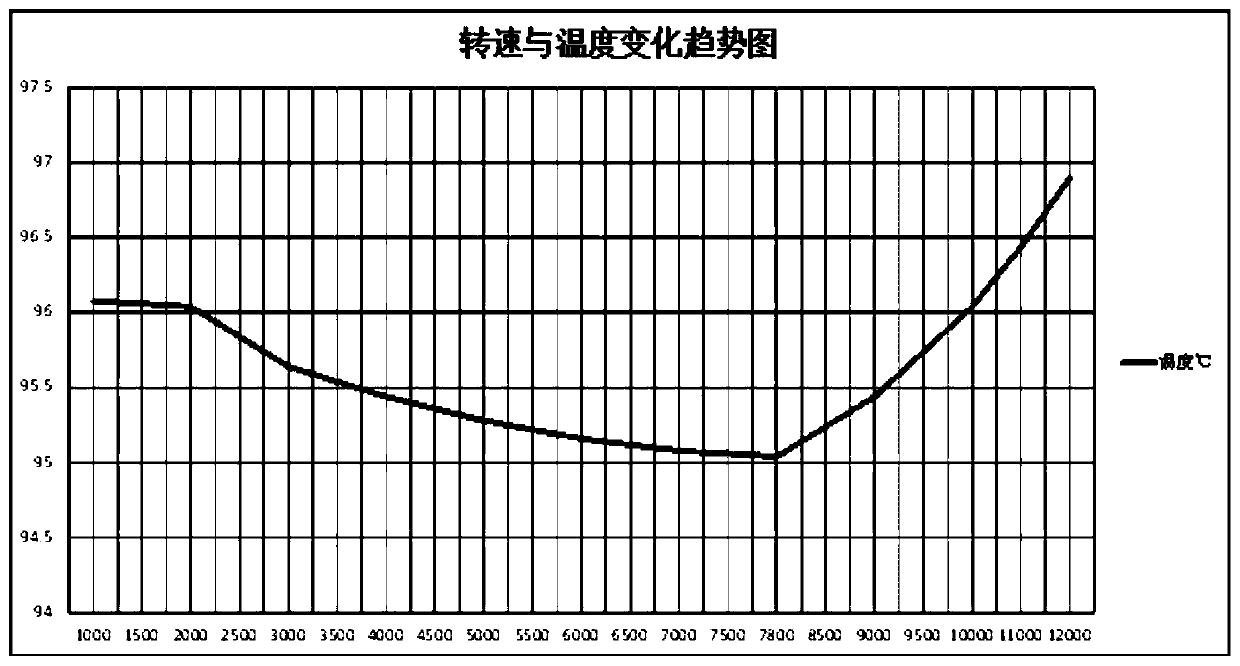

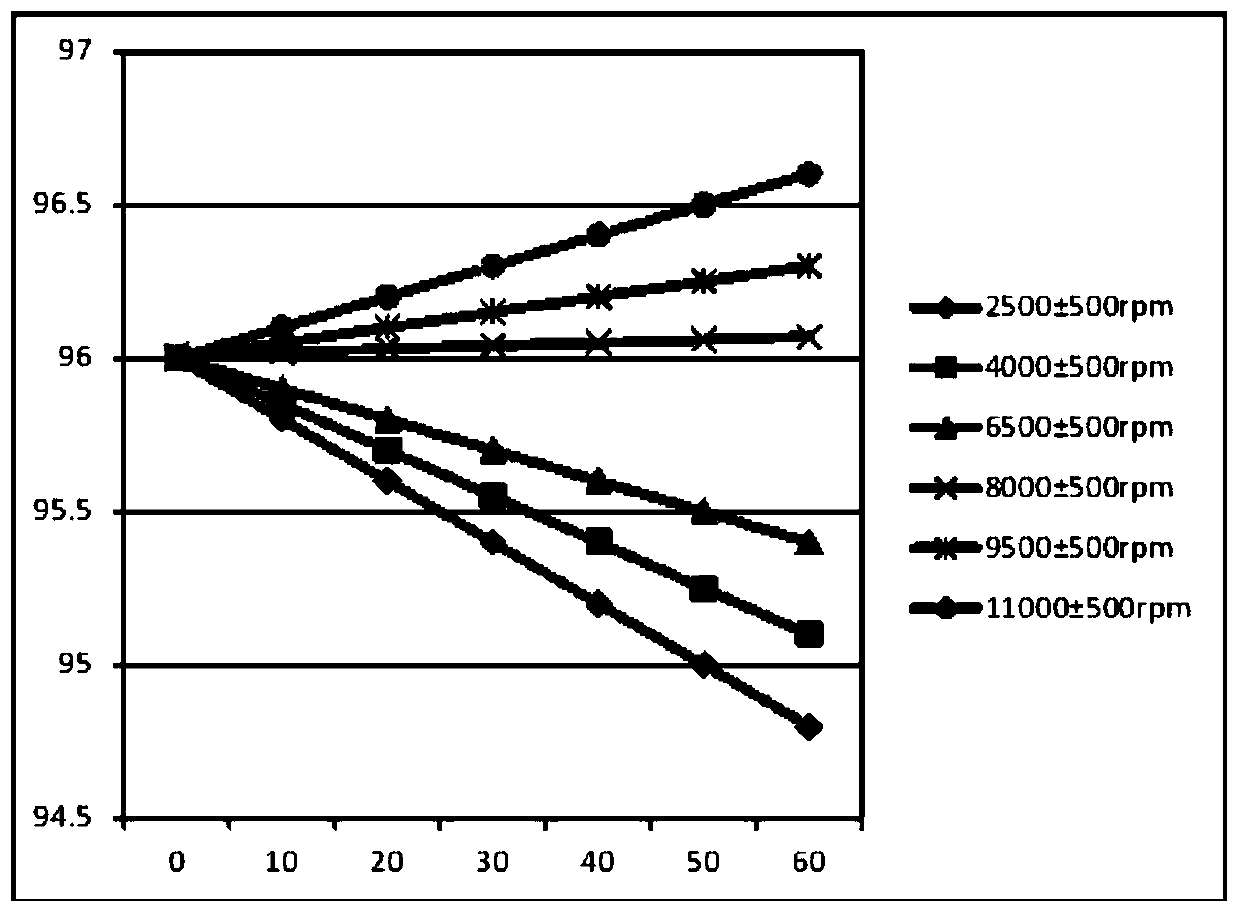

Method for quickly making hot beverage by food processor

InactiveCN109770744APrevent splashPrevent overflowBoiling over preventionWarming devicesPulp and paper industrySlurry

The invention provides a method for quickly making a hot beverage by a food processor. The food processor comprises a machine base, a stirring cup arranged on the machine base and a stirring knife arranged in the stirring cup, wherein a motor and a control unit are arranged in the machine base. The food processor further comprises a heating device. The method comprises the steps: at the first heating stage, heating pulp in the stirring cup by full-power operation of the heating device; at the crushing stage, driving the stirring knife to rotate by the motor and stirring and crushing the pulp in the stirring cup; at the boiling stage, controlling the heating device to operate in a non-full power way by the control unit and boiling the crushed pulp in the stirring cup. The method further comprises the steps: at the stirring and cooling stage, controlling the motor to drive the stirring knife by the control unit to rotate at a rotating speed V1, and stirring and cooling the pulp, wherein2000 rpm <=V1 <= 7800 rpm, the stirring and cooling stage is set after the first heating stage and before the crushing stage, so that the heated pulp is rapidly cooled, and the pulp is prevented fromoverflowing in the high-speed crushing process.

Owner:JOYOUNG CO LTD

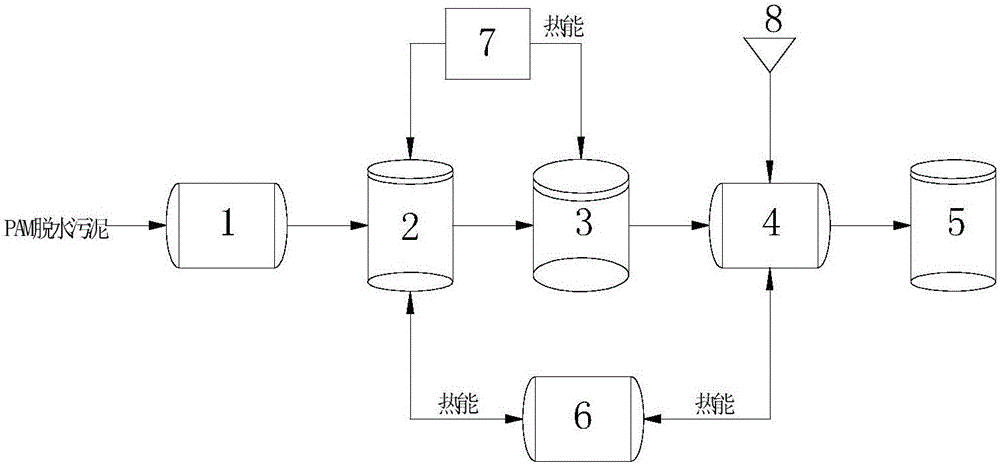

System and method for promoting hydrolysis of PAM (polyacrylamide) in dewatered sludge and simultaneously producing short-chain fatty acids

ActiveCN105948448AIncrease hydrolysis rateRealize resource processingWaste based fuelBiological sludge treatmentPotential toxicityZoogloea

The existing PAM (polyacrylamide) dewatered sludge has poor digestion efficiency due to oversize flocs in the anaerobic digestion process, thereby inhibiting the high-molecular organic matrix in the sludge from leaching, prolonging the retention time of the sludge, and providing possibility for degradation of PAM into the monomer acrylamide. The invention provides a recycling harmless system and method for promoting hydrolysis of residual PAM in dewatered sludge and simultaneously producing short-chain fatty acids, belonging to the field of sludge treatment and disposition. The method comprises the following steps: PAM dewatered sludge is subjected to pyrohydrolysis treatment to promote PAM flocs in dewatered sludge to dissociate; alkaline conditioning is carried out to sufficiently destroy the pyrohydrolysis sludge zoogloea floc structure; and the sludge is sent into an anaerobic fermentation tank to produce short-chain fatty acids. The method enhances the PAM hydrolysis rate, lowers the PAM potential toxicity, and implements recycling harmless utilization of PAM dewatered sludge.

