Patents

Literature

177results about How to "Realize flexible production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

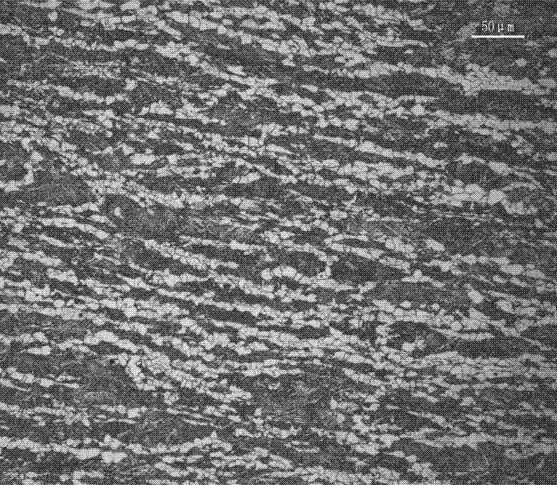

Control method of softness of oxide scales on surface of hot-rolling strip steel

ActiveCN101856669AImprove adhesionReduce FeO fragmentationTemperature control deviceWork treatment devicesOxideRolling speed

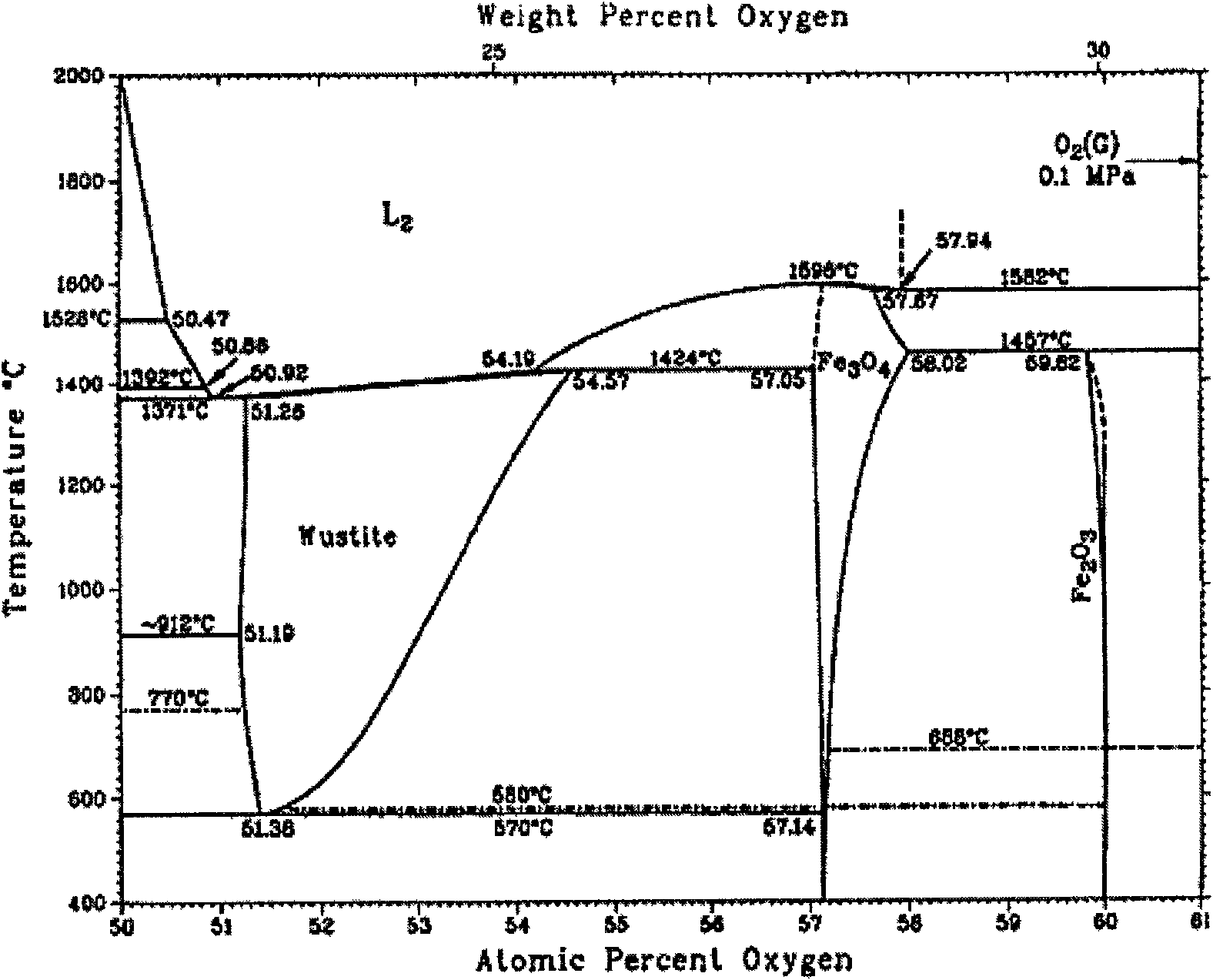

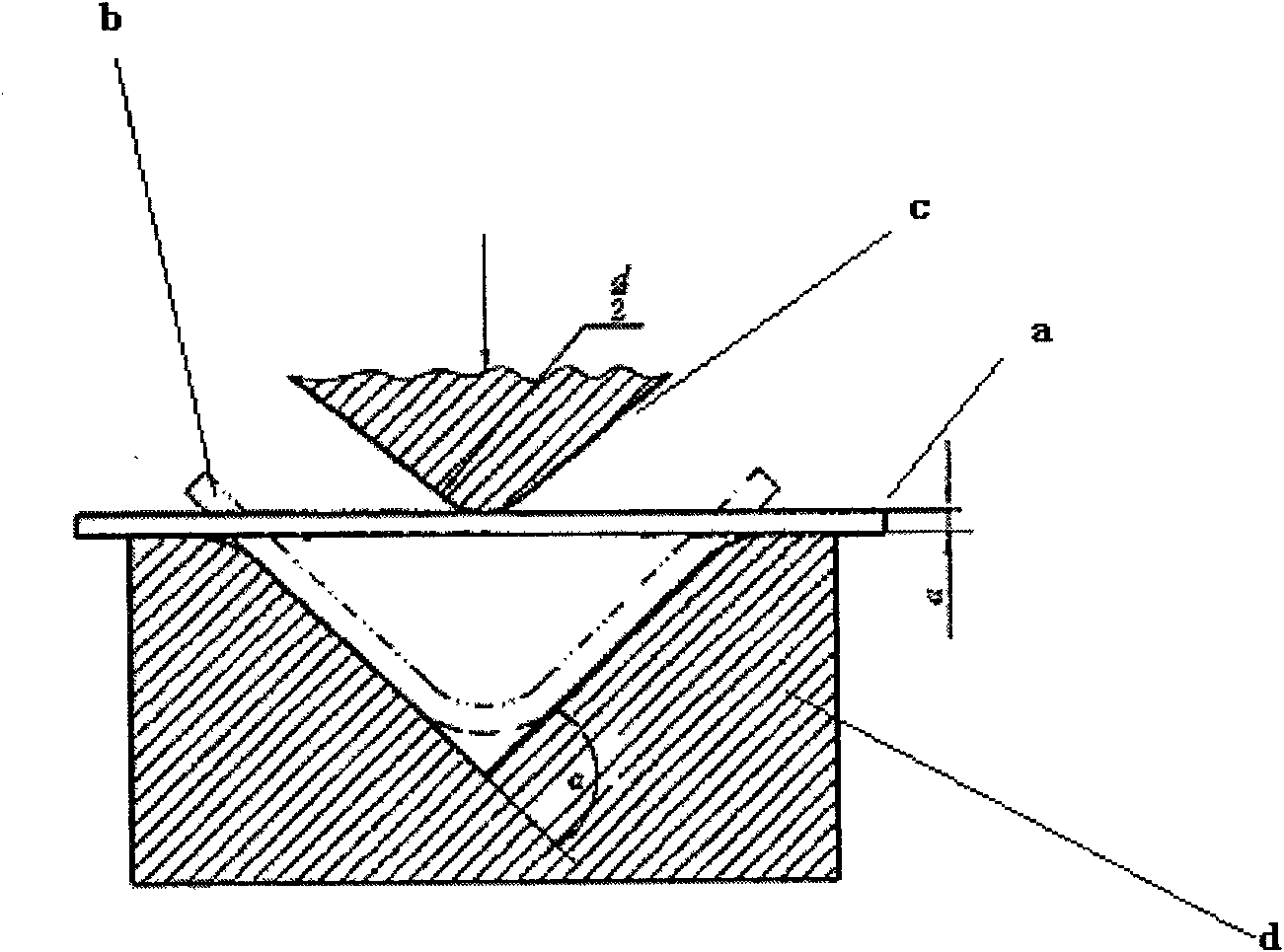

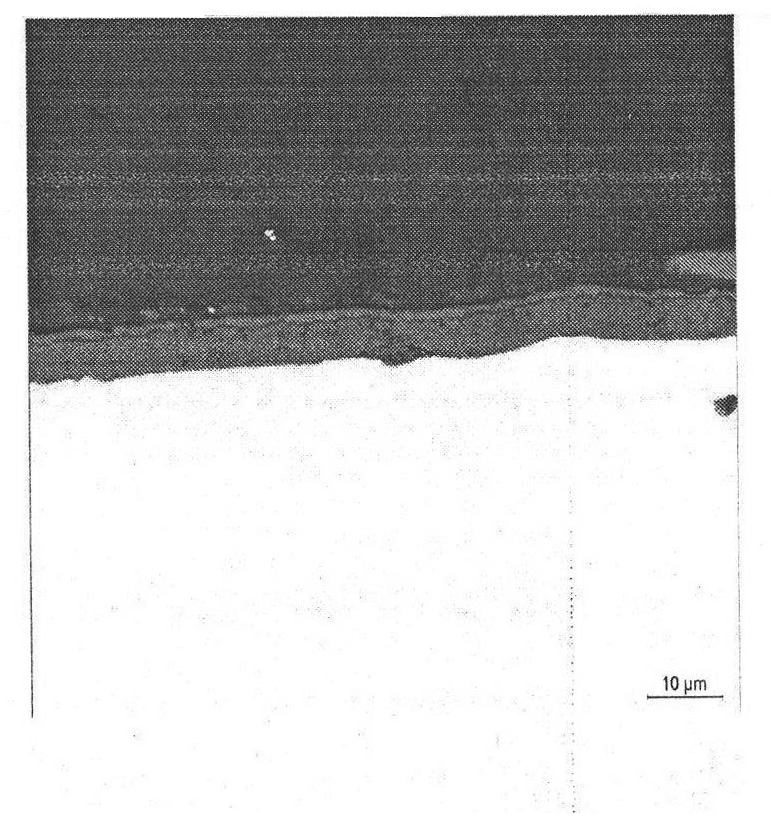

The invention provides a control method of softness of oxide scales on the surface of hot-rolling strip steel, belonging to the technical field of metallurgy. The method comprises the following steps: smelting liquid steel and continuously casting into plate blanks, heating and conducting thermal insulation on the plate blanks, then descaling, and rough rolling; and descaling again, and then finish rolling, wherein the initial rolling temperature is 1020-1070 DEG C, the finish rolling temperature is 870-920 DEG C, the rolling reduction is 75-95%, and the rolling speed is 3.5-12 m / s; cooling to 500-650 DEG C at the speed of 8-25 DEG C / s; and coiling. Aiming to different oxide scales structures, a hot-rolling process regulation scheme is provided in the method. In the hot-rolling process regulation scheme, by controlling the cooling speed and coiling temperature and the degree of a eutectoid reaction of FeO, reasonable control of the structure of the oxide scales is achieved, and loss of mechanical properties of products, which is caused by high temperature rolling, is compensated. The production efficiency is improved by using the existing devices and process conditions in a steel plant, surface quality is improved on the premise of ensuring mechanical properties of the steel plate and flexible production of oxide scale control.

