Aluminum plate fin type radiator vacuum brazing furnace temperature field equilibrium method

A technology of vacuum brazing furnace and temperature field, which is used in instruments, special data processing applications, electrical digital data processing, etc. The effect of improving brazing quality and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described, and concrete method is as follows:

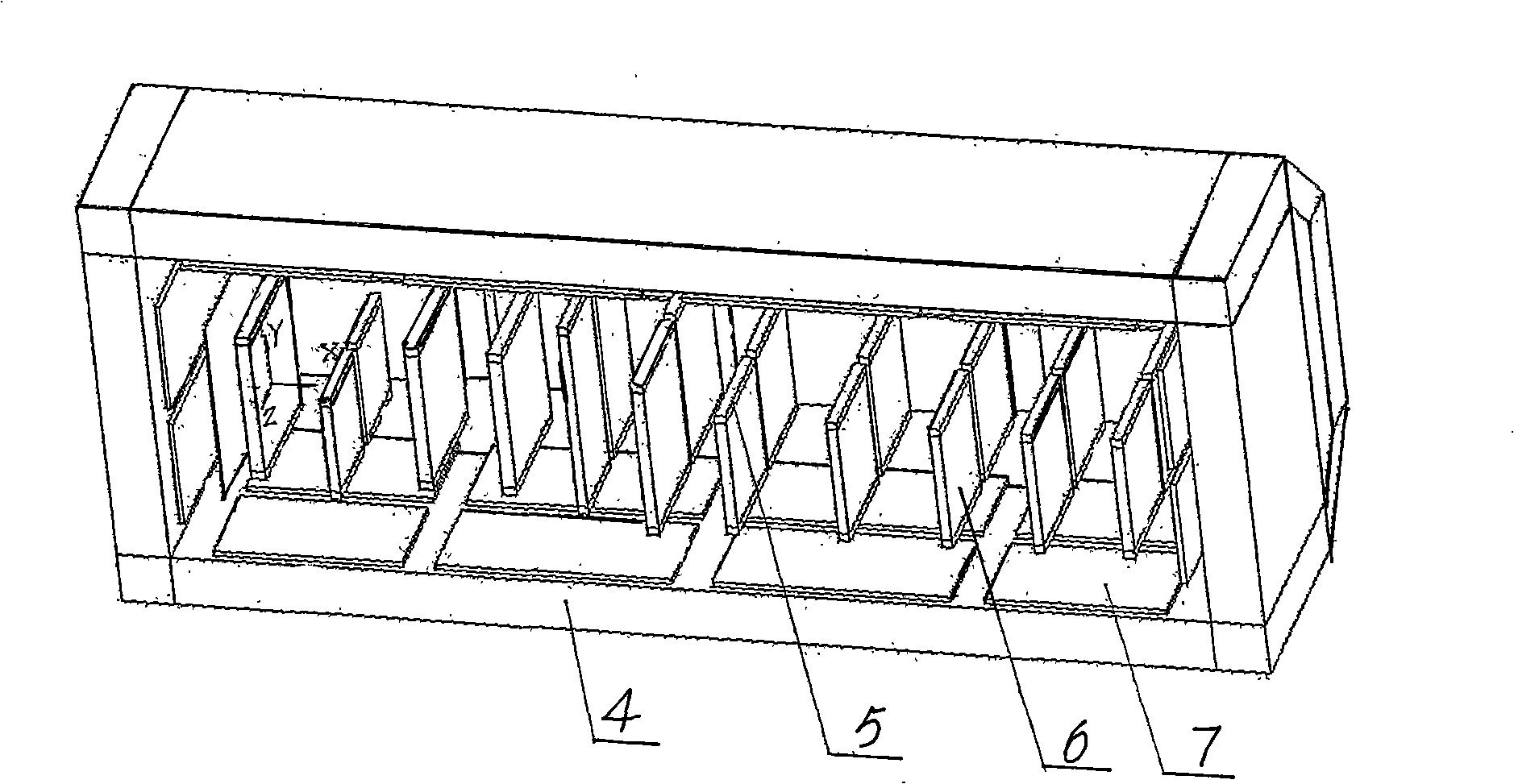

[0041] 1) survey and map the vacuum brazing furnace, and use ANSYS software to establish a furnace body simulation model simulated by a computer and equipped with a simulated heating zone inside; as figure 2 As shown: the furnace body simulation model is composed of a furnace body model 4, a plurality of simulated heating belts 7 set in the furnace body model, and a plurality of product models 6 placed in the furnace body model 4 through the fixture 5, and simulated The heating belt 7 conducts heat transfer with the product model 6 through heat radiation;