Owner:HUNAN UNIV

Method for extracting platycodin

The invention discloses a method for extracting platycodin. The method comprises the following steps that firstly, the platycodon grandiflorum is dried, crushed and screened; secondly, a certain amount of platycodon grandiflorum powder is weighed and wetted through added water, and bio-enzyme reagent with the weight accounting for 0.5%-2% of the weight of the platycodon grandiflorum powder is added for carrying out enzymolysis processing; thirdly, after enzymolysis is finished, the ethanol water is added for reflux extraction, and the extraction solution is obtained; fourthly, the extraction solution is filtered, filter residues are repeatedly extracted, the extraction solution is combined, and vacuum concentration is carried out so that the extract can be formed; fifthly, the extract is dissolved, the dissolved solution is eluted through a macroporous resin column, the eluant is collected for vacuum concentration and drying, and then the platycodin is obtained. By means of the method for preparing the platycodin, the technology is easy to operate, the production cost is low, and the purity of obtained products is high.

Owner:NANJING ZELANG MEDICAL TECH

Anti-pilling treatment method for light and thin wool-polyester fabric

InactiveCN107938309AGood physical and mechanical propertiesImprove felting performanceWeft knittingWarp knittingPolyesterYarn

The invention relates to an anti-pilling treatment method for a light and thin wool-polyester fabric. The method comprises the following steps: weaving wool-polyester yarns, wherein the wool content of the yarns is 20-99%, and the yarns are 12.5-19.23tex; boiling the woven fabric, dehydrating, scotching, performing wool fabric scouring, washing, dehydrating, putting into microwave drying shaping-low-temperature normal-pressure plasma treatment equipment, performing microwave drying shaping firstly, and performing low-temperature normal-pressure plasma treatment secondly; finally performing softening finishing, so as to obtain the light and thin wool-polyester fabric. Microwave heating of the method has the advantages of high efficiency, energy conservation, low temperatures, uniform drying, no thermal inertia, and the like; industrial production of magnetrons is already achieved, so that the equipment is convenient to repair and replace and low in maintenance cost; by using a low-temperature normal-pressure plasma treatment technique, surface modification treatment on wool fibers in the fabric is implemented through medium baffled power discharge, so that the amounts of chemical reagents and water in the after finishing process of a woolen fabric are reduced, the energy is saved, the environment is protected, and the anti-pilling property of the fabric is improved.

Owner:DONGHUA UNIV +1

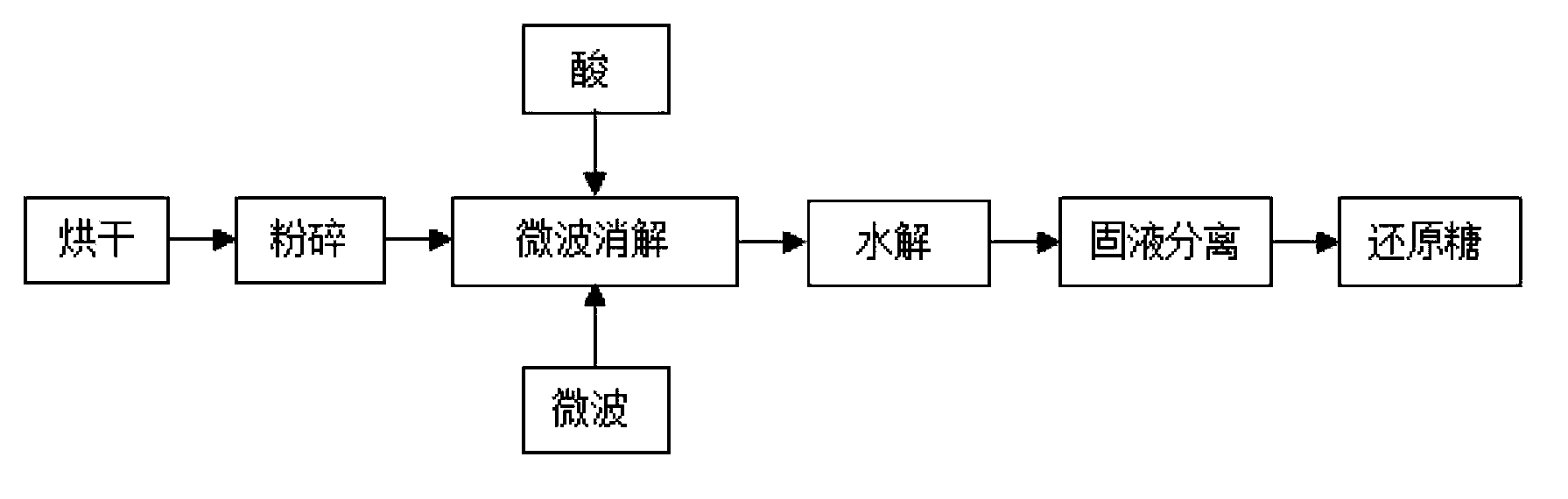

Method for preparing reducing sugar from material containing cellulose

The invention provides a method for preparing reducing sugar from a material containing cellulose. The method comprises a step of subjecting the pretreated material containing cellulose and cellulase to mixing and then to hydrolyzation, wherein pretreatment comprises mixing of the material containing cellulose with an acidic solution and microwave digestion at a temperature of 50 to 200 DEG C and a pressure of 0.05 to 2 MPa with 0.5 to 5 GHz microwaves for 1 to 60 min. With the method, the yield of reducing sugar can be increased.

Owner:COFCO NUTRITION & HEALTH RES INST +2

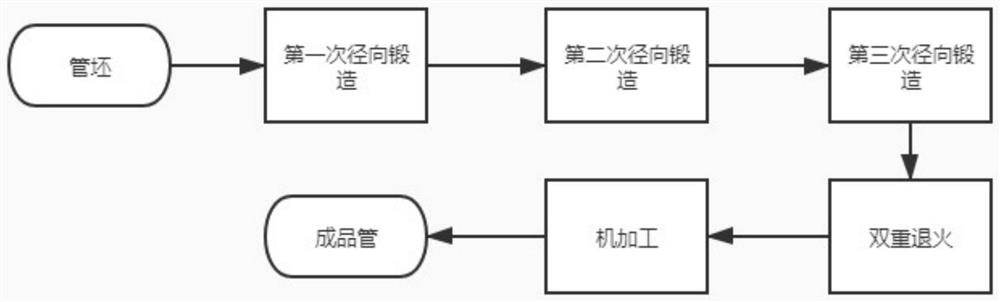

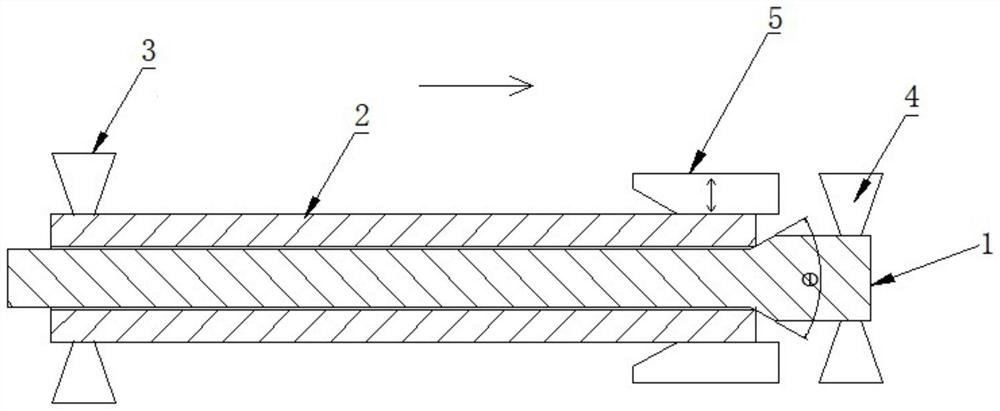

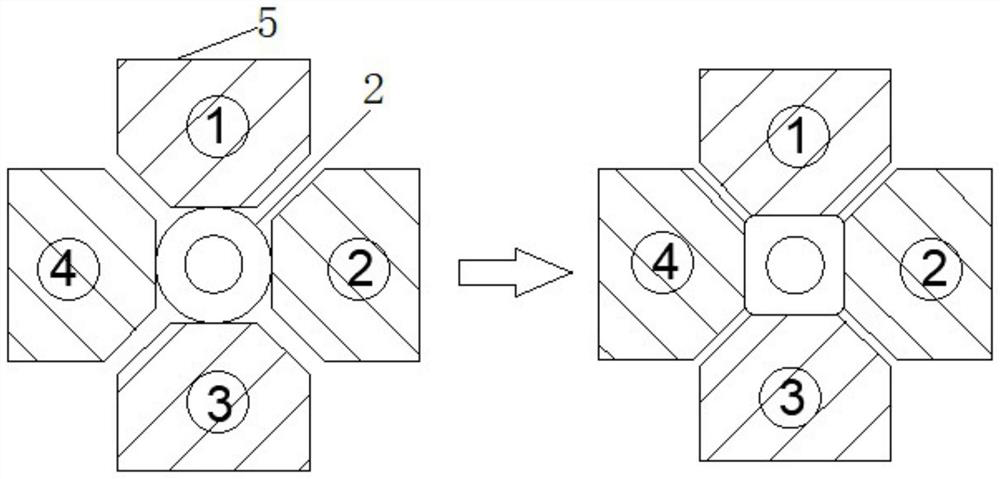

Short-process manufacturing method for titanium and titanium alloy pipes

ActiveCN112775370AIncrease the amount of deformationImprove densification performanceForging hammersFurnace typesProcess manufacturingTitanium

The invention discloses a short-process manufacturing method for titanium and titanium alloy pipes. The method comprises the processes of pipe blank heating, multiple-time radial forging, double annealing and machining, so that the titanium alloy pipes are obtained. The pipe blank heating temperature is 80 DEG C-100 DEG C higher than the titanium alloy beta phase transformation point, and the heat preservation time is larger than or equal to 2h. The multiple-time radial forging process comprises three times of radial forging, wherein the hammering speed of the first time of radial forging is 1000-2000 times per minute, and the pipe blank deformation is controlled to be 40% to 80%; the hammering speed of the second time of radial forging is 2000-3000 times per minute, and the pipe blank deformation is controlled to be 30% to 60%; and the hammering speed of the third time of radial forging is 50-100 times per minute, and the pipe blank deformation is controlled to be 30% to 40%. The manufacturing method is short in processing period and low in cost, the titanium alloy pipes with equiaxial or binary structures and excellent mechanical properties can be directly obtained, and the material utilization rate is high.

