Annular pressure monitoring sealing device for geological drilling

A technology of annular pressure and geological drilling, which is applied in construction and other directions, can solve the problems of inability to pressurize leak plugging, well killing, blowout prevention, monitoring, and inability to perform annular pressure, so as to improve the level of drilling technology and have a long service life , The effect of reducing drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

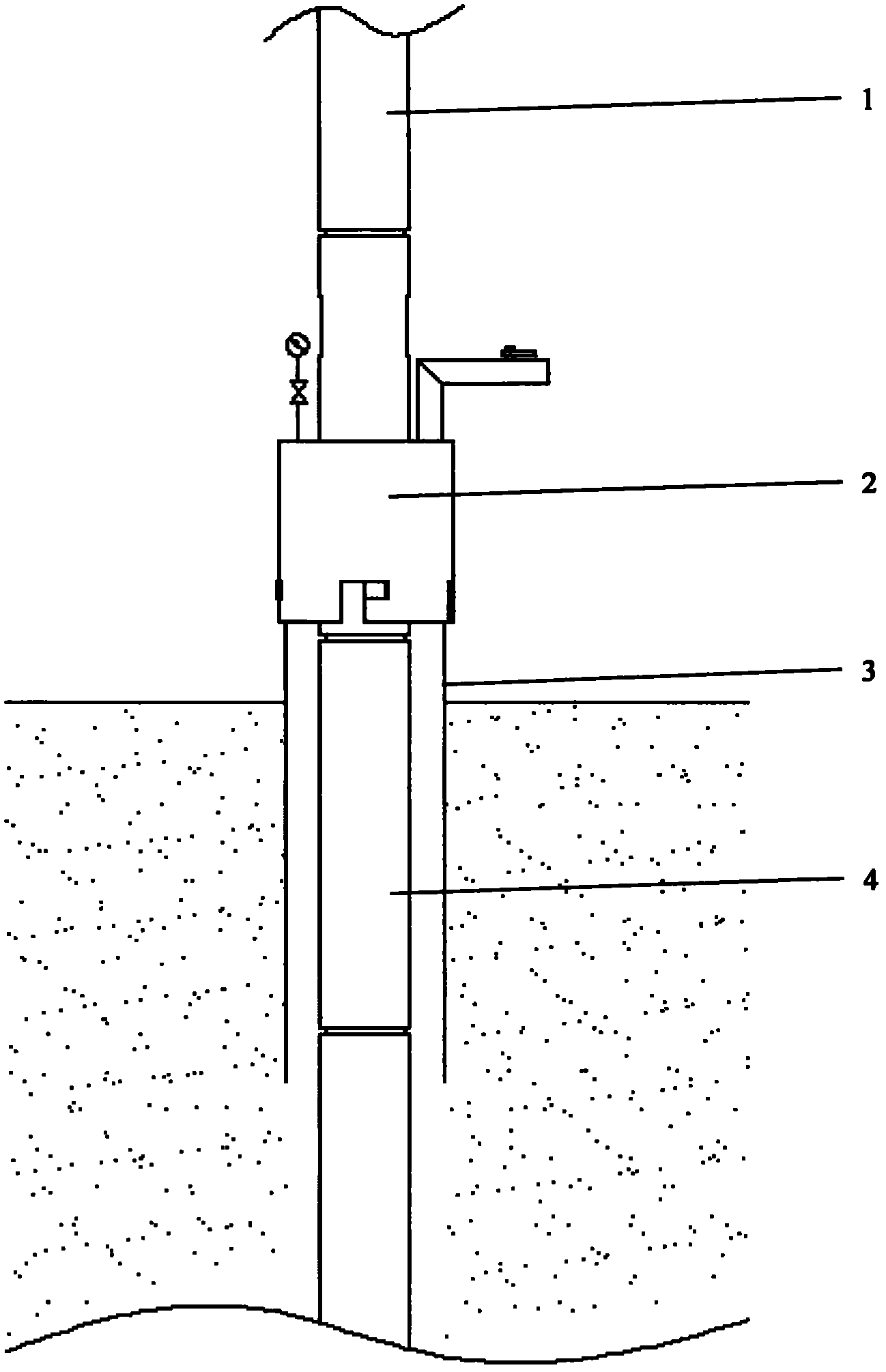