Owner:NORTHEASTERN UNIV

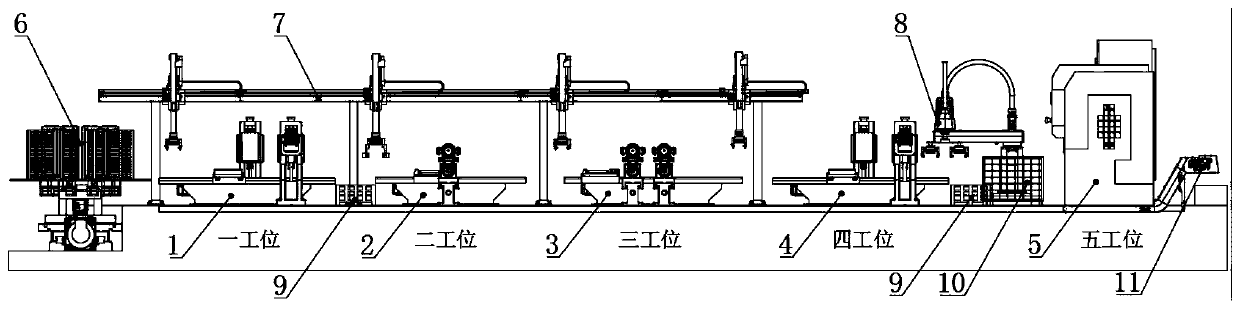

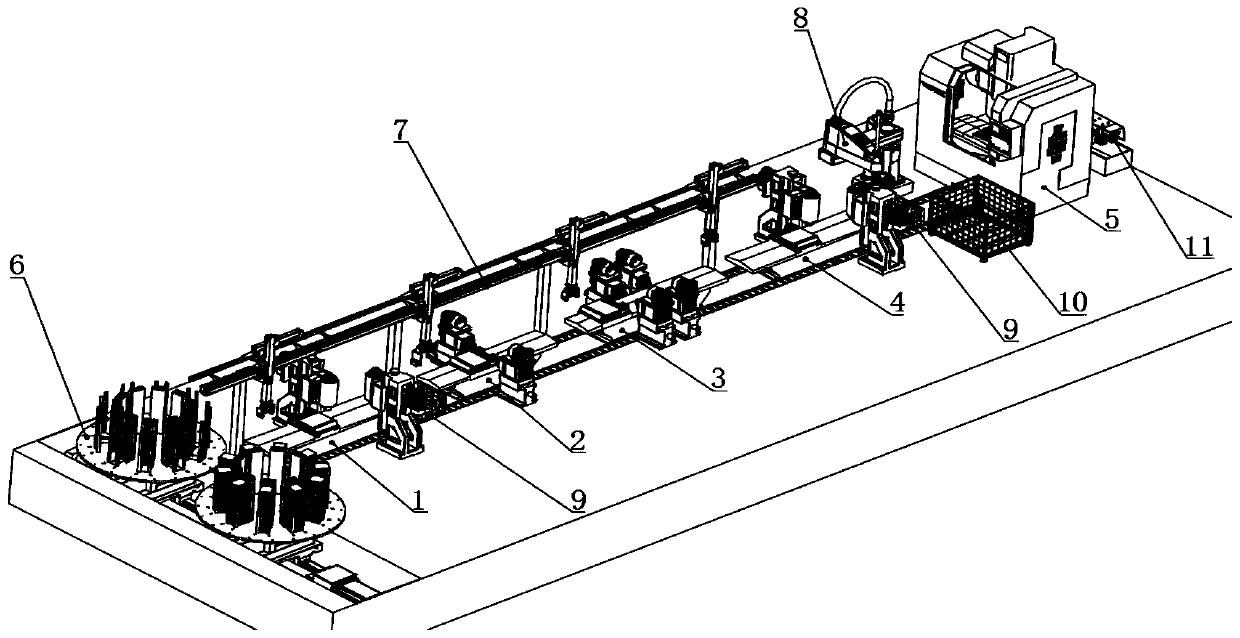

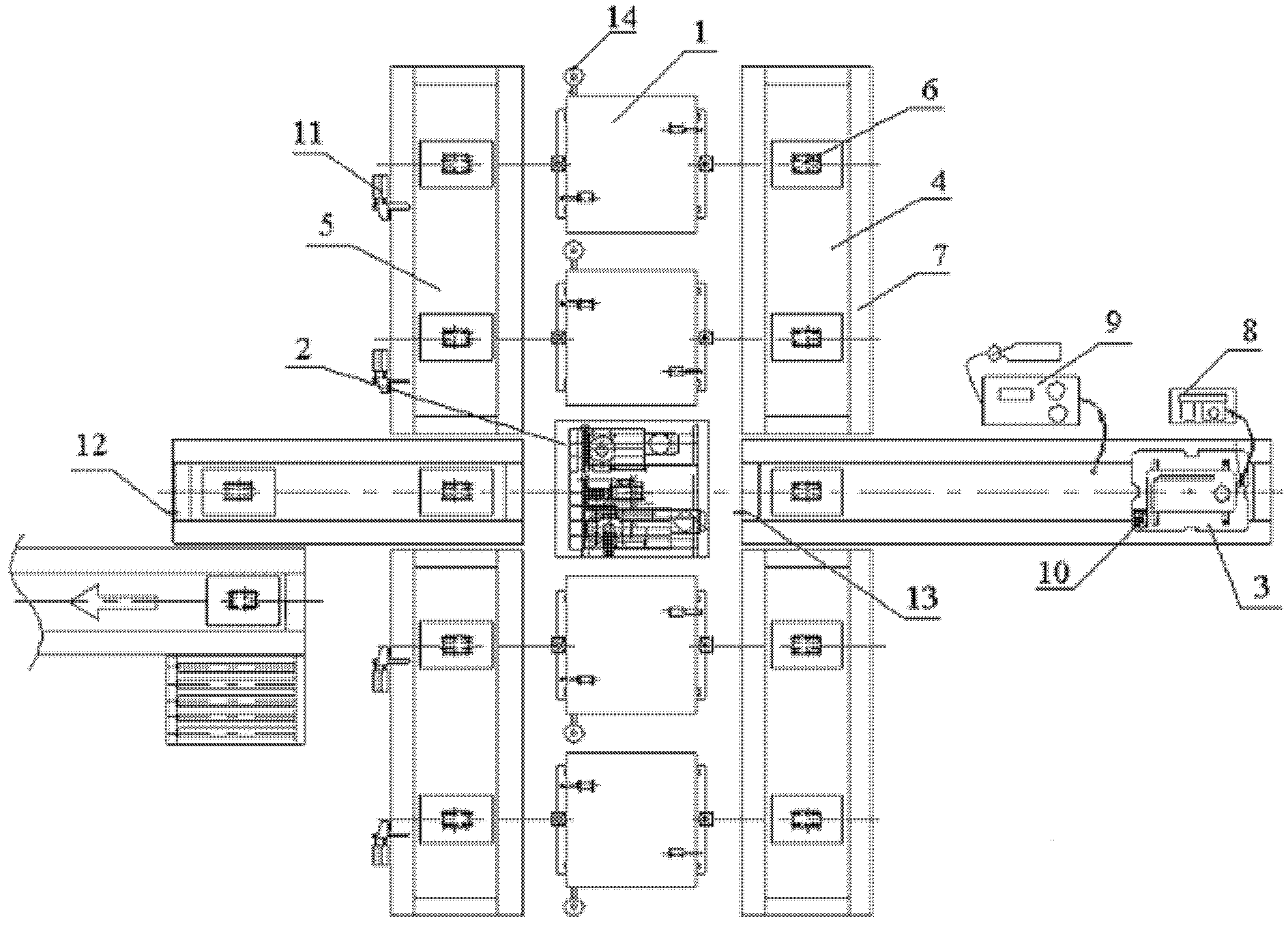

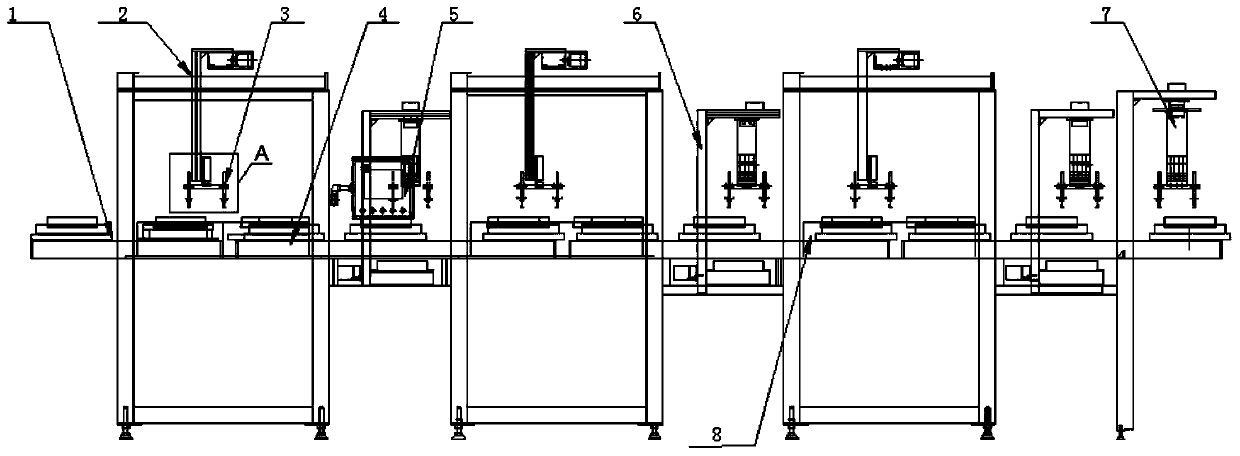

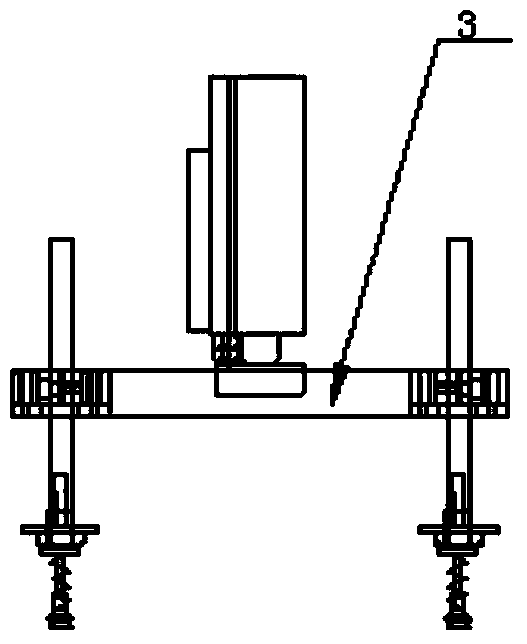

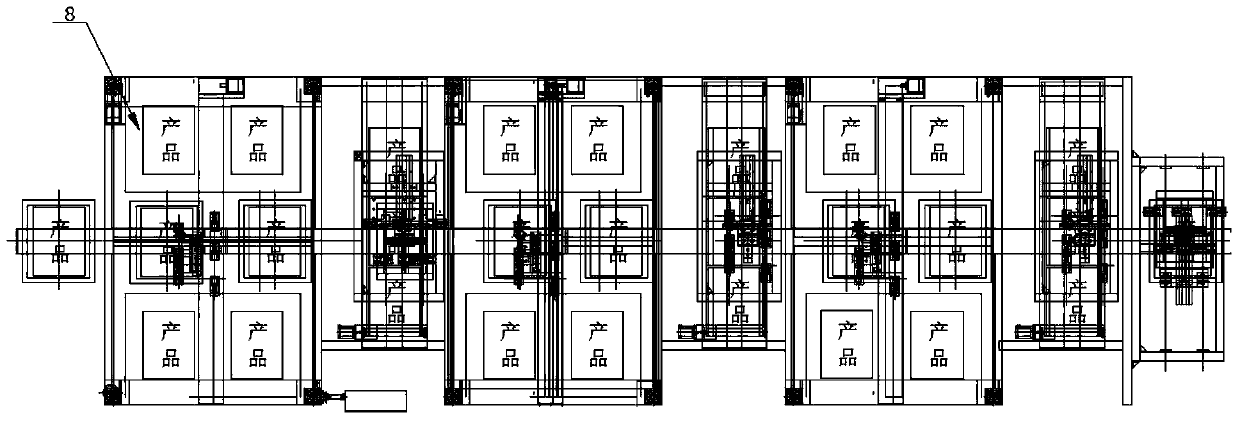

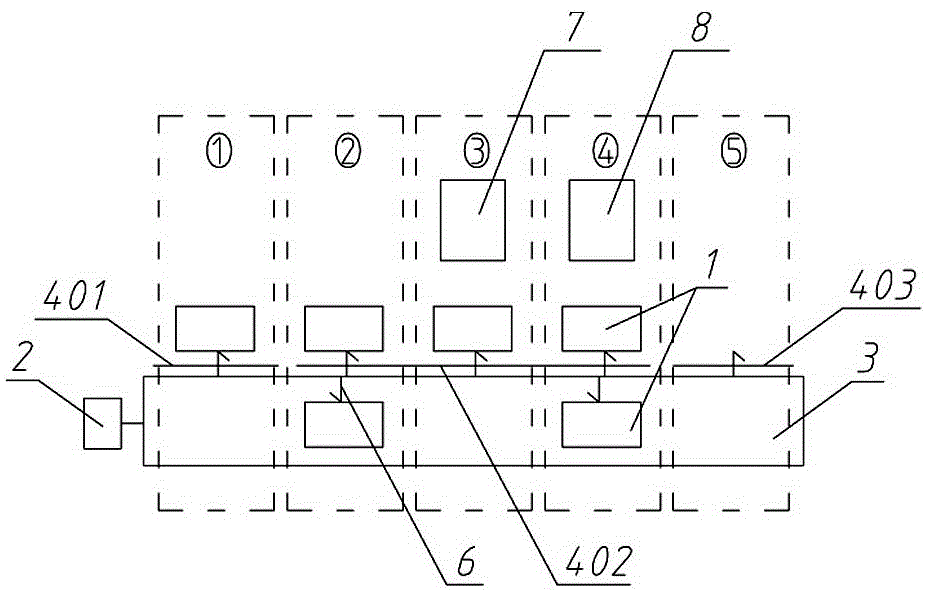

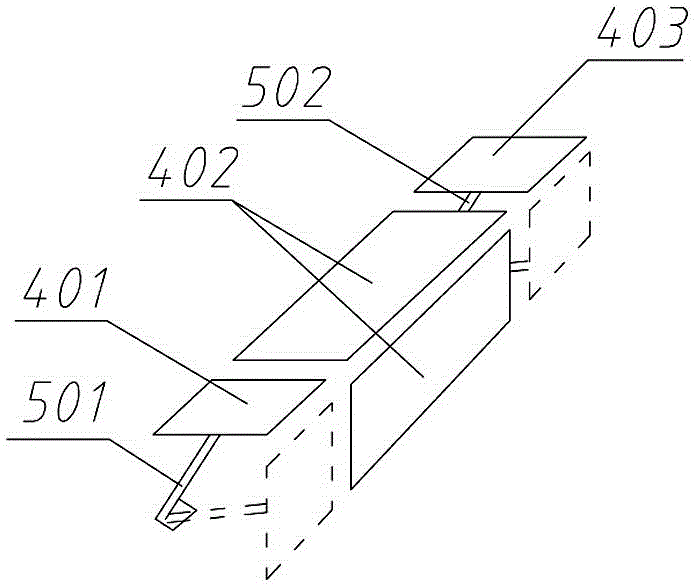

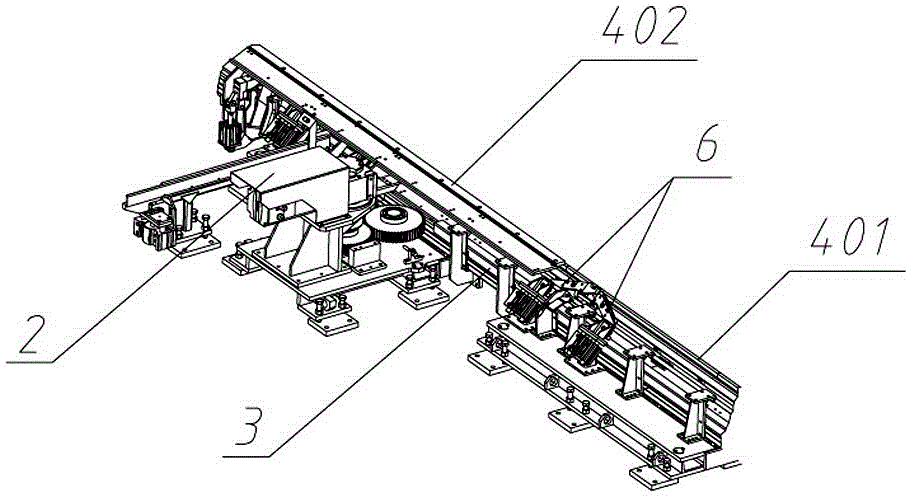

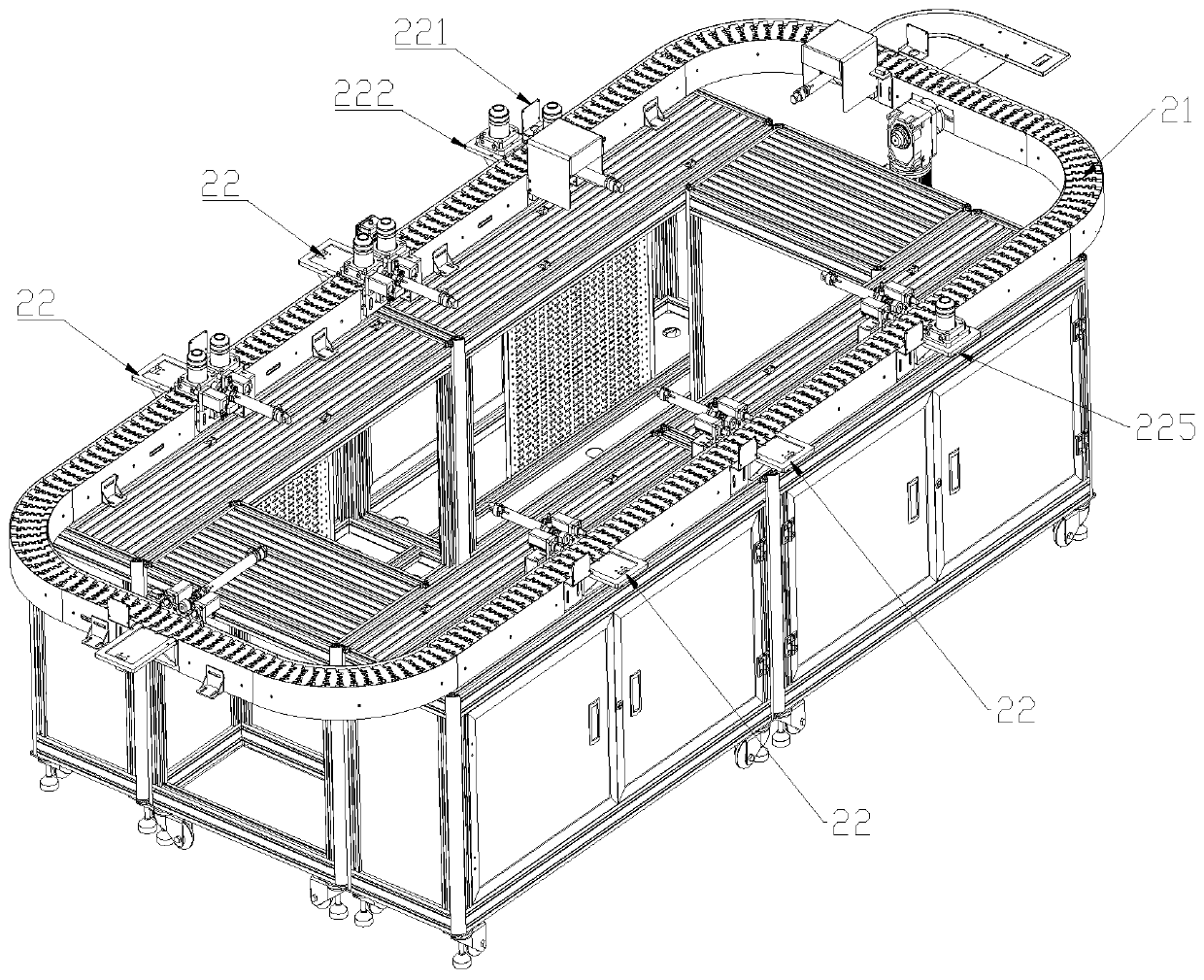

Intelligent plate part machining production line provided with universal equipment and special equipment

ActiveCN110773779AGuaranteed production efficiencyImprove production efficiencyOther manufacturing equipments/toolsMilling equipment detailsProduction lineRobot hand

The invention provides an intelligent plate part machining production line provided with universal equipment and special equipment. Four special machining tools and a universal machining tool are sequentially and linearly arranged from an automatic feeding device, wherein the four special machining tools are located on a first station, a second station, a third station and a fourth station, and the universal machine tool is located on a fifth station; a truss conveying transport device is arranged behind the first station, the second station, the third station and the fourth station in parallel, and four mechanical arms are arranged on the truss transport device to transfer materials on the corresponding stations; a four-axis manipulator is arranged between the fourth station and the fifthstation and is used for transferring the materials between the fourth station and the fifth station and discharging finished products; industrial cameras are arranged on the second-station mechanicalarm and the four-axis manipulator and are used for recognizing defective products; waste boxes are arranged between the first station and the second station as well as between the fourth station andthe fifth station and are used for storing the defective products; a discharging box is arranged on the front side of the fifth station and is used for storing the finished products; and a scrape conveying mechanism is arranged below the whole production line and is used for collecting and transferring scrapes. According to the intelligent plate part machining production line, the universal equipment and the special equipment are combined, and flexible clamps and sliding rail cylinders are used, so that the production line is flexible, the machining times of the stations are balanced, and theproduction efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