Owner:江苏宇钛新材料有限公司

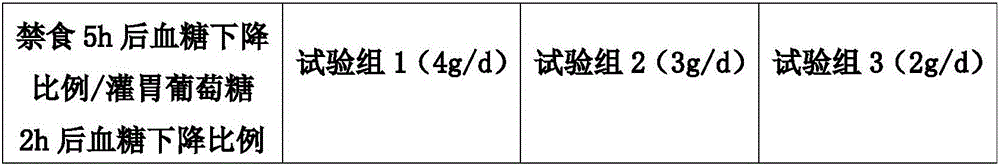

Preparation method and application of mulberry leaf instant tea

InactiveCN105994791AGood instant solubilityFacilitated releasePre-extraction tea treatmentTea extractionCelluloseSolubility

The invention discloses a preparation method and application of mulberry leaf instant tea. The preparation method comprises the following steps of: adopting fresh mulberry leaves as preparation raw materials; and adopting a drying process, a crushing process, a primary extracting process, a primary filter process, a microwave-assisted compound enzyme treatment process, a secondary extracting process, a secondary filter process, a process of combining and extracting extract liquor obtained twice, a drying process and a pelletizing process; an microwave-assisted compound enzyme extracting technology is used for sufficiently breaking and dehydrating cellulose and pectin substances, so that release and dissolution of functional ingredients in mulberry leaves are increased, and therefore, the yield of gamma-aminobutyric acid with a health value and content of functional components such as 1-deoxynojirimycin are improved. The prepared mulberry leaf instant tea is strong in instant solubility, has remarkable healthcare effect of reducing blood sugar, reducing fat and reducing pressure for three-high crowd; the processing method is strong in maneuverability and is beneficial to industrial development of national mulberry leaf instant tea.

Owner:江苏南大耐雀生物技术有限公司

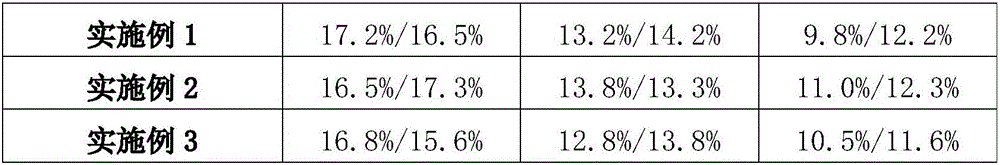

Environment-friendly coating for exterior wall and preparation method thereof

InactiveCN110845953AExtended service lifeImprove adhesionCellulose coatingsAnti-corrosive paintsFiberPolymer science

The invention belongs to the technical field of environment-friendly coatings and relates to an environment-friendly coating for an exterior wall and a preparation method thereof. The environment-friendly coating for the exterior wall comprises the following raw materials in parts by weight: 40 to 50 parts of an acrylic emulsion, 20-30 parts of polyether polyol, 20-30 parts of a filler, 10-20 parts of carboxymethyl betaine, 5-10 parts of isocyanate, 5-10 parts of ceramic fibers, 5-10 parts of nanometer silicon dioxide, 5-8 parts of a surfactant, 3-6 parts of a plasticizer, 1-3 parts of a drying agent, 1-2 parts of an anti-aging agent and 0.5-1 part of an anti-ultraviolet agent, wherein the anti-aging agent is prepared from zirconium oxide, nanometer titanium dioxide and modified graphene according to a mass ratio of (10-5): (4-8): 1. The environment-friendly coating is non-toxic, odorless, green and safe, has good elasticity, flexibility, waterproofness, aging resistance, abrasion resistance and ultraviolet resistance, short curing time, good hardness and long service life, can be directly painted, and is convenient to operate and applicable to exterior walls.

Owner:青川源泰建材科技有限公司

Method for extracting hyoscyamine from mandragora flower

InactiveCN104230919AHigh extraction rateIncrease exercise frequency and speedOrganic chemistrySolventCombined method

The invention discloses a method for extracting hyoscyamine from mandragora flower, and belongs to the chemical fields of natural products, in particular to a combined method of smashing of plant tissue breaking process and ultrasonic extraction. The method comprises the following steps of: adding mandragora flower into 70-80% ethanol solution of which the weight is 1-3 times of that of the mandragora flower; smashing the mixture by means of plant tissue breaking extraction for 1-2 minutes; taking out the mandragora flower and adding 70-80% ethanol of which the weight is 8-10 times of that of the original weight; regulating PH value to be between 4.5 and 5.5; putting the mandragora flower into an ultrasonic extractor for extracting for 30-50 minutes; performing centrifugation; adding supernate into a macroporous resin column for performing adsorption; rinsing the resin column with water; adding 8-10 times of ammonia ethanol solvent elution effective components into the resin column; collecting and condensing eluant to obtain total alkaloids; performing ethanol recrystallization for twice to obtain high-purity hyoscyamine. The method has the advantages of easy operation, low energy consumption, mild reaction condition, low extraction cost and the like, and therefore, the method is a simple and easily-industrialized technique for producing hyoscyamine.

Owner:NANJING BIAOKE BIO TECH

Extraction method for green tea extract

InactiveCN107397225AFacilitate extractionLow costMetabolism disorderTea extractionChemistryRotary evaporator

Belonging to the technical field of tea products, the invention discloses an extraction method for a green tea extract. The method includes: spraying dried green tea wet with water; putting the wet green tea into a pressurization container, pressurizing the container, when the pressure in the container reaches a certain degree, opening a container material spray port, then putting the tea into a pressure reduction container, reducing the pressure in the container, and when the pressure in the container reaches a certain degree, opening the container material spray port; then drying the green tea, and crushing the green tea; firstly soaking the obtained green tea powder with distilled water, and then performing extraction with boiling water; and subjecting the obtained extracted liquid to concentration on a rotary evaporator to obtain a green tea extract. The method provided by the invention employs hot water extraction, and compared with other extraction methods, greatly reduces the extraction cost of tea extracts, avoids the pollution of organic solvents, also has no need for adsorption to remove organic solvents, and the processed tea extract has high safety.

