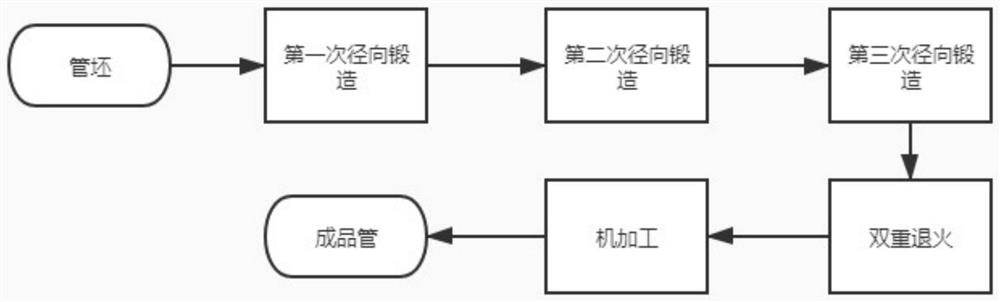

Short-process manufacturing method for titanium and titanium alloy pipes

A titanium alloy and short-process technology, which is applied in the field of titanium alloy pipe preparation, can solve the problems of destroying the as-cast structure, etc., and achieve the effects of increasing deformation, high material utilization rate, and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, a TC4 titanium alloy seamless pipe with a specification of ODФ300*IDФ150 mm is produced through this short-flow production process.

[0048] S1: Prepare a titanium alloy pipe blank with ODФ620mm*IDФ200mm.

[0049] S2: Apply an anti-oxidation coating on the surface of the tube blank, heat it to 1060°C, and keep it warm for 2 hours.

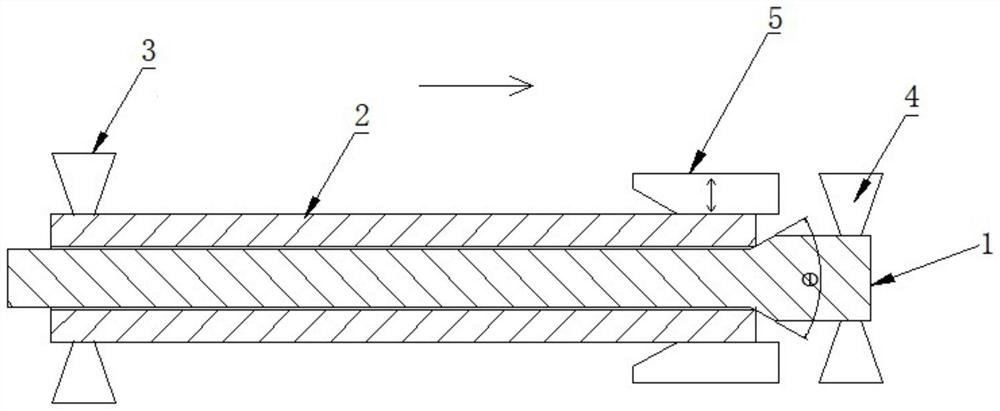

[0050] S3: Clamp the tube blank to the radial forging machine, and the first chuck clamps the tube blank. Prepare a Ф185mm mandrel and insert it into the tube blank. The hammer head is at the other end of the tube, and the mandrel at this end has a taper of 60°. The second chuck is clamped on the mandrel at the same end as the hammer head.

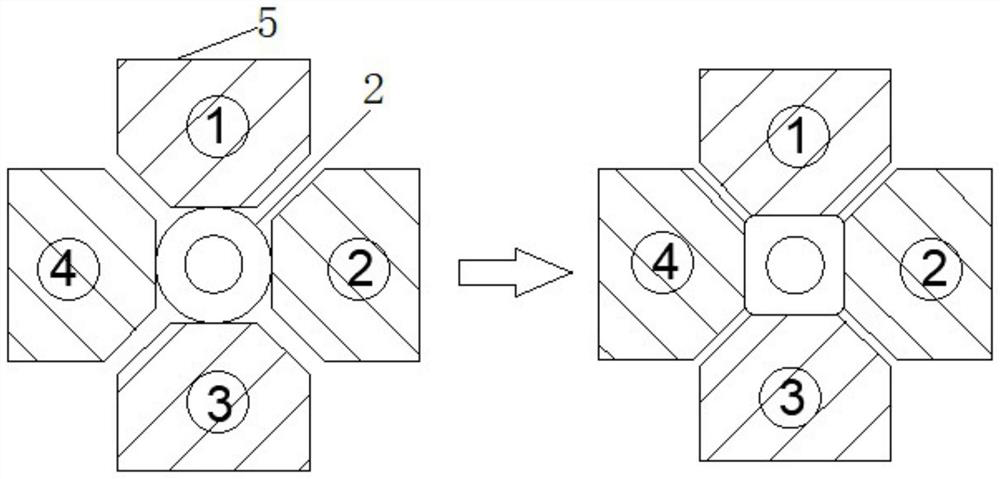

[0051] S4: The first radial forging, the deformation of the tube blank is 40%, the four hammerheads perform radial reciprocating motion, the hammering speed is 2000 times / min, the first chuck and the second chuck control the tube blank and mandrel Move along the direction of the cen...

Embodiment 2

[0059] In this embodiment, a TC4 titanium alloy seamless pipe with a specification of ODФ500*IDФ350 mm is produced through the short-flow production process.

[0060] S1: Prepare a titanium alloy pipe blank with ODФ820mm*IDФ400mm.

[0061] S2: Apply an anti-oxidation coating on the surface of the tube blank, heat it to 1080°C, and keep it warm for 4 hours.

[0062] S3: Clamp the tube blank to the radial forging machine, and the first chuck clamps the tube blank. Prepare a Ф380mm mandrel and insert it into the tube blank. The hammer head is at the other end of the tube, and the mandrel at this end has a taper of 60°. The second chuck is clamped on the mandrel at the same end as the hammer head.

[0063] S4: The first radial forging, the deformation of the tube blank is 80%, the four hammerheads perform radial reciprocating motion, the hammering speed is 1000 times / min, the first chuck and the second chuck control the tube blank and mandrel Move along the direction of the cent...

Embodiment 3

[0071] In this embodiment, a TC4 titanium alloy seamless pipe with a specification of ODФ200*IDФ150 mm is produced through the short-flow production process.

[0072] S1: Prepare a titanium alloy pipe blank with ODФ520mm*IDФ200mm.

[0073] S2: Apply an anti-oxidation coating on the surface of the tube blank, heat it to 1070°C, and keep it warm for 6 hours.

[0074] S3: Clamp the tube blank to the radial forging machine, and the first chuck clamps the tube blank. Prepare a Ф180mm mandrel and insert it into the tube blank. The hammer head is at the other end of the tube, and the mandrel at this end has a taper of 60°. The second chuck is clamped on the mandrel at the same end as the hammer head.

[0075] S4: The first radial forging, the deformation of the tube blank is 60%, the four hammerheads perform radial reciprocating motion, the hammering speed is 1500 times / min, the first chuck and the second chuck control the tube blank and mandrel Move along the direction of the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com