Environment-friendly coating for exterior wall and preparation method thereof

An environmentally friendly coating and exterior wall technology, which is applied in the direction of anti-corrosion coatings, cellulose coatings, polyurea/polyurethane coatings, etc., can solve the problems of long drying time, large weather influence, and impact on engineering, so as to improve anti-aging performance and durability. Effects of abrasion resistance, enhanced adhesion, and enhanced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

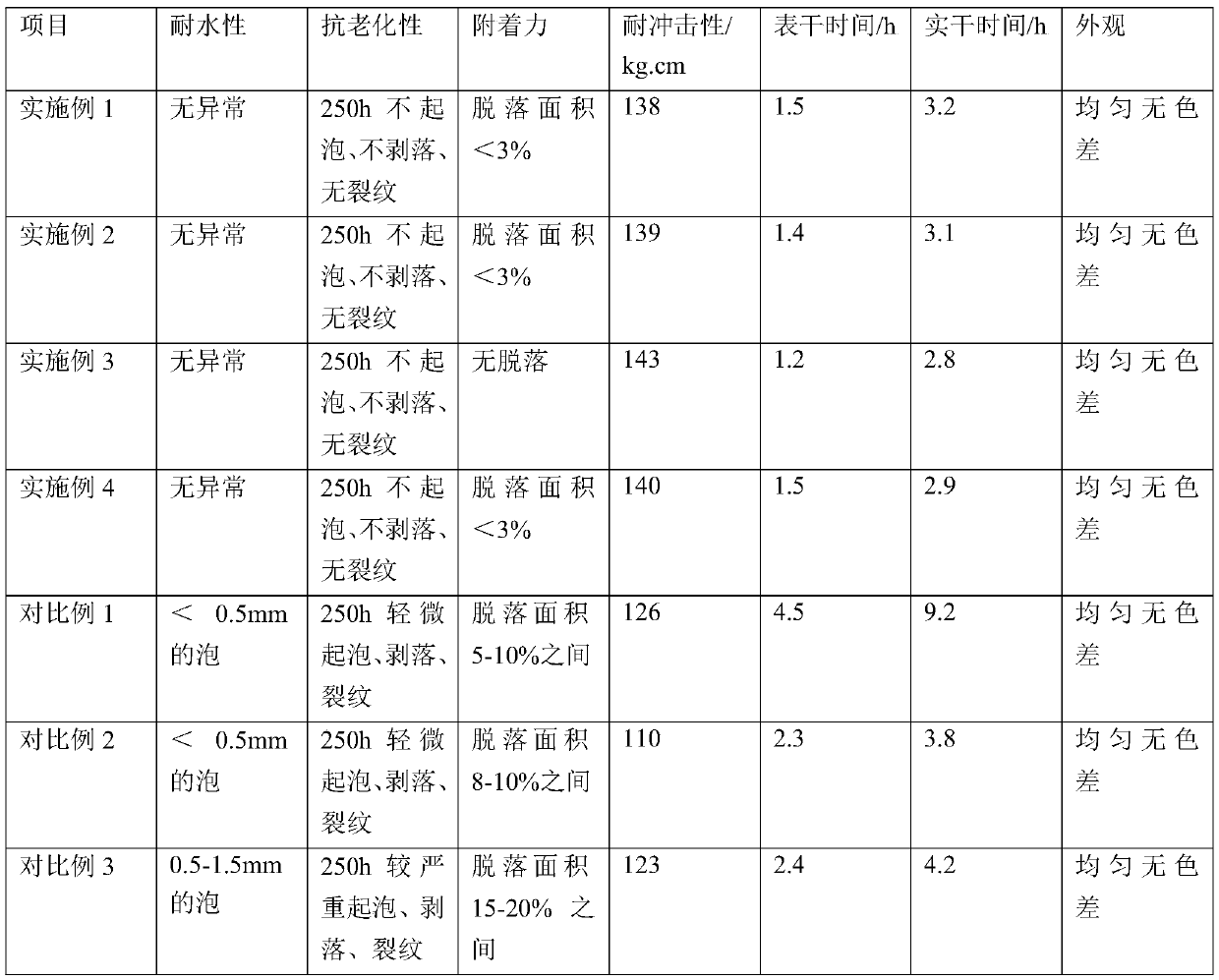

Examples

Embodiment 1

[0028] A kind of external wall environmental protection coating, comprises the raw material of following weight part: 40 parts of acrylic emulsion, 20 parts of polyether polyol, 20 parts of filler, 10 parts of carboxymethyl betaine, 5 parts of isocyanate, 5 parts of ceramic fiber, nanometer dioxide 5 parts of silicon, 5 parts of surfactant, 3 parts of plasticizer, 1 part of desiccant, 1 part of anti-aging agent, 0.5 part of nano zinc oxide;

[0029] Wherein, the filler is a mixture of nano-carbon black, nano-wollastonite, and nano-barium sulfate in a weight ratio of 1:1:1;

[0030] Wherein, the plasticizer is a mixture composed of methyl methacrylate, tricresyl phosphate, and vinyl acetate in a mass ratio of 1:1:1.

[0031] Wherein, the desiccant is composed of the following raw materials in parts by weight: 30 parts of propylene glycol diacetate, 25 parts of polyacrylate polymer, 10 parts of nano-microcrystalline cellulose, and 3 parts of yttrium sulfate;

[0032] Wherein, t...

Embodiment 2

[0037] An environmentally friendly coating for exterior walls, comprising the following raw materials in parts by weight: 50 parts of acrylic emulsion, 20 parts of polyether polyol, 20 parts of filler, 20 parts of carboxymethyl betaine, 10 parts of isocyanate, 10 parts of ceramic fiber, nanometer dioxide 5 parts of silicon, 5 parts of surfactant, 3 parts of plasticizer, 3 parts of desiccant, 1 part of anti-aging agent, 1 part of nano zinc oxide;

[0038] Wherein, the filler is a mixture of nano-carbon black, nano-wollastonite, and nano-barium sulfate in a weight ratio of 3:1:1;

[0039] Wherein, the plasticizer is a mixture composed of methyl methacrylate, tricresyl phosphate, and vinyl acetate in a mass ratio of 1:1:1.

[0040] Wherein, the desiccant is composed of the following raw materials in parts by weight: 30 parts of propylene glycol diacetate, 25 parts of polyacrylate polymer, 10 parts of nano-microcrystalline cellulose, and 3 parts of yttrium sulfate;

[0041] Where...

Embodiment 3

[0046] A kind of external wall environmental protection paint, comprises the raw material of following weight part: 45 parts of acrylic emulsion, 25 parts of polyether polyol, 25 parts of filler, 15 parts of carboxymethyl betaine, 8 parts of isocyanate, 6 parts of ceramic fiber, nanometer dioxide 6 parts of silicon, 6 parts of surfactant, 5 parts of plasticizer, 2 parts of desiccant, 2 parts of anti-aging agent, 1 part of nano zinc oxide;

[0047] Wherein, the filler is a mixture of nano carbon black, nano wollastonite, and nano barium sulfate in a weight ratio of 3:3:1;

[0048] Wherein, the plasticizer is a mixture composed of methyl methacrylate, tricresyl phosphate, and vinyl acetate in a mass ratio of 1:1:1.

[0049] Wherein, the desiccant is composed of the following raw materials in parts by weight: 30 parts of propylene glycol diacetate, 25 parts of polyacrylate polymer, 10 parts of nano-microcrystalline cellulose, and 3 parts of yttrium sulfate;

[0050] Wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com