Owner:贵州苗贵客贸易发展有限公司

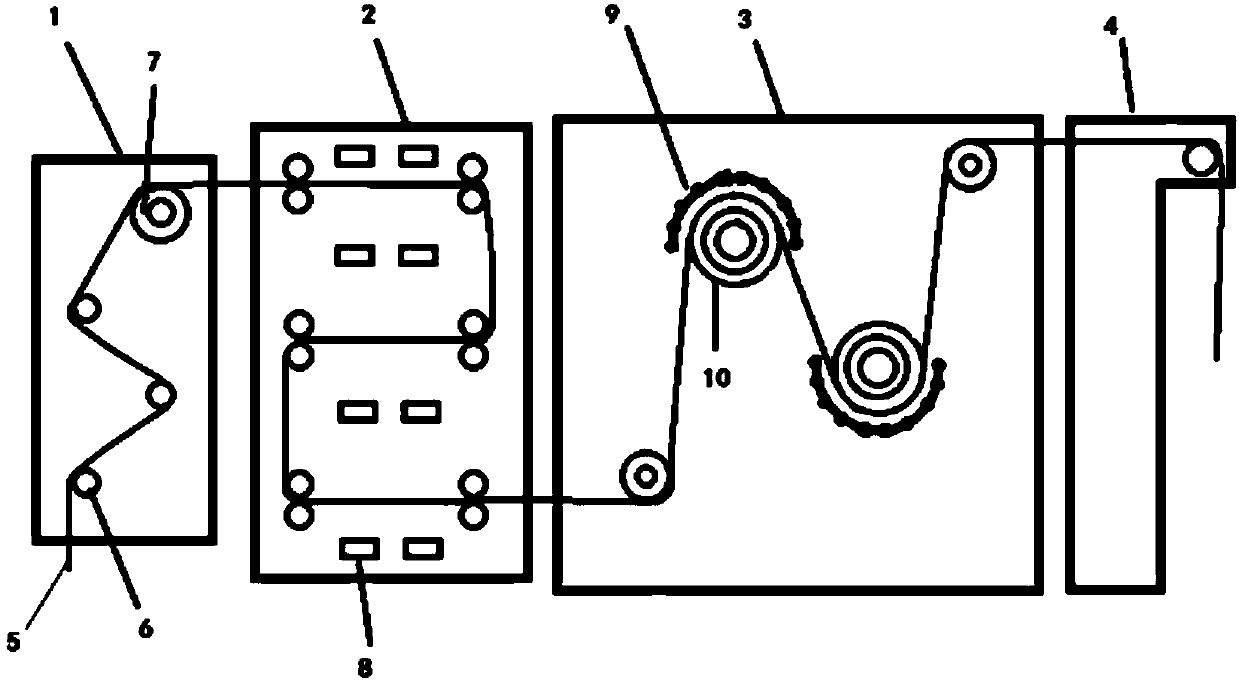

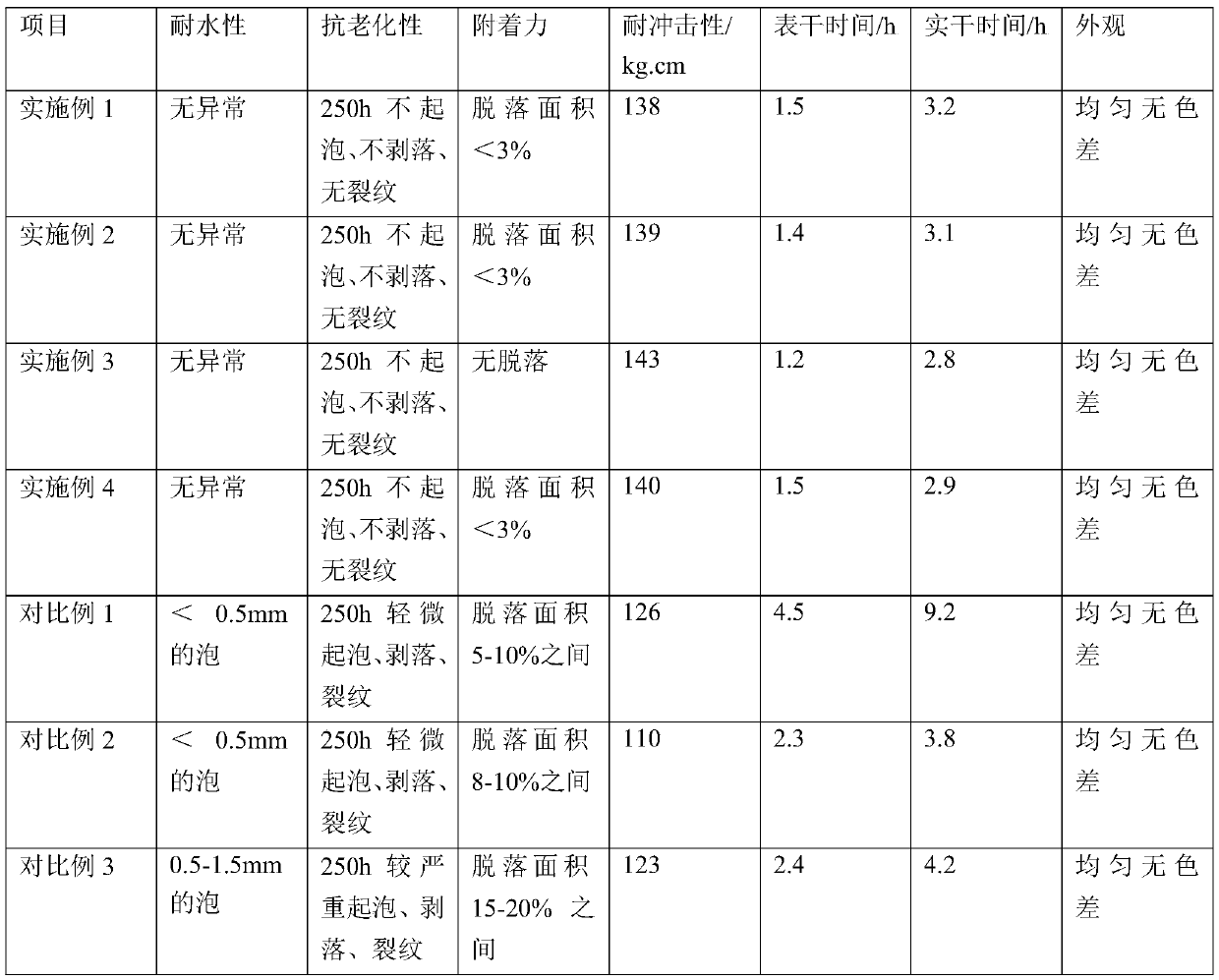

Novel method for preparing granular modified regenerated rubber through two-stage continuous green regeneration of waste rubber

InactiveCN105418962AEnsure recoveryFully destroyedPlastic recyclingPelletizingEnvironmentally friendly

The invention discloses a new method for preparing granular modified regenerated rubber through two-stage continuous green regeneration of waste rubber. The method comprises the steps that rubber granules obtained by performing front section breaking on the waste rubber are spirally conveyed into a rubber regenerator, and on the condition that no chemical auxiliary needs to be added, two-stage continuous mechanical sulfur-breaking green regeneration of the waste rubber, that is, first-stage mechanical sulfur-breaking regeneration of pure rubber granules and second-stage mixing modification with a corresponding polymer modifying agent and mechanical sulfur-breaking regeneration are achieved; purifying and granulating, sealing treating, cooling and drying are sequentially performed to obtain the environment-friendly granular modified regenerated rubber, and finally the regenerated rubber is packaged through a packaging machine and warehoused. According to the method, a traditional one-stage desulfurization regeneration technique is replaced by a novel two-stage pure-mechanical high-shearing-action sulfur-breaking green regeneration technique, no chemical auxiliary needs to be added in the production process, the energy can be saved by 40%, the production process and the corresponding product are truly environmentally friendly and free of pollution, and meanwhile the granular modified regenerated rubber can act with the polymer modifying agent to obtain diverse environment-friendly granular modified regenerated rubber products.

Owner:ANHUI GVG NEW MATERIAL CO LTD

Processing method of green tea

InactiveCN107372931AIncrease internal and external temperatureImprove consistencyPre-extraction tea treatmentHorticultureDissolutionGreen tea

The invention discloses a processing method of green tea, which belongs to the technical field of tea processing. The processing method comprises the following steps: picking, withering, fixing, spreading and air-drying, kneading, removing tealeaf tips, pile-fermenting, pressing, floating, drying and improving the fragrance; the fragrance improvement is to treat a tea block which is dried and cooled to the normal temperature with steam of 100 to 120 DEG C for 6 to 12 min, then to place the tea block into a fragrance improving machine, wherein the temperature in the fragrance improving machine is adjusted to 30 to 50 DEG C, after the tea block is treated for 8 to 15 min, the temperature is increased to 60 to 80 DEG C, after the tea block is treated for 6 to 10 min, the temperature is increased to 90 to 110 DEG C, and then the tea block is treated until the water content is 3.0 to 5.5 percent, thus obtaining the green tea. According to the processing method, when the fragrance is improved, the tea block is firstly preheated with steam, so that substances contained in the tealeaves can be changed, a maturity accelerating effect can be achieved, the fragrance of the tealeaves can be significantly improved, the dissolution of tealeaf substances can be increased, and the content of water extract can be increased.