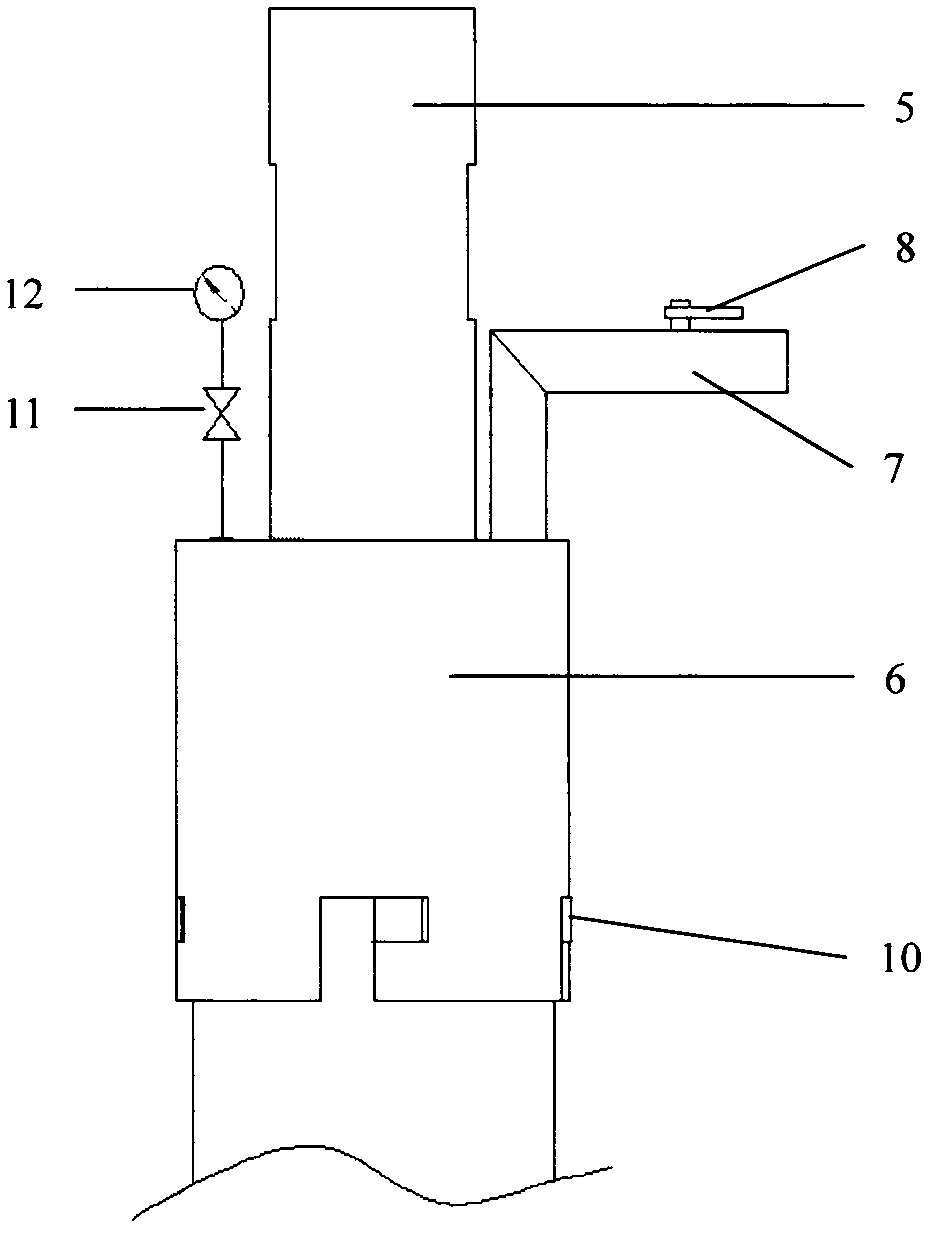

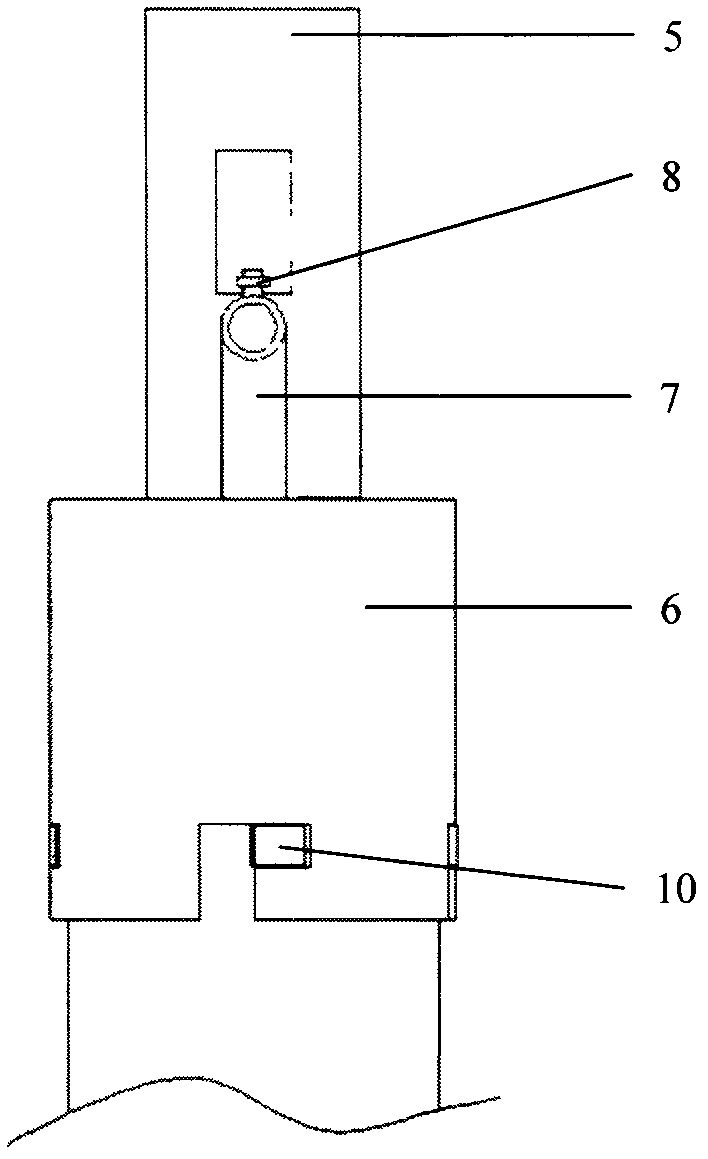

[0016] exist figure 1 Among them, the upper end of the central pipe 5 of the annular pressure monitoring and sealing device 2 is connected to the upper drill pipe 1, and the lower end of the orifice sealing device 2 is connected to the lower drill pipe 4, and is lowered into the designated position in the orifice pipe 3, and the four holes on the orifice pipe 3 A key 10 is screwed into the L-shaped notch of the sealed casing 6 to lock the relative position of the sealed casing 6 and the orifice pipe 3 to complete the installation of the annular pressure monitoring sealing device 2. During work, the annular pressure can be monitored in real time through the pressure gauge 12, and through Changing the opening or closing state of the rotary valve 8 at the upper end of the pressure relief pipe 7 realizes the releasing or maintaining pressure of the annular space.

[0017] exist Figure 5 Among them, the upper and lower ends of the center pipe 5 are processed with trapezoidal thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com