Patents

Literature

150results about How to "High degree of oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

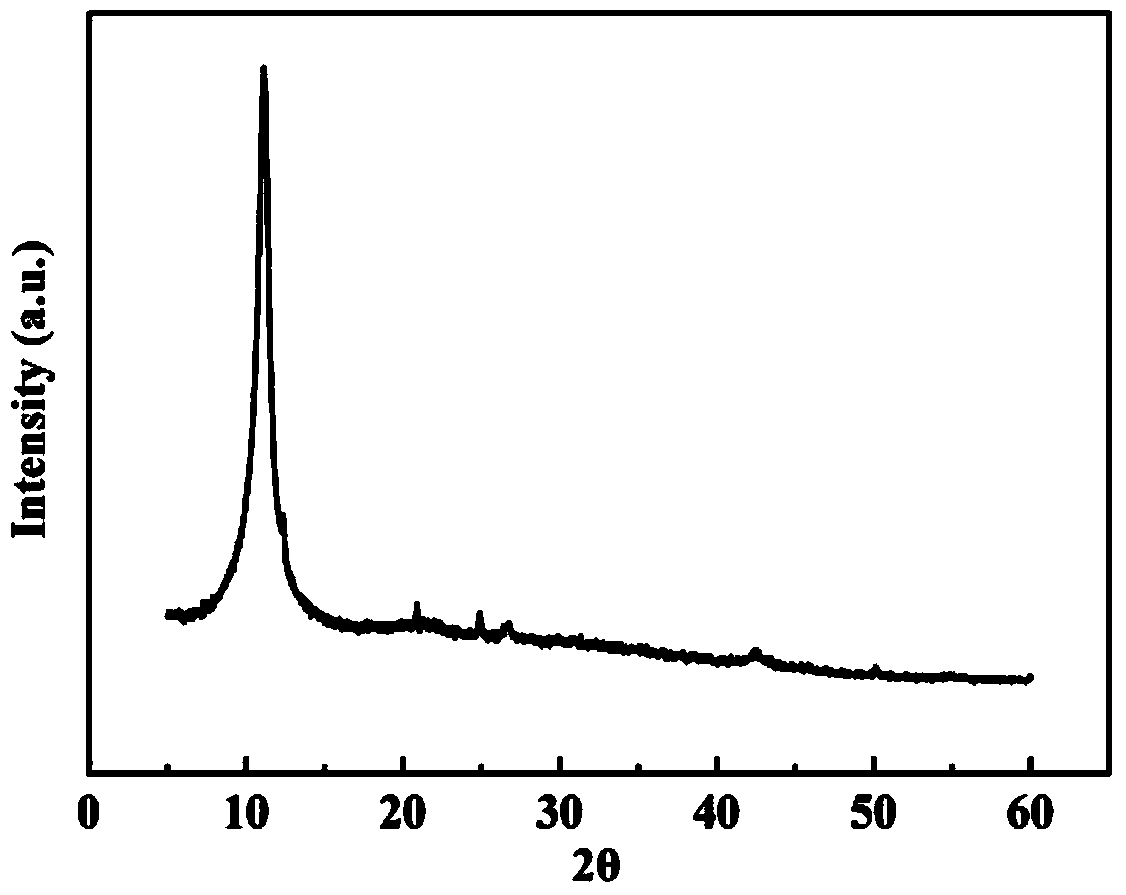

Method for preparing fluorescent graphene quantum dots by solvothermal method

InactiveCN102660270AHigh degree of oxidationLuminescent compositionsChromatographic separationSurface oxidation

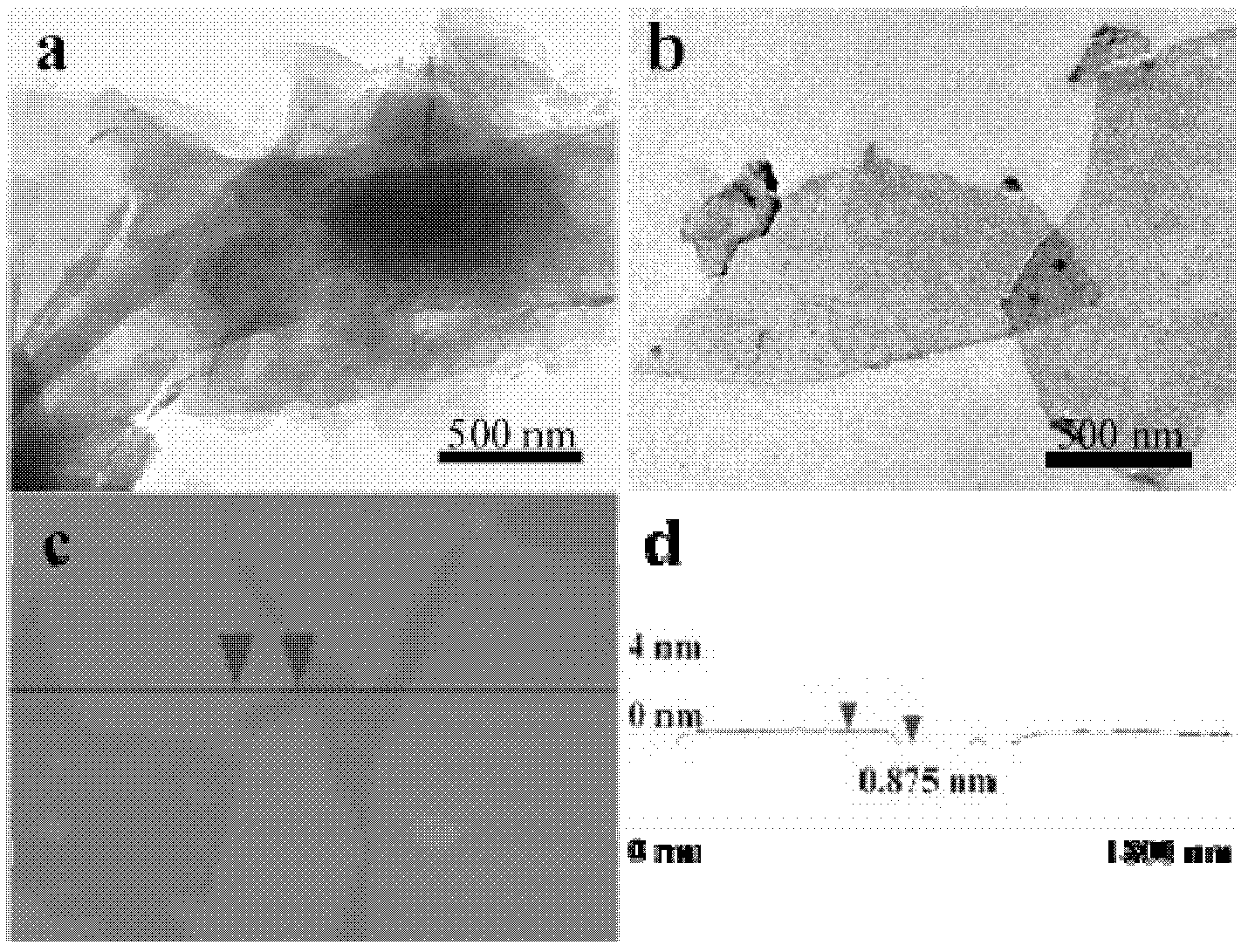

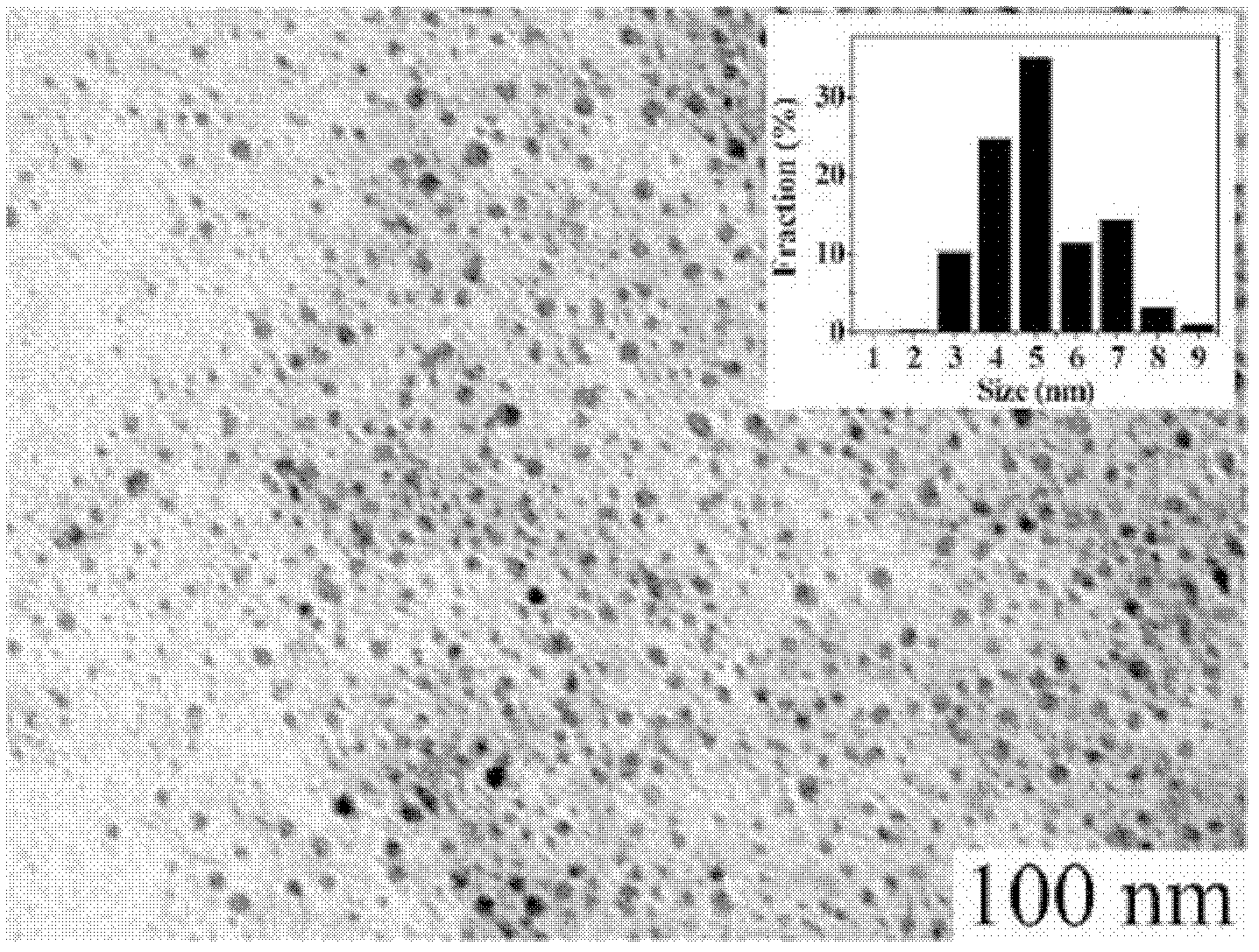

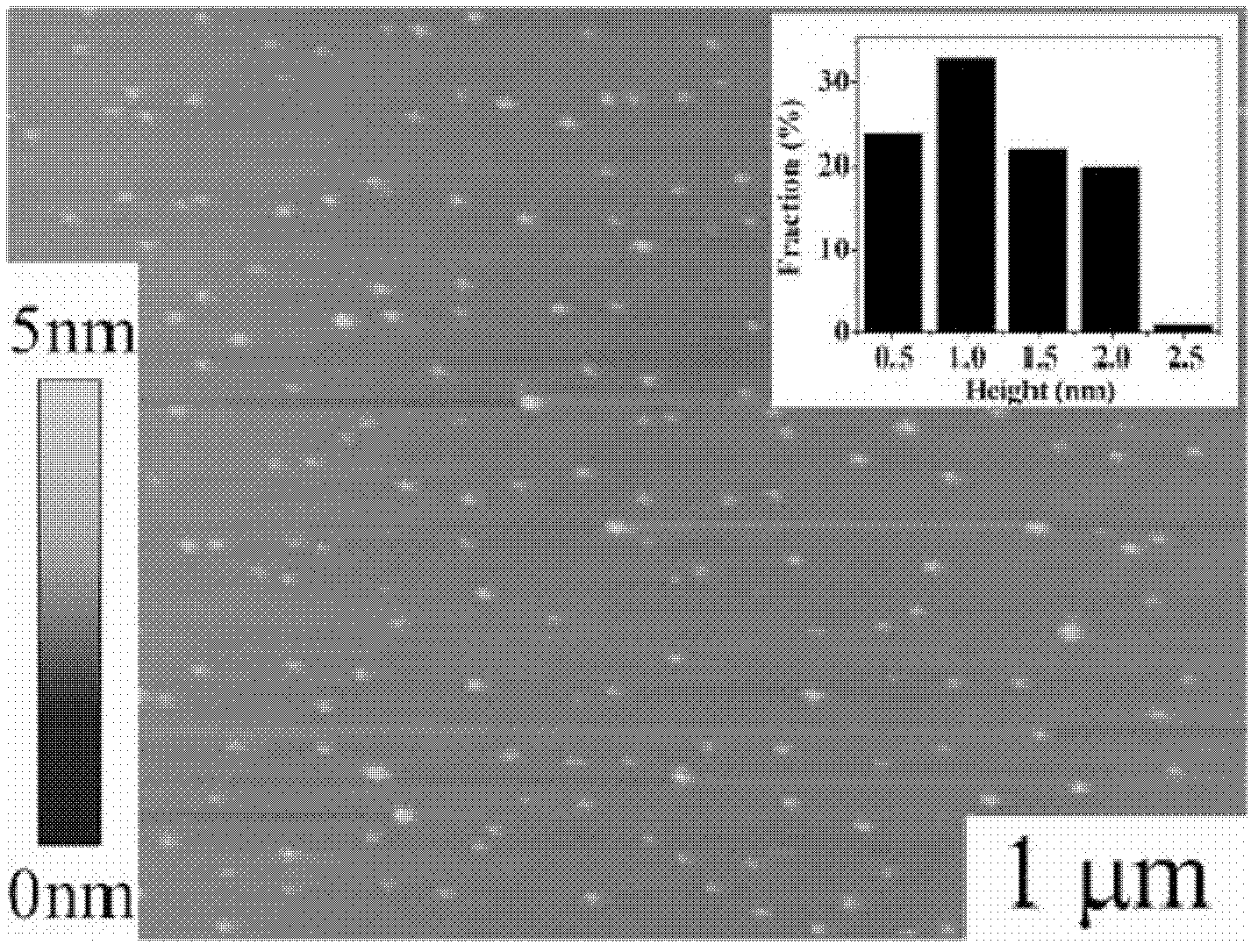

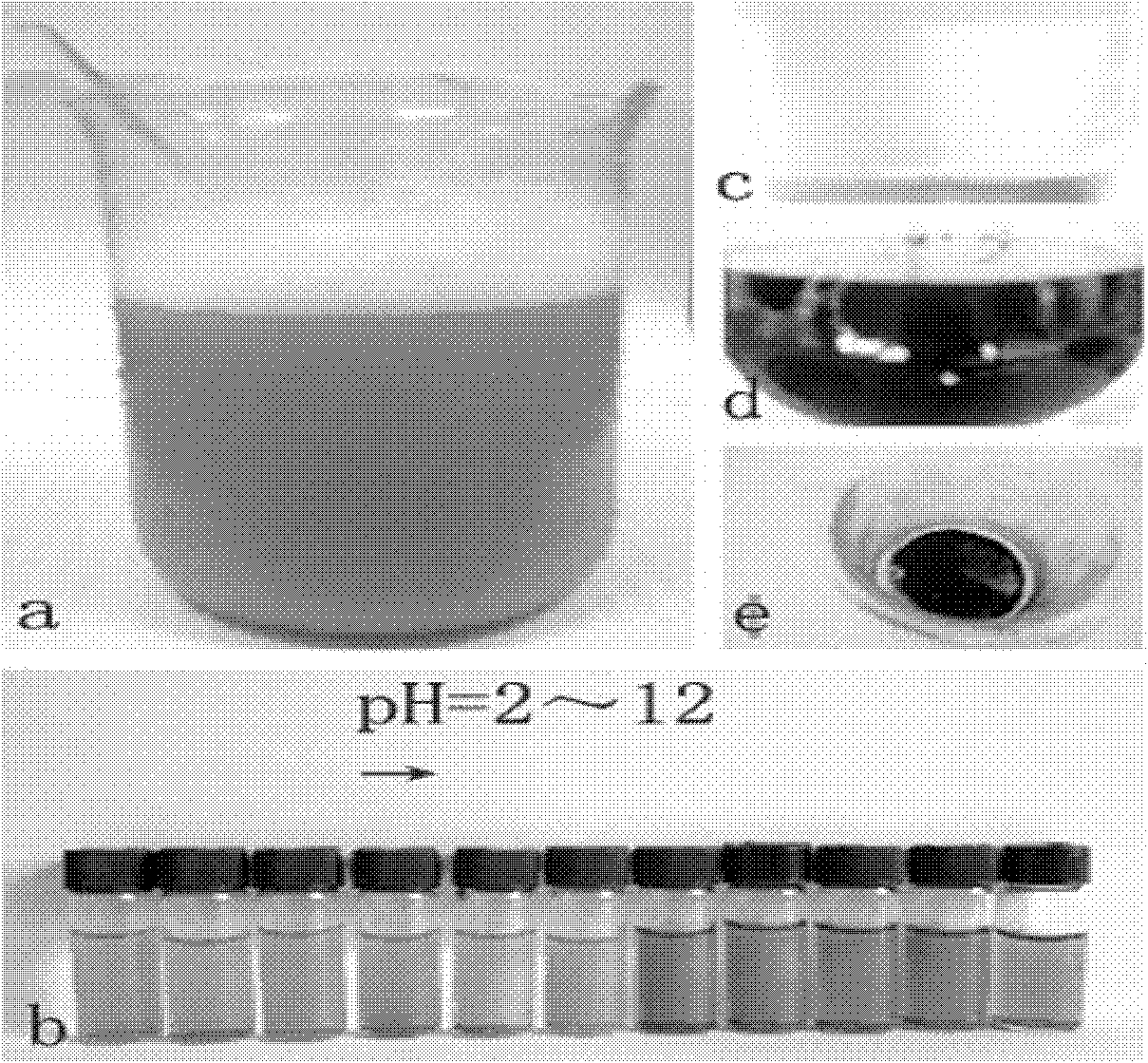

The invention belongs to the technical field of the preparation of graphene quantum dots (GQDs), and particularly relates to a method for preparing fluorescent graphene quantum dots with controllable oxidation degree and fluorescence by a solvothermal method. According to the technical scheme, the method comprises the following steps of: 1, preparing graphene oxide; 2, preparing green fluorescent graphene quantum dots by a single-step method starting from the graphene oxide; and 3, preparing the fluorescent graphene quantum dots with the controllable oxidation degree by a column chromatographic separation method. According to the method, the sizes and surface oxidation degree of the graphene quantum dots can be controlled under the synthetic condition, so that the fluorescent properties and surface chemical characteristics of the graphene quantum dots are controlled. The prepared graphene quantum dots are high in chemical stability and biocompatibility, low in biotoxicity, and high in property of applicable upconversion fluorescence, matt and the like and bleaching performance. By the excellent properties, the graphene quantum dots have a wide application range in aspects of biological imaging, photovoltaic devices and sensors, and are novel promising fluorescent nano materials.