Owner:贵州苗贵客贸易发展有限公司

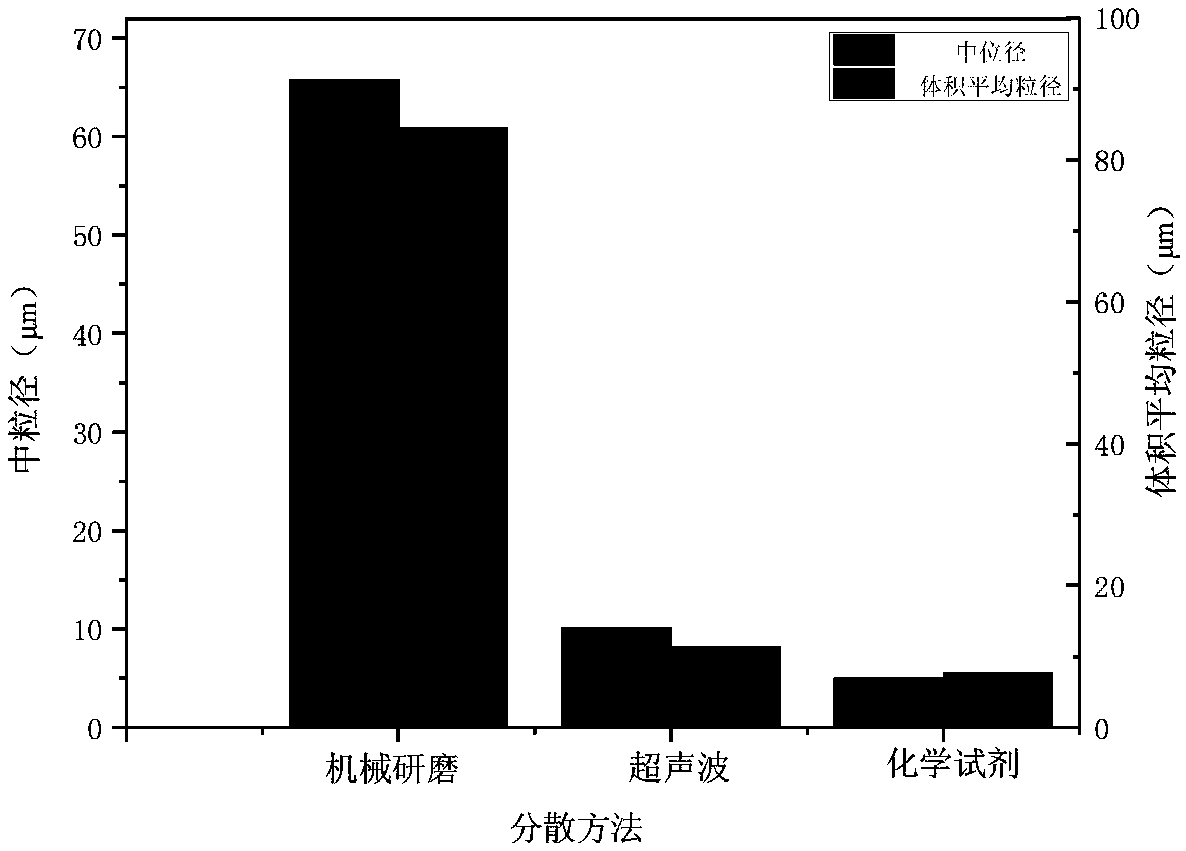

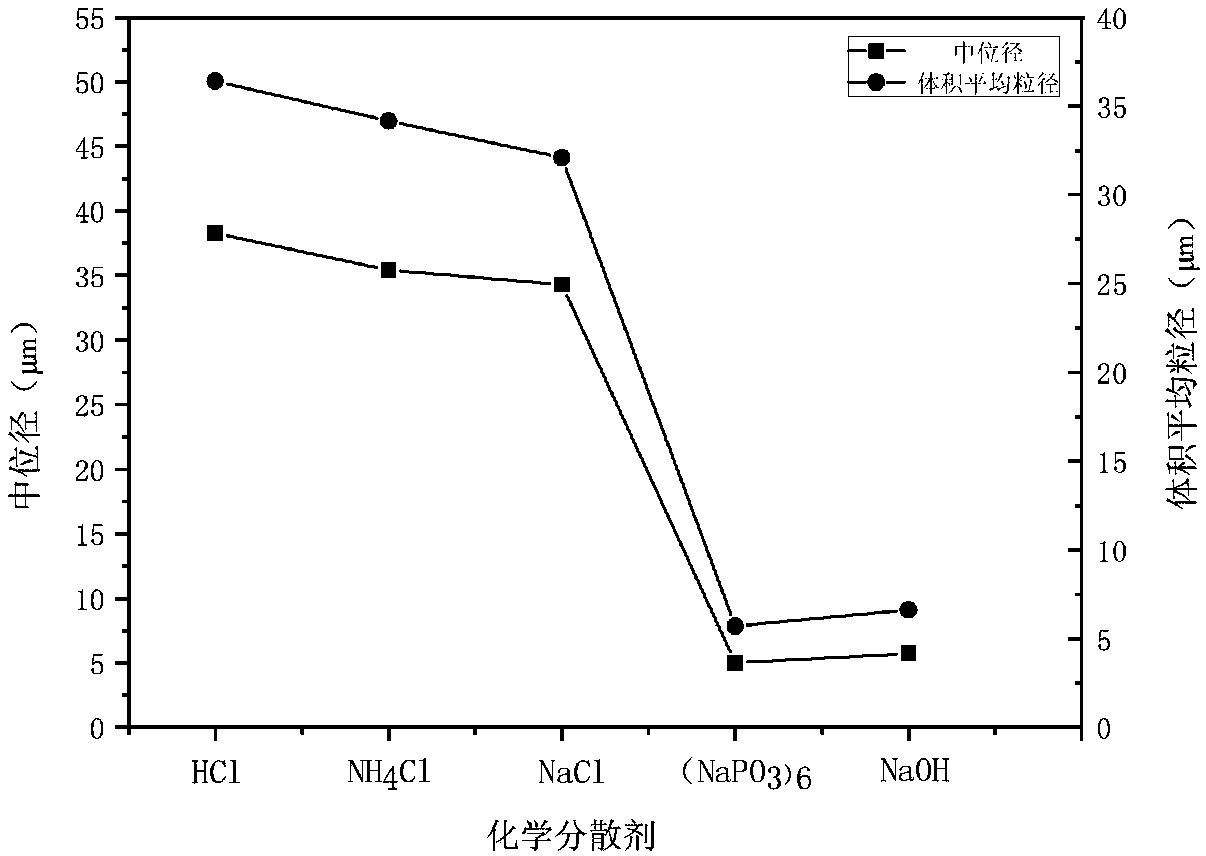

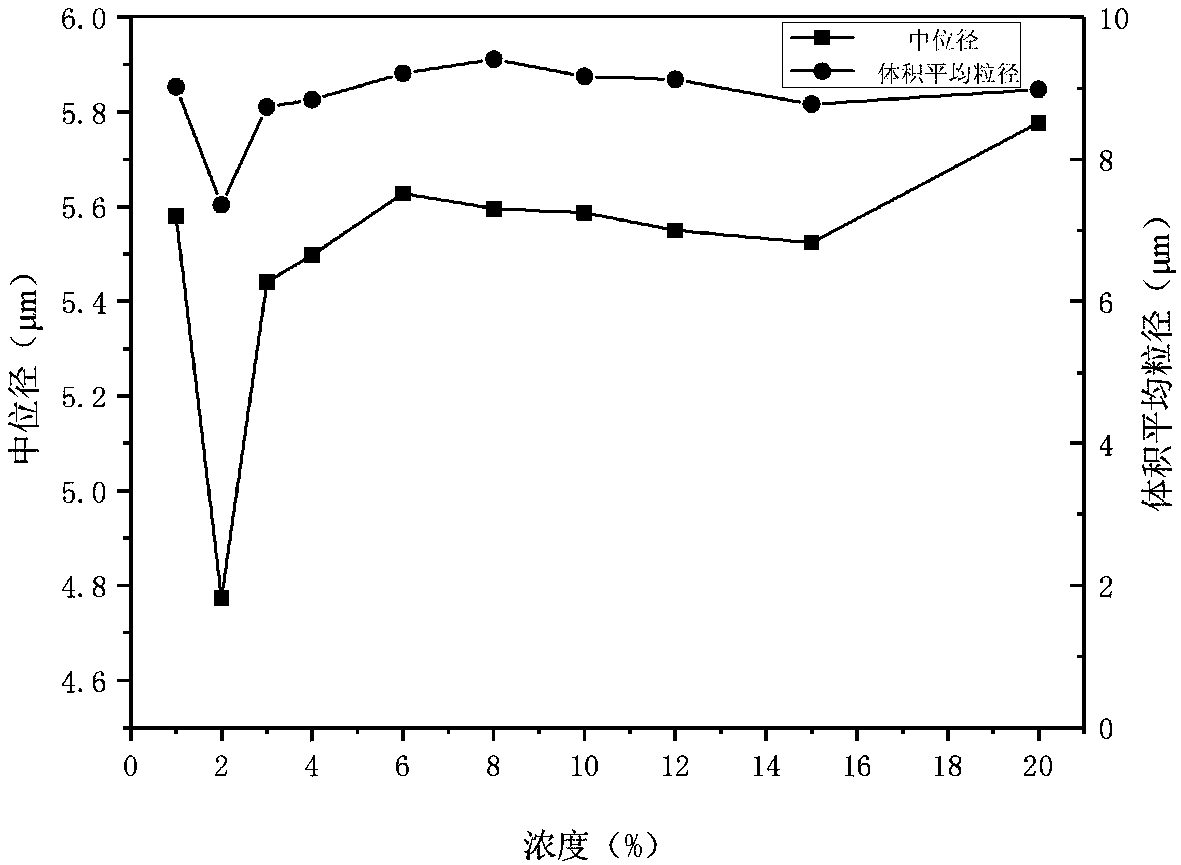

Method for determining particle size distribution of Guiyang red clay based on laser particle size analyzer

PendingCN108593506AFully destroyedHigh degree of separationPreparing sample for investigationParticle size analysisParticle size measurementParticle Size Analyzer

The invention discloses a method for determining the particle size distribution of Guiyang red clay based on a laser particle size analyzer. The method comprises: 1, taking a Guiyang red clay sample in the field, carrying out air drying, taking the dried clay sample, putting the clay sample into a mortar and carrying out full mechanical grinding, 2, screening the ground red clay through a fine sieve with pore sizes of 1 mm, 3, putting 0.3g of the screened red clay into a beaker with 12ml of a sodium hexametaphosphate solution with a concentration of 2% and carrying out immersion, and 4, stirring the immersion solution through a glass rod for 3min, then putting the mixture into a constant temperature oscillator, setting a temperature to 40 DEG C, carrying out constant temperature oscillation for 2h, immediately introducing the red clay into the laser particle size analyzer through the glass rod and carrying out particle size measurement. The method can truly show the particle size distribution of the Guiyang red clay, is simple and feasible and is easy to operate.

Owner:GUIZHOU UNIV

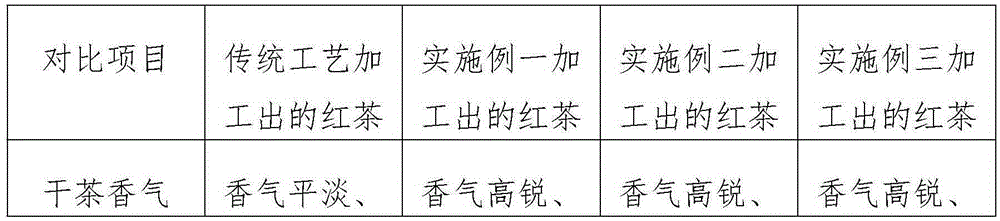

Processing method of black tea

InactiveCN105248710AExquisite appearanceEasy accessPre-extraction tea treatmentIntercellular spaceMoisture

The invention discloses a processing method of black tea. The method comprises the following steps: selecting leaves and pre-treating; withering; rolling; fermenting; removing moisture; shaping; drying; improving aroma; and screening. According to the processing method, moisture in intercellular spaces of the tea leaves is evaporated through stomas and horny layers through sun withering treatment, so that leaf textures become soft and subsequent withering and rolling treatment can be conveniently carried out; in a rolling process, a light-strong-light rolling manner is adopted and the cell disruption rate of the tea leaves can be effectively improved to be more than 91%, leaf tissues are sufficiently damaged and a foundation is laid for shaping; the processing method can be used for shaping the tea leaves into a spherical shape so that the appearance of the tea leaves is relatively exquisite and the tea leaves are convenient to fetch; after the tea leaves are subjected to strict temperature-control fermentation, the aroma is primarily extracted; and after the steps of drying and improving the aroma, the black tea which has the characteristics of rich aroma, rich taste, red and bright soup color and the like can be prepared.