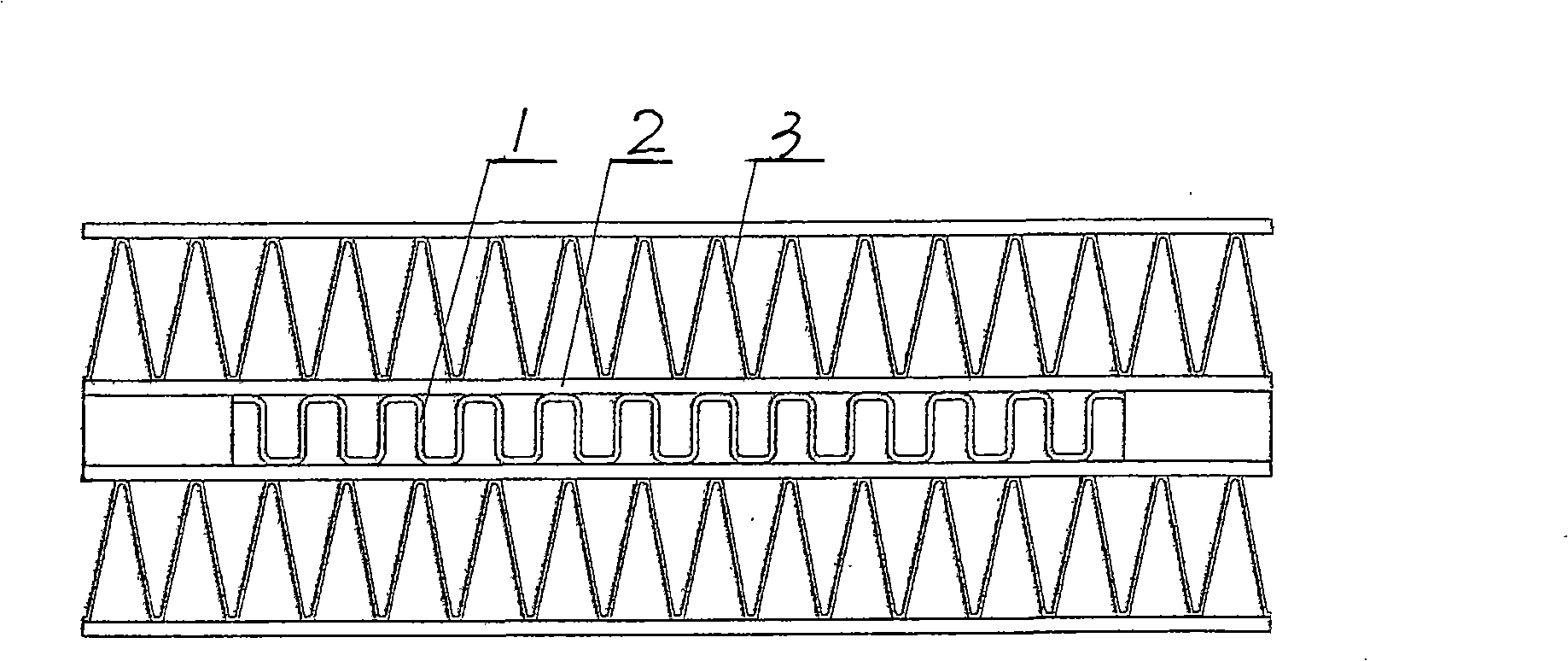

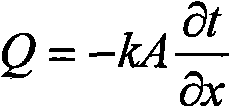

[0042] 2) After surveying and mapping the product, press the following heat conduction formula Q = - kA ∂ t ∂ x Perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com