Patents

Literature

42results about How to "Improve quality and performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

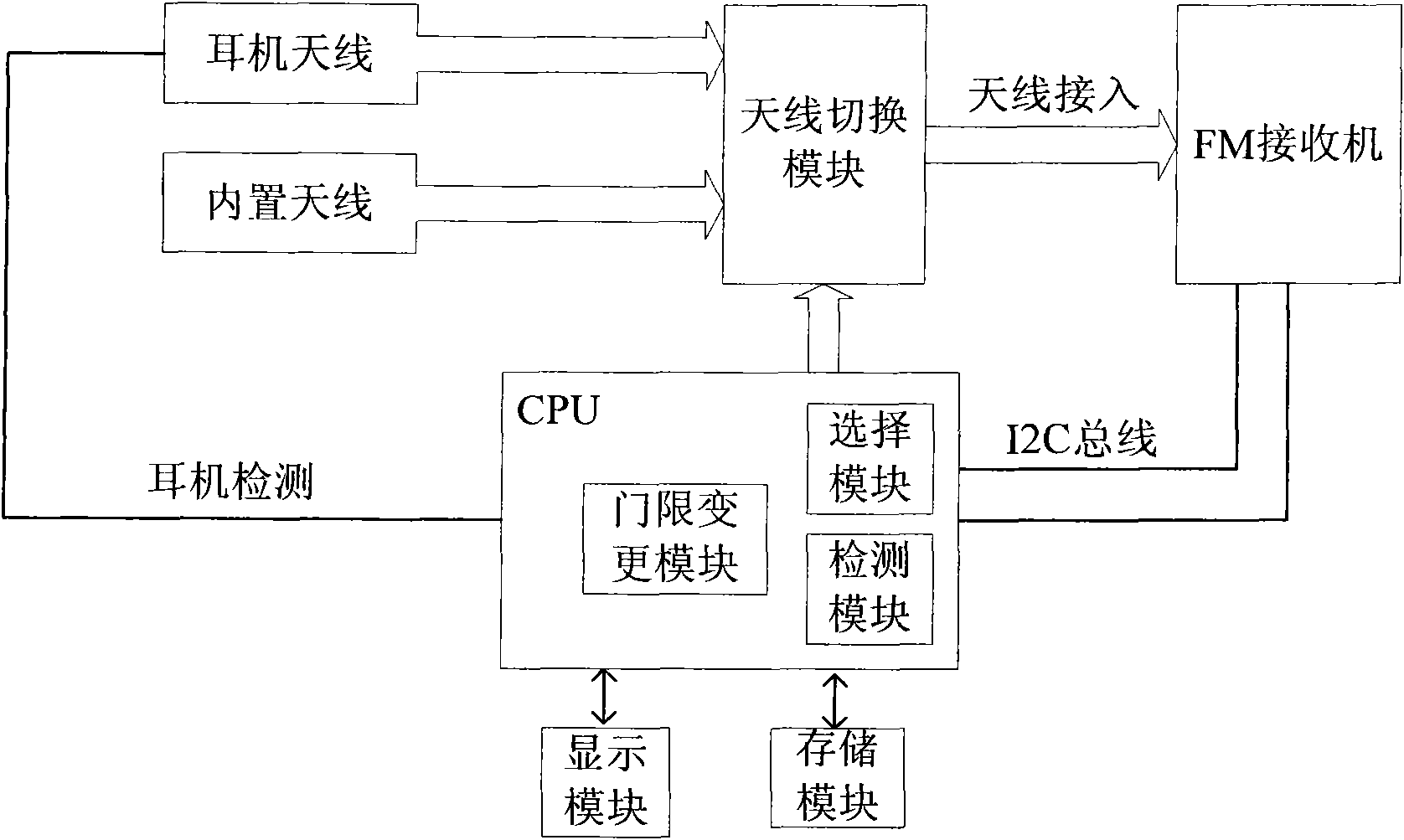

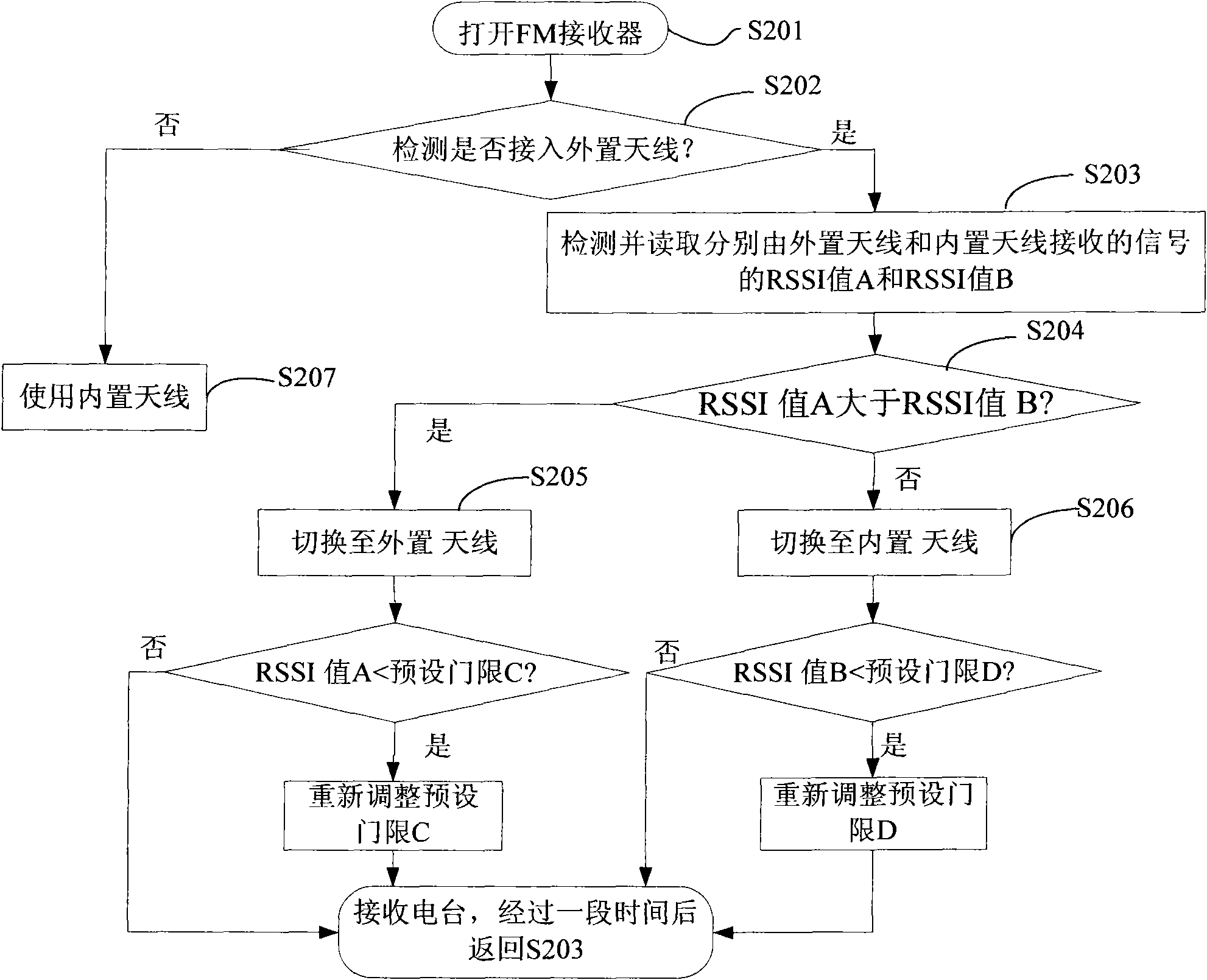

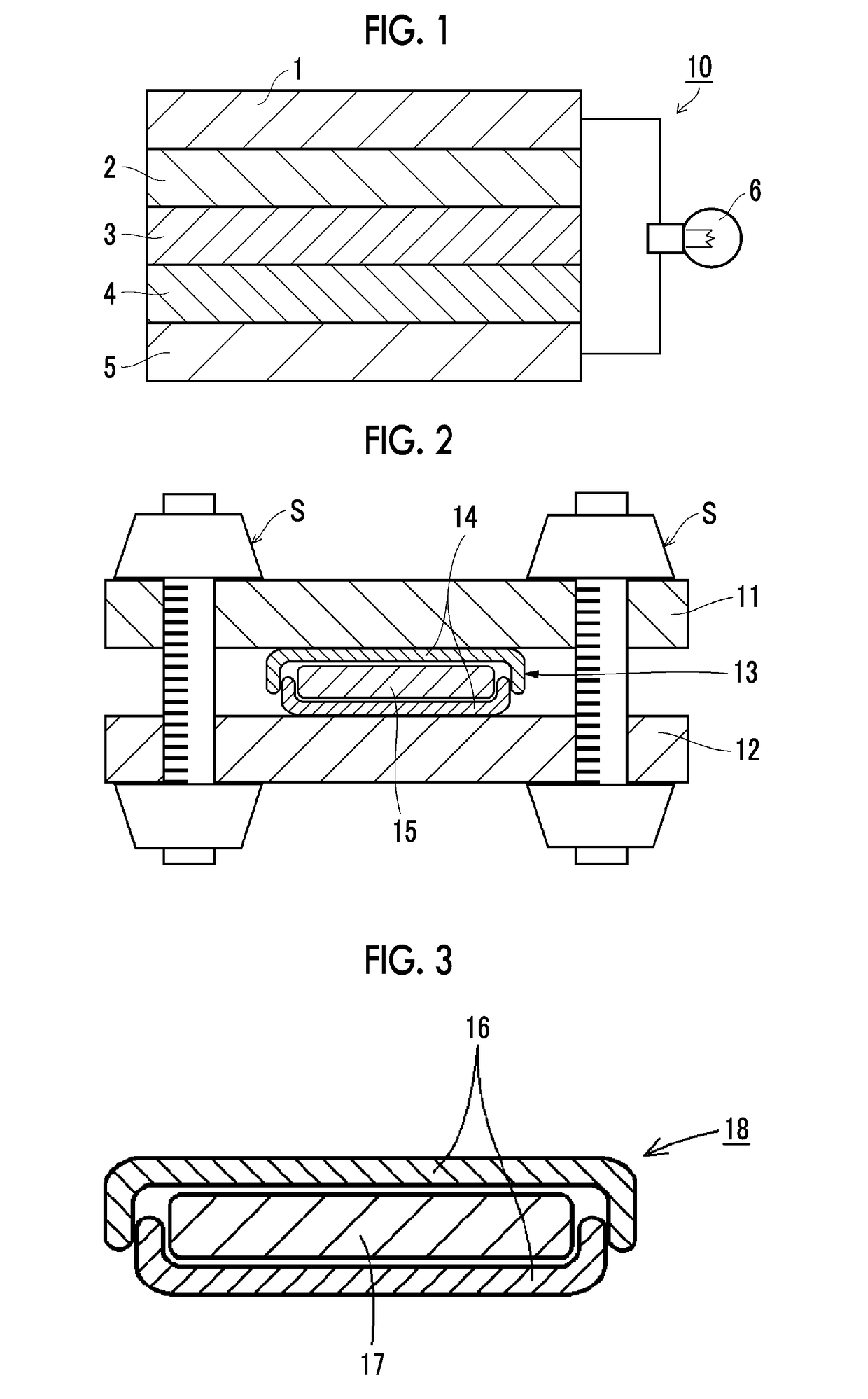

Switching method of built-in antenna and exposed antenna of FM receiver as well as terminal thereof

ActiveCN101626106ARealize seamless switchingImprove quality and performanceAntenna supports/mountingsTransmissionEngineeringSignal quality

The invention provides a switching method of a built-in antenna and an exposed antenna of an FM receiver as well as a corresponding terminal thereof. The terminal comprises an FM receiver, the built-in antenna, the exposed antenna, a CPU, a detection module and an antenna switching module. The CPU detects that the exposed antenna is switched in when the terminal switches in the exposed antenna inthe on-state of the FM receiver; the detection module is used for detecting the RSSI of signals received by the built-in antenna and the exposed antenna; the selection module is used for comparing the RSSI values of the signals received by the built-in antenna and the exposed antenna, which are detected by the detection module. The antenna with the larger RSSI value is selected, and then the CPU controls the antenna switching module to switch in the selected antenna as the current receiving antenna. The switching method performs a switching between the built-in antenna and the exposed antennaaccording to the quality of the signals received by the built-in antenna and the exposed antenna from a station, can realize a seamless switching between the built-in antenna and the exposed antenna,and raises the receiving quality and the effect of the FM receiver.

Owner:罗源县产品质量检验所

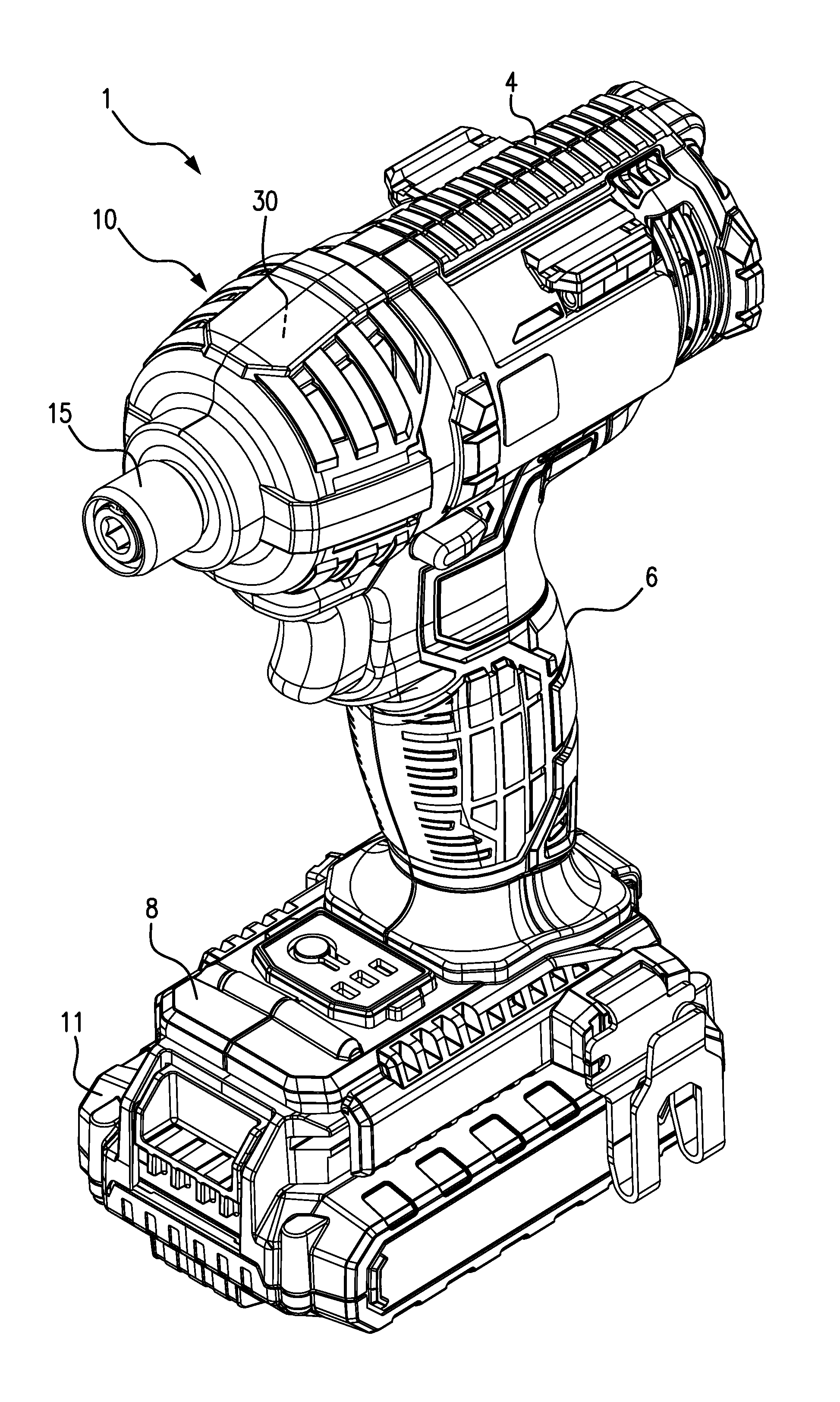

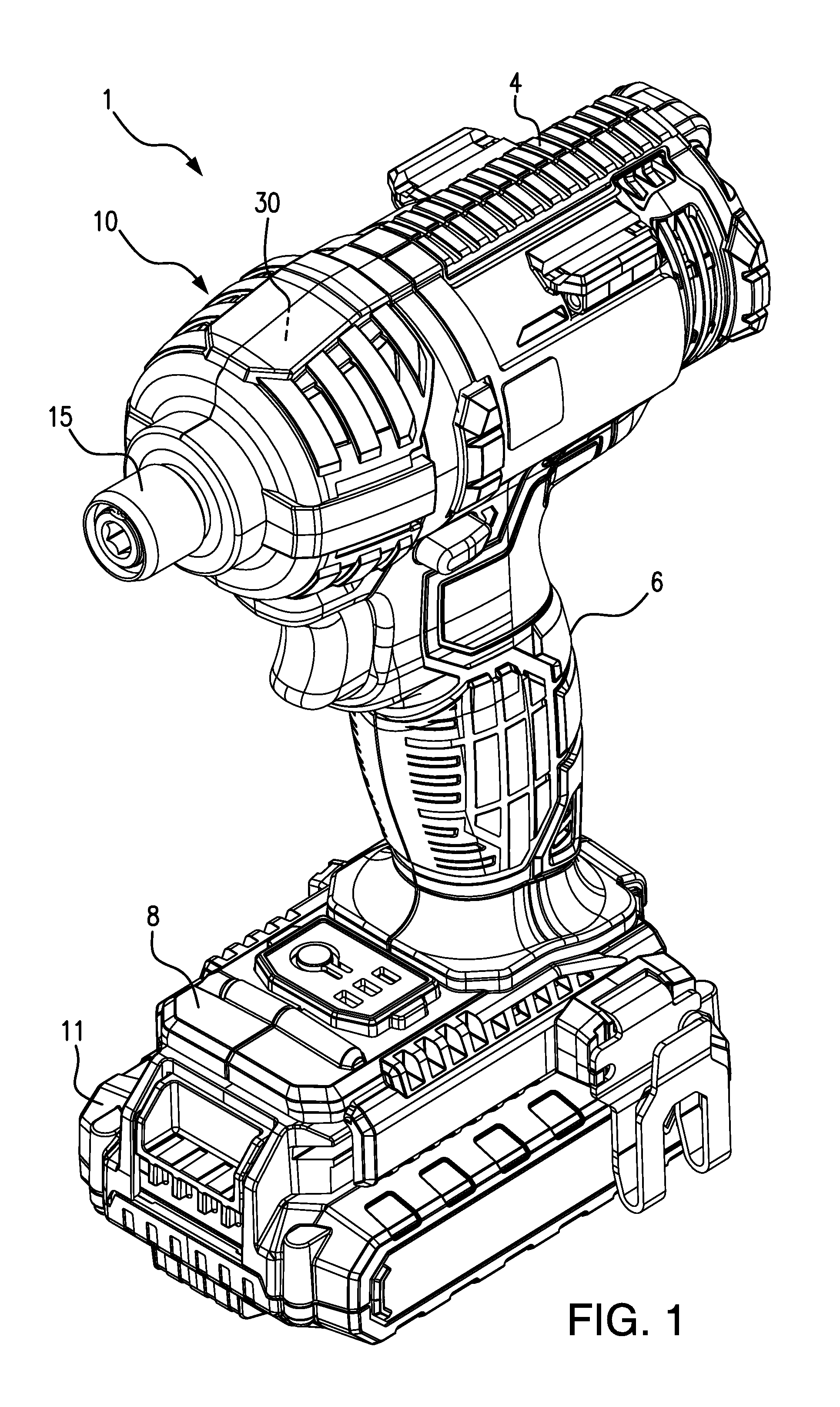

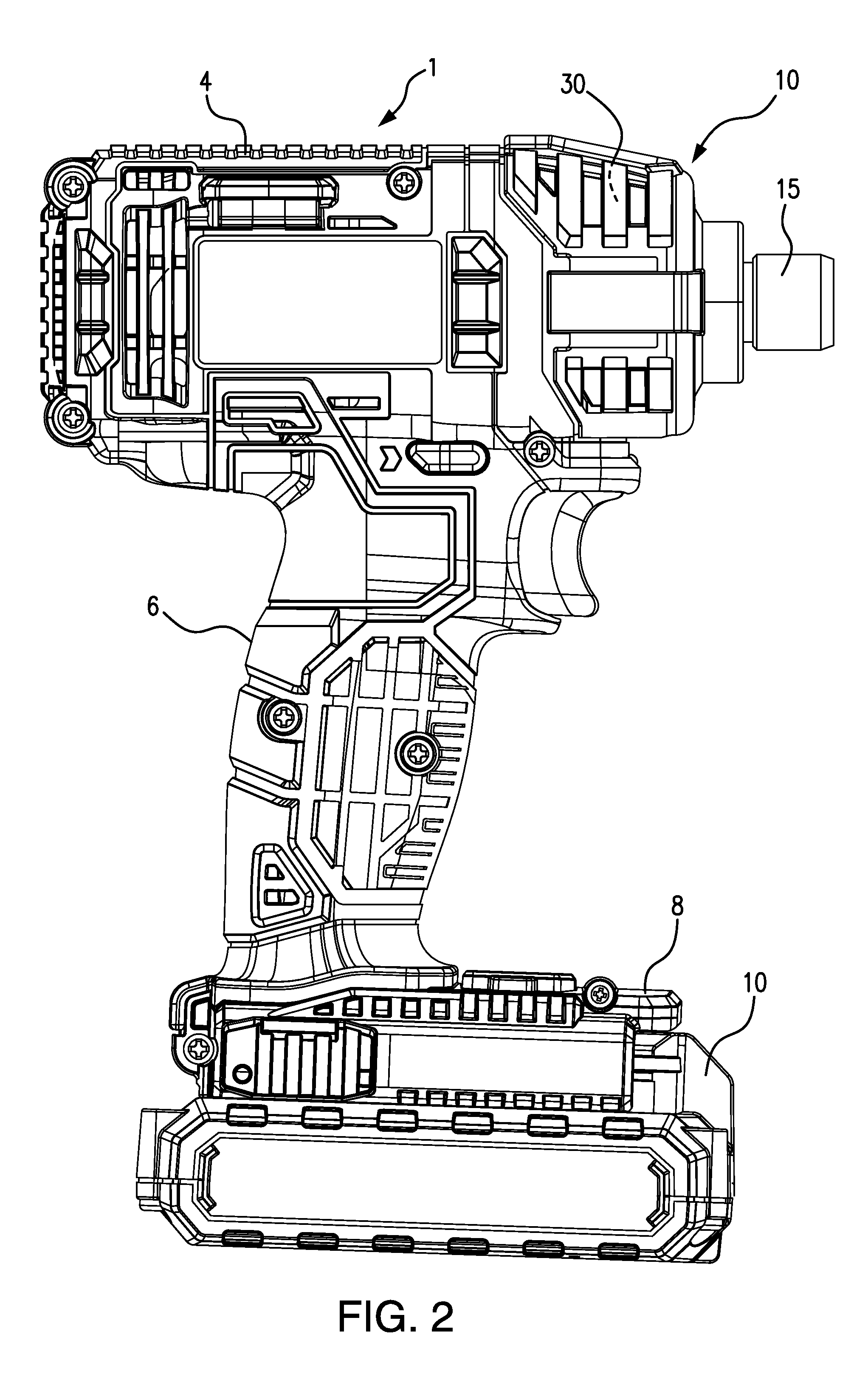

Impact Driver Control System

InactiveUS20160121467A1Reduce motor speedEliminate currentDerricks/mastsSpannersElectronic controllerControl system

An impact driver having an impact driver control system which can activate a driver release. The activation of a driver release can be controlled by an electronic controller which can be set to activate a driver release when parameters of the impact drivers meet specified conditions.

Owner:BLACK & DECKER INC

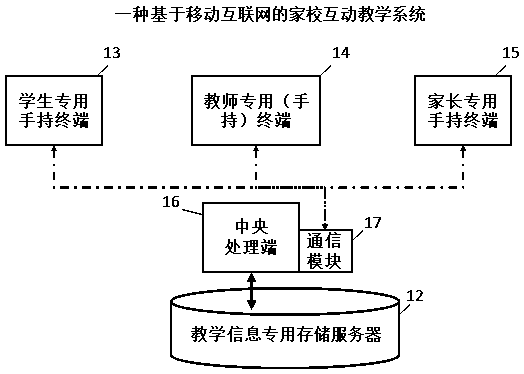

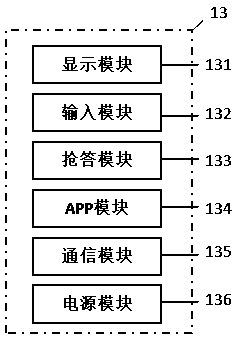

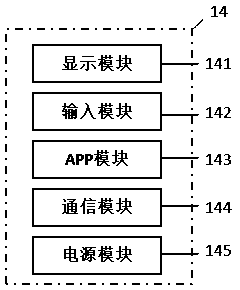

Mobile Internet-based home-school interaction teaching system

ActiveCN105070125AIncrease engagementImprove quality and performanceElectrical appliancesEngineeringKnowledge management

Owner:HUNAN AIBOSI TECH

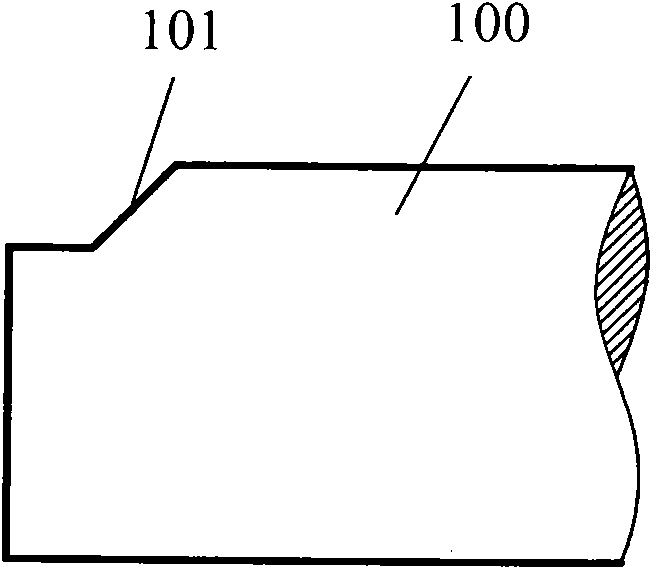

Soldering method of conducting ring of motor rotor

ActiveCN101557145AImprove brazing qualityImprove quality and performanceLine/current collector detailsSoldering apparatusSolderingEngineering

The invention relates to a soldering method of a conducting ring of a motor rotor. In the method, an end ring is heated through improving the structure of a conducting bar of a rotor and adopting a medium frequency induction way, and a super thick conducting ring of a high capacity motor rotor is soldered by the way that two brazing torches respectively assist heating the end head of the conducting bar and the excircle surface of the end ring. The soldering method of the conducting ring of the motor rotor has the advantages of good soldering quality and motor performance and quality improvement when being used for soldering the conducting ring of the high capacity motor rotor.

