Home appliance power supply automatic test device and test method

An automatic test device and home appliance power supply technology, which is applied in power supply testing and other directions, can solve problems such as low production efficiency, large production site area requirements, unstable product quality, etc., and achieve the effects of improving production efficiency and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings.

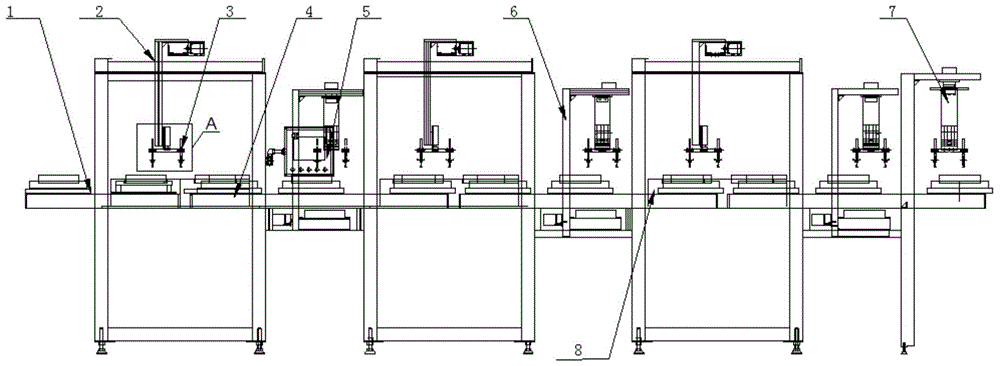

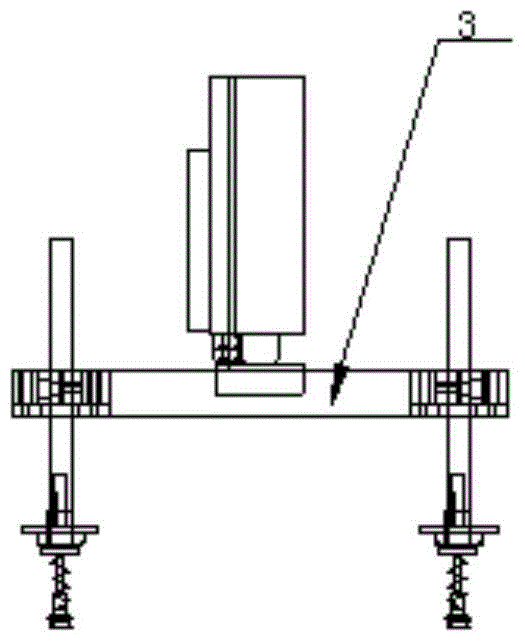

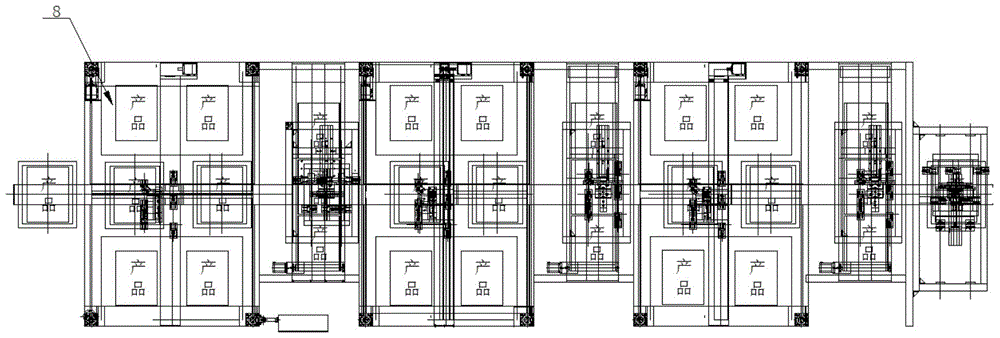

[0023] Such as figure 1 , figure 2 , image 3 as shown, figure 1 A schematic structural diagram of an embodiment of the present invention is shown. The automatic test device for the power supply of household appliances in this embodiment includes: a first test station, a second test station, a third test station, a first transmission module 1, a manipulator 2, a suction mechanism 3, and a second transmission module that are independent of each other. Group 4, main control system 5, defective product picking mechanism 6, test fixture 8; the first test station, the second test station and the third test station are connected in series through the second transmission module; the suction mechanism is set on the manipulator ; The manipulator is arranged above each test station, and the main control system is connected with the manipulator for controlling the manipulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com