Patents

Literature

43 results about "Test series" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for correcting faults in a passive optical network

ActiveUS8090258B2Transmission monitoringTransmission monitoring/testing/fault-measurement systemsSignal-to-noise ratio (imaging)Engineering

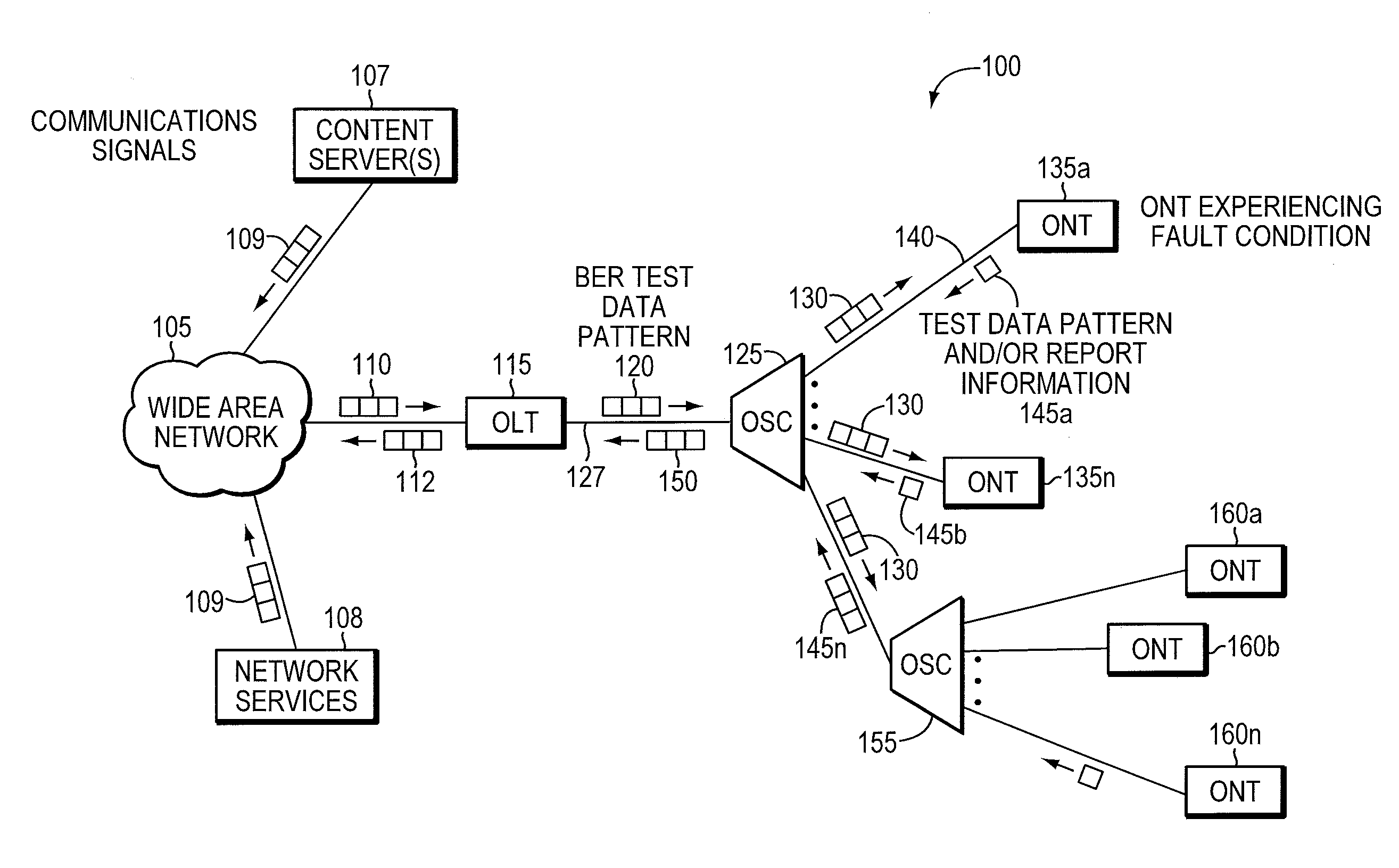

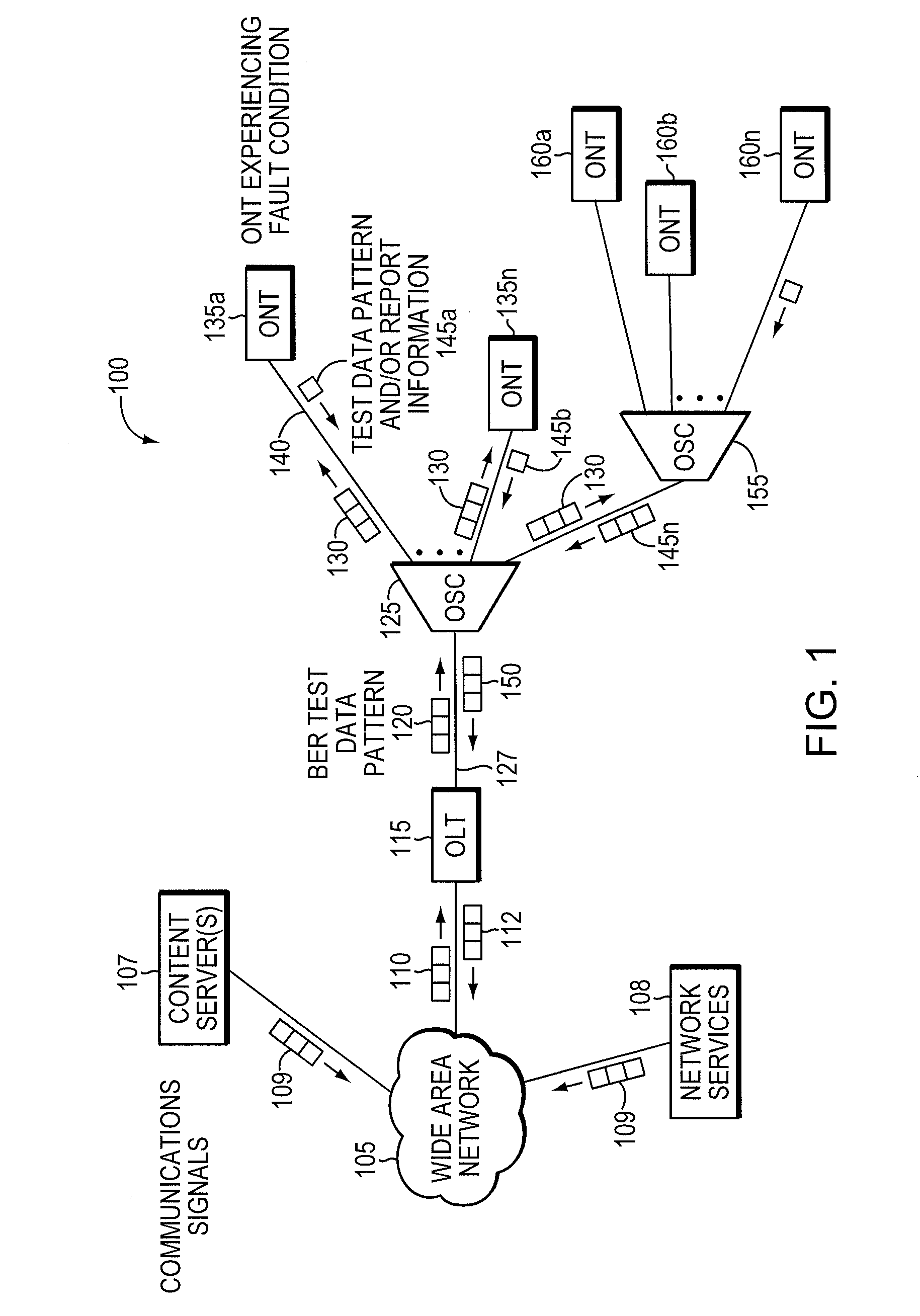

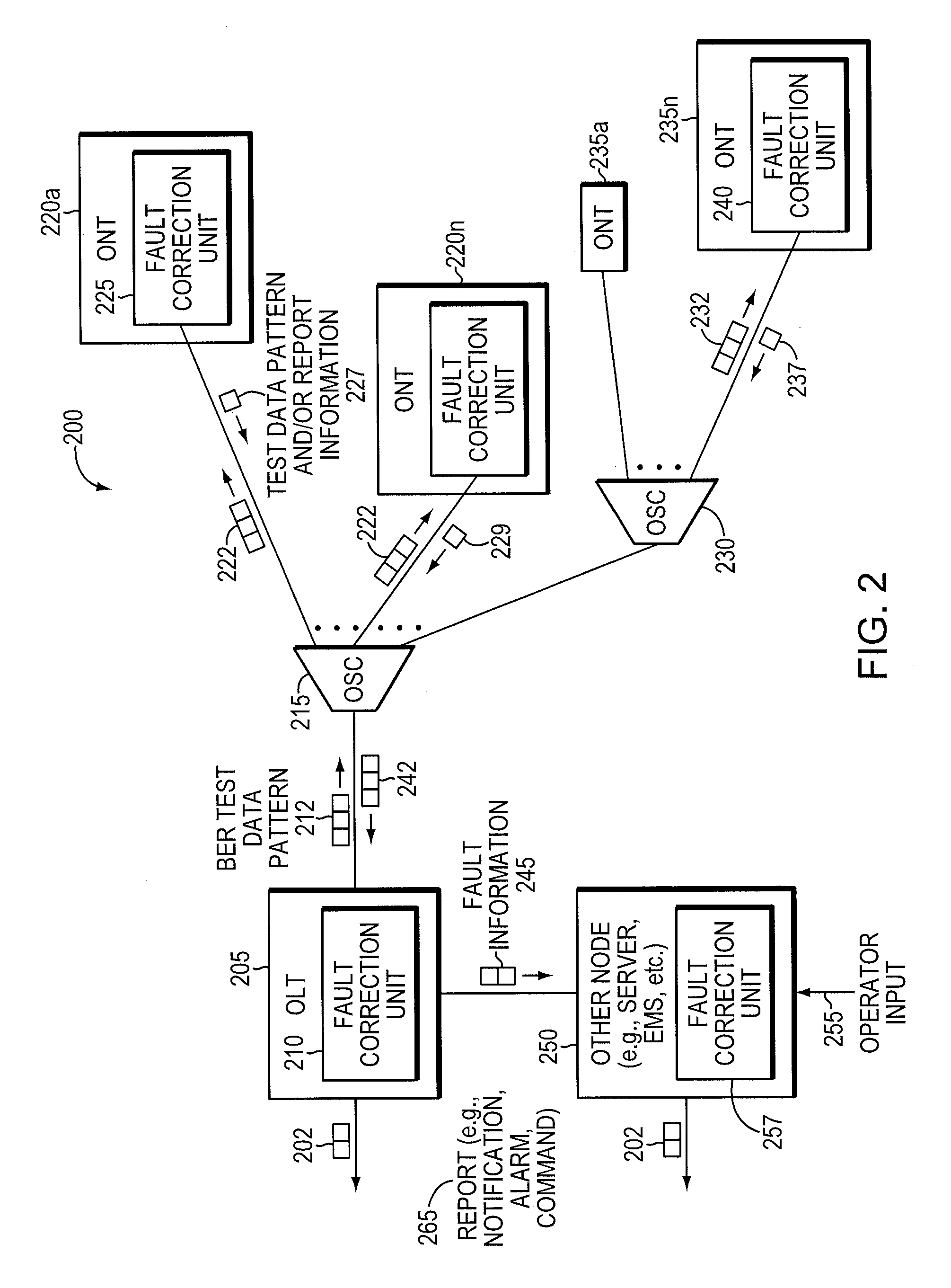

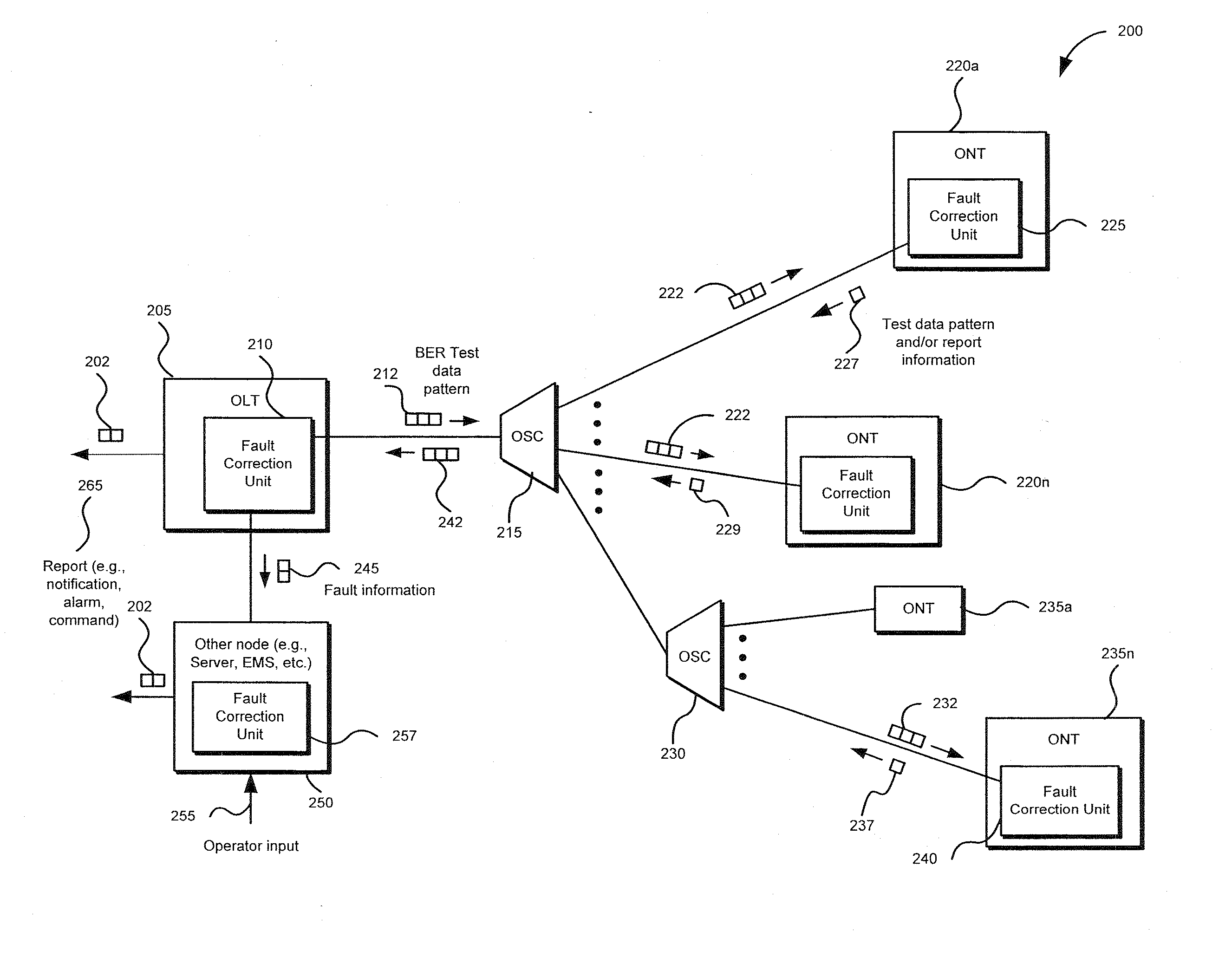

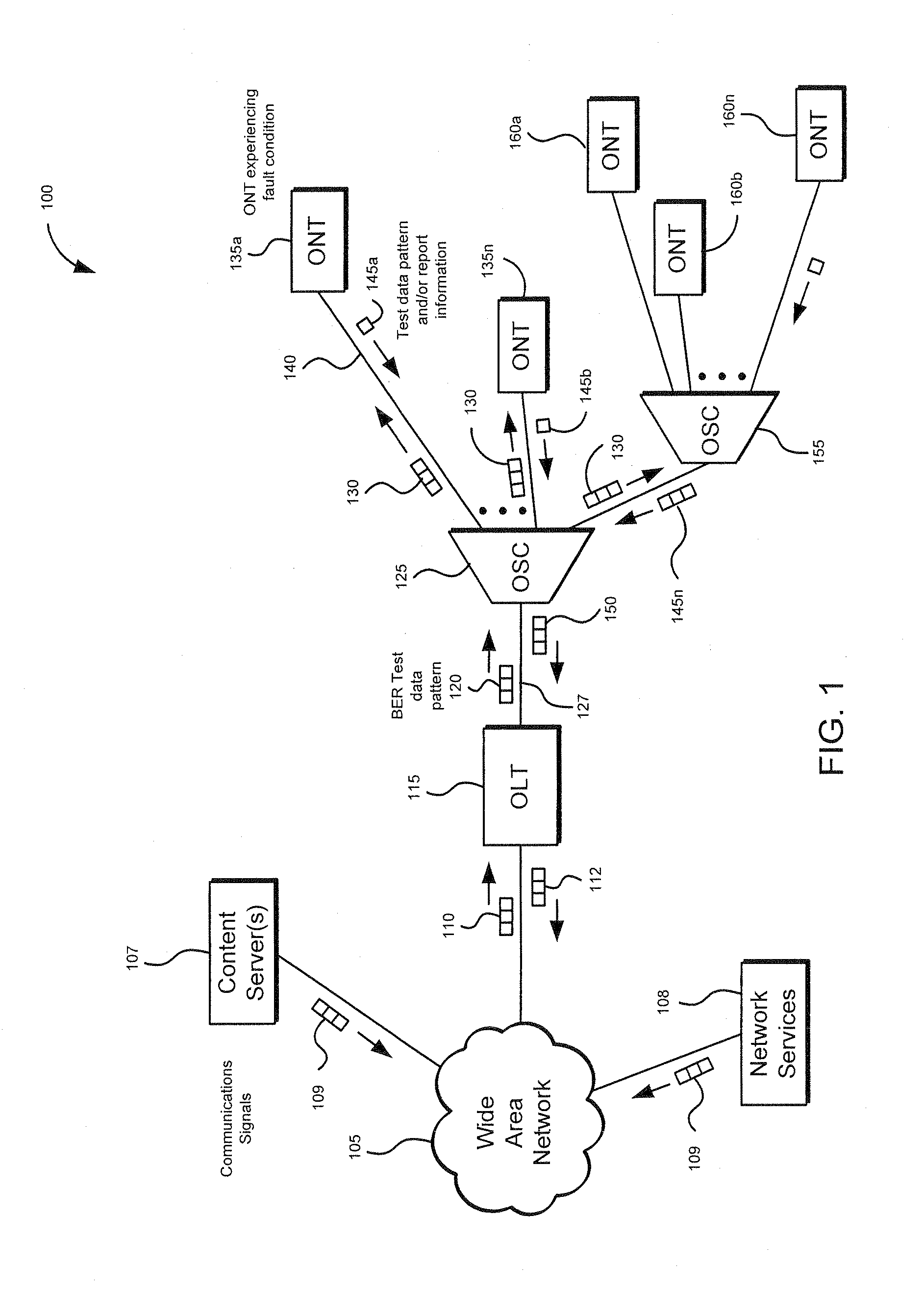

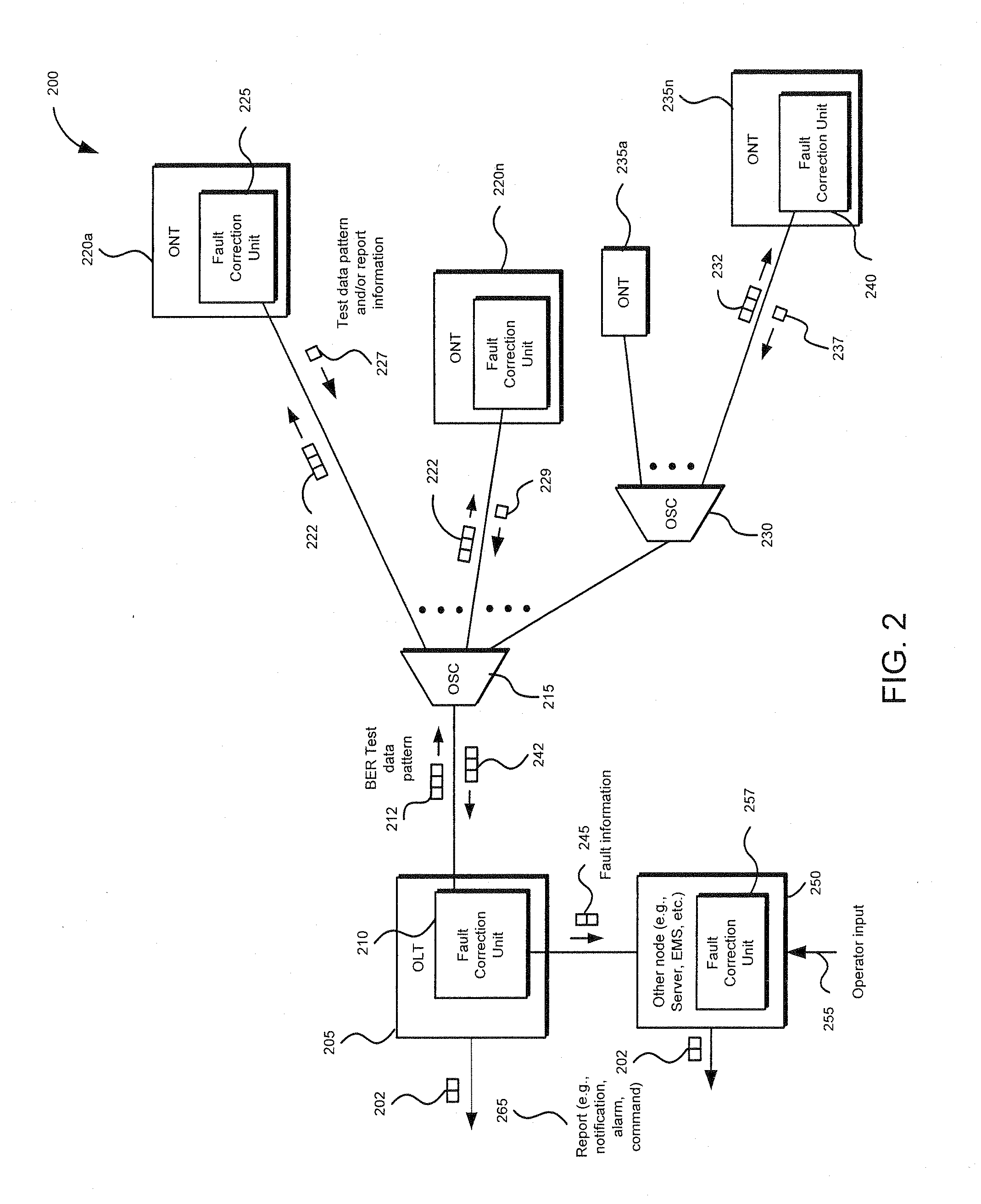

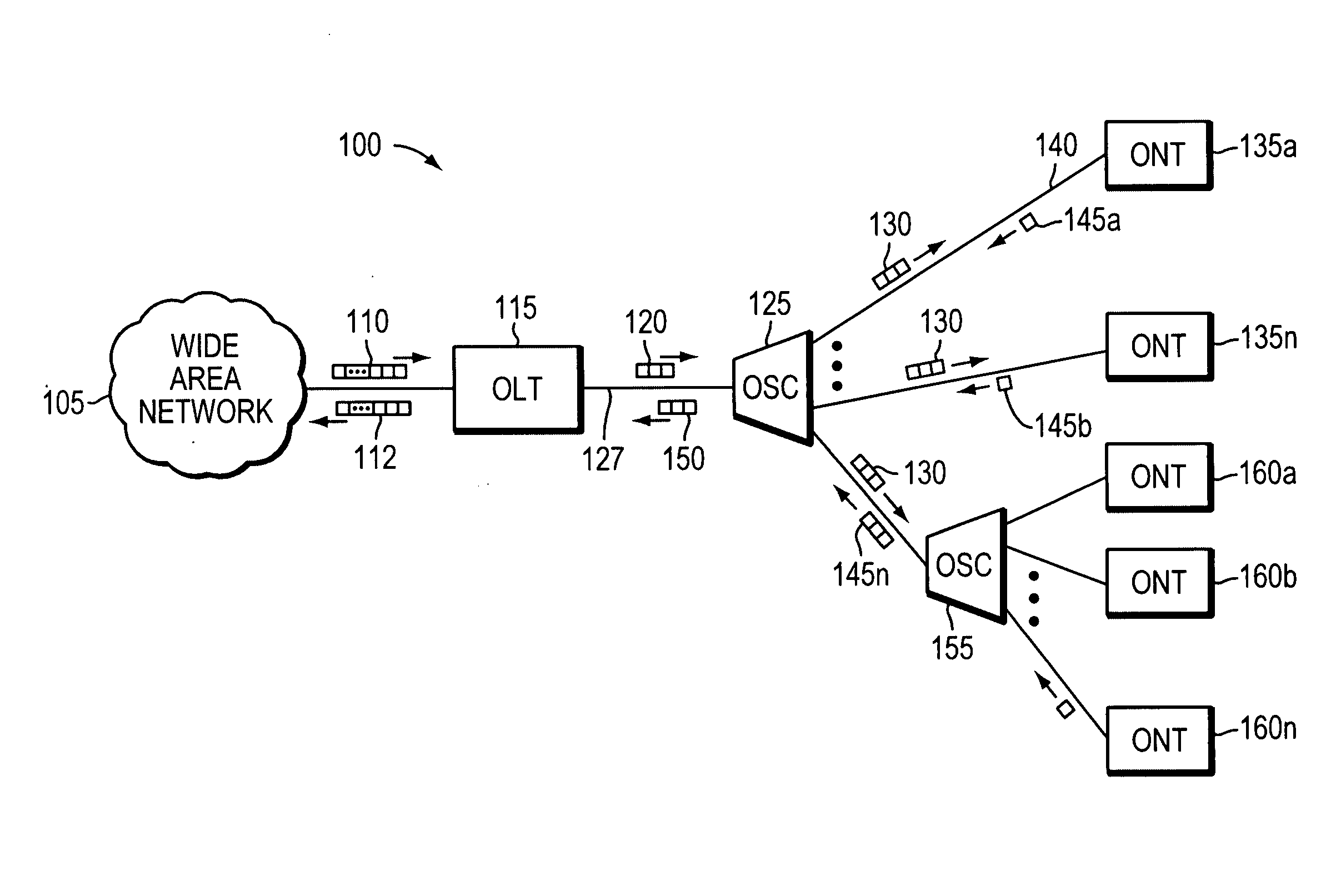

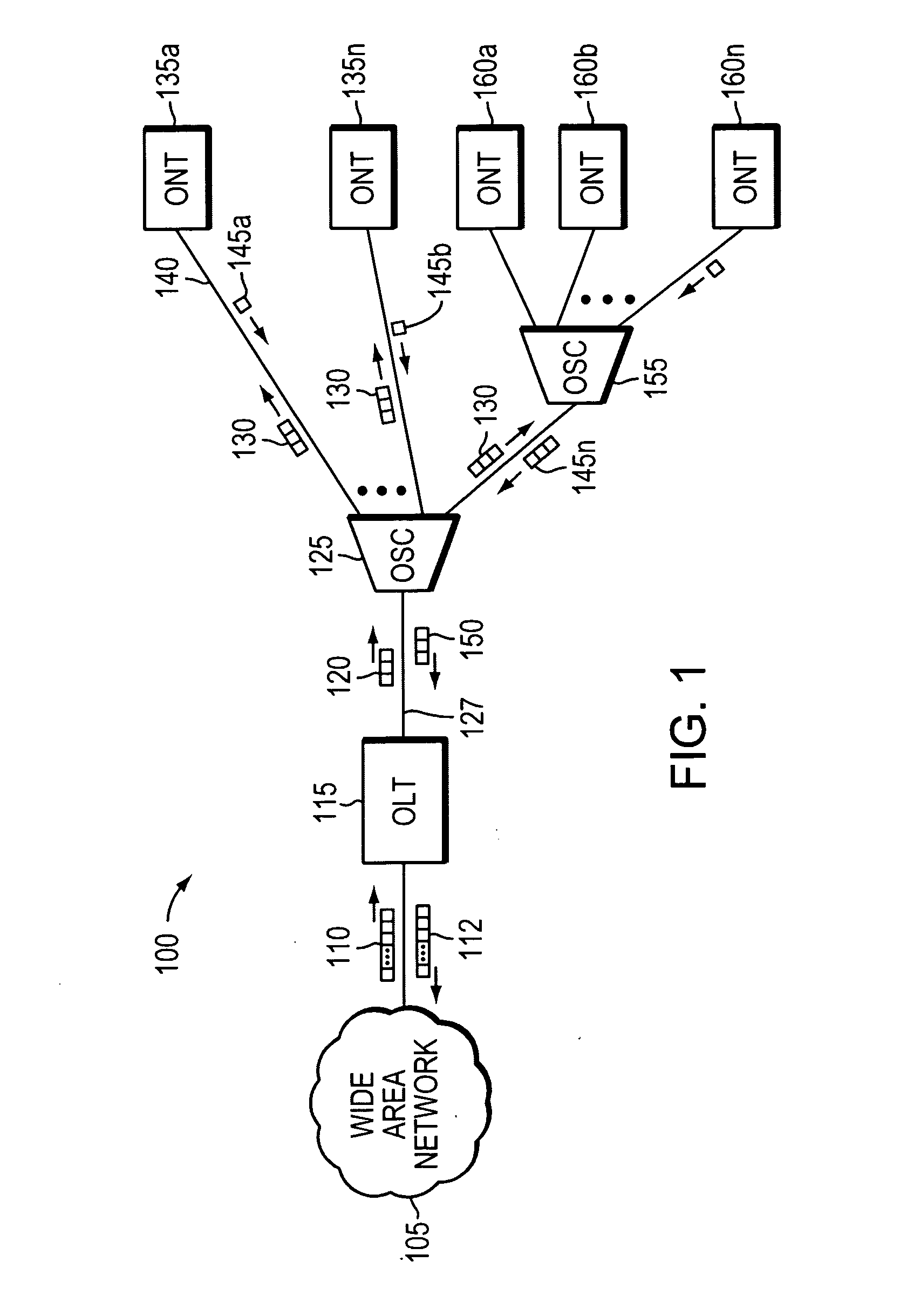

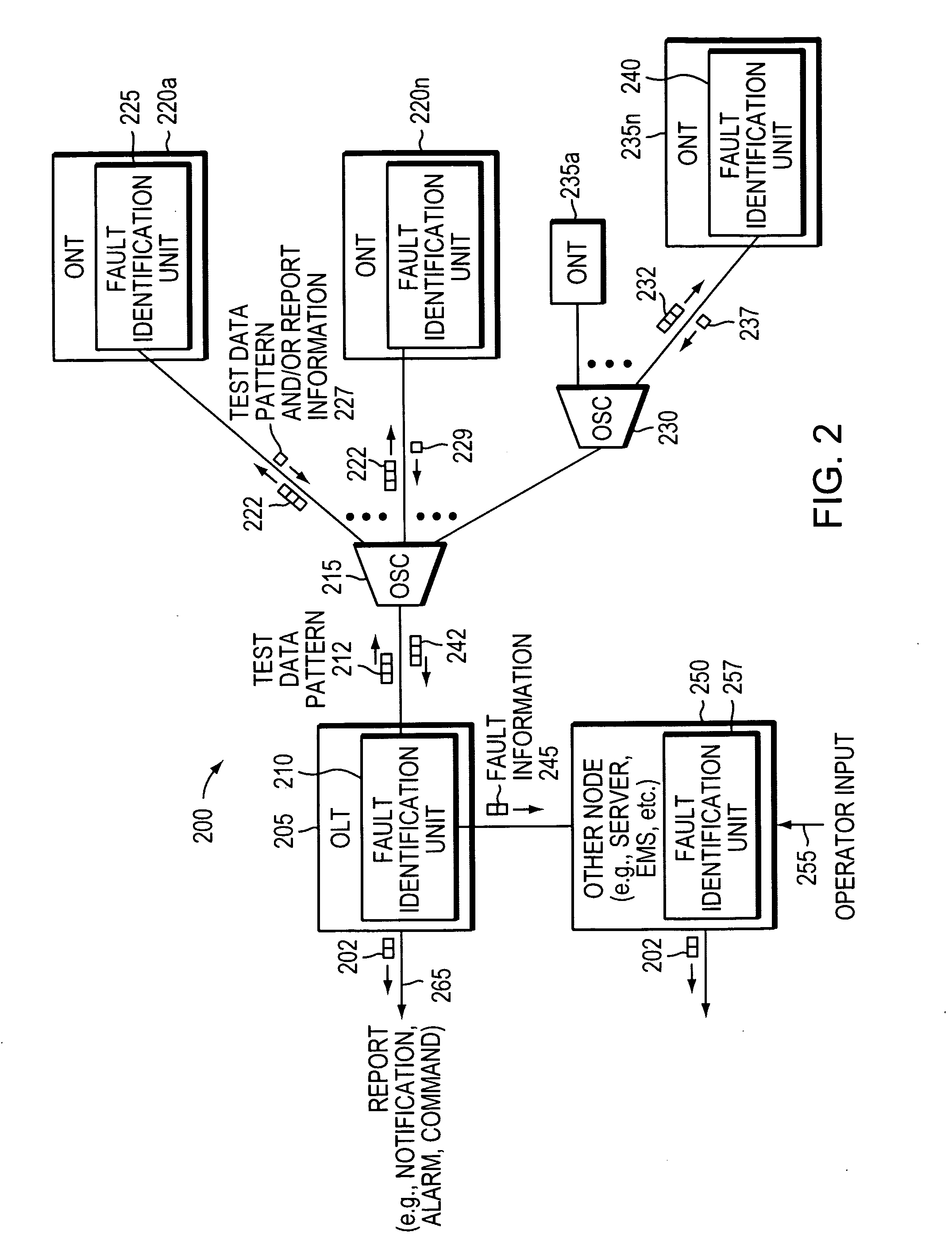

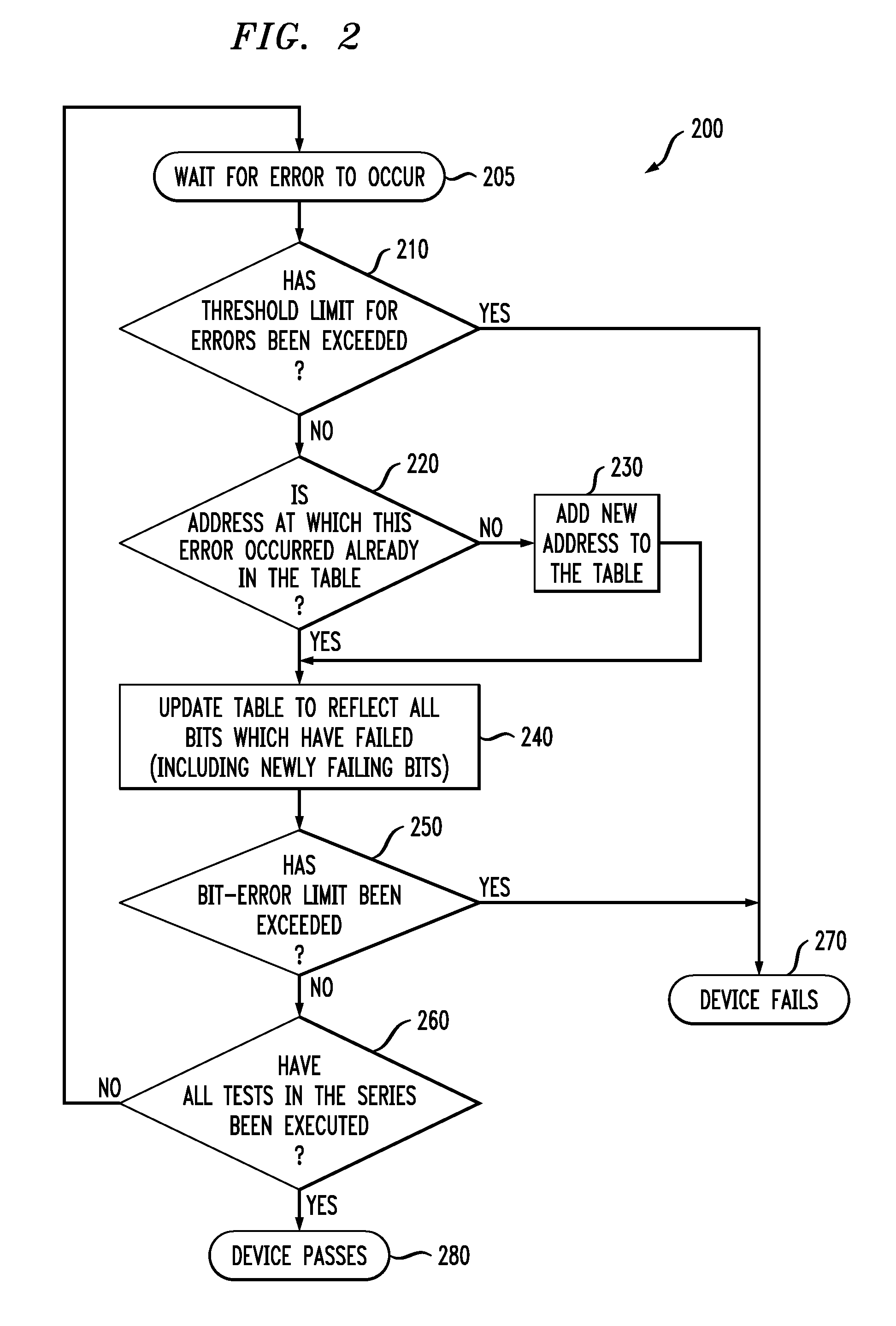

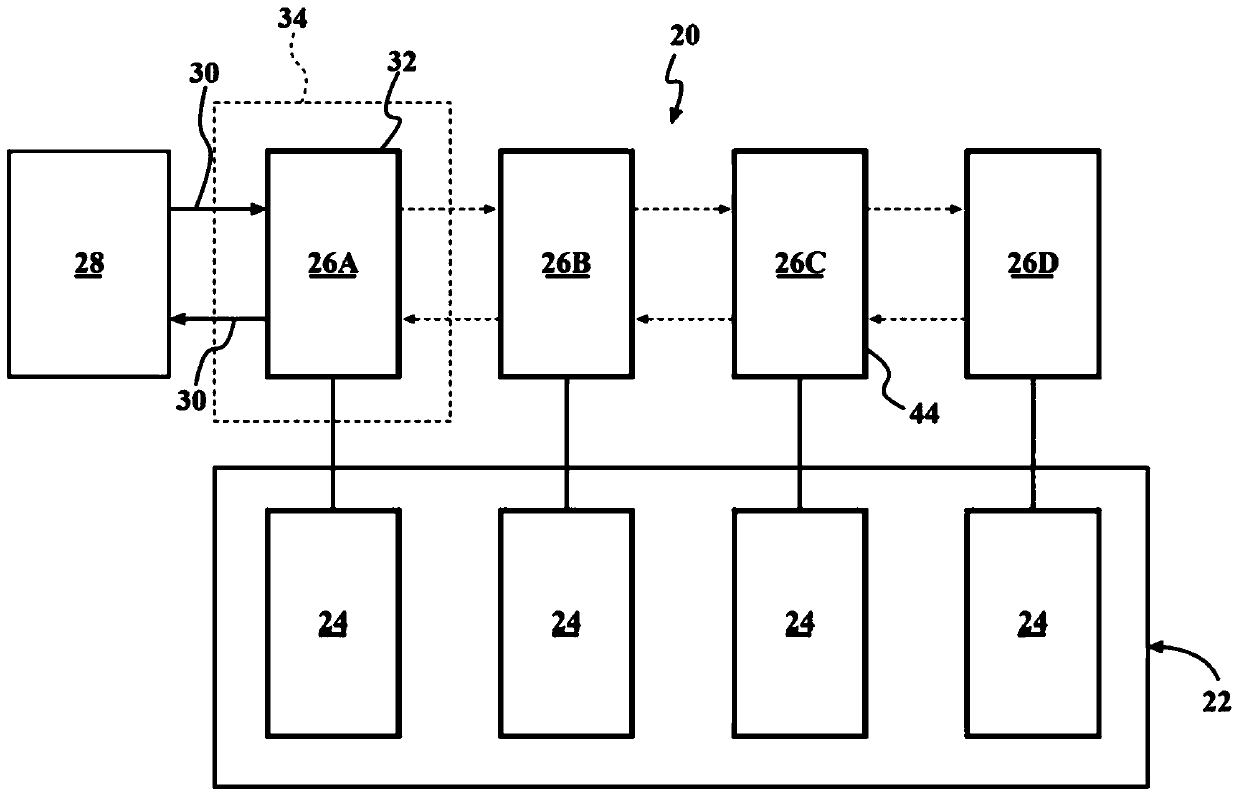

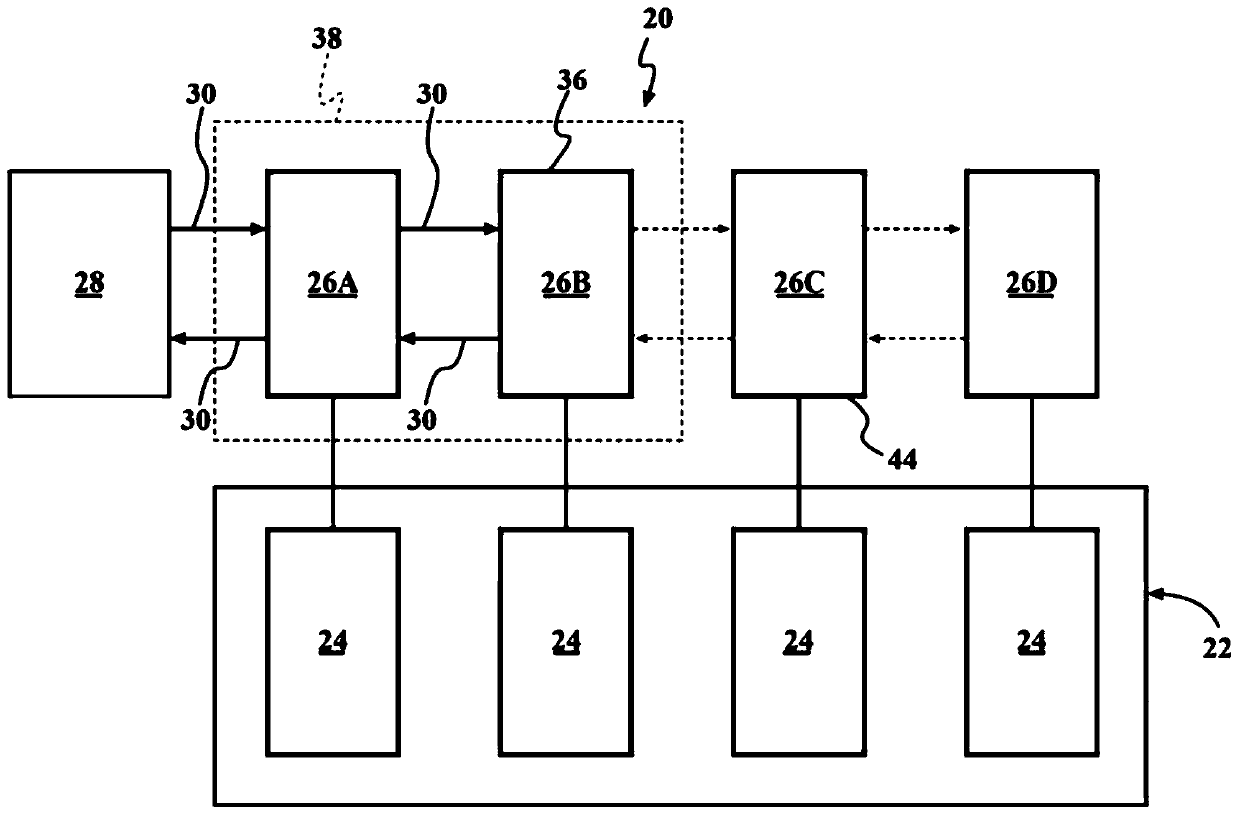

Component malfunctions in passive optical networks (PON) can increase bit error rates and decrease signal-to-noise ratio of communications signals. These faults may cause the receivers of the signals, either the optical line terminal (OLT) or optical network terminals (ONTs), to experience intermittent faults and / or may result in misinterpreted commands that disrupt other ONT's communication, resulting in a rogue ONT condition. Existing PON protocol detection methods may not detect these types of malfunctions. An embodiment of the present invention identifies faults in a PON by transmitting a test series of data patterns via an optical communications path from a first optical network node to a second optical network node. The test series is compared to an expected series of data patterns. An error rate may be calculated as a function of the differences between the test series and expected series. The error rate may be reported to identify faults in the PON. Through use of the embodiment, network faults can be identified and optionally automatically corrected, saving a network service provider from expending technician time and maintaining an operating state of the network.

Owner:TELLABS PETALUMA

Method and apparatus for correcting faults in a passive optical network

ActiveUS20100074614A1Transmission monitoringTransmission monitoring/testing/fault-measurement systemsEngineeringOptical communication

Component malfunctions in passive optical networks (PON) can increase bit error rates and decrease signal-to-noise ratio of communications signals. These faults may cause the receivers of the signals, either the optical line terminal (OLT) or optical network terminals (ONTs), to experience intermittent faults and / or may result in misinterpreted commands that disrupt other ONT's communication, resulting in a rogue ONT condition. Existing PON protocol detection methods may not detect these types of malfunctions. An embodiment of the present invention identifies faults in a PON by transmitting a test series of data patterns via an optical communications path from a first optical network node to a second optical network node. The test series is compared to an expected series of data patterns. An error rate may be calculated as a function of the differences between the test series and expected series. The error rate may be reported to identify faults in the PON. Through use of the embodiment, network faults can be identified and optionally automatically corrected, saving a network service provider from expending technician time and maintaining an operating state of the network.