Owner:上海电气集团上海电机厂有限公司

Quenching process of H13 steel aluminum alloy die-casting die

InactiveCN106755880AThe quenching process is simpleImprove quality and performanceFurnace typesHeat treatment furnacesQuenchingStress relief

Owner:巴南区伟鹏机械加工厂

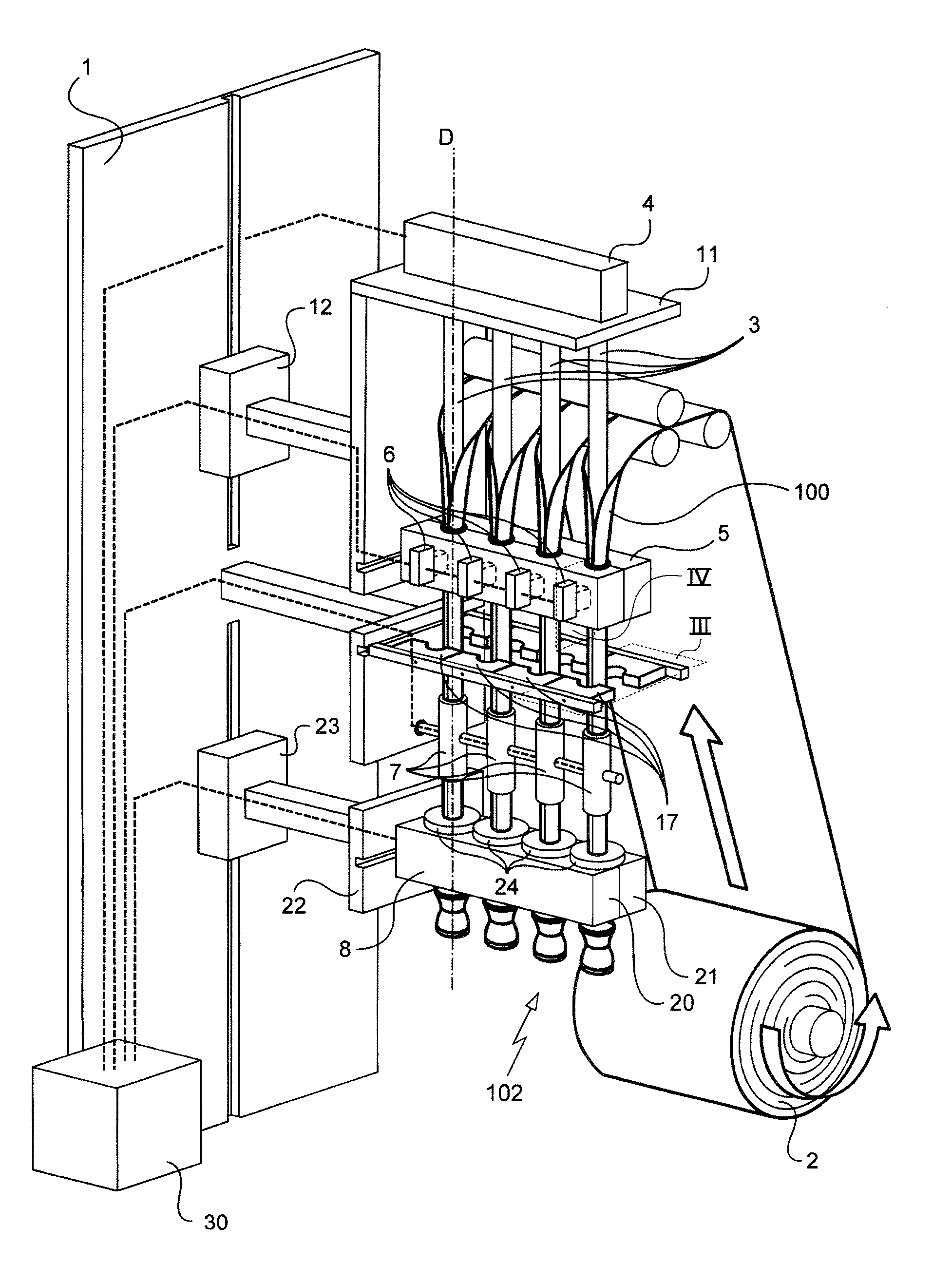

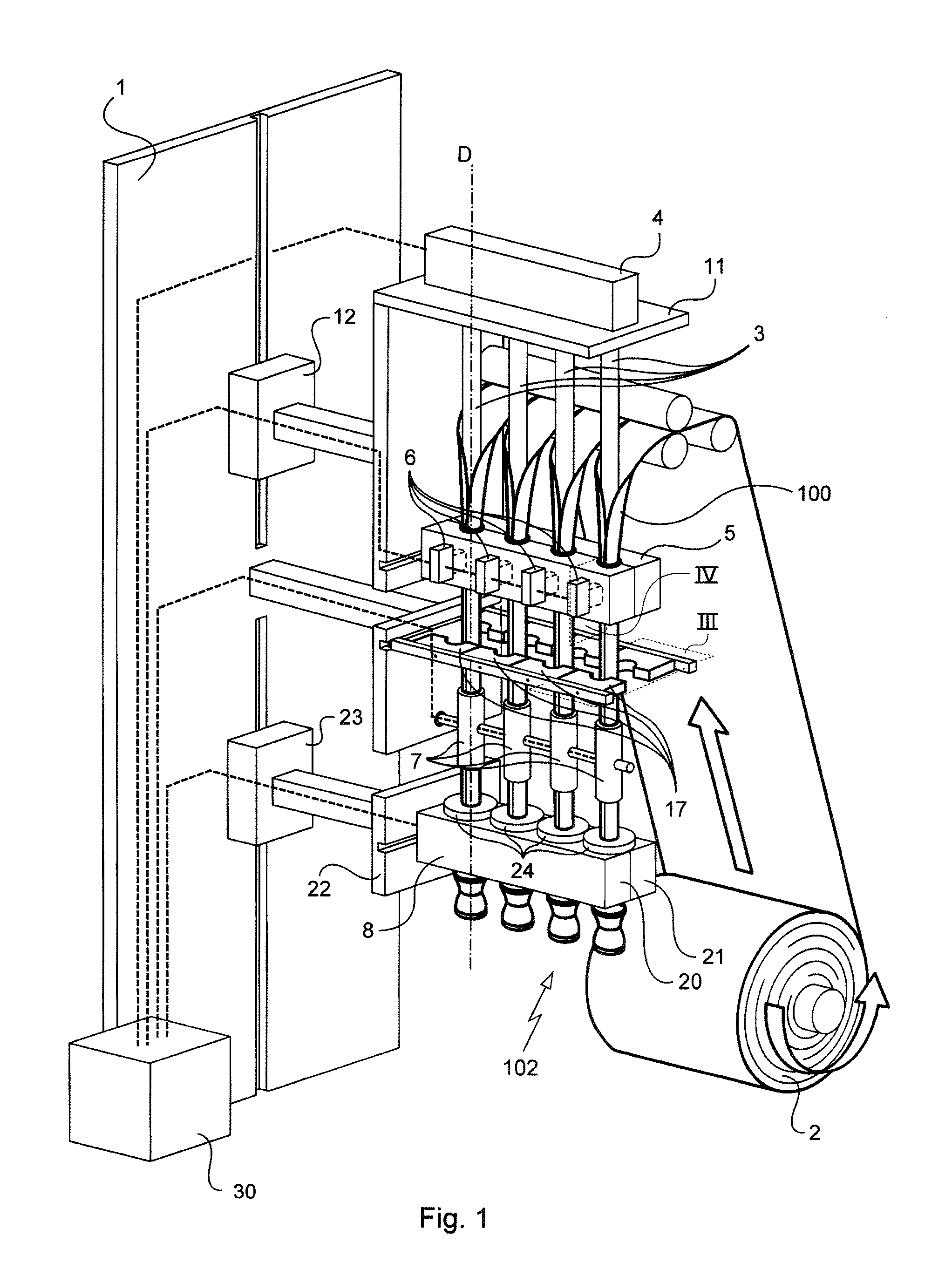

Machine for blowing molding articles such as containers

A machine is provided for blow-molding articles from a strip of material. The machine has a mount with two frames mounted thereon. Each frame is connected to a movement actuator so as to be movable along a path of the strip between respective positions that are upstream and downstream relative to a travel direction of the strip through the machine. A pipe, a holder member, and a mold are mounted respectively on an item selected from the mount and the frames. A control unit is connected to the movement actuators to control them in such a manner as to generate a sequence of moving the guide pipe and the mold relative to the holder member and of opening and closing the mold in such a manner as to cause the strip to advance along the rectilinear path.

Owner:SERAC GROUP

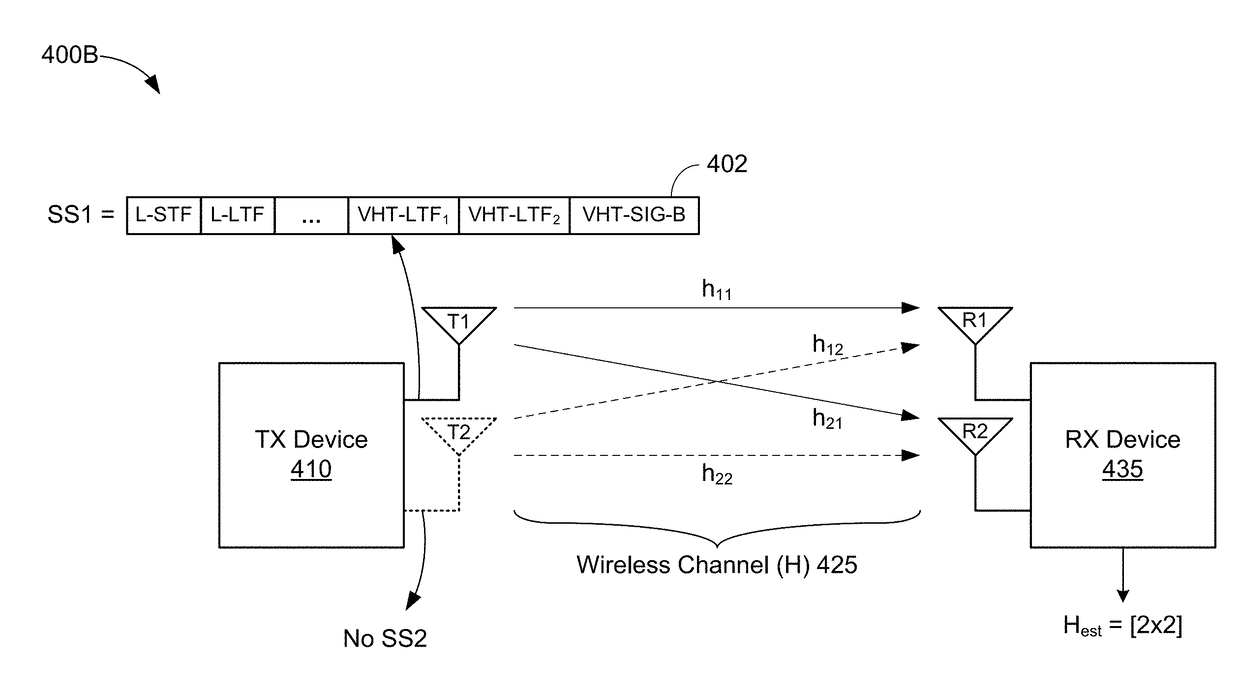

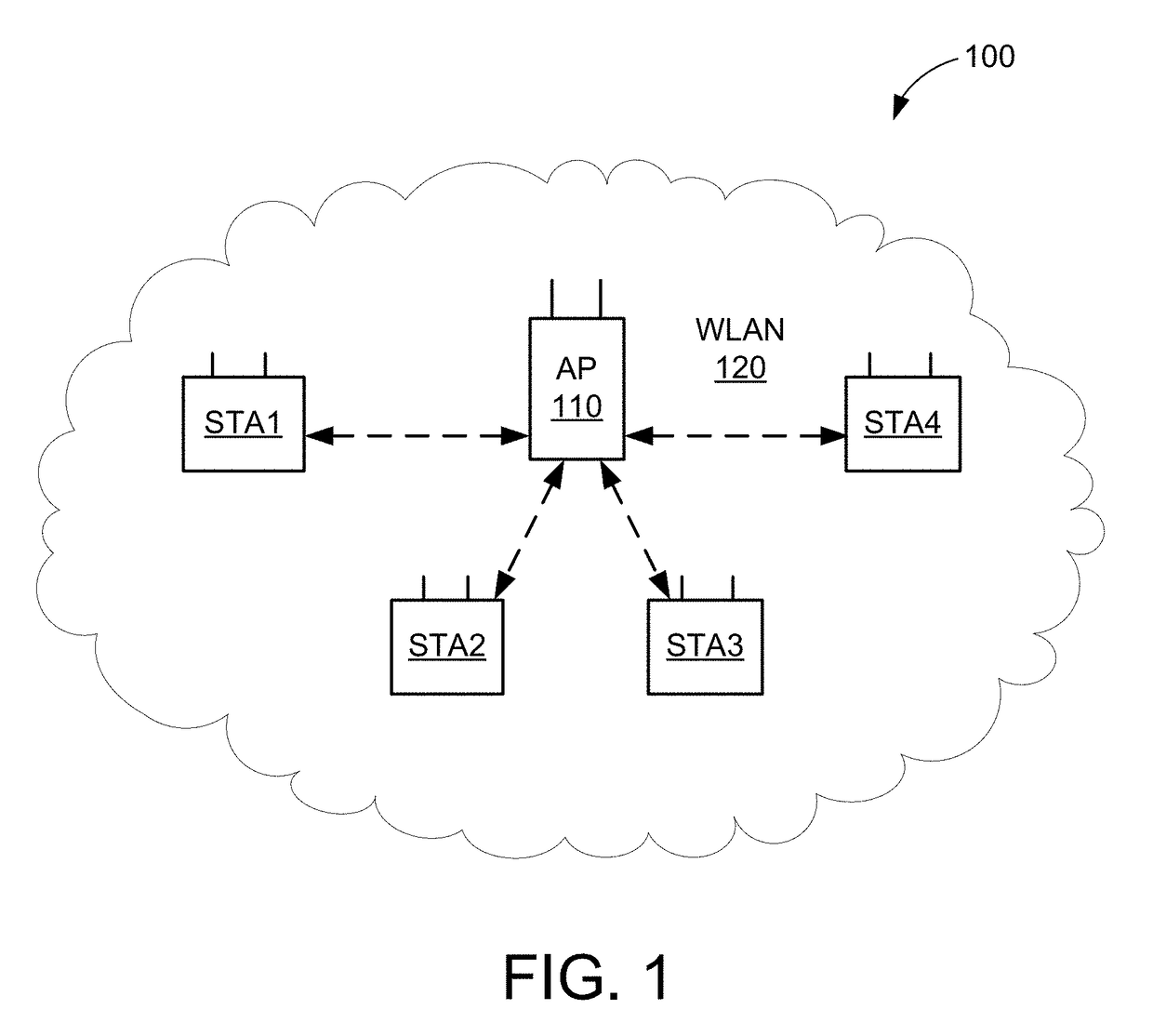

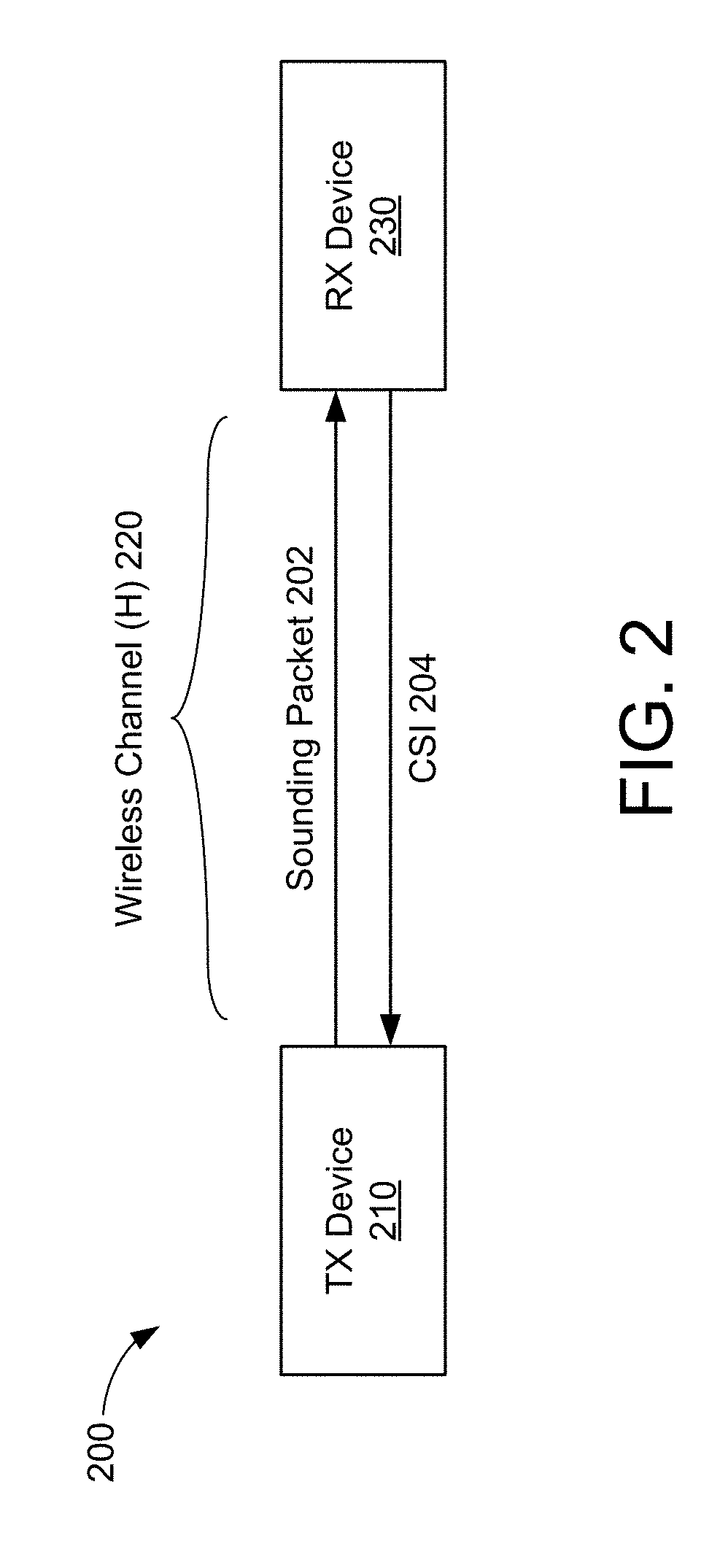

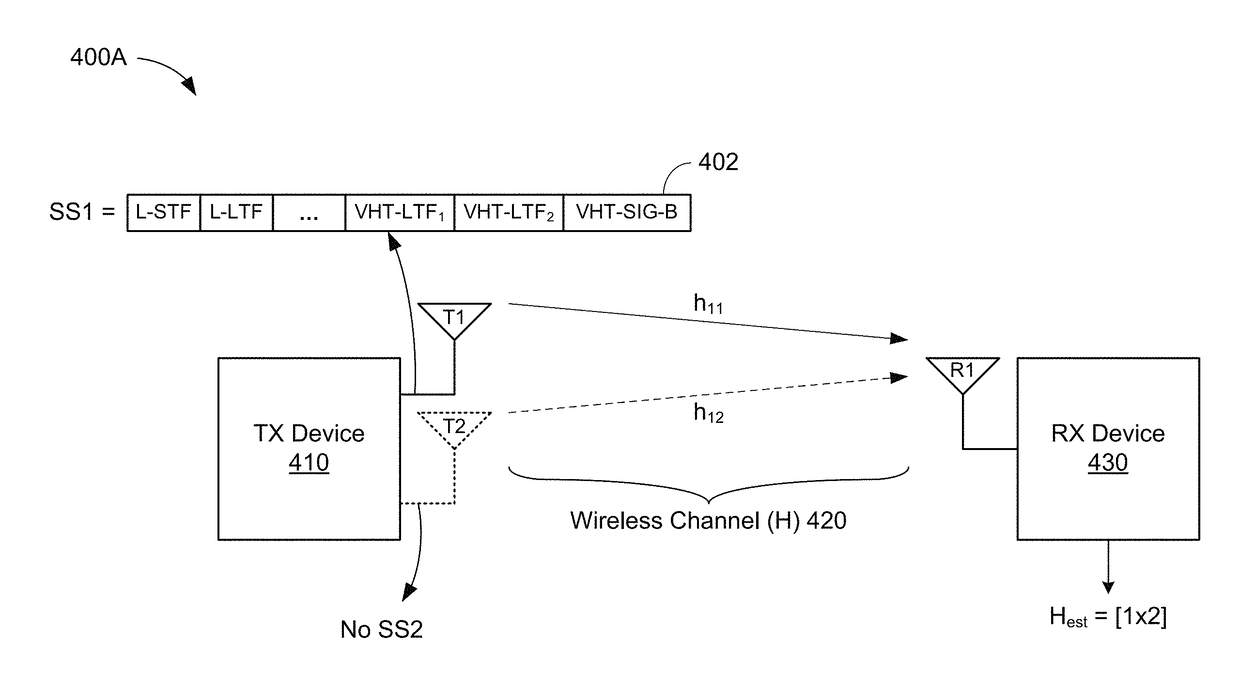

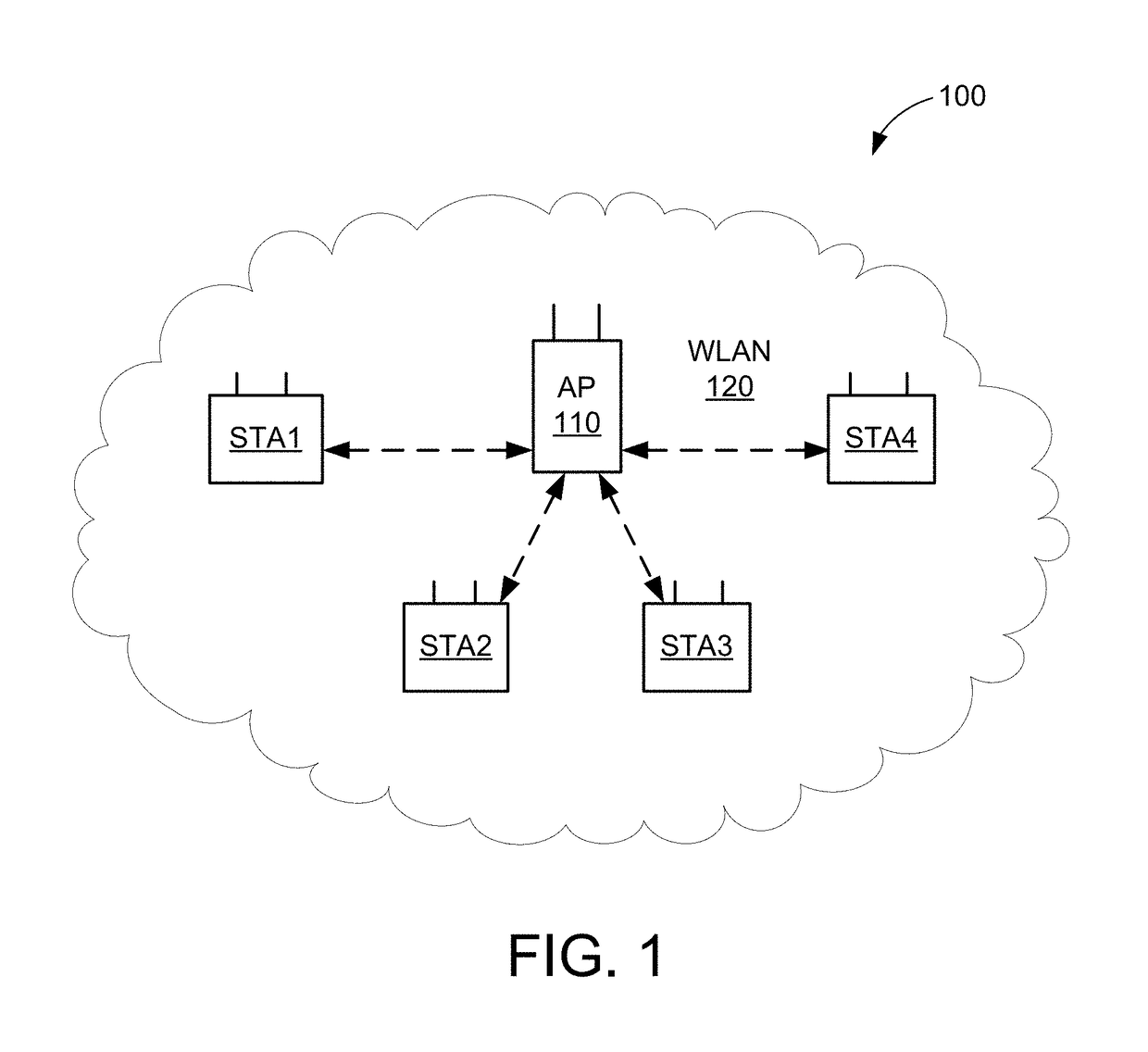

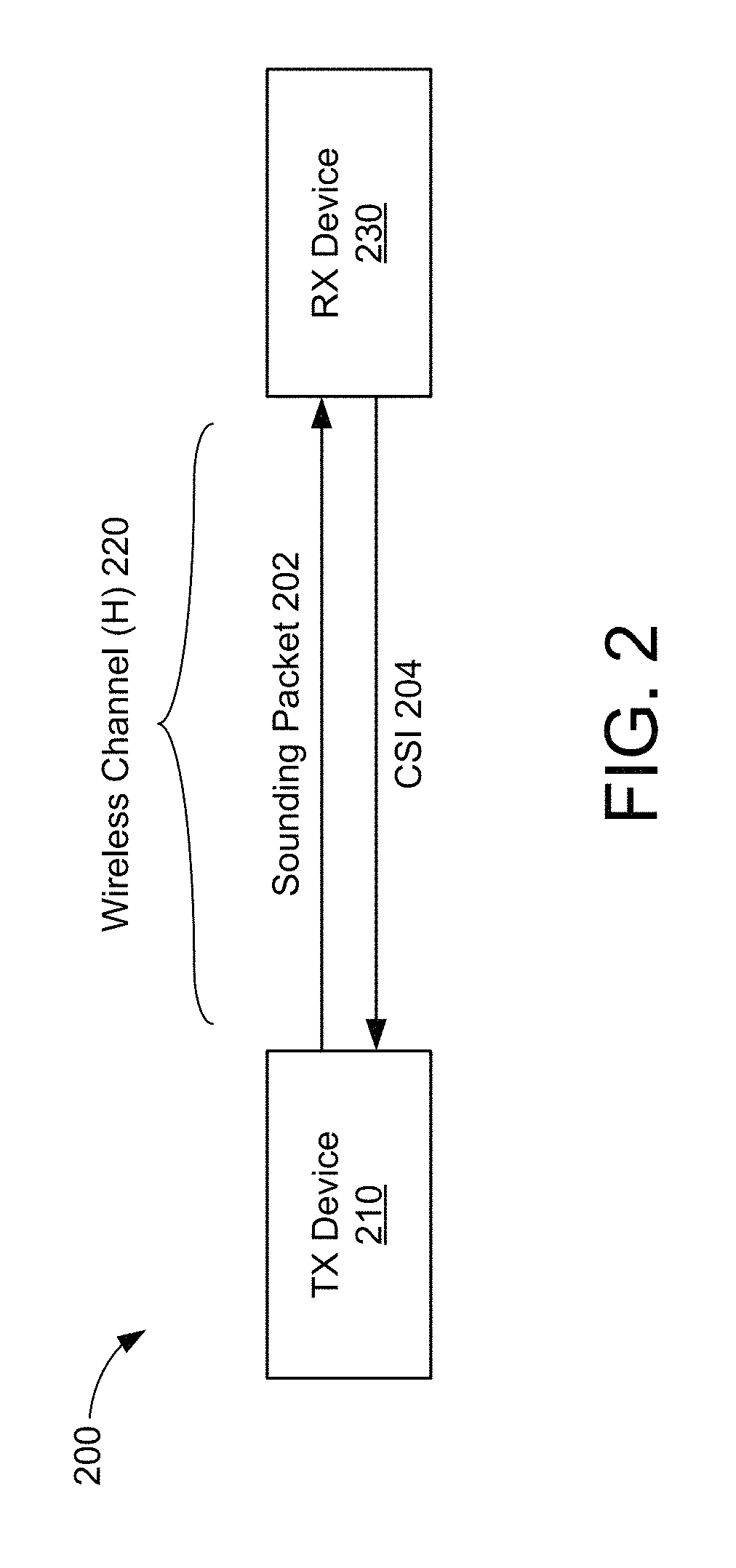

Beamforming techniques for single-stream communications

InactiveUS20170222706A1Reduce per-tone power loadingIncrease power loadPower managementSpatial transmit diversityChannel state informationTelecommunications

A method of adjusting single-stream transmissions by a wireless device based on channel state information (CSI). The wireless device generates a sounding packet formatted for transmission via multiple spatial streams, and transmits the sounding packet to a receiving device via a single one of the multiple spatial streams. For example, the wireless device may be a single-antenna device. The wireless device further receives channel state information (CSI) from the receiving device based at least in part on the sounding packet. The wireless device then adjusts one or more characteristics of single-stream transmissions to the receiving device based at least in part on the received CSI.