Owner:FENGGANG XIUGU TEA CO LTD

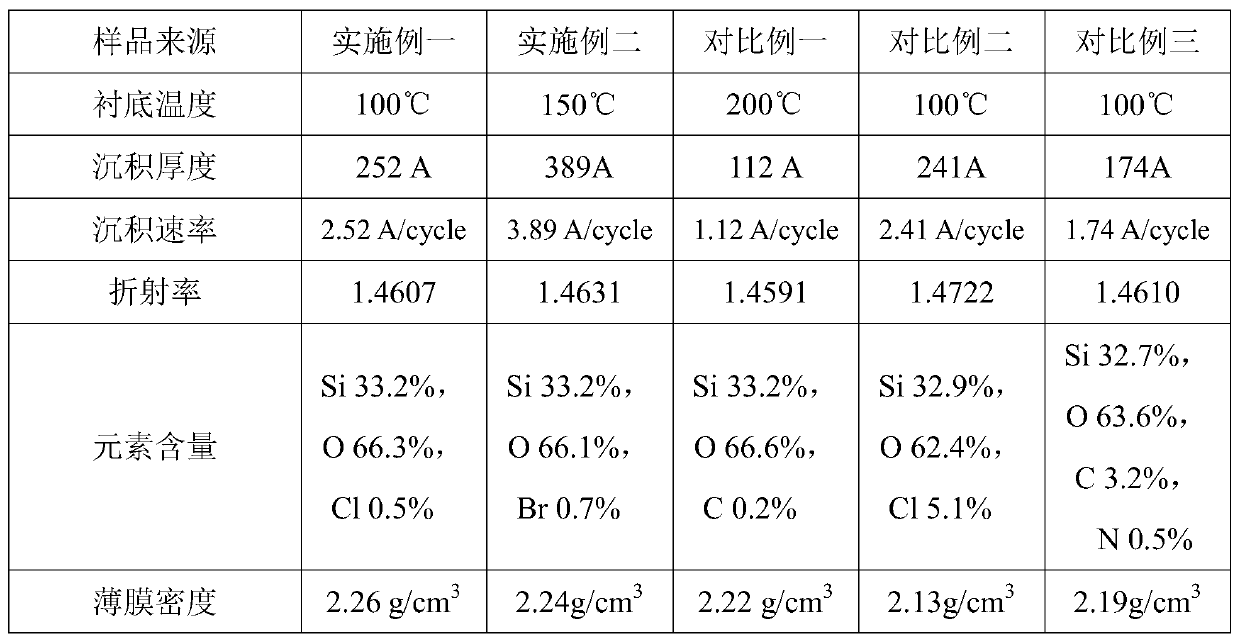

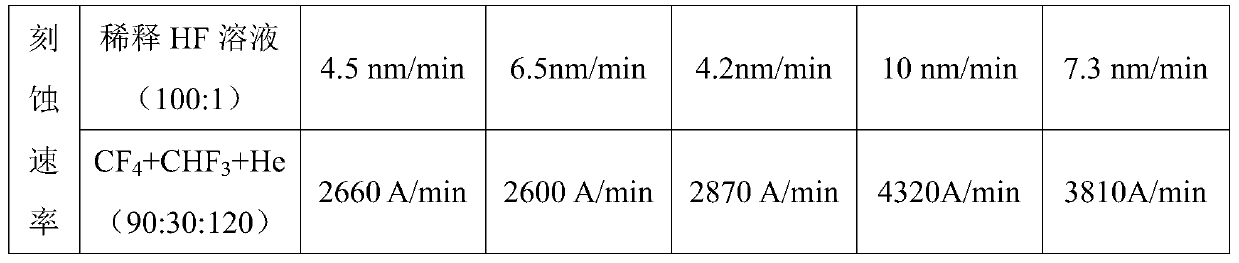

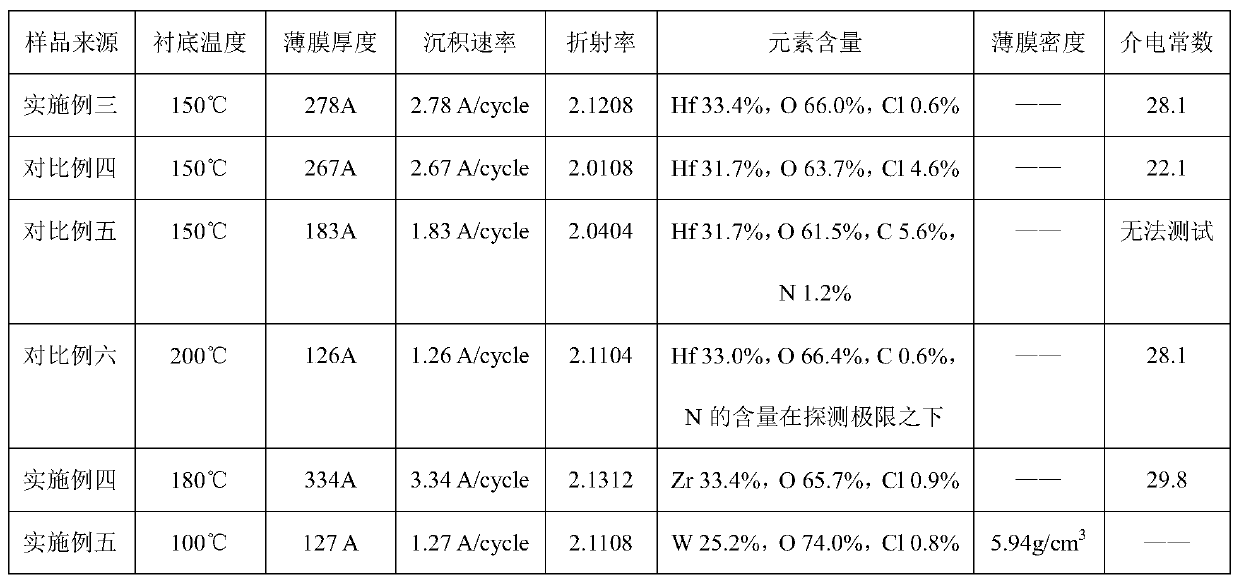

Low-temperature atomic layer deposition method for oxide film

ActiveCN109811329AQuality improvementAvoid damageChemical vapor deposition coatingHalogenChemical adsorption

The invention provides a low-temperature atomic layer deposition method for an oxide film. The low-temperature atomic layer deposition method is applied to the field of semiconductor films, can realize film deposition under a relatively low temperature, can also control the content of impurities in the film and maintains the deposition efficiency to be 1A / cycle or higher. According to the low-temperature atomic layer deposition method provided by the invention, a silicon halide or a metal halide or a metal oxyhalide is taken as a precursor material to implement atomic layer deposition on a substrate or an element; and after a chemical adsorption step is ended, halogen is removed by adopting plasma. The plasma treatment can damage the Si-X bond or the M-X bond (X represents halogen and M represent a metal), so that halogen residues in the film are effectively removed, and the quality of the film is improved; meanwhile, the Si-X bond or the M-X bond is damaged before oxidization, so someof halogen atoms are effectively removed, thus metal atoms are fully oxidized, and the deposition rate is also increased.

Owner:合肥安德科铭半导体科技有限公司

Technique for processing and preparing kelp seaweed spore powder

InactiveCN102138679AFully destroyedFully dissolvedFood preparationManufacturing technologyHigh energy

The invention relates to the technical field of marine biological products. The invention provides a technique for processing and preparing kelp seaweed spore powder so as to solve the technical problem that nutritional ingredients in the conventionally processed kelp seaweed powder and spore thereof are limited by a spore wall and cannot be dissolved out completely. The technique comprises the following steps of: cleaning and desalinating the kelp seaweed raw material; stripping spore tissues; performing enzymolysis; breaking the wall by high-energy electron beams; filtering; and drying. Kelp seaweed spore liquid is subjected to enzymolysis and high-energy electron beam treatment, so that the cell wall of the kelp seaweed sporophyte can be damaged completely, wall-broken rate is over 90 percent, and nutritional substances in the kelp seaweed sporophyte can be dissolved out completely.

Owner:山东海之宝海洋科技有限公司

Antrodia cinnamomea health tea and preparation method thereof

InactiveCN105475555AIncreased release rate and volumeGreat tastePre-extraction tea treatmentChemistryDrug biological activity

The invention discloses an antrodia cinnamomea health tea. The antrodia cinnamomea health tea is prepared from tea and an antrodia cinnamomea extracting solution. The preparation method comprises the following steps: 3-4 parts by weight of the antrodia cinnamomea extracting solution is added into 100 parts by weight of tea in the way that the antrodia cinnamomea extracting solution is twice sprayed onto tea, 35%-40% of the antrodia cinnamomea extracting solution is added during rolling, and the rest of the antrodia cinnamomea extracting solution is added in the frying process. The invention also discloses a preparation method of the antrodia cinnamomea health tea. The antrodia cinnamomea health tea has the advantages of being good in taste, high in biological activity and favorable for human absorption.