Owner:JILIN UNIV

A kind of preparation method of graphene material

The invention discloses a preparation method of a graphene material. The preparation method comprises the following steps of: with graphite carbon as a raw material, adding potassium hypermanganate and concentrated sulfuric acid in batches in different stages to control an oxidation process of graphite; adjusting the pH value of the oxidized solution to obtain graphene oxide colloidal dispersing solutions (GOS) with different concentrations; dropwise adding the GOS on the surface of a carrier or spreading out the GOS on a non-intersolubility liquid / liquid interface and drawing into a grapheneoxide thin-film (GOF); carrying out high-speed centrifugation and drying treatment on the GOS to obtain graphene oxide solid powder (GOP); reducing the GOS by selecting an appropriate reducing agent,and centrifugally drying to obtain reduced graphene solid powder (GRP); dispersing a proper amount of GRP in an organic solvent to prepare a reduced graphene oxide colloidal dispersing solution (GRS); and dropwise adding the GRS on the surface of the carrier or spreading out on the non-intersolubility liquid / liquid interface and drawing into the reduced graphene thin-film (GRF). Various graphene materials prepared by the invention are easy to mutually transform; and the concentration of the colloidal solution and the thickness of the thin-film can be controlled in a certain range.

Owner:CENT SOUTH UNIV

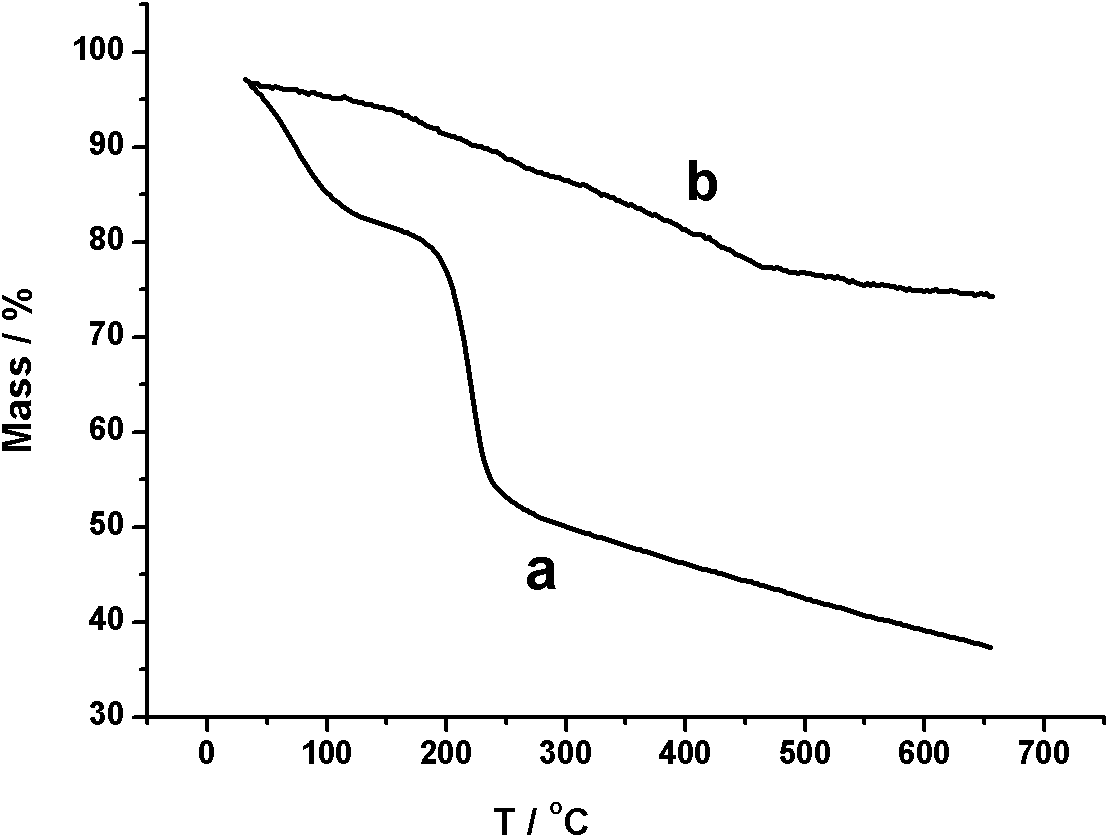

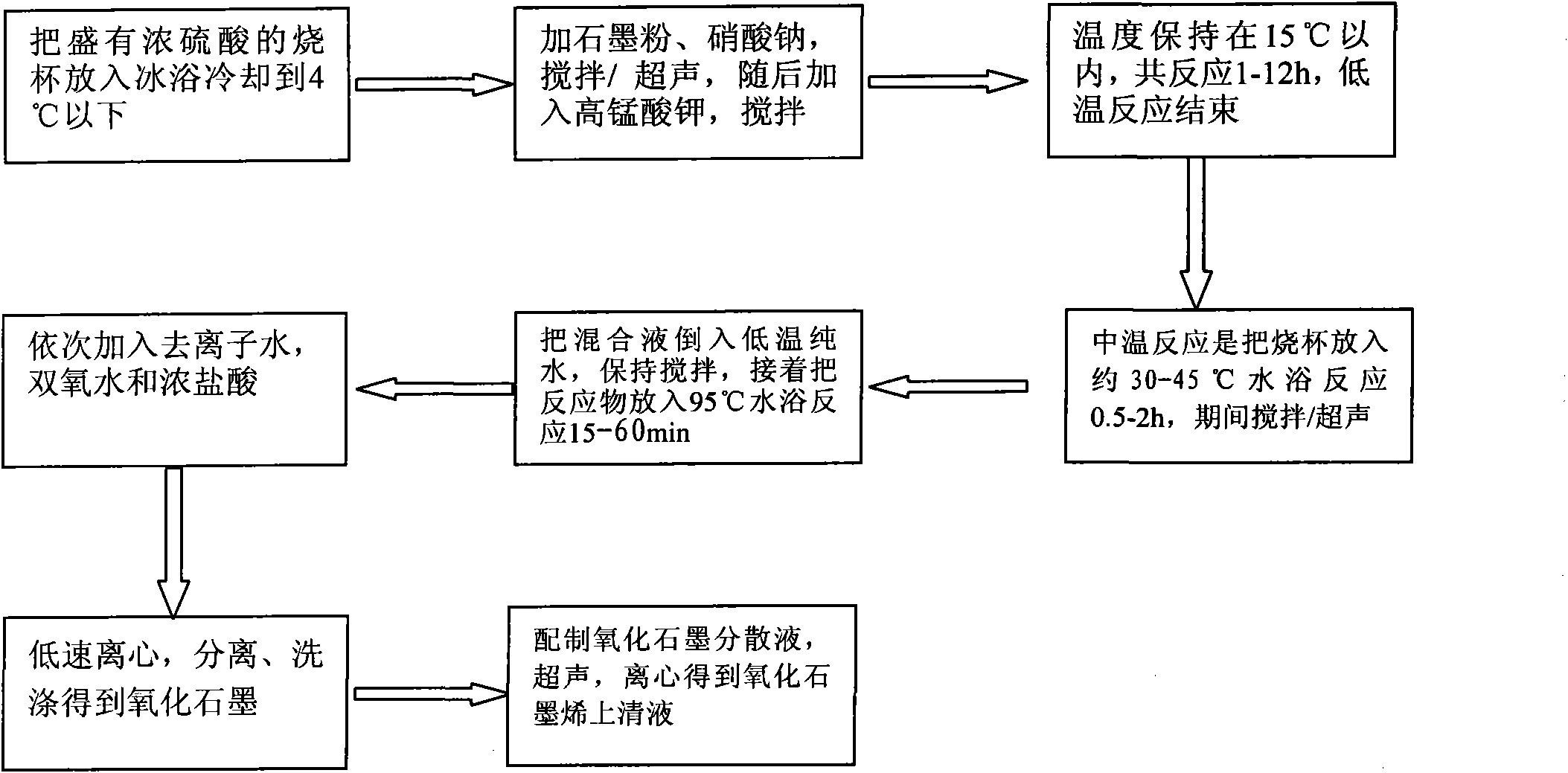

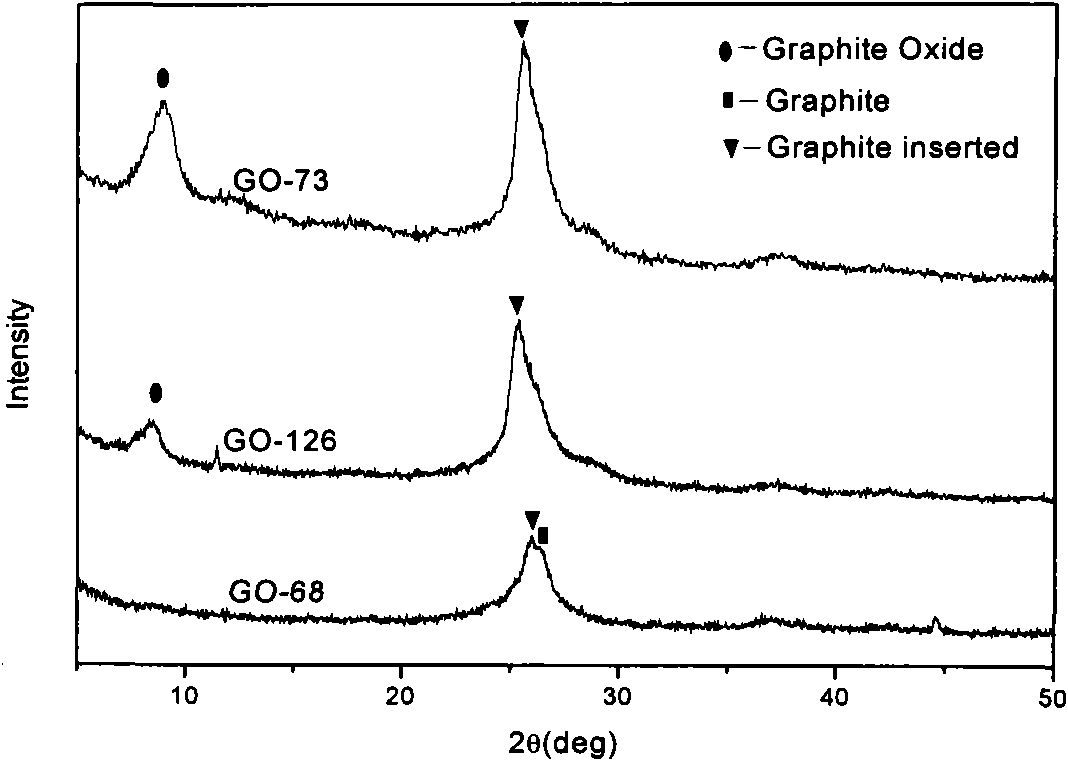

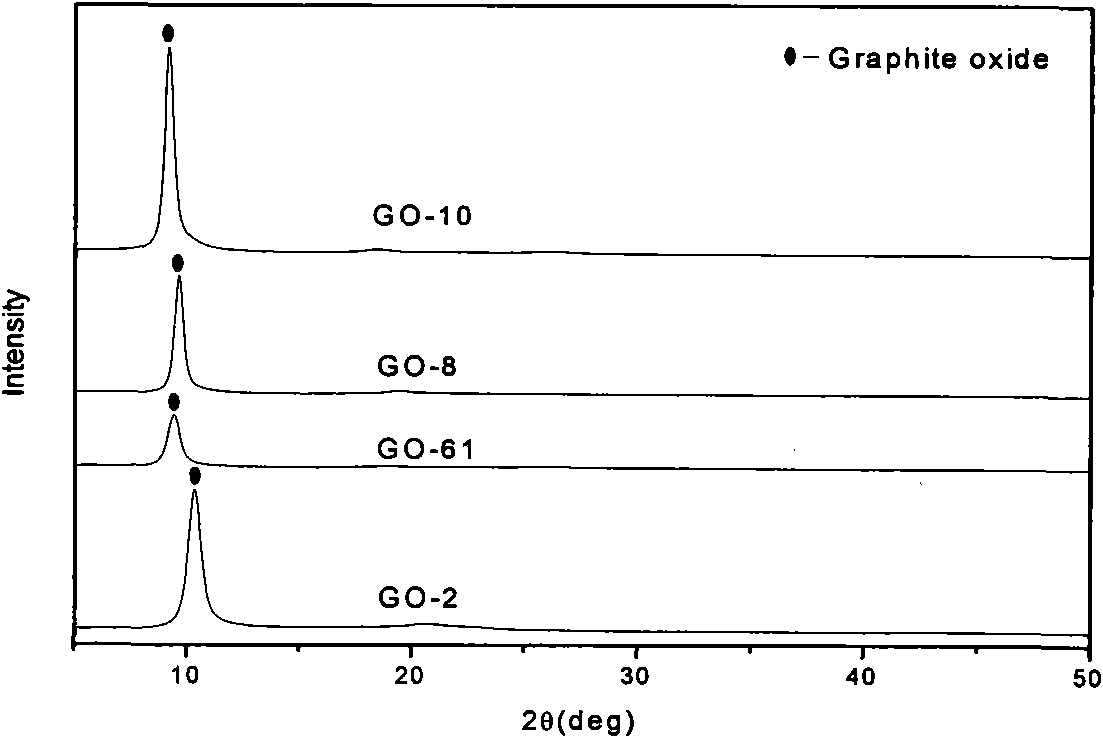

Method for synthesizing graphene oxide by ultrasonic assistance Hummers method

InactiveCN102153075AImprove efficiencyHigh degree of oxidationUltrasonic oscillationMechanical property

The invention relates to a method for synthesizing graphene oxide by an ultrasonic assistance Hummers method. The method for synthesizing the graphene oxide includes the steps as follows: firstly adding ultrasonic oscillation in low-temperature and middle-temperature reaction stages of the Hummers method to improve the intercalation efficiency and the oxidation degree of graphite oxide; secondly slowly dropping mixed liquor containing concentrated sulphuric acid into low-temperature deionized water to increase temperature when high-temperature reaction begins, thus effectively preventing intercalated materials such as sulphuric acid molecules and the like from rapidly escaping from graphite layers due to overhigh local temperature; and finally obtaining the graphite oxide through low-speed centrifugation. The method for synthesizing the graphene oxide by using the ultrasonic assistance Hummers method is convenient and fast, saves resources, and can effectively increase spacings of graphite oxide layers. The prepared graphene oxide can serve as a wild phase of a composite material and papyraceous laminated graphite oxide based composite material with high mechanical property and the like can be prepared. The reduction product graphene can be used for preparing graphene-based composite materials such as transparent electrodes, super capacitors, hydrogen storage materials, chemical / biological sensors, thin film transistors and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