Owner:QUALCOMM INC

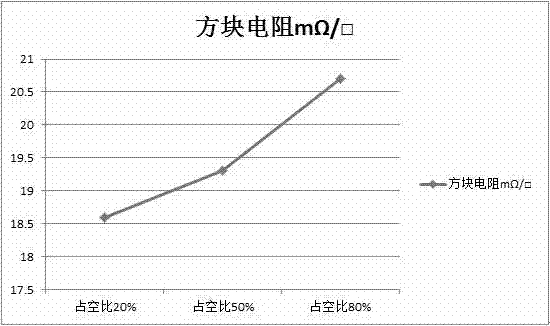

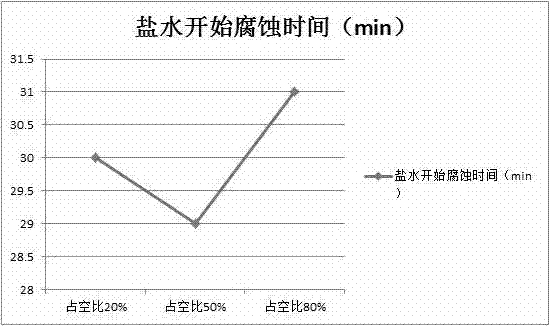

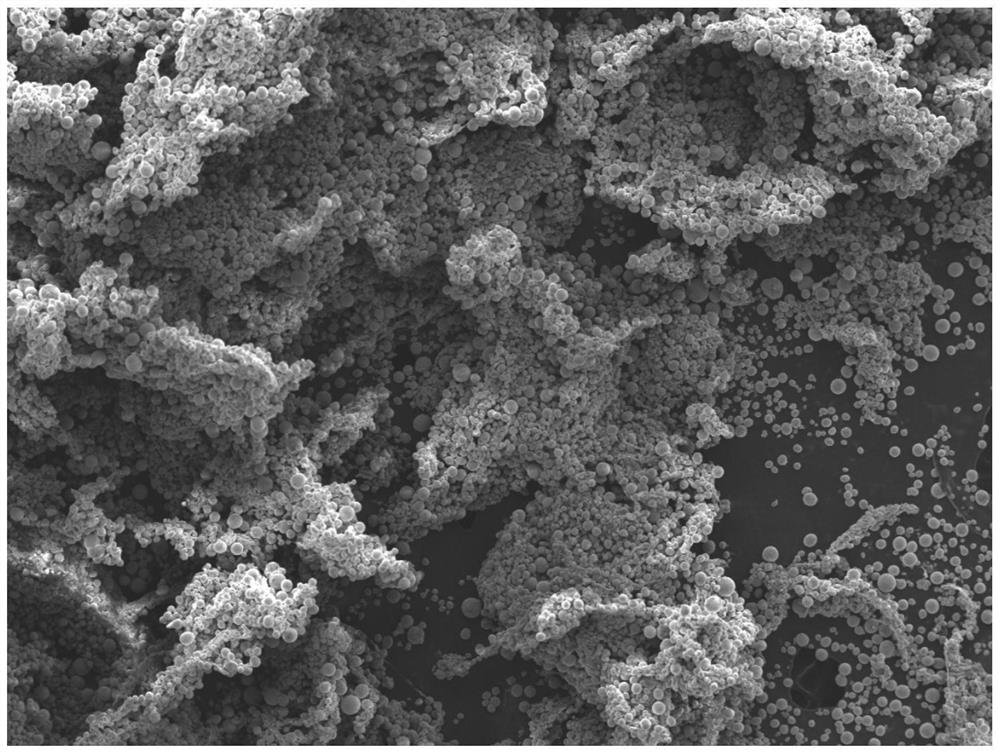

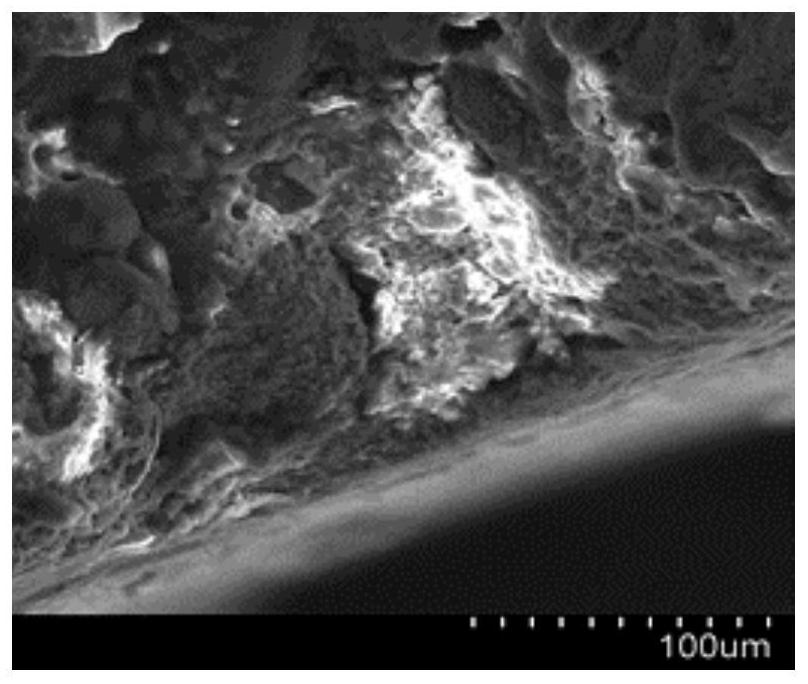

Preparation method for conductive, anti-corrosive, wear-resistant and high-hardness diamond-like coating layer

InactiveCN107338414ADroplet count reductionImprove quality and performanceVacuum evaporation coatingSputtering coatingIonizationVacuum pressure

The invention discloses a preparation method for a conductive, anti-corrosive, wear-resistant and high-hardness carbon-based film. The preparation method comprises the following steps: heating by virtue of a heating pipe in a vacuum chamber; ionizing argon gas by virtue of an ion source; cleaning and activating a base material clamped on a rotating stand in the vacuum chamber; carrying out magnetic target deposition on titanium metal after a vacuum pressure is achieved; then carrying out acetylene ionization by virtue of the ion source; and finally cooling in an inert gas. The conductivity, anti-corrosive property, wear resistance, high hardness and other performance of the film prepared by the preparation method disclosed by the invention meet the application needs of many industries such as semiconductors, mobile phones, chemical electrolysis and electric spark machining.

Owner:大连金泰正新科技有限公司

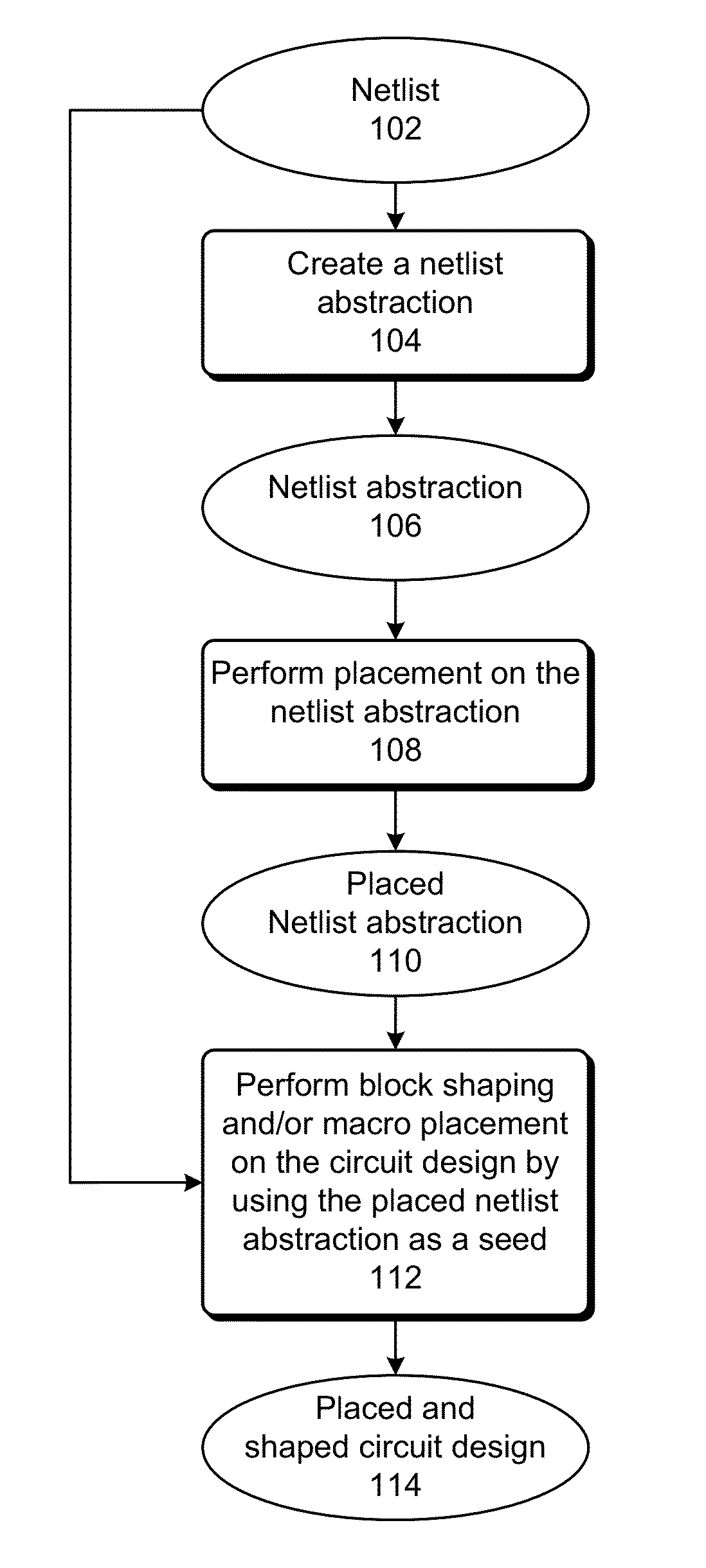

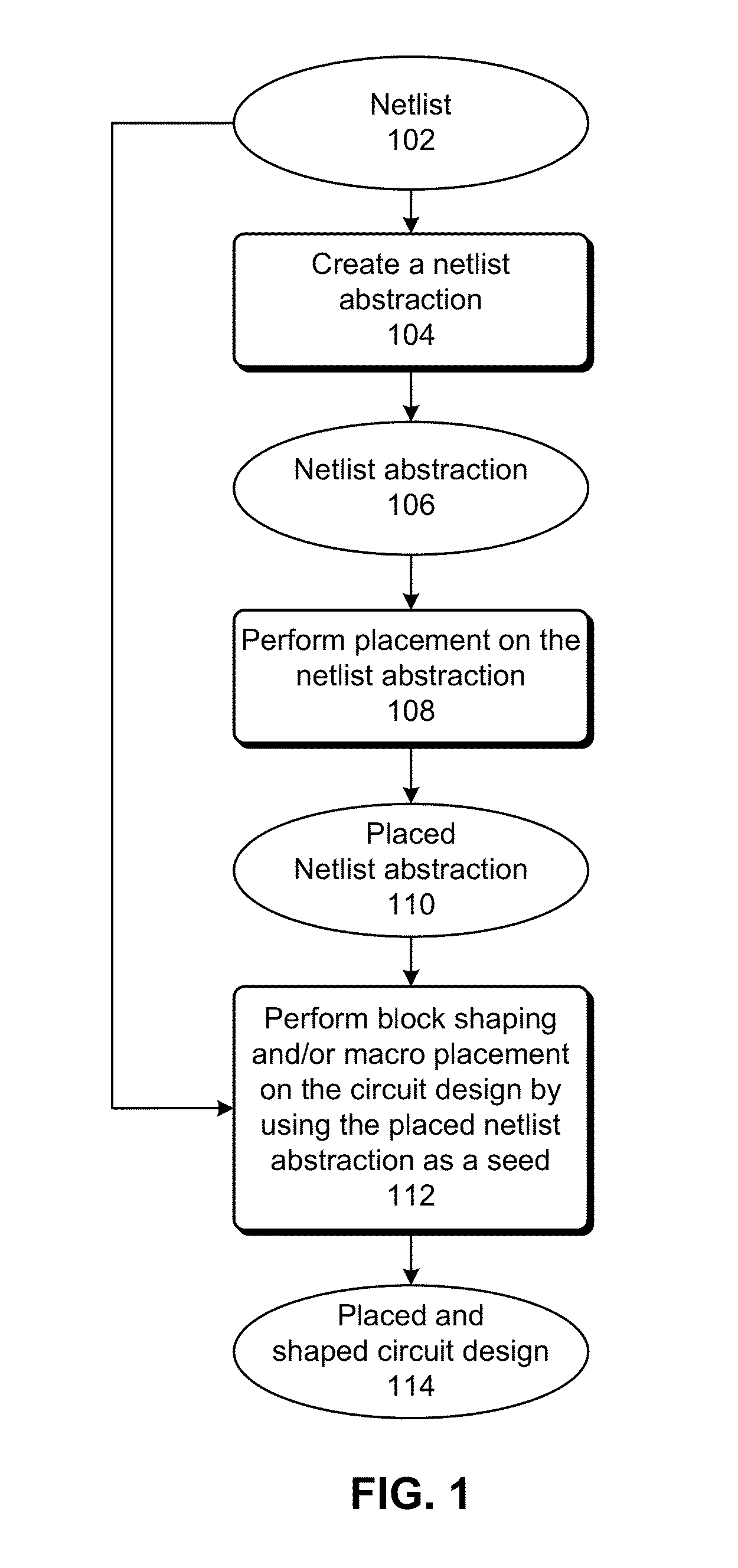

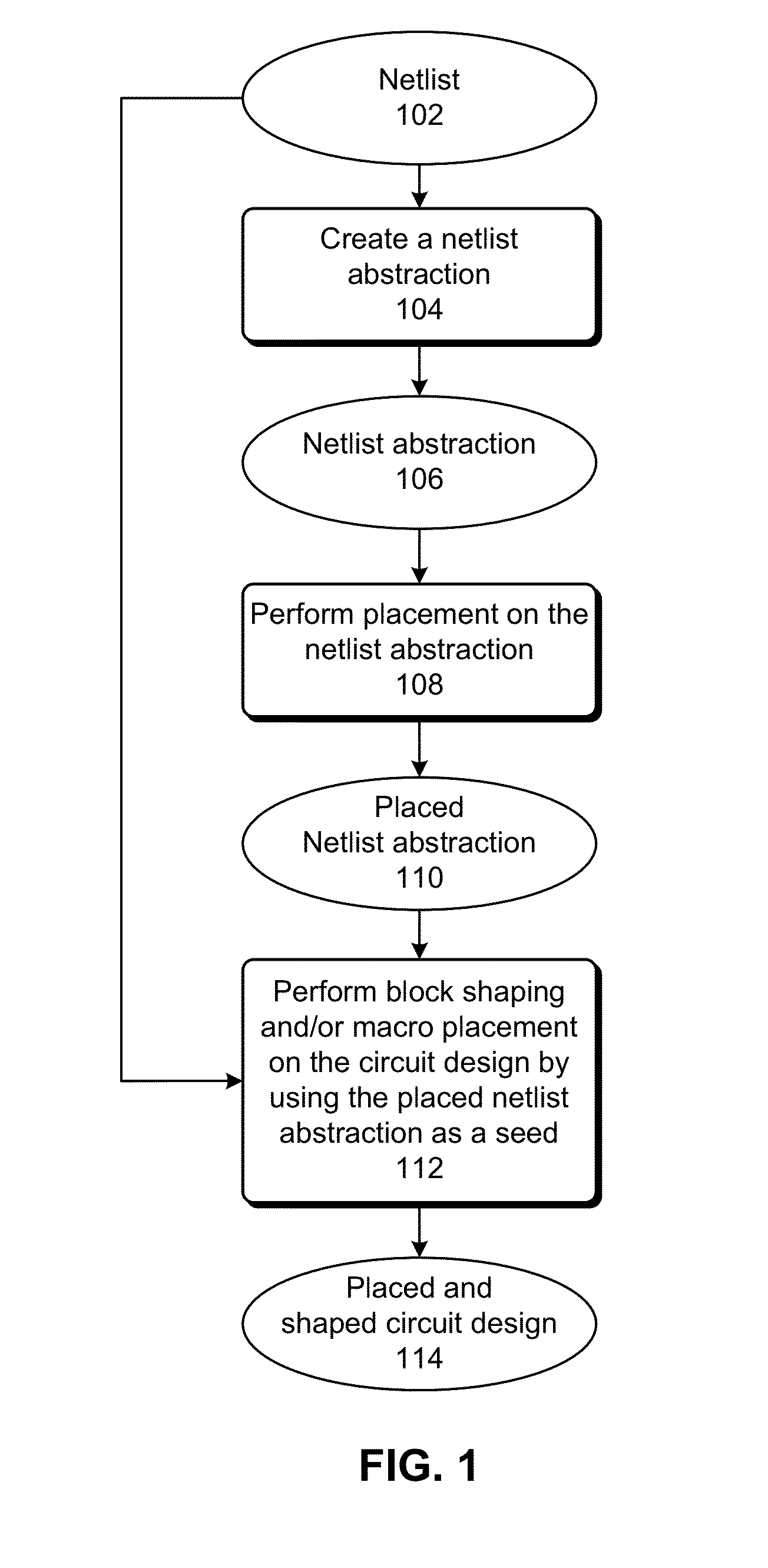

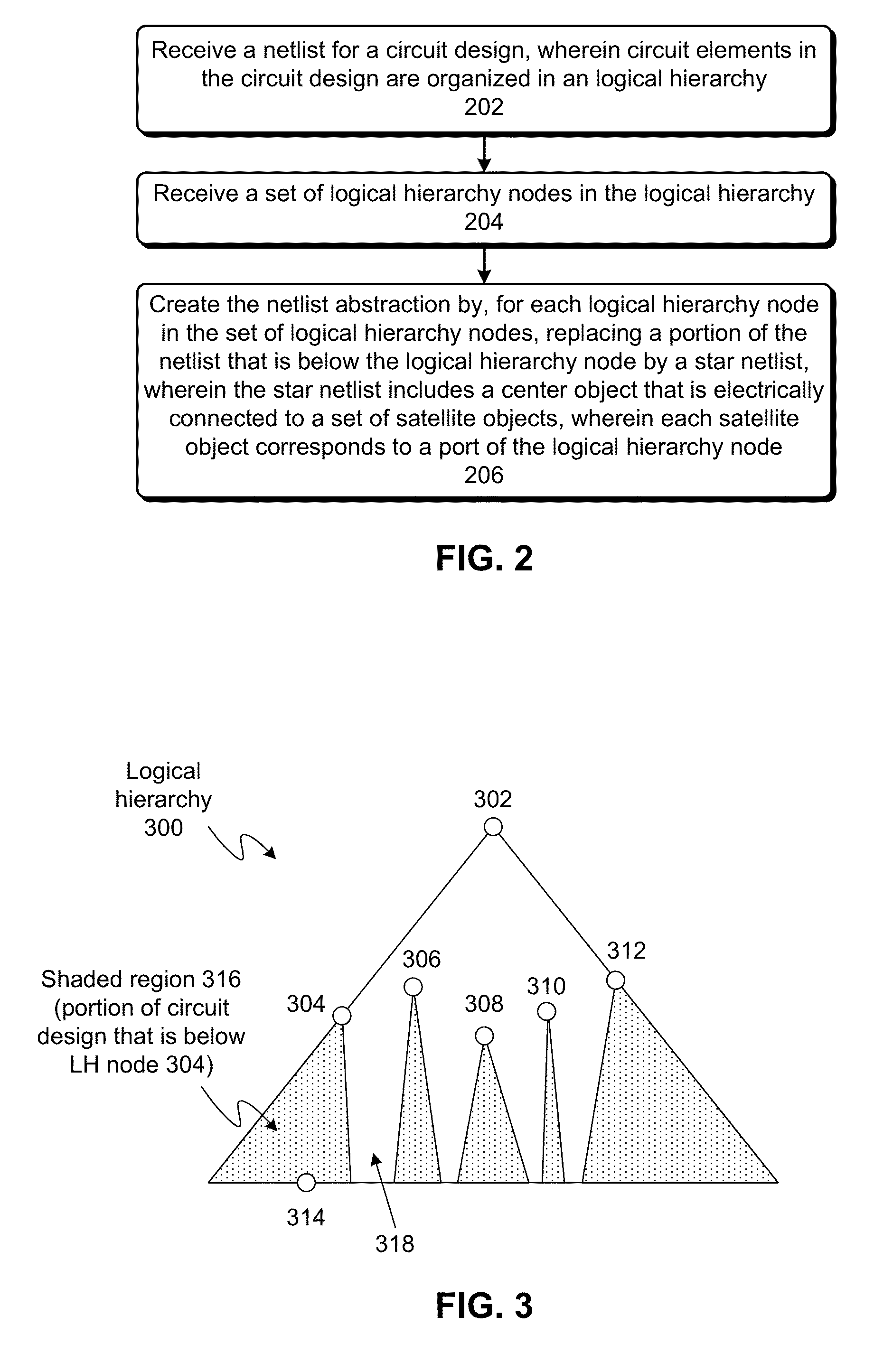

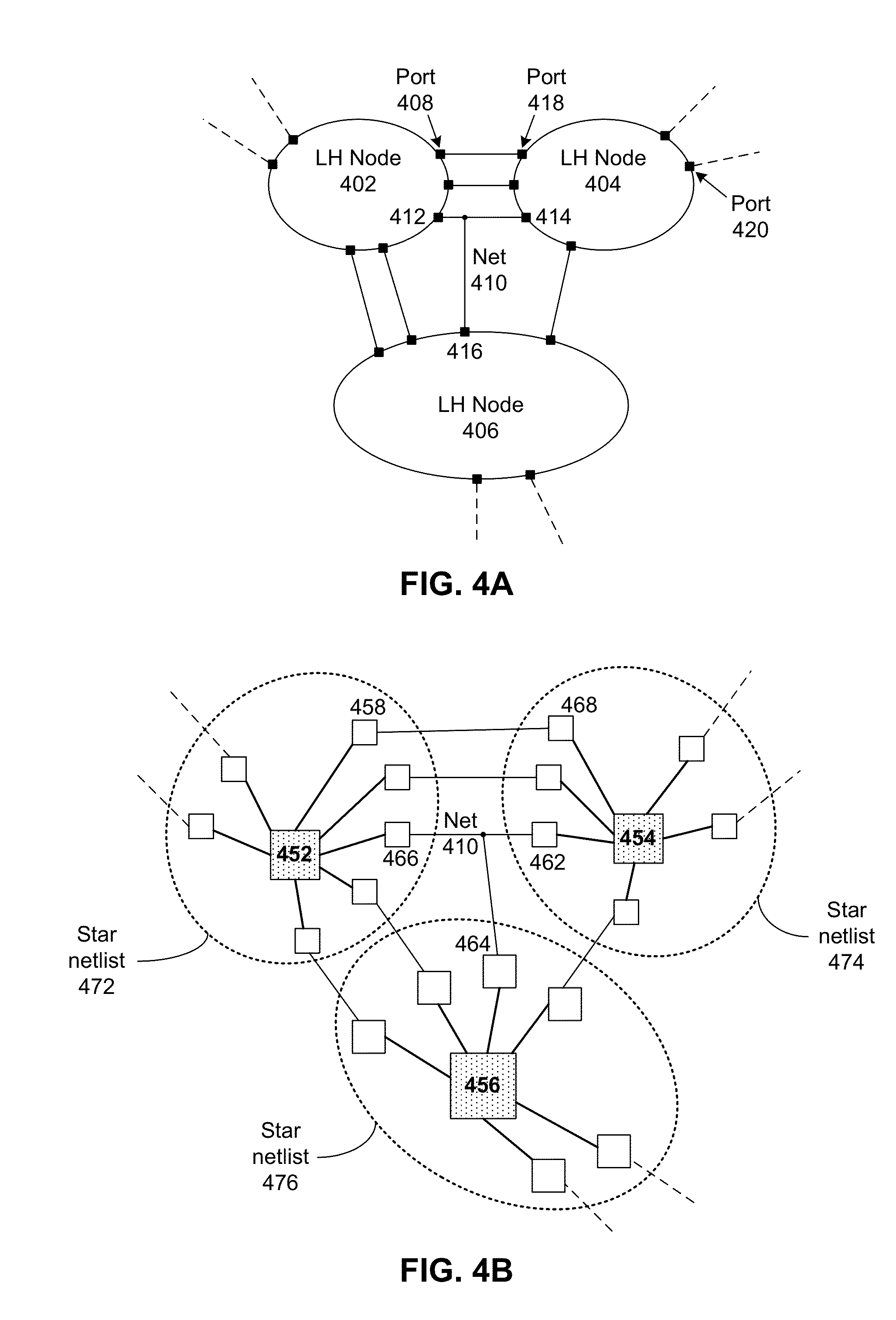

Netlist abstraction

ActiveUS8910097B2Improve quality and performanceQuick buildProgram controlComputer aided designTheoretical computer scienceComputer science

Systems and techniques for creating a netlist abstraction are described. During operation, an embodiment can receive a netlist for a circuit design, wherein circuit elements in the circuit design are organized in a logical hierarchy (LH). Next, the embodiment can receive a set of LH nodes in the LH. The embodiment can then create the netlist abstraction by, for each LH node in the set of LH nodes, replacing a portion of the netlist that is below the LH node by a star netlist, wherein the star netlist includes a center object that is electrically connected to a set of satellite objects, wherein each satellite object corresponds to a port of the LH node.

