Vertical oscillation mechanism for extraction pretreatment

A vibration mechanism and extraction technology, which is applied in the field of experimental instruments, can solve the problems of high-intensity labor, strong shaking force, and short vibration distance of organic matter for operators, and achieve the effects of avoiding inertial damage, strong shaking force, and stable mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

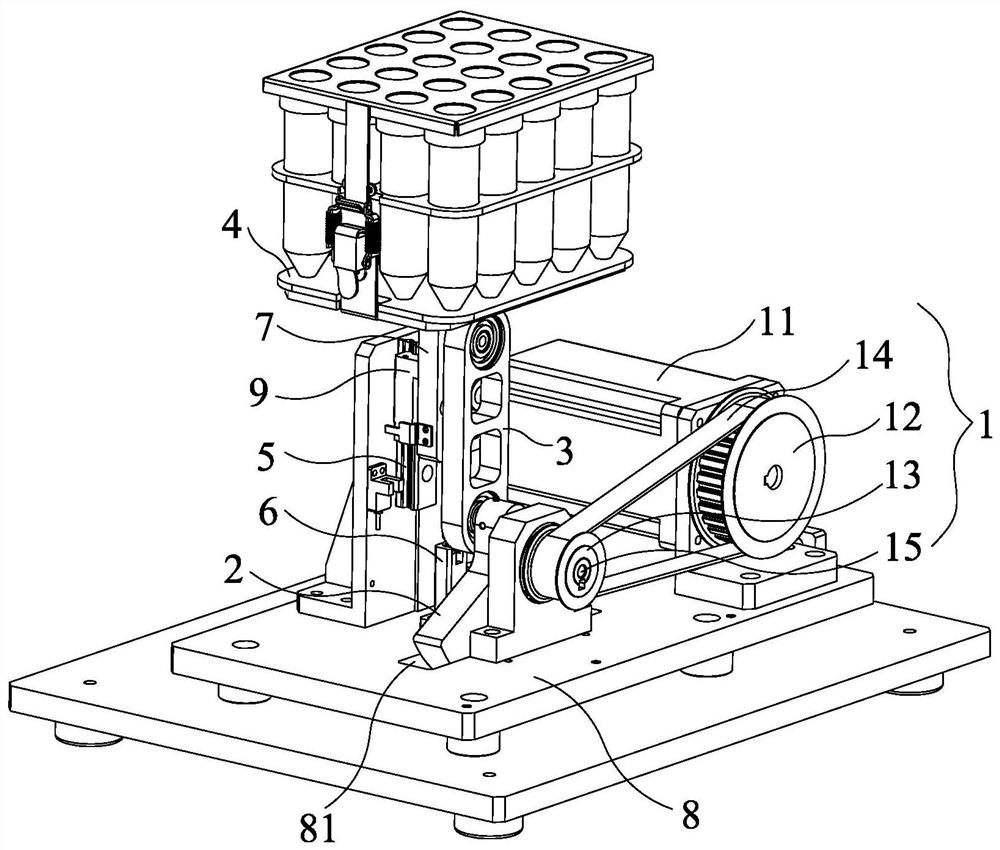

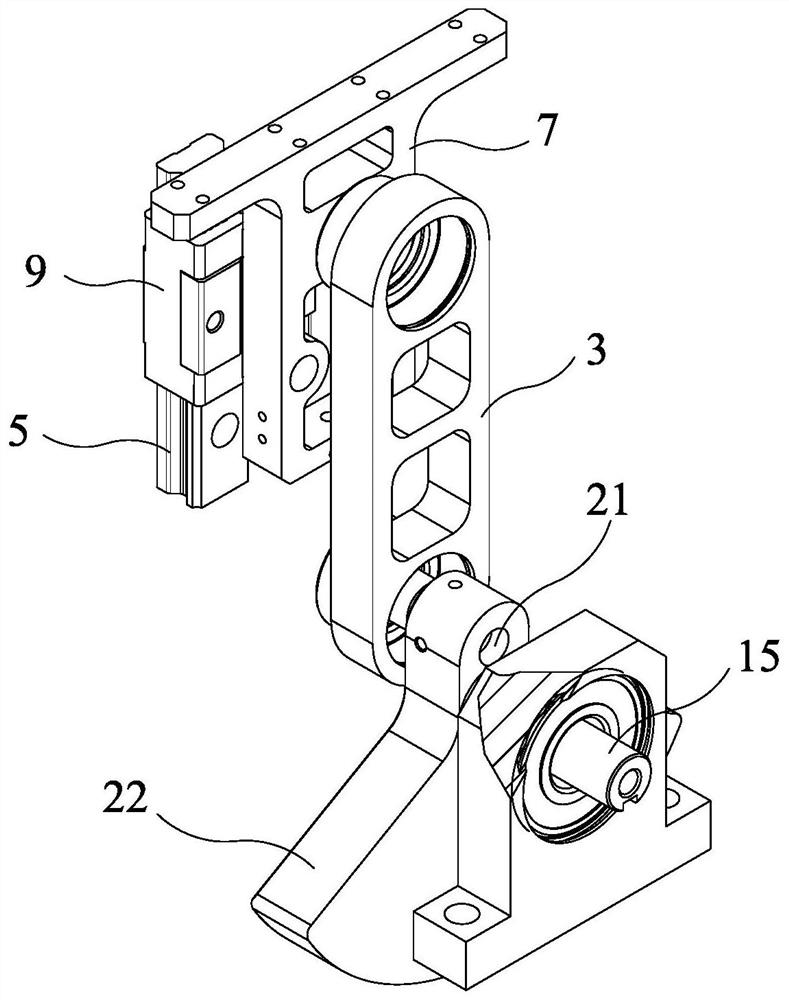

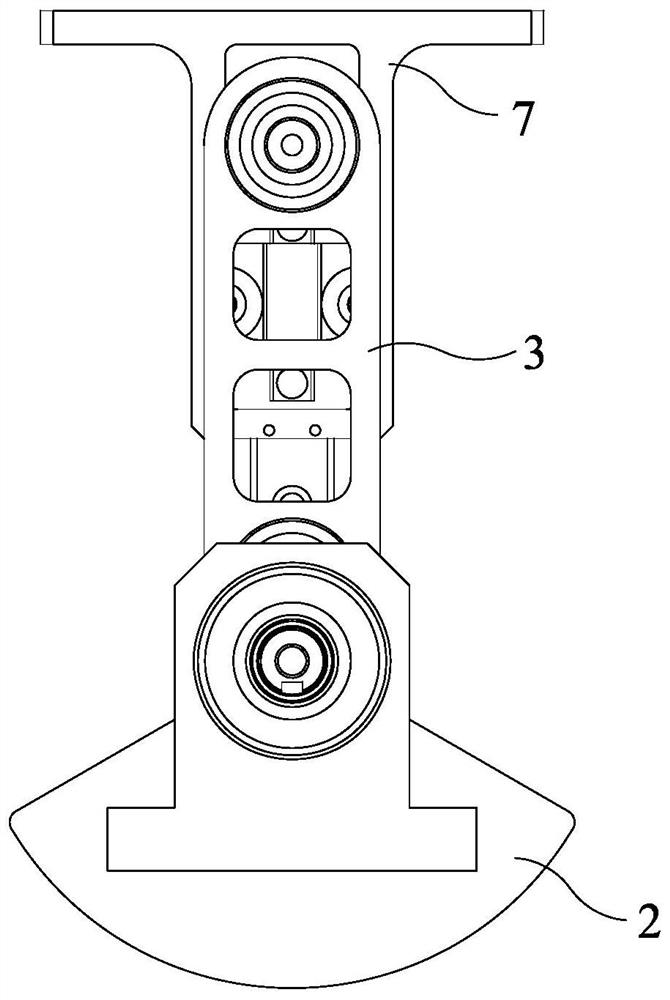

[0028] The invention provides a pre-extraction treatment vertical oscillation mechanism, such as figure 1 As shown, it includes a driving mechanism 1, an eccentric weight 2, a crank 3, a test tube rack 4, a vertical slide rail 5, an elastic mechanism 6, a bracket 7, a base 8 and a slider 9.

[0029] The base 8 is located at the bottom, and the driving mechanism 1 , the vertical slide rail 5 and the elastic mechanism 6 are fixed on the base 8 .

[0030] The vertical slide rail 5 is vertically arranged, and the test tube rack 4 can be used to place a plurality of test tubes, and the test tube rack 4 is slidably arranged on the vertical slide rail 5, specifically, a bracket 7 is arranged at the bottom of the test tube rack 4, combine Image 6 , one side of the bracket 7 is provided with a slider 9, and the slider 9 is slidably fitted on the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com