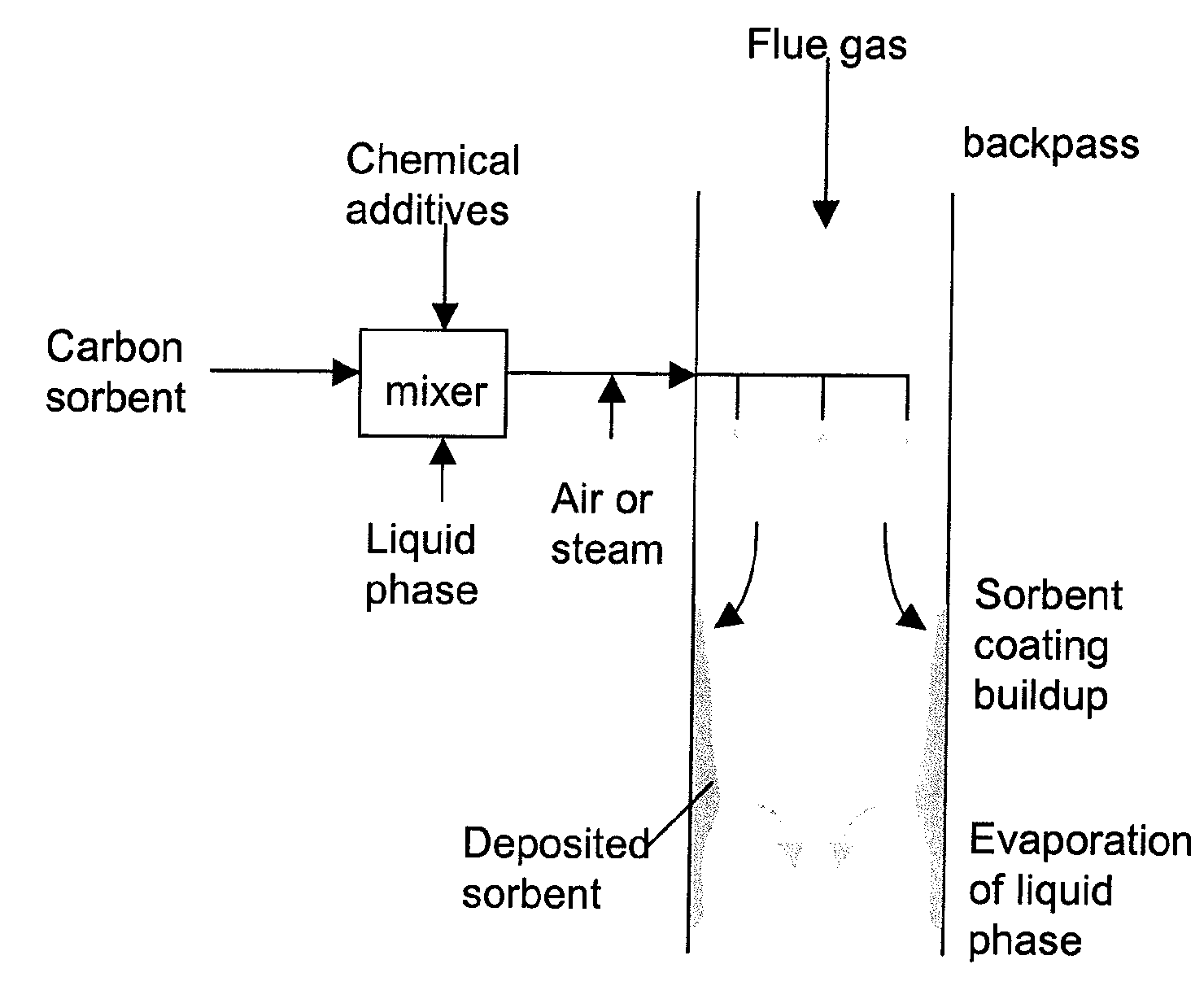

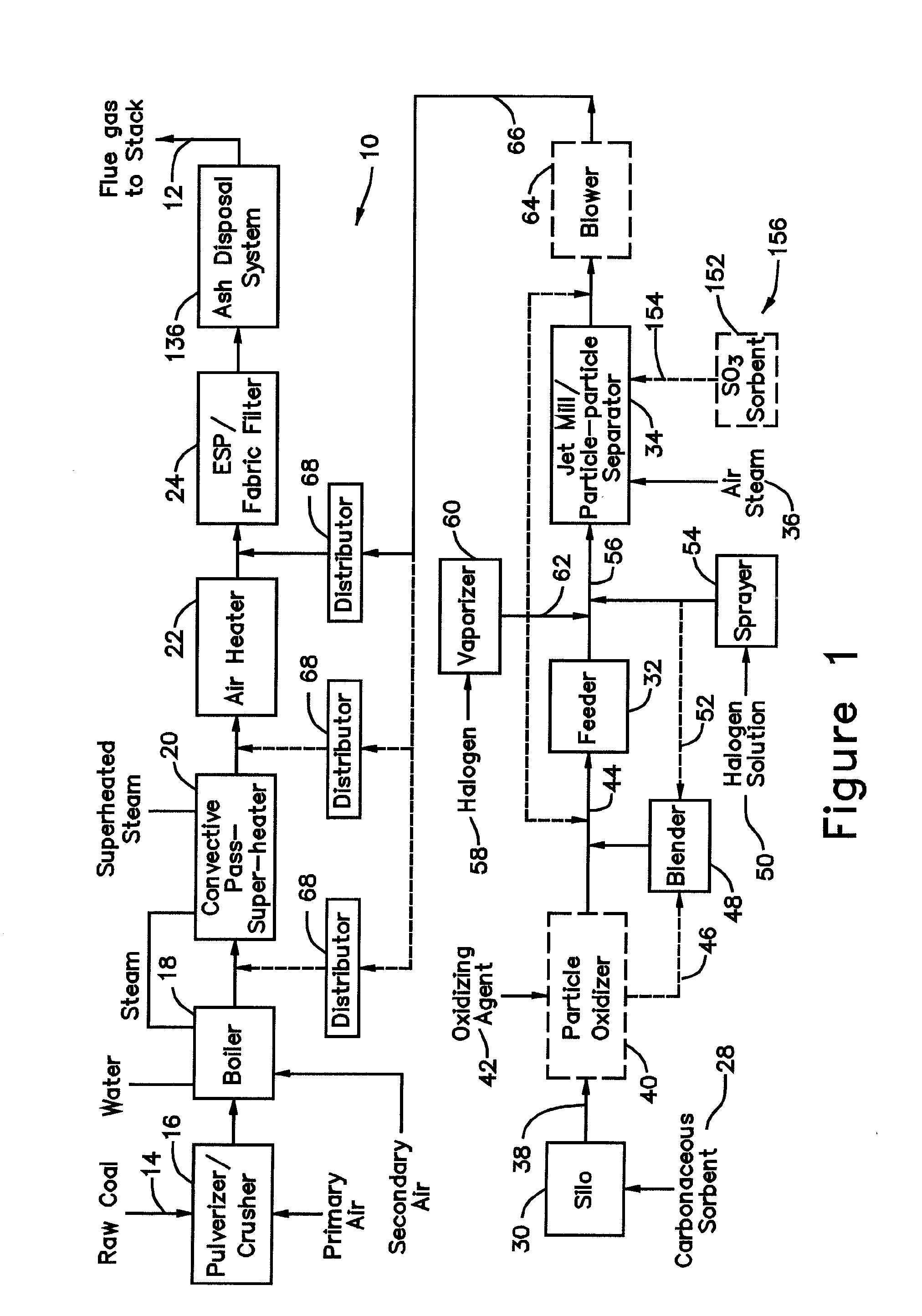

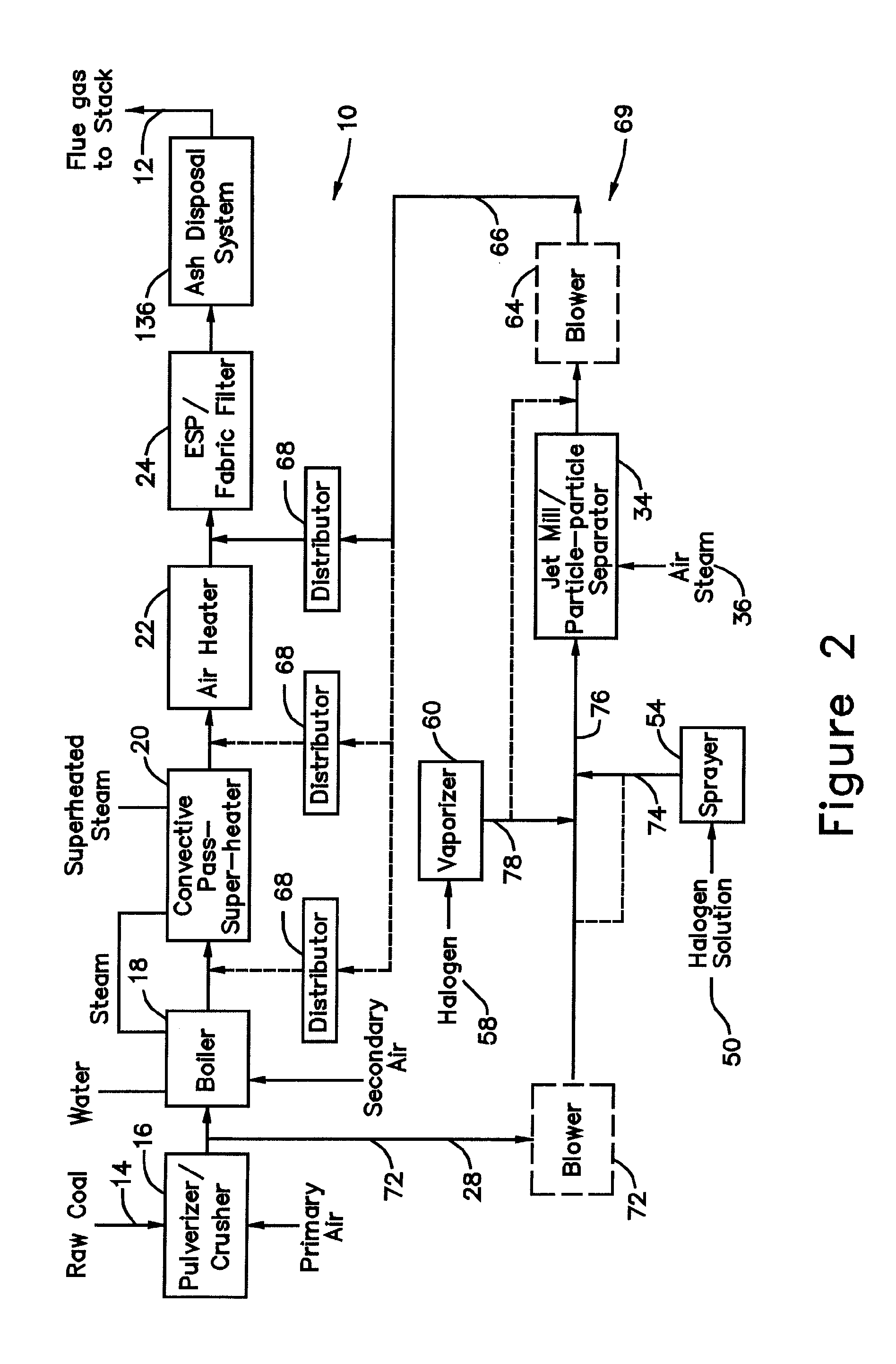

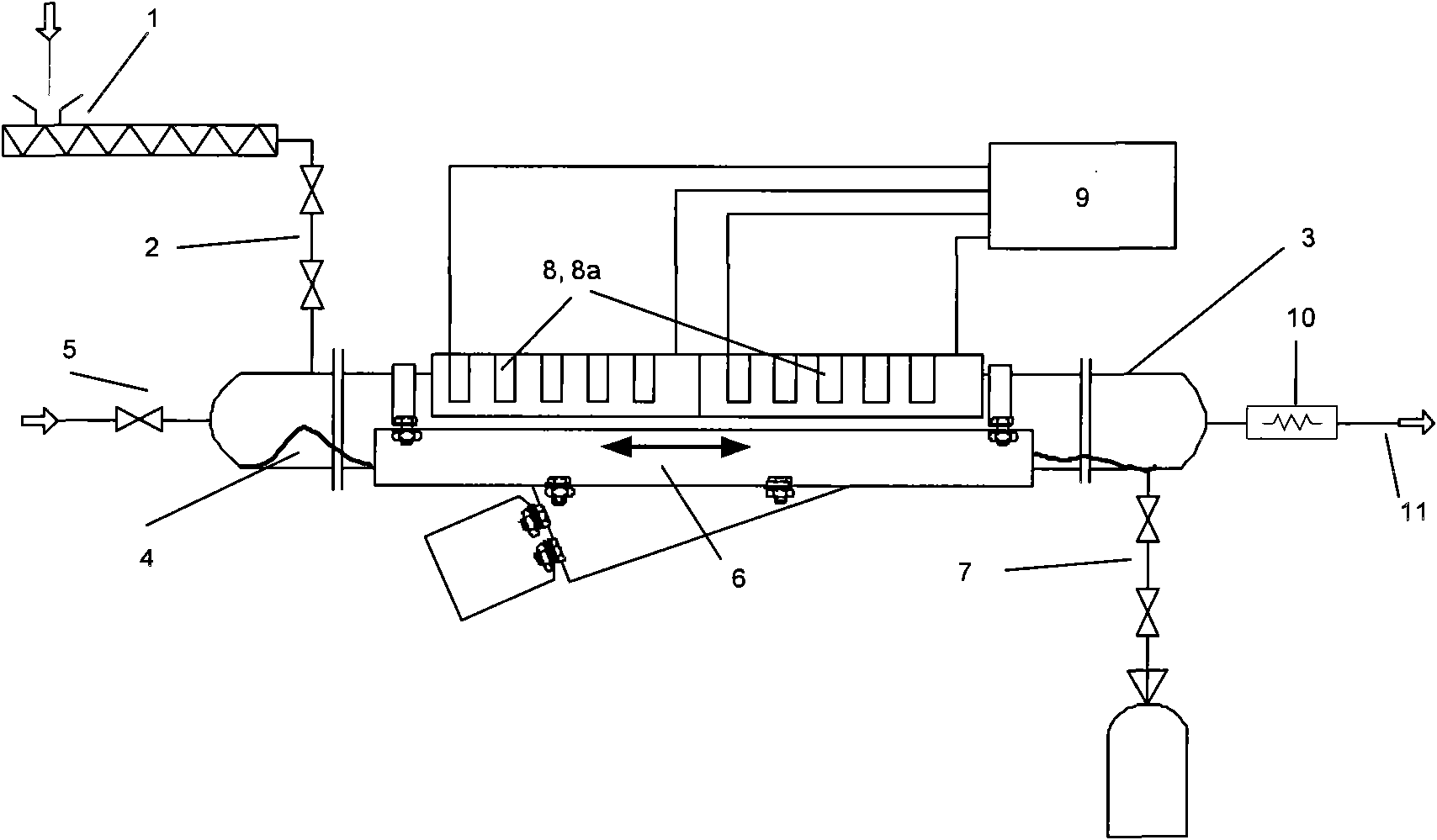

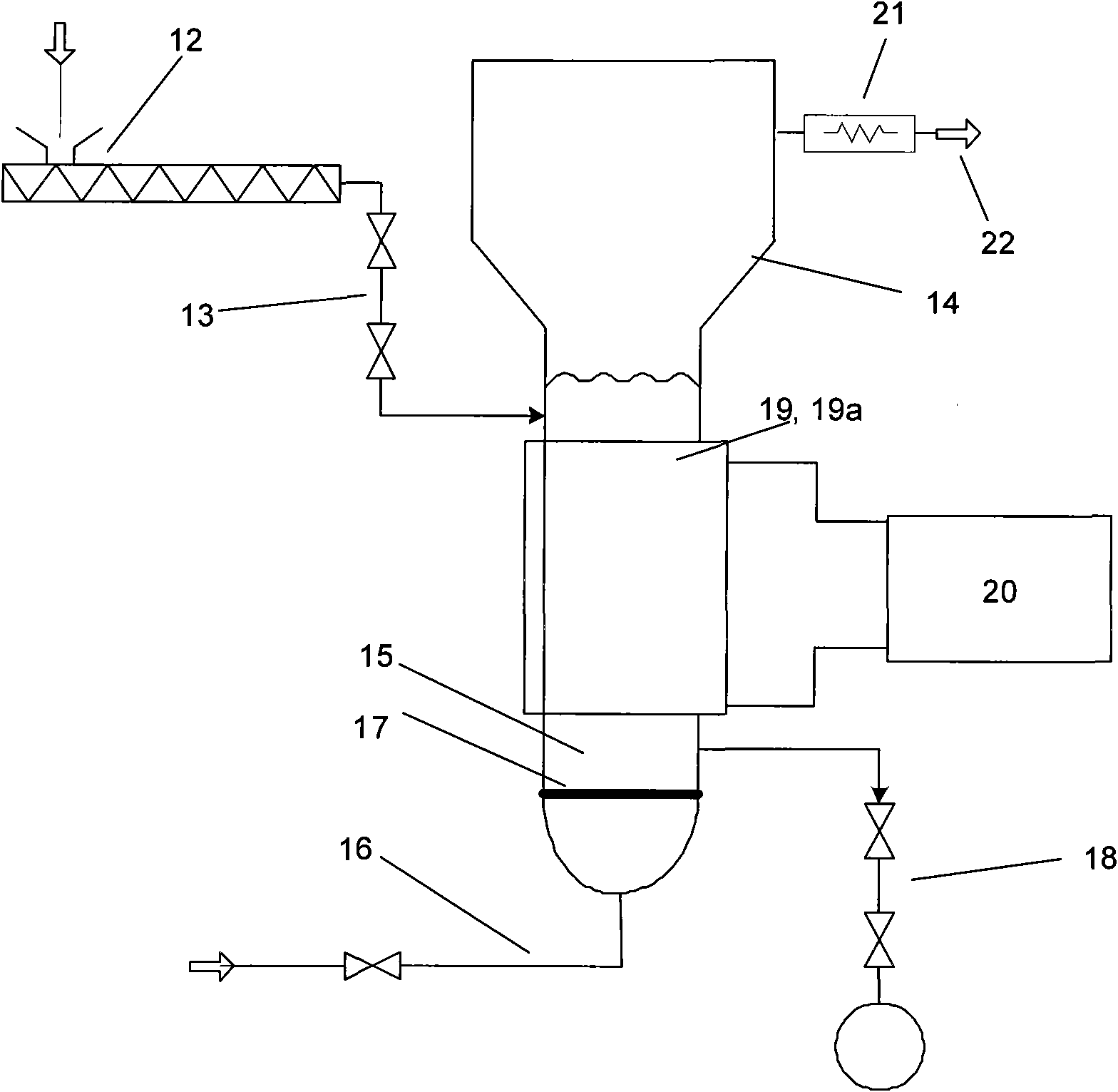

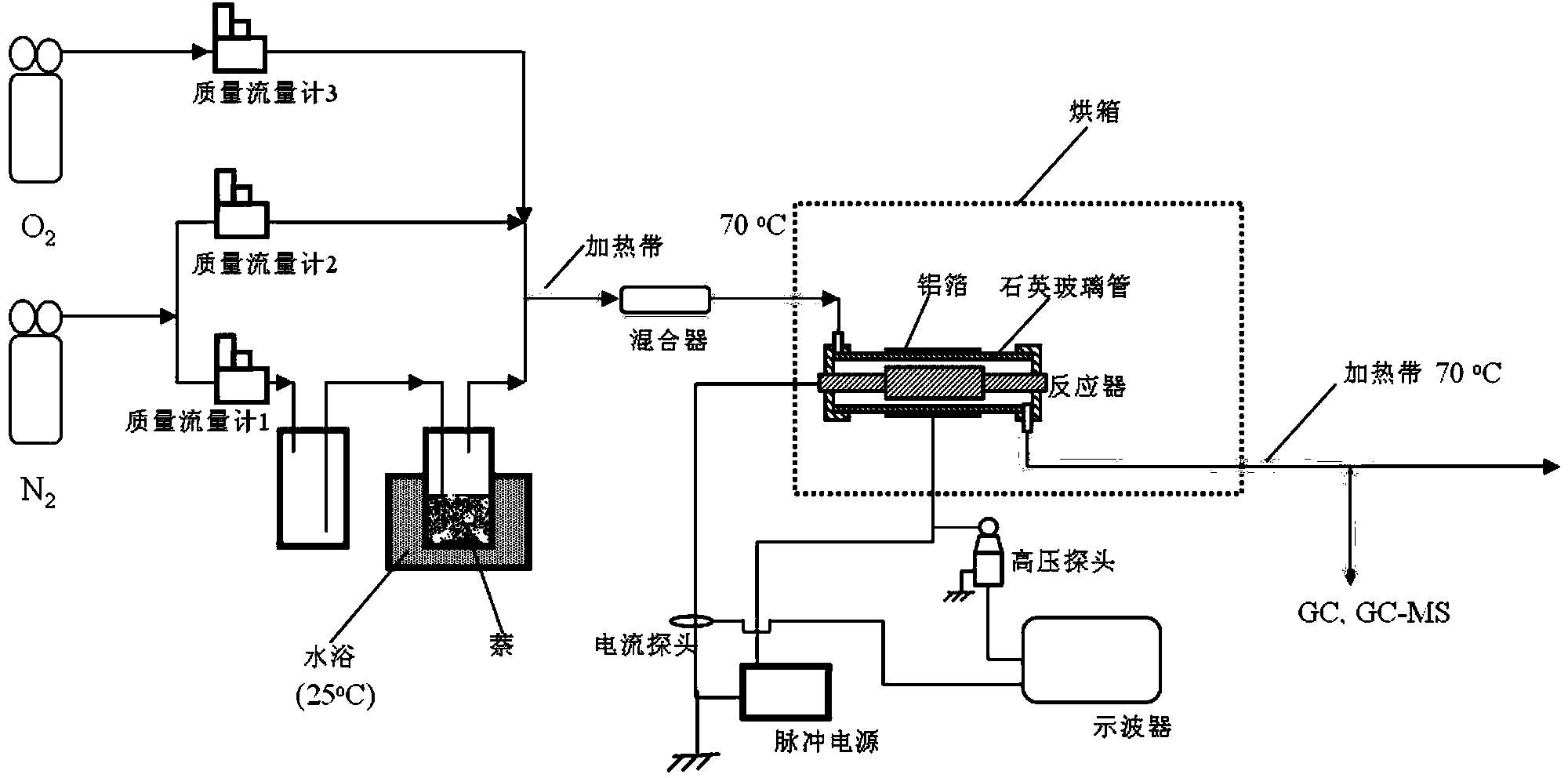

Control of mercury emissions from solid fuel combustion

InactiveUS20090056538A1Easy to captureReduce consumptionGas treatmentElectrostatic separationActivated carbonFlue gas

A method for removing mercury from flue gases generated by the combustion of coal comprises: storing a starter batch of activated carbon in an agglomerated state; de-agglomerating the starter batch in a separation device to create a contact batch of activated carbon; transporting the contact batch to a contact location; injecting the contact batch into contact with the flue gas at a contact location having a temperature between 400° F. and 1100° F., whereupon the activated carbon of the contact batch adsorbs mercury from the flue gas; and removing the activated carbon having mercury adsorbed thereon from the flue gas. The transporting step is conducted with substantially no intermediate storage of the contact batch following the de-agglomeration of the starter batch to prevent re-agglomeration of the activated carbon prior to injection.