Owner:SHENZHEN RENTAI BIOLOGICAL TECH

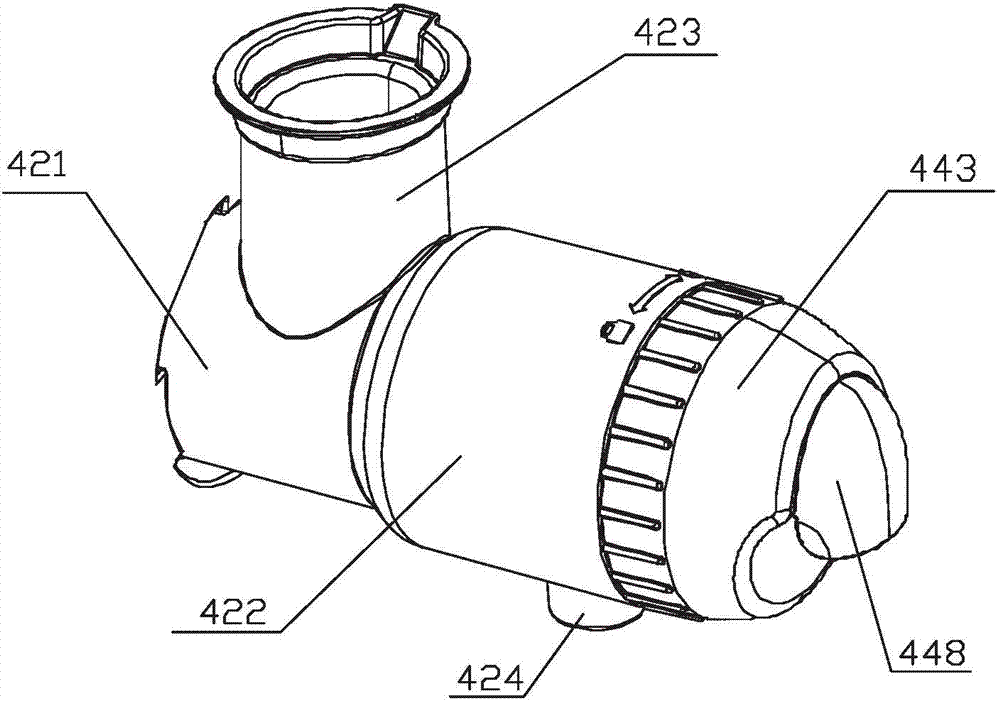

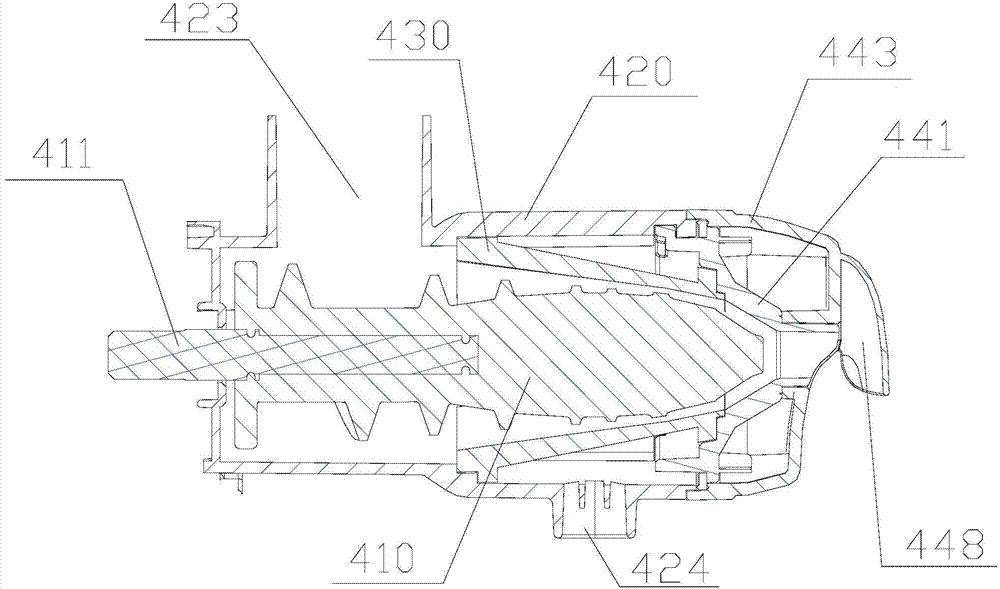

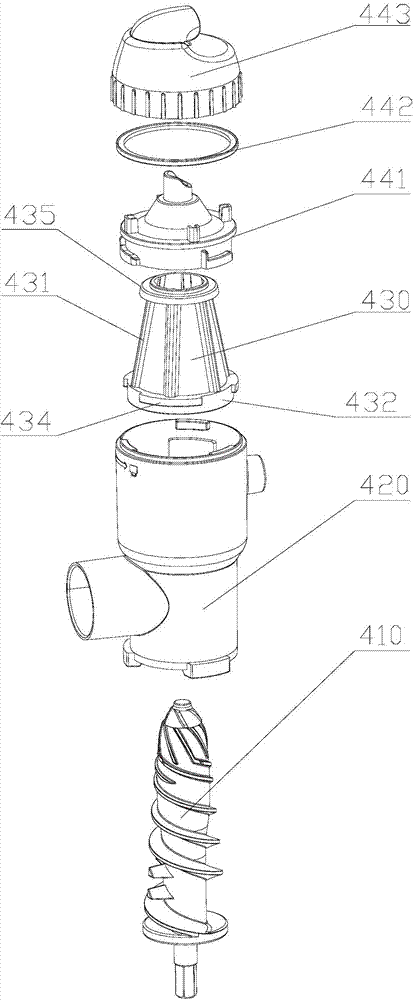

Juicing device of full-automatic fruit and vegetable facial mask machine

The invention relates to a juicing device of a full-automatic fruit and vegetable facial mask machine. The juicing device comprises a barrel, a threaded rod and a driving device, and is characterized in that the driving device and the threaded rod are connected in a driving mode, the threaded rod is arranged in the barrel in a sleeved mode, protruding threads are arranged on the surface of the threaded rod, the gap between the threaded rod and the barrel gradually narrows in the juice outlet direction, a residue outlet end is arranged at the other end of the barrel, the barrel comprises a front barrel body and a rear barrel body, a feed pipe communicated with the inner portion of the barrel is arranged on the upper portion of the front barrel body, a conical cover is coaxially arranged in the rear barrel body, a filter screen is arranged on the conical cover, the conical cover shrinks in the juicing direction, and a juice outlet is formed in the portion, below the conical cover, of the rear barrel body. When the juicing device is used for squeezing of the facial mask machine, the squeezing speed is low, the temperature is low, nutritional ingredients in fruits and vegetables are not prone to damage, fiber compositions reserved in the fruits and vegetables are beneficial to facial mask forming, and facial mask forming quality is improved.

Owner:袁厚兵 +3

Method for comprehensively using orange peels

The invention discloses a method for comprehensively using orange peels. The method comprises the steps: drying fresh orange peels, soaking in salt water for 8 to 12 hours, filtering, taking out the orange peels, and freeze-drying at a low temperature for 10 to 18 hours; putting the freeze-dried orange peels into a distillation tank, introducing steam to distill for 3 to 5 hours, and getting mixed steam; condensing the mixed steam through a condenser, conducting oil-water separation through an oil-water separator, and getting orange peel crude oil; standing the orange peel crude oil at low temperature, filtering, and getting orange peel essential oil. The orange peel essential oil extracted by the invention has a sweet orange aroma and can be applied in the fields of cosmetics, medicine and the like. The market prospect is good, and the abandoned orange peels are used comprehensively and reasonably, and have good economic benefit, ecological benefit and social benefit.