Owner:SYNOPSYS INC

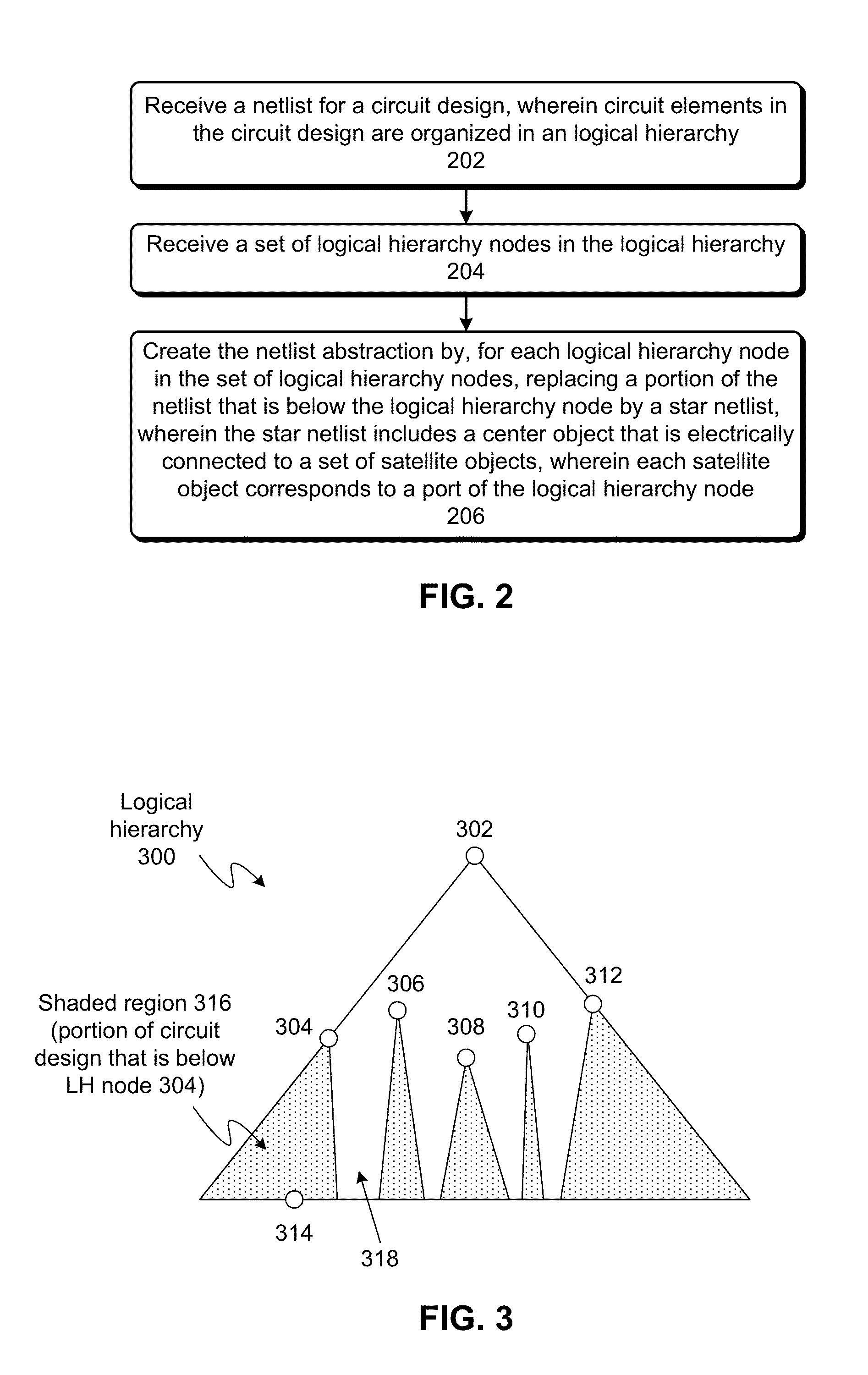

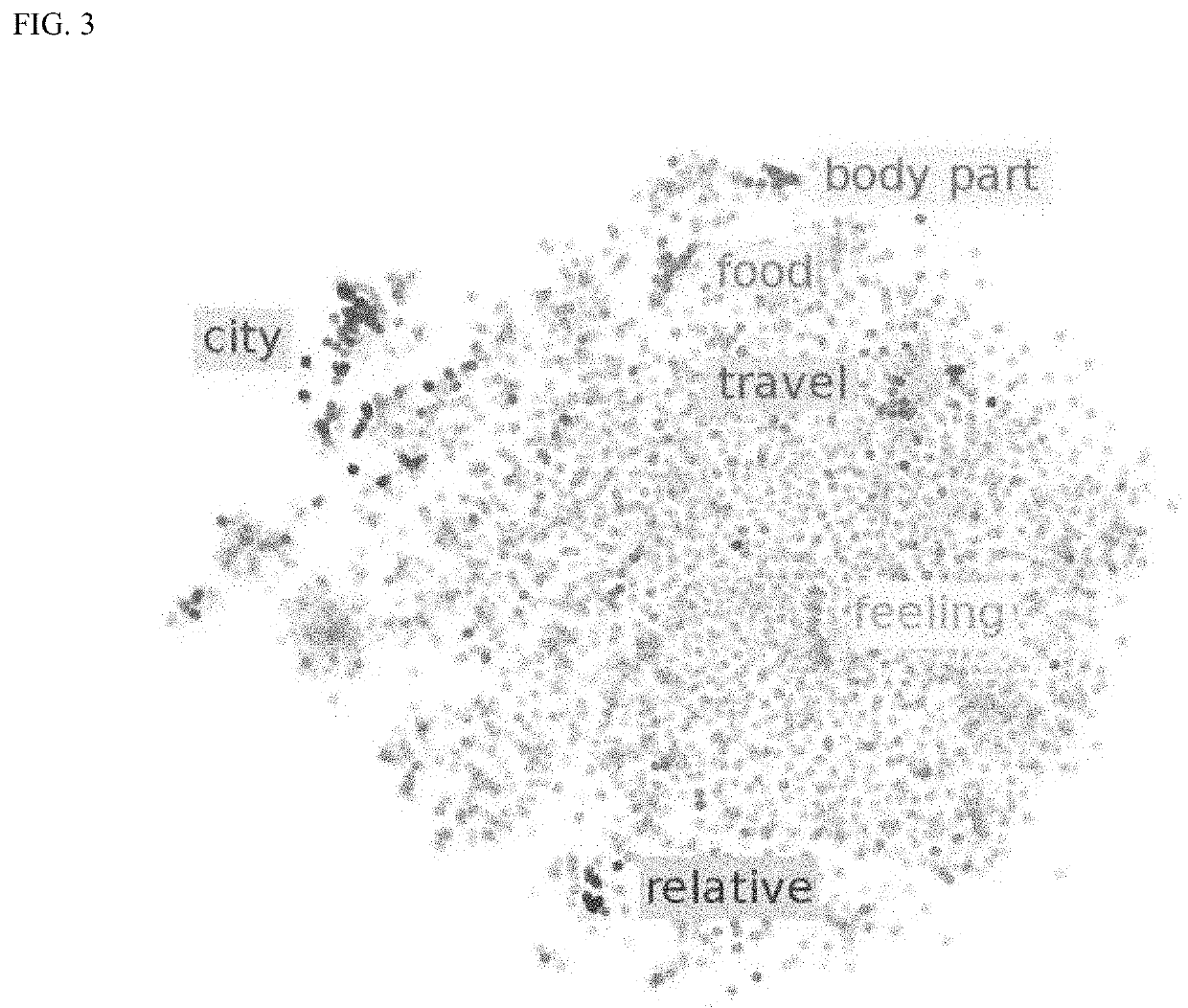

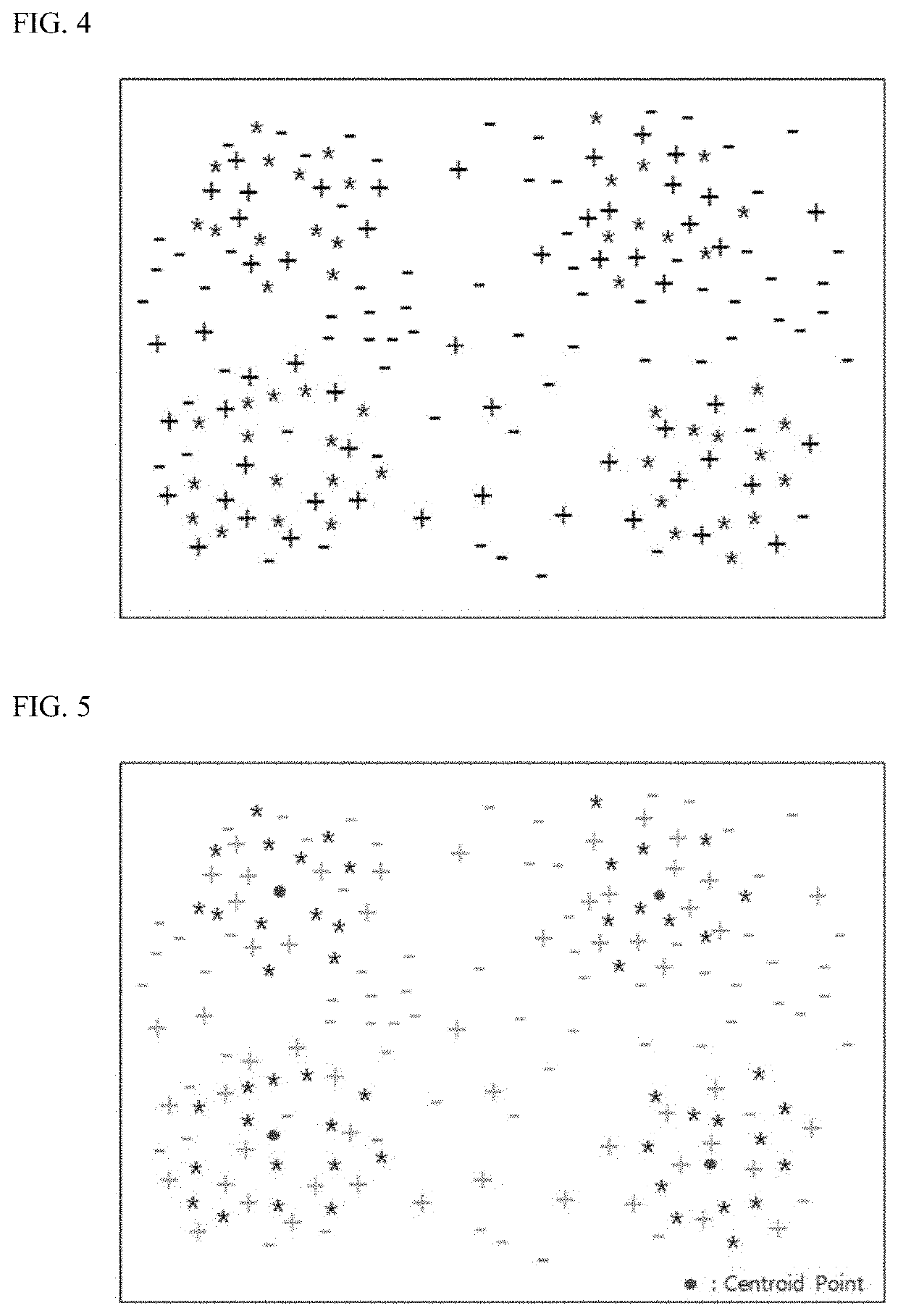

System and method for detecting incorrect triple

ActiveUS20200175226A1Quality improvementImprove performanceNatural language analysisEnsemble learningAlgorithmTheoretical computer science

Provided is an incorrect triple detection system including a triple selector configured to select a target triple (subject, type, object) in a knowledge base, a sampler configured to create a sentence model by connecting object triples sharing entities included in the target triple, a model builder configured to embed the sentence model into a vector space to create a training entity vector and build an embedding model, and an incorrect triple detector configured to detect an incorrect triple by inputting a test triple into the embedding model.

Owner:FOUND OF SOONGSIL UNIV IND COOP

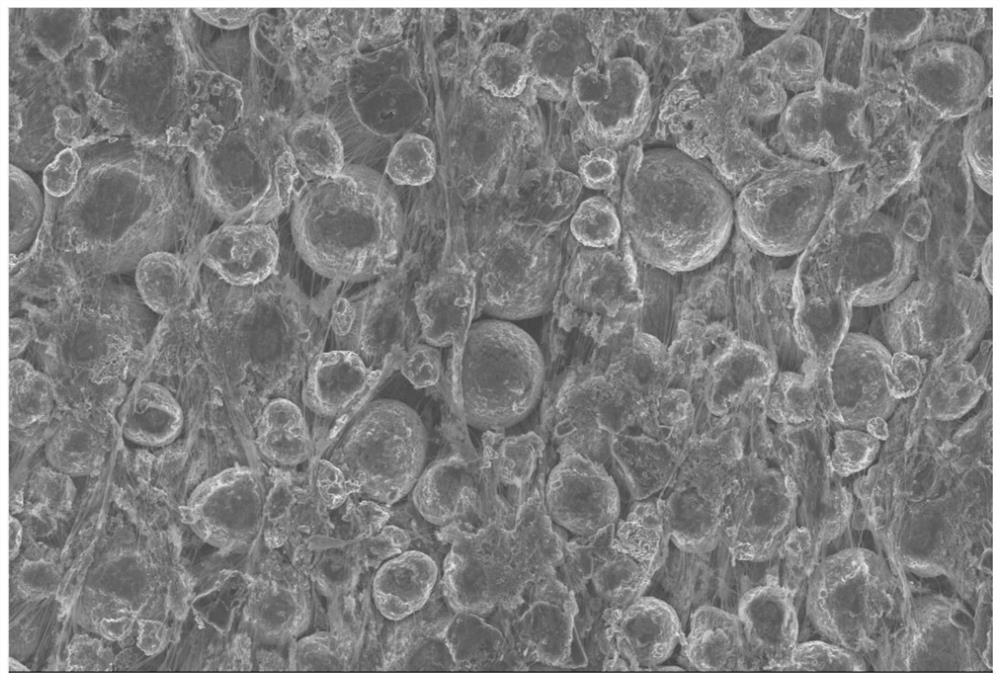

Ceramic friction material mixture and mixing method thereof

ActiveCN105112016AReduce wear rateImprove quality and performanceOther chemical processesFriction liningSODIUM DODECYL BENZENE SULFONATEGraphite

The invention relates to the technical field of ceramic friction materials, particularly a ceramic friction material mixture and a mixing method thereof. Silicon dioxide, molybdenum disulfide, diesel, manganese carbonate ore, phosphorite, graphite, diatomite, ceramic fibers, carbon fibers, a phenolic resin and sodium dodecyl benzene sulfonate used as raw materials are selected and proportioned to prepare the ceramic friction material. The kinetic friction coefficient of the ceramic friction plate prepared from the ceramic friction material is 0.22-0.23, the static friction coefficient is 0.24-0.25, the kinetic / static friction ratio is 0.88-0.955, and the wear rate is 7.5*10<-6>mm<3>.J<-1>-9*10<-6>mm<3>.J<-1>. By combining the raw material proportioning and adding the manganese carbonate ore and phosphorite, the properties of the ceramic friction material mixture are improved, so that the frictional properties (especially stability, oil conductivity and physical and mechanical properties) of the ceramic friction material are improved.

Owner:贵州领想科技制造有限公司

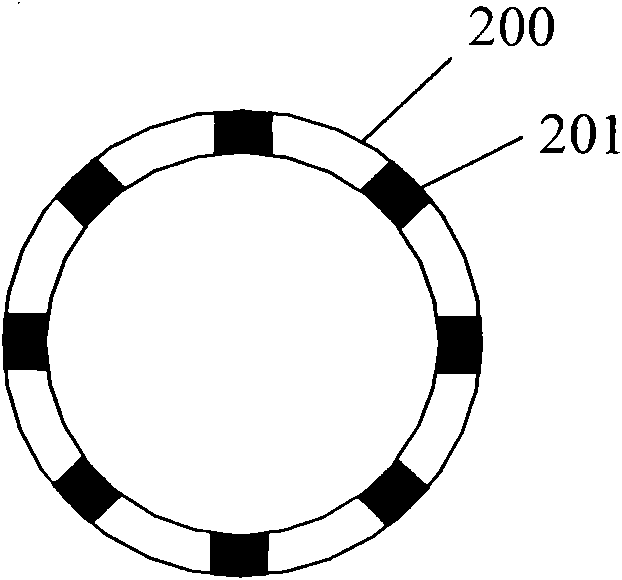

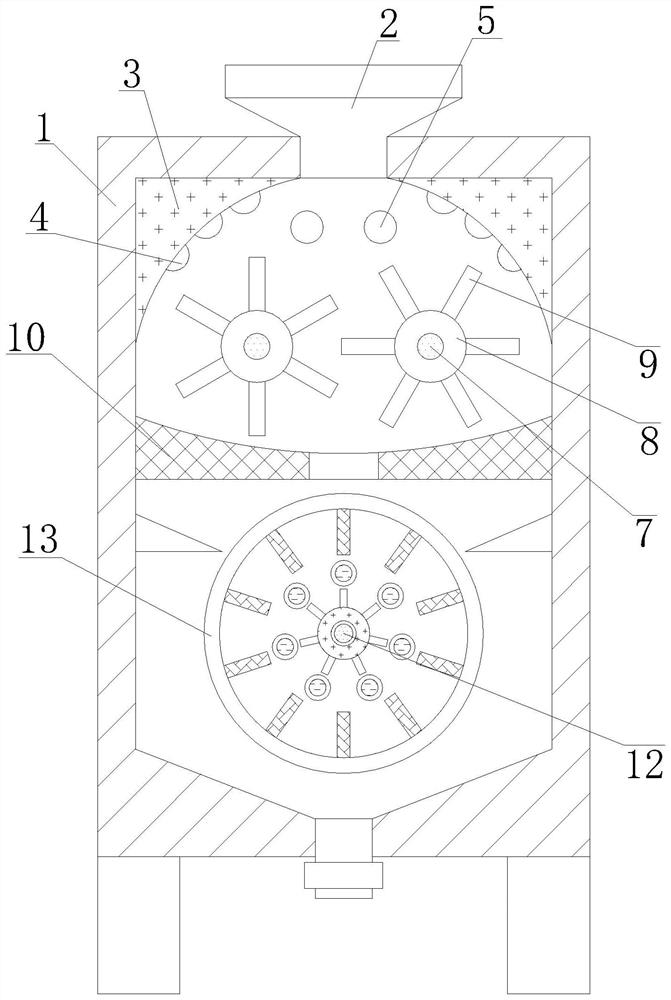

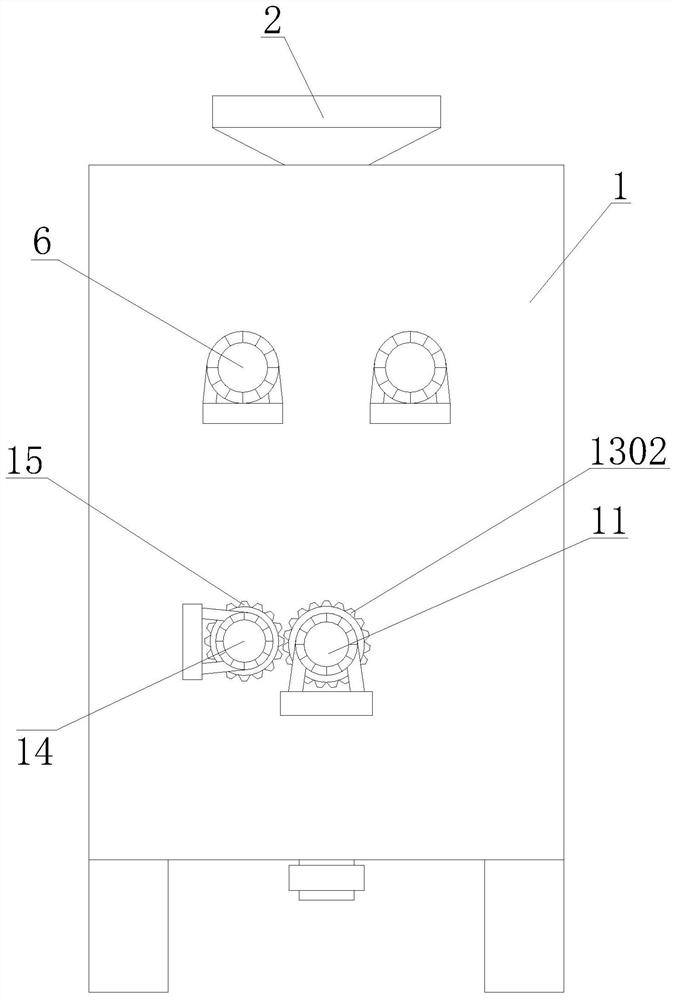

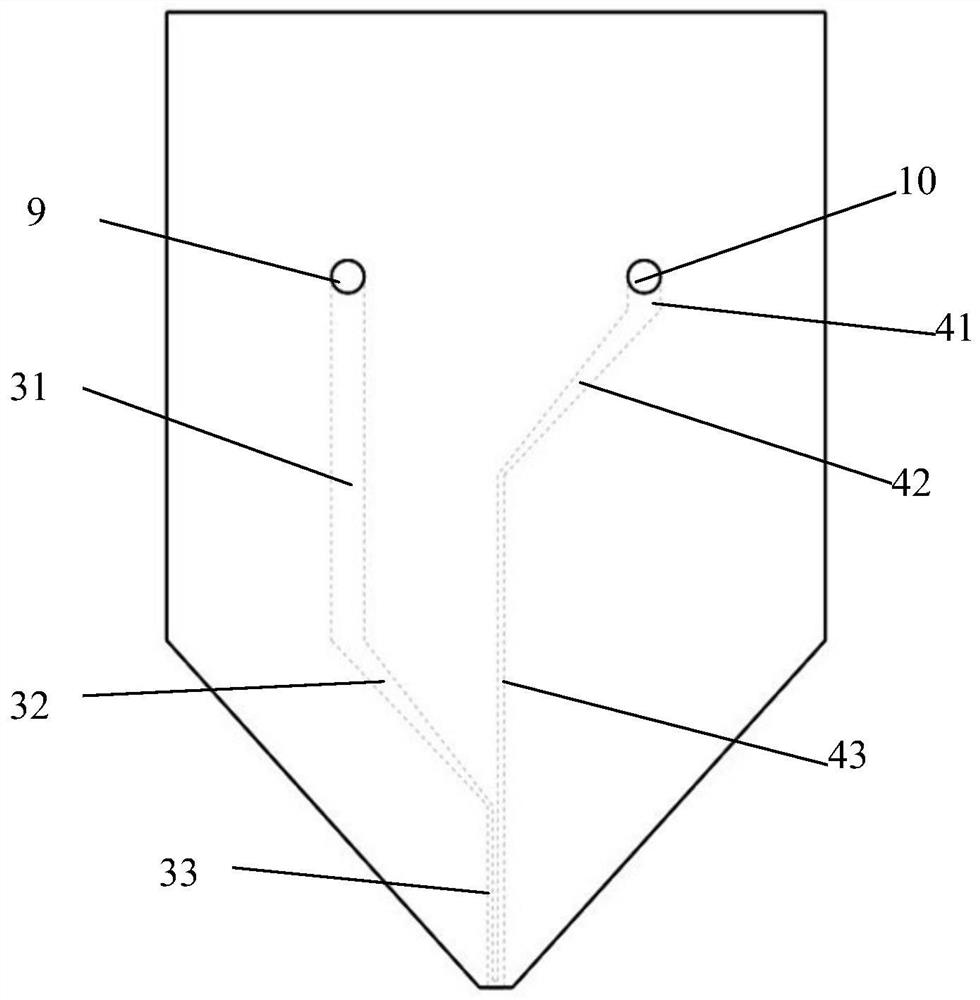

Efficient iron removal device for rice processing

ActiveCN111841879AImprove the effect of iron removalImprove quality and performanceMagnetic separationElectric machineryAgricultural engineering

The invention relates to the technical field of rice iron removal. The invention discloses an efficient iron removal device for rice processing. The device comprises a work box, the top of the work box communicates with a feeding hopper. Two stop blocks are symmetrically and fixedly connected to the inner top wall of the work box; and the front and rear side faces of the stop blocks are fixedly connected with the front inner wall and the rear inner wall of the work box correspondingly, a plurality of electromagnet blocks are fixedly connected to the side faces, close to each other, of the twostop blocks, two electromagnetic rods are symmetrically and fixedly connected between the front inner wall and the rear inner wall of the work box, and two first motors are symmetrically and fixedly connected to the back face of the work box through supporting plates. The problems that according to an existing rice iron removing device, generally, a magnet is placed at a rice conveying channel toremove iron from rice, so that iron residues in the rice are difficult to remove thoroughly, and the quality and the effect of rice iron removing processing are seriously reduced are solved.