Owner:GENERAL ELECTRIC TECH GMBH

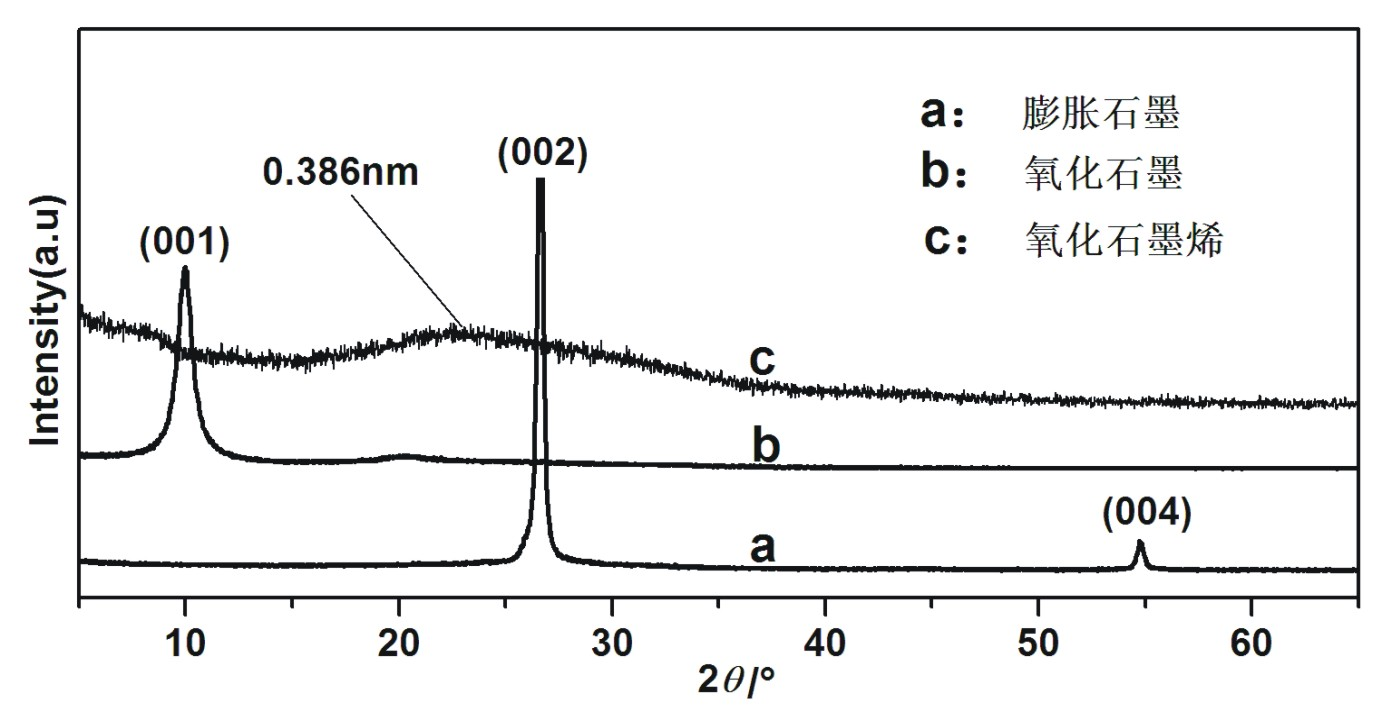

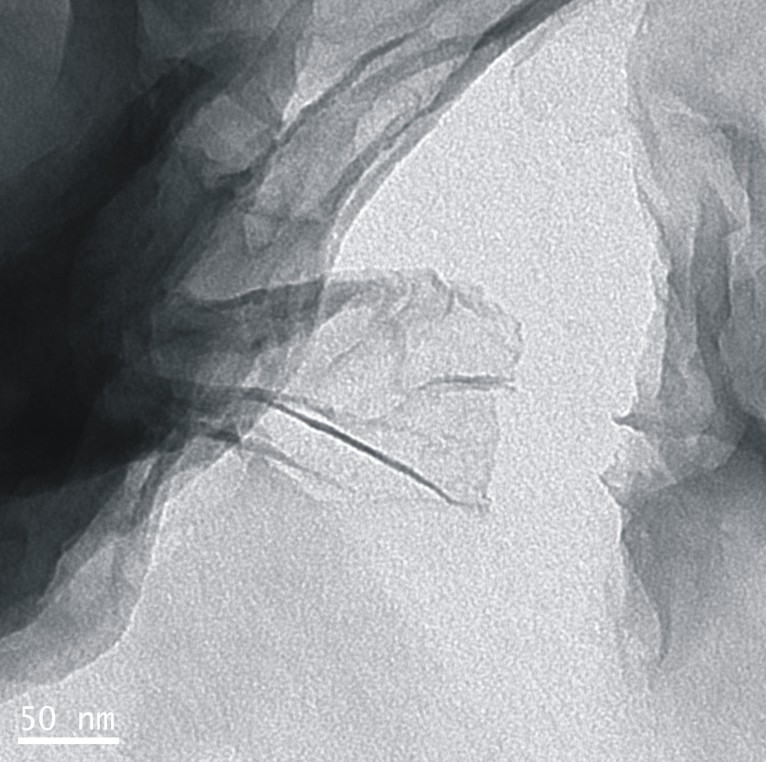

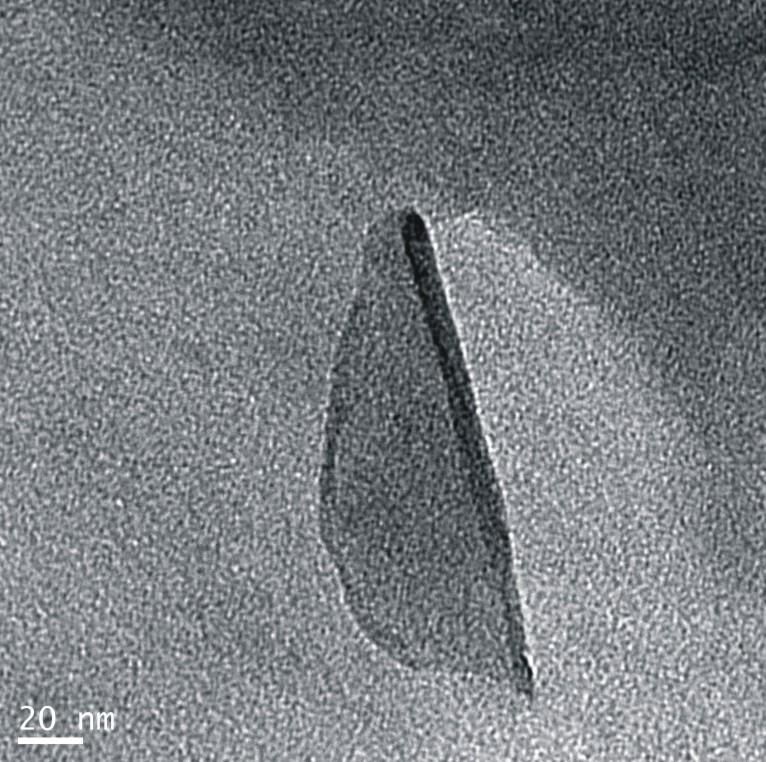

Method for preparing graphene oxide by chemical peeling

The invention relates to a method for preparing graphene oxide by chemical peeling, belonging to the field of graphene oxide preparation. The method comprises the following steps: (1) graphite oxide preparation: selecting expanded graphite, strong acid, oxidant and distilled water according to the proportion of (0.1-0.8g):(10-90ml):(0.6-12g):(40-300ml); mixing the expanded graphite with the strong acid evenly, adding oxidant and then carrying out a reaction on the mixture for 0.25-4 hours in a condition of 30-45 DEG C; adding distilled water to react for 0.5-2.5 hours and washing the filter cake to neutral with distilled water; rinsing the filter cake with absolute ethyl alcohol, drying the cake in a condition of 30-45 DEG C to obtain the graphite oxide. (2) graphene oxide preparation: selecting the graphite oxide and organic solvent according to the proportion of (0.02-0.1g):(15-70ml); adding the graphite oxide to the solvent and dispersing with a 40-50kHz ultrasonic sound for 0.5-10 hours; centrifugating at a rate of 3000-5000r / min for 20-90 minutes; taking the suspension solution and drying in a condition of 30-45DEG C to obtain the graphene oxide. The method in the invention is safe in operation and has low costs.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Preparation method of graphene/g-C3N4 compound photocatalyst

InactiveCN103769187AHigh degree of oxidationIncrease the areaPhysical/chemical process catalystsDecompositionHigh energy

The invention relates to a preparation method of a graphene / g-C3N4 compound photocatalyst, and adopts a high temperature decomposition method to prepare the graphene / g-C3N4 compound photocatalyst. The method comprises the following steps of (1) preparing g-C3N4 powder by adopting concentrated hydrochloric acid melamine through high temperature decomposition; (2) synthesizing high specific surface area graphite oxide by adopting an improved Hummers method, stripping the graphite oxide in an ultrasound manner, removing the graphene with the low oxidation degree through centrifugation, finally extracting a supernatant liquid, drying, and preparing polarity graphene oxide powder; and (3) uniformly mixing the prepared graphene oxide powder and the g-C3N4 through a high energy ball grinder to dissolve in hydrazine hydrate, and preparing the graphene / g-C3N4 compound photocatalyst with a high photocatalytic activity. The preparation method provided by the invention has the advantages that a raw material is cheap, the technology is simple and convenient and the like, and the prepared compound photocatalyst has the wide application prospect on the fields such as wastewater treatment and gas purification.

Owner:JIANGSU YUEDA NEW MATERIALS TECH

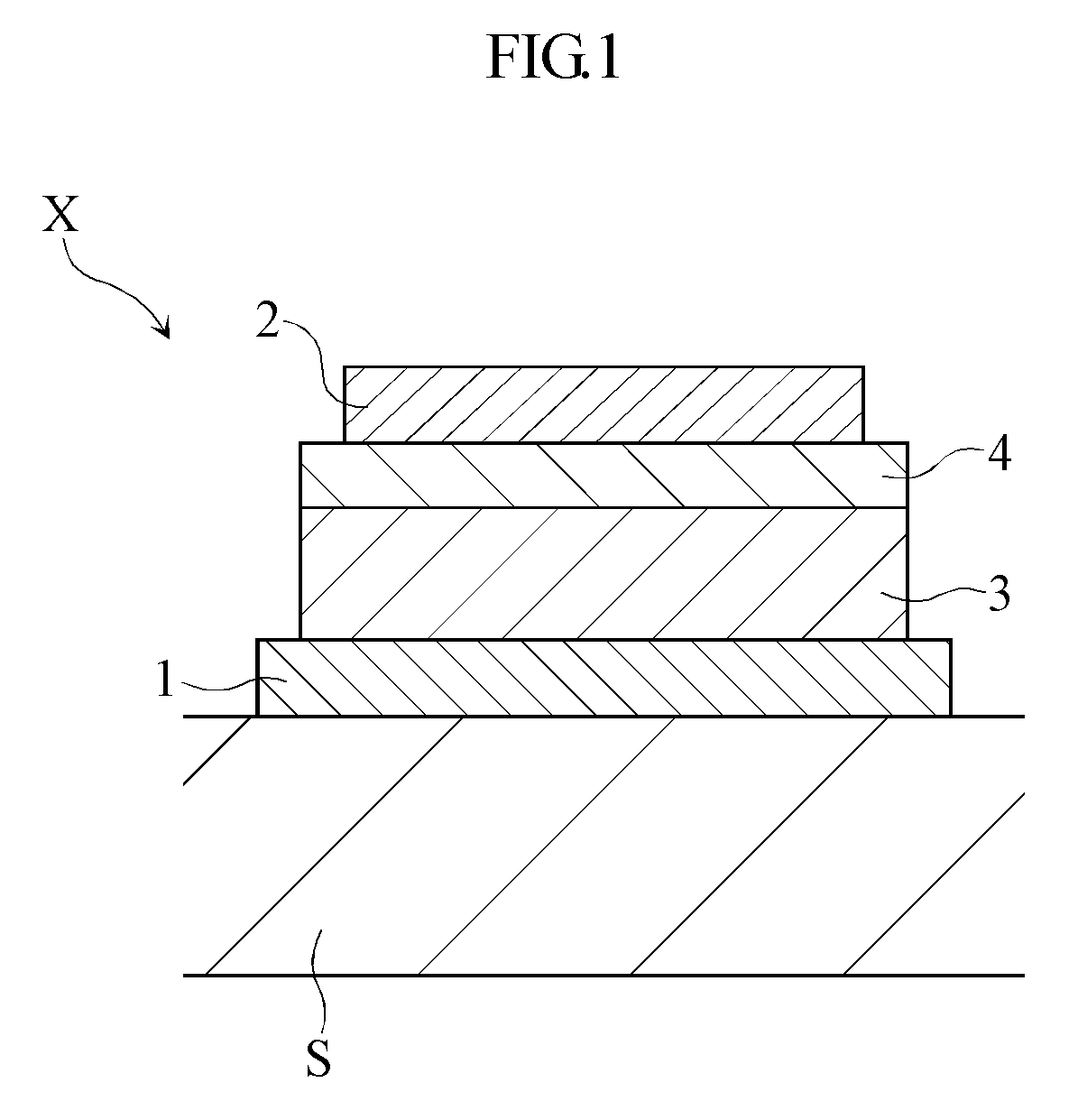

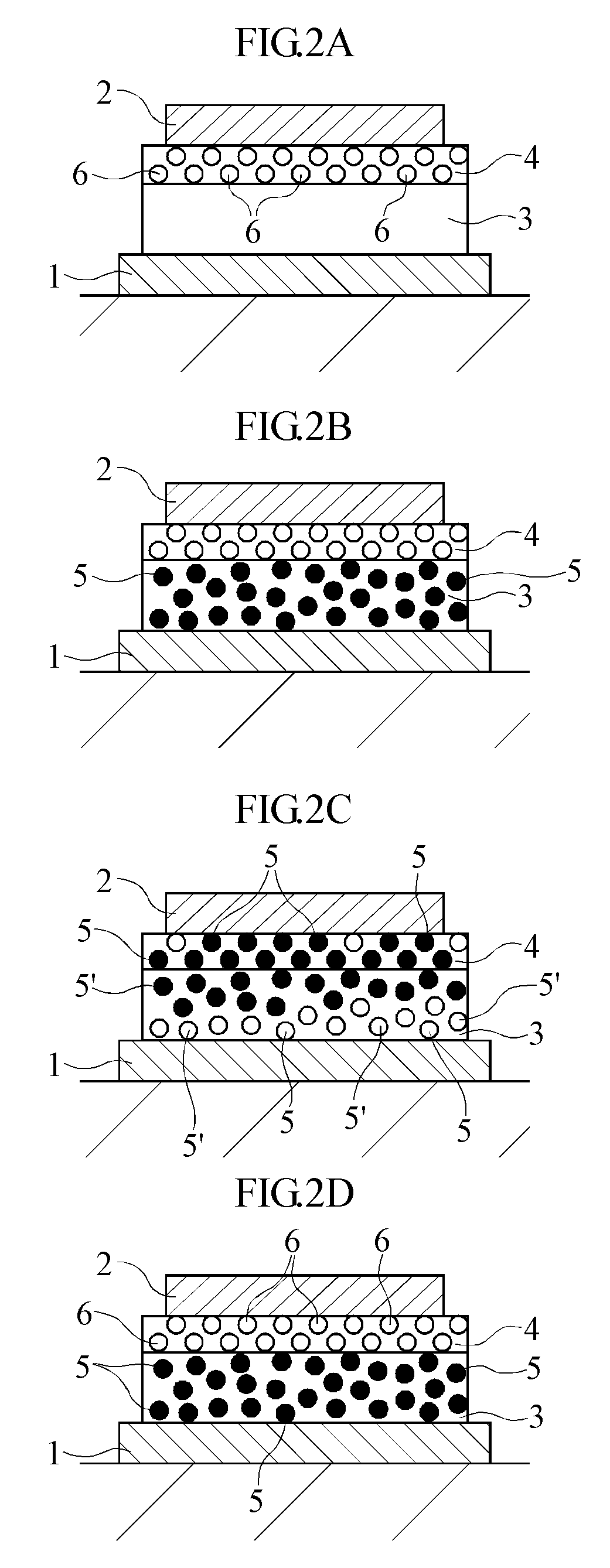

Resistance variable element

InactiveUS20090218565A1High degree of oxidationPrevent movementSolid-state devicesDigital storageHigh resistanceOxygen ions

A resistance variable element is provided, which is capable of performing bipolar operation by a specified mechanism and usable as a memory. The resistance variable element has a laminated structure including an electrode, an electrode, an oxide layer between the electrodes, and an oxide layer in contact with the oxide layer between the oxide layer and the electrode. The oxide layer is switchable from the low-resistance state to the high-resistance state by donating oxygen ions to the oxide layer, and from the high-resistance state to the low-resistance state by accepting oxygen ions from the oxide layer. The oxide layer is switchable from the low-resistance state to the high-resistance state by accepting oxygen ions from the oxide layer, and from the high-resistance state to the low-resistance state by donating oxygen ions to the oxide layer.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +1

Preparation method of graphene oxide with uniform size

The invention discloses a preparation method of graphene oxide with a uniform size. The preparation method comprises the following steps: preparing pre-oxidized graphene oxide under the effect on graphite and an oxidant, thus enhancing the oxidization degree of graphite powder, then continuously further oxidizing the obtained pre-oxidized graphene oxide, and preparing the graphene oxide with the uniform size. The method is easy to operate, high in oxidization degree, green and environment-friendly; the prepared graphene oxide is uniform in size.

