Multi-stage processing system for crop straw and operation method thereof

A crop straw and processing system technology, which is applied in the field of multi-stage processing system of crop straw, can solve problems such as equipment failure and poor fuel rod molding quality, and achieve the effects of fine fuel particle size, promotion of combustion performance, and improvement of crushing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

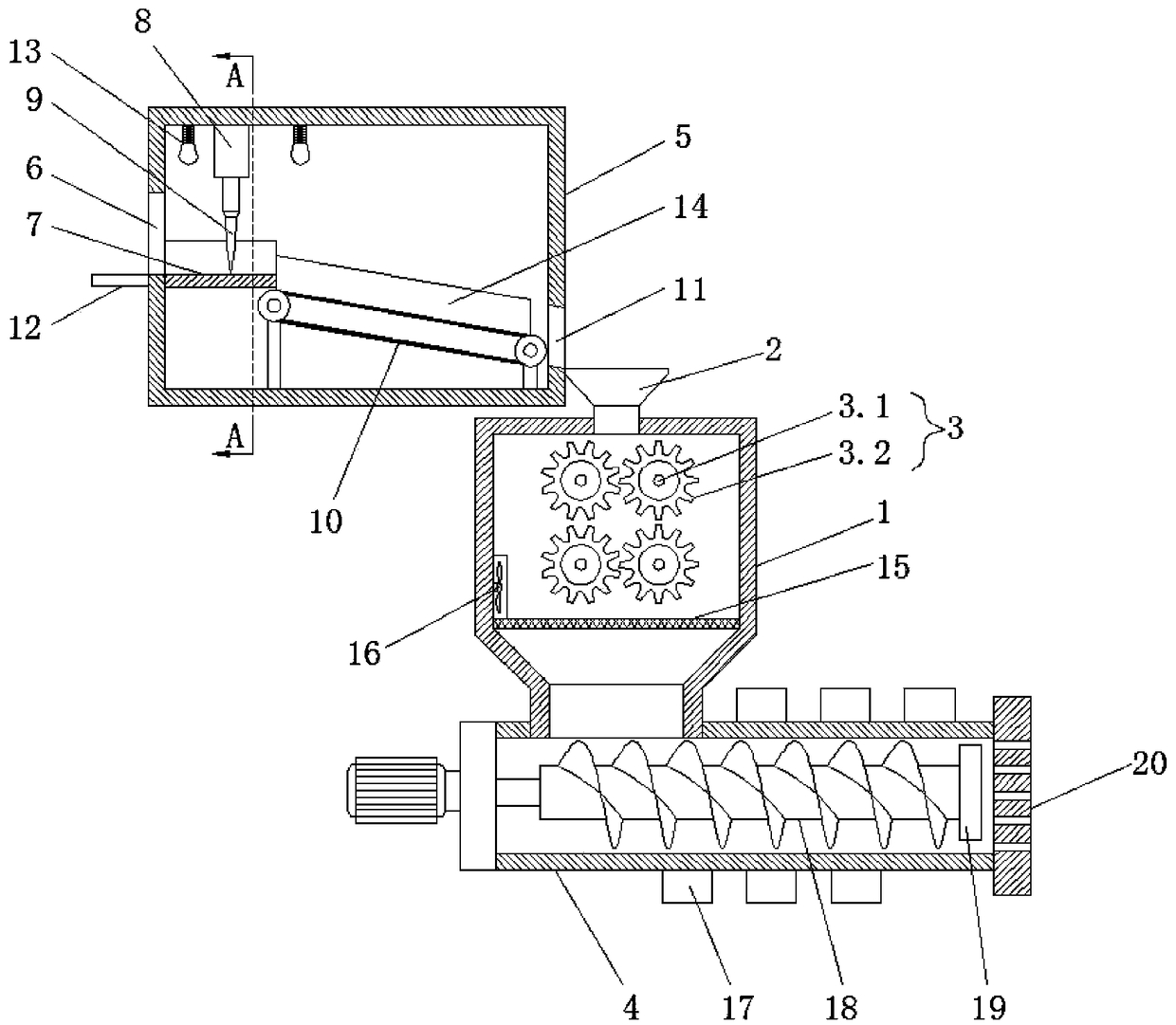

[0028] Such as figure 1 As shown, this embodiment provides a multi-stage processing system for crop stalks, including a pretreatment machine for cutting straw raw materials into strips, a pulverizer 1 is provided under the pretreatment machine, and a pulverizer 1 is provided on the top of the pulverizer 1 The feeding hopper 2 close to the discharge end of the pretreatment machine, inside the pulverizer 1 is provided with at least two groups of pulverizing mechanisms 3 arranged from top to bottom. The pulverizing mechanisms 3 are all directly below the feeding hopper 2. Press processing machine 4.