Owner:TELLABS PETALUMA

Method and apparatus for identifying faults in a passive optical network

InactiveUS20090010643A1Transmission monitoringTransmission monitoring/testing/fault-measurement systemsOptical communicationSignal-to-quantization-noise ratio

Component malfunctions in passive optical networks (PON) can increase bit error rates and decrease signal-to-noise ratio in communications signals. These faults may cause the receivers of the signals, either the optical line terminal (OLT) or optical network terminals (ONTs), to experience intermittent faults and / or may result in misinterpreted commands that disrupt other ONT's communication, resulting in a rogue ONT condition. Existing PON protocol detection methods may not detect these types of malfunctions. An embodiment of the present invention identifies faults in a PON by transmitting a test series of data patterns via an optical communications path from a first network node to a second network node. The test series is compared to an expected series of data patterns. An error rate may be calculated as a function of the differences between the test series and expected series. The error rate may be reported to identify faults in the PON.

Owner:TELLABS PETALUMA

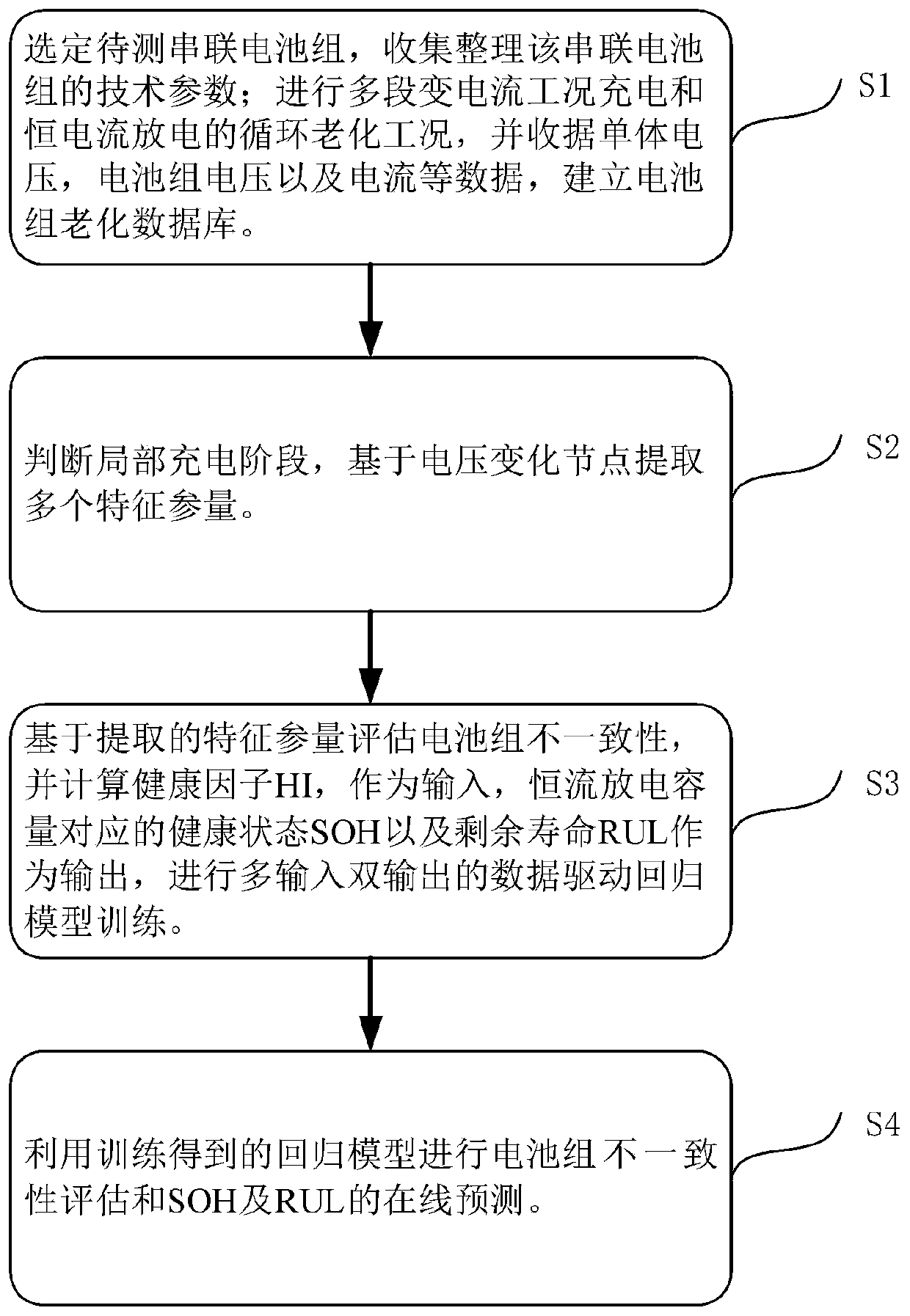

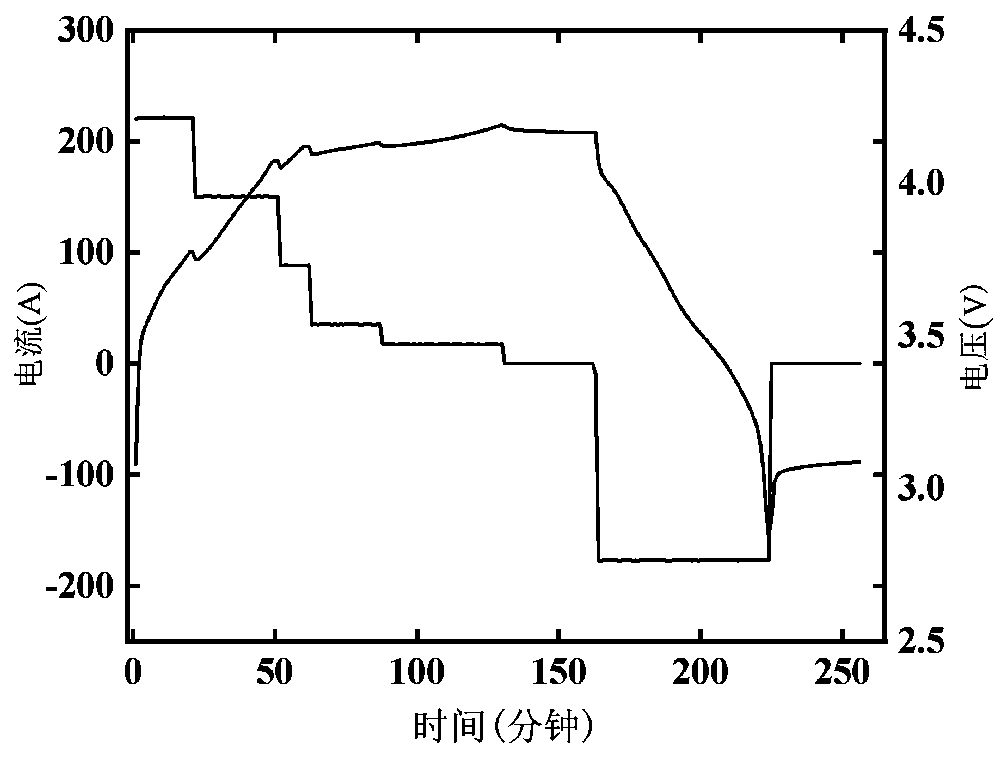

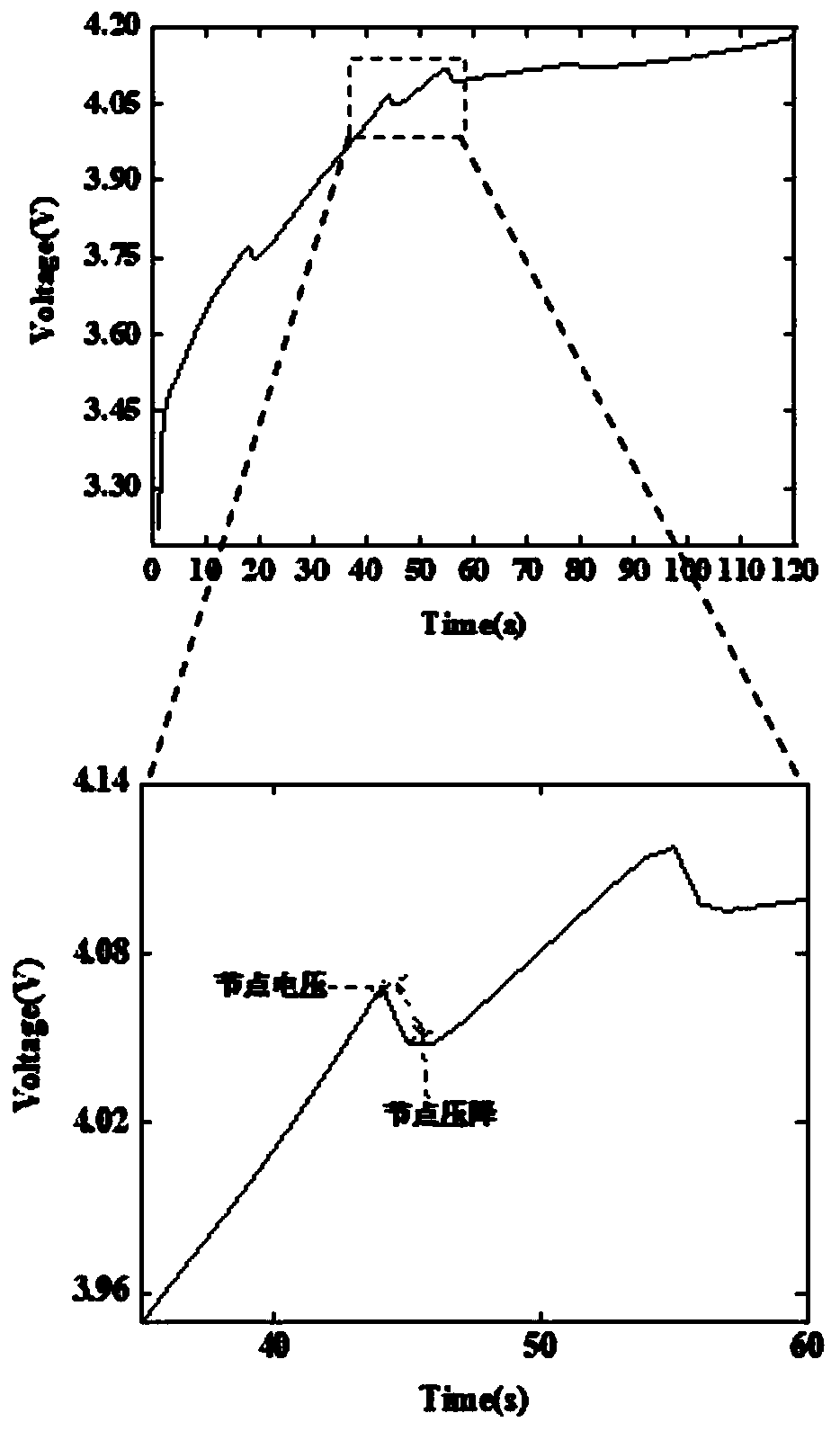

Battery pack SOH and RUL prediction method and system based on inconsistency evaluation

The invention relates to a battery pack SOH and RUL prediction method and system based on inconsistency evaluation, and belongs to the technical field of battery management. The method comprises the following steps: selecting a to-be-tested series battery pack, and collecting and arranging technical parameters of the series battery pack; and carrying out a cyclic aging condition of multi-section variable current condition charging and constant current discharging, and establishing a battery pack aging database according to data such as single voltage, battery pack voltage, battery pack currentand the like; judging a local charging stage, and extracting a plurality of characteristic parameters based on a voltage change node; evaluating the inconsistency of the battery pack based on the extracted characteristic parameters, and carrying out the multi-input and double-output data-driven regression model training; evaluating the inconsistency of the battery pack by using the test set data;and predicting the SOH and RUL of the battery pack online by using the regression model obtained by training. On the basis of evaluating the inconsistency of the battery pack, the state and the service life of the battery pack are predicted, and the method adapts to incomplete charging and discharging conditions in actual use.