Owner:ZHEJIANG SCI-TECH UNIV

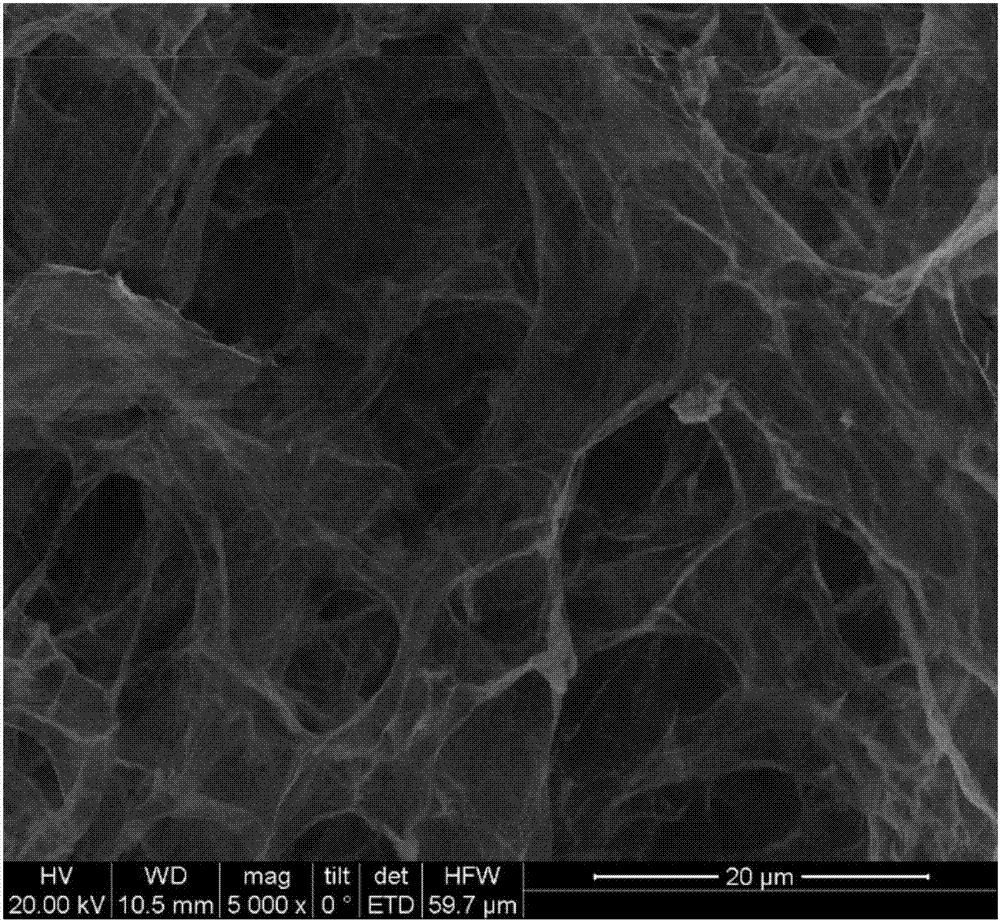

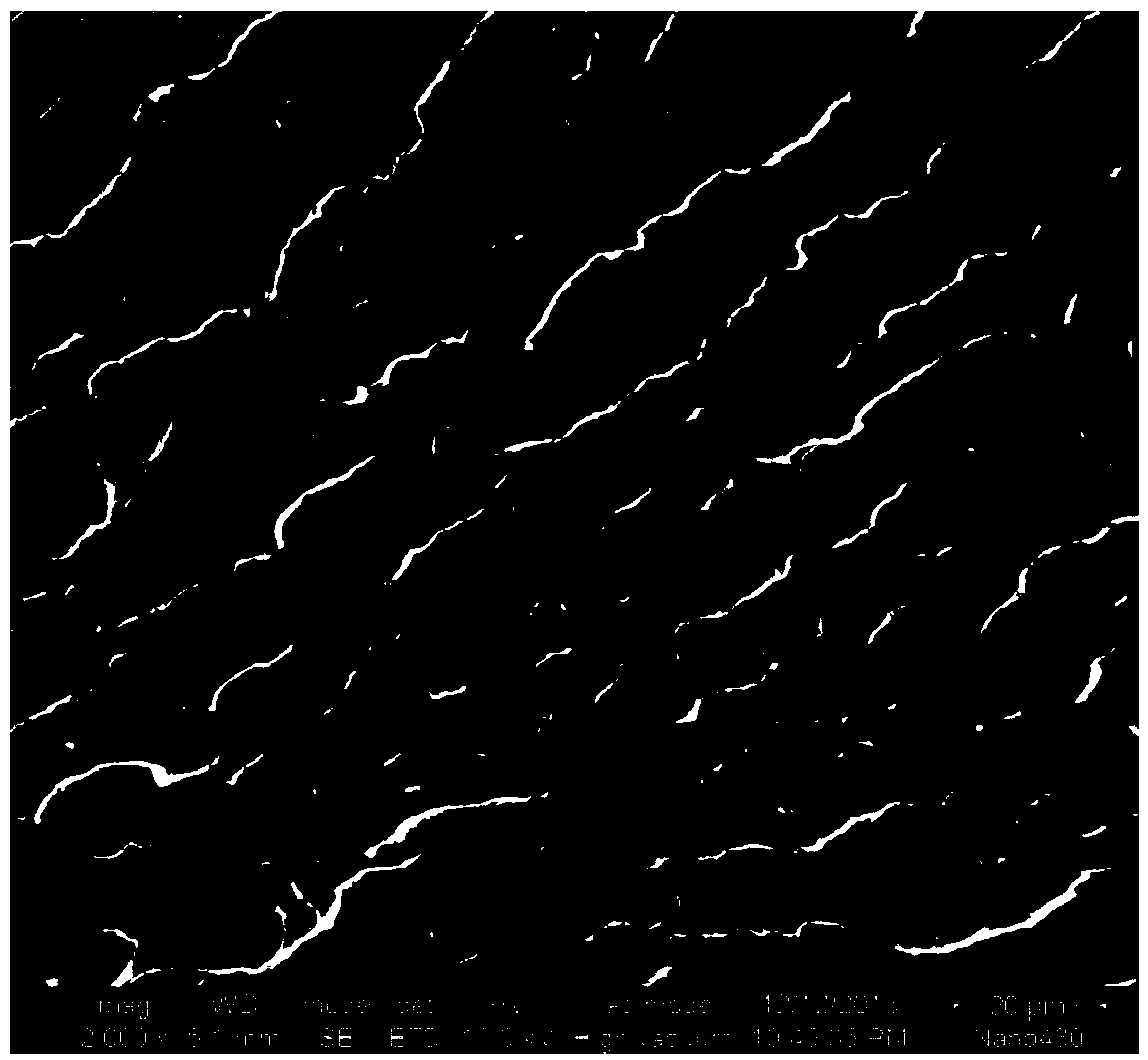

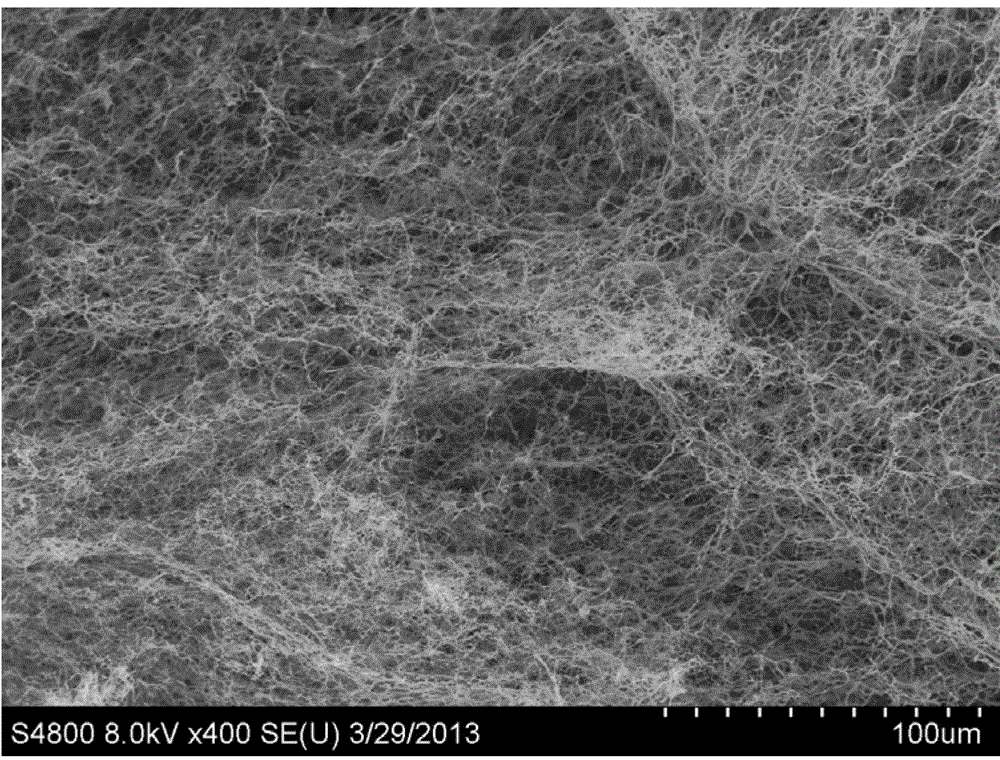

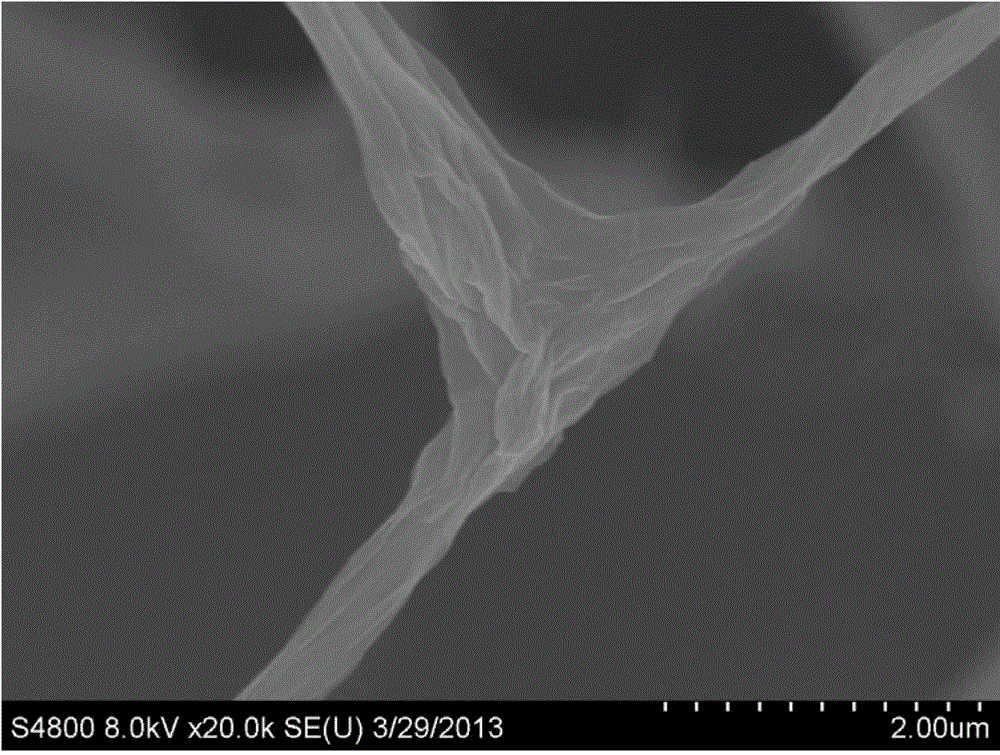

Graphene oxide fiber, preparation method, and preparation method of graphene oxide fiber composite material

The invention provides a graphene oxide fiber, a preparation method of the graphene oxide fiber, and a preparation method of a graphene oxide fiber skeleton based composite material. The preparation method of the graphene oxide fiber comprises the following steps: carrying out quenching setting of an aqueous graphene oxide solution in liquid nitrogen, extruding the graphene oxide between nanometer ice crystals to form a fiber skeleton having a tridimensional network structure, and lyophilizing for sublimating the ice crystals between the graphene oxide in order to realize the in-situ preservation of the fiber skeleton having a tridimensional network structure. The fiber diameter of the prepared graphene oxide fiber skeleton is 100-500nm, and the tensile strength of the graphene oxide fiber compounded with an epoxy resin is 85% higher than that of the graphene oxide fiber, and is 38% higher than that of carbon fiber non-crimp fabric reinforced epoxy resin having a same matrix and a same mass fraction.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

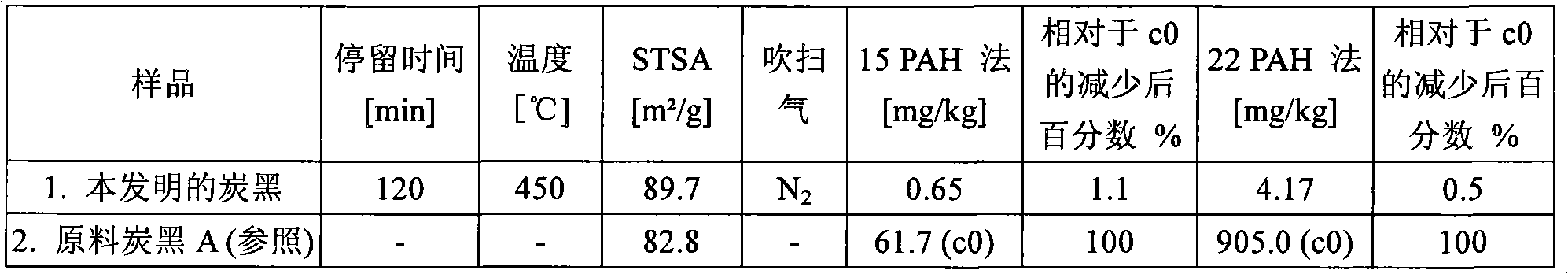

Carbon black, method for its manufacture and application

ActiveCN102060281AControl and regulate input volumeHigh degree of oxidationInorganic pigment treatmentInksPolycyclic aromatic hydrocarbonFuel cells

The invention relates to a carbon black, a method for its manufacture and an application. Carbon black with a content of polycyclic aromatic hydrocarbons measured by the 22 PAH method of less than 5 ppm and an STSA surface area of <90 m2 / g. The carbon black is prepared by treating the starting carbon black with electromagnetic radiation. The carbon black can be used in rubber, plastics, printing inks, liquid inks, inkjet inks, toners, coating materials, paints, adhesives, batteries, pastes, paper, fuel cells, bitumen, concrete and other building materials.

Owner:EVONIK CARBON BLACK GMBH

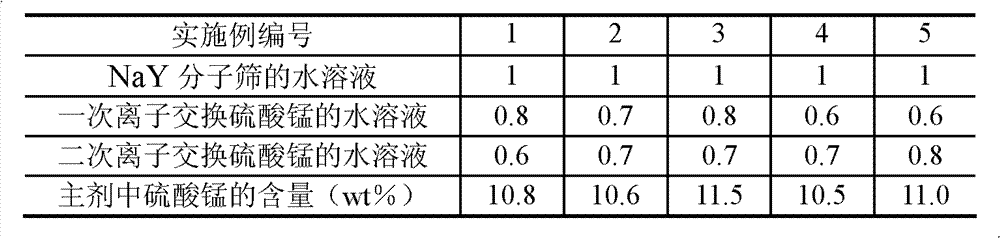

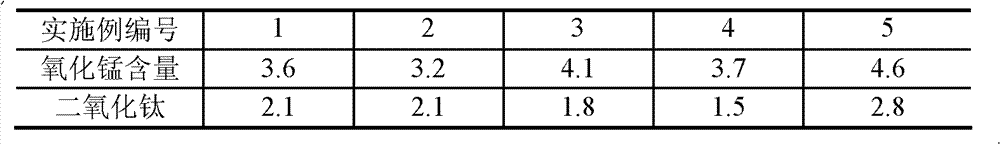

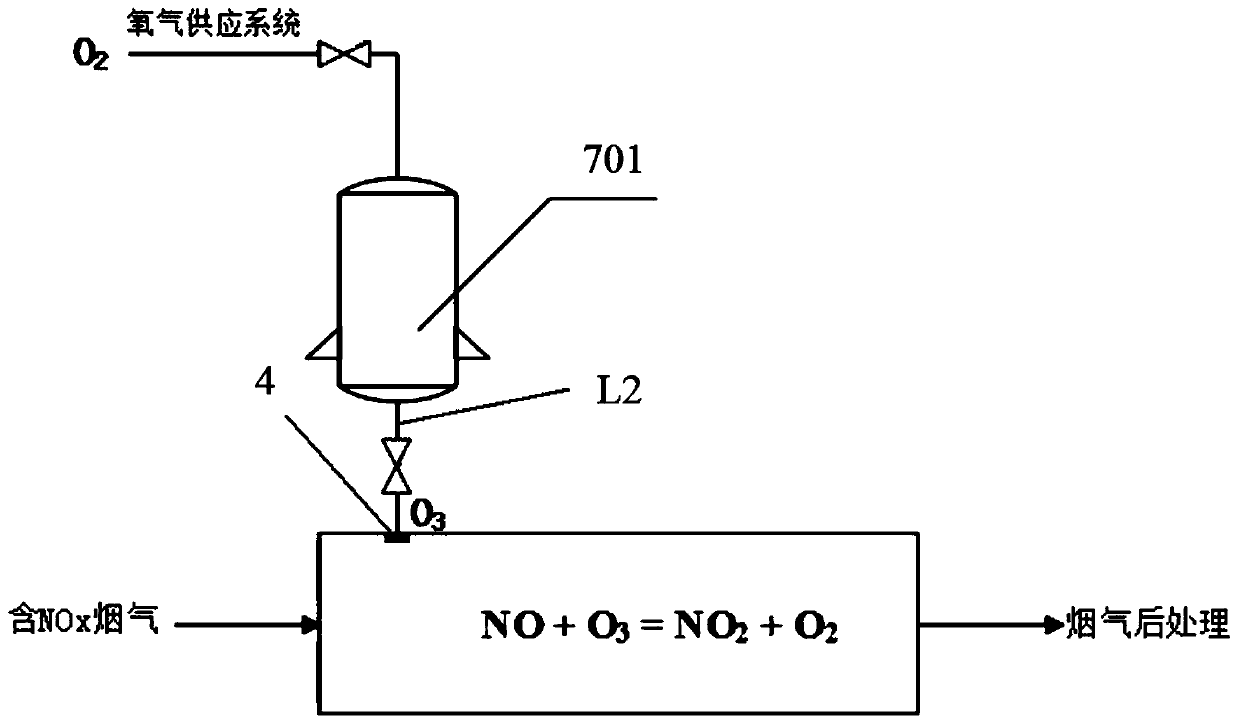

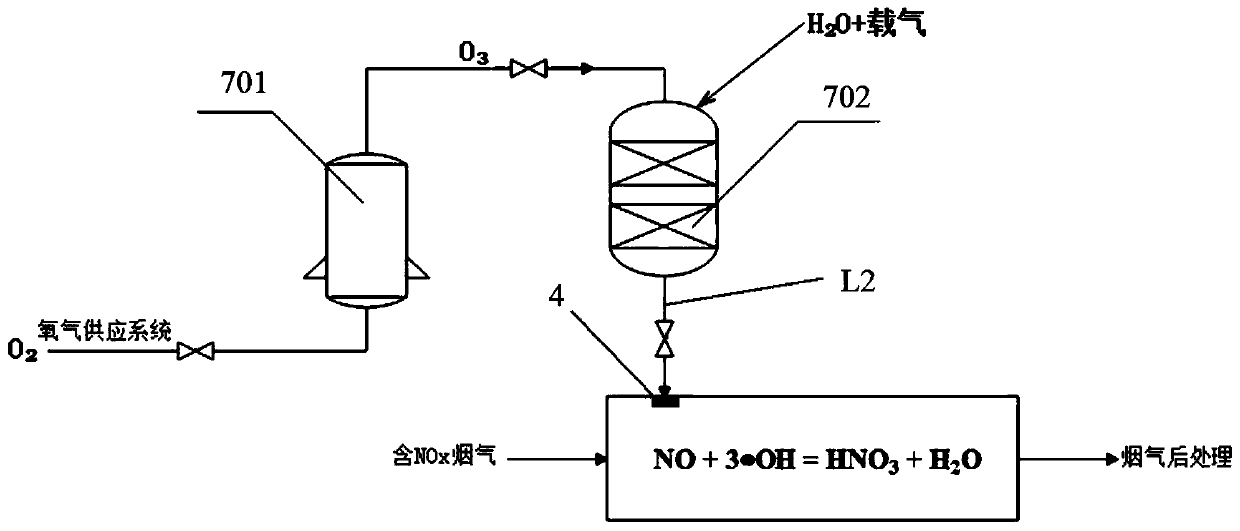

Supported catalytic ozonation catalyst and its preparation method

ActiveCN103240115AHigh activityStable structureMolecular sieve catalystsWater contaminantsMolecular sievePtru catalyst

