Novel method for preparing granular modified regenerated rubber through two-stage continuous green regeneration of waste rubber

A technology of regenerated rubber and waste rubber, which is applied in recycling technology, plastic recycling, etc., can solve the problems of high pollution, unstable quality of regenerated rubber products, high energy consumption, etc., and achieve the effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

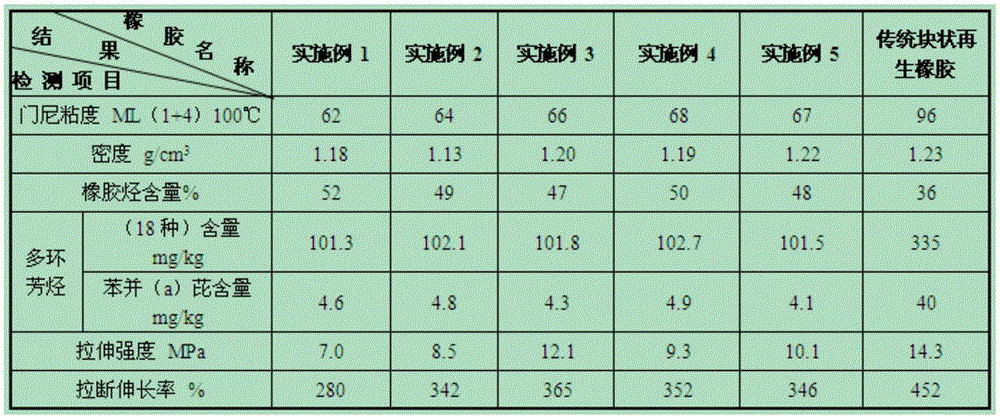

Examples

Embodiment 1

[0020] A new method for preparing granular modified regenerated rubber through two-stage continuous green regeneration of waste rubber, comprising the following process steps:

[0021] Waste tires are crushed and separated in the front stage to obtain 2-10mm rubber particles. Without adding any chemical additives, they are screwed to the first-stage sulfur-cutting regeneration equipment of the rubber recycling machine through the rubber quantitative feeder. Under the pure mechanical strong shearing and extrusion of rubber particles, the sulfur-containing molecular chains are selectively broken, destroying its cross-linked network structure, and realizing its initial continuous sulfur-breaking green regeneration. The screw speed is between 20-30r / min. The temperature is between 150-200°C, and the sulfur break regeneration time is between 5 and 15 minutes to obtain the environmentally friendly recycled rubber crude product; then it is conveyed to the secondary sulfur break regene...

Embodiment 2

[0023] A new method for preparing granular modified regenerated rubber through two-stage continuous green regeneration of waste rubber, comprising the following process steps:

[0024] Waste tires are crushed and separated in the front stage to obtain 2-10mm rubber particles. Without adding any chemical additives, they are screwed to the first-stage sulfur-cutting regeneration equipment of the rubber recycling machine through the rubber quantitative feeder. Under the pure mechanical strong shearing and extrusion of rubber particles, the sulfur-containing molecular chains are selectively broken, destroying its cross-linked network structure, and realizing its initial continuous sulfur-breaking green regeneration. The screw speed is between 20-30r / min. The temperature is between 150-200°C, and the regeneration time of sulfur breaking is between 5-15 minutes, so that the crude recycled rubber can be obtained. Level sulfur break regeneration equipment, in which the environment-fri...

Embodiment 3

[0026] A new method for preparing granular modified regenerated rubber through two-stage continuous green regeneration of waste rubber, comprising the following process steps:

[0027] Waste tires are crushed and separated in the front stage to obtain 2-10mm rubber particles. Without adding any chemical additives, they are screwed to the first-stage sulfur-cutting regeneration equipment of the rubber recycling machine through the rubber quantitative feeder. Under the pure mechanical strong shearing and extrusion of rubber particles, the sulfur-containing molecular chains are selectively broken, destroying its cross-linked network structure, and realizing its initial continuous sulfur-breaking green regeneration. The screw speed is between 20-30r / min. The temperature is between 150-200 ℃, and the regeneration time of sulfur breaking is between 5-15 minutes, so as to obtain the crude regenerated rubber product of environment-friendly type; the polymer modifier polytetrafluoroethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com