Owner:CHONGQING UNIV +1

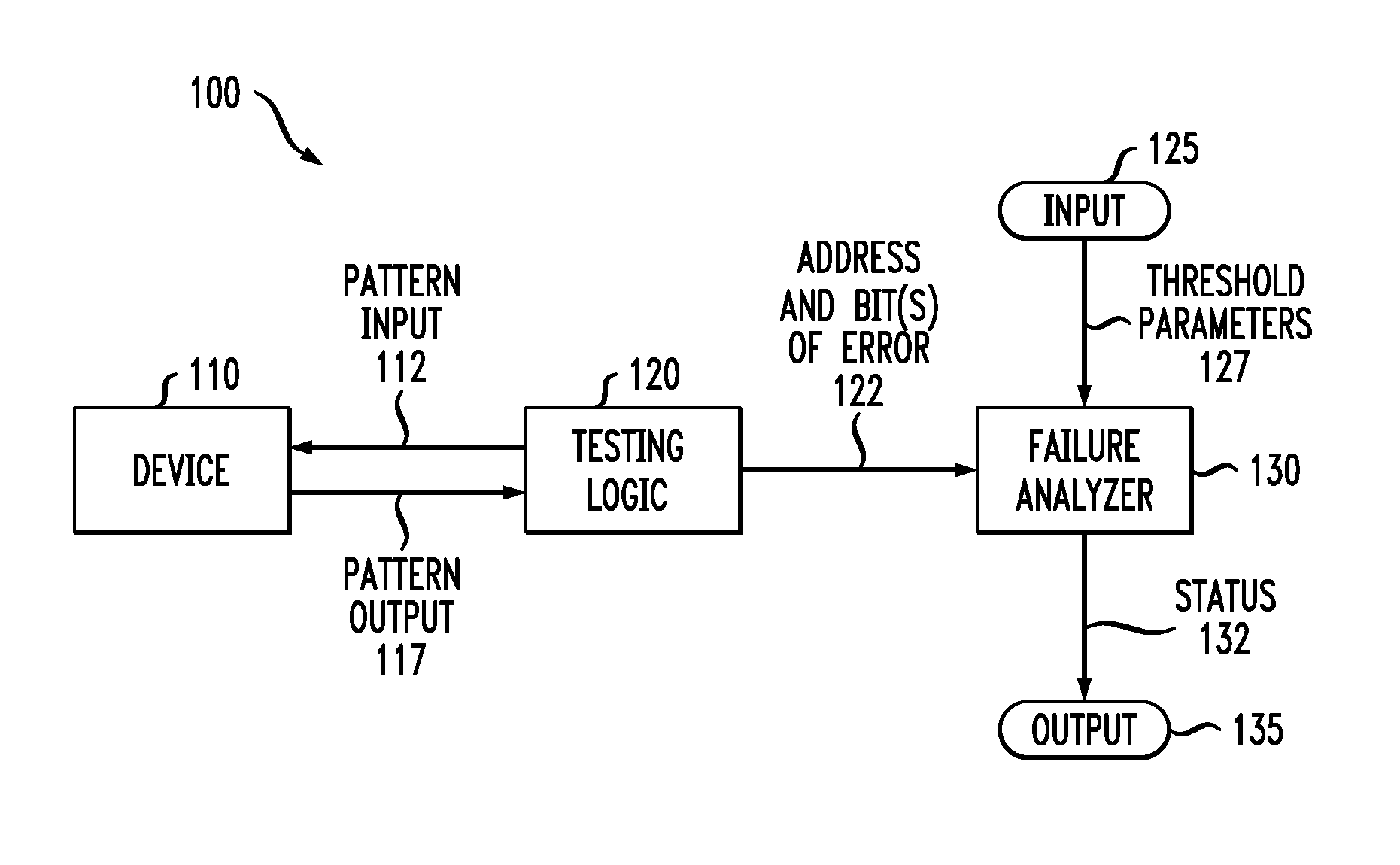

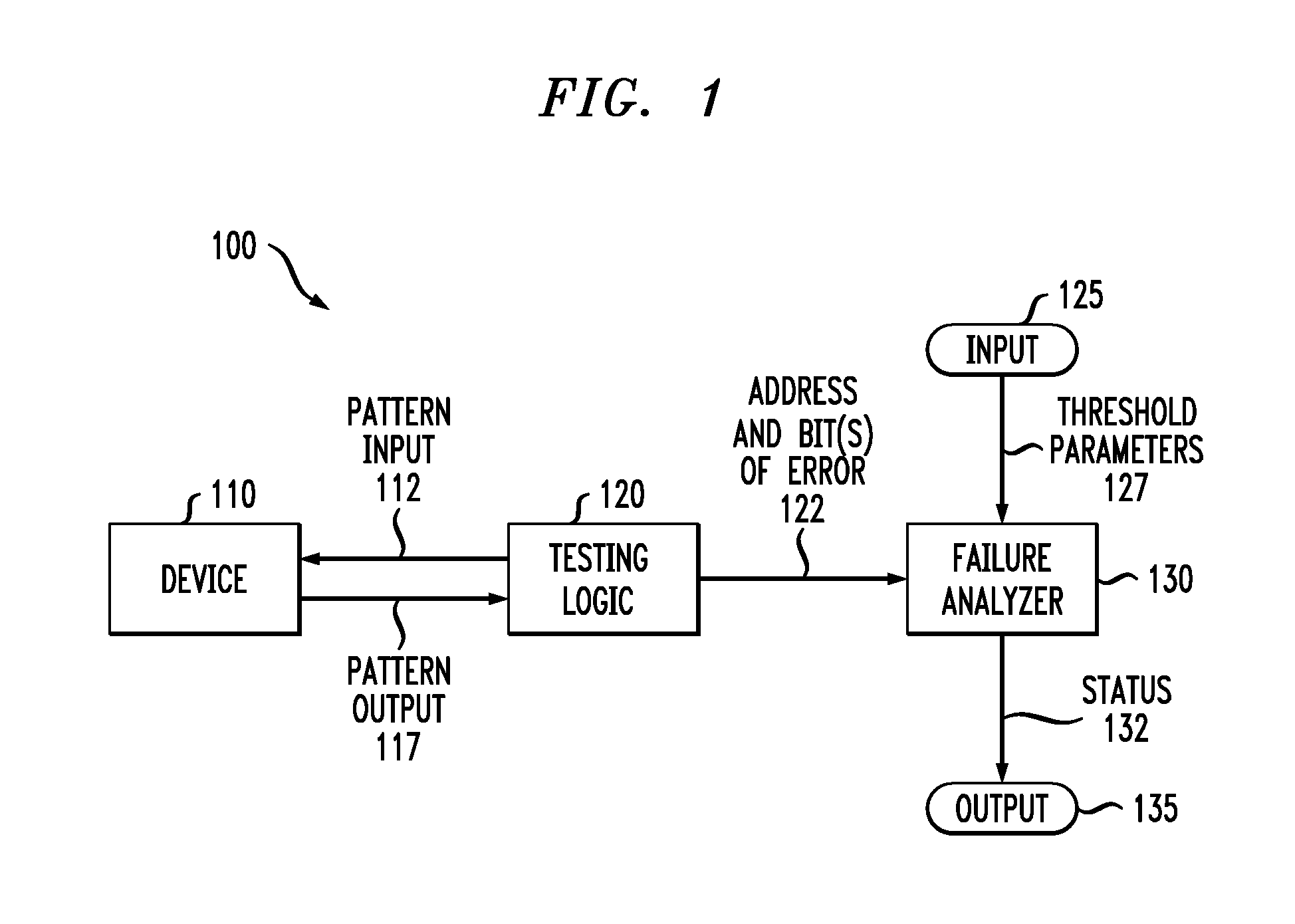

Yield-Enhancing Device Failure Analysis

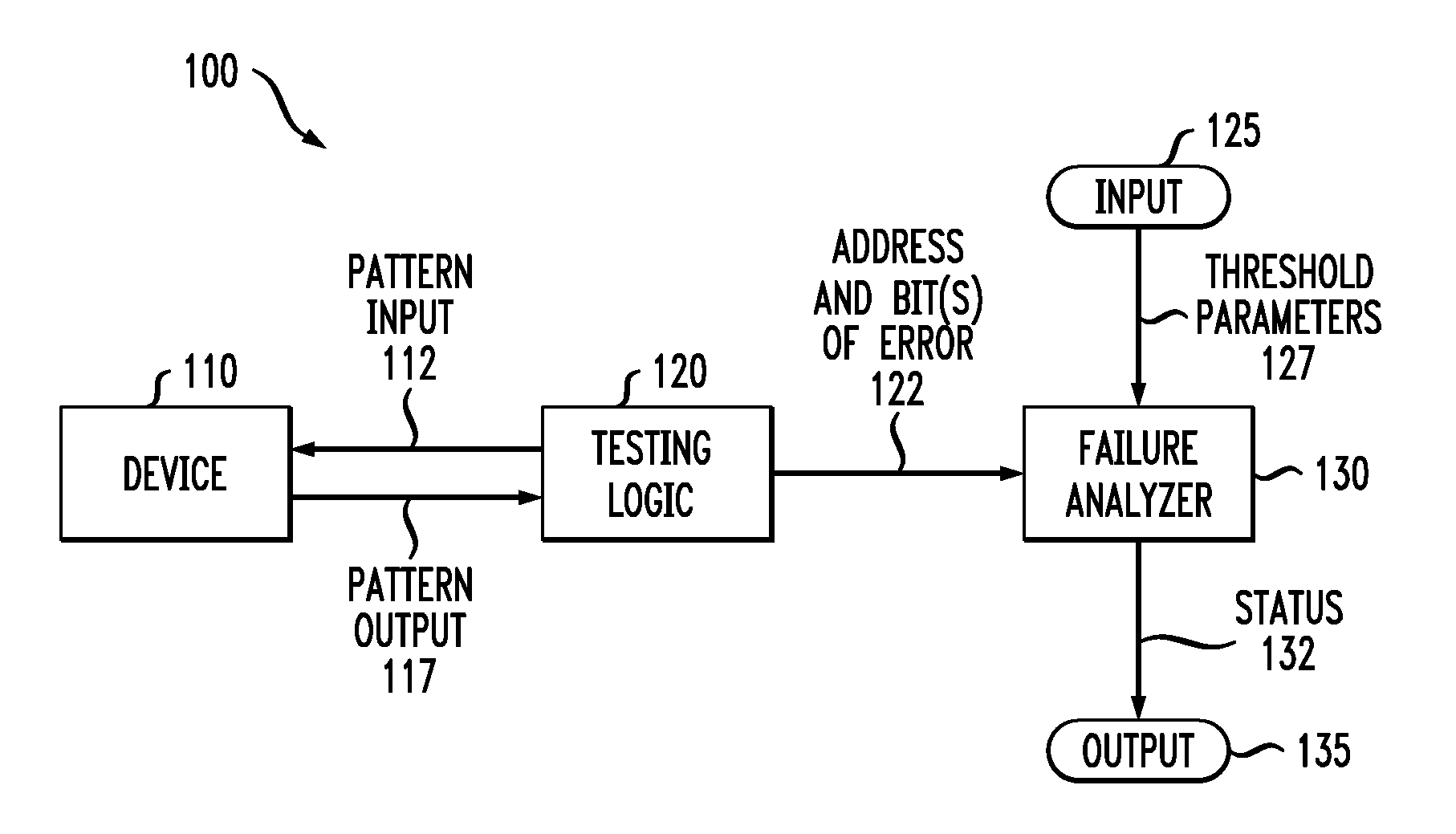

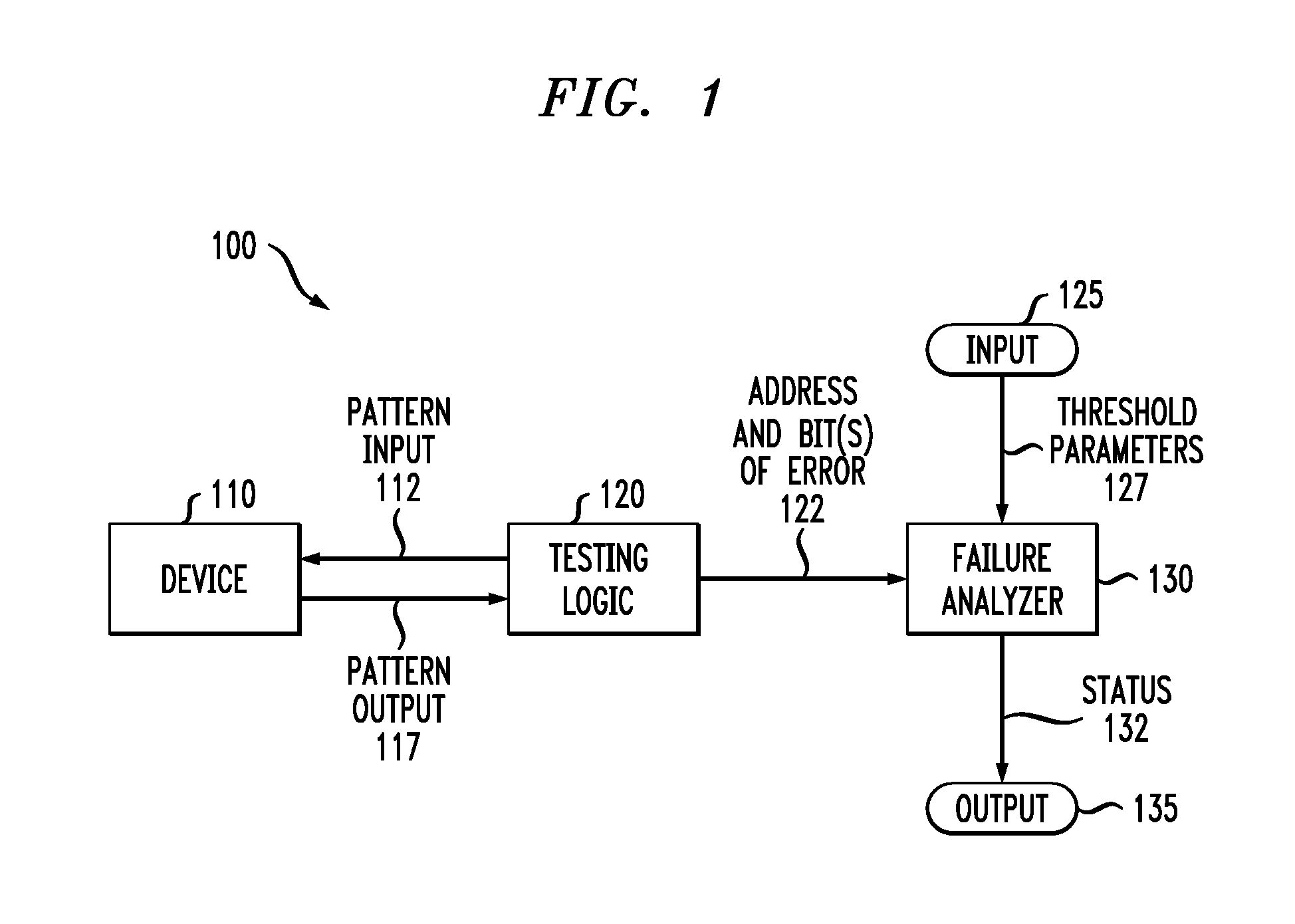

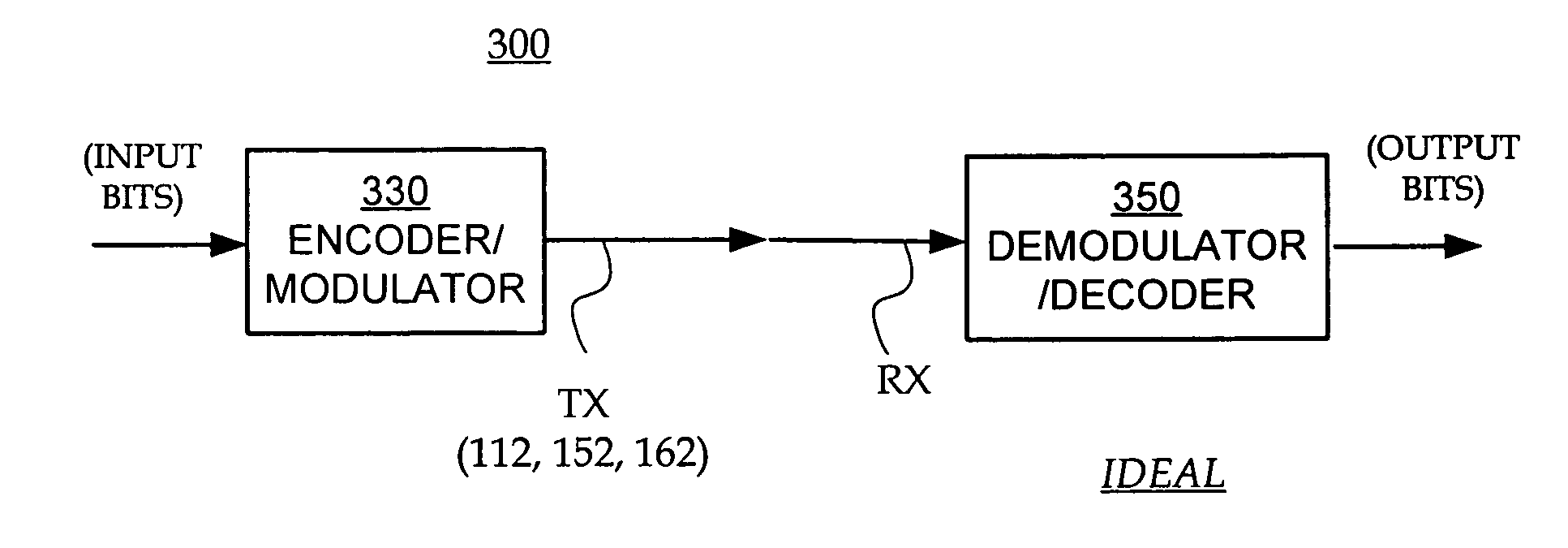

ActiveUS20080072118A1Improve manufacturing yieldIncrease productionStatic storageTest seriesReliability engineering

In a system including a processor and memory coupled to the processor, a method of device failure analysis includes the steps of: upon each error detected within a test series performed on a device, the processor storing within a table in the memory an address at which the error occurred in the device and storing a bit position of each failed bit corresponding to that address; for each unique address at which at least one error occurred, determining how many different bit positions corresponding to the address failed during the test series; and based on results of the test series, determining whether the device failed the test series.