The invention relates to a catalytic ozonation catalyst and its preparation method. The catalyst is mainly composed of a carrier NaY molecular sieve, active metal oxides manganese oxide and titanium dioxide, and catalyst molding auxiliary agents. The carrier NaY molecular sieve supported with manganese oxide is a main catalyst agent. The content of manganese oxide in the main agent is 10.5wt%-11.5wt%. The catalyst molding auxiliary agents contain kaolin, a binder, a lubricant and a pore forming agent, wherein the weight ratio of the main agent to kaolin is 1:0.3-0.6; the weight ratio of the main agent to the binder is 1:0.5-0.9; the weight ratio of the main agent to the lubricant is 1:0.5-0.85; the weight ratio of the main agent to the pore forming agent is 1:0.02-0.04; and the content of titanium dioxide in the catalyst is 1.5wt%-3.0wt%. By using the NaY molecular sieve as the carrier, by the adoption of ion exchange and dipping methods and with the combination of supporting heterogeneous metal, the comprehensive catalytic ozonation catalyst is prepared. The catalytic ozonation catalyst can be used to process organic wastewater and has advantages of high utilization rate, high dispersiveness, obvious processing effect and long service cycle.

Owner:PETROCHINA CO LTD

Honey-aroma type congou black tea processing method

ActiveCN104886288AConducive to mutual frictionEasy to convertPre-extraction tea treatmentBlack teaFermentation

The invention discloses a honey-aroma type congou black tea processing method and belongs to the technical field of tea processing. The method includes: firstly, picking fresh leaves of large-leaf tea, and placing the fresh leaves of a tea tree in a withering trough for green leaf cooling; repeatedly subjecting the fresh leaves of the tea tree to rocking process and green leaf cooling for twice, and spreading the obtained rocked leaves in the withering trough for withering processing; twisting the obtained withered leaves heavily and slightly alternatively; sending the obtained twisted leaves to a fermentation chamber for fermentation; subjecting the fermented leaves to drying processing, taking out the fermented leaves for sizing and sending to a dryer for drying process after spreading for cooling; spreading and cooling the dried leaves to obtain the spread and cooled leaves which are sent to a baking machine for aroma extraction to obtain the honey-aroma type congou black tea. Compared with the prior art, the honey-aroma type congou black tea processing method has the advantages that the processed tea leaves are tightly knotted and black, even, fragrant, remarkable in honey aroma, red and bright in soup, rich in taste and bright red in infused leaves.

Owner:贵州怡壶春生态茶业有限公司

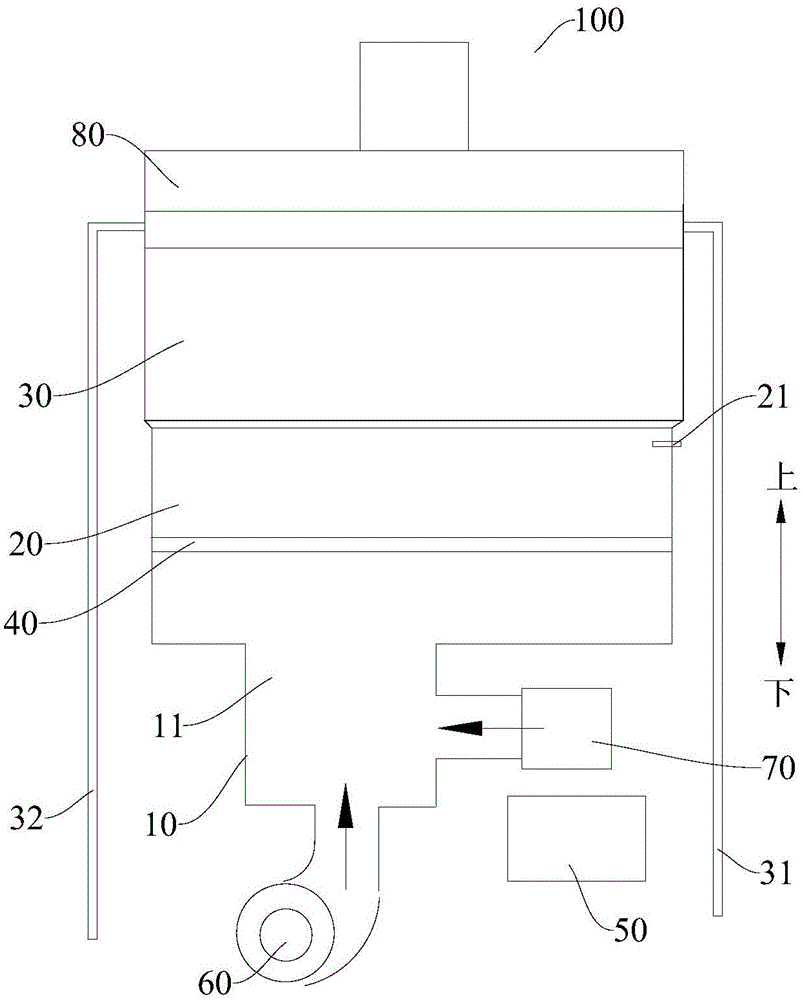

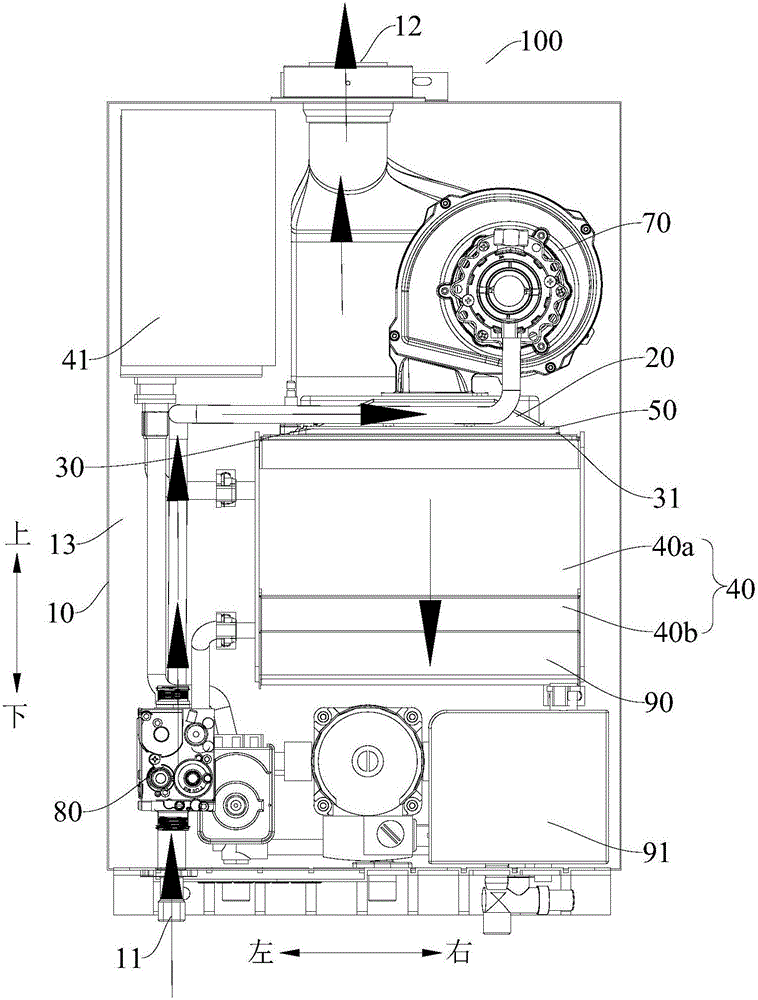

Gas water heater

InactiveCN105841340ASimple structureEasy to assemble and disassembleWater heatersGaseous fuel burnerReaction rateProcess engineering

The invention discloses a gas water heater. The gas water heater comprises a pre-mixing cavity shell, a combustor, a heat exchanger, a pre-heating disc and controller; a mixing cavity is limited in the pre-mixing cavity shell, and the pre-mixing cavity shell is provided with a gas inlet, an air inlet and a mixed gas outlet which are communicated with the mixing cavity; the combustor is communicated with the mixed gas outlet, and a catalyst for catalyzing the combustor to carry out smokeless catalytic combustion is arranged in the combustor; the heat exchanger is connected with the combustor so as to absorb heat generated by combusting of the combustor and is provided with a water inlet and a water outlet; the pre-heating disc is connected with the combustor so as to preheat the combustor; and the controller is connected with the pre-heating disc so as to control heating temperature of the pre-heating disc. According to the gas water heater, the reaction rate of fuel can be improved, the utilization rate of the fuel is improved, generation of harmful gas can be avoided, the fuel can be subject to flameless catalytic combustion in the combustor, generation of the harmful gas is greatly reduced, and use is safe and environment-friendly.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

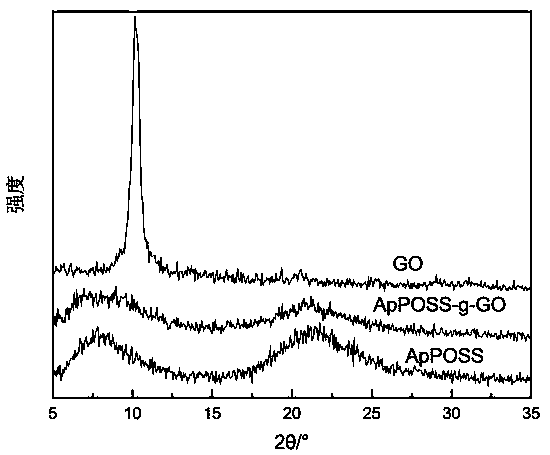

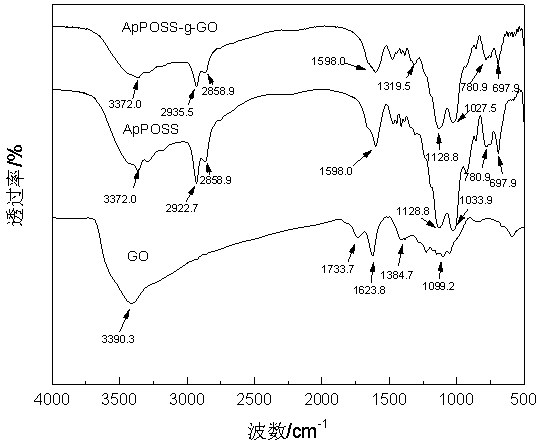

Method for preparing flame retardant epoxy resin from modified graphene

The invention discloses a method for preparing flame retardant epoxy resin from modified graphene, and relates to a method for preparing epoxy resin. The method comprises preparation of graphene oxide; preparation of octa-aminopropyl cage-like silsesquioxane; and modifying of epoxy resin with functionalized graphene, to be more specific, heating and melting the epoxy resin, mixing and curing the epoxy resin and the functionalized graphene to obtain modified epoxy resin. According to the method, the graphene oxide (GO) is prepared by modifying, silane coupling agent KH-550 is used as a raw material for preparation of the octa-aminopropyl cage-like silsesquioxane (ApPOSS), the modified graphene is prepared by grafting reaction of the GO and the ApPOSS, the modified graphene and EP are mixedand cured to improve the compatibility of the modified graphene with the epoxy resin, the modified graphene and the epoxy resin are compounded for preparation of an epoxy resin nanocomposite, and thecomprehensive effect is obvious.

Owner:盘锦职业技术学院

Preparation method of novel graphene composite heat conduction film

ActiveCN104354447AImprove toughnessImprove the shortcomings of brittle and fragileLaminationLamination apparatusCvd grapheneFilm material

The invention relates to a film material, and in particular relates to a preparation method of a novel graphene composite heat conduction film. The preparation method comprises the steps of preparing an oxidized graphene solution by an improved hummers method, and then adding carbon fibers to perform mixed coating to prepare a film, wherein the film is subjected to chemical reduction to obtain the graphene composite heat conduction film. The composite heat conduction film prepared by the method disclosed by the invention can be implemented under normal temperature and normal pressure; furthermore, defects of fragility and hardness of the graphene film are also improved. The heat conduction coefficient of the heat conduction film is 500-2,000w / (m.k), and the tensile strength is 2-100MPa.