Owner:王再青

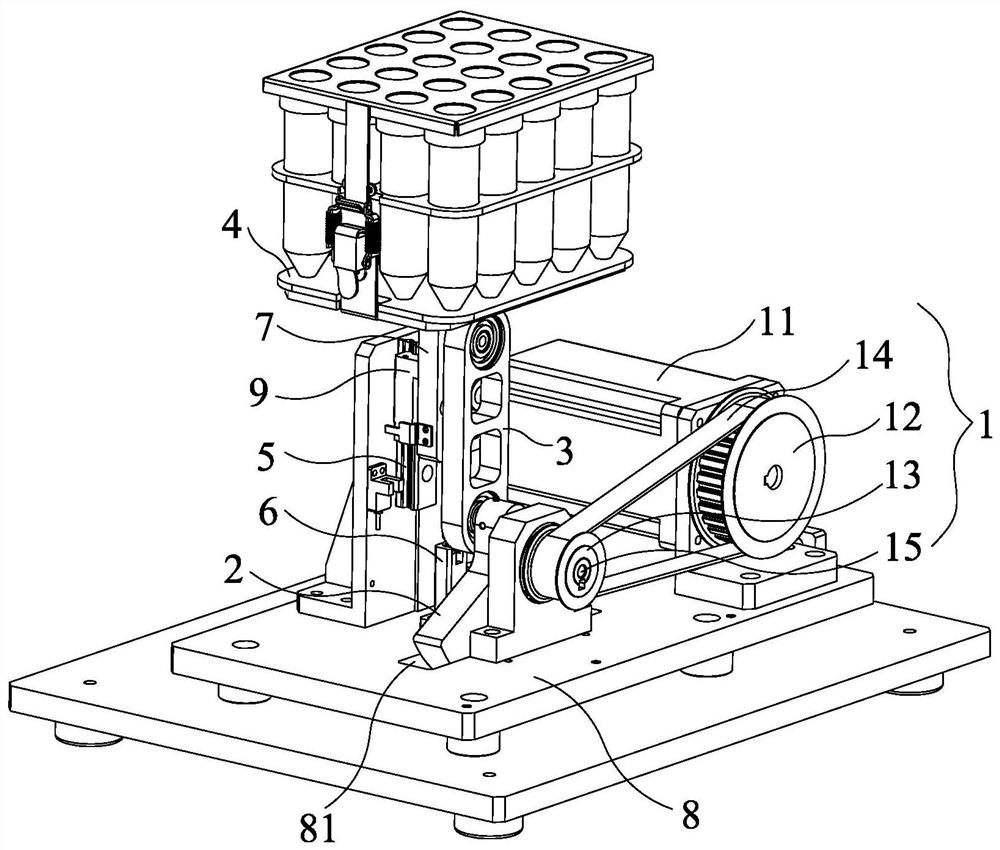

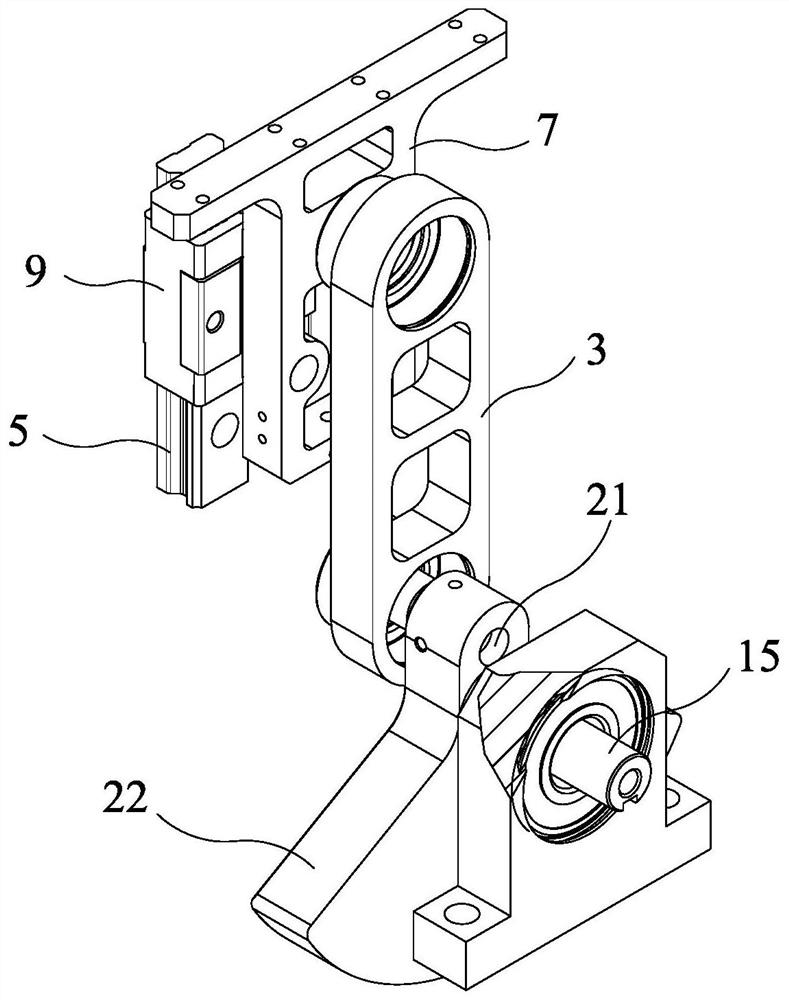

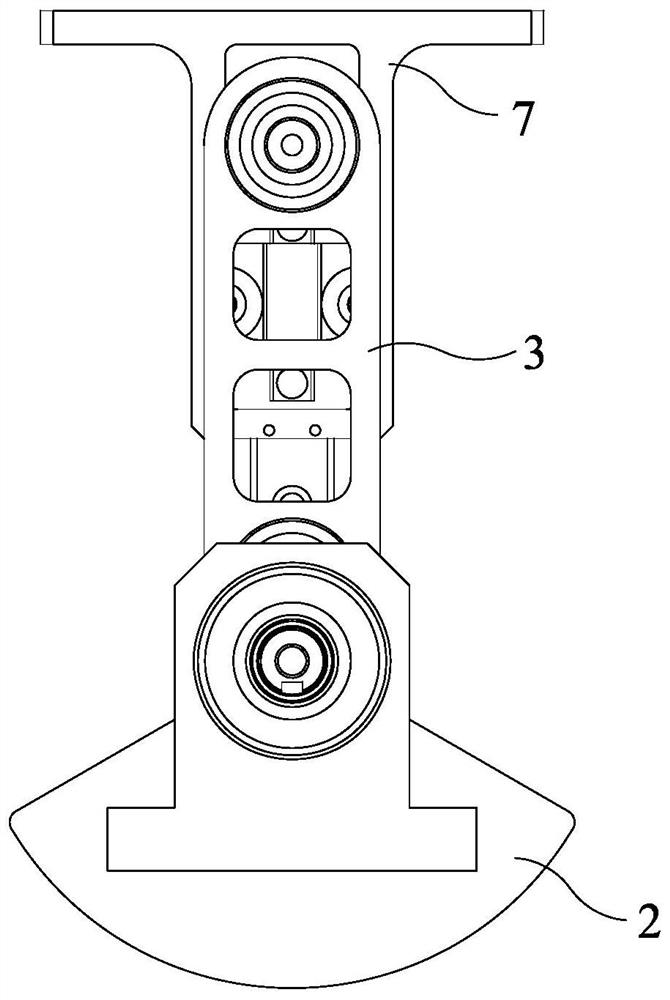

Vertical oscillation mechanism for extraction pretreatment

PendingCN113640095AFully destroyedMeet extraction requirementsPreparing sample for investigationPesticide residueReciprocating motion

The invention discloses a vertical oscillation mechanism for extraction pretreatment. The vertical oscillation mechanism comprises a driving mechanism, an eccentric balancing weight, a crank, a test tube rack, a vertical slide rail and an elastic mechanism; the driving mechanism is connected with the middle of the eccentric balancing weight and drives the eccentric balancing weight to rotate; an eccentric shaft and a balancing weight are arranged at the two ends of the eccentric balancing weight respectively and are symmetrically arranged, and the eccentric shaft is hinged to the lower end of the crank; the upper end of the crank is hinged to a test tube rack, and the test tube rack is arranged on the vertical sliding rail in a sliding mode, and thus the driving mechanism drives the test tube to do vertical reciprocating motion along the vertical slide rail; and an elastic mechanism is arranged below the test tube rack in the direction of the vertical sliding rail, the bottom of the test tube rack is connected with the elastic mechanism, and the balancing weight is used for balancing the centrifugal force of the vertical reciprocating motion of the test tube rack and the test tube. According to the vertical oscillation mechanism, high-speed reciprocating motion is realized on an organic matter sample, so that the organic matter fully collides with the tube wall of the test tube, the cell wall of the organic matter is damaged, pesticide residues in the organic matter are extracted, the impact inertia is balanced, and the stability is good.

Owner:RAYKOL GROUP XIAMEN CO LTD

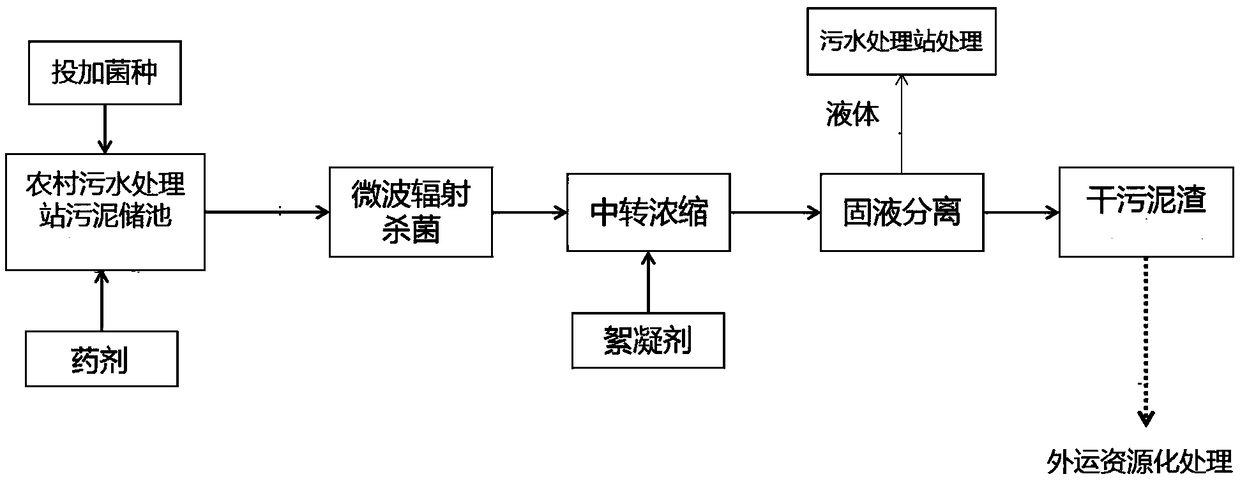

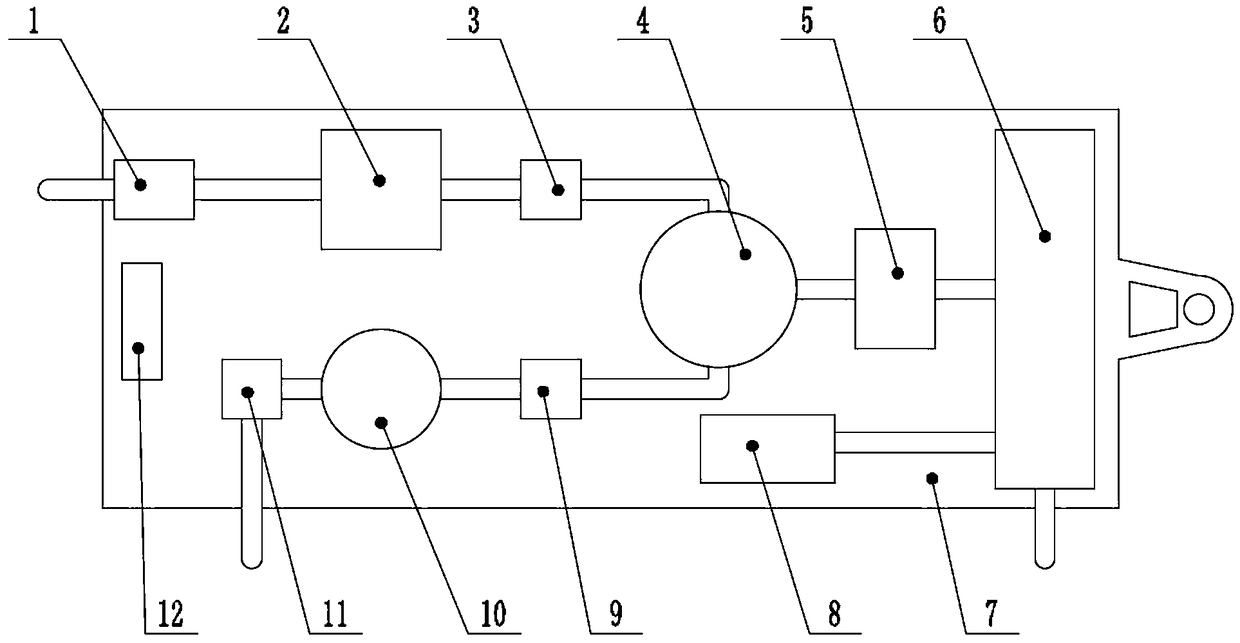

Agent, method and device for deeply dehydrating sludge

PendingCN109485232AOutstanding dehydrationHighlight the sterilization effectSludge treatment by de-watering/drying/thickeningBiological sludge treatmentMicrowaveFiltration

The invention provides an agent for deeply dehydrating sludge. The agent belongs to a compound microbial reagent and has prominent dehydrating and sterilizing effects. The invention further provides amethod for deeply dehydrating sludge. The method comprises the steps such as agent dehydration, sterilization, concentration, filtration and squeezing as well as solid-liquid separation and is simplein process, convenient to operate, low in treatment cost and remarkable in dehydration effect, and the water content of the dehydrated mud cake is low and reaches 50% or lower, so that the mud cake is convenient to transport and further treat. The invention further provides a device for deeply dehydrating sludge, due to the integrated optical layout of the device, devices relevant to sludge microwave disinfection, agent dissolution, dosing, solid-liquid separation and the like are mounted on a frame, and the frame is placed on a truck, so that the device is low in investment and cost, convenient to move and capable of solving the problem of sewage treatment for rural sewage treatment stations.

Owner:HENAN LICHENG ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com