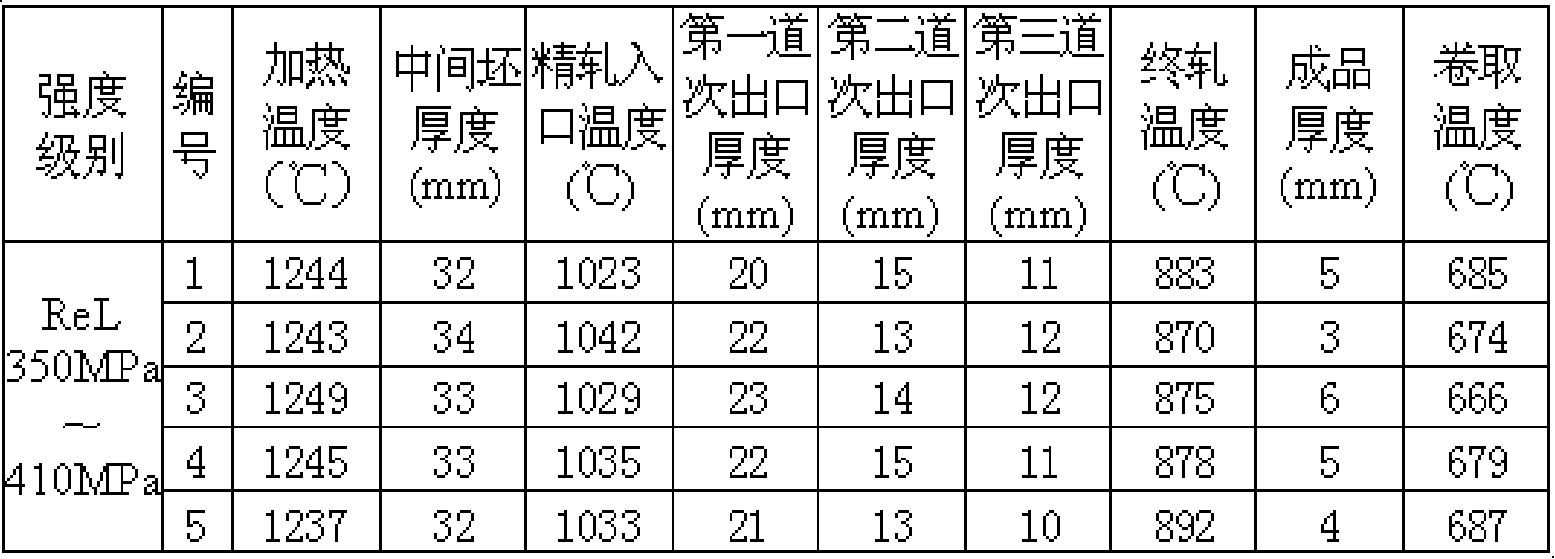

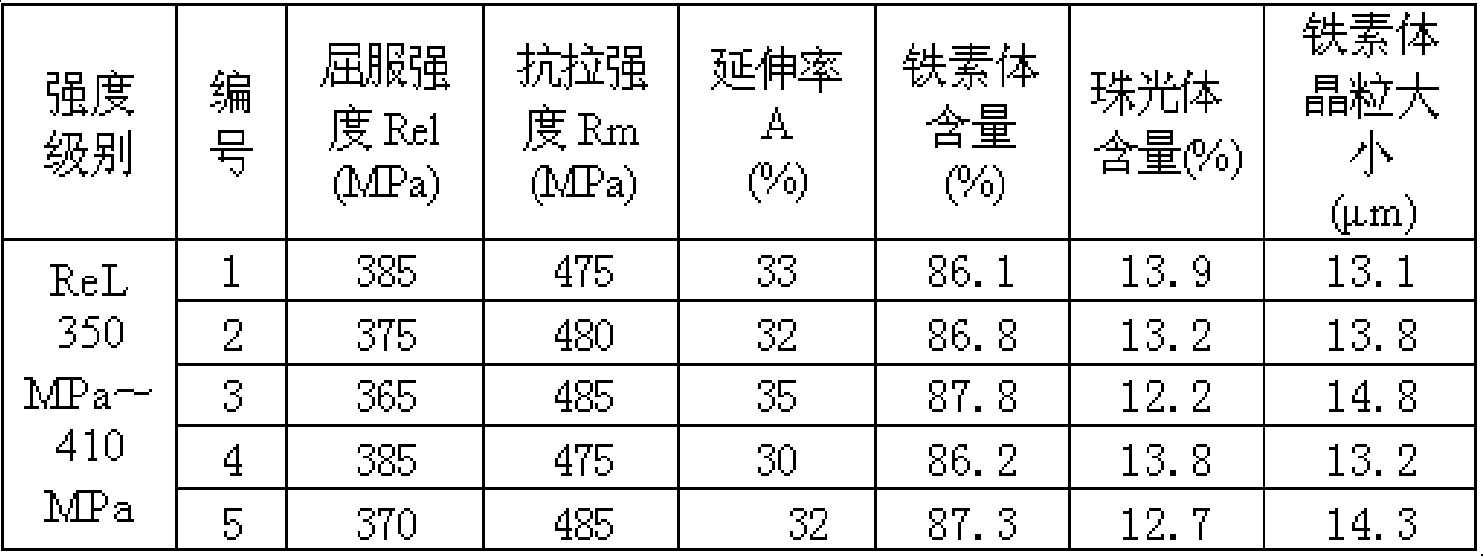

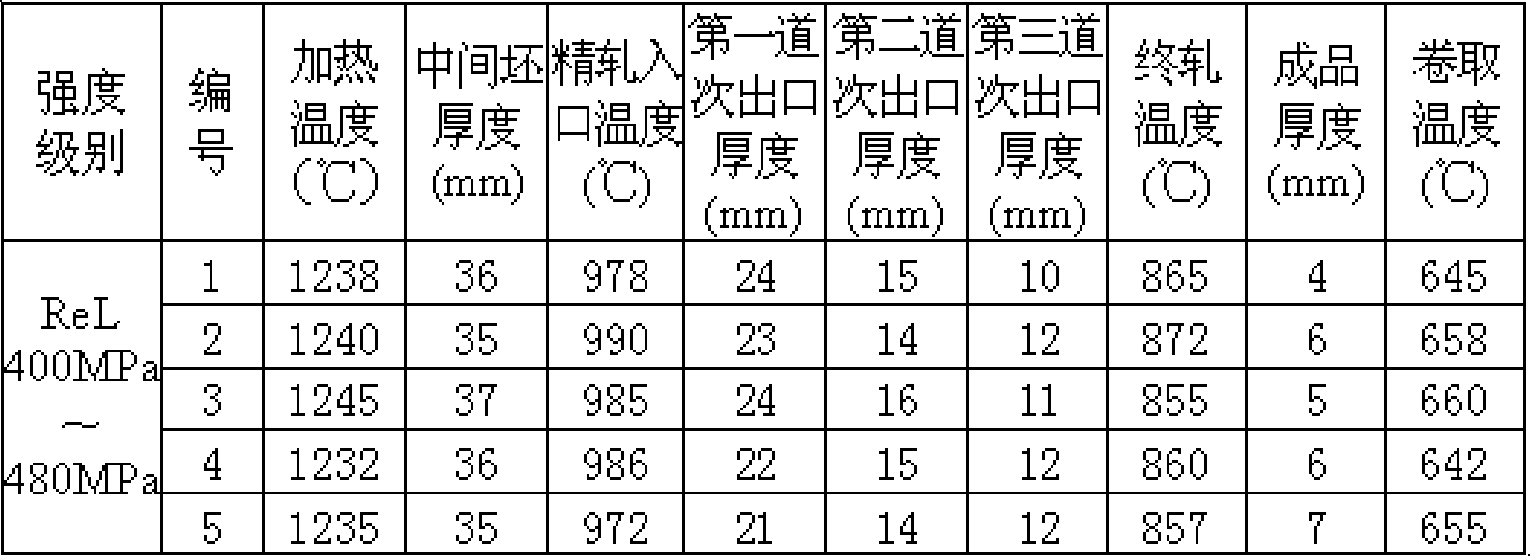

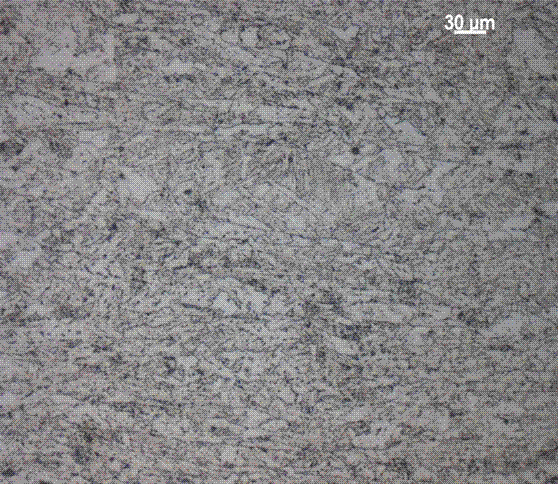

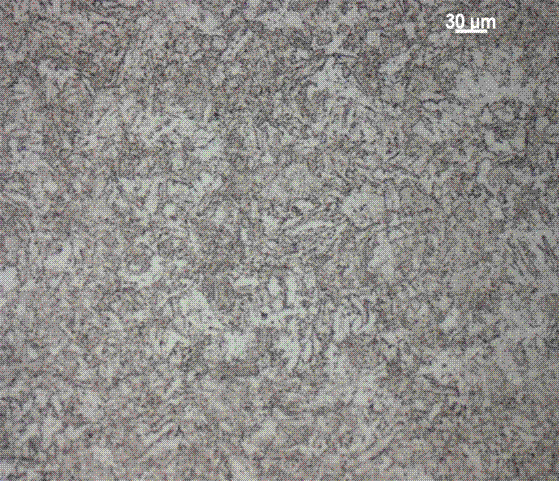

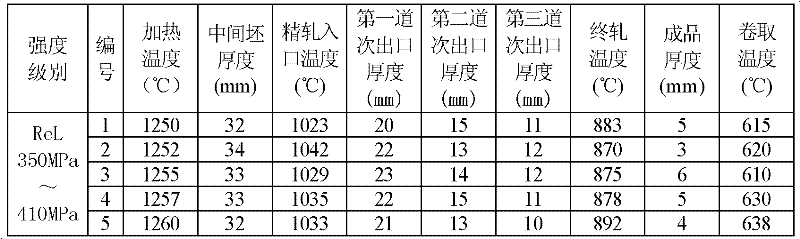

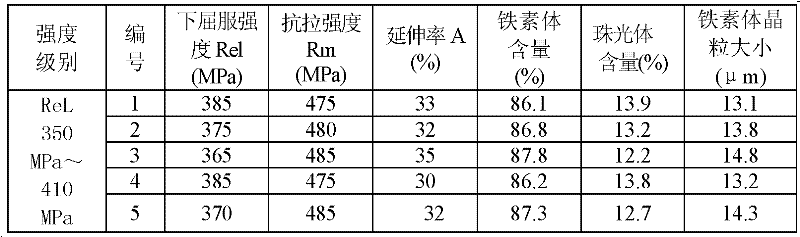

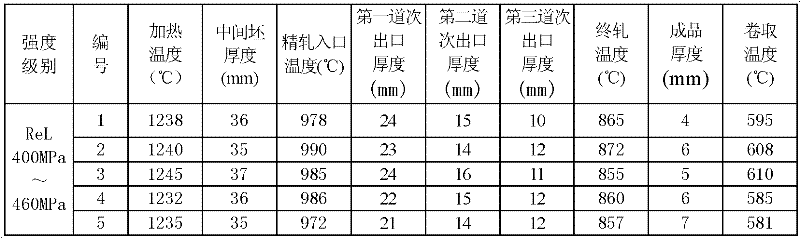

Vanadium-containing hot rolled steel plate and preparation method thereof

InactiveCN101168819AMeet the use requirementsReduce the amount addedRoll mill control devicesProcess efficiency improvementSheet steelChemical composition

The invention relates to a vanadium-bearing hot rolled steel plate and the preparation method thereof, and belongs to the metallurgy field. The invention solves the technical difficult problem that the steel plates of various mechanical properties can not be produced with the identical continuous casting plate blank. The chemical components of the vanadium-bearing hot rolled steel plate of the invention has the mass percentage that: C occupies 0.06 to 0.12 percent, Si is lower than or equal to 0.30 percent, Mn occupies 0.90 to 1.40 percent, V occupies 0.02 to 0.10 percent, P is lower than or equal to 0.025 percent, S is lower than or equal to 0.015 percent, and the residual is Fe and inevitable foreign impurities; the content of ferrolites in the vanadium-bearing hot rolled steel plate is 71 to 89 percent, the content of pearlite is 11 to 29 percent, and the crystal grain size of the ferrolites is 5 to 16 micrometers. The preparation method of the vanadium-bearing hot rolled steel plate of the invention comprises the steps of heating, rough rolling, precision rolling, final rolling, and balling. The vanadium-bearing hot rolled steel plate of the invention can be used for the manufacture of structural parts of the cross beam of a vehicle, a vehicle wheel, a construction structure and an engineering machinery.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