Owner:中科悦达(上海)材料科技有限公司

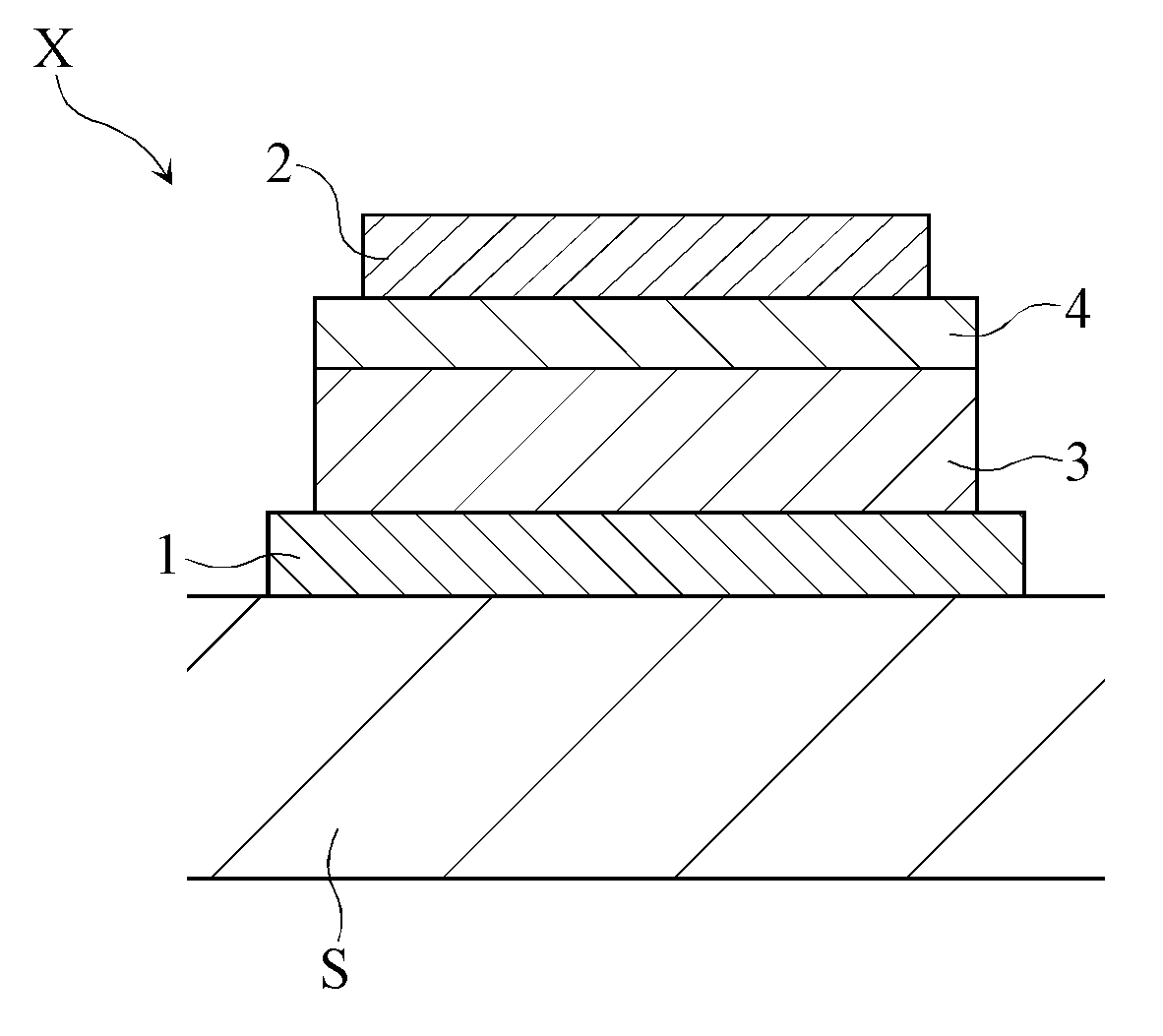

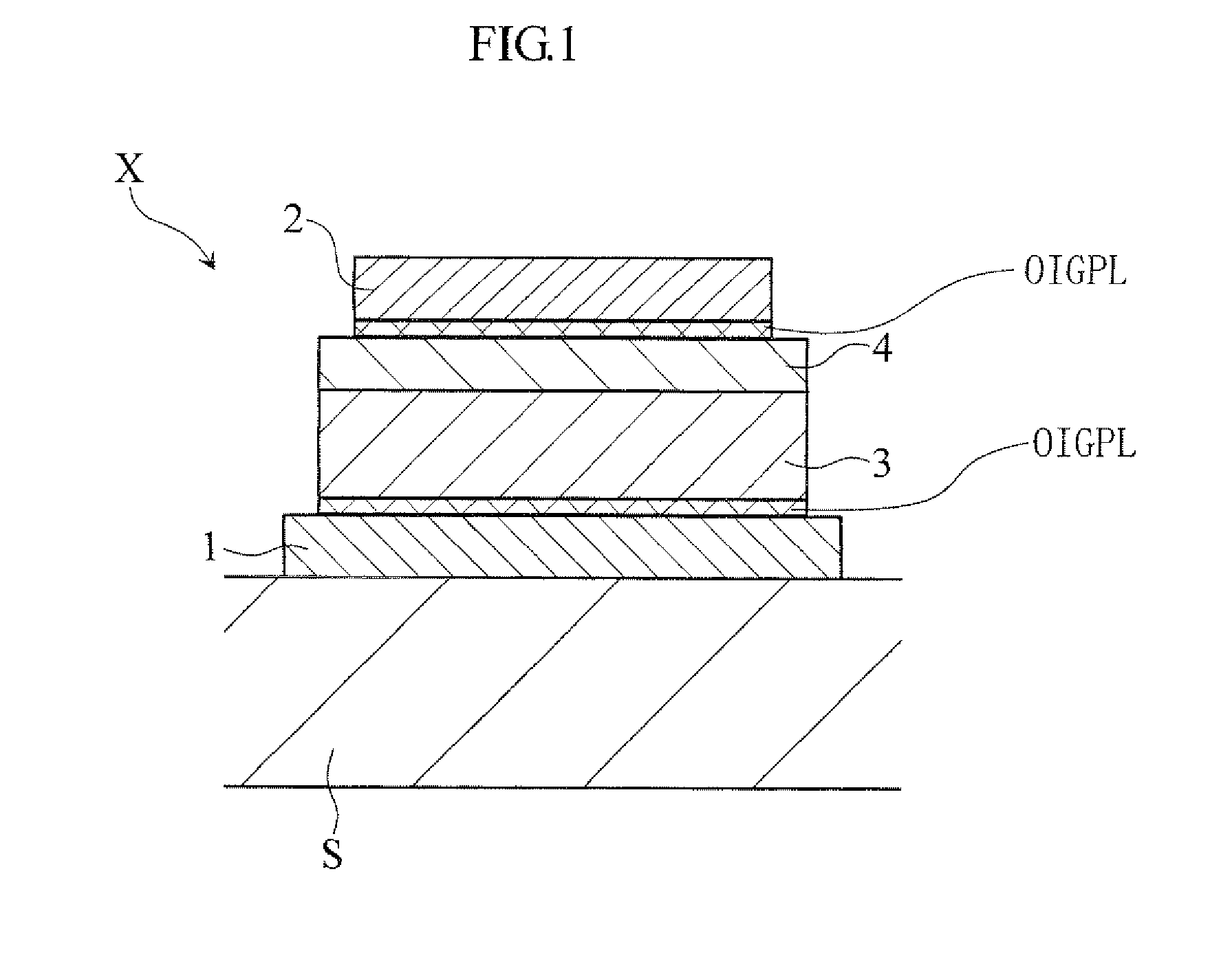

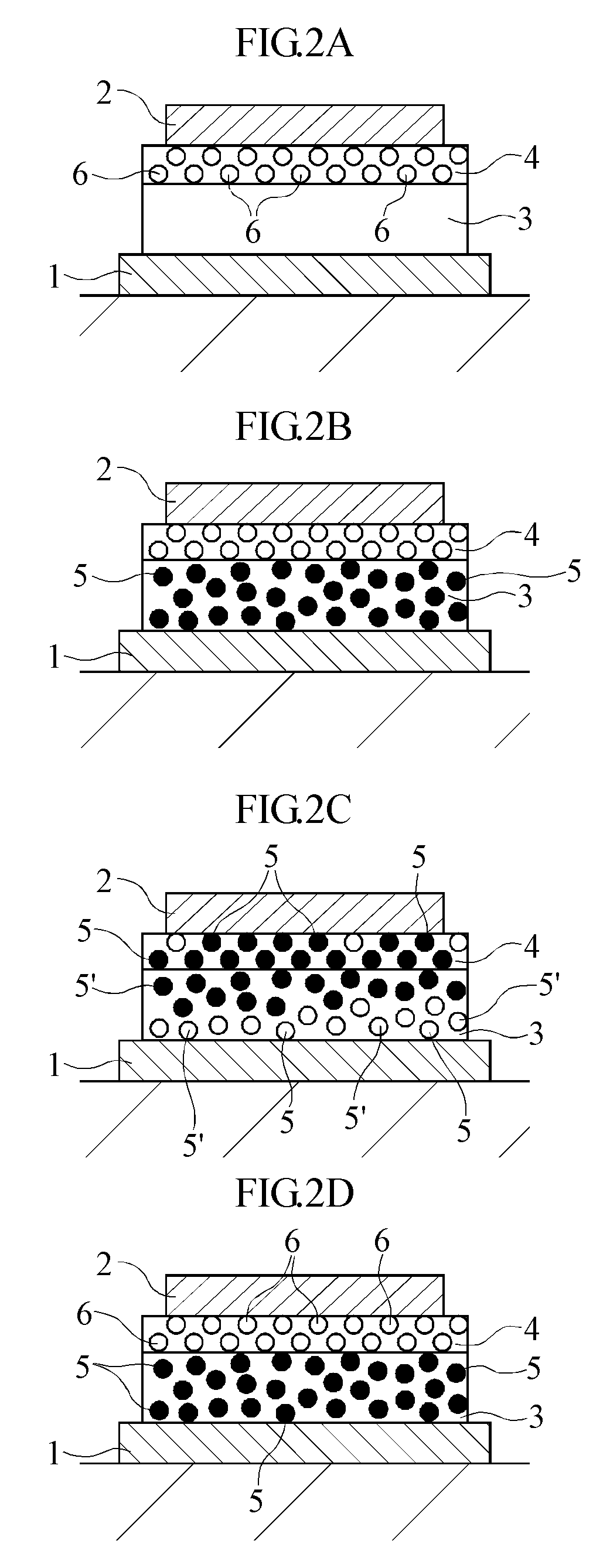

Resistance variable element

InactiveUS8188466B2High degree of oxidationPrevent movementSolid-state devicesDigital storageHigh resistanceOxygen ions

A resistance variable element is provided, which is capable of performing bipolar operation by a specified mechanism and usable as a memory. The resistance variable element has a laminated structure including an electrode, another electrode, an oxide layer between the electrodes, and an oxide layer in contact with the oxide layer between the oxide layer and the electrode. The oxide layer is switchable from the low-resistance state to the high-resistance state by donating oxygen ions to the oxide layer, and from the high-resistance state to the low-resistance state by accepting oxygen ions from the oxide layer. The oxide layer is switchable from the low-resistance state to the high-resistance state by accepting oxygen ions from the oxide layer, and from the high-resistance state to the low-resistance state by donating oxygen ions to the oxide layer.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +1

Wall-broken glossy ganoderma spore powder antioxidation method

InactiveCN101380340APrevent oxidative deteriorationKeep active ingredientsFungi medical ingredientsPharmaceutical non-active ingredientsSporeBULK ACTIVE INGREDIENT

The invention relates to an antioxidation method of sporoderm-broken ganoderma lucidum spore powder, the method is characterized in that vitamin E with 0.1-10 parts by weight is added in ganoderma lucidum spore powder with 100 parts by weight, excipients are added after the ultramicro smashing for breaking sporoderm, and then granules, capsules, tablets and pills are further prepared. The method can effectively prevent the oxidation deterioration of the sporoderm-broken ganoderma lucidum spore powder, maintain active ingredients of the sporoderm-broken ganoderma lucidum spore powder to the maximum extent, improve the quality of the sporoderm-broken ganoderma lucidum spore powder and allow the sporoderm-broken ganoderma lucidum spore powder to have higher utilization ratio and be easily absorbed by human body; the added vitamin E can simultaneously supplement the needs of the human body, thereby being perfect in color, aroma and taste and having more significant health care effect.

Owner:广东南领药业有限公司

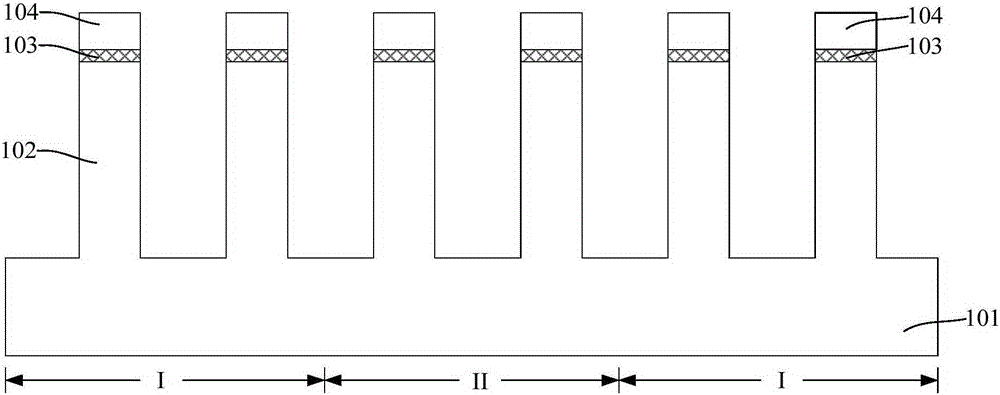

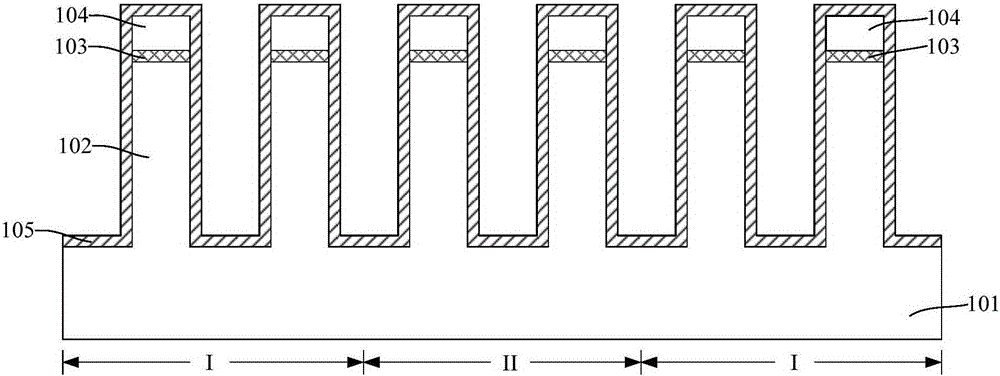

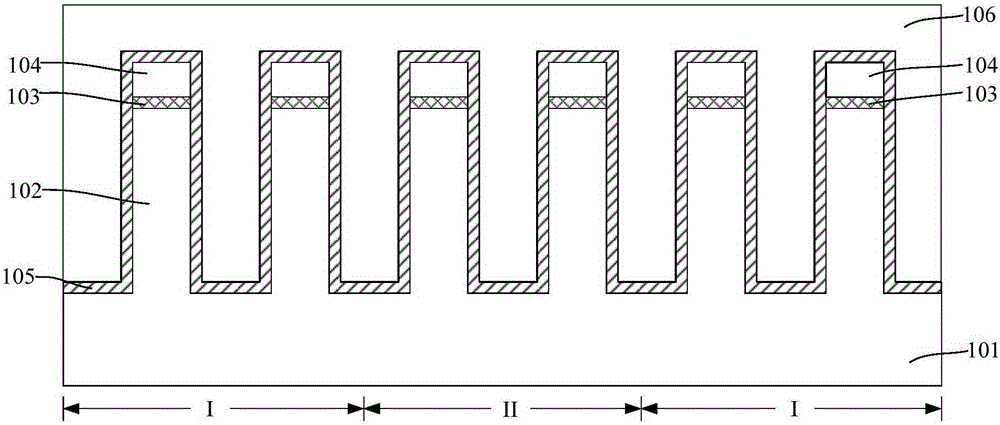

Method for forming fin field effect transistor

ActiveCN106571336AImprove electrical performanceGood feature sizeSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringElectrical performance

A method for forming a fin field effect transistor comprises: providing a substrate, wherein the substrate includes first regions and second regions located between adjacent first regions, a plurality of discrete fins are formed on the surface of the substrate, and the distances between the adjacent fins are the same; fully filling the surface of the substrate between the adjacent fins with a first dielectric layer, wherein the first dielectric layer covers the sidewall surfaces of the fins; removing the first dielectric layer of the second regions to expose the sidewall surfaces of the fins in the second regions; oxidizing the fins of the second regions to convert the fins of the second regions into an oxidizing structure; forming a second dielectric layer on the substrate in the second regions, wherein the second dielectric layer also covers the sidewall surface of the oxidizing structure, and the sidewall surface of the first dielectric layer in the first regions; etching back a part of thickness of the first dielectric layer, the second dielectric layer, and the oxidizing structure. The method forms a number of fins with different pattern densities and with good feature sizes and morphology so as to improve the electrical performance of the fin field effect transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

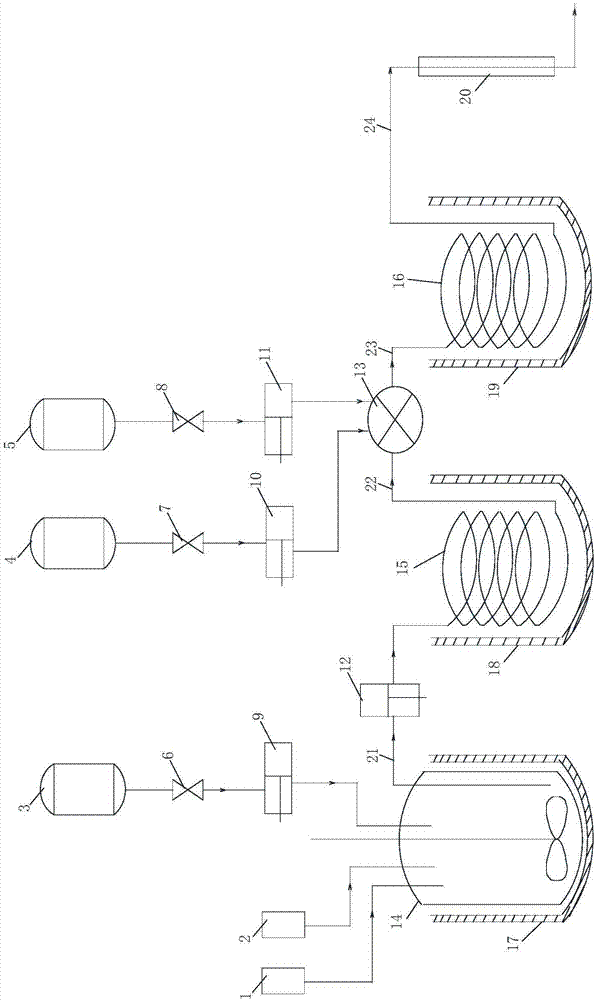

Method and device for preparing graphene oxide

The invention relates to the field of preparation of graphene oxide, in particular to a method for preparing graphene oxide. The method comprises the following steps of adding graphite, acid and an oxidant into a material mixing kettle, mixing at low temperature, sending into a first pipeline reactor, and performing oxidizing reaction; adding a solvent and a reducing agent, uniformly mixing, sending into a second pipeline reactor, dispersing and reducing, and performing post-treatment, so as to obtain the graphene oxide. The method has the advantages that the material mixing and reaction types are controlled by pipelines, so that the defect of one-pot boiling type of the traditional kettle type reactor is overcome; the production process is safe and efficient, the product quality is more stable, the continuity of the material in the reaction process is guaranteed, the materials are uniformly mixed, and the utilization rate of the oxidant of potassium permanganate is higher; the oxidizing degree of a product is higher, and the method is suitable for industrialized production.

Owner:JIANGNAN GRAPHENE RES INST +3

Preparation method of thin-layer graphene oxide material

The invention discloses a preparation method of a thin-layer graphene oxide material. As preferable one of embodiments, the preparation method of the thin-layer graphene oxide material comprises the following steps of: sufficiently mixing graphene microchip, acid solvent and oxidant uniformly for reacting under a set temperature; and washing the mixture to be neutral and untrasonically treating the mixture to obtain the thin-layer graphene oxide material. A reducing agent is added to the thin-layer graphene oxide to carry out the reducing reaction to produce the reduced thin-layer graphene oxide material. Furthermore, the obtained thin-layer graphene oxide and the reduced thin-layer graphene oxide are dispersed in a solvent to obtain thin-layer graphene oxide dispersion liquid and reduced thin-layer graphene oxide dispersion liquid. The preparation method disclosed by the invention is simple in process, simple in needed equipment, safe and simple to operate, low in cost, strong in controllability, easy to realize large-scale industrial production, and capable of expanding the different application needs of the graphene oxide.

Owner:苏州格瑞丰纳米科技有限公司

Preparation method of graphene for heater

InactiveCN106276874AHigh degree of oxidationIncrease layer spacingSingle layer grapheneAfter treatmentHydrogen

The invention relates to the technical field of graphene, in particular to a preparation method of graphene for a heater. The method is characterized in that the graphene is prepared by adopting an oxidation-reduction method and specifically comprises the following steps: firstly, peroxidation of the graphene; secondly, oxidization of graphite, wherein oxidation treatment comprises four stages, namely low-temperature reaction, medium-temperature reaction, high-temperature reaction and after treatment; in the low-temperature reaction and the medium-temperature reaction, an ultrasonic and mechanical stirring combined action is adopted, and hydrogen is introduced into a reaction system; thirdly, preparation of the graphene, wherein a drying mode in the preparation process adopts freeze drying. According to the preparation method of the graphene for the heater, provided by the invention, a production process is controllable, and large-scale production can be realized; nano ions are not easy to agglomerate in the preparation process; a prepared graphene crystal is complete in structure and excellent in conductivity.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

Method for preparing graphene/polyaniline composite film electrode

ActiveCN105810455ASimple and fast operationShort timeHybrid capacitor electrodesHybrid/EDL manufactureFiberComposite film

The invention discloses a method for preparing a graphene / polyaniline composite film electrode. The method comprises the following steps: adding aniline in hydrochloric acid, and stirring to obtain a product A; adding ammonium persulfate in the hydrochloric acid, and stirring to obtain a product B; mixing the product A with the product B, stirring, filtering, cleaning through distilled water and alcohol, and drying a sample obtained by filtering to obtain a product C; adding the product C in deionized water, and carrying out an ultrasonic oscillating treatment until a homogeneous polyaniline aqueous solution is obtained, namely, a product D; adding graphite oxide in the product D, and carrying out the ultrasonic oscillating treatment to obtain a product E; stewing the product E to obtain a product F; depositing the product F on a flexible plastic film, and drying to obtain a product G; soaking the product G in a hydrogen iodide solution, reducing, and cleaning to obtain a product H; soaking the product H in a hydrochloric acid solution, and drying to obtain a product I. The composite film of graphene / polyaniline fibers prepared by the method disclosed by the invention can be directly used as an electrode material of a flexible film super capacitor, and the method is simple to operate, short in time consumption, little in material consumption and is environmental friendly.