Owner:TAHOE RES LTD

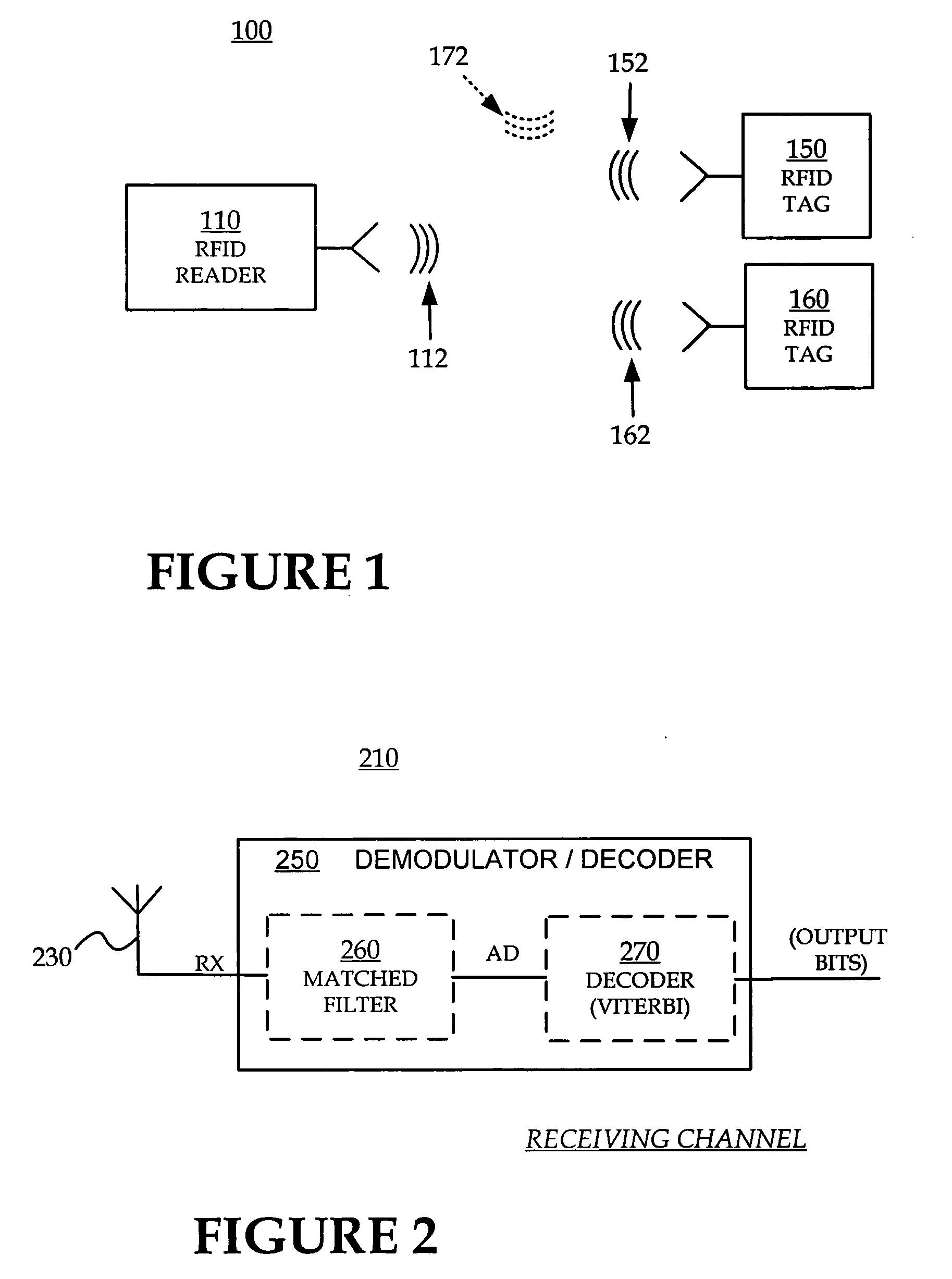

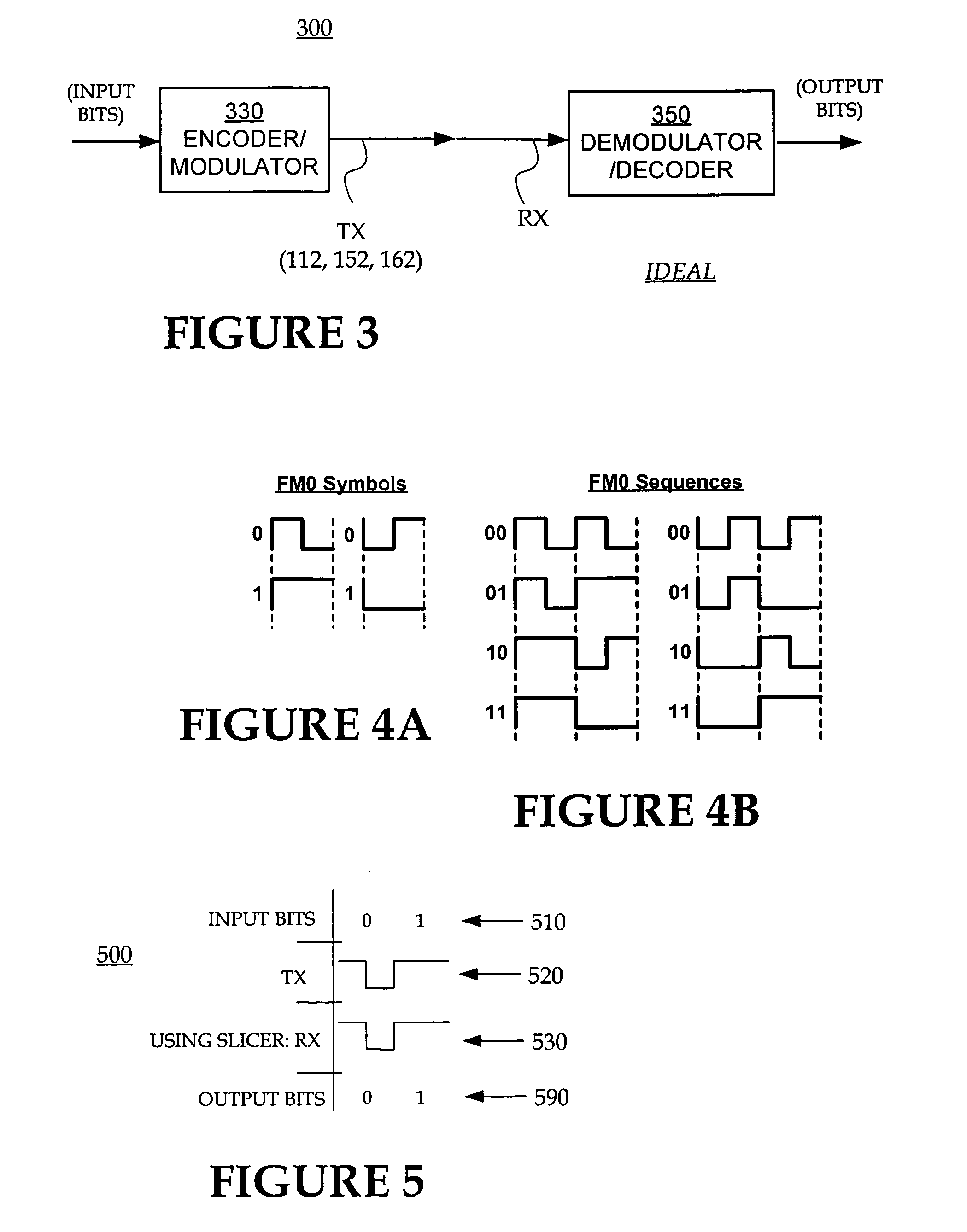

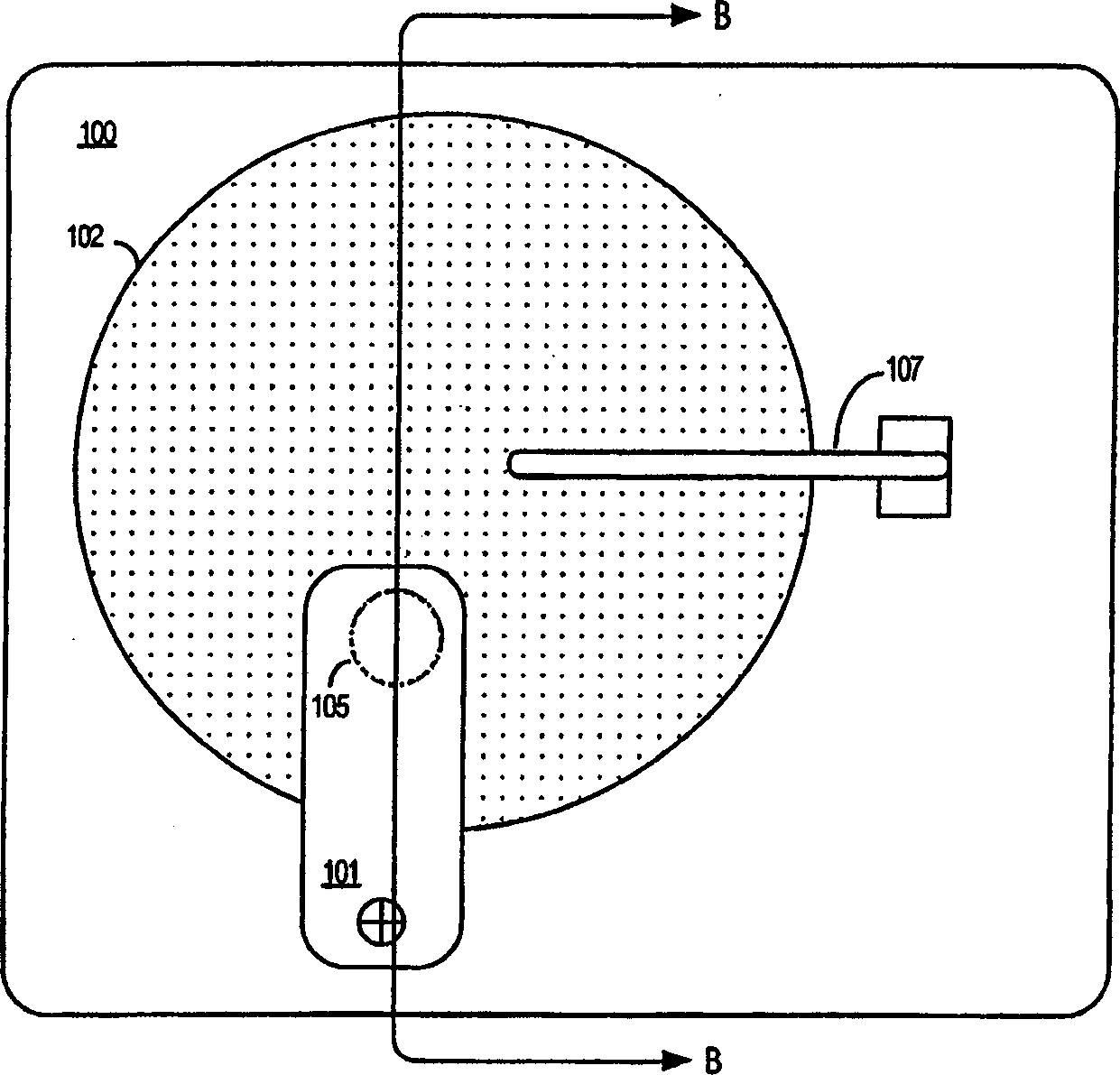

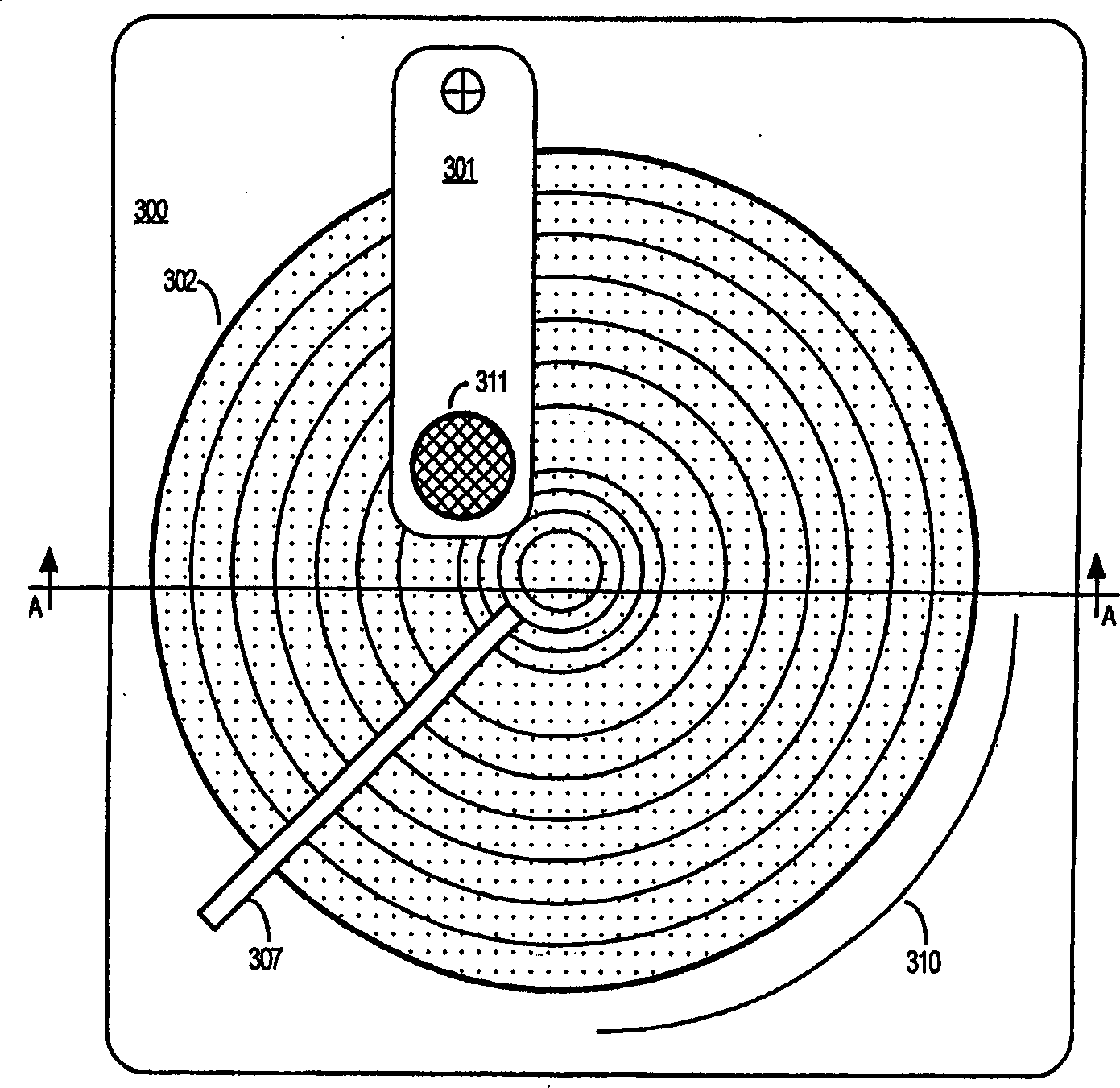

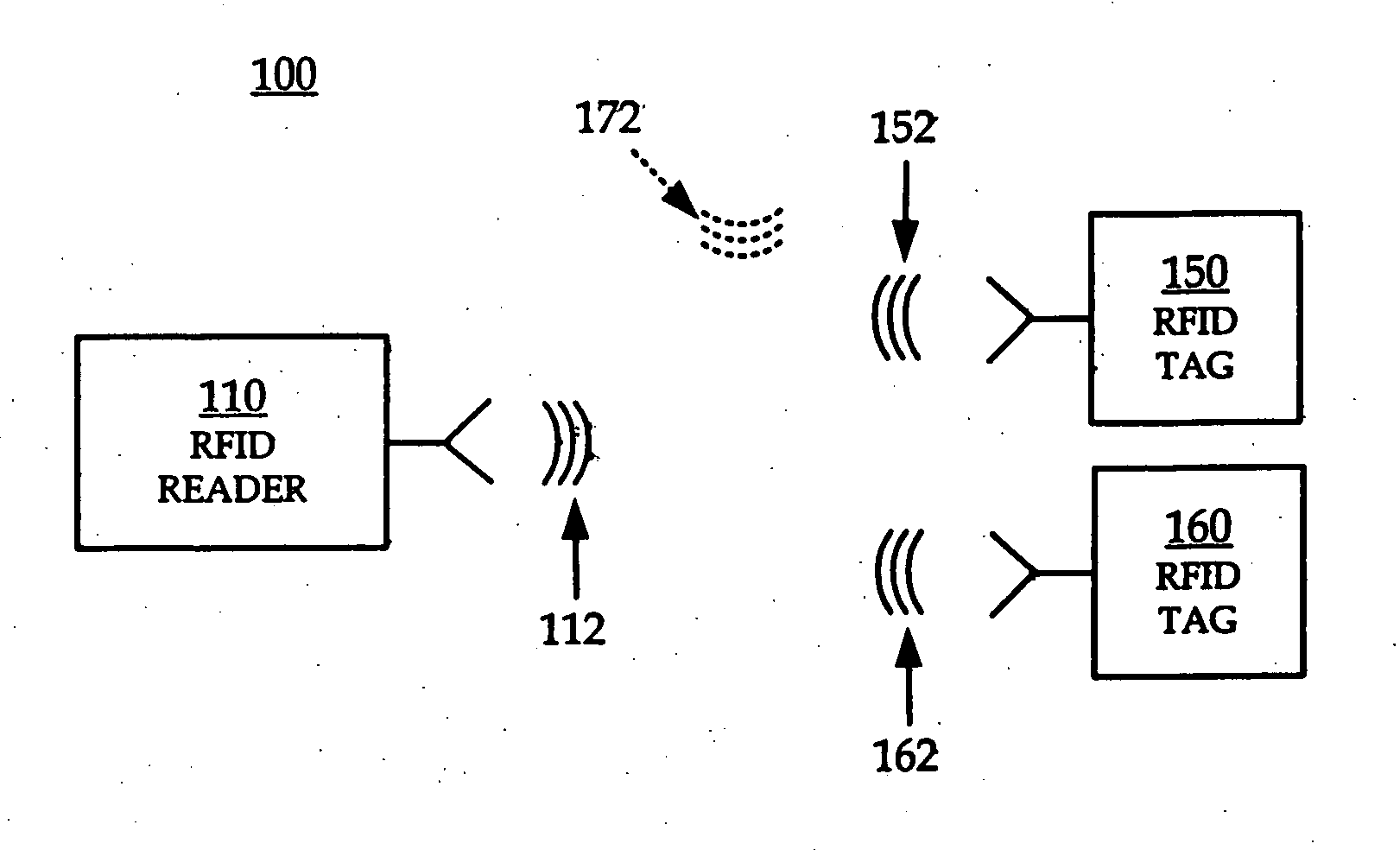

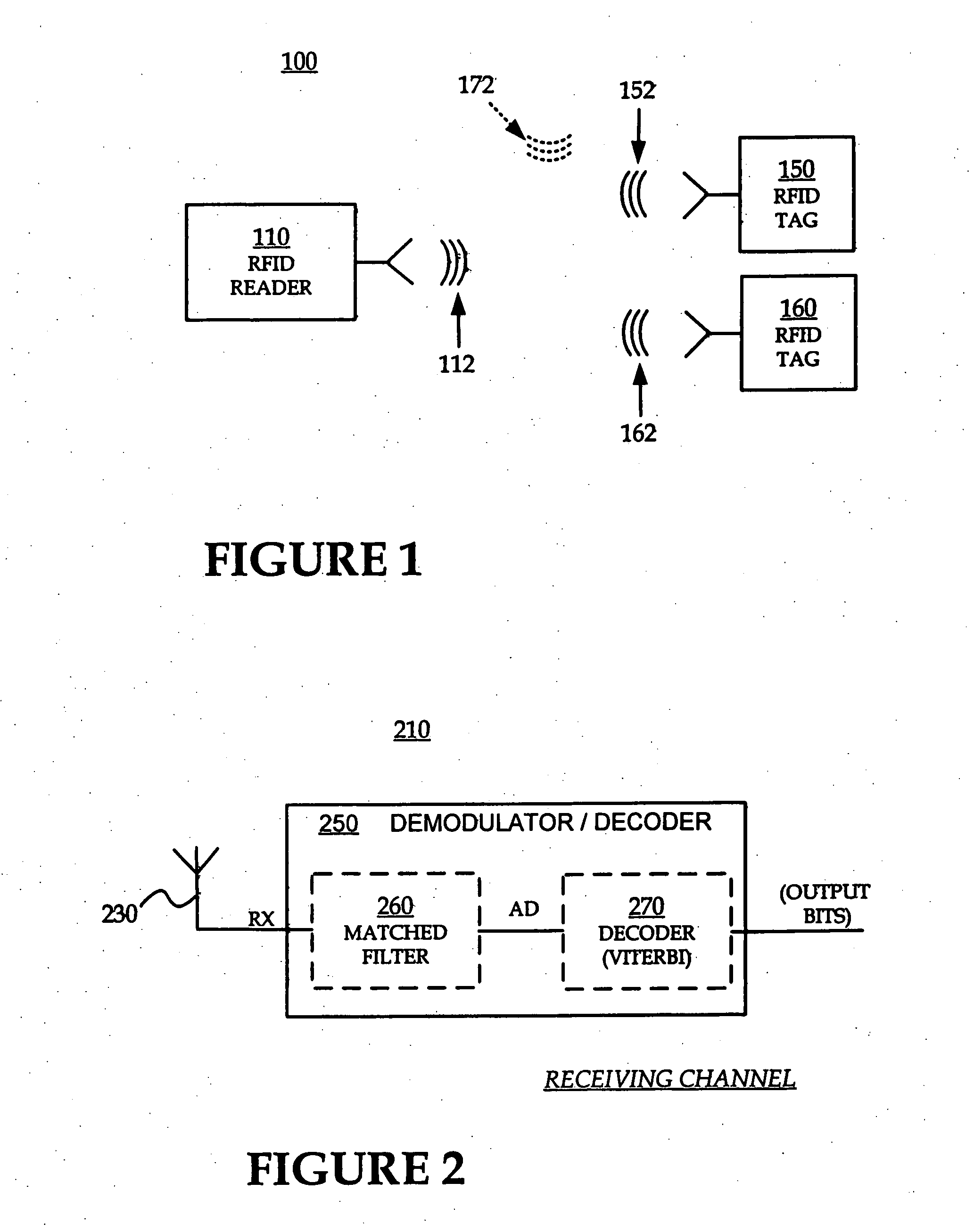

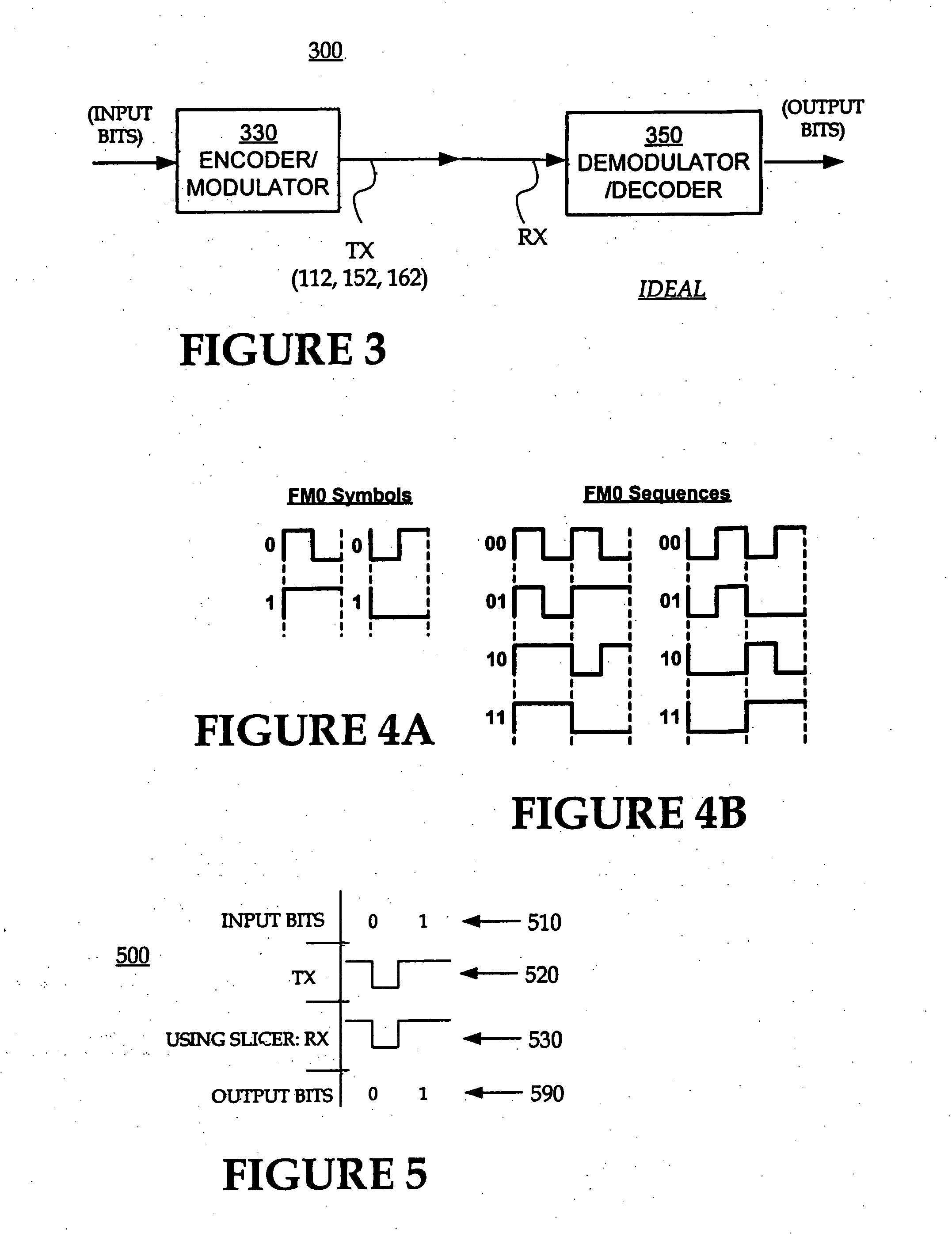

Decoding with memory in RFID system

ActiveUS20050270185A1Increase rangePoor receptionMemory record carrier reading problemsCode conversionComputer scienceTest series

RFID readers, RFID tags, software, and methods decode a signal received in an RFID system. From received data, a decoder determines a number of possible test series for the output. In one embodiment, the decoder uses a memory of a previous sample to derive a subsequent sample in the test series, so as to ensure that all the test series are valid. A metric is then computed for how well each test series fits the received data. The metrics are compared to select for output the test series with the best fit. In a further embodiment, at least one of the metrics is further used to determine if a collision were present.

Owner:IMPINJ

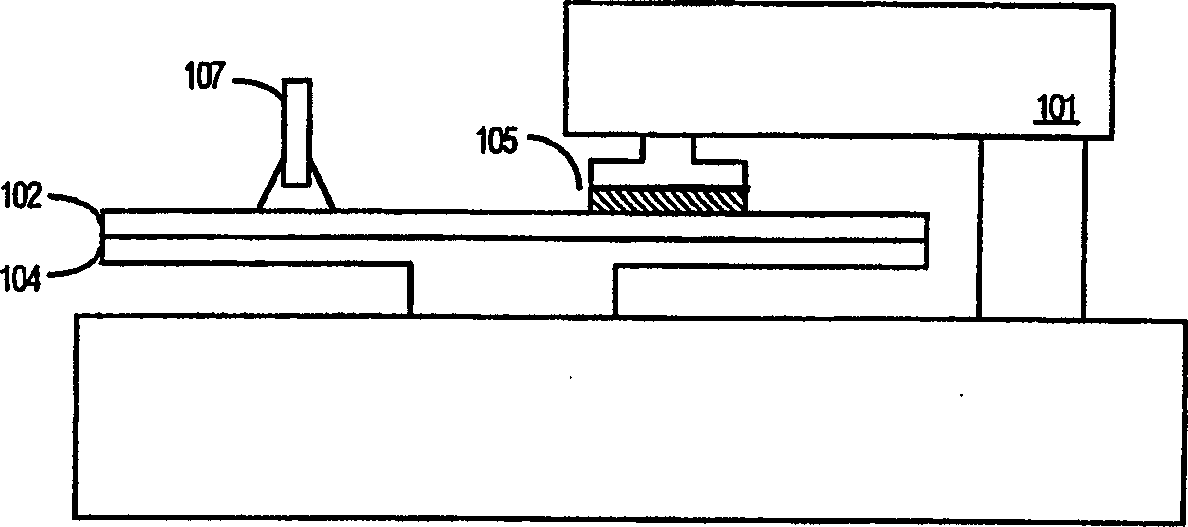

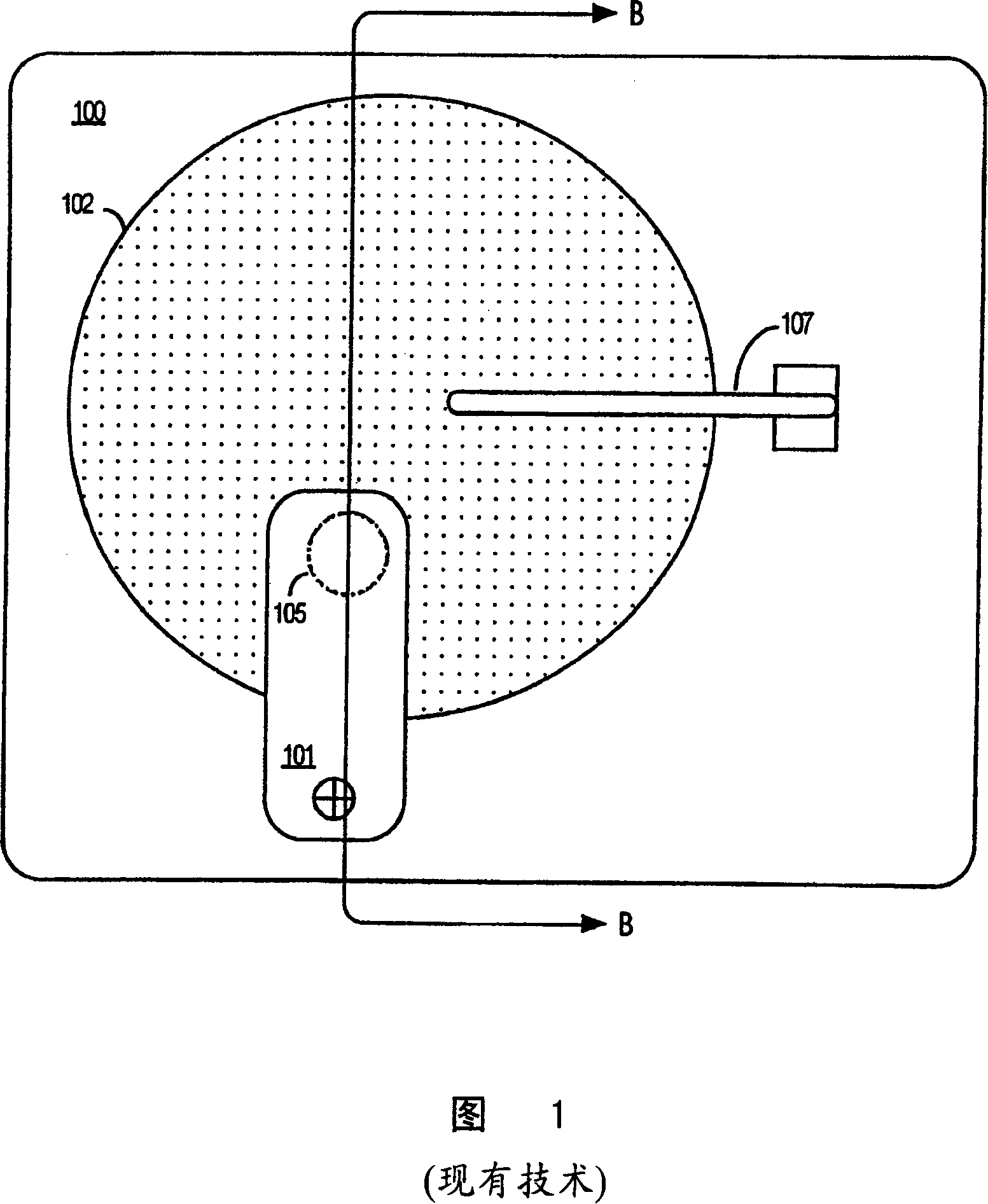

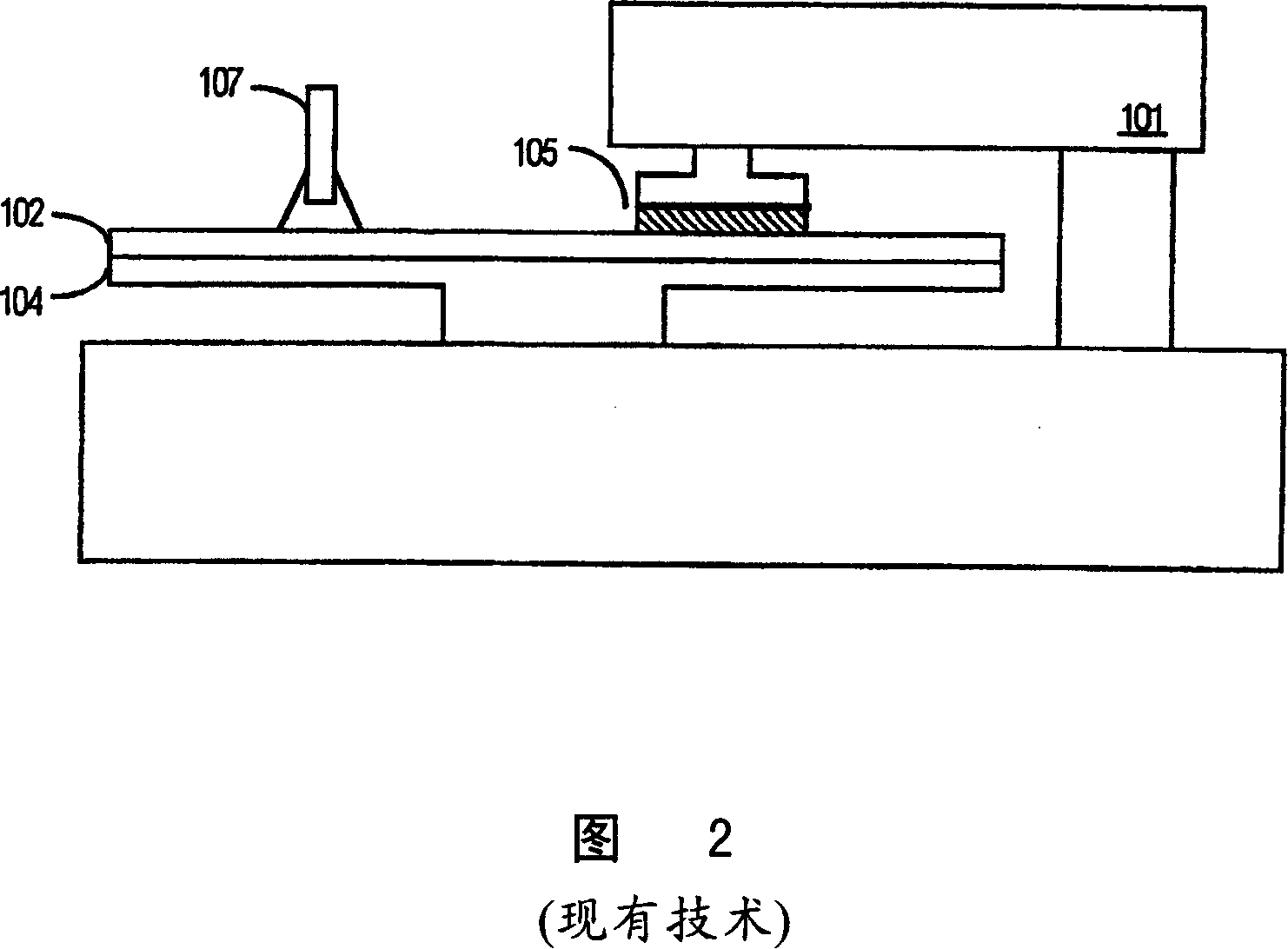

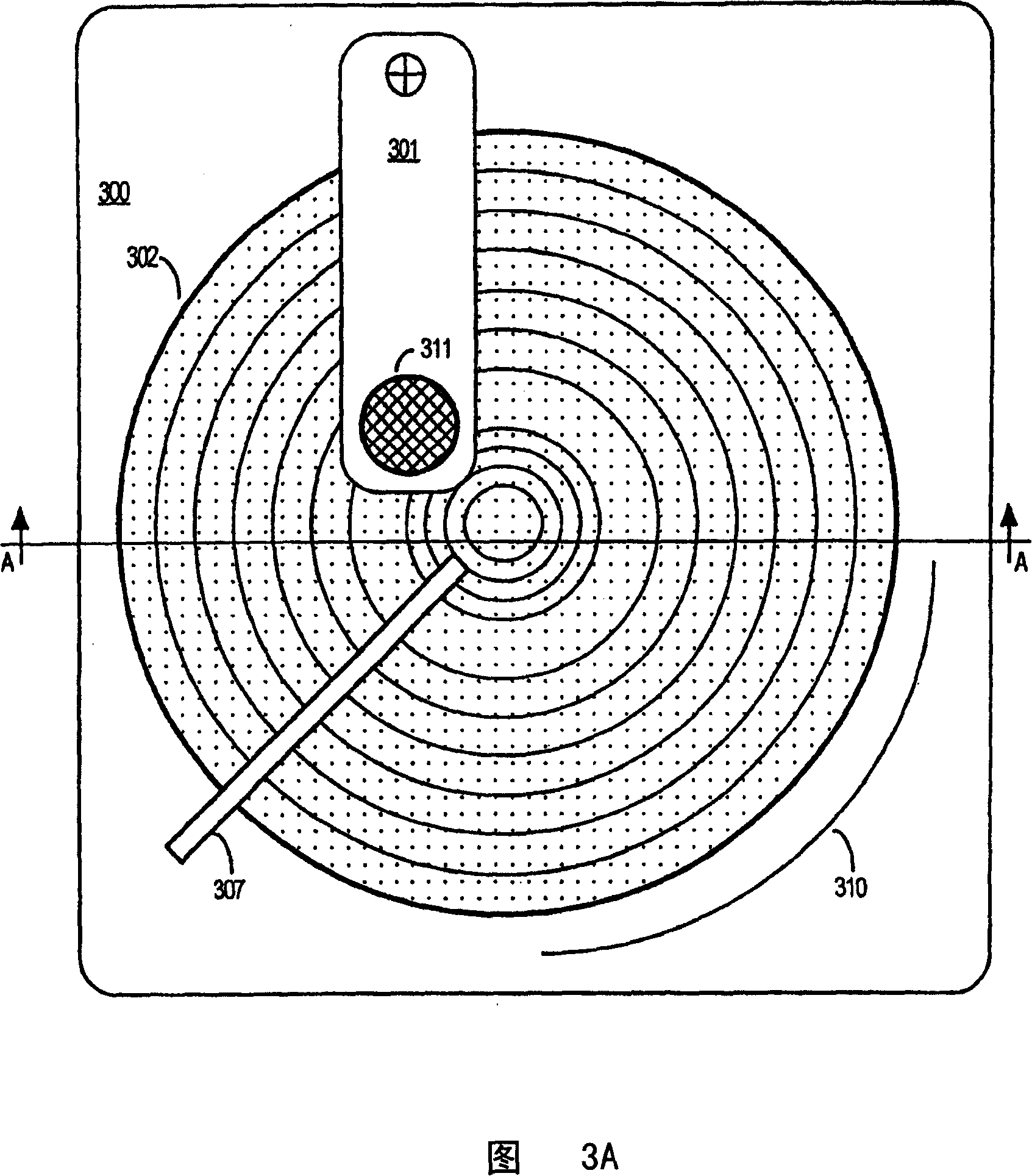

Method and system for polishing semiconductor wafers

InactiveCN1340210ALow costSampled-variable control systemsSemiconductor/solid-state device testing/measurementEngineeringSemiconductor

A method for optimizing CMP (chemical mechanical polishing) processing of semiconductor wafers on a CMP machine. The optimization method includes the steps of polishing a test series of semiconductor wafers on a CMP machine. During the CMP processing, a film thickness is measured at a first point proximate to the center of each respective wafer using a film thickness detector coupled to the machine. A film thickness at a second point proximate to the outside edge of the respective wafers is also measured. Based upon the in-process film thickness measurements at the first point and the second points, the optimization process determines a polishing profile describing a removal rate and a removal uniformity with respect to a set of process variables. The process variables include different CMP machine settings for the polishing process, such as the amount of down force applied to the wafer. The polishing profile is subsequently used to polish production wafers accordingly. For each production wafer, their respective removal rate and removal uniformity is determined by measuring a film thickness at the center of each production wafer and a film thickness at the outside edge of each production wafer using the film thickness detector. Based upon these measurements, the set of process variables is adjusted in accordance the removal rate and the removal uniformity measurements to optimize the CMP process for the production wafer as each respective wafer is being polished.

Owner:NXP BV

Decoding with memory in RFID system

ActiveUS20070152073A1Minimize impactImprove fitMemory record carrier reading problemsCode conversionComputer scienceTest series

RFID readers, RFID tags, software, and methods decode a signal received in an RFID system. From received data, a decoder determines a number of possible test series for the output. In one embodiment, the decoder uses a memory of a previous sample to derive a subsequent sample in the test series, so as to ensure that all the test series are valid. A metric is then computed for how well each test series fits the received data. The metrics are compared to select for output the test series with the best fit. In a further embodiment, at least one of the metrics is further used to determine if a collision were present.

Owner:IMPINJ

Method and system for testing a mechatronic system

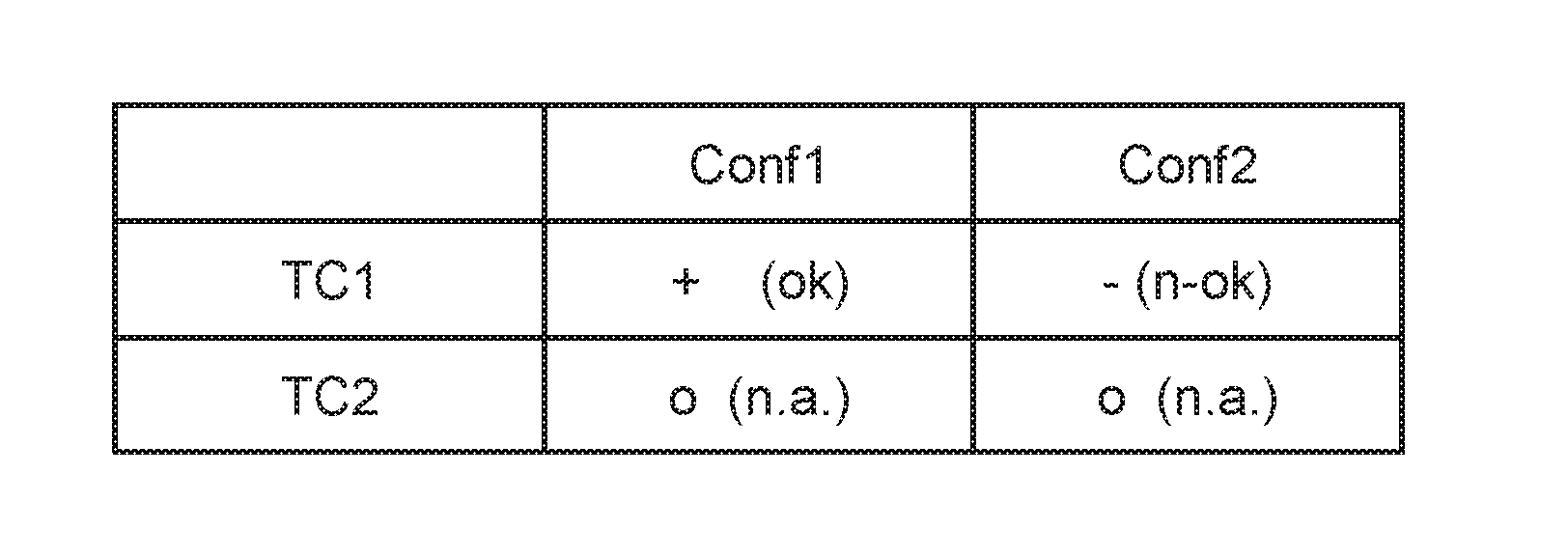

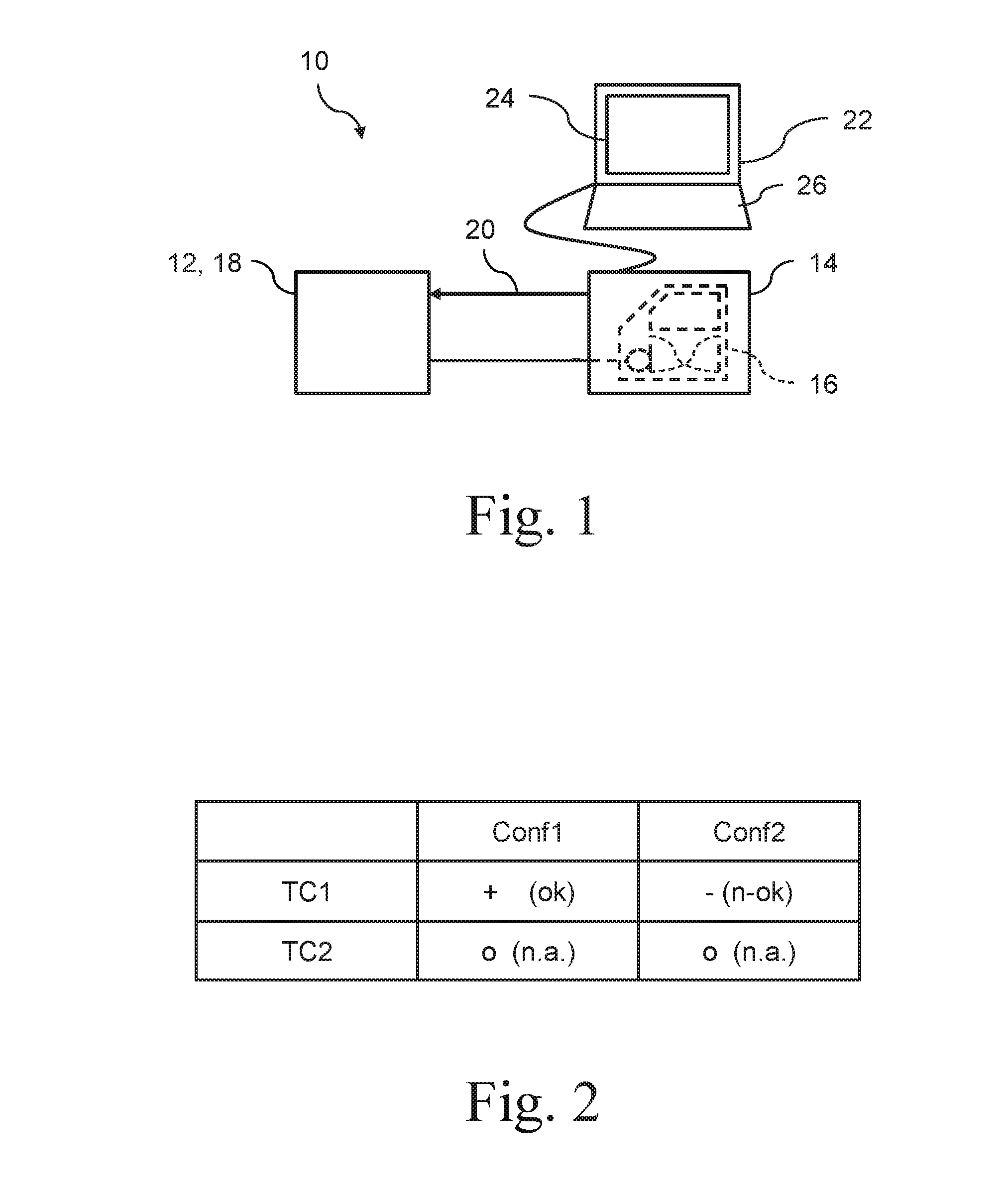

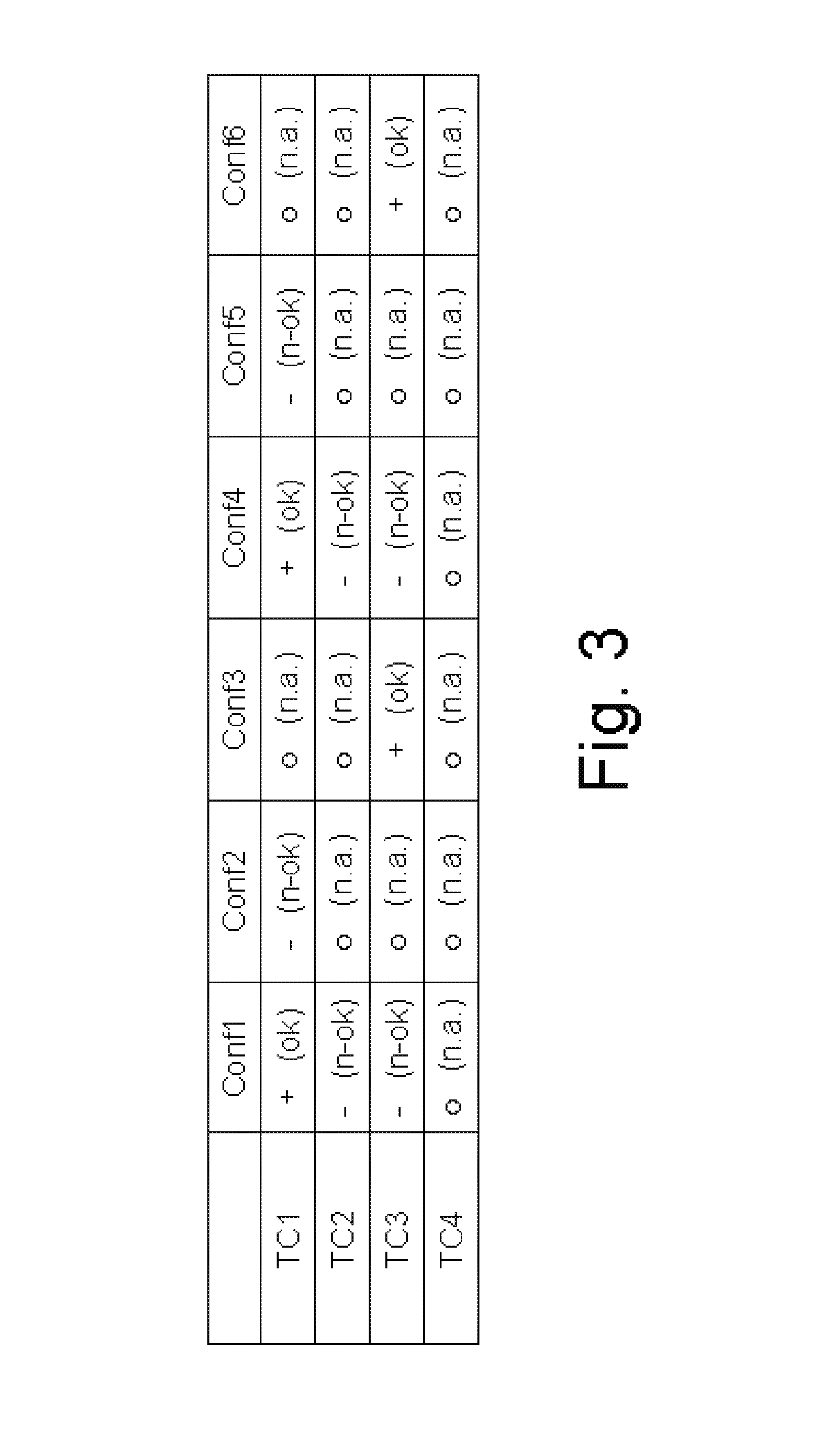

ActiveUS20160305853A1High possible test coverageProgramme controlGeometric CADComputer hardwareTest status

A computer-implemented method for testing an real and / or virtual automotive system through a test by a test environment interacting with the real and / or virtual part, which includes a test series with different test cases of the test for different execution conditions that are specified in test configurations. Each combination of test case and test configuration is assigned a test status value from a group of predefined test status values in accordance with an evaluation of the function of the system in the corresponding test. For further planning, execution, and / or evaluation of the test series at least once a relative test coverage of at least one of the status values is determined in the resulting test case configuration matrix and / or a relative potential for improvement of the test coverage of at least one of the status values with regard to a test case and / or with regard to a configuration is determined.

