Carbon black, method for its manufacture and application

A technology of carbon black and polycyclic aromatic hydrocarbons, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of reducing the content of functional groups and reducing the degree of oxidation of volatile components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

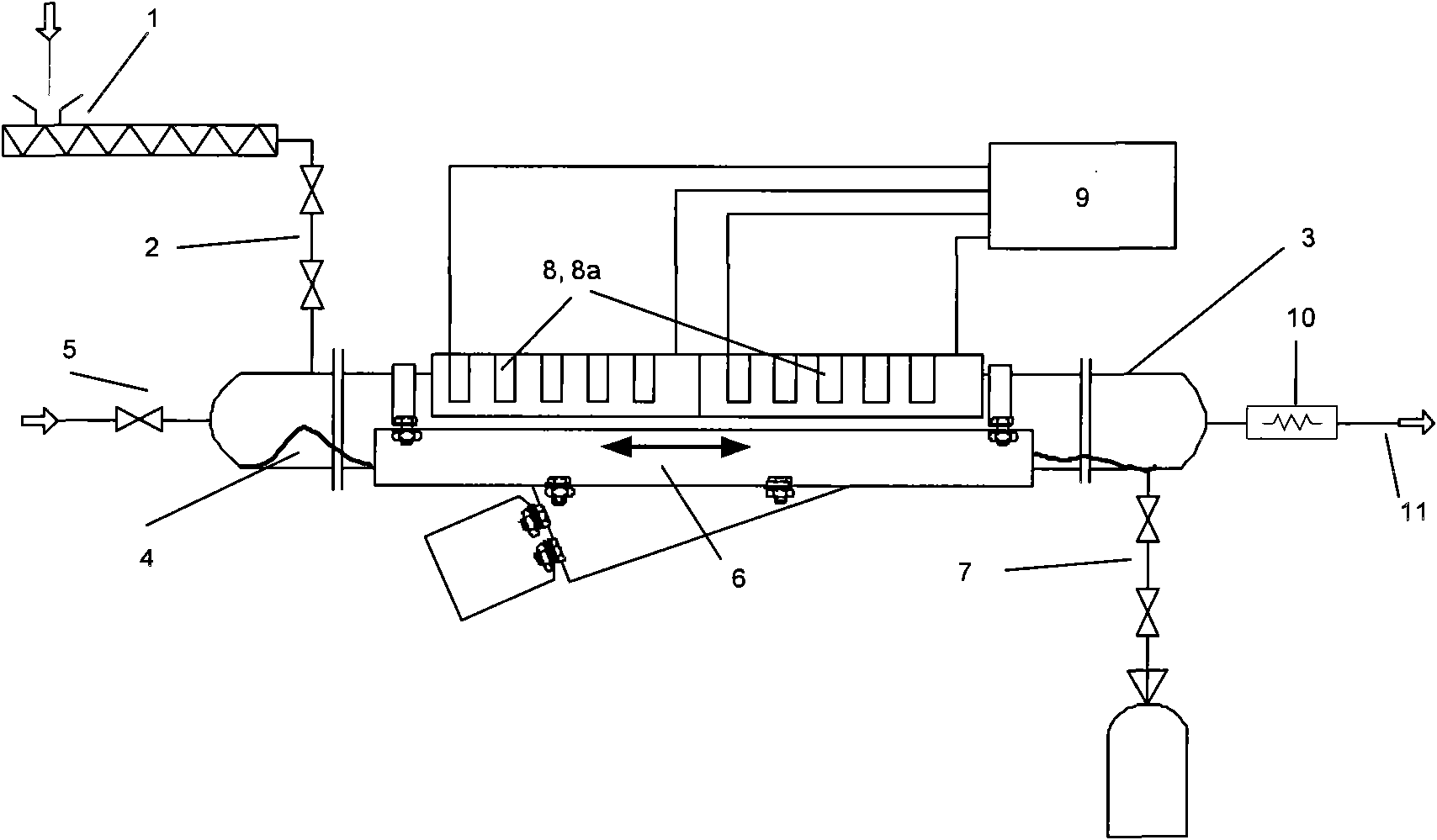

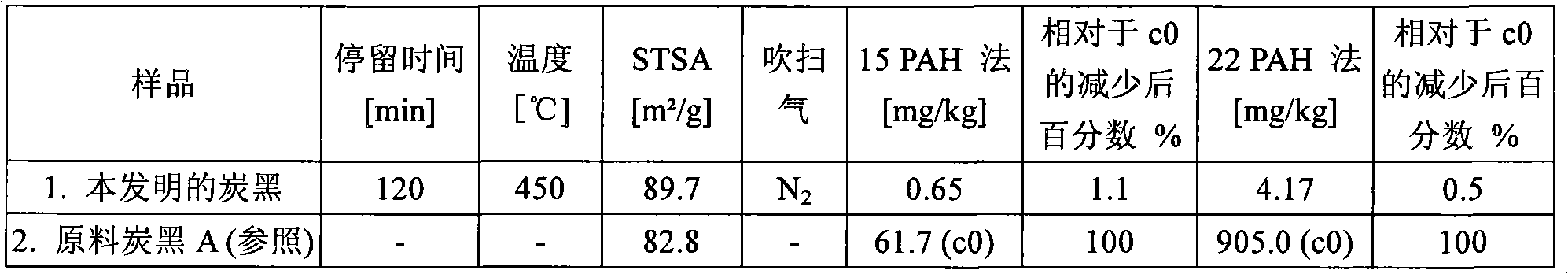

[0125] In order to reduce the content of polycyclic aromatic hydrocarbons (PAHs), the pelletized carbon black was figure 1 Processing was performed in the IR pilot plant shown. The residence times and temperatures are shown in Table 1.

