1045mw ultra-supercritical coal-fired unit boiler blowpipe debugging method and system

A coal-fired unit, ultra-supercritical technology, applied in the field of thermal power plants, can solve problems that endanger the safe operation of turbo-generator units, high-temperature corrosion, tube bursts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

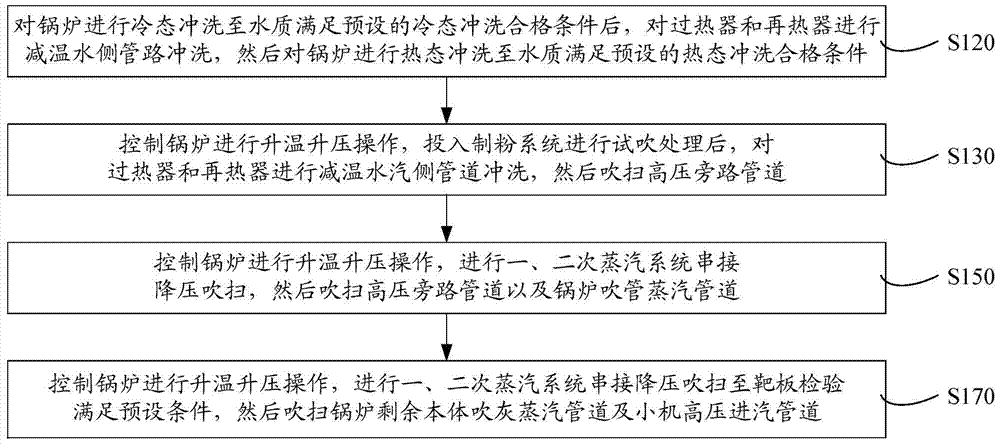

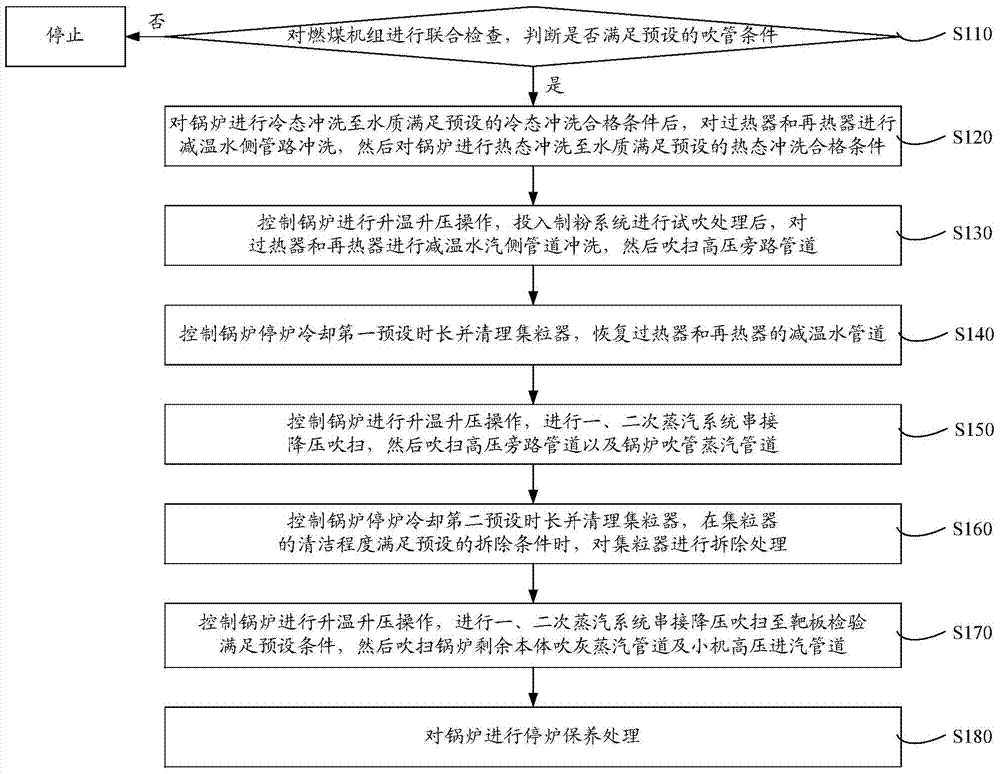

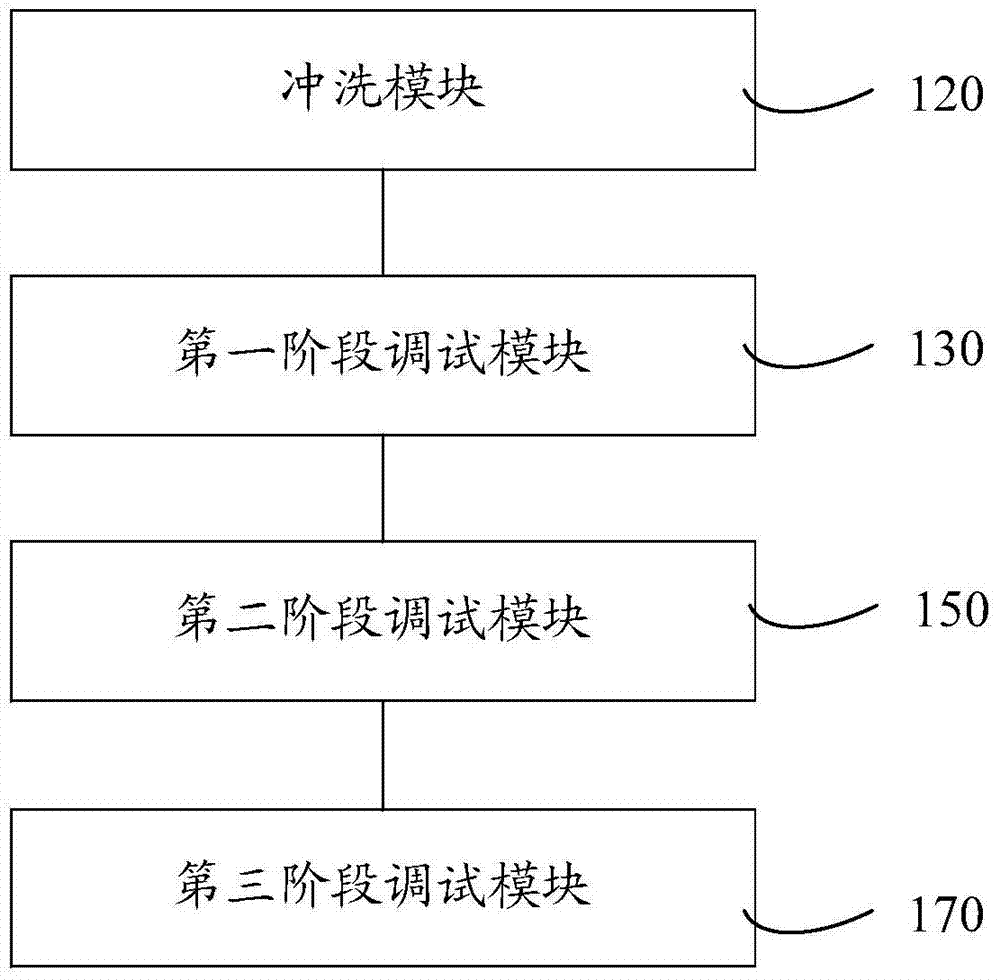

[0019] A blowpipe debugging method for a 1045MW ultra-supercritical coal-fired unit boiler is suitable for blowpipe debugging for a 1045MW ultra-supercritical coal-fired unit boiler. The boiler is an ultra-supercritical once-through boiler with variable pressure operation, which adopts a П-shaped layout, a single furnace, an intermediate reheating, and low NO X The main burner and high-level burn-off air staged combustion technology and reverse double tangential circular combustion method, the furnace is an internal thread tube vertical rising membrane water wall, and the atmosphere expansion type start-up system; in addition to the coal / water ratio, the temperature adjustment method also adopts Flue gas distribution baffle, burner swing, water spray, etc. The boiler adopts balanced ventilation, open-air layout, solid slag discharge, all-steel frame, and full-suspension structure. Each boiler is equipped with 6 medium-speed grinding and cooling primary fans, positive pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com