Owner:DSPACE DIGITAL SIGNAL PROCESSING & CONTROL ENG

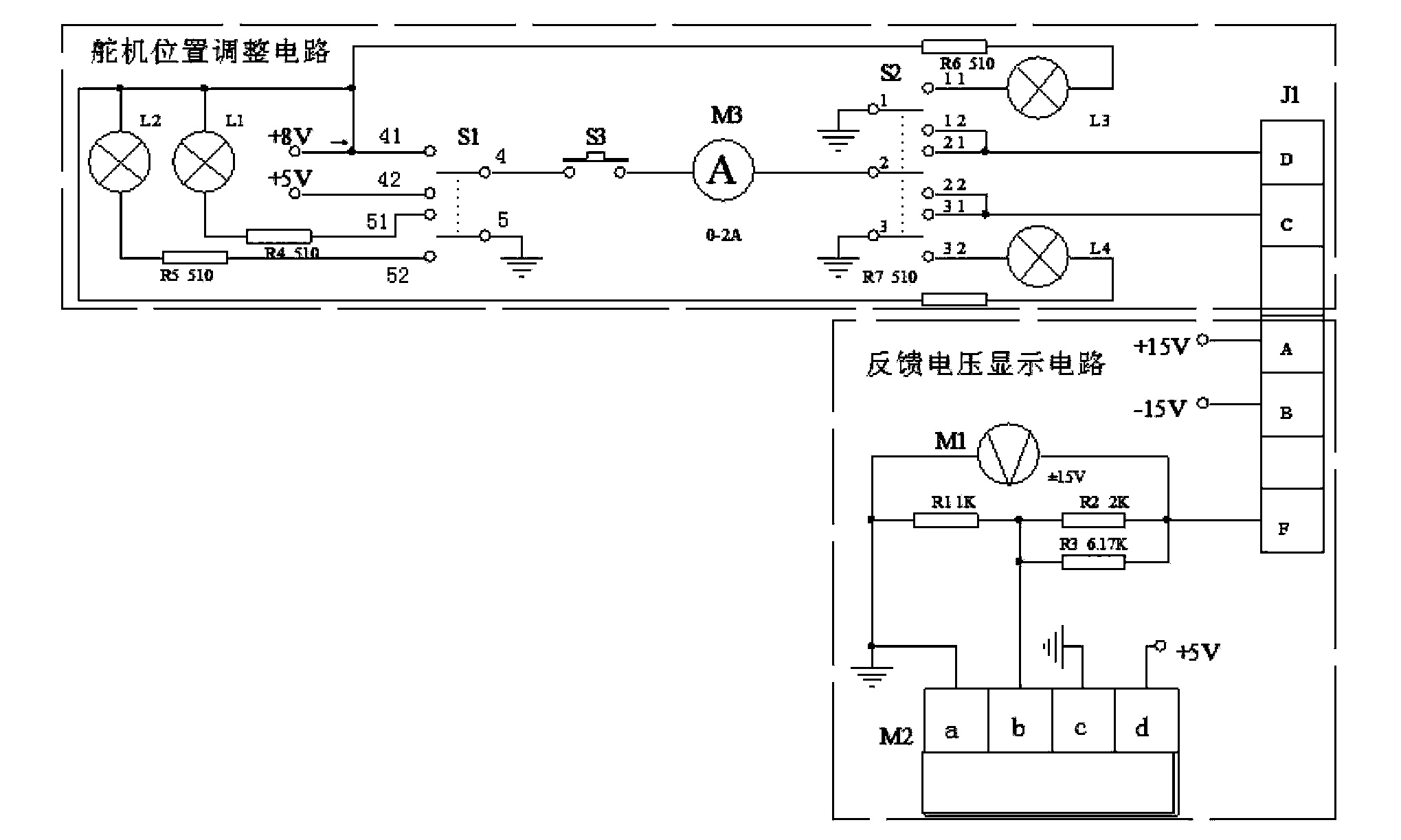

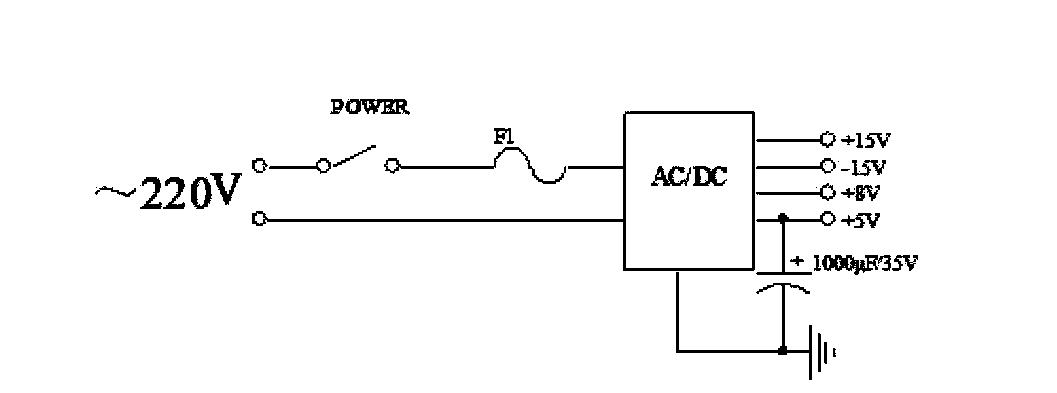

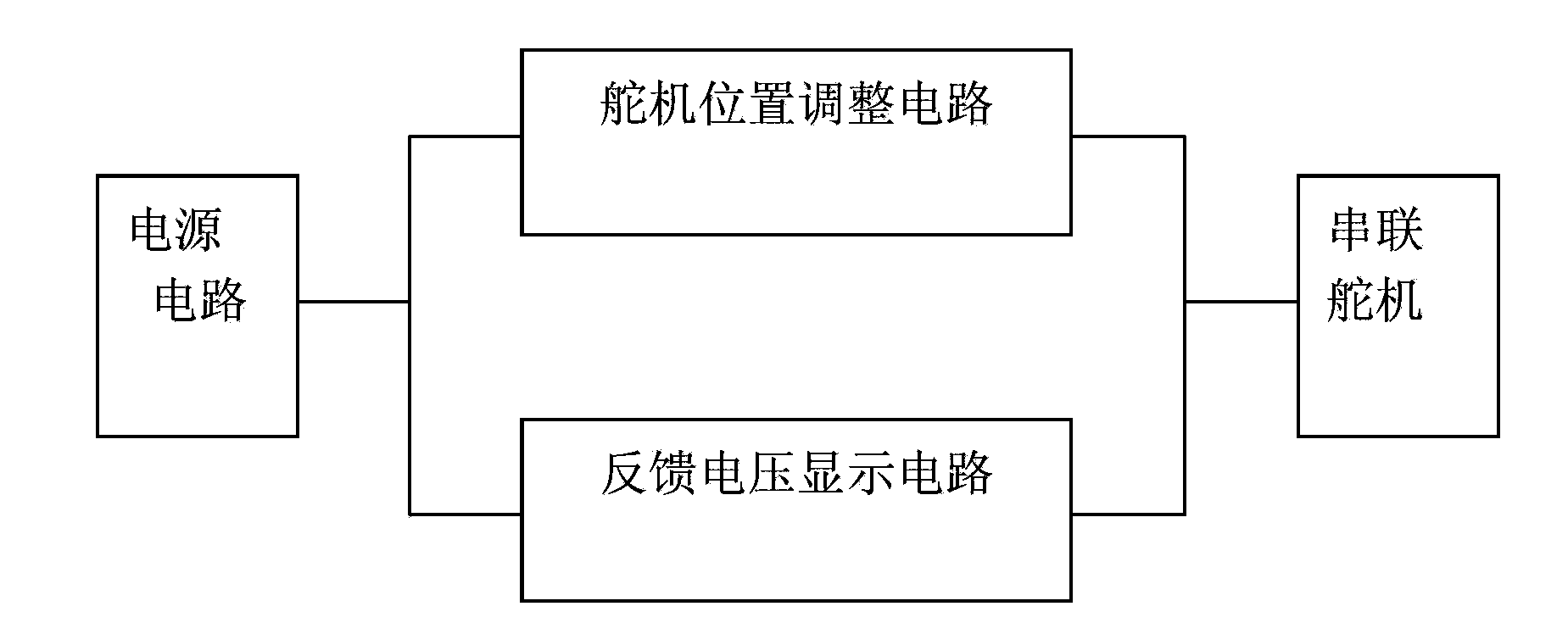

Series steering engine tester

ActiveCN103822790AImprove test accuracyReduce operational complexityStructural/machines measurementInternal conversionPower circuits

The invention belongs to the technical field of helicopter test, and especially relates to a steering engine tester. The series steering engine tester is composed of a power supply circuit, a steering engine position adjustment circuit and a feedback voltage display circuit. The power supply circuit adopts standard 220VAC input, outputs direct-current power after internal conversion, provides working power for the steering engine position adjustment circuit and the feedback voltage display circuit, and provides working power for a to-be-tested series steering engine component. The steering engine position adjustment circuit is used for controlling extension and retraction movement of an output shaft of a series steering engine and adjusting a steering engine installation position. The feedback voltage display circuit is used for monitoring a position feedback voltage value of the serial steering engine in real time during steering engine position adjustment. Continuous position correction on a series steering engine can be effectively realized, and the neutral point and the extension and retraction limit installation positions of the series steering engine can be precisely positioned.

Owner:HARBIN

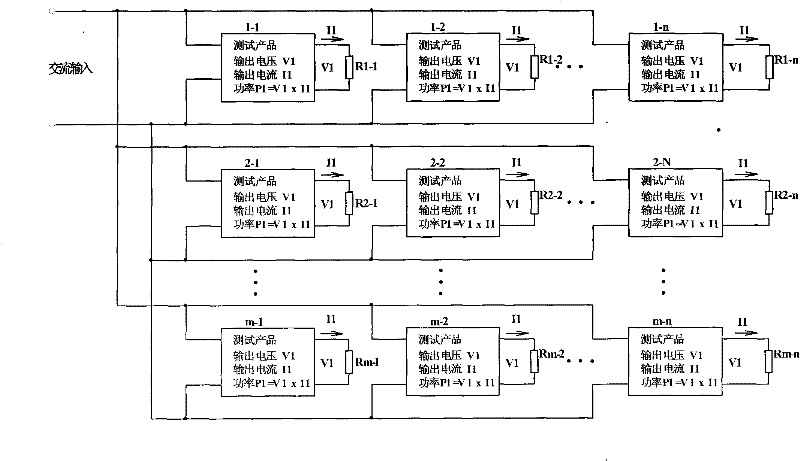

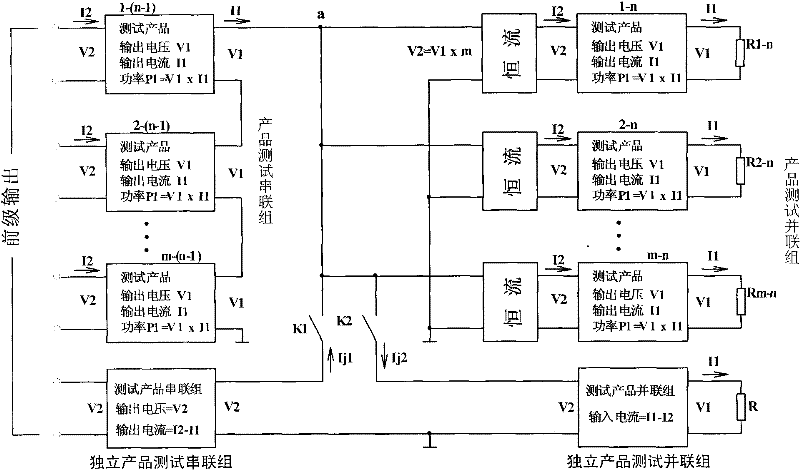

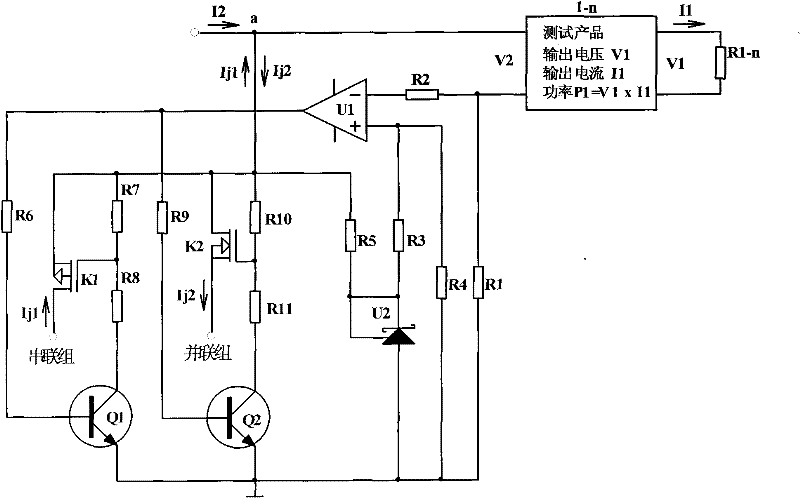

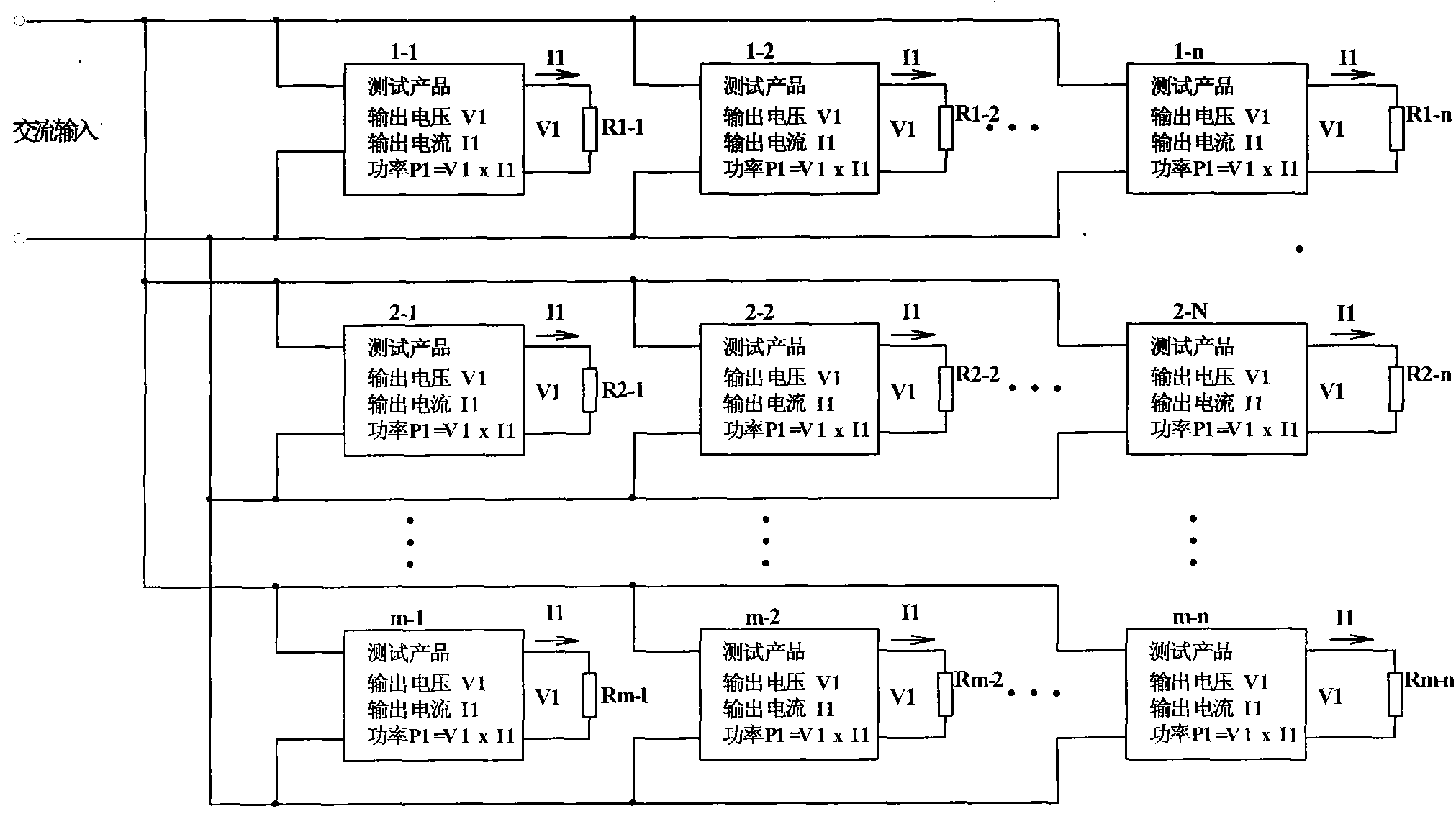

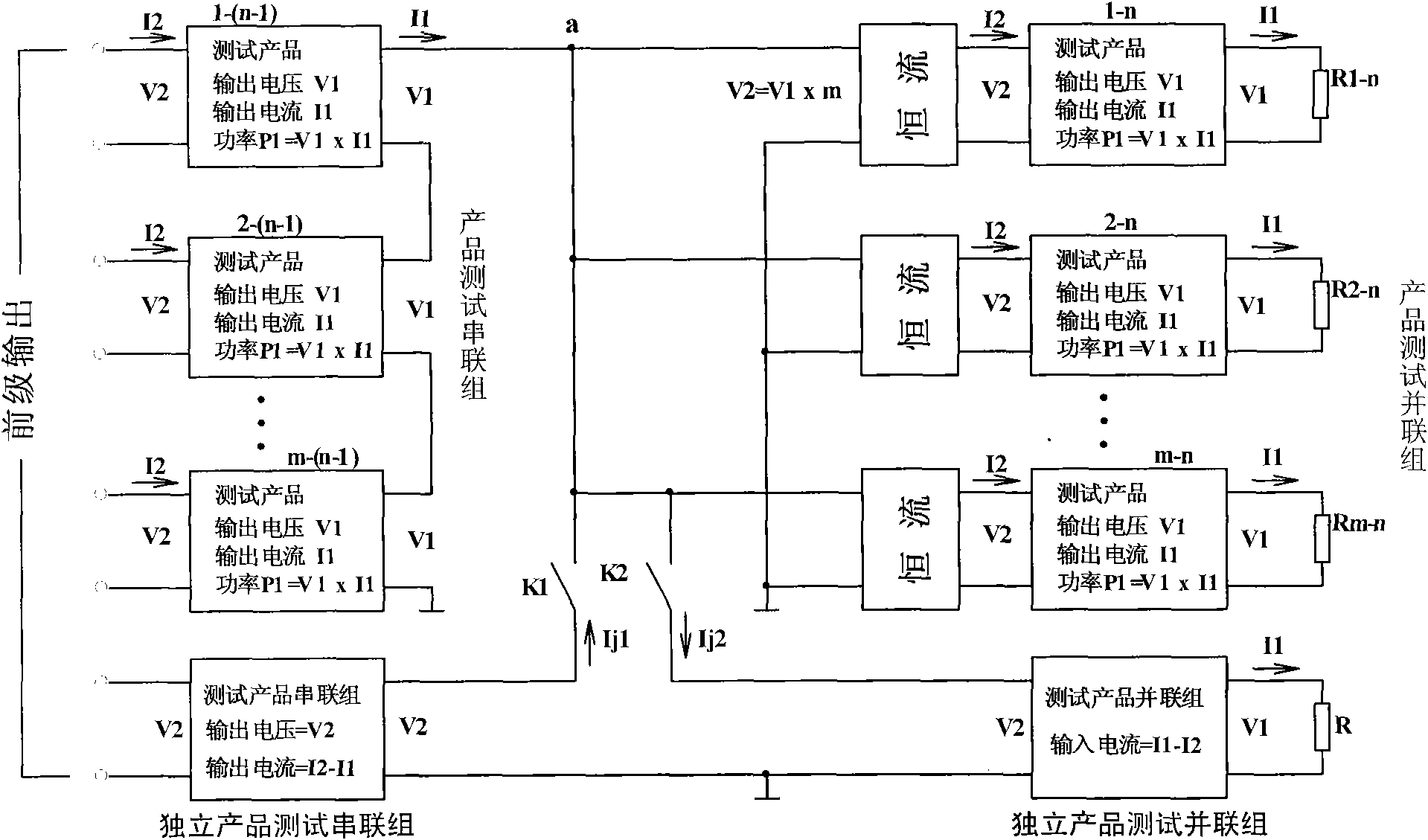

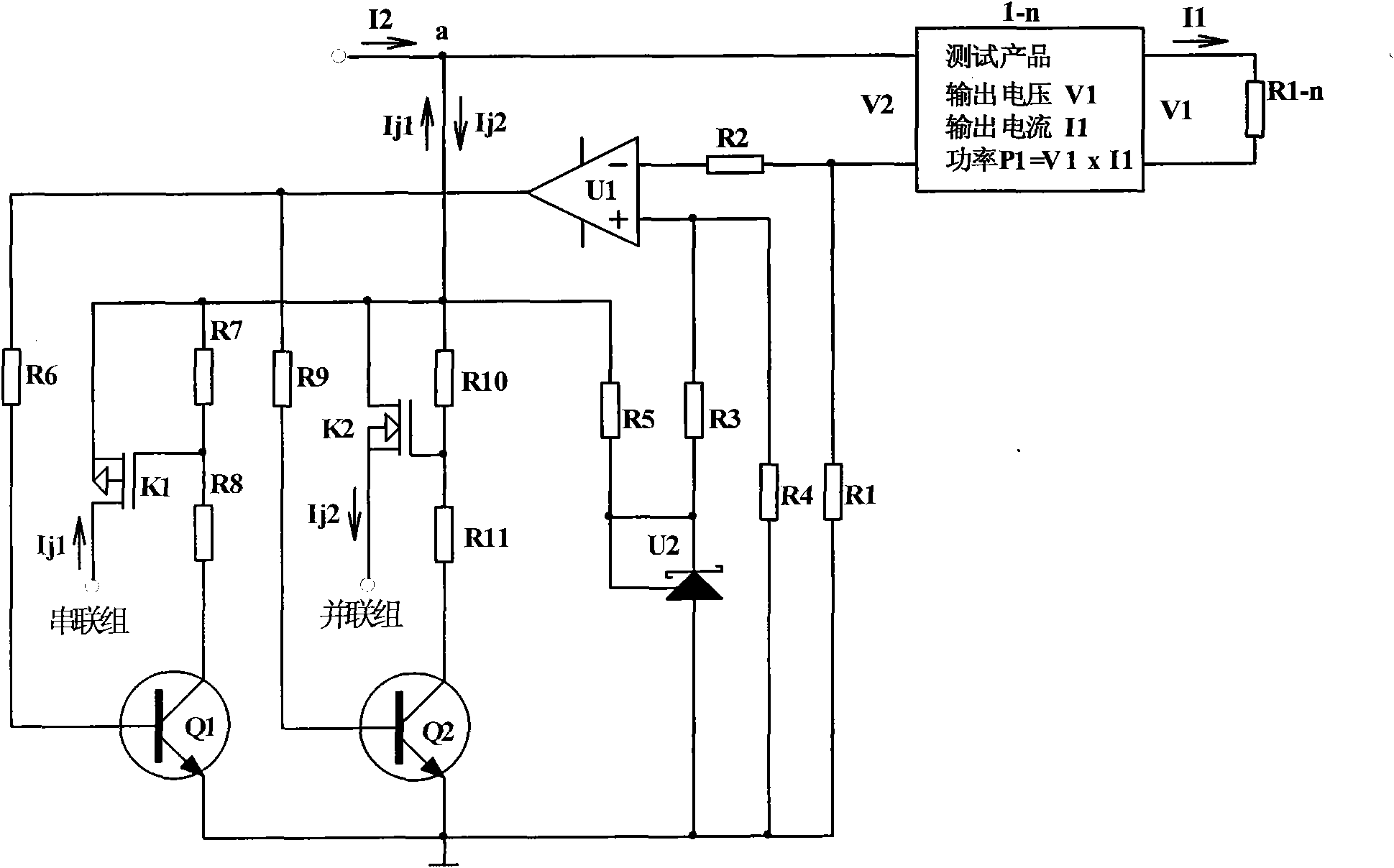

Energy-saving method and device for product aging test

The invention provides an energy-saving method for a product aging test. A product test parallel group, multiple product test series groups, corresponding independent product test series groups and independent product test parallel groups are included, wherein the front stage of the product test series group supplies power to the later stage; each independent product test series group compensates output current for the front stage; each independent product test parallel group shunts the current for the later stage; and current compensation and shunting are realized by controlling corresponding on-off switches through a constant current unit. The invention also provides a device for implementing the method. By using the method and the device, only a rated load is added at the output of the test product of the last stage, so that a large amount of energy consumption is saved; and by using the constant current unit for controlling the constant input current in test units, the stability of the product test is greatly improved.

Owner:东莞市奇立电源有限公司

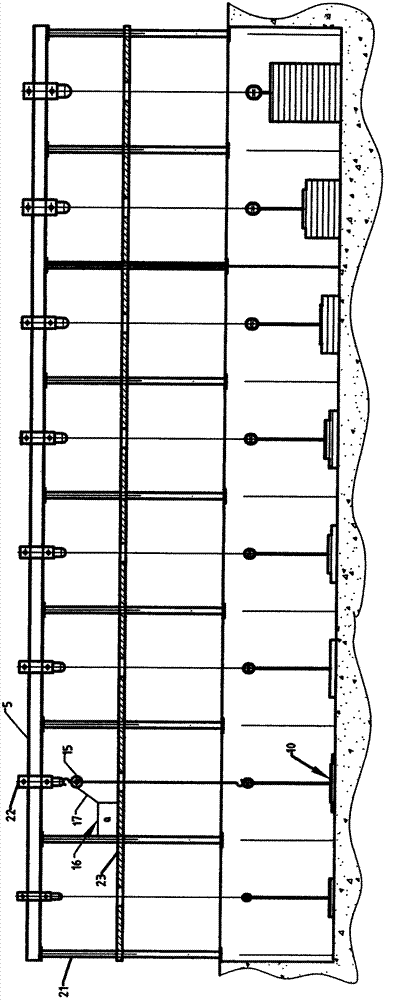

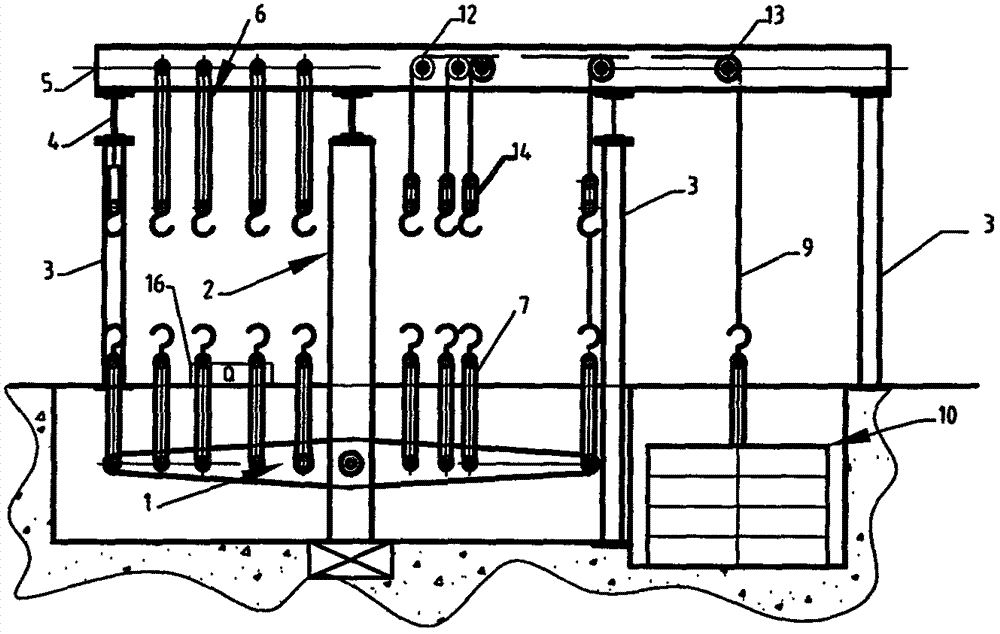

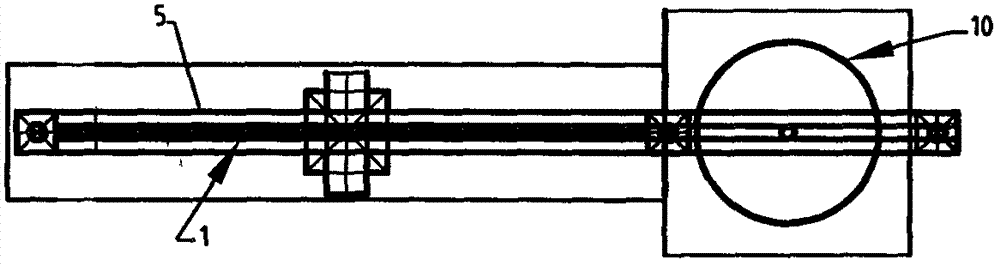

Lever type dynamic load test platform with loads adjustable

InactiveCN103196688AMeet the requirements of testing standardsSolution areaStructural/machines measurementEngineeringTest platform

The invention discloses a lever type dynamic load test platform with loads adjustable which is suitable for a loading detecting test on chain block products in the field of hoist machinery. The lever type dynamic load test platform with the loads adjustable adopts a special lever capable of adjusting loads, a framework and an external force source, wherein the framework and the external force source are matched with the special lever. The theories that the product of a force and a force arm equals to the product of a weight and a weight arm, and a fixed pulley can change the transmission direction of the force and a movable pulley can change the transmission speed and the size of the force are utilized, and therefore a complete integral system capable of adjusting the loads is achieved. The requirement for achieving different test loads is met by adjusting the distance between the force arm and the weight arm and the positions of the force arm and the weight arm, so that tests and detection of products of different specifications are achieved. The lever type dynamic load test platform with the loads adjustable has the advantages of being economical, safe, reliable, convenient and simple to operate, and capable of meeting the detection standard requirements of a test piece and improving working efficiency and the like, solves the problem of adjustment under the condition of testing series products with different specifications and different loads on the same test platform, and solves the problems of large occupied area, high manufacturing cost, many weights, difficult operations, low efficiency, high cost, maintenance difficulties and the like. In addition, the problem that an original hydraulic loading condition does not accord with the practical working condition is solved.

