Vehicle brazing method and vehicle brazing device

An automobile and brazing technology, which is applied in the direction of electric heating devices, auxiliary devices, vehicle parts, etc., can solve the problems of low production efficiency, achieve the effects of improving welding efficiency, improving melting efficiency, and improving brazing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

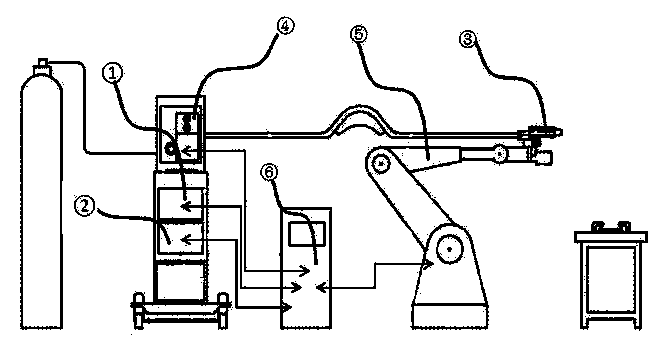

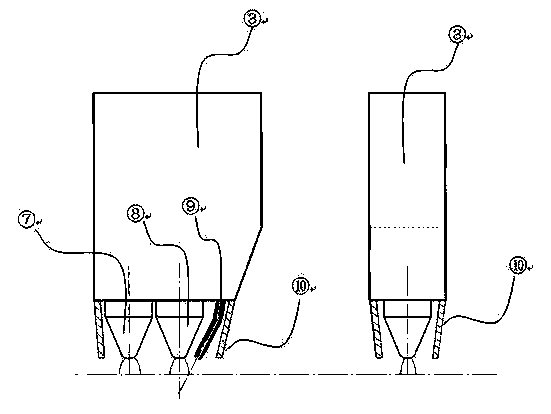

[0040] figure 1 and figure 2 Shown is an embodiment of the automobile brazing device, a kind of automobile brazing device, including front-end plasma power supply 1, back-end plasma power supply 2, brazing welding torch 3, wire feeding mechanism 4, robot 5 and controller 6, The front-end plasma power source 1 and the rear-end plasma power source 2 jointly form a welding heat source, and the welding torch 3 is arranged on the automatic arm of the robot. The welding torch 3 includes a front-end plasma nozzle 7, a rear-end plasma nozzle 8 and a wire guide nozzle 9. , the rear end plasma nozzle 8 and the wire guide nozzle 9 are arranged in sequence, the end of the welding torch 3 is provided with a protective cover 10, and the front end plasma nozzle 7, the rear end plasma nozzle 8 and the wire guide nozzle 9 are all wrapped in it. The welding torch 3 also includes a pipeline communicating with the gas cylinder, the gas cylinder is equipped with shielding gas, and the shield...

Embodiment 2

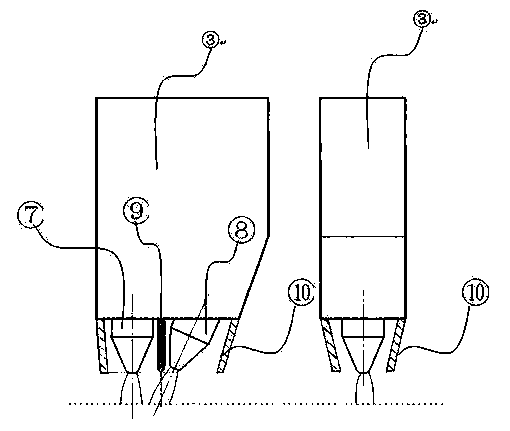

[0048] Such as image 3 As shown, different from Embodiment 1, the wire guide nozzle 9 is located between the front plasma nozzle 7 and the rear plasma nozzle 8, and there is an included angle of about 30° between the rear plasma nozzle 8 and the wire guide nozzle 9 ( Filling wire angle), can be adjusted in the range of 20°~40°, the effect is to obtain a stable welding process. If the wire filling angle is too small, it will affect the melting effect of the back-end plasma arc on the wire filling. If the wire filling angle is too large, the inclination angle of the back-end plasma nozzle 8 will be increased, and the size of the welding torch will be increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com