Soldering method of conducting ring of motor rotor

A brazing method and technology for motor rotors, applied in the manufacture of motor generators, circuits, electromechanical devices, etc., can solve the problem of long heating time, affecting the mechanical properties of copper materials, and inability to adapt to the brazing of large-capacity motor rotors with ultra-thick conductive rings and other problems to achieve the effect of improving performance and quality and high brazing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

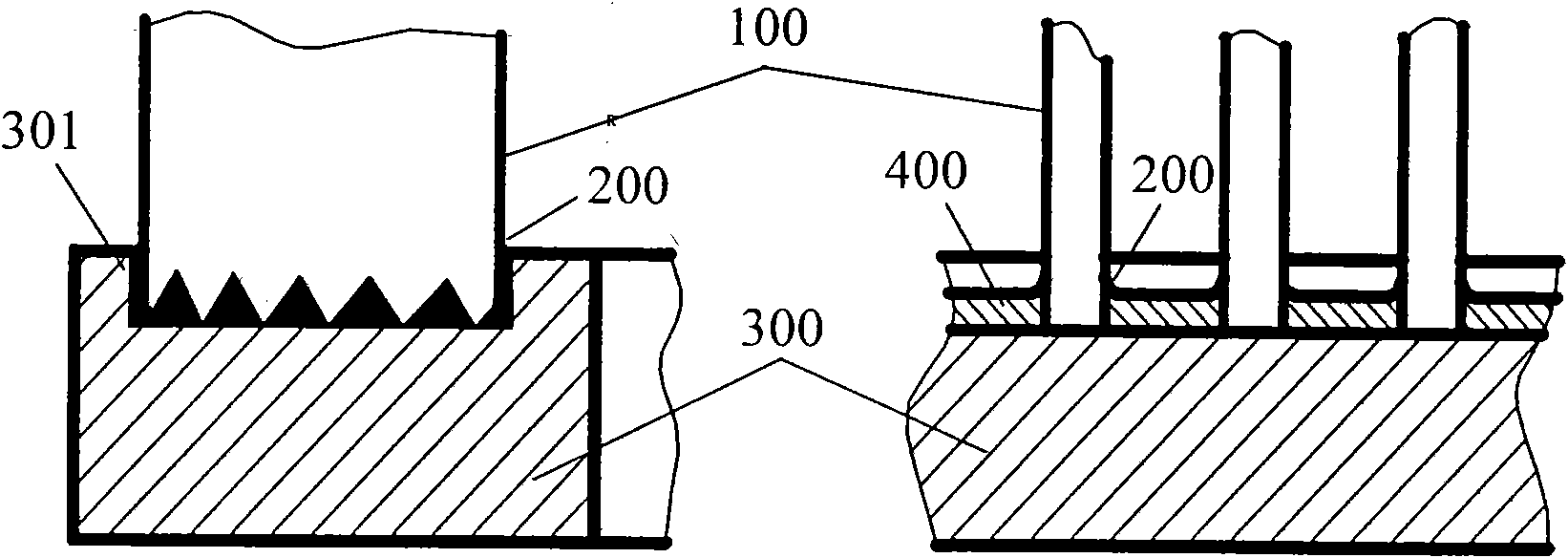

[0024] The motor rotor conductive ring brazing method specially aimed at large-capacity motors of the present invention adopts the following steps:

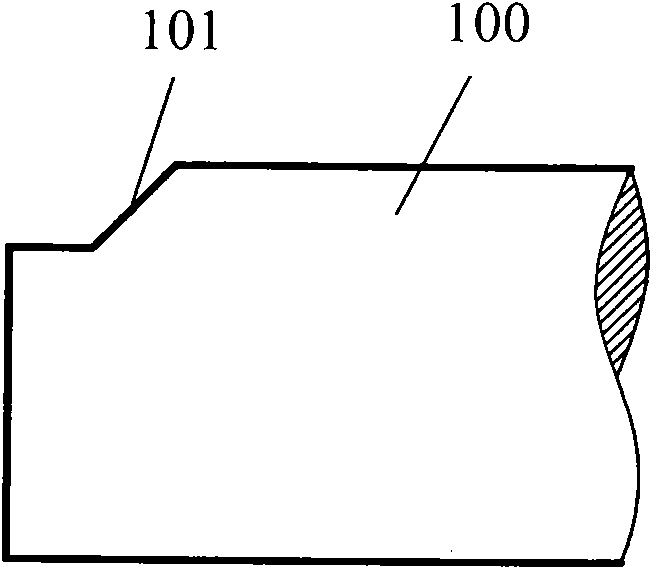

[0025] 1. If figure 1 As shown, the outer corners at both ends of the rotor bar 100 of the motor rotor are processed into a chamfer 101 of 14×45°. After chamfering the outer corners at both ends of the guide bar, the welding area of the rotor guide bar can be reduced; the outer diameter of the end ring can also be reduced correspondingly, and the quality of the end ring can also be reduced accordingly, which also reduces the number of segmented welding segments and shortens the welding time. The heating time is shortened, and the deformation of the rotor squirrel cage can be reduced, and no large internal stress is generated, and the phenomenon of bending of the rotor bar can also be reduced or even avoided.

[0026] Due to the surface of the parts to be welded, it will inevitably be covered with oxides, grease and dust during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com