Owner:怀宁县谷丰米业有限公司

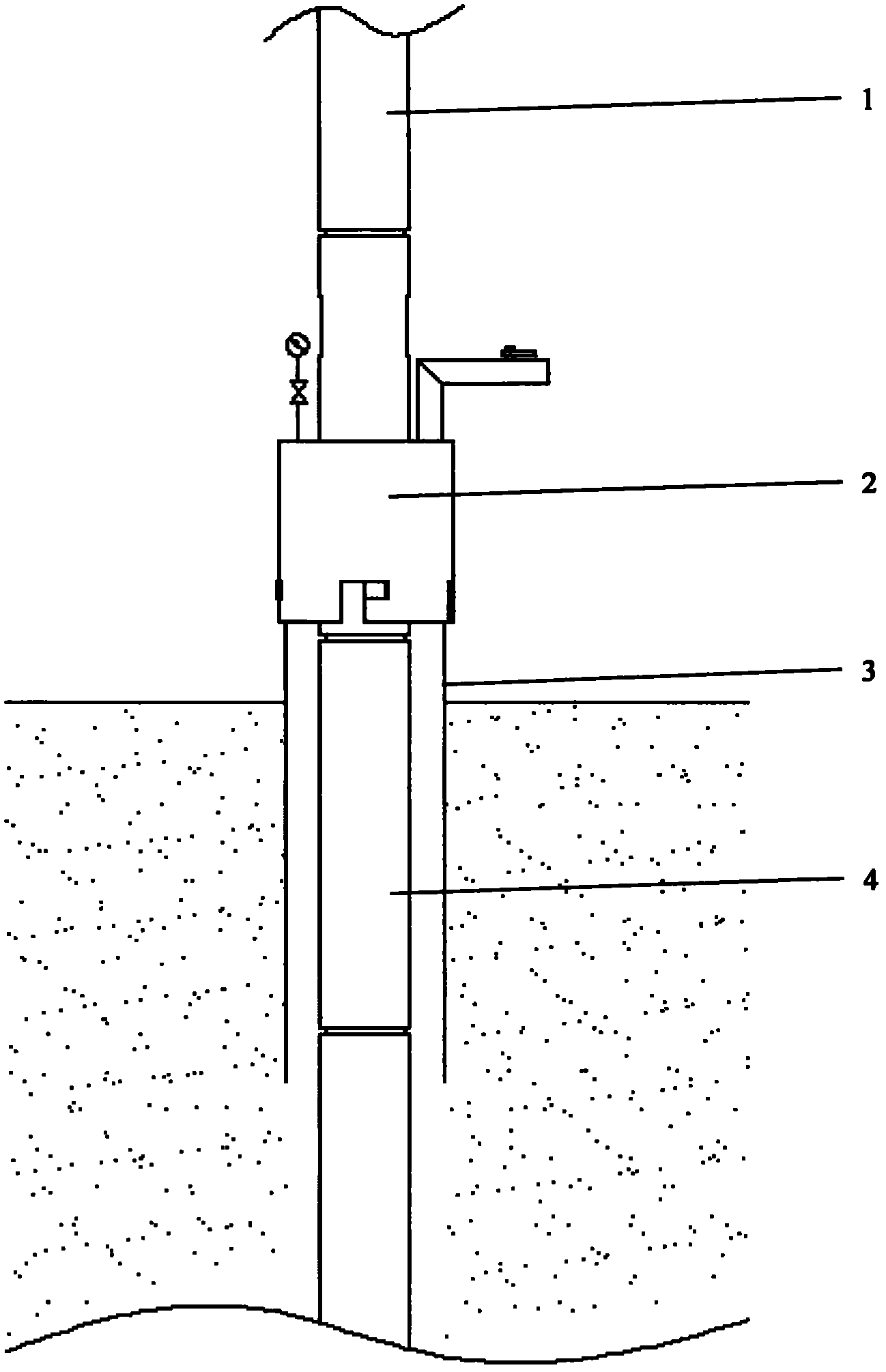

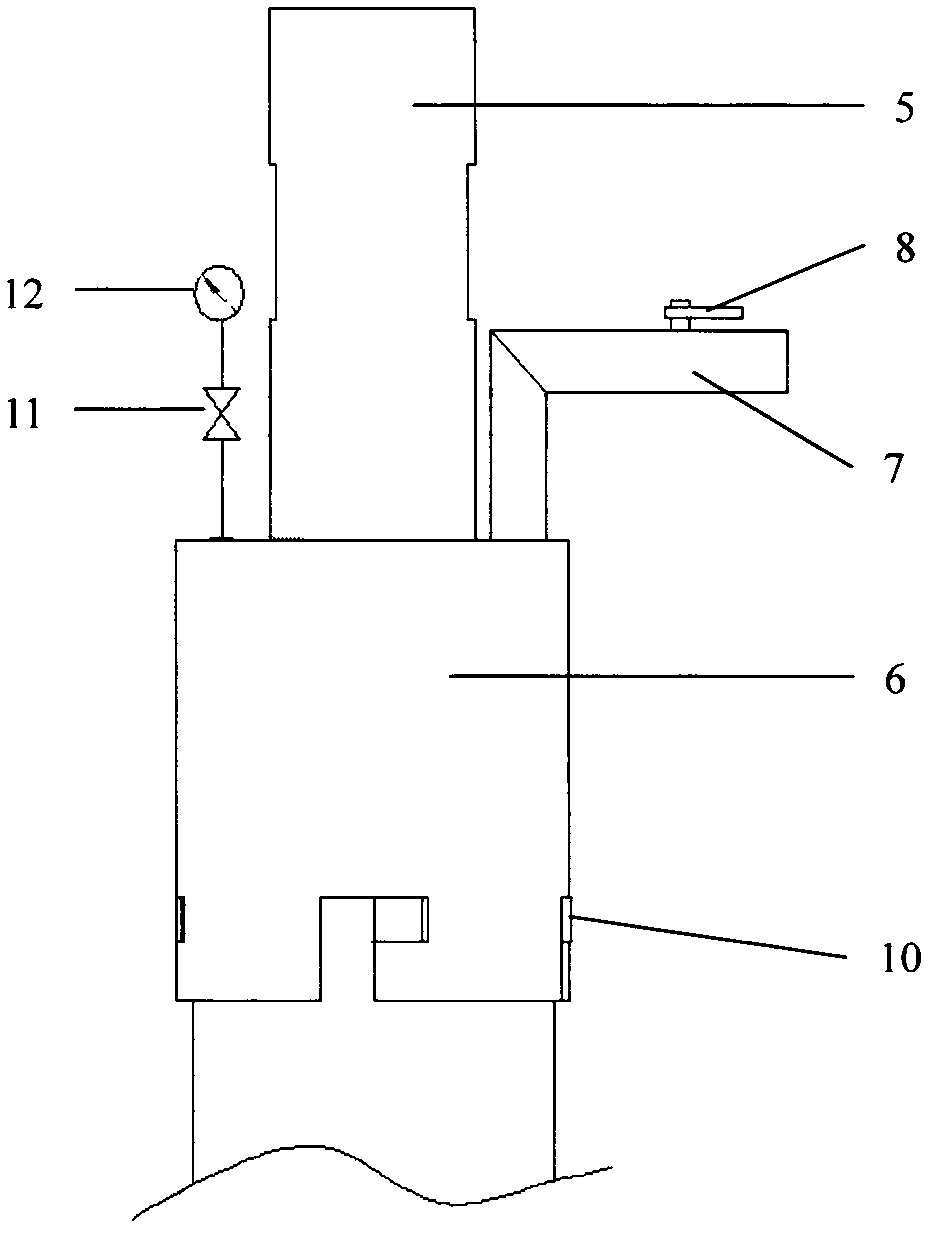

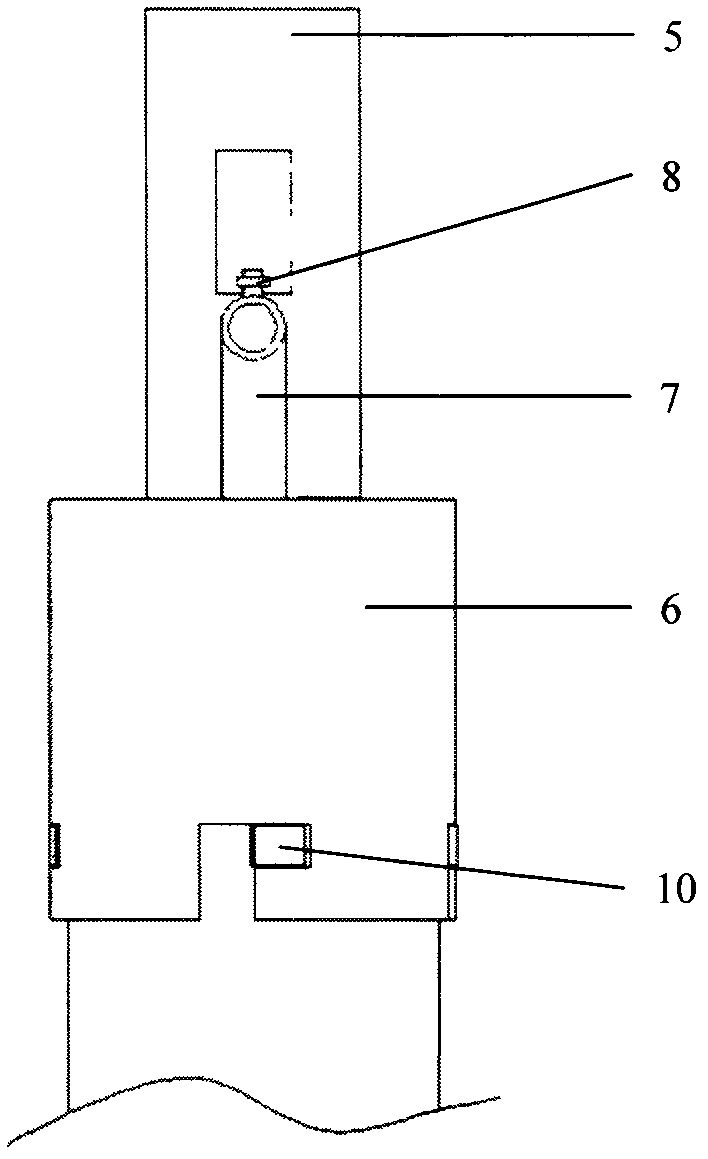

Annular pressure monitoring sealing device for geological drilling

InactiveCN103216224AImprove quality and performanceEasy to kill wellConstructionsDrill holeEngineering

The invention relates to an annular pressure monitoring sealing device for geological drilling, which is applicable to drilling hole maintenance operation such as pressure monitoring, pressure control and pressure leak stopping in geological drilling construction. The device consists of a central pipe, a sealing shell, a pressure gauge, a safety valve, a pressure relief pipe, a spin valve, an orifice pipe, keys and a seal ring, wherein the sealing shell is arranged on the central pipe; four L-shaped notches are formed in the sealing shell; the pressure gauge and the safety valve are arranged on the sealing shell in a connected way; the pressure relief pipe is arranged on the sealing shell; the upper end of the pressure relief pipe is provided with the spin valve; the seal ring is arranged on the orifice pipe; the orifice pipe is arranged in the sealing shell; and four keys are welded on the outer wall of the orifice pipe for locking the relative position of the sealing shell and the orifice pipe. According to the device, the annular pressure change of a shaft can be monitored in real time, and meanwhile, operations such as sealing pressure maintaining and pressure relief can be performed; the device has effects of monitoring and controlling the pressure, keeping a hole wall stable and the like; the leak stopping effect and quality can be greatly improved and water burst is controlled to facilitate kill operation; and thus, the level of the drilling technology is improved and the drilling cost is effectively reduced.

Owner:BEIJING INST OF EXPLORATION ENG

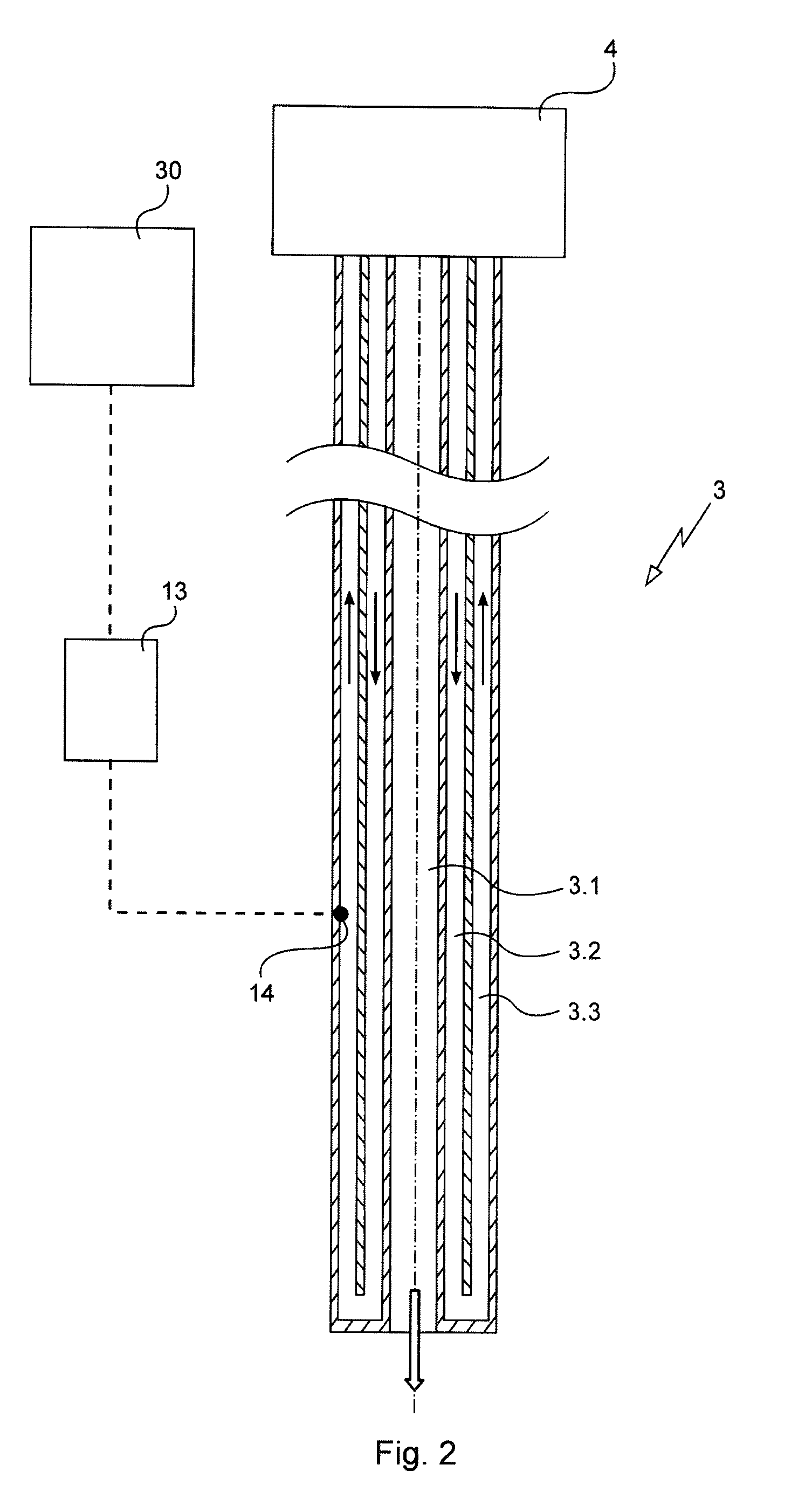

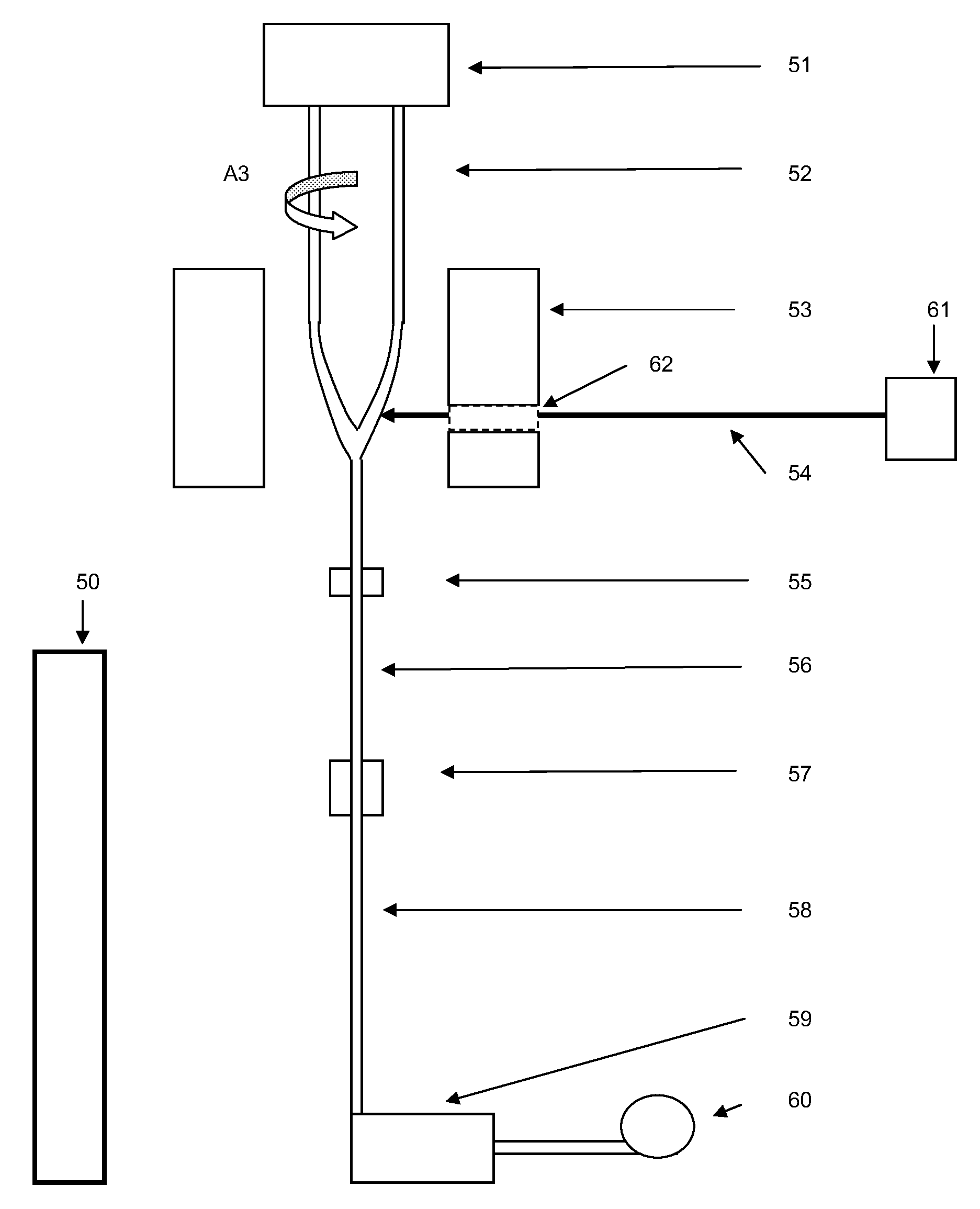

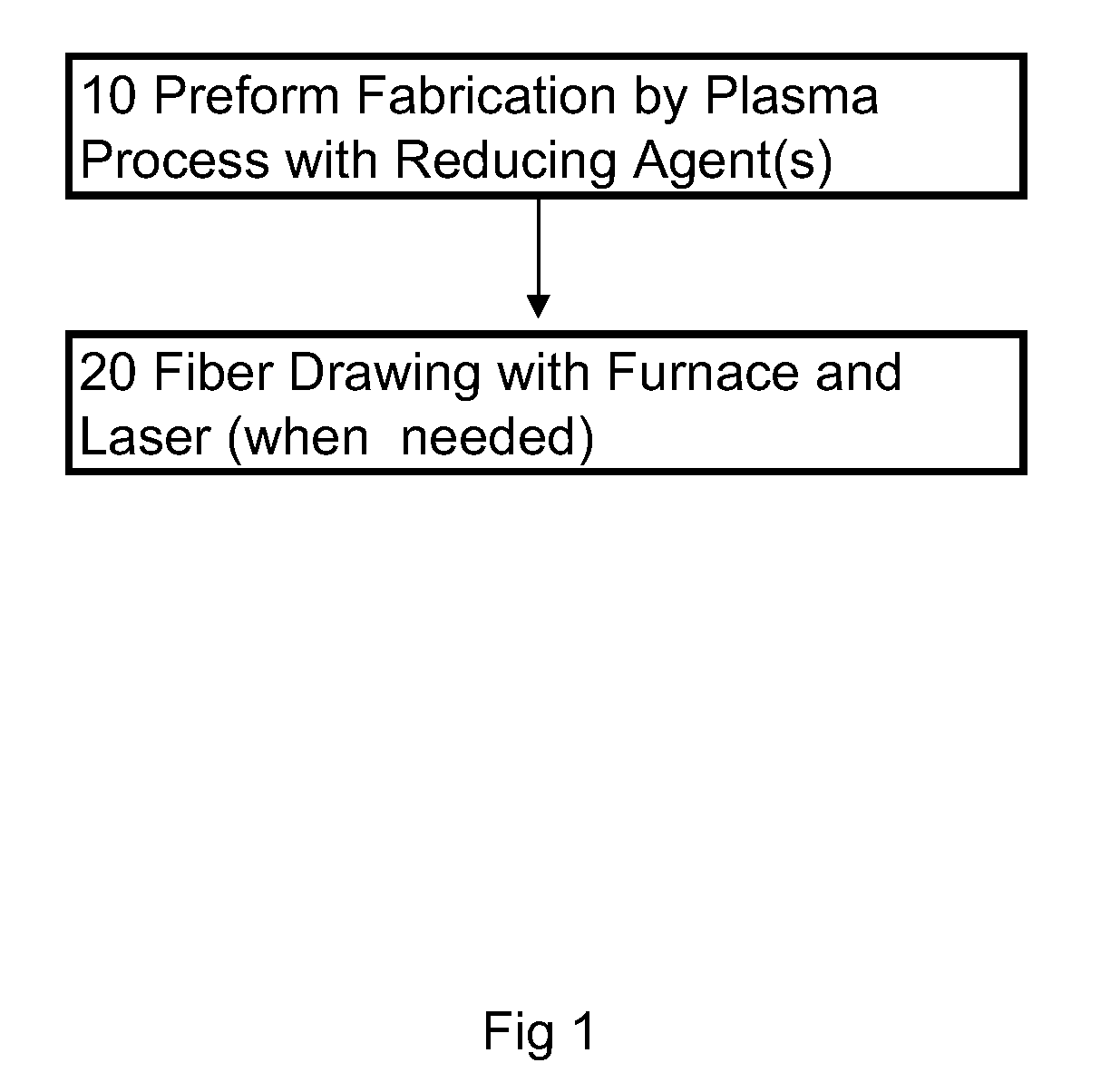

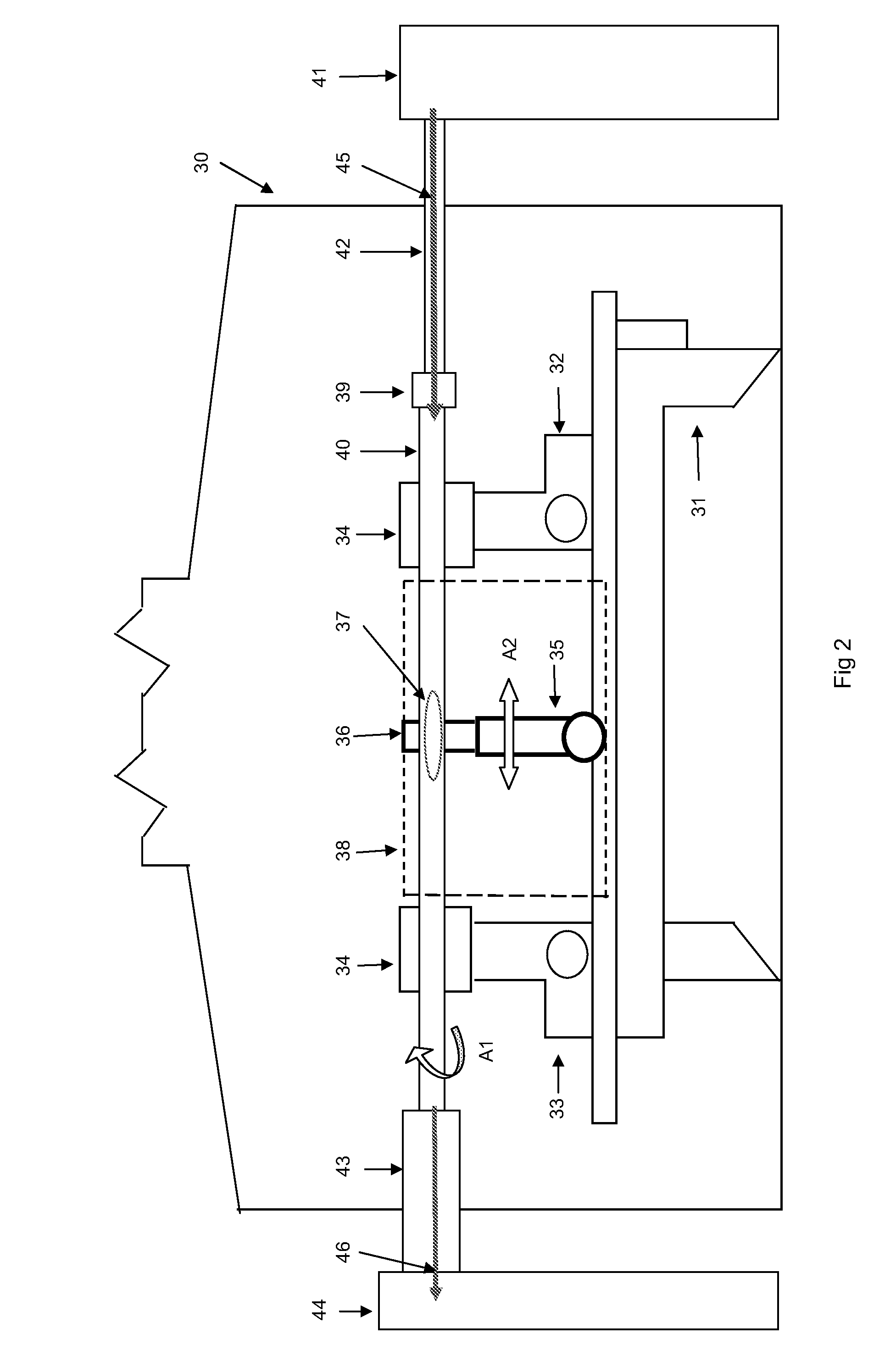

Process, apparatus, and material for making silicon germanium core fiber

InactiveUS20110006398A1Minimize processing problemImprove quality and performanceGlass making apparatusElectric discharge tubesFiber drawingGermanium

A process and apparatus for making silicon or silicon / germanium core fiber is described, which uses a plasma process with reducing agent to make preform. The process also makes the recommendations in selecting the adequate cladding tube for better fiber properties. An improved fiber drawing apparatus is also disclosed in order to draw this new type of preforms.