Owner:北京起重工具厂

Yield-enhancing device failure analysis

ActiveUS8738977B2Improve manufacturing yieldIncrease productionError detection/correctionStatic storageFault analysisComputer science

In a system including a processor and memory coupled to the processor, a method of device failure analysis includes the steps of: upon each error detected within a test series performed on a device, the processor storing within a table in the memory an address at which the error occurred in the device and storing a bit position of each failed bit corresponding to that address; for each unique address at which at least one error occurred, determining how many different bit positions corresponding to the address failed during the test series; and based on results of the test series, determining whether the device failed the test series.

Owner:TAHOE RES LTD

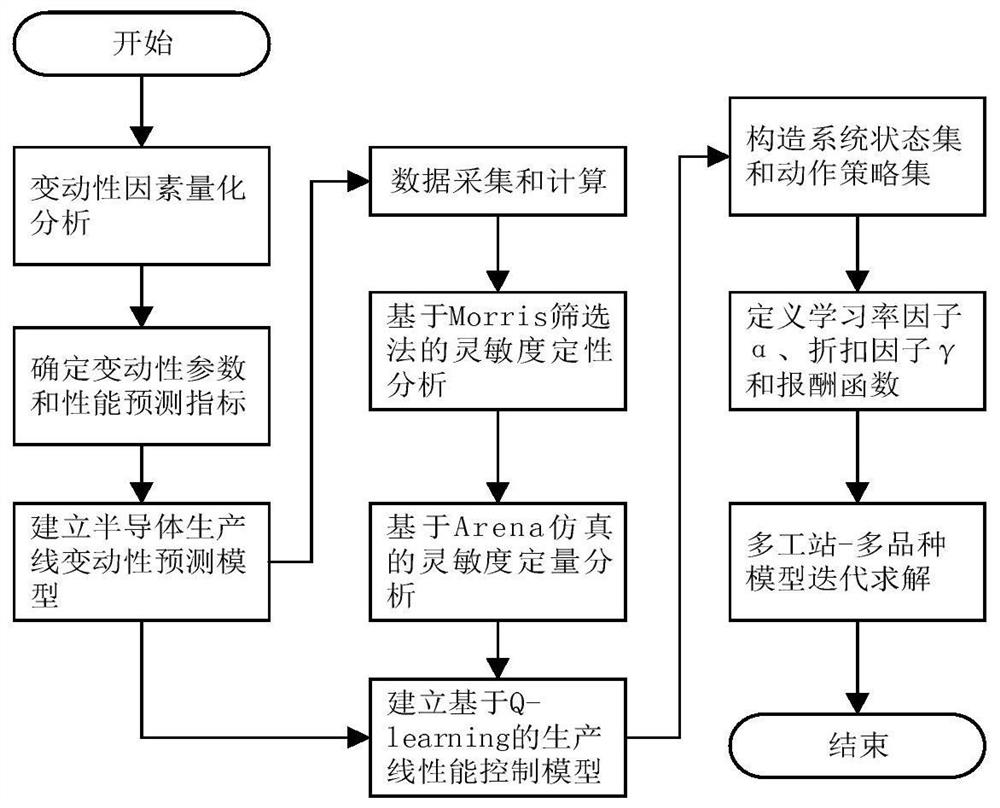

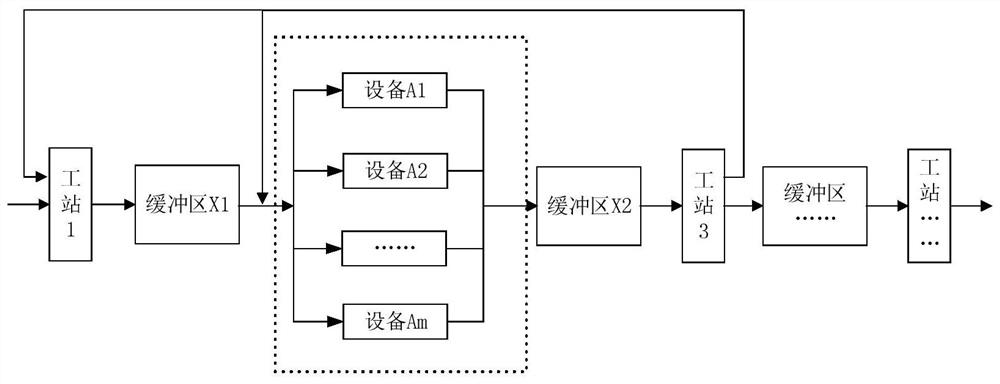

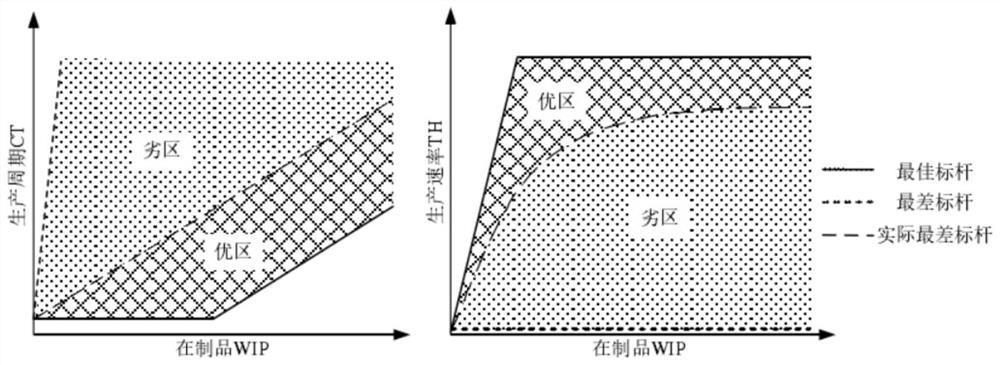

Chip packaging test production line performance control method based on Q-learning reinforcement learning

ActiveCN111857081AAvoid situations where analysis does not applyFast convergenceTotal factory controlProgramme total factory controlSemiconductor chipIndustrial engineering

The invention relates to the field of semiconductor chip packaging test production line performance control and optimization, and particularly relates to a chip packaging test production line performance control method based on Q-learning reinforcement learning. According to the invention, a more accurate semiconductor packaging test series-parallel production line performance prediction model isestablished; and a Morris screening method and an Arena simulation method are comprehensively used for carrying out global sensitivity quantitative analysis, a plurality of influence factors which have the greatest influence on the production line performance and influence rules thereof are obtained, and the conditions that the Markov state space of equipment is huge and traditional mathematical model analysis is not suitable are avoided. According to the method, the variability factors of the production line are controlled on the basis of performance prediction and sensitivity analysis, and the valuing mode of the parameter [epsilon] is improved, so that the convergence rate of the algorithm is higher, local optimization is avoided, and meanwhile, the performance control method has betterflexibility and real-time performance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

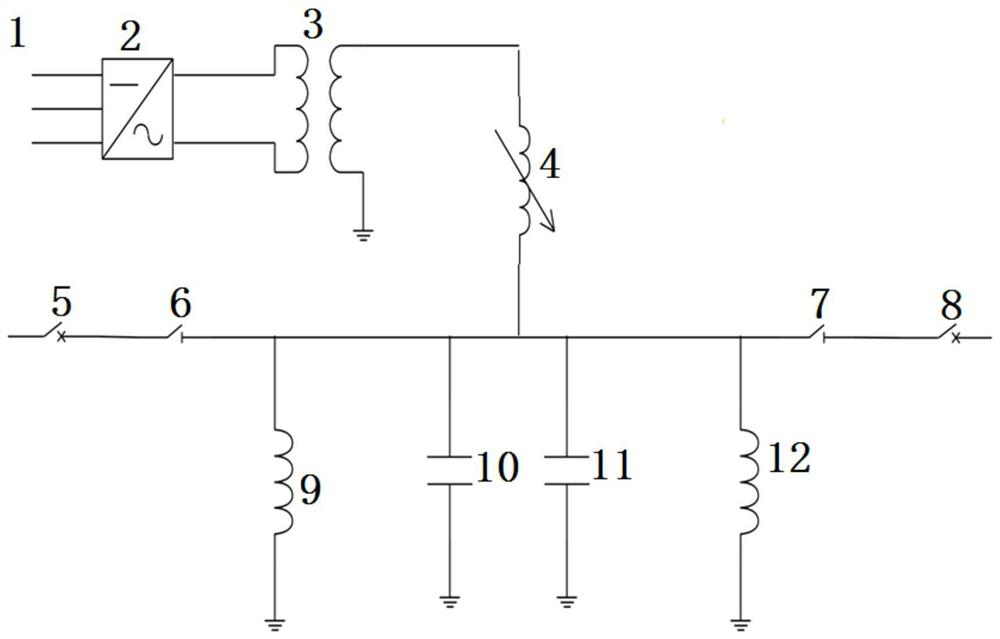

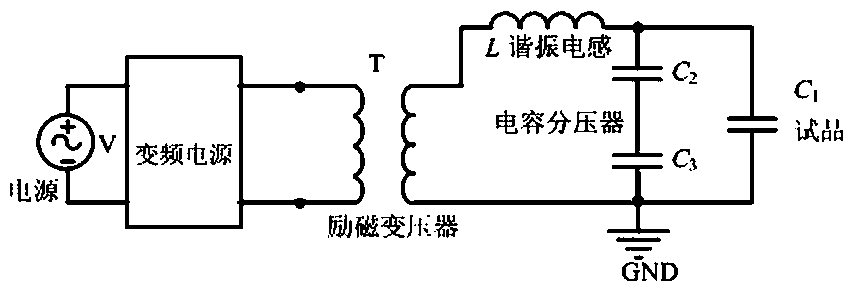

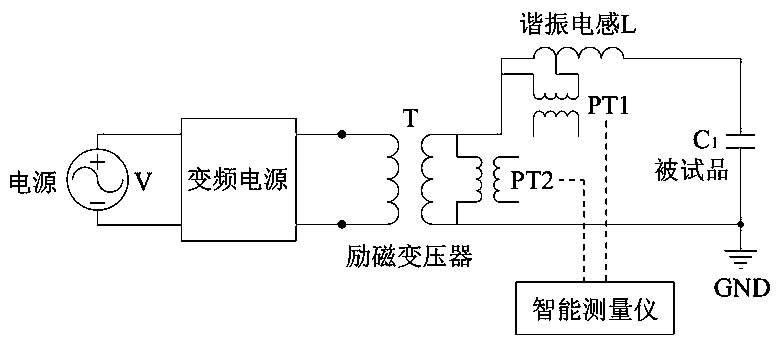

Method for carrying out long-distance submarine cable pressure test by using reactive compensation reactor

The invention discloses a method for carrying out a long-distance submarine cable pressure test by using a reactive power compensation reactor. The method comprises the following steps: calculating aparallel compensation inductance value L2 according to reactance values of a land station reactive power compensation reactor and a sea station reactive power compensation reactor; calculating an inductance value L1 of a test series adjustable reactor according to a series-parallel resonance calculation formula when series-parallel resonance is reached; adjusting the inductance value of the test series adjustable reactor according to the calculated inductance value of the test series adjustable reactor 4; setting the frequency of a variable frequency power supply, carrying out slow boost testing, when the reading of the test capacitive voltage divider reaches a test voltage, stopping boosting, keeping the station for preset time, disconnecting the variable frequency power supply to carry out discharging at the end of time so as to complete long-distance submarine cable pressure testing by a reactive compensation reactor. With the method, the alternating-current pressure test can be carried out on the submarine cable, the capacity and the number of field test equipment are relatively small, and the test difficulty and the test cost are relatively low.

Owner:XIAN THERMAL POWER RES INST CO LTD

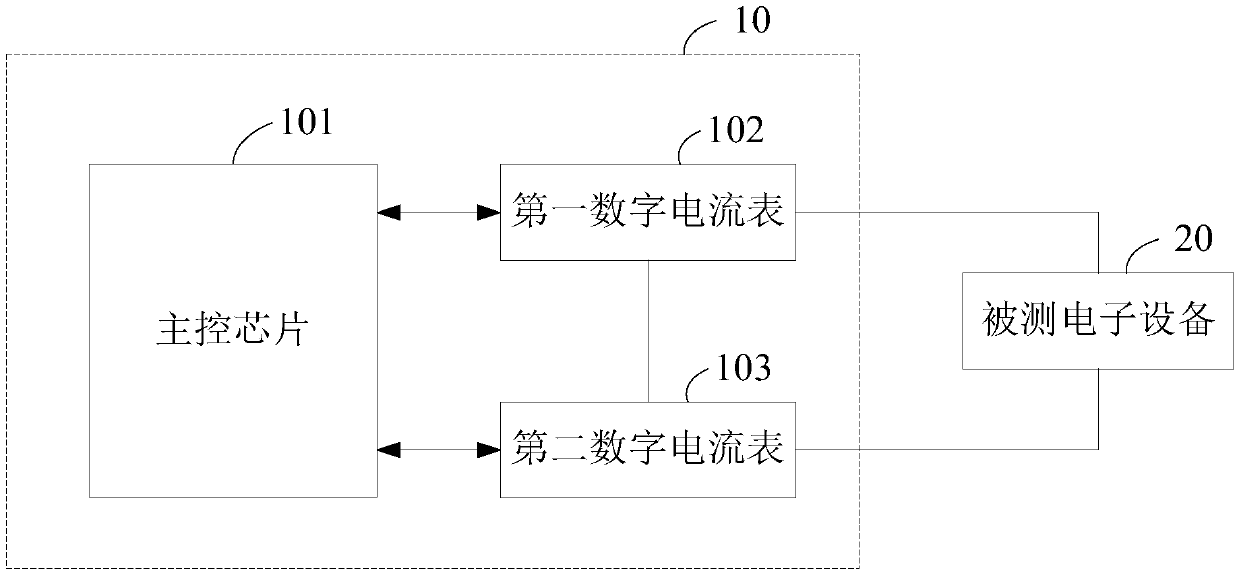

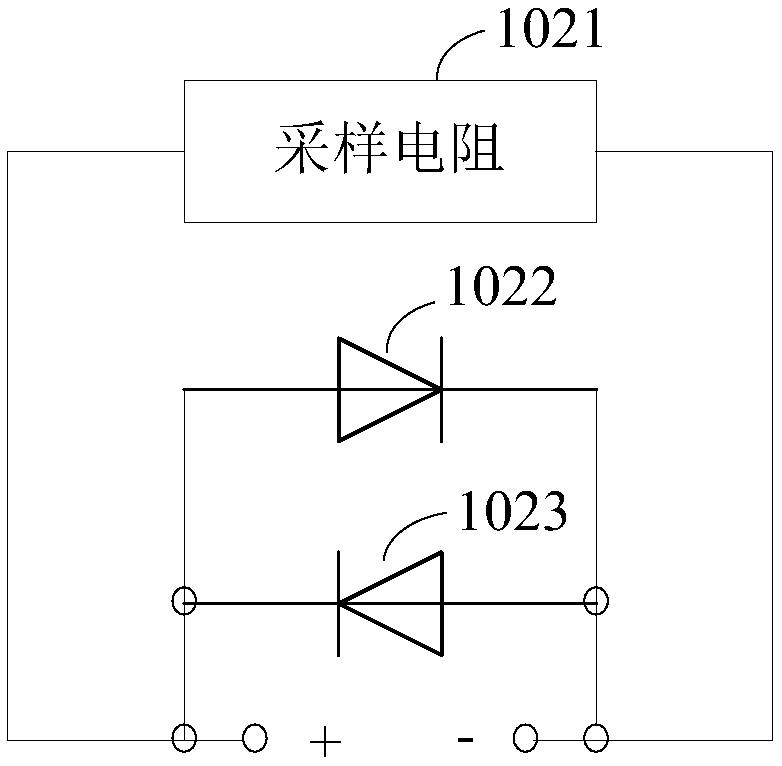

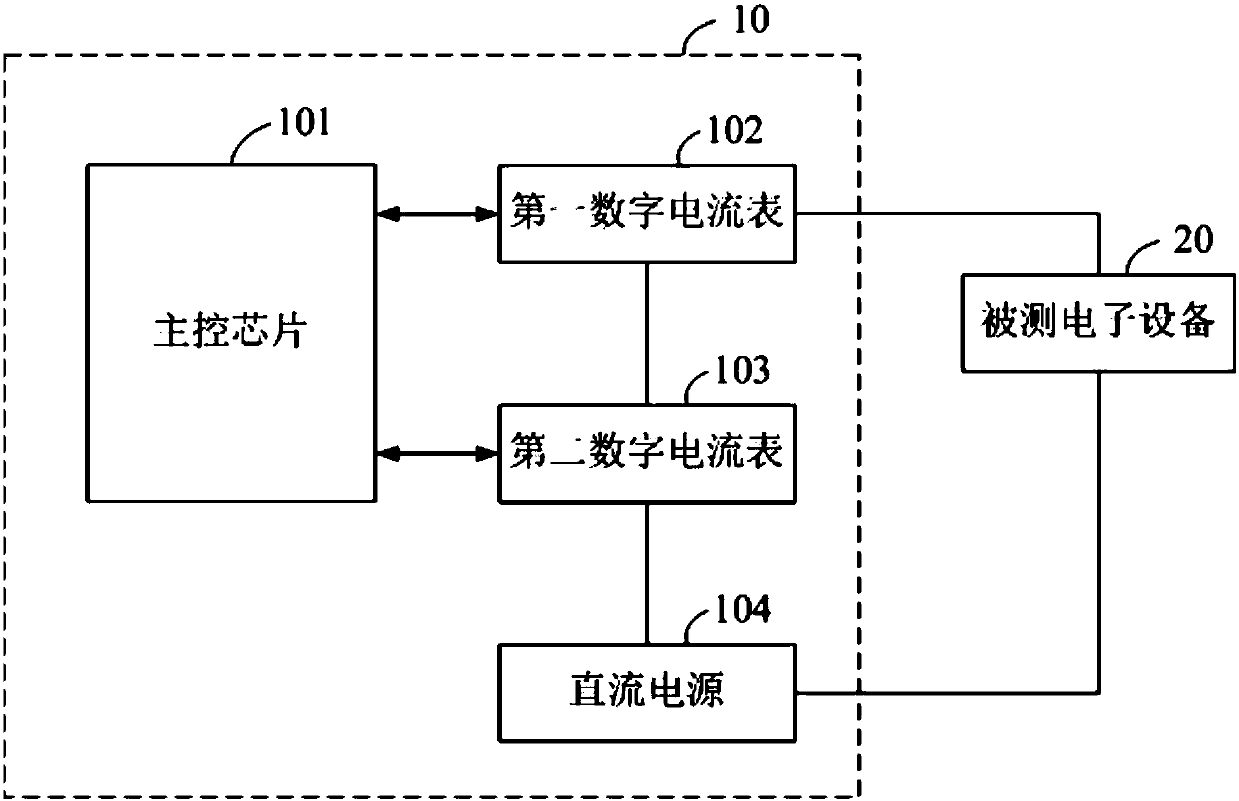

Power consumption test system and method

PendingCN107918050AEnsure safetyAvoid errorsPower measurement by digital techniqueElectrical resistance and conductanceCurrent meter

The invention provides a power consumption test system and method. The power consumption tester in the power consumption test system is formed by a main control chip, a first digital electronic ammeter and a second digital electronic ammeter, wherein two ends of the sampling resistor of the first digital electronic ammeter and two ends of the sampling resistor of the second digital electronic ammeter are each in parallel connection with two diodes, and the measuring range of the first digital electronic ammeter is greater than the measuring range of the second digital electronic ammeter; the first digital electronic ammeter, the second digital electronic ammeter and the tested electronic device form one series circuit; the main control chip controls on / off of the series circuit; when the series circuit is turned on, the first digital electronic ammeter and the second digital electronic ammeter respectively measures the current value of the tested electronic device in the current state;and the main control chip acquires the first current value of the first digital electronic ammeter and the second current value of the second digital electronic ammeter at the same time. The power consumption test system and method can also measure the current of the tested electronic device in any state, and can avoid the error which is caused when the ammeters are observed by human eyes, thus improving reliability.

Owner:YUNDING NETWORK TECH BEIJING

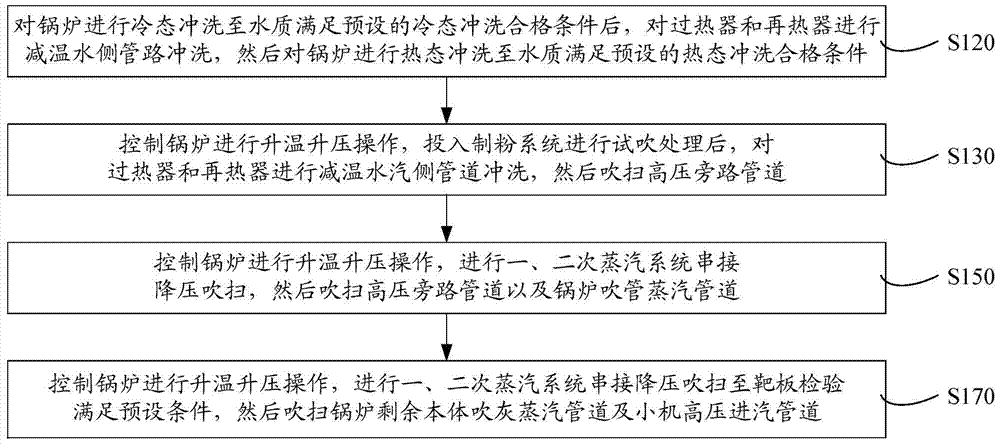

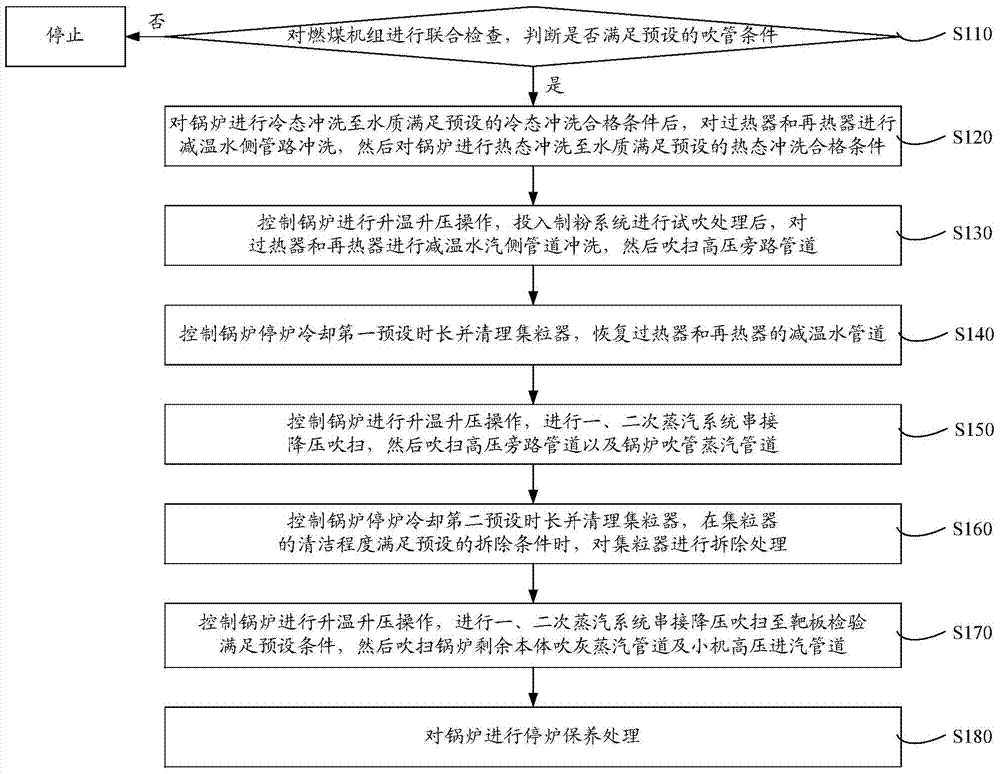

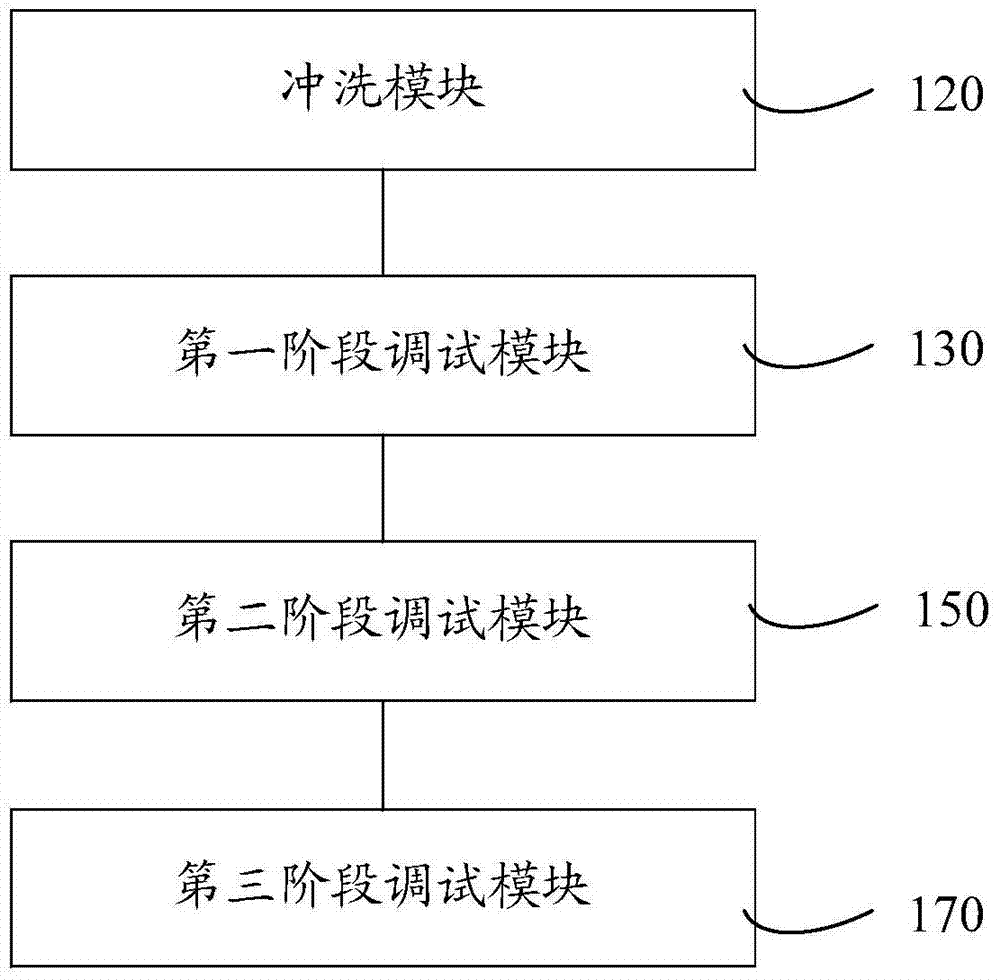

1045mw ultra-supercritical coal-fired unit boiler blowpipe debugging method and system

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

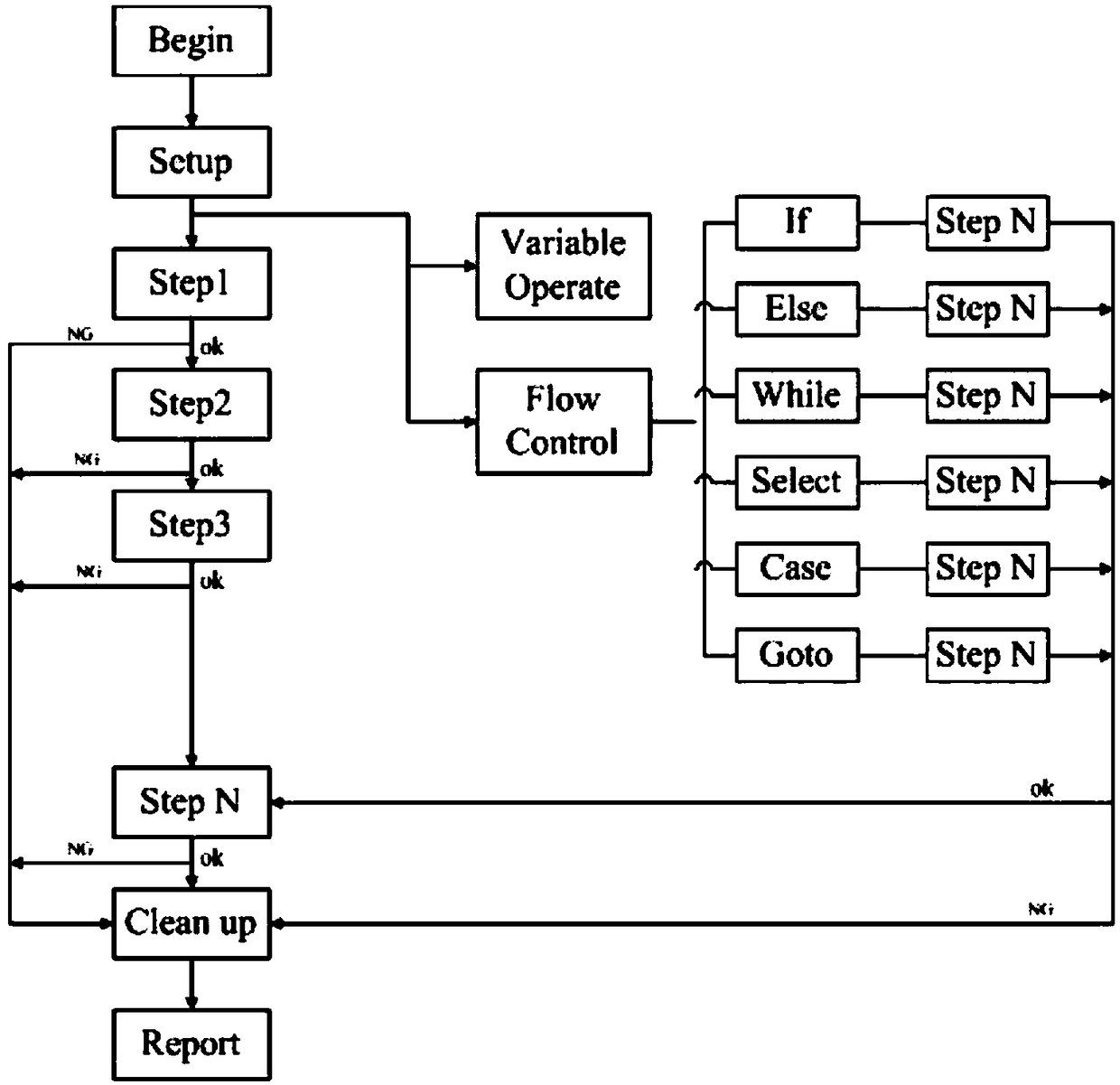

Software testing method based on rapid demand version iteration

PendingCN111459809ARealize hierarchical and hierarchical managementRapid positioningSoftware testing/debuggingTestwareProcessing

The invention provides a software testing method based on rapid demand version iteration. The software testing method comprises the following steps: step 1, setting a basic testing type library (100);step 2, setting a test case priority (200); and step 3, selecting a test type, confirming a test key point, outputting a test case priority, automatically executing a case, and outputting a test report (300) according to a requirement specification. According to the method, a client can be helped to quickly build an automatic test and verification system, quickly edit test series files, perform multi-process control and multi-thread execution and improve test throughput, test requirements of most products can be compatible under the condition of meeting most test processing requirements and test drive support, and the execution efficiency is high. With the help of the method, the work of engineers is more targeted, and the design and development work of a test software stage in a projectis greatly shortened.

