System and method for promoting hydrolysis of PAM (polyacrylamide) in dewatered sludge and simultaneously producing short-chain fatty acids

A short-chain fatty acid and dewatered sludge technology, which is applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc., can solve secondary pollution and other problems, save energy and improve sludge recycling Utilization efficiency and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

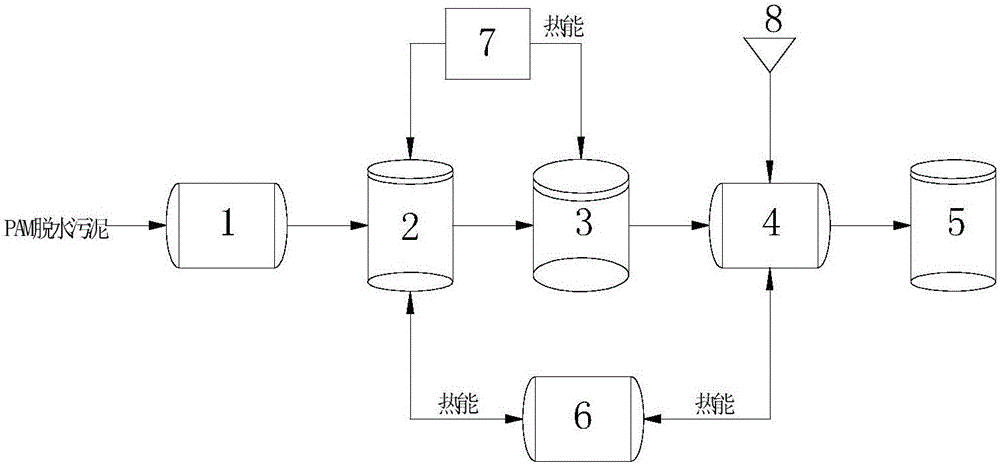

[0030] A system that promotes the hydrolysis of PAM in dewatered sludge and produces short-chain fatty acids at the same time. It is carried out according to the following steps: PAM dewatered sludge is poured into the sludge storage tank 1, and then transported to the preheating tank 2 by a screw pump conveying device, and then transferred to the preheating tank 2 by a heat exchanger. 6 and boiler room 7 provide heat to heat the dewatered sludge, keeping the temperature at 50°C; at the same time, stir at a stirring intensity of 100rpm, and control the residence time at 30min. Afterwards, the sludge is transported to the thermal hydrolysis reactor 3 by the anti-corrosion pump conveying device, heated by saturated steam provided by the boiler room 7, and the temperature is maintained at 100°C, while rapid stirring is performed at 200rpm; the residence time is 40min. After thermal hydrolysis, the sludge is transported to the alkali conditioning chamber 4, and the heat exchange is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com