Owner:WU DAU

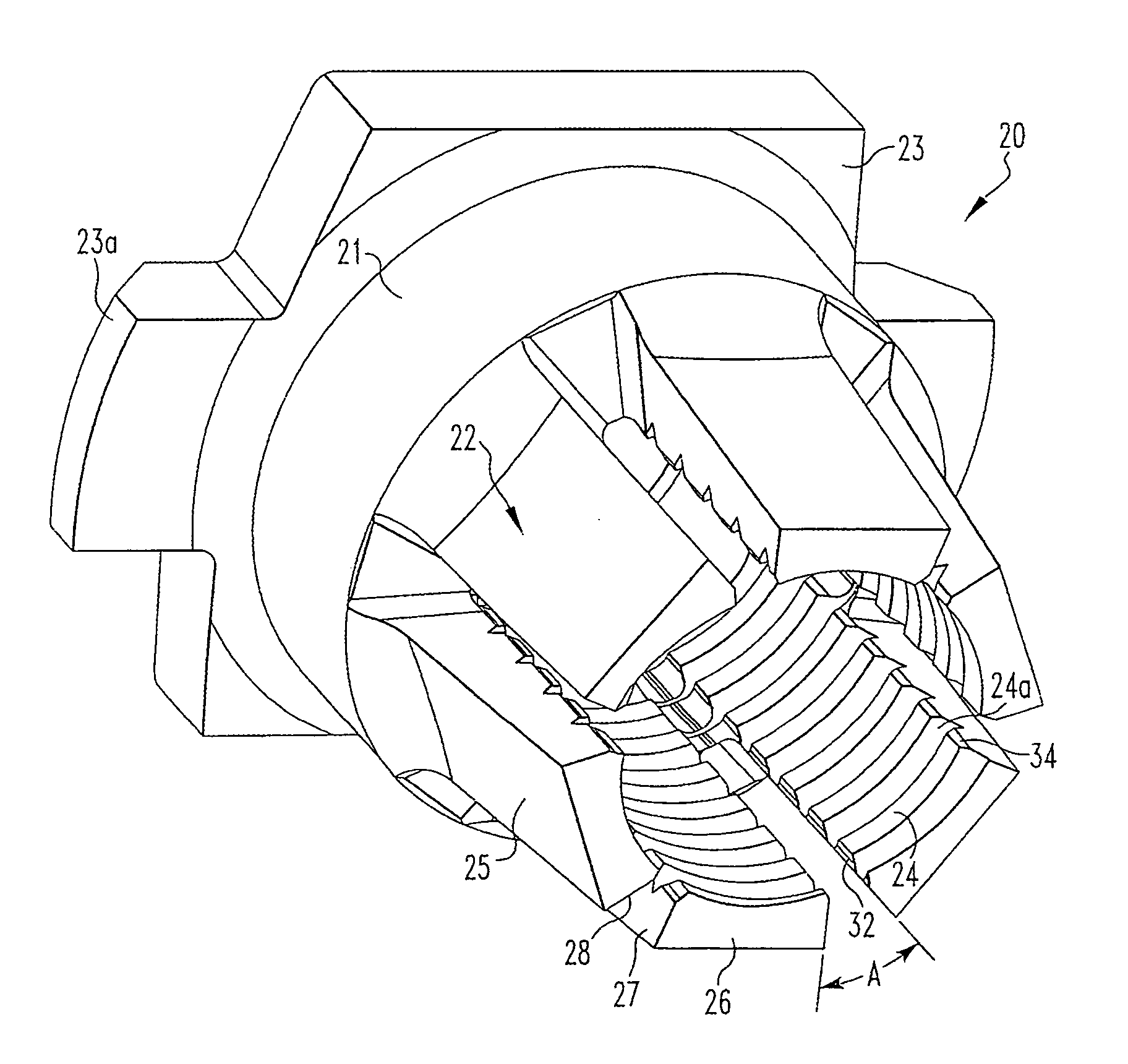

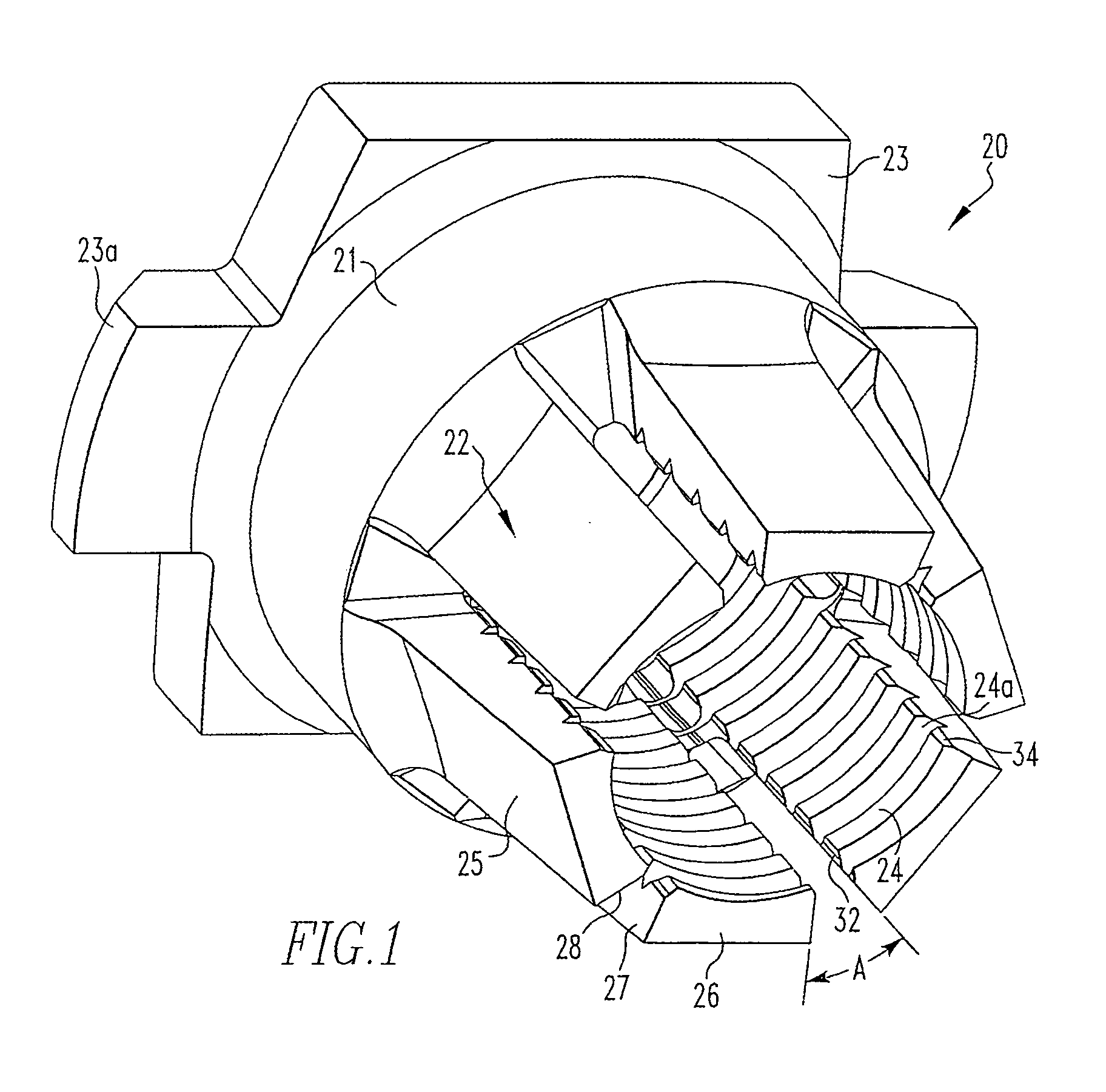

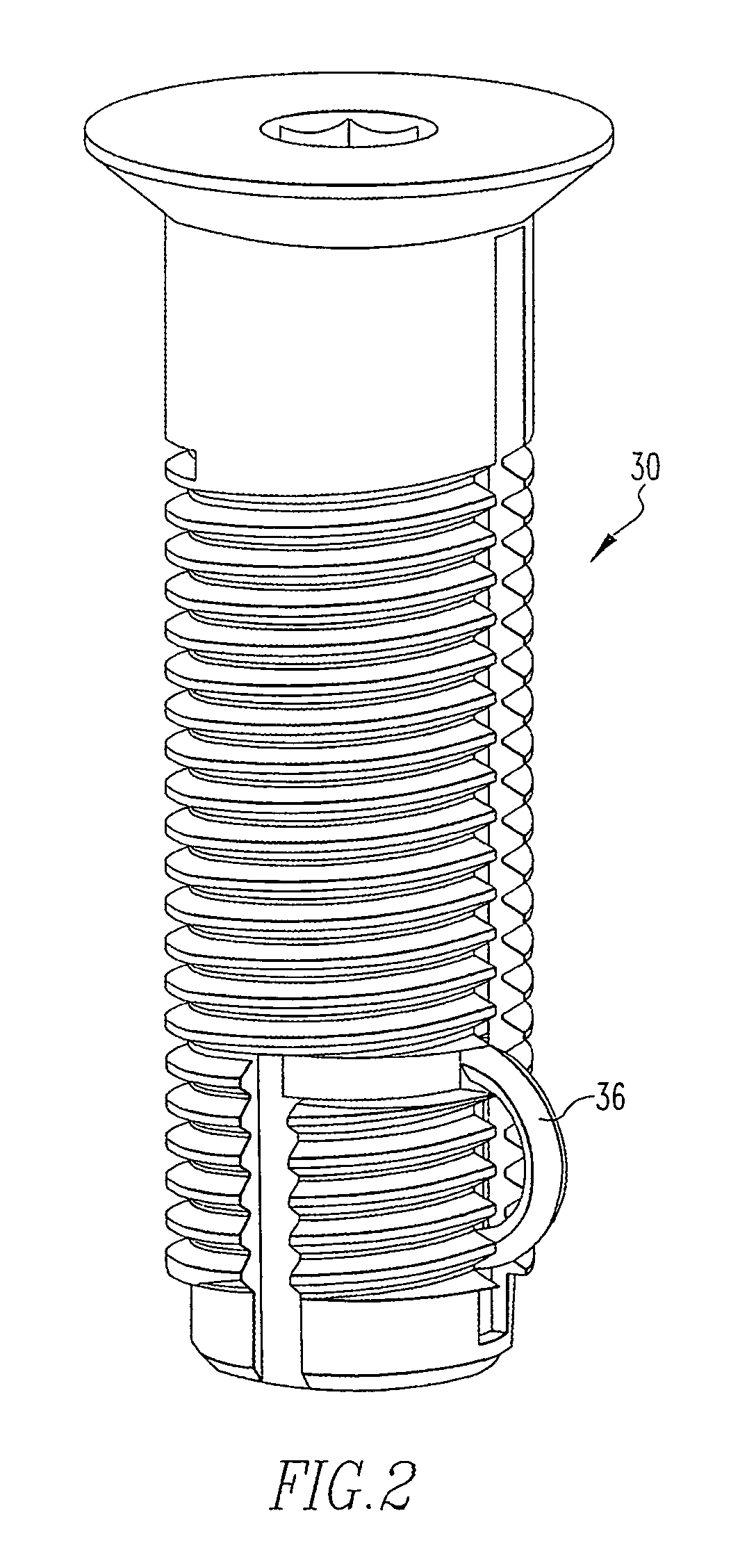

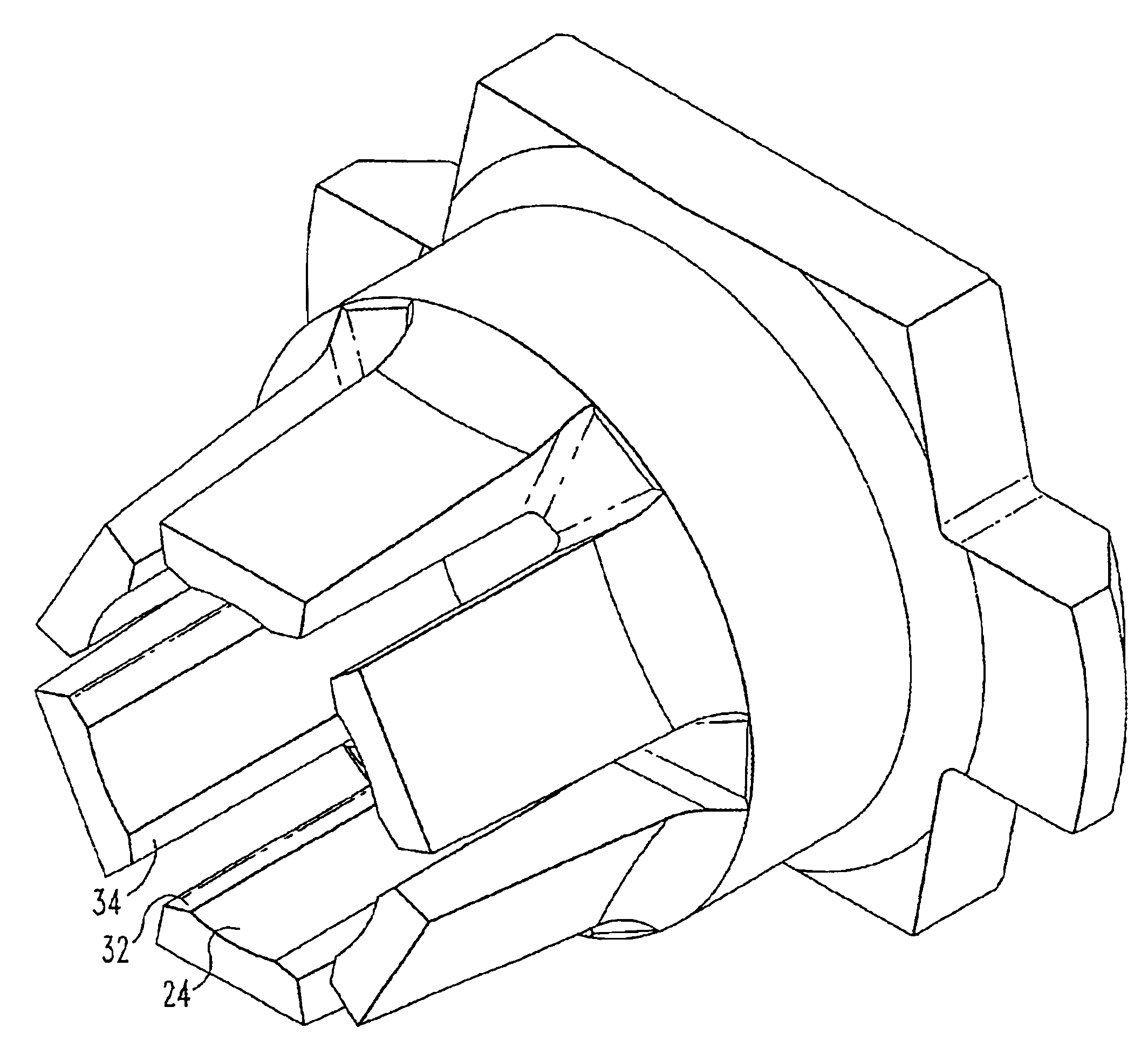

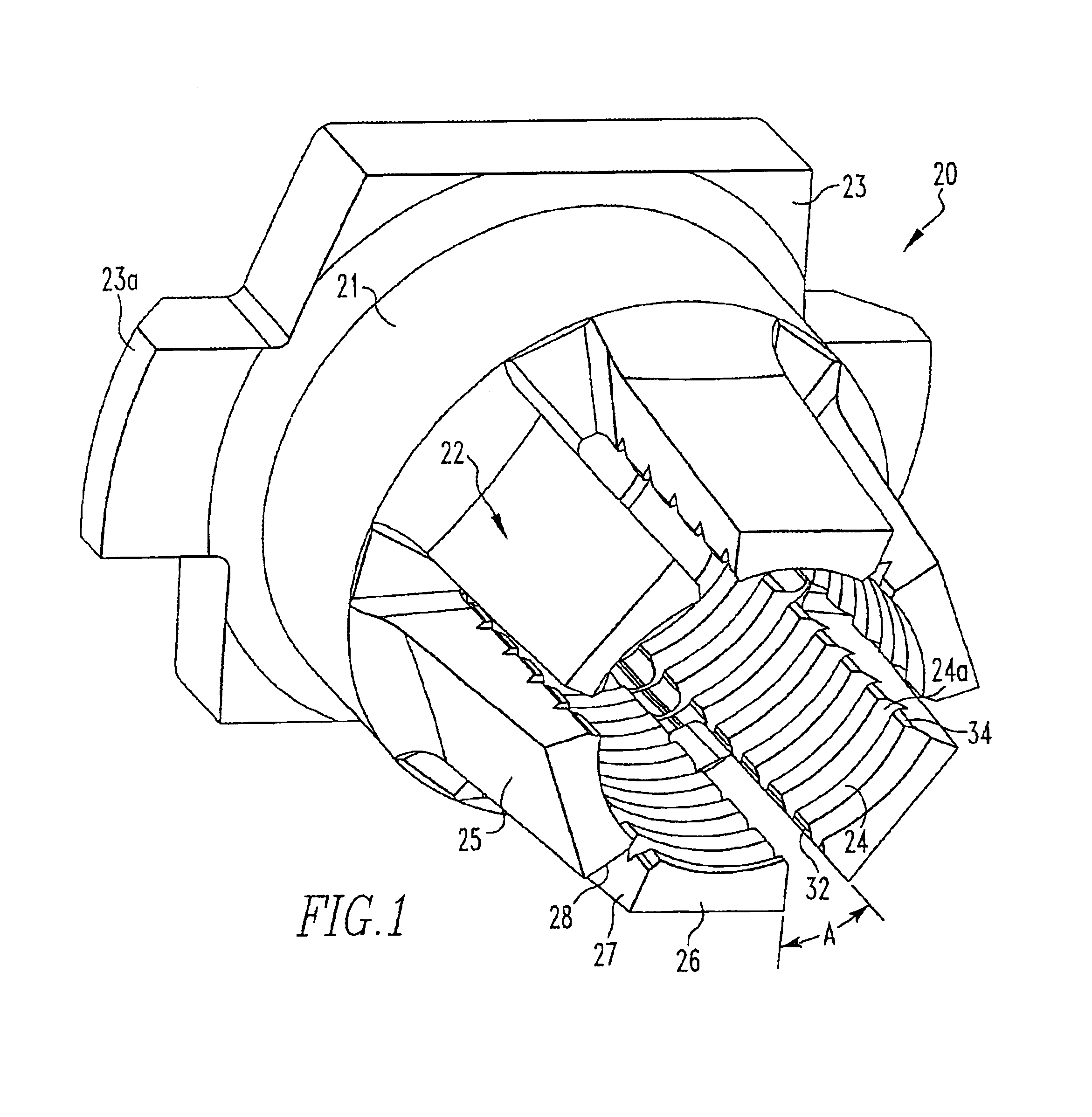

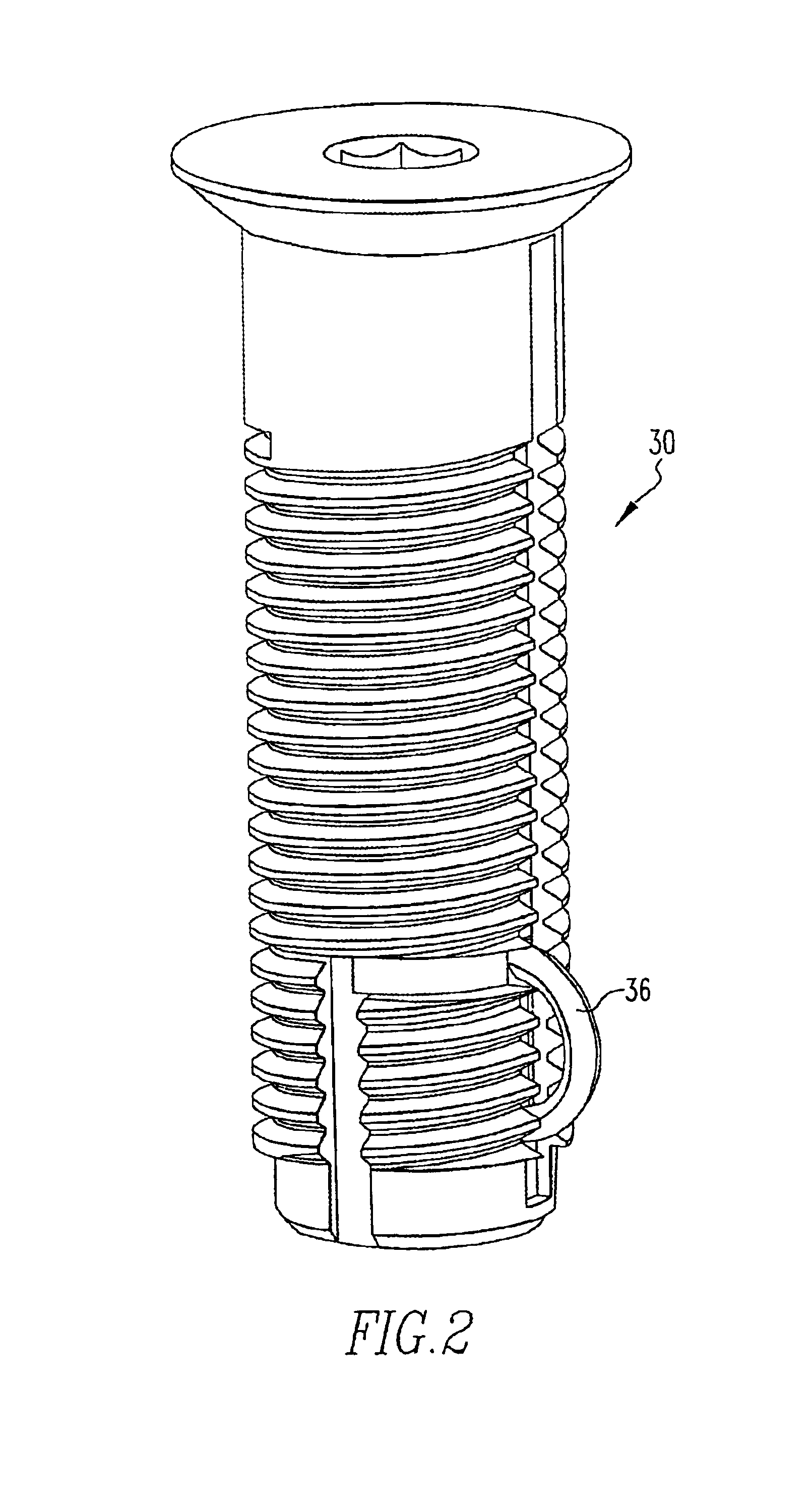

Lock nut member

A threaded locking beam nut having a plurality of locking beams configured such that the inside edge surface of each locking beam has a radially inwardly angled surface thereby forming substantially a V-shaped channel between adjacent beams.

Owner:ALCOA GLOBAL FASTENERS

Netlist abstraction

ActiveUS20140189620A1Improve performanceQuality improvementProgram controlComputer aided designNODALTheoretical computer science

Systems and techniques for creating a netlist abstraction are described. During operation, an embodiment can receive a netlist for a circuit design, wherein circuit elements in the circuit design are organized in a logical hierarchy (LH). Next, the embodiment can receive a set of LH nodes in the LH. The embodiment can then create the netlist abstraction by, for each LH node in the set of LH nodes, replacing a portion of the netlist that is below the LH node by a star netlist, wherein the star netlist includes a center object that is electrically connected to a set of satellite objects, wherein each satellite object corresponds to a port of the LH node.

Owner:SYNOPSYS INC

Lock nut member

InactiveUS6908395B2Improve quality and performanceImprove cycle life and reusability performanceRivetsNutsEdge surfaceMechanical engineering

Owner:ALCOA GLOBAL FASTENERS

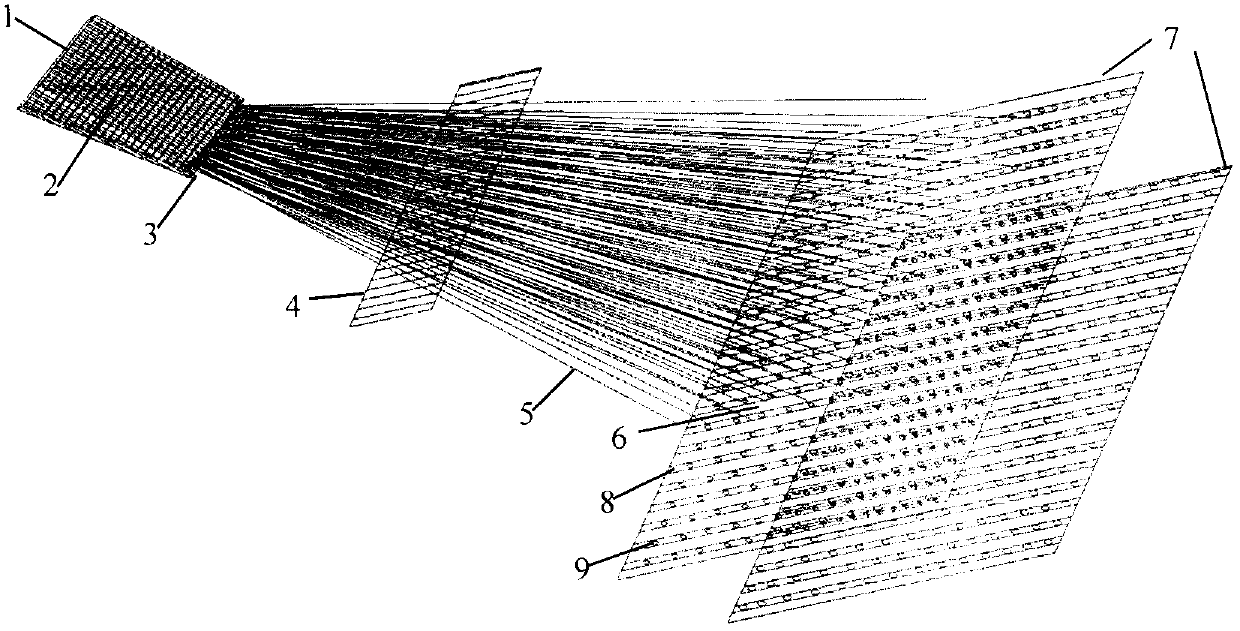

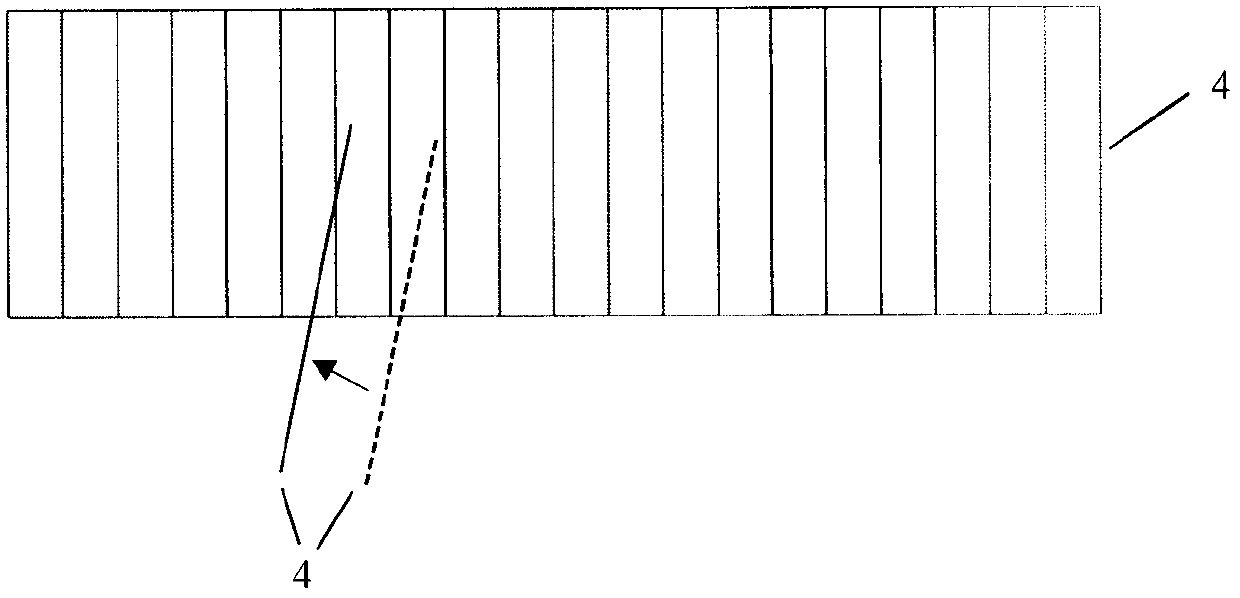

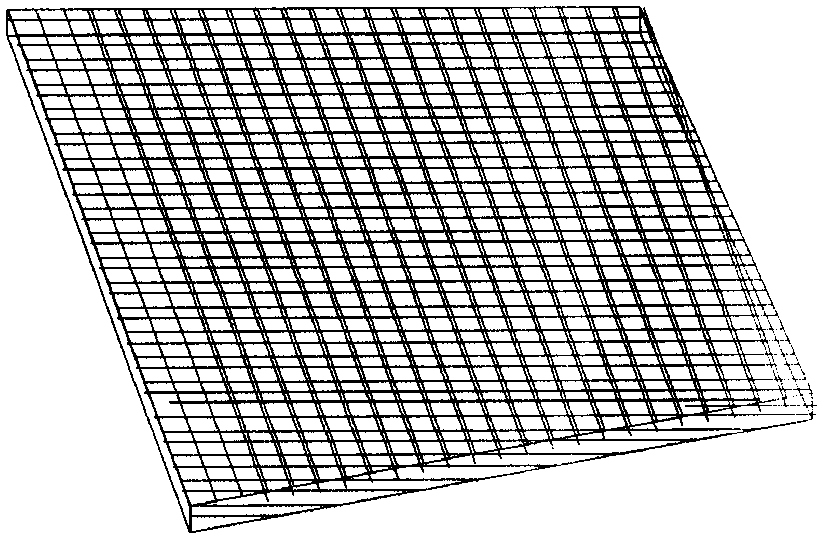

Method for weaving 2.5D angle-interlock preformed part with section gradually decreasing

InactiveCN107740220ALess fiber damageImprove quality and performanceWoven fabricsYarnBiomedical engineering

The invention relates to a method for weaving a 2.5D angle-interlock preformed part with the section gradually decreasing. On the basis of a layer-layer angle-interlock weaving process, the method ischaracterized in that in the weaving process, with one end surface of the preformed part as a standard, according to the change of the size of the section of the preformed part and the movement law ofyarn, the quantity and positions of yarn-reducing points in a plane in the weaving direction are designed, and the yarn-reducing points are evenly distributed; by means of the methods of yarn reduction, yarn movement and yarn reed replacement, the section change of the preformed part is achieved, and the section-variable preformed part is woven. The method is simple and high in applicability, thewoven formed part is good in integrity, and the mechanical properties of composites can be improved.