Owner:GUIZHOU UNIV

Preparation method for high-electrical-conductivity graphene material

InactiveCN104629049AHigh degree of oxidationImprove conductivityOrganic conductorsPolypyrroleSolvent

The invention discloses a preparation method for a high-electrical-conductivity graphene material, and is characterized in that the preparation method comprises the following steps: (1) pre-processing graphite, (2) preparing a graphene oxide solution, (3) preparing a graphene colloid, (4) preparing a graphene composite material, and (5) obtaining the electrically conductive material. The oxidation degree of the obtained graphite oxide is higher, and the graphene oxide can still be adsorbed on the surface of polymer particles during a reduction process, all used solvents can be recycled, and the cost is saved. Process conditions are simple, the cost is low, polypyrrole in the prepared composite material is evenly coated with graphene, and the composite material as a super capacitor is high in electrical conductivity and good in electrochemical performance and can be used in super capacitor electrode materials, fuel cell materials, catalysis and the like.

Owner:QINGDAO WEITENG GRAPHITE

Gas water heater

InactiveCN105823204ASimple structureEasy to assemble and disassembleWater heatersGaseous fuel burnerNitrogen oxidesEngineering

The invention discloses a gas water heater which comprises a shell, a premixing cavity shell, a burner, a heat exchanger, a preheating plate and a controller, wherein an accommodating cavity is defined inside the shell; the shell has an exhaust hole, a hot water outlet and a cold water inlet; the premixing cavity shell is arranged in the accommodating cavity; a mixing cavity is defined in the premixing cavity shell; the burner is arranged below the mixing cavity, and communicates with the mixing cavity; a catalyst for allowing smokeless catalytic combustion of a catalytic burner is arranged in the burner; the heat exchanger is arranged below the burner and is connected with the burner for absorbing heat generated from combustion of the burner; the heat exchanger has a water inlet and a water outlet; the water inlet communicates with the cold water inlet; the water outlet communicates with the hot water outlet; the preheating plate is connected with the burner for preheating the burner; and the controller is connected with the preheating plate for controlling the heating temperature of the preheating plate. According to the gas water heater provided by the embodiment of the invention, the generation of carbon monoxide and nitrogen oxide can be controlled from the source, and the utilization is safe and environment-friendly.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

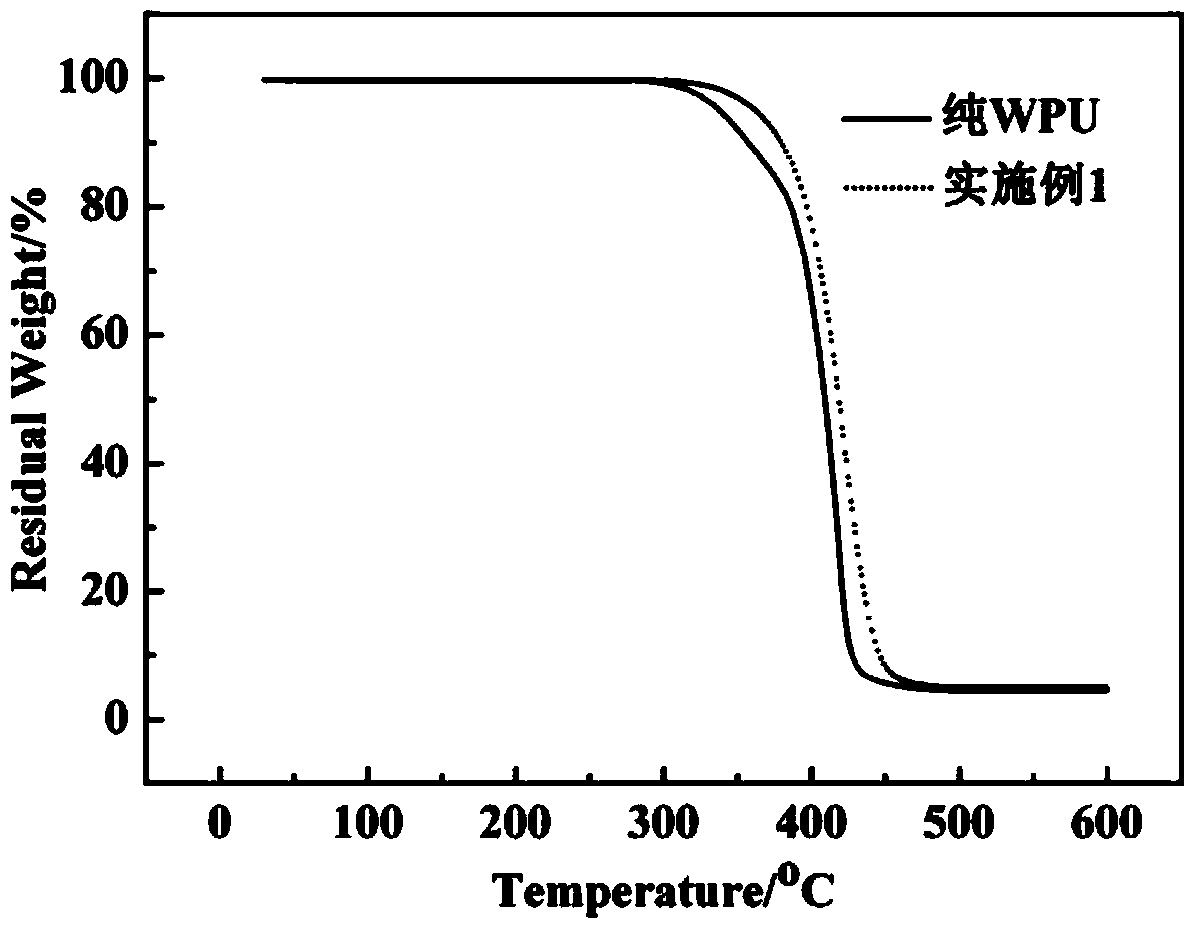

Graphene oxide sulfonate type waterborne polyurethane composite material and preparation method thereof

The invention discloses a graphene oxide sulfonate type waterborne polyurethane composite material and a preparation method thereof. The preparation method comprises the following steps of (1) preparing graphite oxide by using an improved Hummers method; (2) dispersing the prepared graphite oxide into water to prepare an aqueous dispersion solution of graphene oxide; and (3) blending the aqueous dispersion solution of graphene oxide and a sulfonate type waterborne polyurethane emulsion to prepare the graphene oxide sulfonate type waterborne polyurethane composite. The two components in the graphene oxide sulfonate type waterborne polyurethane composite material prepared by the invention are relatively good in compatibility; and in addition, the thermal stability of sulfonate type waterborne polyurethane is improved through graphene oxide modification.

Owner:SOUTH CHINA UNIV OF TECH

Deep desulfurization method for diesel by coupling of oxidation and extraction

InactiveCN101717659AHigh catalytic activityHigh yieldCatalyst activation/preparationTreatment with plural serial refining stagesTungstateCatalytic oxidation

The invention relates to a deep desulfurization method for diesel by coupling of oxidation and extraction, that is a catalyzed oxidation desulfurization method for diesel in petroleum refining technologies. The method comprises the following steps of crushing and fine grinding a zirconium hydroxide carrier, dipping into impregnation liquid formed by aqueous ammonium meta-tungstate solution, placing the impregnation liquid in an ultrasonic generator to carry out ultrasonic facilitating impregnation, boiling off water after the impregnation is finished, drying and baking at high temperature to obtain a WO3 / ZrO2 super solid acidic catalyst; adding aqueous hydrogen peroxide solution, extraction solvent and the WO3 / ZrO2 super solid acidic catalyst in diesel containing sulfur, carrying out catalyzed oxidation desulfurization reaction under the action of power ultrasonics, cooling to the room temperature after the reaction is finished, separating and recycling the solid catalyst, standing and layering, wherein the upper layer is desulfurized diesel and the lower layer can be reused after regeneration. The invention has simple process, mild condition, high desulfurization degree and gasoline recovery, low cost and no pollution to environment and can obtain ultra-low sulfur clean diesel products.

Owner:YANGZHOU UNIV

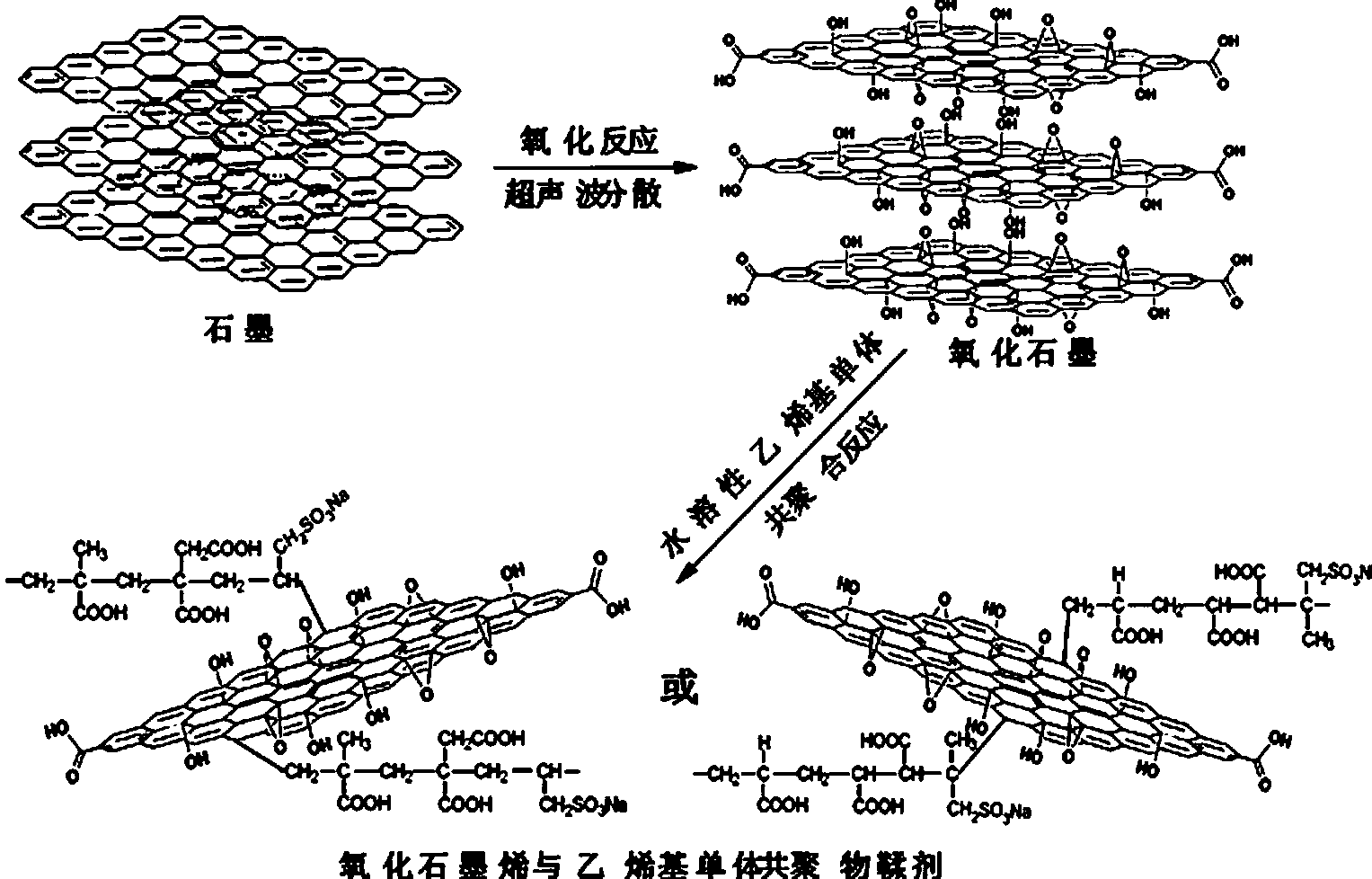

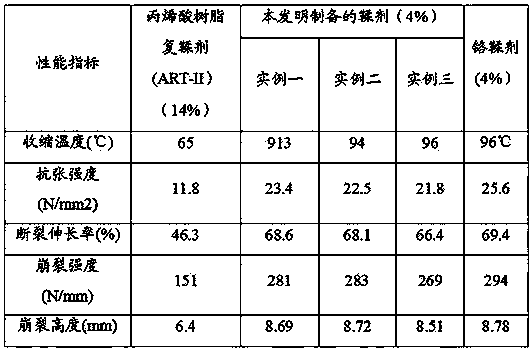

Oxidized graphene and water-soluble vinyl monomer copolymerized leather tanning agent and preparation method thereof

The invention discloses an oxidized graphene and water-soluble vinyl monomer copolymerized leather tanning agent. The leather tanning agent is prepared from the following raw materials in parts by weight: 20-30 parts of oxidized graphene nanosheet dispersion liquid, 0.5-1 part of an oxidizing agent, 60-80 parts of a monomer mixed solution, and 20-30 parts of an initiator. The invention further discloses a preparation method of the oxidized graphene and water-soluble vinyl monomer copolymerized leather tanning agent. The preparation method adopts the water-solution free radical polymerization reaction to implement the free radical copolymerization reaction for double bonds in the oxidized graphene structure and the water-soluble vinyl monomer, so that the obtained copolymer both comprises the oxidized graphene nanosheet and the water-based vinyl structural unit; furthermore, the size of the oxidized graphene nanosheet can be reduced and the distribution can be more uniform, and the tanning agent can generate the chemical bond function and the nanometer size effect after the tanning agent permeates the leather collagenous fibers, so as to obtain the tanning effect on the leather fibers; the tanning agent can serve as the leather tanning agent separately.

Owner:苏州盛泽科技创业园发展有限公司

Preparation method for catalysis/adsorption material by taking kieselguhr as carrier

InactiveCN104226240AExtended stayHigh degree of oxidationOther chemical processesDispersed particle separationGlass fiberAlcohol

The invention discloses a preparation method for a catalysis / adsorption material by taking kieselguhr as a carrier. The preparation method comprises the following steps of adding 15-20 parts of absolute ethyl alcohol into 1 part of purified kieselguhr, then adding 1-3 parts of a metal compound, 0.1-0.3 part of aluminum oxide, 0.1-0.3 part of glass fibers, 0.02-0.04 part of nitric acid and 5-7 parts of deionized water in sequence under magnetic stirring for mixing and stirring; performing centrifugal washing on obtained substances by the deionized water; and drying washed ore pulp at first, and then calcining the ore pulp, thus obtaining the catalysis / adsorption material. The catalysis / adsorption material prepared by the method disclosed by the invention can prolong the retention time of organic pollutants in a reactor by using the adsorption capacity of kieselguhr, and loaded metal oxide can generate a relatively good catalytic oxidation effect in a discharging process, so that the oxidization degree of organic pollutants is increased.

Owner:杭州最清环保科技有限公司 +1

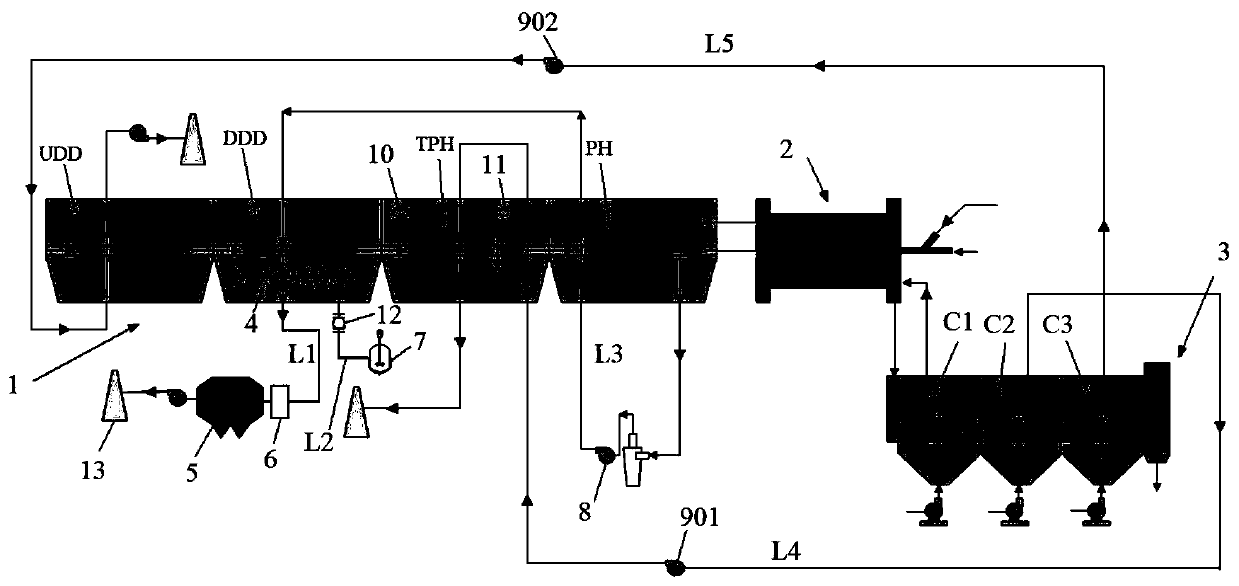

Oxidized pellet production process and system using chain grate-rotary kiln system

ActiveCN110894573AReduce wind temperatureIncrease wind temperatureRotary drum furnacesThermodynamicsProcess engineering

The invention discloses an oxidized pellet production process using a chain grate-rotary kiln system, which comprises the following steps: (1) green pellets are dried, preheated and oxidized through achain grate, then materials passing through the chain grate are conveyed to the rotary kiln to be roasted and then conveyed to an annular cooler to be cooled, and pellet ore is obtained; 2) hot air exhausted from the first circular cooling section is conveyed to the rotary kiln, the hot air exhausted from the rotary kiln is conveyed to a second preheating section, and the hot air exhausted from the second preheating section is conveyed to an air draft drying section in an air draft manner; 3) hot air exhausted from the second annular cooling section is conveyed to the first preheating sectionin an air blowing manner; and 4) the hot air exhausted from the third annular cooling section is conveyed to an air blast drying section in an air blast manner. According to the scheme, hot air is blown into the first preheating section, so that the air pressure in the first preheating section is greater than that of the second preheating section, and gas in the first preheating section does notneed to be denitrified; and meanwhile, a stable hot air area is formed in the first preheating section, and the preheating effect of upper-layer and lower-layer pellets is guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Graphene oxide fiber, preparation method, and preparation method of graphene oxide fiber composite material

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com