Method for preparing reducing sugar from material containing cellulose

A technology of cellulose and cellulase, applied in the direction of fermentation, etc., can solve the problem of low yield of reducing sugar and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

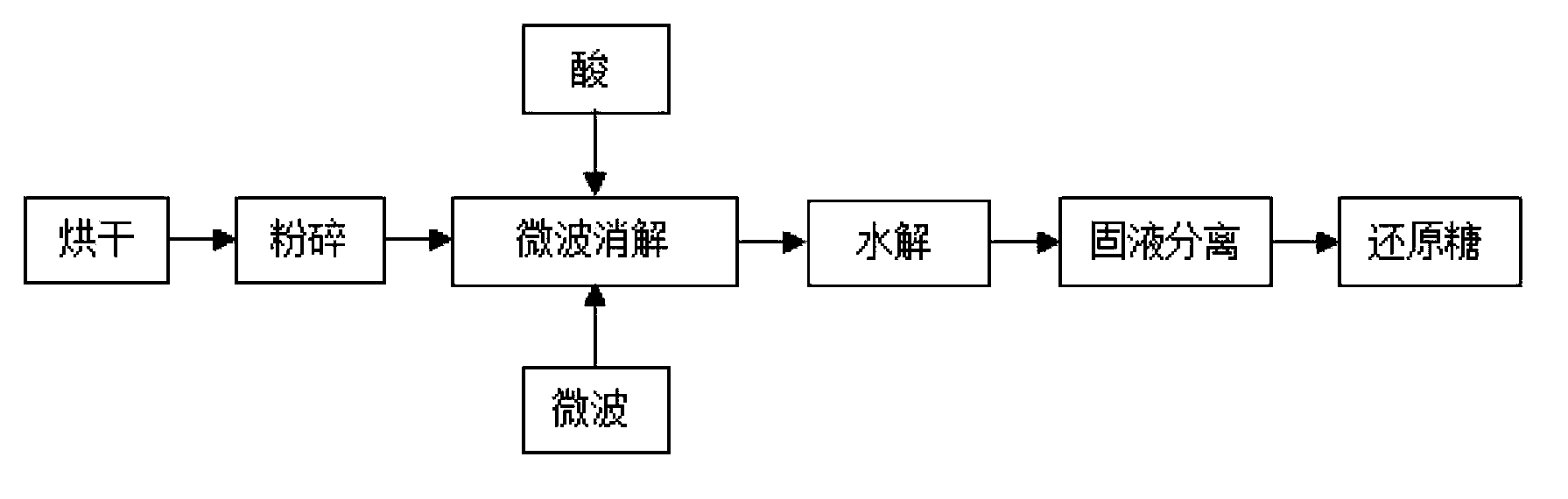

Method used

Image

Examples

Embodiment 1

[0038] This example is used to illustrate the method for preparing reducing sugar from cellulose-containing raw materials provided by the present invention.

[0039] The wheat straw was dried at 100° C. so that the water content therein was 1.5% by weight. And the obtained wheat stalks were crushed into granules with a particle size less than 500 microns, then mixed evenly with a dilute sulfuric acid solution with a concentration of 0.5% by weight in a weight ratio of 4:100, and then in a microwave digestion instrument (purchased from Shanghai Yiyao Instruments) Science and Technology Development Co., Ltd., model WX-8000, the same below) for microwave digestion at 100°C for 30 minutes. Wherein, the microwave frequency used in the microwave digestion is 2.45GHz, and the pressure used is 0.1MPa. The microstructure of the cellulose-containing raw material obtained after microwave digestion is as follows: figure 2 shown. from figure 2 It can be seen that the surface and inte...

Embodiment 2

[0041] This example is used to illustrate the method for preparing reducing sugar from cellulose-containing raw materials provided by the present invention.

[0042] The wheat straw was dried at 105° C. so that the water content therein was 1.8% by weight. And the obtained wheat straw is crushed into powder particles with a particle size of less than 212 microns, and then mixed evenly with a dilute sulfuric acid solution with a concentration of 1% by weight in a weight ratio of 2:100, and then microwaved at 150°C in a microwave digestion apparatus. Digest for 5 minutes. Wherein, the microwave frequency used in the microwave digestion is 2.45GHz, and the pressure used is 0.8MPa. The resulting microwave digestion product was transferred to a hydrolysis vessel and its pH was adjusted to 4 with a 20% by weight sodium hydroxide solution, followed by the addition of 5% by weight of cellulose based on the dry weight of the cellulose-containing raw material used Enzyme (purchased fr...

Embodiment 3

[0044] This example is used to illustrate the method for preparing reducing sugar from cellulose-containing raw materials provided by the present invention.

[0045] The corn stalks were dried at 100° C. so that the water content therein was 1.6% by weight. And the obtained corn stalks are crushed into powder particles with a particle size of less than 270 microns, and then mixed evenly with dilute hydrochloric acid with a concentration of 2% by weight in a weight ratio of 3:100, and then microwave digestion is carried out at 130°C in a microwave digestion apparatus 25 minutes. Wherein, the microwave frequency used in the microwave digestion is 2.45GHz, and the pressure used is 0.2MPa. The resulting microwave digestion product was transferred to a hydrolysis vessel, and its pH was adjusted to 4.8 with a 20% by weight potassium hydroxide solution, followed by the addition of 3% by weight of cellulose based on the dry weight of the cellulose-containing raw material used Enzyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com