GC-MS-based plant non-targeted metabolomics sample pretreatment method

A sample pretreatment and metabolomics technology, applied in the field of GC-MS-based plant non-targeted metabolomics sample pretreatment, can solve the problems of less mass spectrometry information, poor reproducibility, and non-general screening, etc., to achieve Improving research efficiency, strengthening data exchange, and simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

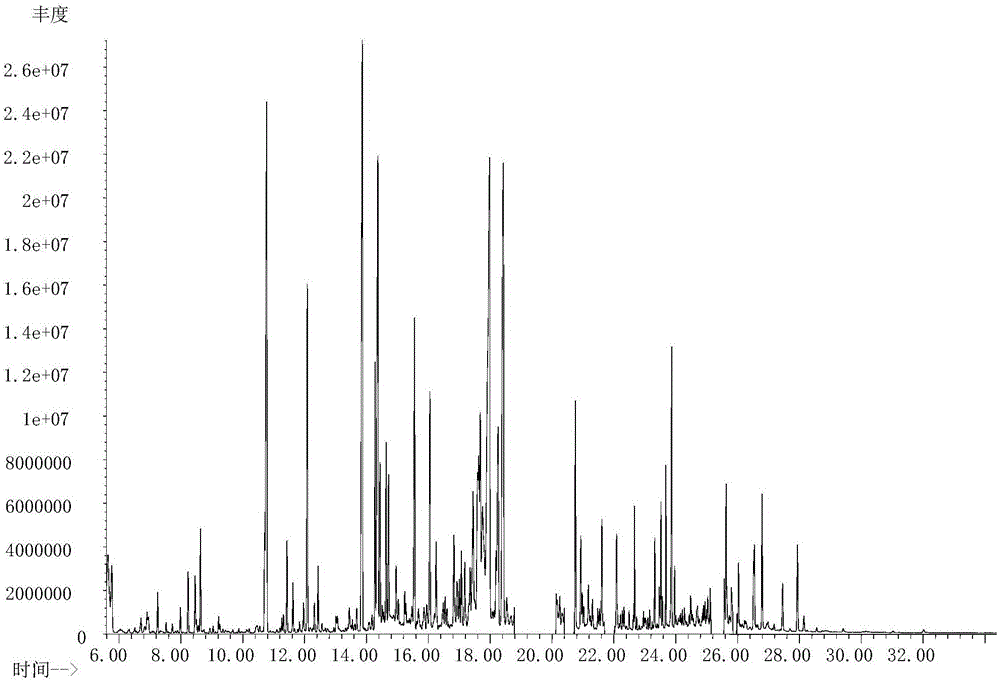

[0031] The pretreatment of embodiment 1 tea tree leaf (sugar content 1~5%)

[0032] The following steps were used to pretreat fresh tea tree leaves and perform GC-MS detection. The parallel experiments were repeated 6 times (1A-1F).

[0033] The specific steps of preprocessing are:

[0034] 1) Accurately weigh 60 mg of tea tree leaves, put them into a 1.5 mL centrifuge tube; add two small steel balls, 360 μL methanol at 4 °C and 40 μL internal standard methanol solution (L-2-chloro-phenylalanine, 0.3 mg / mL), placed in a -80°C refrigerator for 2 min; put into a grinder for grinding (60 Hz, 2 min), removed from the grinder, and ultrasonically extracted for 30 min;

[0035] 2) Add 200 μL of chloroform, vortex in a grinder (20 Hz, 2 min), add 400 μL of water, vortex in a grinder (20 Hz, 2 min), and ultrasonically extract for 30 min;

[0036] 3) Centrifuge at low temperature for 10 minutes (14000rpm, 4°C), take 200-700μL supernatant, put it into a glass derivatization bottle, and...

