Anti-pilling treatment method for light and thin wool-polyester fabric

A technology of anti-pilling and treatment method, applied in the treatment of textile materials, fiber treatment, physical treatment and other directions, can solve the problems of pollution and damage to the hand of the fabric, achieve uniform drying, reduce the consumption of chemical reagents and water, The effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

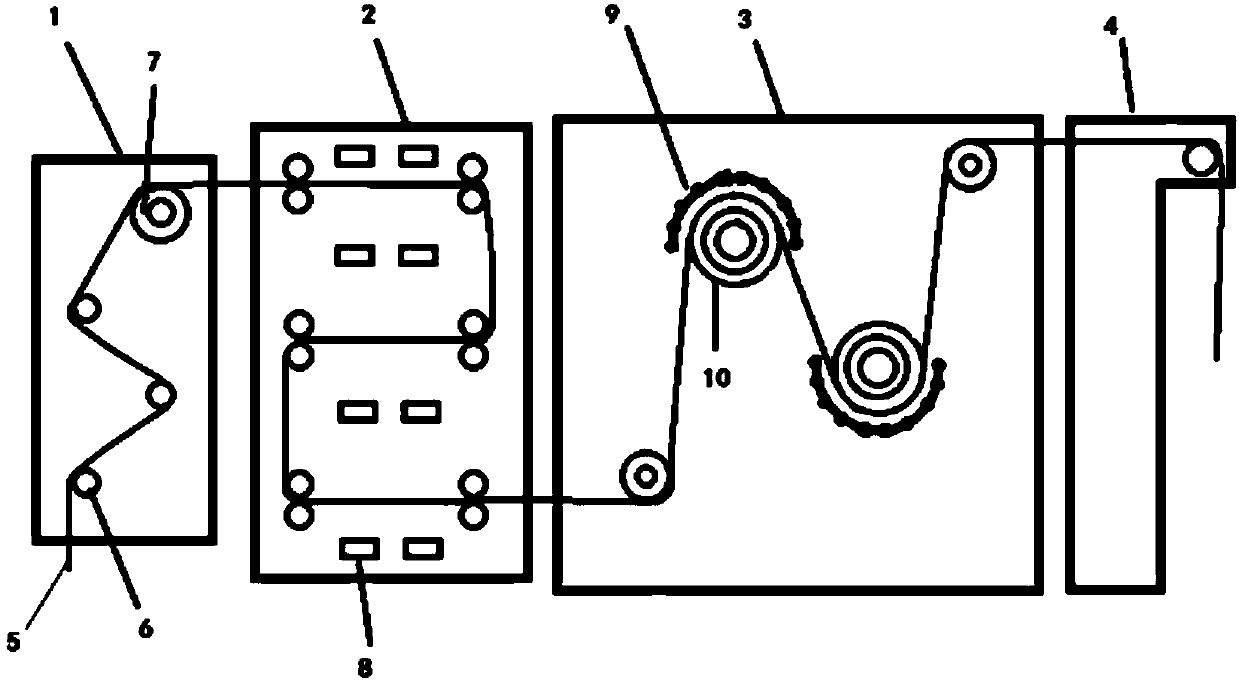

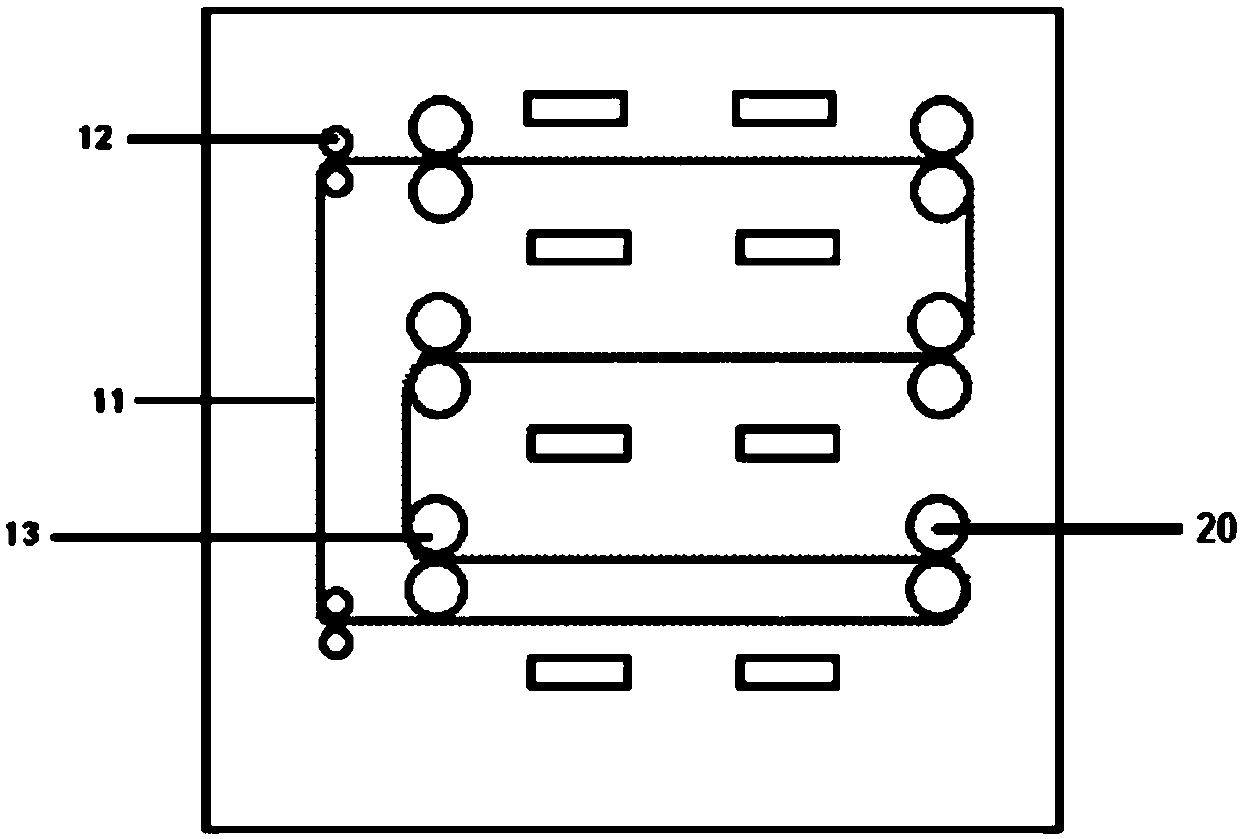

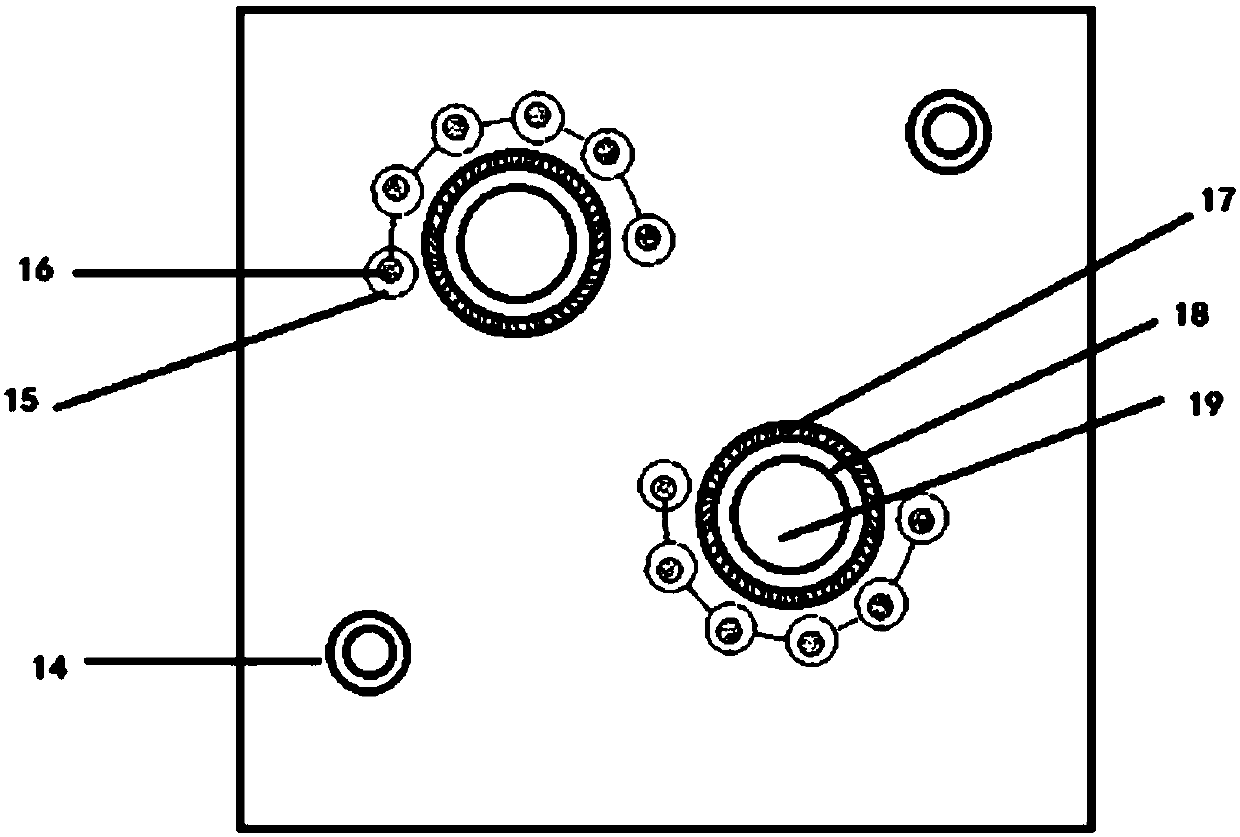

[0034] like Figure 1-Figure 3 As shown, this embodiment provides microwave drying and shaping-low temperature and normal pressure plasma processing equipment, which is composed of cloth feeding machine 1, microwave drying and shaping equipment 2, low temperature and normal pressure plasma processing equipment 3 and cloth placing machine 4, wherein the cloth feeding machine 1 is equipped with cloth guide roller 6 and opening roller 7, microwave drying and setting equipment 2 is equipped with acupuncture shaft 11, cloth pressing roller 12, guide roller 13 and guide roller 20, and low temperature and atmospheric pressure plasma processing equipment 3 is equipped with There are cloth guide rollers 14, electrode dielectric tubes 9 and ground electrode dielectric tubes 10.

[0035] The distance between the guide roller 13 and the guide roller 20 is 5-10 m; three electrode groups 8 are arranged between the guide roller 13 and the guide roller 20 .

[0036] The surface layer of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com