Owner:HUITONGDA NETWORK CO LTD

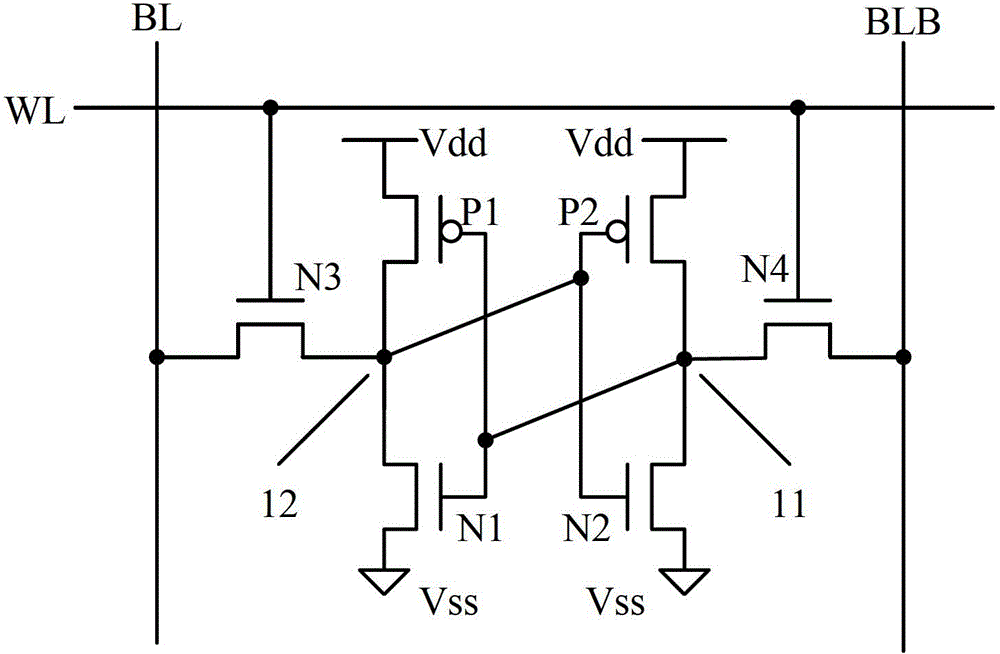

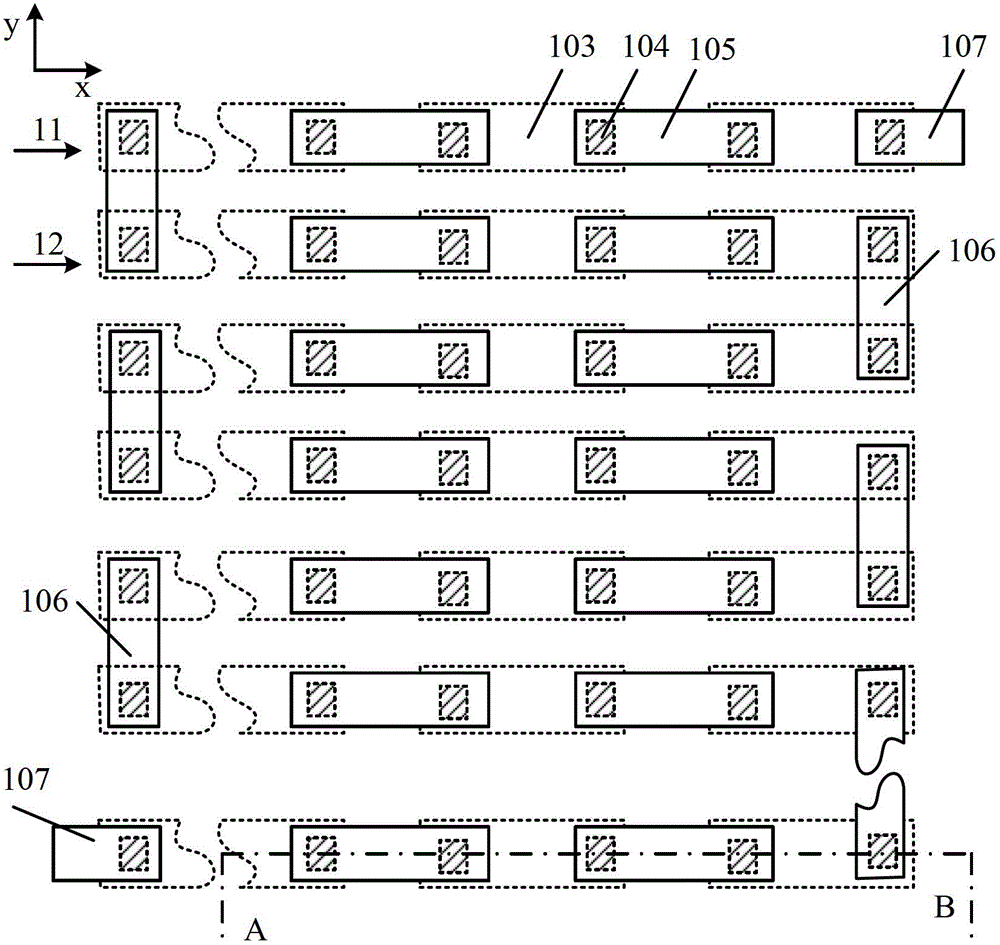

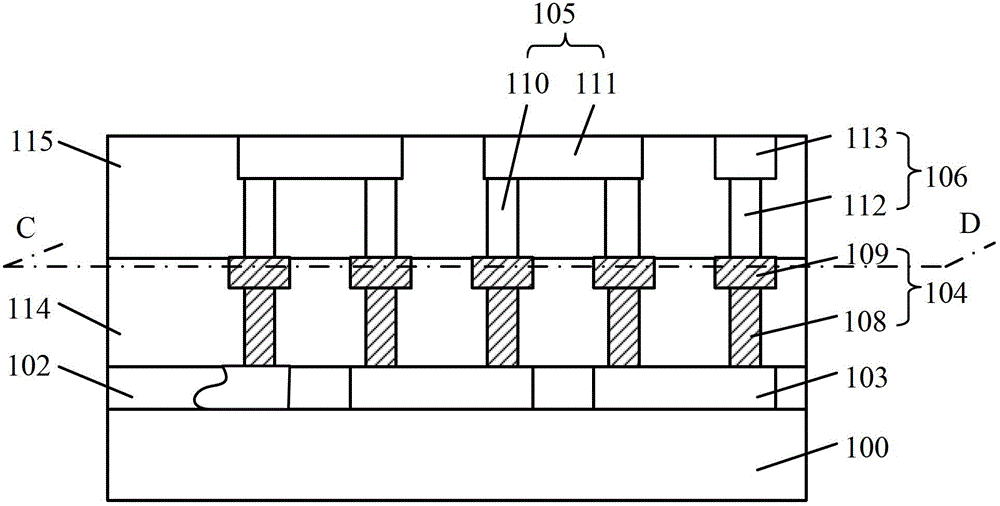

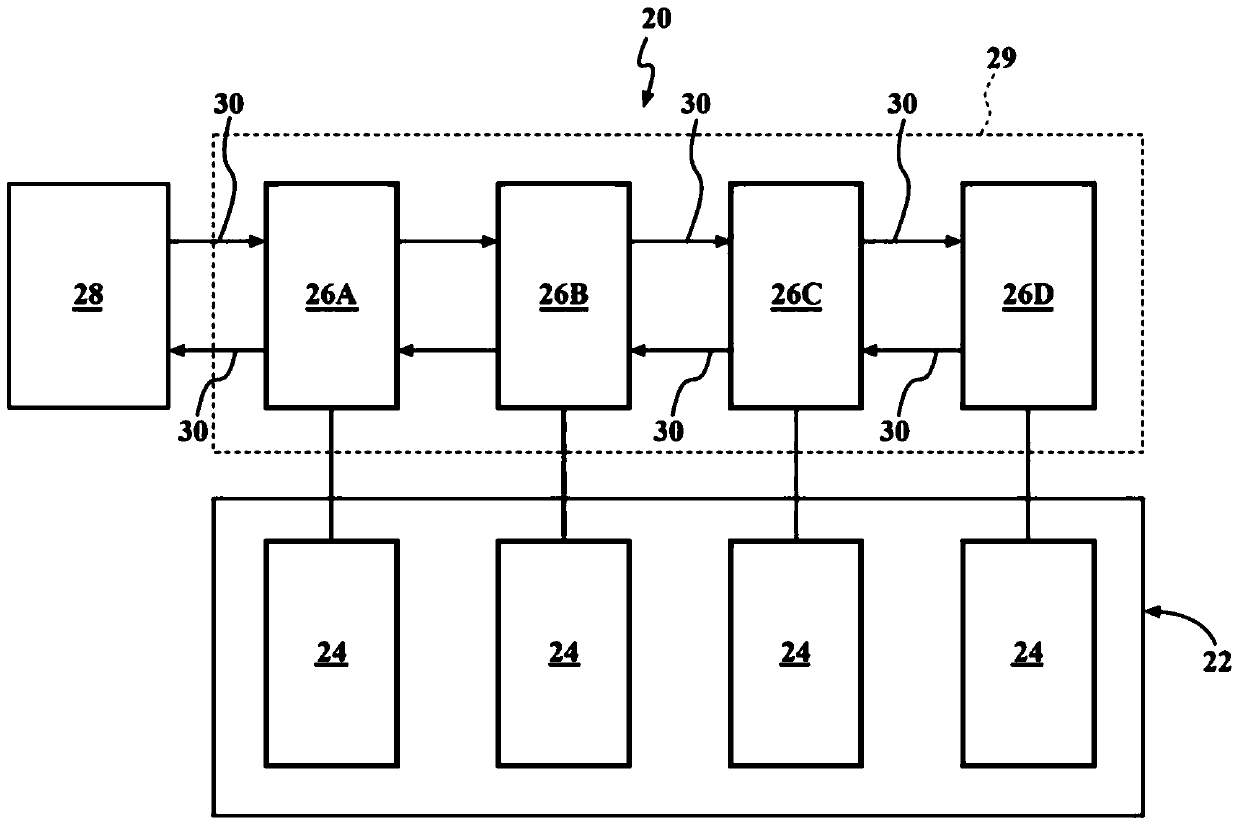

Semiconductor test structure and its test method, detection method

ActiveCN103839922BSave spaceOptimizing the forming processSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsTest efficiencyTest series

Owner:SEMICON MFG INT (SHANGHAI) CORP

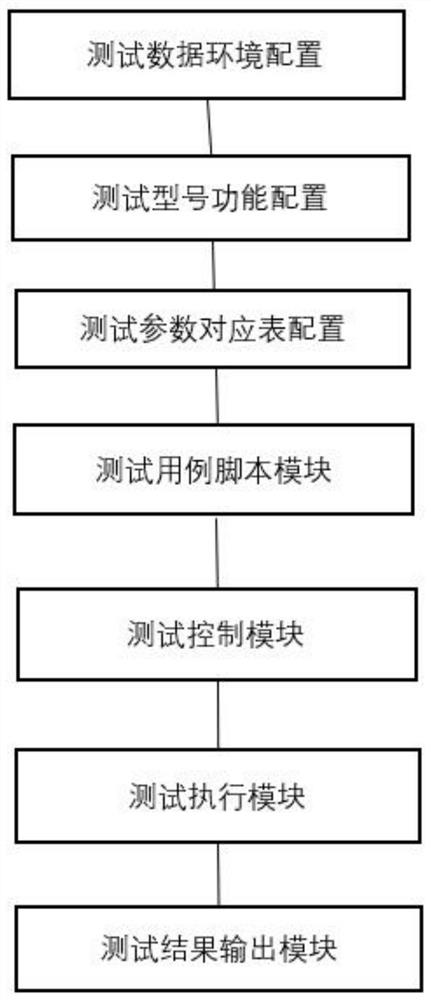

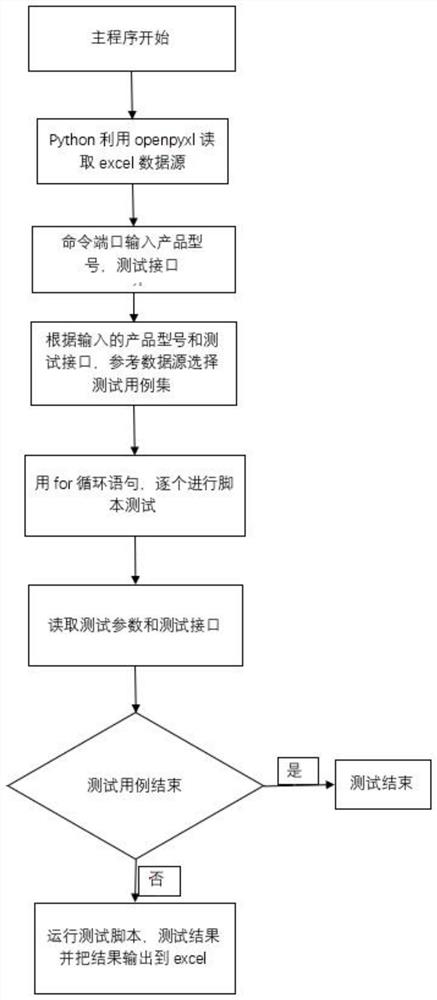

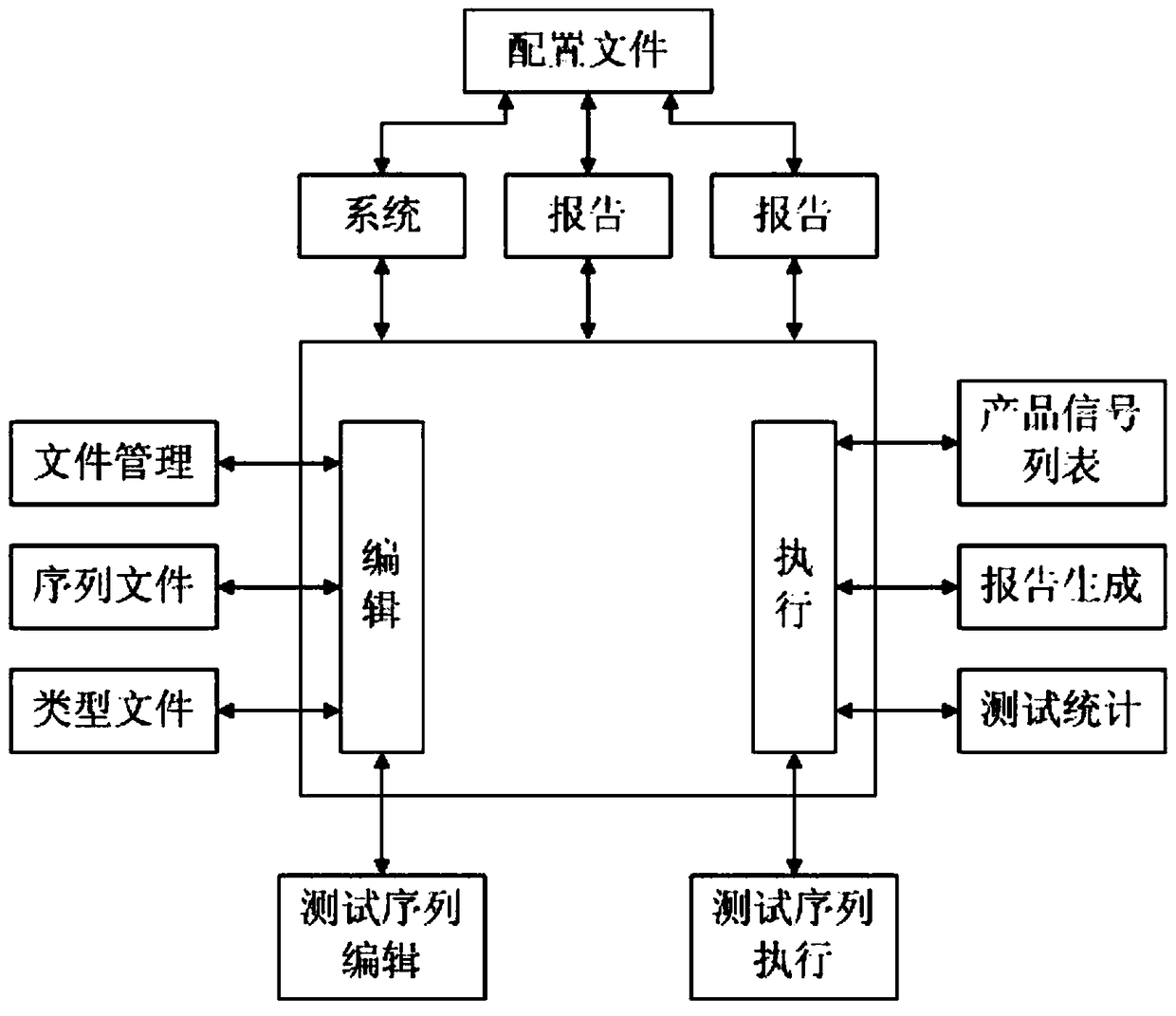

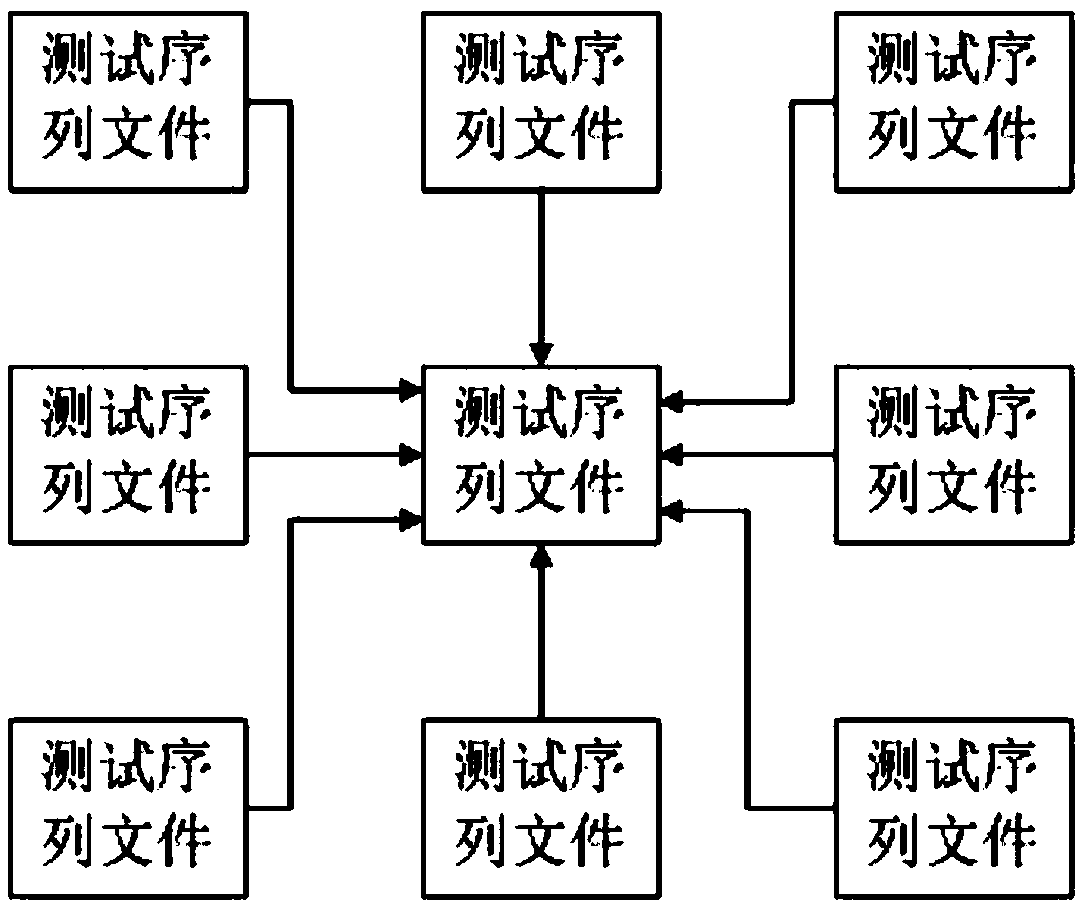

Frame system for python automatic test series products

PendingCN111723009AOptimized formatEasy to modifySoftware testing/debuggingData sourceTest execution

The invention discloses a frame system for python automatic test series products. The frame system comprises a test data source module A; a test data source module B; a test data source module C; a test case script module which is used for inputting a tested product model and a test interface by using a client and a tester; a test control module which is used for reading each data configuration source and setting product parameters and environmental parameters; a test execution module which is used for executing the test case set selected by the product; a test result verification module; anda test output module which is used for comparing an output value actually obtained by the test environment end with a theoretical result, and outputting a test result to an excel test result table according to a certain format after the execution module. According to the invention, through configuring a unified data source, configuring a test environment parameter, selecting a test case and selecting a test corresponding parameter table, an automatic test system is carried out; and unified testing of unified series of products of different models is achieved.

Owner:芯河半导体科技(无锡)有限公司

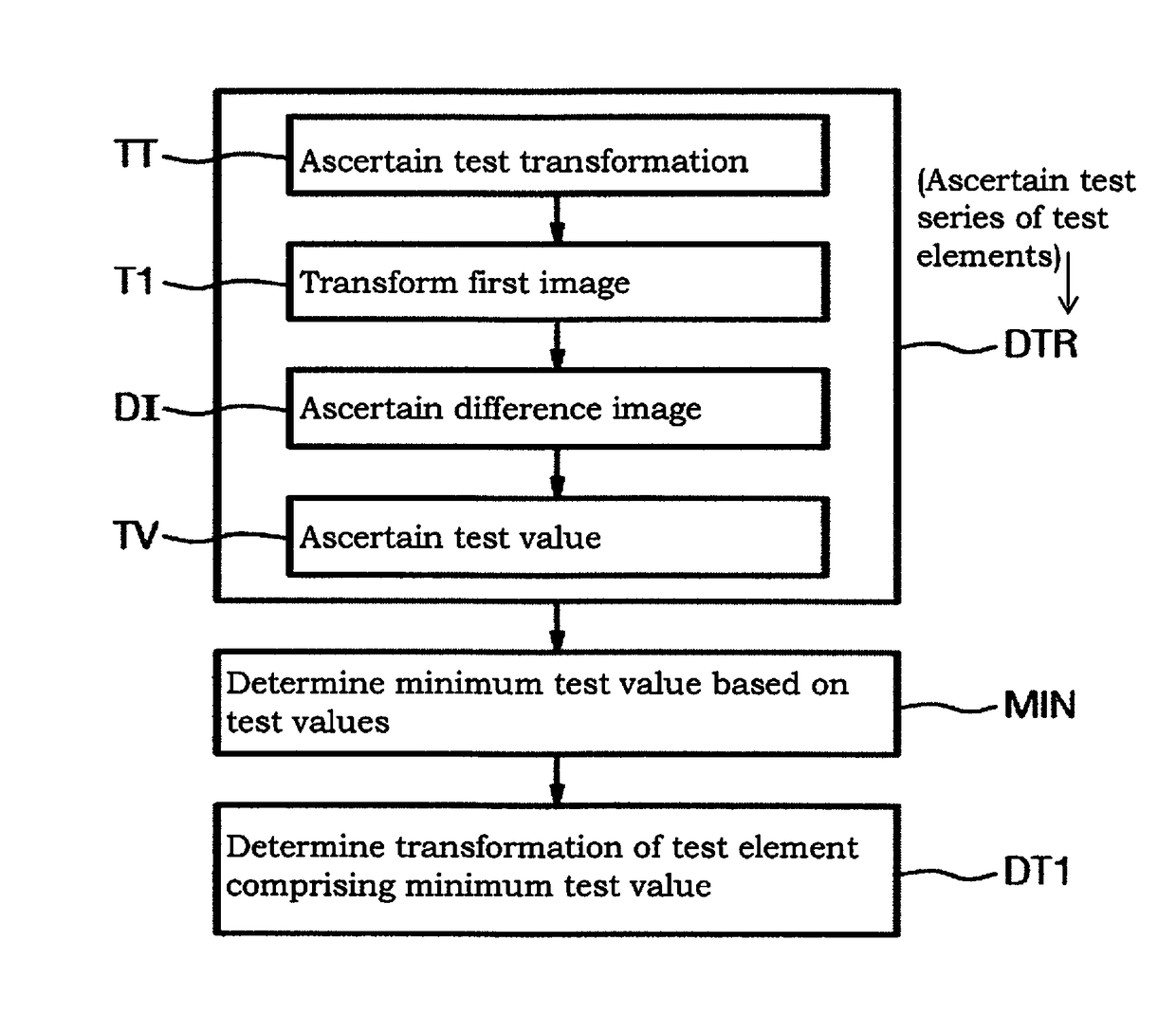

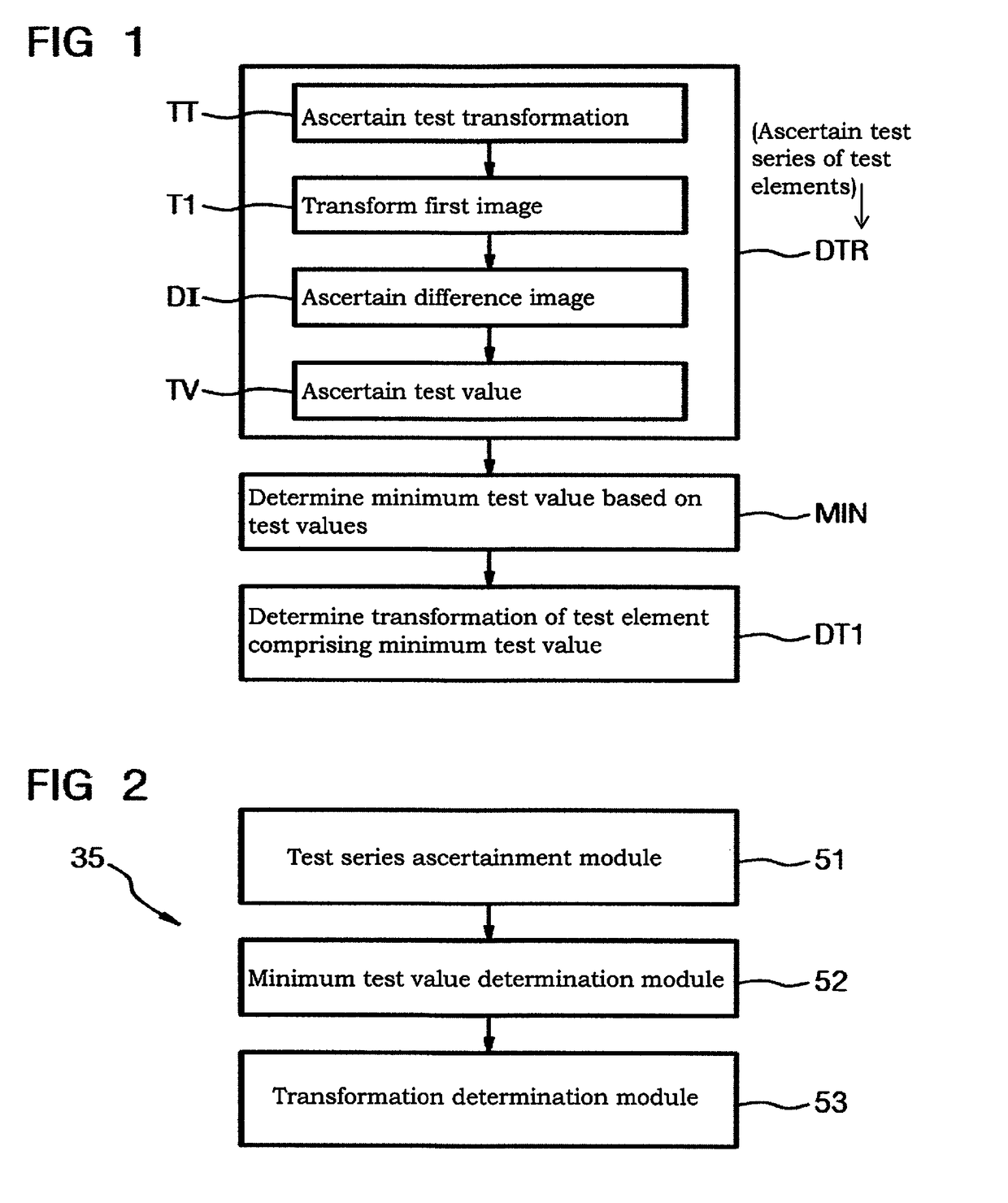

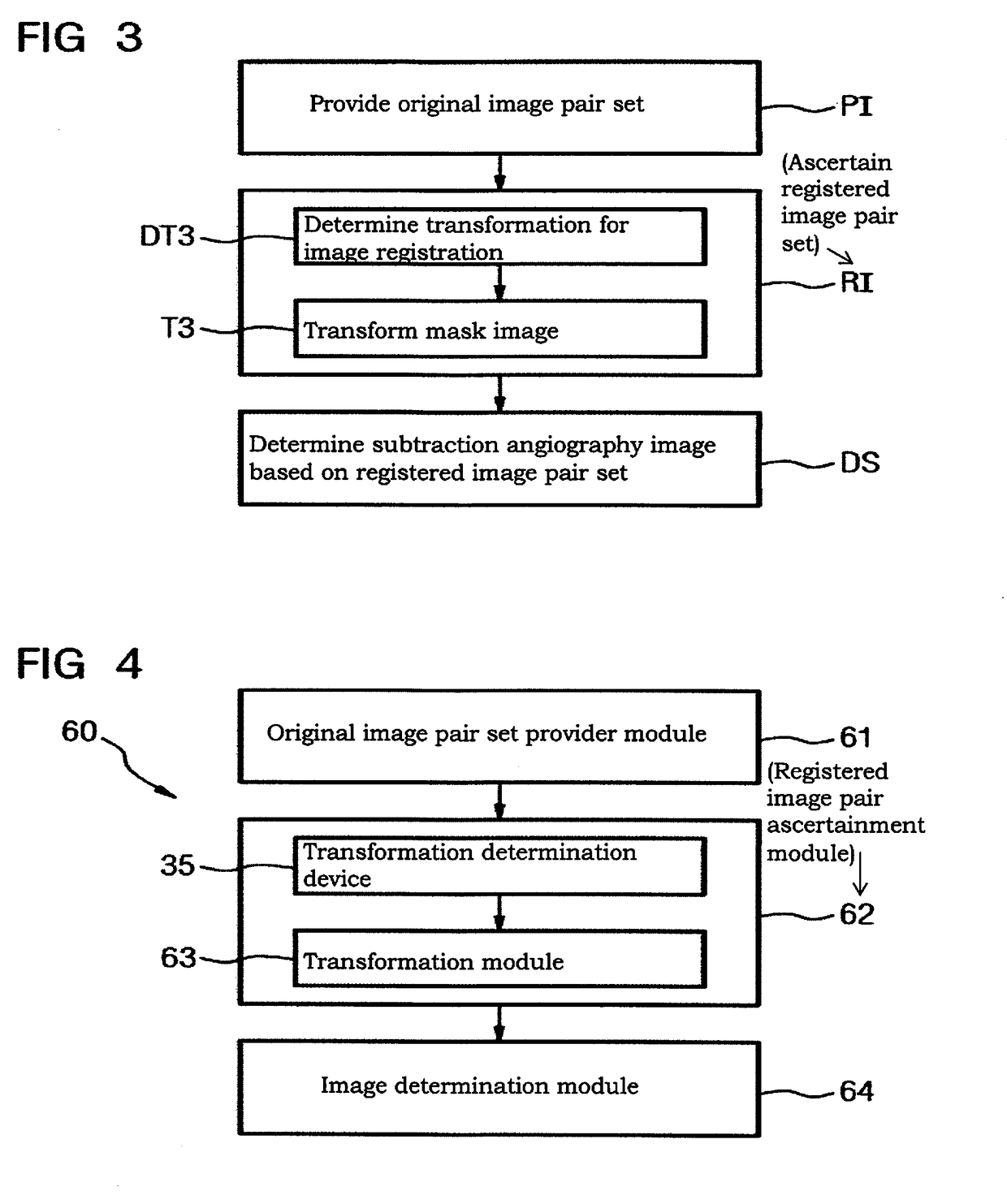

Transformation determination device and method for determining a transformation for image registration

ActiveUS10121244B2Improve registrationEasy to upgradeImage enhancementMedical imagingTest elementComputer science

A method is for determining a transformation for image registration of a first image relative to a second image. The method includes ascertaining a test series of test elements including a test transformation and a test value, the ascertaining including ascertaining the test transformation based on a sequence of test transformations and / or based on previously ascertained test elements, transforming the first image via the ascertained test transformation, ascertaining a difference image, and ascertaining the test value of the test element based on the difference image such that the test value is a measure for an extension of a frequency distribution of values of pixels of the difference image in a direction of pixel value increase. It further includes determining a minimum test value based on test values encompassed by the test elements and determining the transformation which is the test transformation of a test element including the minimum test value.