[0126] The raw carbon black used was raw carbon black A. In the test series described here, the PAH content was determined according to the 22PAH method and the 15PAH method (Table 1).

[0127] Table 1

[0128]

[0129] It was found that PAHs could be reduced to less than 1% of the original loading of PAHs.

Embodiment 2

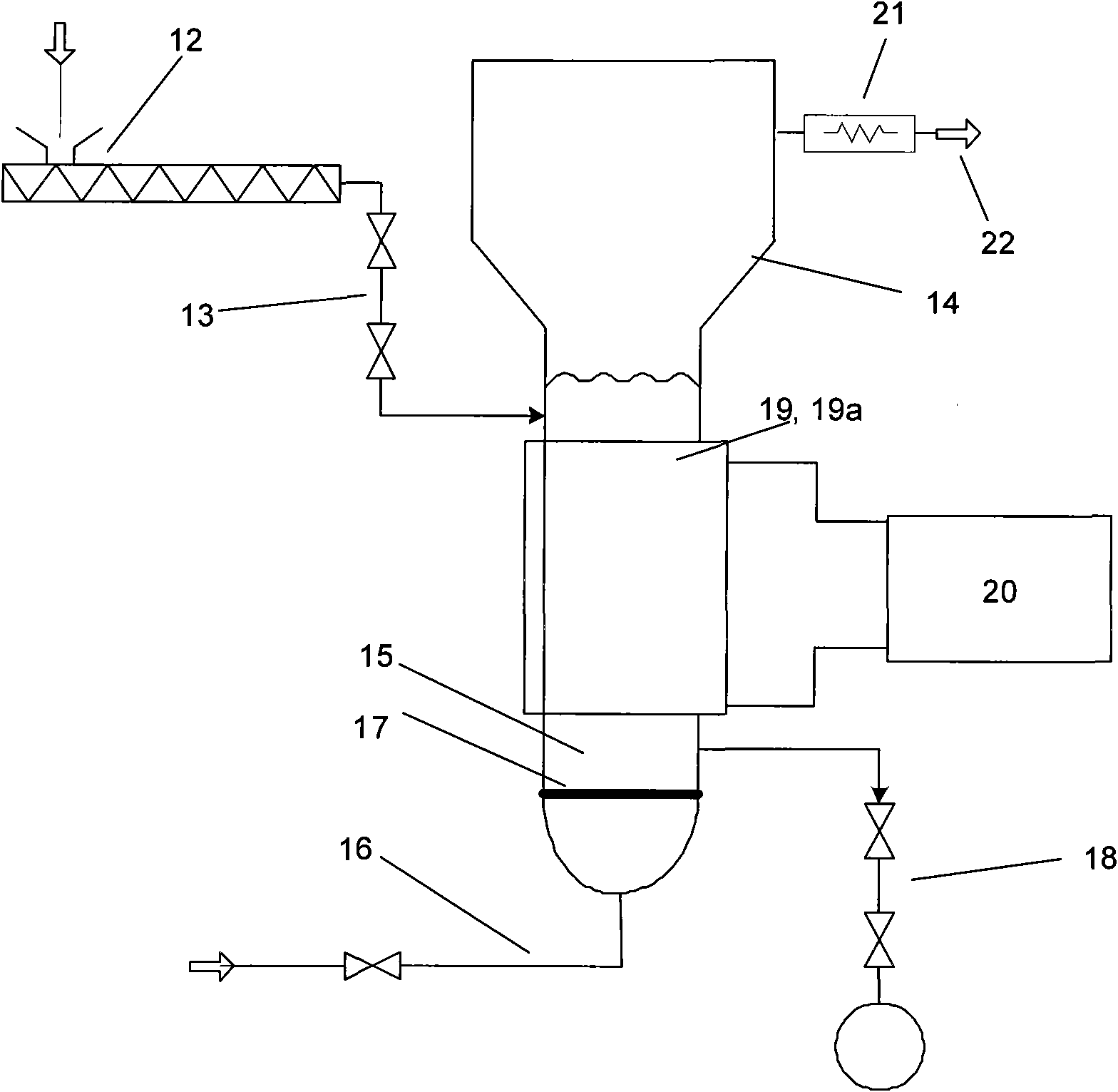

[0131] In order to reduce the content of polycyclic aromatic hydrocarbons (PAHs), in such as figure 2 The pelletized carbon black was processed in the microwave system shown. The residence times and temperatures are shown in Table 2.

[0132] The raw carbon black used was raw carbon black A. In the test series described here, the PAH content was determined according to the 22PAH method and the 15PAH method (Table 2).

[0133] Table 2

[0134]

[0135] n.d. = not determined

[0136] In the case of the microwave-treated samples, a very significant reduction of PAHs to 0.1% of the original loading of PAHs was achieved.

Embodiment 3

[0138] exist figure 2 In the microwave system shown, about 80 g of raw carbon black A was added. The microwave reactor was purged with nitrogen (5 l / h) before the start of the experiment, then irradiated with microwaves, and after the end of the experiment, the reactor was cooled to a temperature <120°C under nitrogen.

[0139] The residence time and temperature were varied from 1-20 min and 400-600°C, respectively. The time after reaching the target temperature is measured.

[0140] The temperature was recorded by PC.

[0141] In Table 3, different parameters were varied.

[0142] table 3

[0143]

[0144] In the case of the carbon blacks of the invention, the content of PAHs is significantly reduced. At 600°C, the content of PAHs decreased to less than 0.4ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com