Compostie damp rubber wirerope shock-resistance isolator

A composite damping and steel wire rope technology, applied in the direction of low internal friction springs, etc., can solve the problems that cannot be popularized and used, and have not been achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

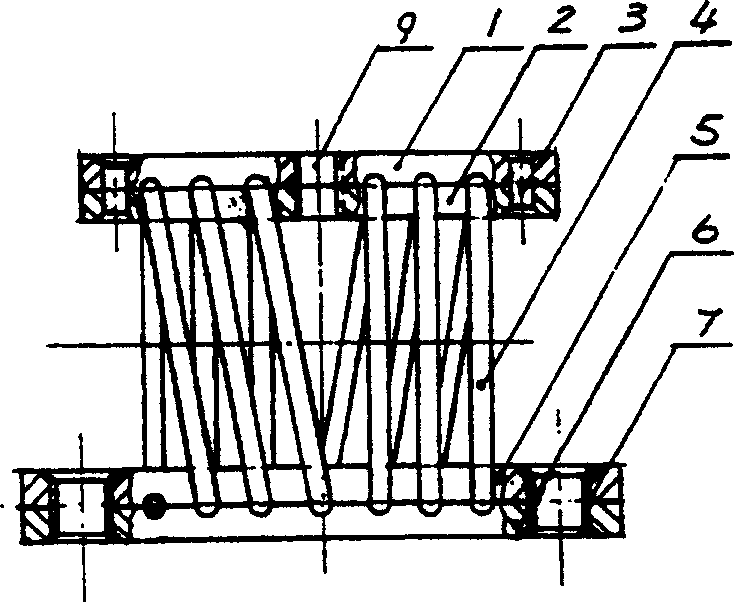

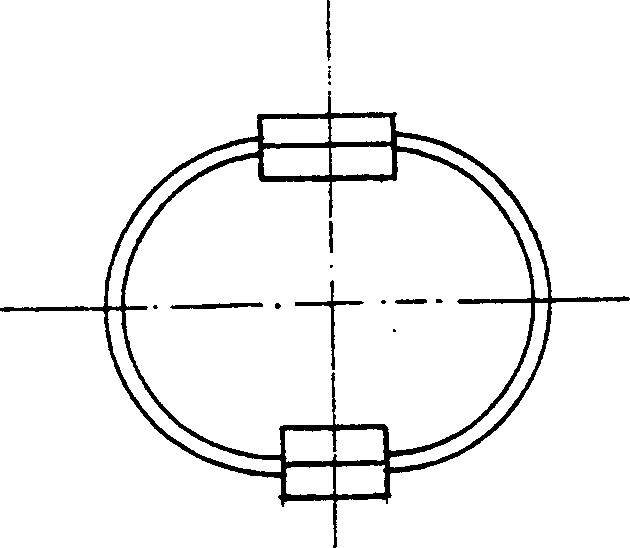

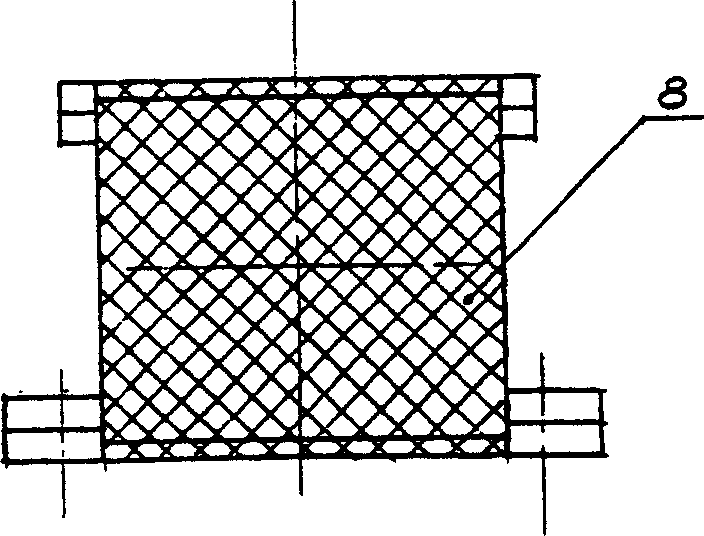

[0018] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention forms a skeleton structure by the upper clamping plates 1, 2 of the steel wire rope, the lower clamping plates 5, 6 and the high-strength steel wire rope 4 spirally wound therebetween, and the upper and lower clamping plates are respectively composed of rivets 3 and hollow rivets 7 Riveting, can also be connected with countersunk screws, the upper and lower clamping plates are respectively provided with screw holes or straight holes connected with the equipment and the base, the rubber 8 is covered on the outside of the steel wire rope 4, and the elastic limiter 10 is covered with rubber 8 part.

[0019] A screw hole 9 is provided with a screw hole 9 in the center of the clamping plates 1 and 2 on the steel wire rope and is used for connecting with equipment. This screw hole 9 is finished after the wire rope is wound and the rivets are riveted. The upper and lower halves of clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com