Owner:TIANJIN POLYTECHNIC UNIV

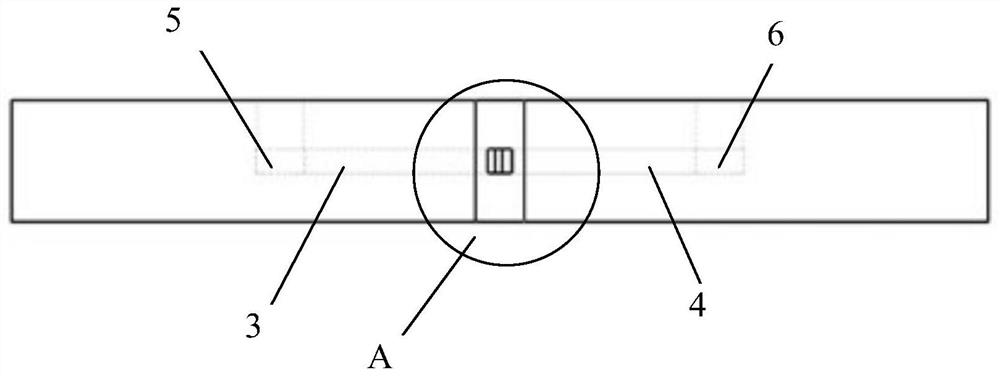

Preparation method of dry-method electrode pole piece, electrode pole piece and battery cell

ActiveCN113871561AImprove poor film uniformityImprove quality and performanceElectrode rolling/calenderingLi-accumulatorsComposite materialBattery cell

The invention provides a preparation method of a dry-method electrode pole piece, an electrode pole piece and a battery cell. The preparation method of the dry-method electrode pole piece comprises the following steps of preparing a fibrillated mixed material from raw material powder, stirring and sieving the mixed material to obtain pole piece powder, and processing the pole piece powder to obtain the electrode pole piece. According to the preparation method of the dry-method electrode pole piece, the material fibration degree before feeding can be regulated and controlled by stirring and sieving the mixed material, so that the thickness of a rolled film is regulated and controlled, and the problems of poor uniformity and poor neatness of the film are solved, so that the electrode pole piece prepared by the method is used for preparing a battery cell, and the quality and the performance of the battery cell are favorably improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

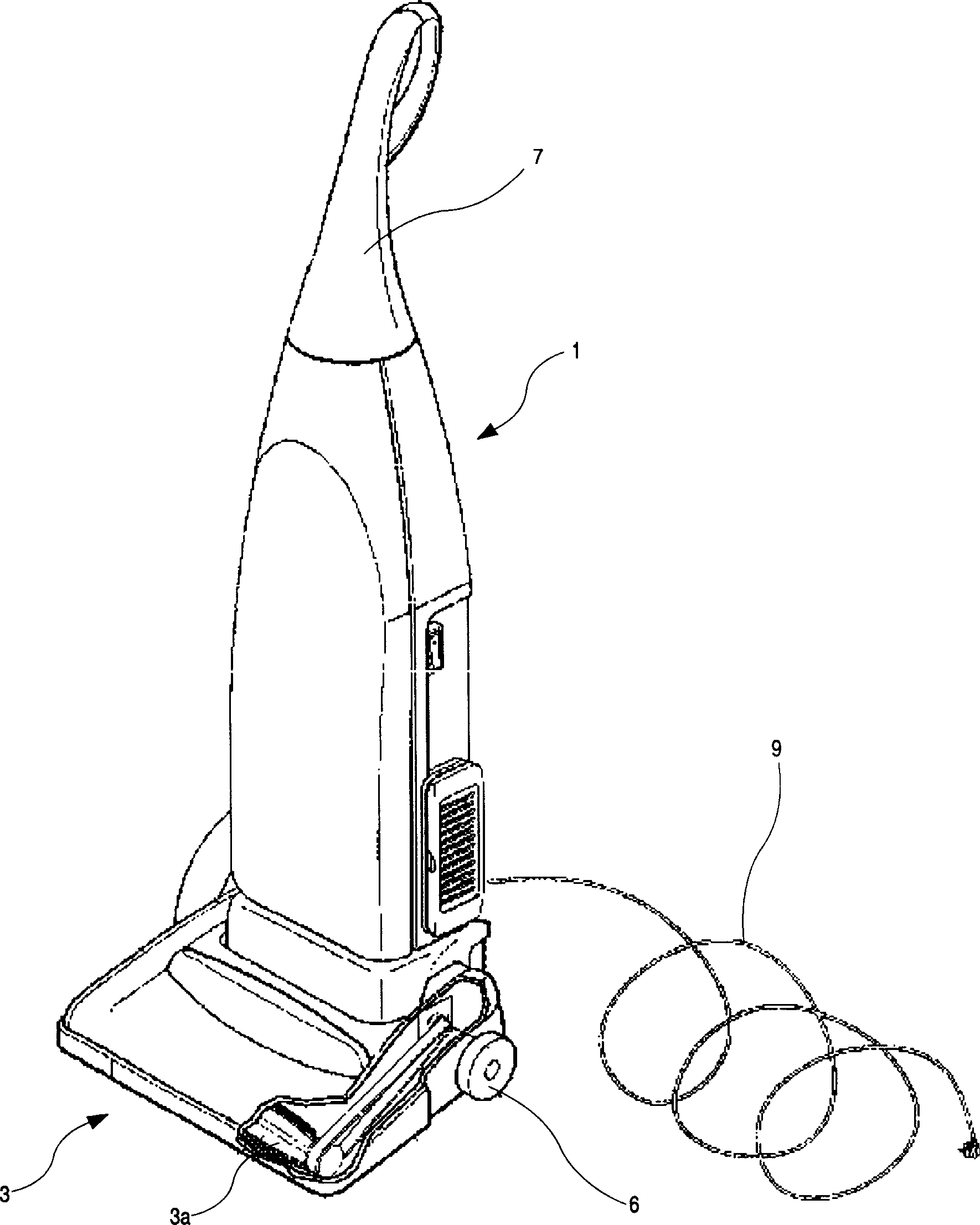

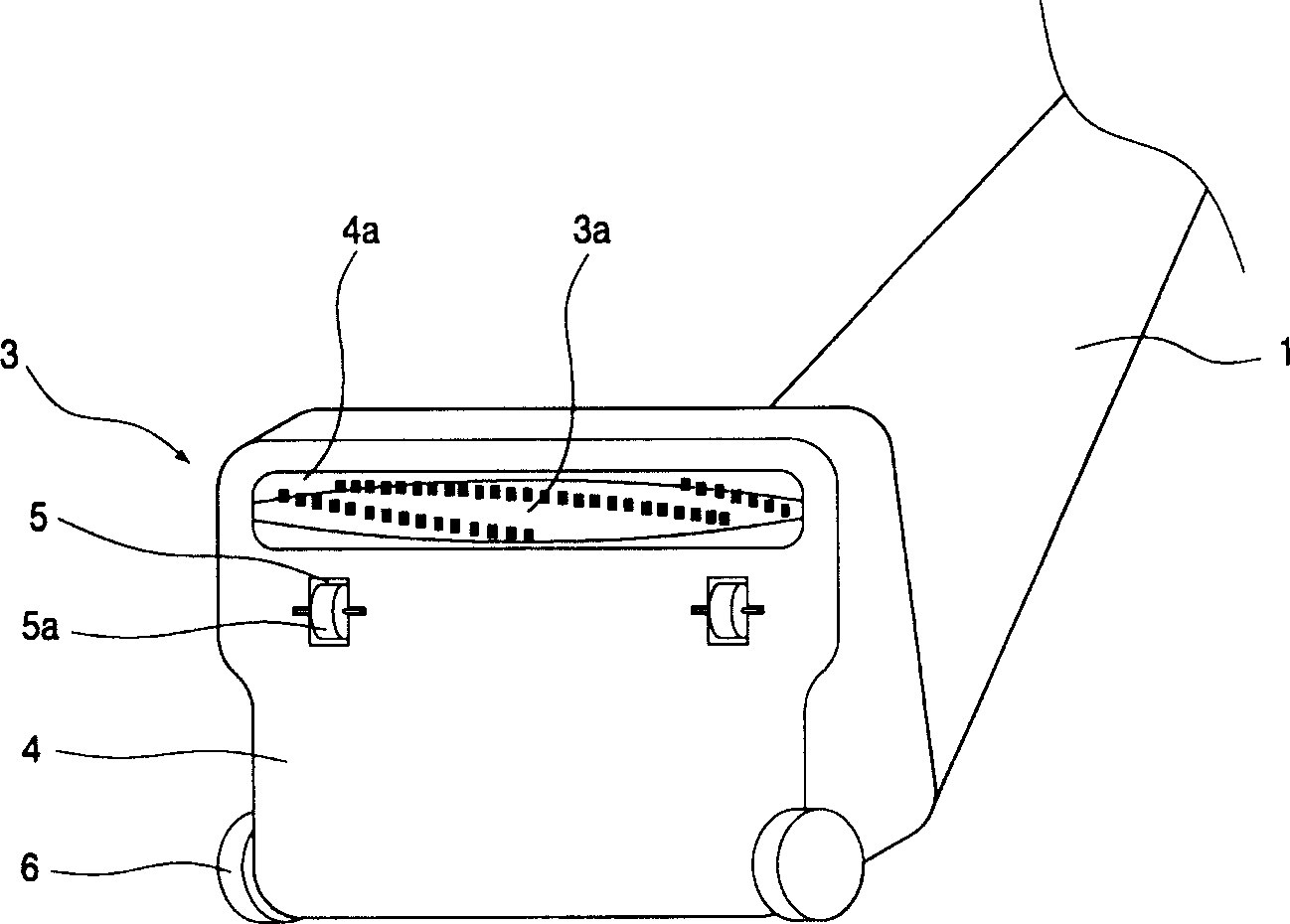

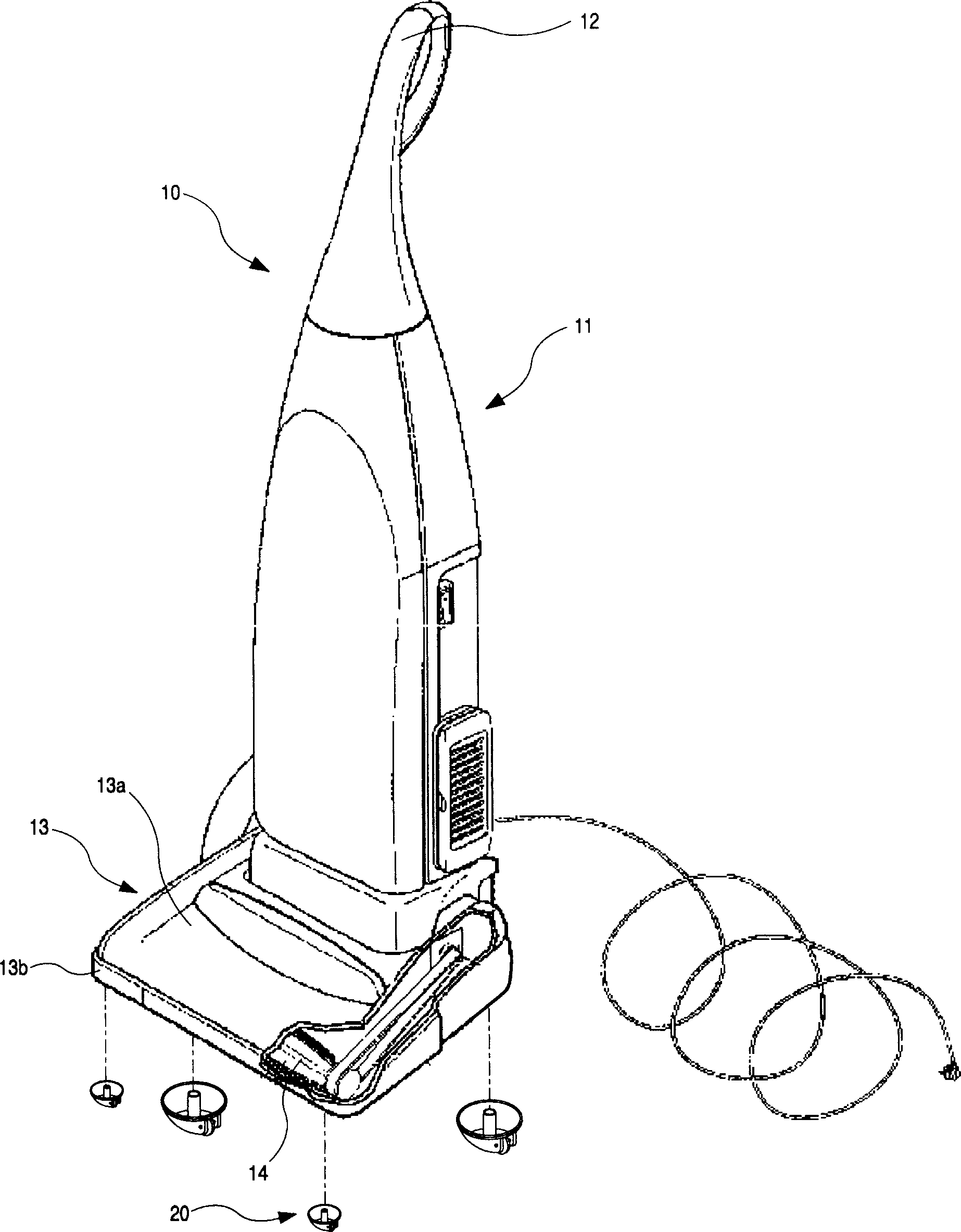

Direction conversion apparatus of vertical vacuum cleaner

InactiveCN1698517AReduce cleaning timeImprove quality and performanceSuction cleanersForeign bodyVacuum cleaner

The invention provides a vacuum cleaner which mainly comprises a body member, a suction portion and a deflecting roller portion, the body member is provided with a dust collection filter for collecting the foreign bodies sucked in through the ventilating fan, the suction portion is formed at the lower portion of the body member for sucking foreign bodies, the deflecting roller portion is formed at the lower portion of the suction portion, whose direction is changed with the rotation of the deflecting roller. The vertical vacuum cleaner can be moved not only from front to rear, but also from left to right.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

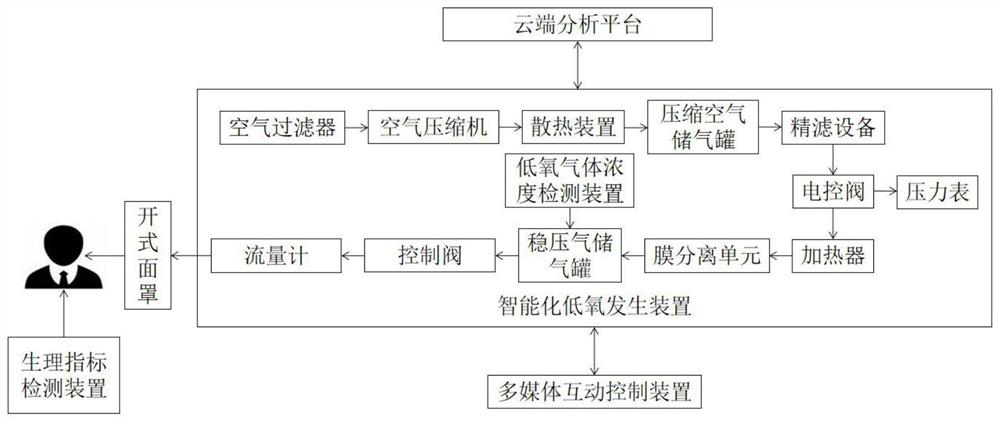

Intelligent hypoxia health care system based on physical training

PendingCN113209583AImprove adaptability and toleranceImprove quality and performancePhysical therapies and activitiesTherapy exerciseLung functionEngineering

The invention discloses an intelligent hypoxia health care system based on physical training. The system comprises an intelligent hypoxia generation device, a multimedia interaction control device, a cloud analysis platform, an open mask and a physiological index detection device. The intelligent hypoxia generation device comprises an air filter, an air compressor, a compressed air storage tank, fine filtration equipment, an electric control valve, a heater, a membrane separation unit, a pressure-stabilized air storage tank, a control valve and a flow meter which are sequentially connected through a pipeline; the physiological index detection device is used for detecting various physiological indexes of the body of the trained person under the hypoxia condition; and the cloud analysis platform is used for collecting working data and physiological indexes of the intelligent hypoxia generation device and generating a training scheme. A hypoxia product is generated through the intelligent hypoxia generation device and provided for the user to breathe through the open mask, the cloud analysis platform collects the physiological index data of the user to generate the training scheme, and the cardio-pulmonary function of the human body and the adaptive capacity and endurance capacity in the hypoxia environment are improved.

Owner:合肥恒诚智能技术有限公司

Flatting agent for dyeing chinlon

The invention relates to the technical field of dyeing additives and especially provides a flatting agent for dyeing chinlon. The flatting agent is composed of lauryl sodium sulfate, tetrachloroethylene, glacial acetic acid, wax emulsion, methylbenzene, butanone, silicon dioxide, organic bismuth and water according to the following ratio, by mass, 2-4 parts of the lauryl sodium sulfate, 15-18 parts of the tetrachloroethylene, 15-20 parts of the glacial acetic acid, 5-13 parts of the wax emulsion, 1-3 parts of the methylbenzene, 6-10 parts of the butanone, 3-9 parts of the silicon dioxide, 2-5 parts of the organic bismuth, and 40-50 parts of water. The flatting agent can eliminate an aurora-like phenomenon on a chinlon fabric, thereby improving performance and quality of the chinlon fabric. The flatting agent is low in usage cost.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

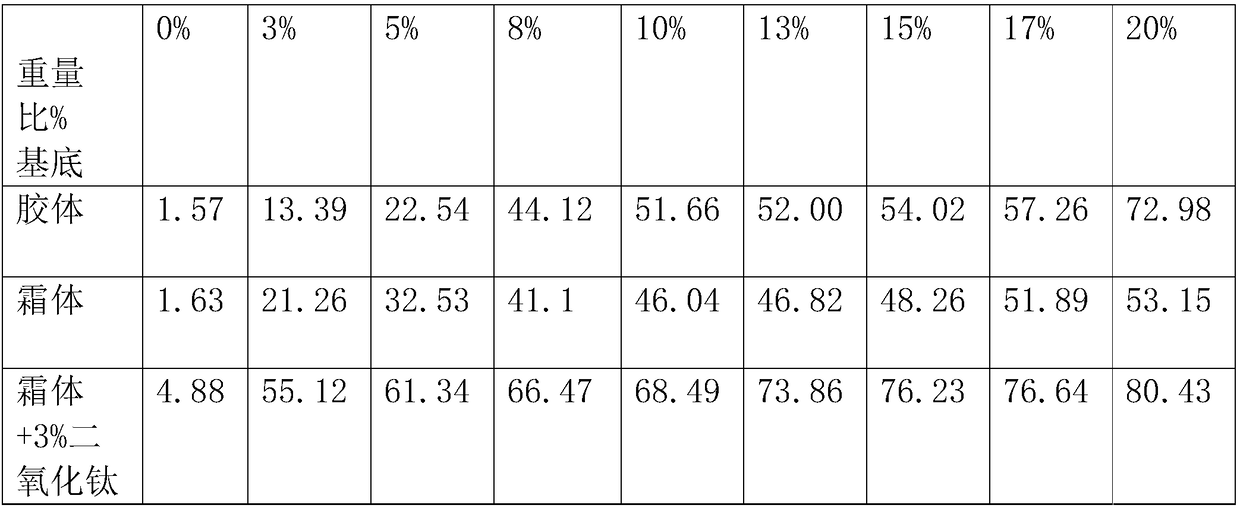

Sunscreen cream and preparation method thereof

InactiveCN108186387AAdd lessImprove quality and performanceCosmetic preparationsToilet preparationsChemistrySunscreen agents

The invention discloses sunscreen cream and a preparation method thereof. The sunscreen cream is prepared from the following raw materials in parts by weight: a polydimethylsiloxane PEG-10 / 15 cross-linked polymer, 3-4 parts of polydimethylsiloxane, 2.5-3.5 parts of polydimethylsiloxane / vinyl polydimethylsiloxane cross-linked polymer / decamethylcyclopentasiloxane, 1-2 parts of cetyl PEG / PPG-10 / 1 polydimethylsiloxane, 8-10 parts of decamethylcyclopentasiloxane, 4-6 parts of diphenylsiloxy phenyl trimethicone, 2-4 parts of SunCat MTA, 2-4 parts of titanium dioxide, 0.5-1.5 parts of shark glycol, 0.3-0.7 part of phenoxyethanol and 68-73 parts of water. SunCat MTA is matched with titanium dioxide, so that a higher SPF value can be achieved with fewer sunscreen ingredients and lower concentrations, the addition amount of the traditional sunscreen agent is reduced, and the processing cost is reduced; shark glycol is used for inhibiting skin inflammation caused by ultraviolet light, the chemical sunscreen agent is wrapped in a double-layer phospholipid film for shark glycol, and the skin feeling of the sunscreen cream is greatly improved.

Owner:广州市韵丽生物科技有限公司

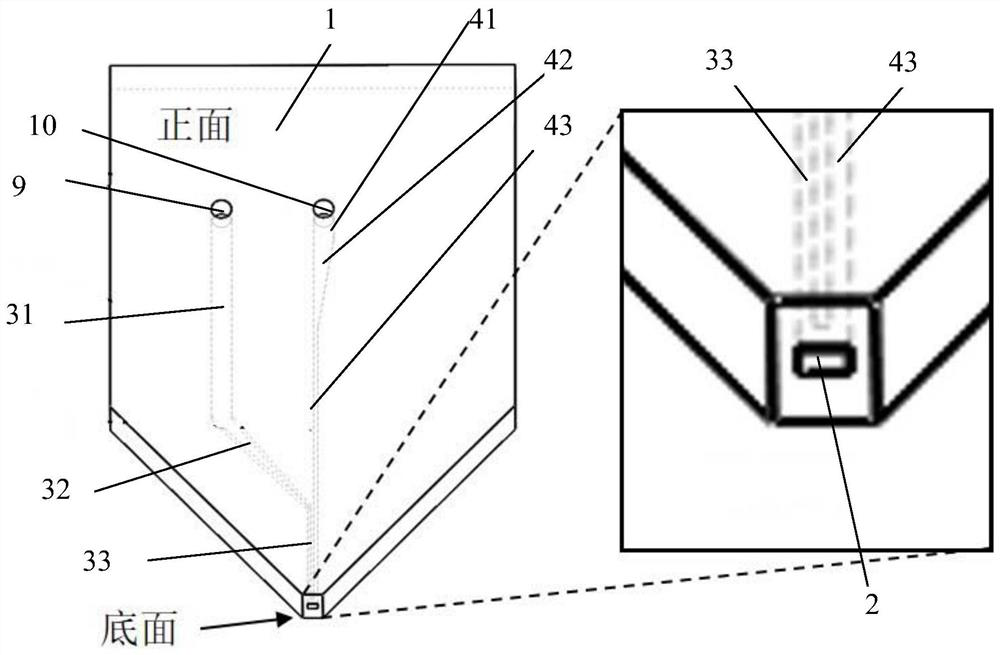

Mass spectrum imaging high-spatial-resolution surface sampling head based on microfluidic technology and sampling method

ActiveCN112768338AImprove quality and performanceGood biocompatibilitySamples introduction/extractionMaterial analysis by electric/magnetic meansPhysicsMass spectrum analysis

The invention relates to a mass spectrum imaging high-spatial-resolution surface sampling head based on a microfluidic technology and a sampling method. The mass spectrum imaging high-spatial-resolution surface sampling head based on the microfluidic technology comprises a sampling head body, the bottom of the sampling head body is provided with a sampling cavity, the sampling head body is internally provided with a first flow channel and a second flow channel, the first flow channel is used for injecting an extraction solvent, and the second flow channel is used for caching and spraying out a sample; each of the first flow channel and the second flow channel comprises a first interface and a second interface, the first interfaces of the first flow channel and the second flow channel are respectively communicated with the sampling cavity, and the second interfaces of the first flow channel and the second flow channel are respectively communicated with the outside of the sampling head body. The sampling cavity and the flow channels are designed, so that the sampling head has the characteristic of compact structure, meanwhile, the sampling spatial resolution and the sampling effect are improved, and the sampling head is provided with a planar design and a gas-liquid path interface, and can be conveniently combined with external movement equipment such as a robot and the like for use.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

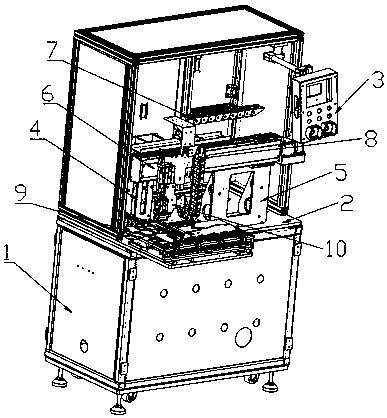

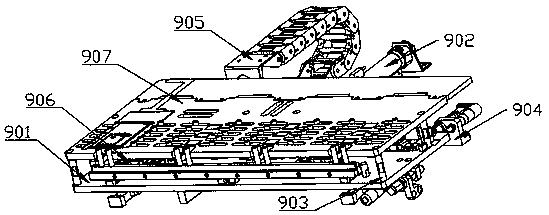

Quick cooling equipment for massive products

InactiveCN109780815AImprove quality and performanceImprove production safetyDomestic cooling apparatusLighting and heating apparatusTransfer mechanismEngineering

The invention discloses quick cooling equipment for massive products, which comprises a rack, wherein the rack is internally provided with a workbench; an operation device is arranged at the top end of the rack; a transfer mechanism and a waiting platform are arranged on the workbench; the waiting platform is arranged below the transfer mechanism; the waiting platform comprises a bearing plate, abearing translation air cylinder, struts, buffers, a drag chain component, electric cylinders, heat radiators, first carrying plates and a second carrying plate; the bearing translation air cylinder and the drag chain component are connected with the side face of the bearing plate in parallel through working ends; the buffers are connected with the two sides of the bearing plate; the struts are fixed on the upper surface of the bearing plate; the upper end of the electric cylinders are connected with the lower ends of the struts; the first carrying plates are arranged on the struts; the heat radiators are fixed on the first carrying plates; the first carrying plates are connected with the second carrying plate through a plurality of heat dissipation columns; and the side face of the secondcarrying plate is connected with waiting platform in parallel. The quick cooling equipment achieves massive cooling, improves production efficiency and has a good market application value.