Owner:SIEMENS HEALTHCARE GMBH

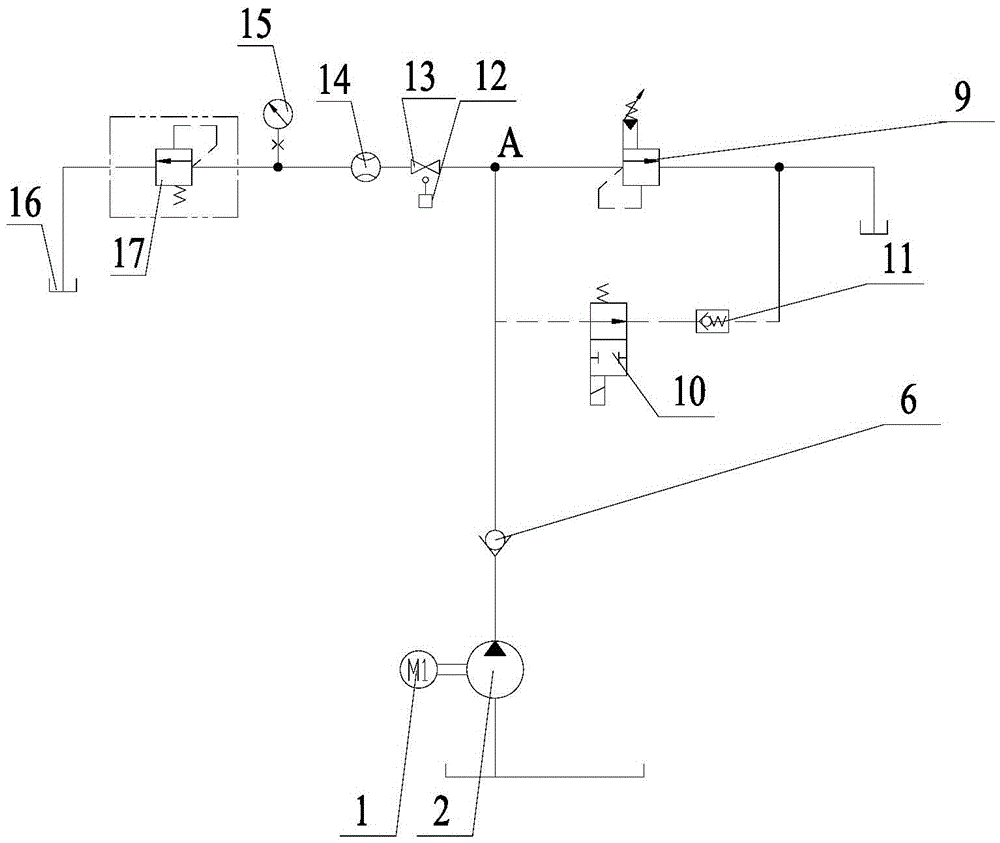

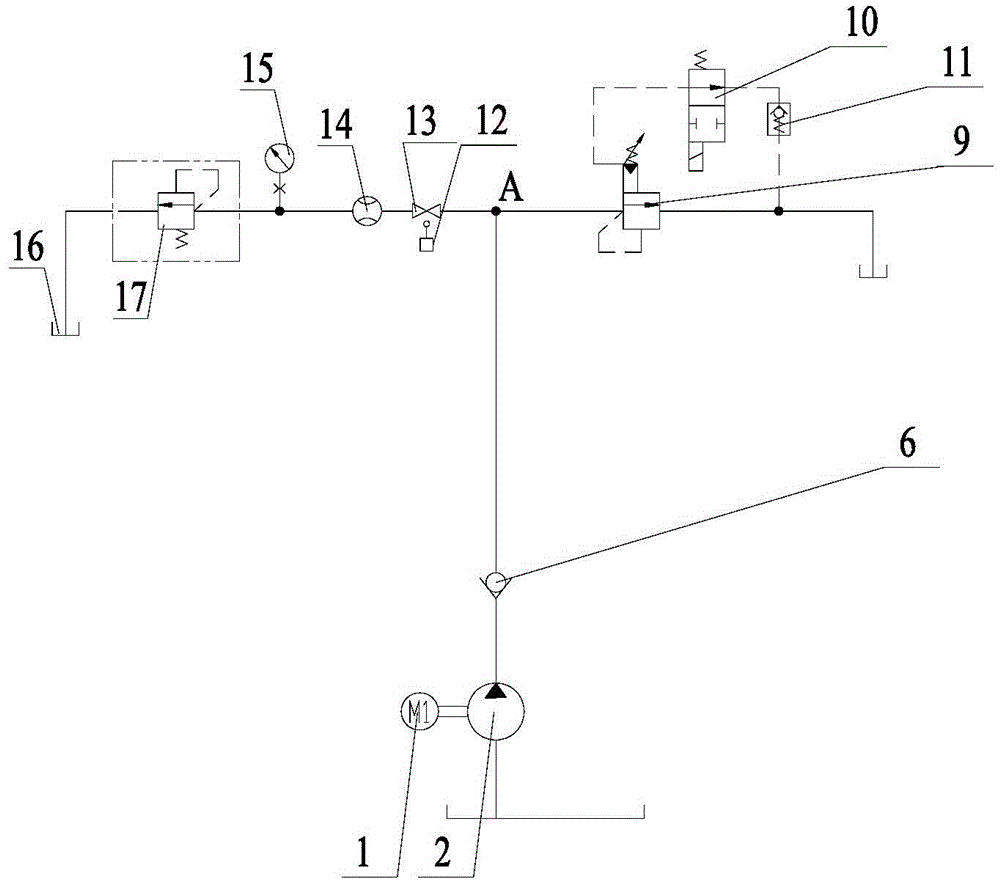

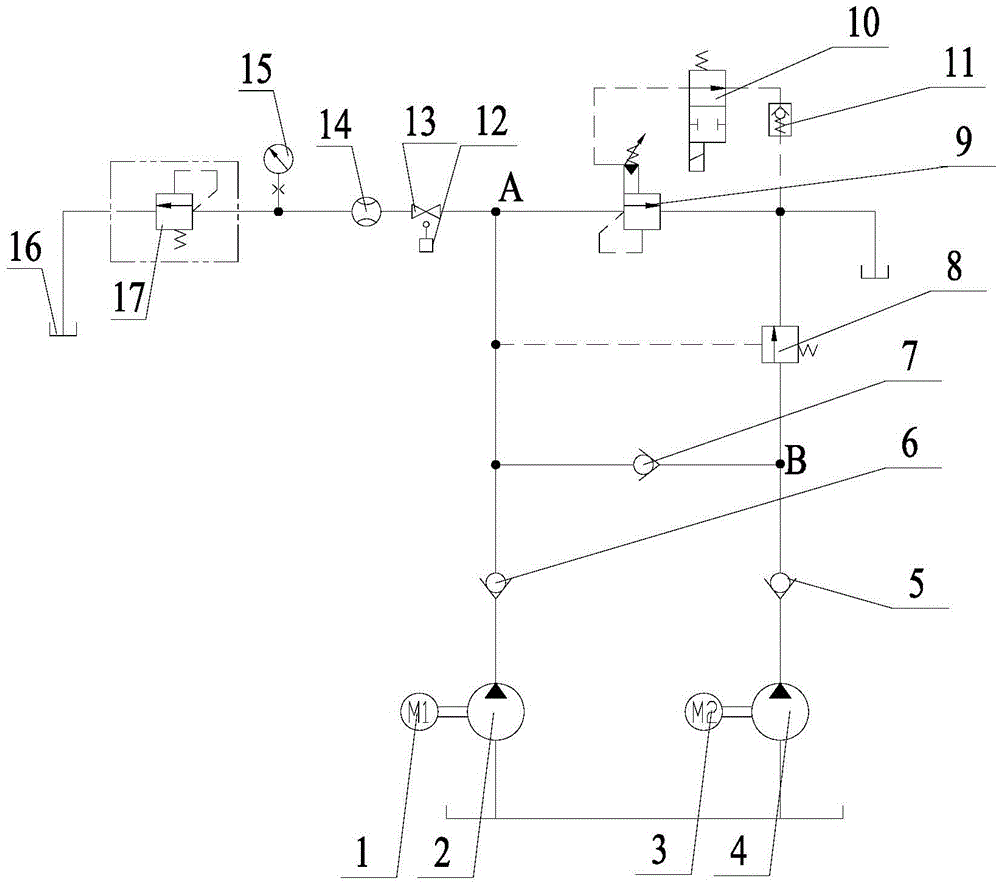

Pressure valve debugging system

ActiveCN103452958BLower requirementPrevent Cleanliness CompromiseFluid-pressure actuator testingSystem pressureProblem solve

The invention provides a pressure valve debugging system, comprising: an oil supply circuit, including at least one oil pump, the output pipeline of the oil pump has a first output node; a pressure regulation test oil circuit, connected to the first output node, used for installation The pressure regulating valve, the pressure regulating test oil circuit includes a flow meter and a pressure detection access point arranged in series between the pressure valve to be regulated and the first output node; the pressure limiting oil circuit is connected to the first output node and is used to limit the Pressure test oil circuit pressure. In the present invention, the pressure valve to be adjusted is connected to the pressure regulating test oil circuit, and the oil supply circuit regulates the pressure and flow of the pressure regulating test oil circuit, that is, the pressure valve to be adjusted adopts a unified connection mode, and the pipeline does not need to be modified during adjustment, thereby Effectively reduce the operation volume of pressure adjustment, solve the problem of limited operating space, and prevent the impact of disassembly and assembly of pipelines on the cleanliness of the hydraulic system; in addition, pressure adjustment operators do not need to understand the working principle of the circuit, reducing the requirements of operators.

Owner:ZOOMLION HEAVY IND CO LTD

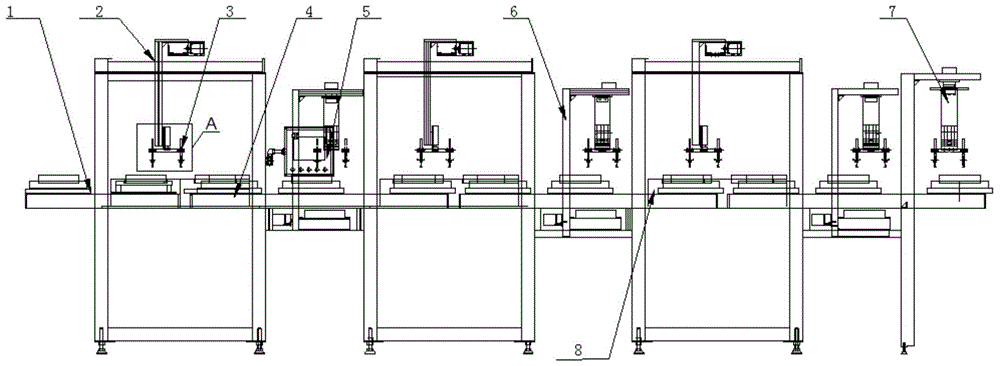

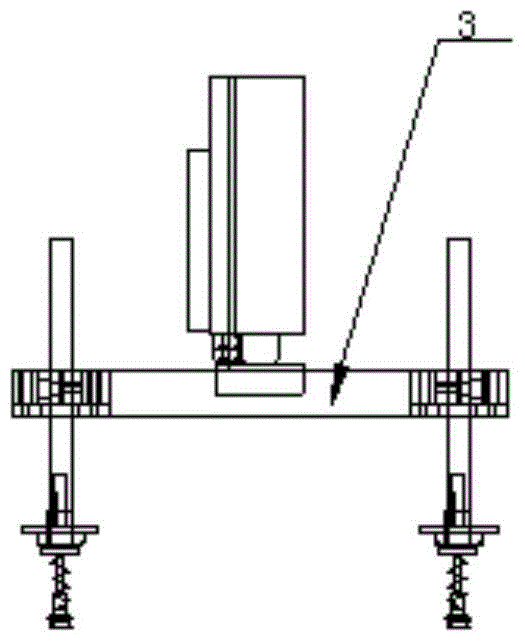

Home appliance power supply automatic test device and test method

ActiveCN103630849BMeet the automatic loading and unloading testRealize information productionPower supply testingControl systemTest fixture

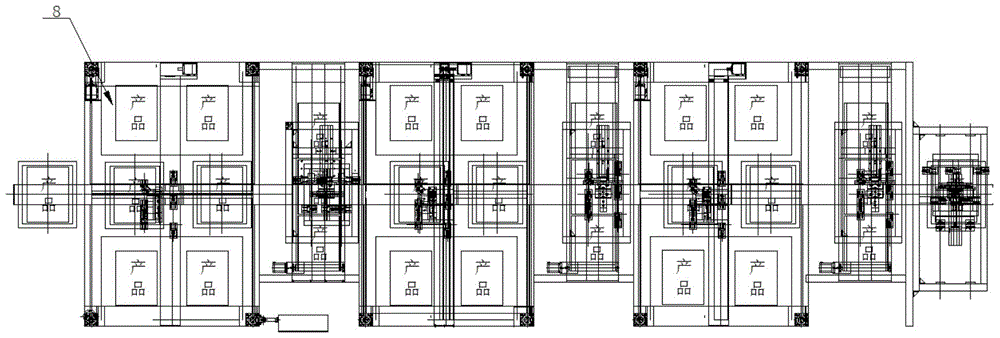

The invention discloses an automatic test device and a test method for a power supply of household appliances. The test device includes: at least two test stations, a first transmission module, a manipulator, a suction mechanism, a second transmission module, a main control system, and defective products. Picking mechanism and test fixture; two test stations are connected in series through the second transmission module; the suction mechanism is set on the manipulator; the manipulator is set above the test station, and the main control system is connected with the manipulator to control the manipulator; the main control system It is connected with the defective product picking mechanism and is used to control the defective product picking mechanism; the test fixture is set on the testing station. The invention adopts an independent testing station, and according to the requirements of the product testing process, arbitrarily combines product testing equipment to meet the automatic loading and unloading test of different products, and interacts with the main control system through software to monitor the information of each product in real time and form a record , realize product information production, save production cost and improve production efficiency.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

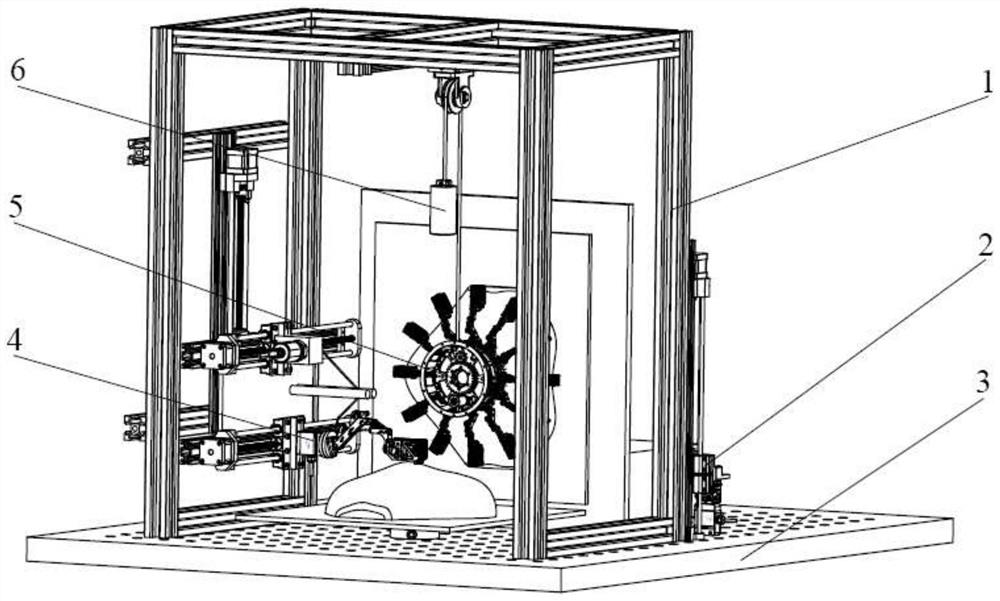

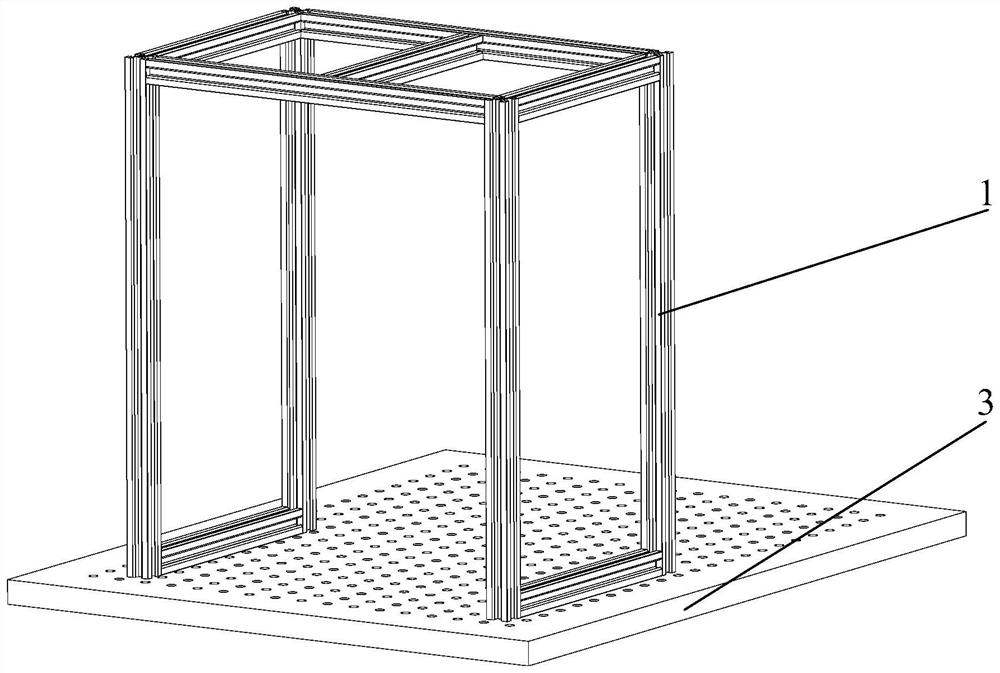

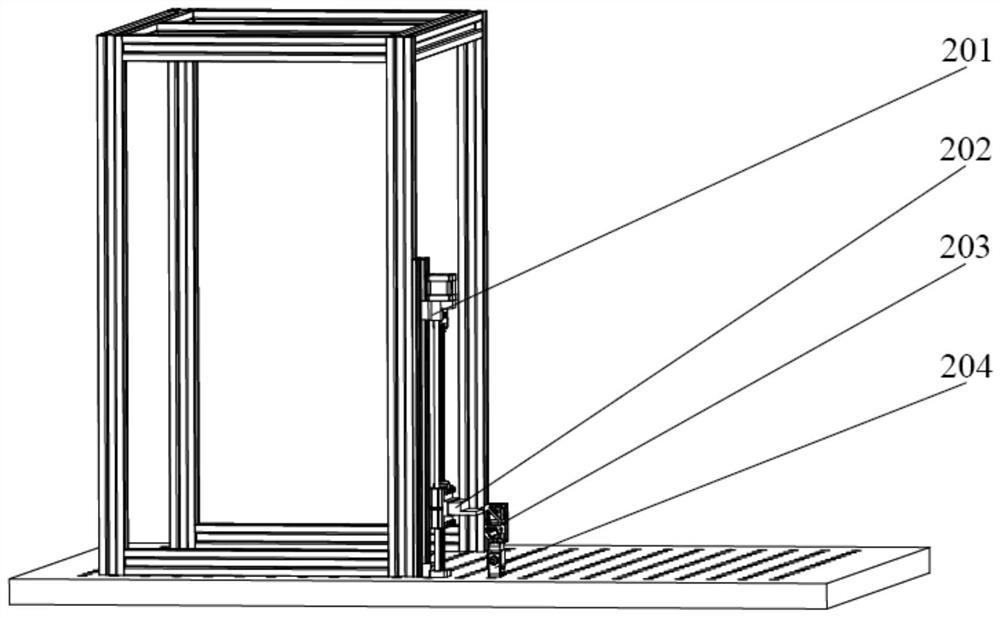

Ground multi-mode force hybrid test platform for small celestial body detection attachment mechanism

PendingCN114852382AHighly integratedIncrease flexibilityMachine part testingCosmonautic condition simulationsEngineeringHybrid testing

The invention relates to a ground simulation test platform for a deep space exploration attachment mechanism, in particular to a ground multi-mode force hybrid test platform for a small celestial body exploration attachment mechanism. Comprising a main body frame, a single attachment unit testing device, a testing platform, a series attachment unit testing device and an integral attachment mechanism testing device, wherein the main body frame is arranged on the testing platform; the single attachment unit testing device is mounted on the main body frame and is used for testing the adsorption rigidity limit of the single attachment unit and the testing platform; the series attachment unit testing device is mounted on the main body frame and is used for testing the attachment and desorption mechanical properties of the series attachment unit mechanism on the simulated rock; the overall attachment mechanism testing device is installed on the main body frame and used for testing the adhesive force mechanical property of the whole attachment device on the simulated rock. The system has the characteristics of high integration level, high flexibility, high measurement and control index precision and the like, the control precision and the safety performance of the system are ensured, and the technical requirements for microgravity coupling and compensation of small celestial bodies are met.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Method and system for polishing semiconductor wafers

InactiveCN100378940CLow costSampled-variable control systemsSemiconductor/solid-state device testing/measurementEngineeringTest series

A method for optimizing CMP (chemical mechanical polishing) processing of semiconductor wafers on a CMP machine. The optimization method includes the steps of polishing a test series of semiconductor wafers on a CMP machine. During the CMP processing, a film thickness is measured at a first point proximate to the center of each respective wafer using a film thickness detector coupled to the machine. A film thickness at a second point proximate to the outside edge of the respective wafers is also measured. Based upon the in-process film thickness measurements at the first point and the second points, the optimization process determines a polishing profile describing a removal rate and a removal uniformity with respect to a set of process variables. The process variables include different CMP machine settings for the polishing process, such as the amount of down force applied to the wafer. The polishing profile is subsequently used to polish production wafers accordingly. For each production wafer, their respective removal rate and removal uniformity is determined by measuring a film thickness at the center of each production wafer and a film thickness at the outside edge of each production wafer using the film thickness detector. Based upon these measurements, the set of process variables is adjusted in accordance the removal rate and the removal uniformity measurements to optimize the CMP process for the production wafer as each respective wafer is being polished.

Owner:NXP BV

Detection diagnostics for loss of communication with multiple battery cell sense boards

InactiveCN105280966BBatteries circuit arrangementsElectrical testingDetection diagnosisBoard communication

The present invention discloses detection and diagnosis of loss of communication with multiple battery cell sense boards. A method of identifying a non-communicating battery CSB in a plurality of cell sense boards (CSBs) arranged in a serial chain includes sequentially reconfiguring the series chain of battery CSBs to sequentially define each of the plurality of battery CSBs as a temporary test series The last battery CSB in the chain. Using the loopback feature of the battery CSBs, communication is sequentially established with the last battery CSB of each temporary test series chain. When a communication interruption between the battery system manager controller and the last battery CSB of the current temporary test series chain is detected, the current temporary test last battery CSB of the series chain is identified as a non-communicating battery CSB.

Owner:GM GLOBAL TECH OPERATIONS LLC

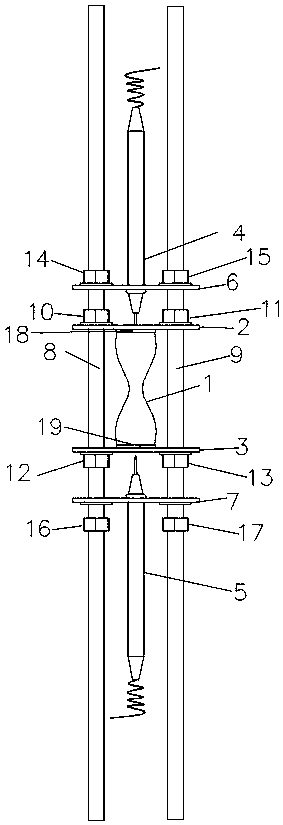

A micro-resistance measuring fixture device for detecting metal material damage and its use method

InactiveCN105319402BImprove stabilityGuaranteed stabilityResistance/reactance/impedenceMeasurement instrument housingElectrical resistance and conductanceEnvironmental effect

A micro-resistance measuring fixture device for detecting metal material damage and a use method thereof. The micro-resistance measurement fixture device used to detect metal material damage consists of two specimen fixing pieces for fixing metal specimens, two probes for measuring the resistance of metal specimens, and two probes for fixing probes Fixing piece, two screw rods for connecting the specimen fixing piece and the probe fixing piece in series, eight nuts (with washers) for fixing the specimen fixing piece and the probe fixing piece, two pieces for the test piece and the probe fixing piece It is composed of insulating spacers that are insulated between the fixed pieces of the test piece. A micro-resistance measuring fixture device for detecting metal material damage can fix the probe on the end of the test piece to ensure the stability of the resistance measurement reading, detect the slight change in the resistance of the metal test piece under the action of load or environment, and improve the accuracy of the measurement And accuracy, in order to use the resistance change to characterize the damage of the metal material. The invention is applicable to the field of micro-resistance and micro-resistance change measurement.

Owner:XIANGTAN UNIV

Energy-saving method and device for product aging test

The invention provides an energy-saving method for a product aging test. A product test parallel group, multiple product test series groups, corresponding independent product test series groups and independent product test parallel groups are included, wherein the front stage of the product test series group supplies power to the later stage; each independent product test series group compensates output current for the front stage; each independent product test parallel group shunts the current for the later stage; and current compensation and shunting are realized by controlling corresponding on-off switches through a constant current unit. The invention also provides a device for implementing the method. By using the method and the device, only a rated load is added at the output of the test product of the last stage, so that a large amount of energy consumption is saved; and by using the constant current unit for controlling the constant input current in test units, the stability of the product test is greatly improved.

Owner:东莞市奇立电源有限公司

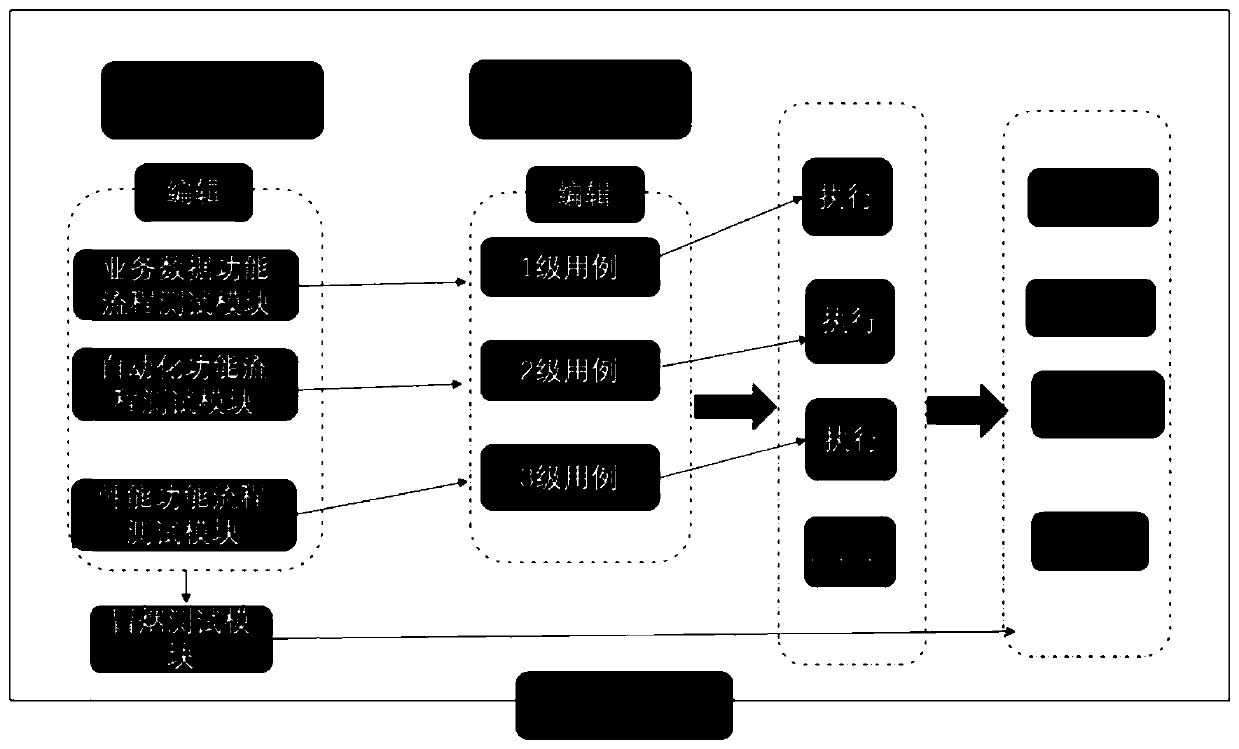

A Standard Software Testing Platform and Its Testing Method

ActiveCN106294122BQuick editShorten design and development effortsSoftware testing/debuggingTestwareSoftware engineering

The invention discloses a standard software test platform and a test method thereof. The standard software test platform comprises a file management module, a user management module, a test sequence file module, a custom type module, a report generation module, a system configuration module, a test statistic module, an editing module and a performance module. According to the platform and the method, a customer is help to establish an automatic test and verification system rapidly, edit test series files rapidly, carry out multi-process control, carry out multiple threads and improve test throughput. Most of test processing demands can be satisfied. Under the test drive supporting condition, the test demands of most products are compatible. The performance efficiency is high. According to the platform, a modular flexible design is employed. Rapid replacement and update can be carried out. With the help of the platform and the method, the work of an engineer is more targeted, time and vigor can be used for solving various difficulties which are really difficult to solve, and the design development work of a test software stage in a project is greatly reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

Incorporated series connection resonance inductor voltage-dividing high-voltage measurement system

PendingCN107728023AImprove test efficiencyReduce testing costsTesting dielectric strengthSystem configurationHigh pressure

The invention relates to an incorporated series connection resonance inductor voltage-dividing high-voltage measurement system. The incorporated series connection resonance inductor voltage-dividing high-voltage measurement system comprises a resonance inductor having a voltage-dividing tap, an excitation transformer having a primary side and a secondary side, a first measurement module used for measuring voltage on two terminals of the resonance inductor, a second measurement module used for measuring voltage on two terminals of the secondary side of the excitation transformer and an intelligent measurement instrument which is connected to the first measurement module and the second measurement module and performs summation on voltage on two terminals of the resonance inductor and voltageon two terminals of the secondary side of the excitation transformer, wherein the secondary side of the excitation transformer is connected to two ends of a tested object in parallel after connectingto the resonance inductor in series to form a series connection resonance test circuit. The incorporated series connection resonance inductor voltage-dividing high-voltage measurement system uses a reactor of a resonance system and makes the reactor become a resonance reactor having a voltage measurement function through a voltage-dividing tap design. The incorporated series connection resonanceinductor voltage-dividing high-voltage measurement system has the AC high-voltage voltage divider which is configured in a normal resonance system removed, saves investment cost and operation expense,reduces workload of mounting and dismounting and has significance to ultra-high voltage and extra-high voltage AC withstand voltage test devices.

Owner:SUZHOU HUADIAN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com