[0029] In this embodiment, the longer straw raw materials are first cut into short strips by the pretreatment machine, which is convenient for post-processing. Under the action of the mechanism, the straw material is crushed into small particles. During the crushing process, the crude fiber in the straw can be fully destroyed, and the crude fiber content of the straw is greatly red...

Embodiment 2

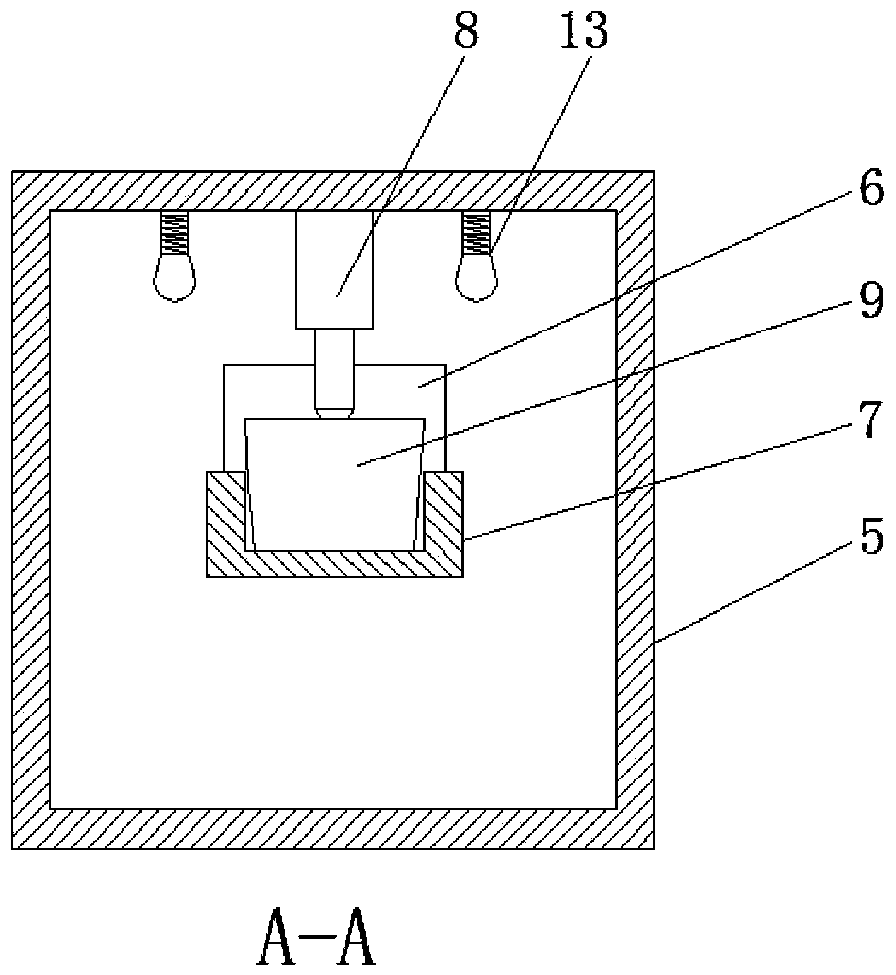

[0031] Such as Figures 1 to 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the pretreatment machine includes a cabinet 5, a feeding port 6 is opened on the left side of the cabinet 5, and a U-shaped Processing tank 7, telescopic cylinder 8 is arranged on the top of the cabinet 5, and the bottom of the telescopic cylinder 8 is connected with a cutting tool 9 that cooperates with the U-shaped processing tank 7, and a belt conveyor 10 located below the U-shaped processing tank 7 is arranged in the cabinet 5 , the right side of the cabinet 5 is provided with a discharge port 11 that cooperates with the belt conveyor 10, the feed hopper 2 is close to the bottom of the discharge port 11, the outer wall of the cabinet 5 is provided with a pallet 12 near the feed port 6, and the top of the cabinet 5 is provided with A number of lighting lamps 13, the belt conveyor 10 is inclined downward along the conveying direction, and both sides of th...

Embodiment 3

[0034] Such as figure 1 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the crushing mechanism 3 includes two rollers 3.1 that rotate inward, and the outer walls of the two rollers 3.1 are provided with crushing teeth 3.2. The crushing teeth 3.2 mesh with each other, the meshing line between the two crushing teeth 3.2 is located directly below the feed hopper 2, the inside of the grinder 1 is provided with a filter screen 15 located below the crushing mechanism 3, and the inner wall of the grinder 1 is provided with a screen located at the upper end of the filter screen 15 blower 16, several heaters 17 are arranged on the extrusion machine 4, an extrusion screw 18 is arranged inside the extrusion machine 4, an extrusion plate 19 is arranged at the end of the extrusion screw 18, and the extrusion machine 4 is close to the extrusion One end of the platen 19 is provided with a die head 20 with several discharge holes.

[0035] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com