Owner:深圳市中科创想科技有限责任公司

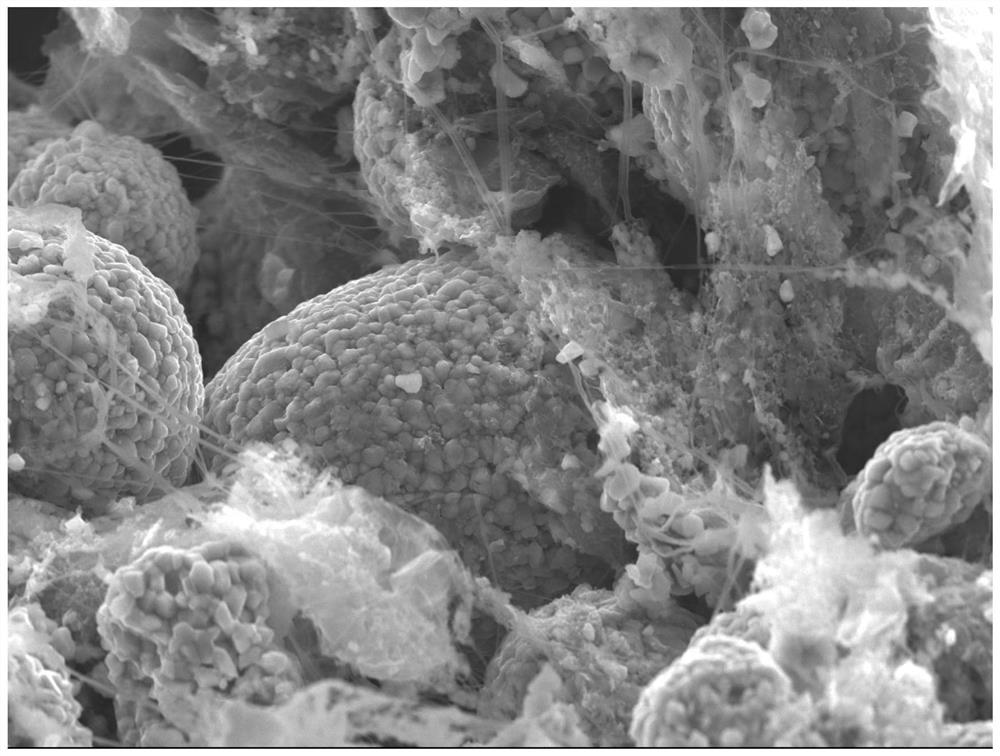

Solid electrolyte composition, solid electrolyte-containing sheet, all-solid state secondary battery, and methods for manufacturing solid electrolyte-containing sheet and all-solid state secondary battery

InactiveUS20190088994A1Improve performanceImprove quality and performanceSolid electrolytesFinal product manufactureIonHalogen

Provided are a solid electrolyte composition containing an inorganic solid electrolyte having conductivity of ions of metals belonging to Group I or II of the periodic table, a binder, and a dispersion medium, in which the dispersion medium includes an alicyclic compound composed of a carbon atom, a hydrogen atom, and / or a halogen atom, and a boiling point of the alicyclic compound at 760 mmHg is 100° C. or higher and 180° C. or lower, a solid electrolyte-containing sheet, an all-solid state secondary battery, and methods for manufacturing a solid electrolyte-containing sheet and an all-solid state secondary battery.

Owner:FUJIFILM CORP

High-temperature alloy slag inclusion filter screen and application

InactiveCN112537950AGreat controllability and practicalityImprove quality and performanceCasting cleaning apparatusCeramicwareSlagMetallic materials

The invention relates to the field of precision casting and material preparation, in particular to a high-temperature alloy slag inclusion filter screen and application. Firstly, corundum powder, silicon dioxide, carbon powder, silica sol and the like are selected as raw materials of the filter screen, and the corundum powder comprises corundum powder with the granularity of 20-80 meshes and corundum powder with the granularity of 200-1000 meshes. Then, corundum powder with two particle sizes is uniformly mixed; carbon powder is added and uniformly mixed; and silica sol is added and uniformlyblended. A filter screen with the high-temperature strength of 30-100 MPa is manufactured through the steps of cold static pressure forming, vacuum thermal sintering strengthening, polishing cleaningand the like, and the filter screen is placed in a pouring system. Finally, the alloy liquid is puored under a casting process at the pouring temperature of 1350-1550 DEG C for 3-60 seconds, cooling is carried out, components O, N and S are detected, and the effectiveness of the filter screen is verified. The method is suitable for the casting process of all metal materials, and is particularly suitable for the pouring process of high temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

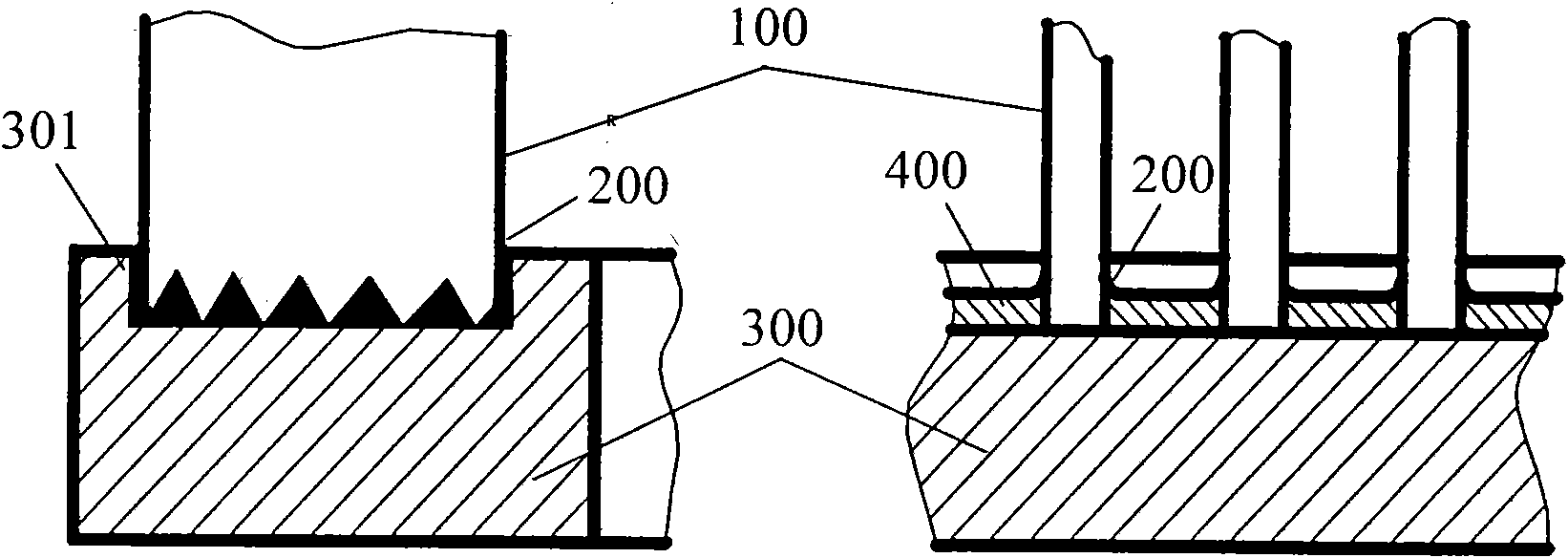

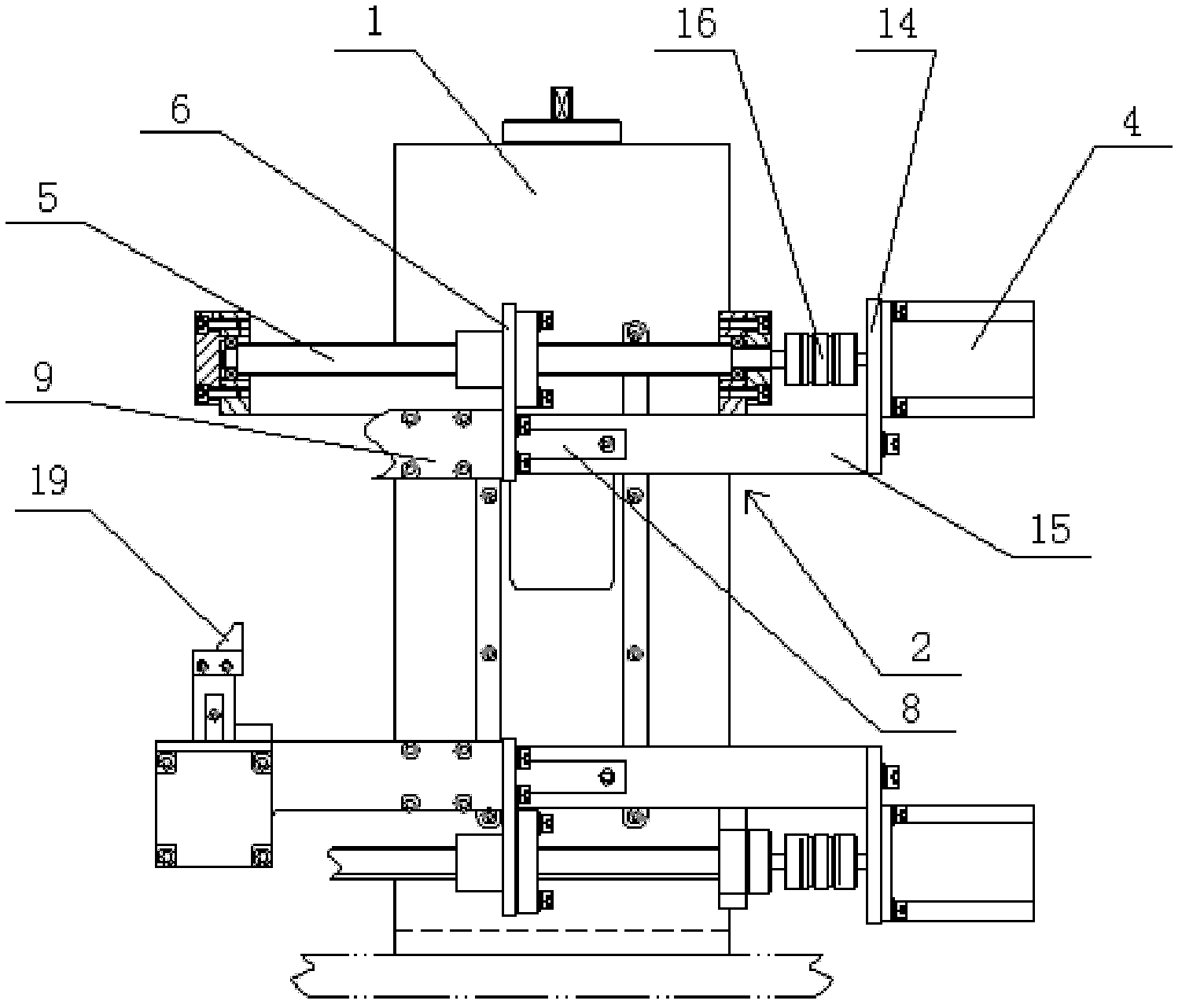

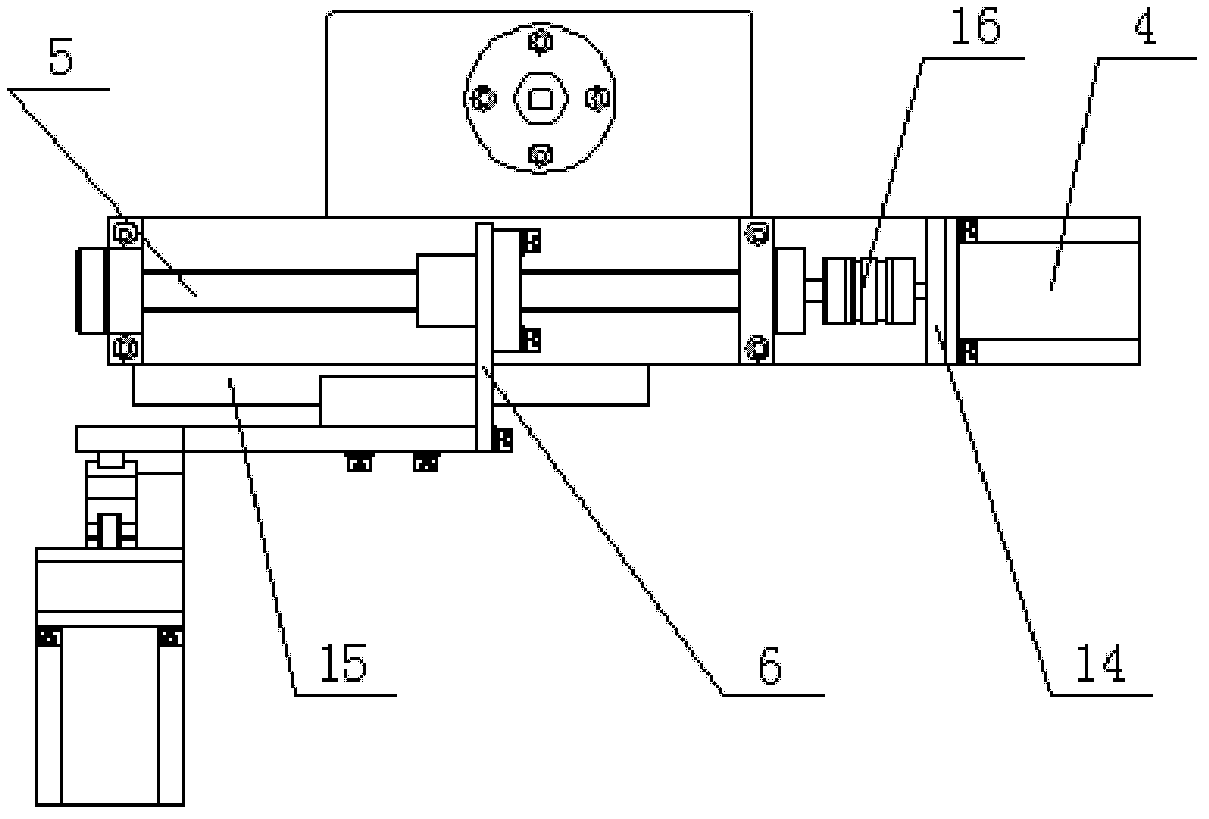

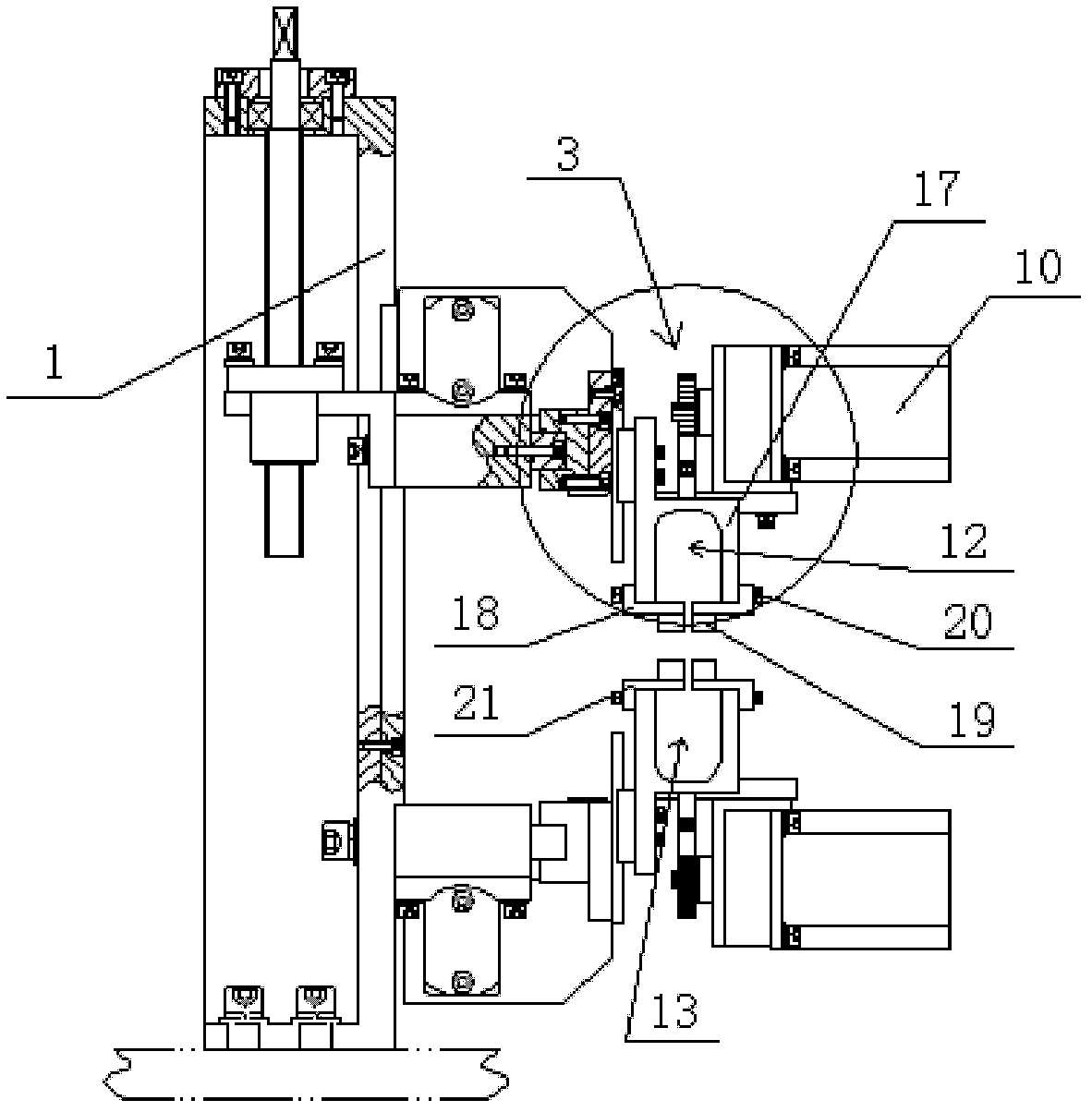

Angle pressure device on outer rotor winding machine

InactiveCN102684422AImprove quality and performanceImprove performanceManufacturing dynamo-electric machinesWinding machineRotational axis

The invention discloses an angle pressure device on an outer rotor winding machine, which is characterized by comprising a pair of angle pressure mechanisms oppositely arranged up and down, wherein each angle pressure mechanism consists of a forward linear motion pair, a lifting linear motion pair and an angle pressure structure arranged on the lifting linear motion pair; each forward linear motion pair comprises a forward stepping motor, a forward ball screw connected with the forward stepping motor, a forward screw connecting block in threaded connection with the forward ball screw and a forward guide rail which is arranged perpendicular to the rotating axis of a winding machine rotor indexing; each lifting linear motion pair comprises a lifting stepping motor, a lifting guide rail and a gear transmission mechanism connected between the lifting stepping motor and the corresponding angle pressure structure; and operating surfaces of the upper and the lower angle pressure mechanisms correspond to the position of a stator cable channel on the winding machine rotor indexing. According to the invention, due to the arrangement of the pair of angle pressure mechanisms which are symmetrical up and down, the winding displacement and the compression of a stator coil are implemented and the performance of the finished product coil is improved.

Owner:NIDE MECHANICAL EQUIP

Beamforming techniques for single-stream communications

InactiveUS9876552B2Reduce per-tone power loadingIncrease power loadPower managementSpatial transmit diversityChannel state informationTelecommunications

A method of adjusting single-stream transmissions by a wireless device based on channel state information (CSI). The wireless device generates a sounding packet formatted for transmission via multiple spatial streams, and transmits the sounding packet to a receiving device via a single one of the multiple spatial streams. For example, the wireless device may be a single-antenna device. The wireless device further receives channel state information (CSI) from the receiving device based at least in part on the sounding packet. The wireless device then adjusts one or more characteristics of single-stream transmissions to the receiving device based at least in part on the received CSI.

Owner:QUALCOMM INC

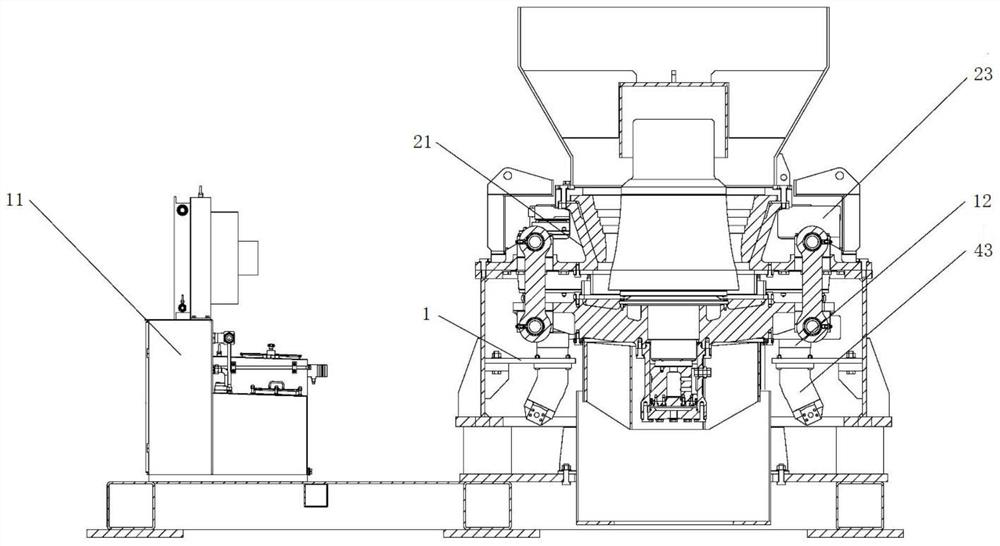

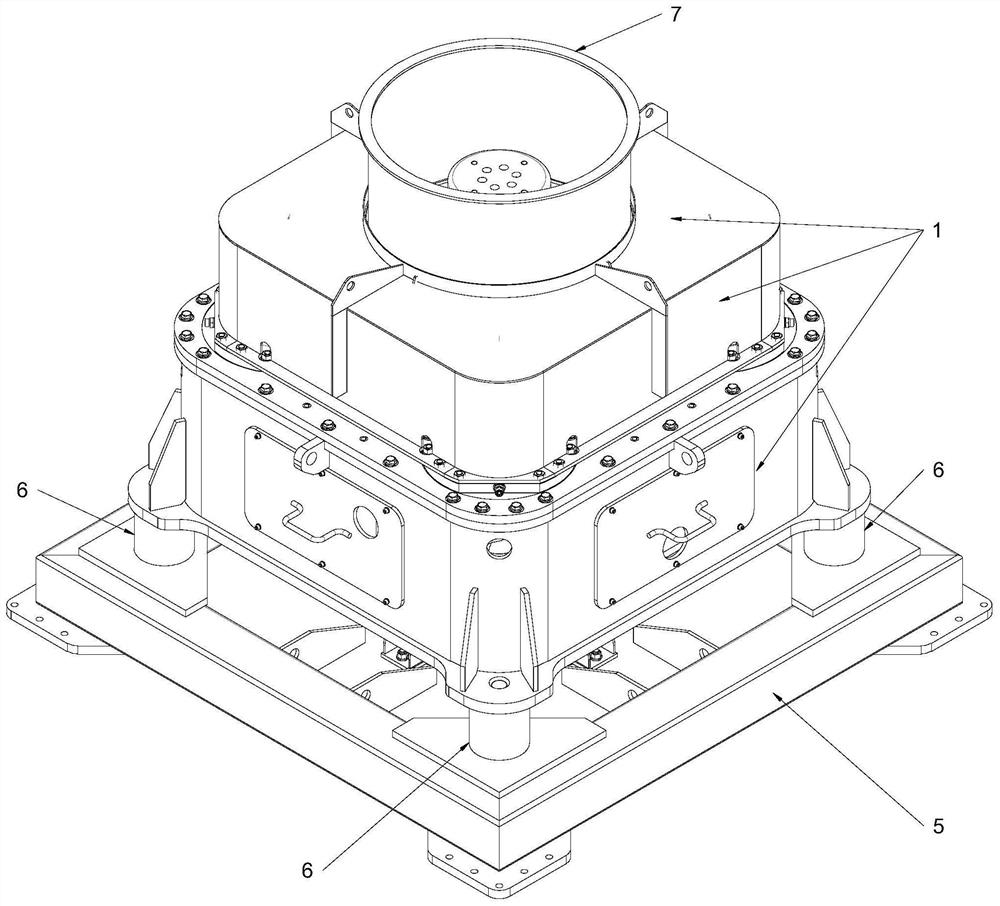

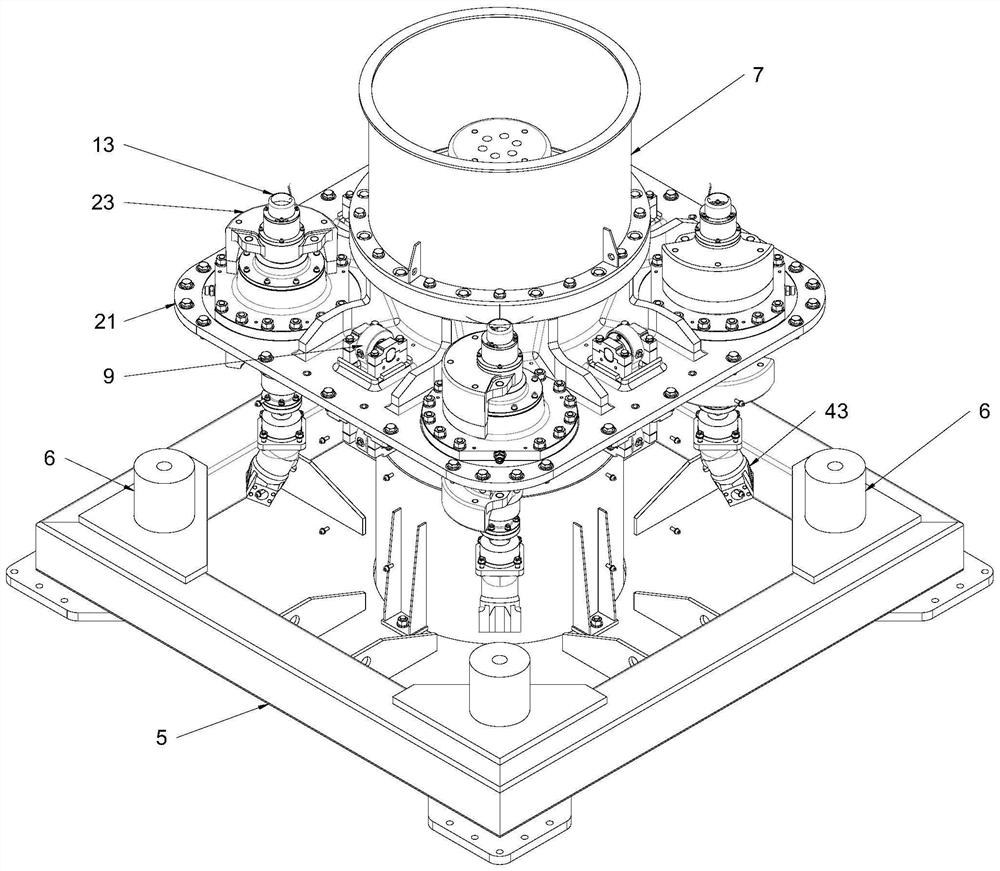

Hydraulic cone crusher

ActiveCN112827547AImprove quality and performanceLarge crushing ratioSolid waste managementGrain treatmentsStructural engineeringClassical mechanics

The invention provides a hydraulic cone crusher. The hydraulic cone crusher comprises a machine shell, an upper machine frame assembly, a lower machine frame assembly, a hydraulic driving assembly and a control system; the upper machine frame assembly is movably arranged on the machine shell; the lower machine frame assembly is located in the machine shell and movably connected to the upper machine frame assembly; the hydraulic driving assembly is connected to the upper machine frame assembly so as to drive the upper machine frame assembly to swing; and the control system is electrically connected to the hydraulic driving assembly, wherein a crushing cavity used for crushing materials is formed between the upper machine frame assembly and the lower machine frame assembly, and swing of the upper machine frame assembly acts on the materials and is transmitted to the lower machine frame assembly, so that the lower machine frame assembly is forced to swing. The problem of huge investment in the artificial sand crushing process is solved. According to the hydraulic cone crusher, the lower machine frame assembly is driven by the upper machine frame assembly to swing in a forced manner, and the upper machine frame assembly and the lower machine frame assembly form opposite movement in the crushing process, so that the absolute value of crushing force is increased, and the crushing quality and effect are advantageously improved.

Owner:成都卓山机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com