Method for quickly making hot beverage by food processor

A food processor, fast technology, applied in applications, heating devices, household appliances, etc., can solve the problems of uneven density of the upper and lower layers of the slurry, loss of motor life, and the inability of the slurry to fall back quickly, so as to shorten heating and cooking. Time required, high cooling efficiency and cooling effect, effect of shortening the time required for cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

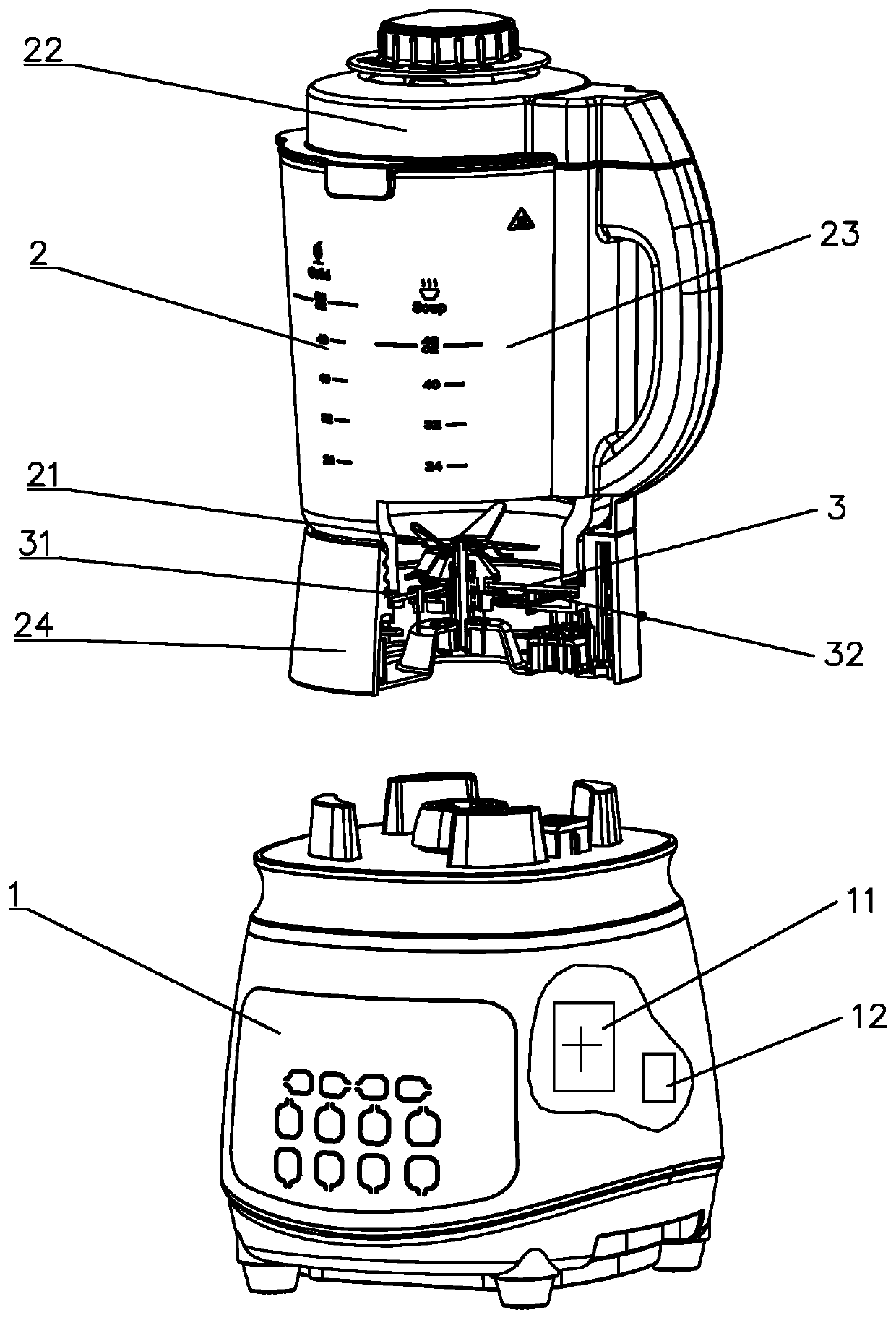

[0032] like Figure 1 to Figure 3 As shown, the present invention provides a method for quickly making hot drinks with a food processing machine. The food processing machine includes a machine base 1, a stirring cup 2 arranged on the machine base and a stirring knife 21 arranged in the stirring cup, and the stirring cup The upper port cover is closed with a cup cover 22, and the motor base is provided with a motor 11 and a control unit 12. In this embodiment, the control unit is specifically a microcontroller arranged on the control board. The food processor also includes a heating device 3, Specifically, the stirring cup includes a cup body 23 and a cup holder 24 arranged under the cup body, and the heating device 3 is arranged in the cup holder, and is used to heat the material in the cup body after being energized. In this embodiment, the electric heating device includes a heat conduction plate 31 and an electrothermal film 32 fixedly arranged on the heat conduction plate. ...

Embodiment 2

[0041] The difference between this embodiment and the first embodiment is that the crushing stage is different, and this embodiment provides a more optimized method for quickly making hot drinks.

[0042] In this embodiment, the food processor further includes a temperature detection device electrically connected to the control unit for detecting the temperature of the slurry, and the method for quickly making hot drinks with the food processor includes:

[0043] In the first step, the user puts the solid-liquid ingredients into the mixing cup, starts the program after turning on the power, and executes the first heating stage. The control unit controls the heating device 3 to run at full power to heat the slurry in the mixing cup, so that the mixed The slurry of solid ingredients can heat up quickly in a short period of time, shortening the time required for heating and cooking, and at the same time, it can keep the nutrients of the ingredients from diverging or damaging to th...

Embodiment 3

[0053] The difference between this embodiment and the first embodiment is that the heating stage is different, and this embodiment provides a more optimized method for quickly making hot drinks.

[0054] In this embodiment, the food processor includes an anti-overflow detection device, and the anti-overflow detection device includes a trigger pole, and the slurry in the stirring cup surges up and contacts the trigger pole to trigger an anti-overflow signal. Specifically, the anti-overflow detection device The detection device is an anti-overflow probe arranged on the lid of the mixing cup. The anti-overflow probe is installed vertically. One end of the anti-overflow probe is fixed on the bottom of the cup lid, and the other end extends into the mixing cup as the detection end.

[0055] In this embodiment, the method for quickly making hot drinks with a food processor includes:

[0056] In the first step, the user puts the solid-liquid ingredients into the mixing cup, turns on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com