Embodiment 2

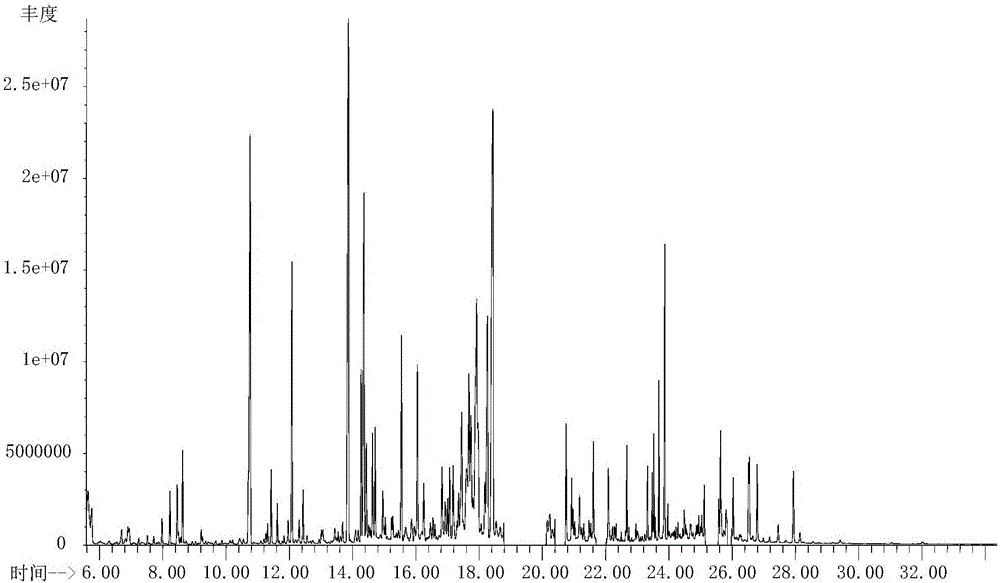

[0045] The pretreatment of embodiment two watermelon stems (sugar content about 2%)

[0046] The fresh watermelon stems were pretreated and detected by GC-MS using the following steps, and the parallel experiments were repeated 6 times (2A-2F).

[0047] The specific steps of preprocessing are:

[0048] 1) Accurately weigh 60mg of watermelon stem, put it into a 1.5mL centrifuge tube; add two small steel balls, 360μL-20℃ ethanol and 40μL internal standard ethanol solution (L-4-chlorophenylalanine, 0.3 mg / mL), placed in a refrigerator at -20°C for 2 min; put into a grinder for grinding (60 Hz, 2 min), take it out from the grinder, and ultrasonically extract for 30 min;

[0049] 2) Add 200 μL ether, put it into a grinder and vortex (20Hz, 2min), add 400μL water, put it into a grinder, vortex (20Hz, 2min), and ultrasonically extract for 30min;

[0050] 3) Centrifuge at low temperature for 10min (14000rpm, 16°C), take 200-700μL of the supernatant, put it into a glass derivative bo...

Embodiment 3

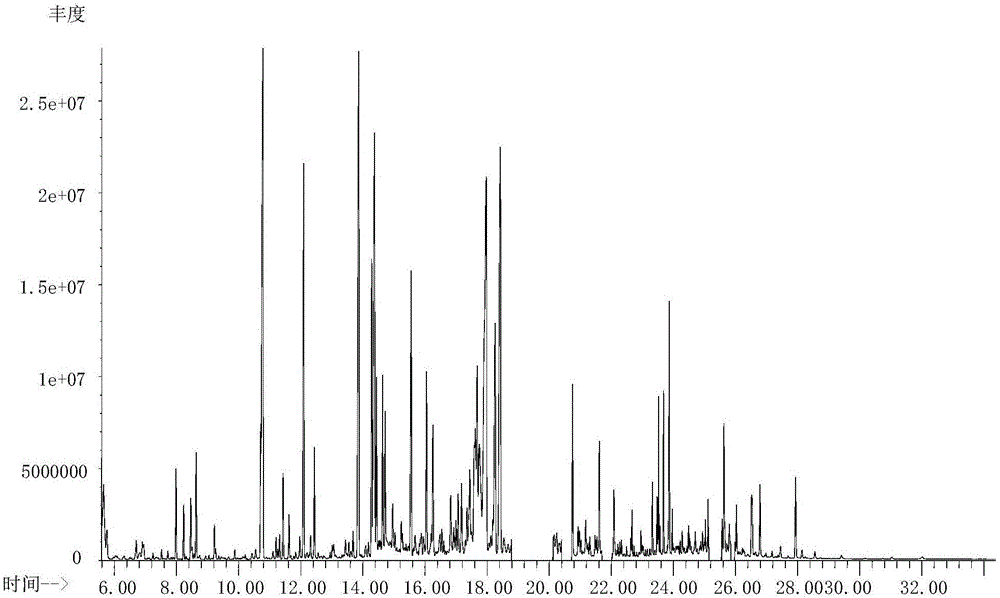

[0058] Example 3 Pretreatment of Zanthoxylum bungeanum root (sugar content is about 1%)

[0059] The fresh Zanthoxylum bungeanum root was pretreated and detected by GC-MS using the following steps, and the parallel experiments (3A-3F) were repeated 6 times.

[0060] The specific steps of preprocessing are:

[0061] 1) Accurately weigh 60mg of Zanthoxylum bungeanum root, put it into a 1.5mL centrifuge tube; add two small steel balls, 360μL-10℃ acetone and 40μL internal standard acetone solution (3,4-dichlorophenylalanine, 0.3mg / mL), placed in a refrigerator at -10°C for 2min; put into a grinder for grinding (60Hz, 2min), took it out of the grinder, and ultrasonically extracted for 30min;

[0062] 2) Add 200 μL of ethyl acetate, vortex in a grinder (20 Hz, 2 min), add 400 μL of water, vortex in a grinder (20 Hz, 2 min), and ultrasonically extract for 30 min;

[0063] 3) Centrifuge at low temperature for 10 minutes (14000rpm, 10°C), take 200-700μ of the supernatant, put it into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com