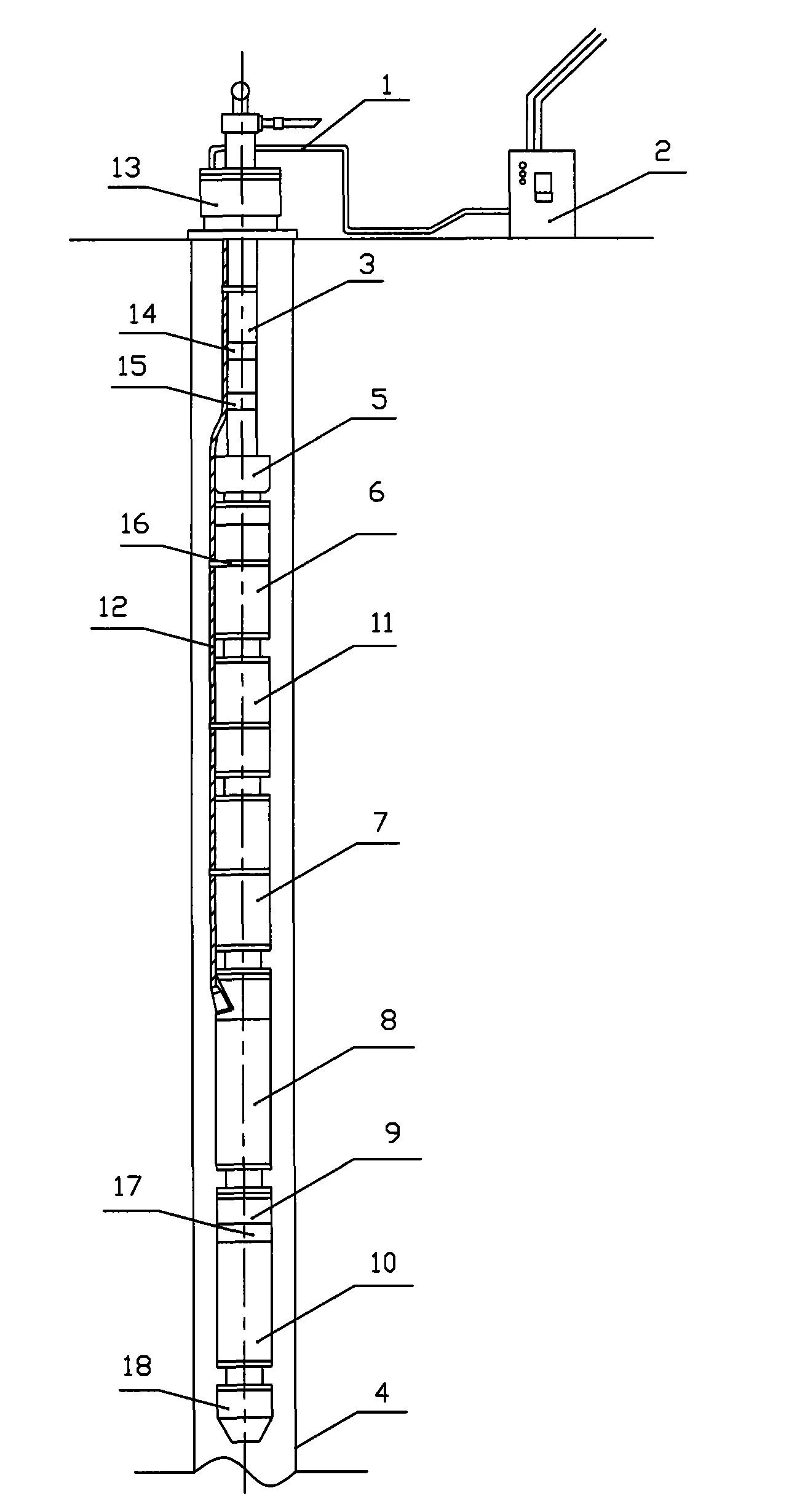

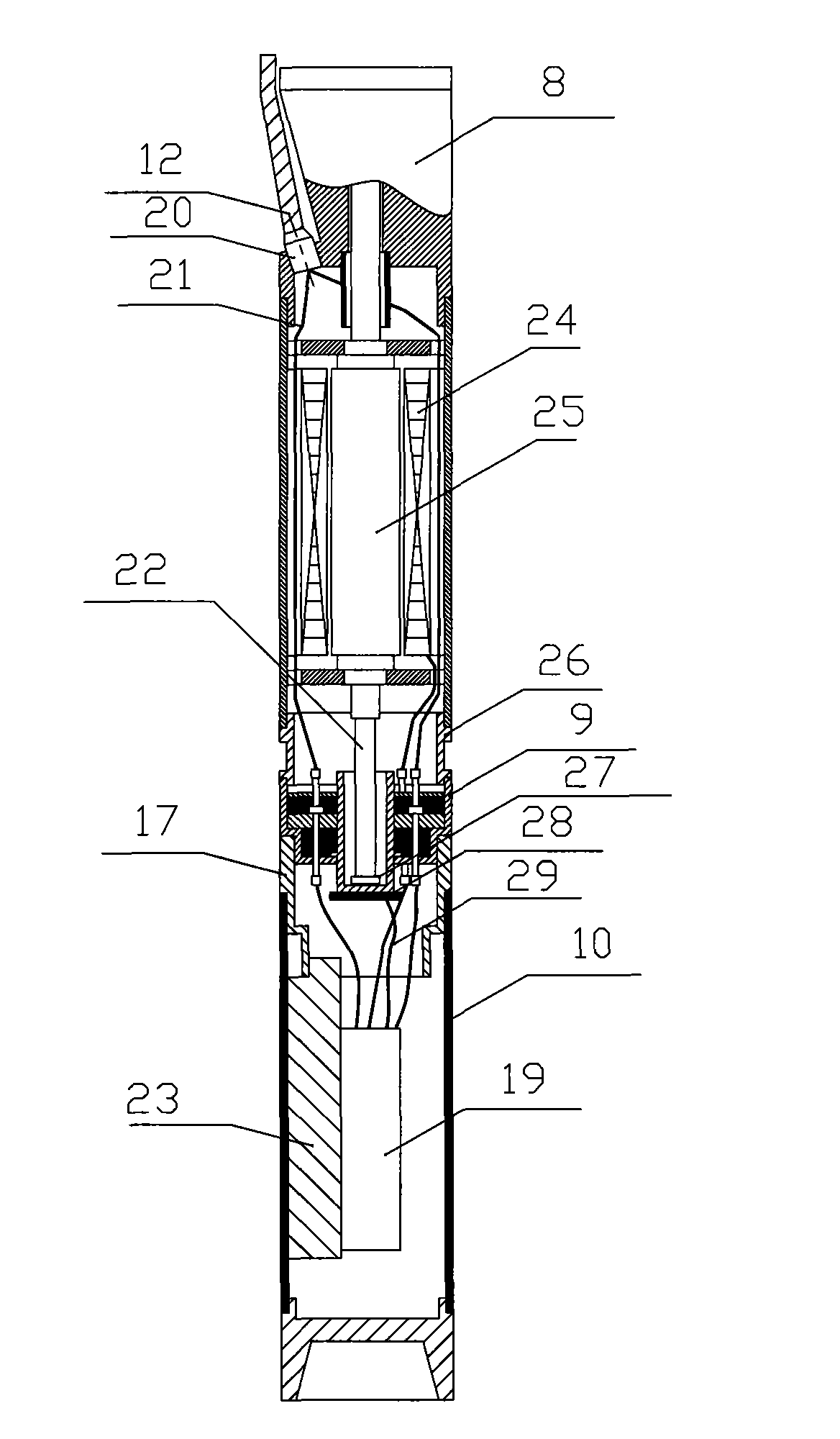

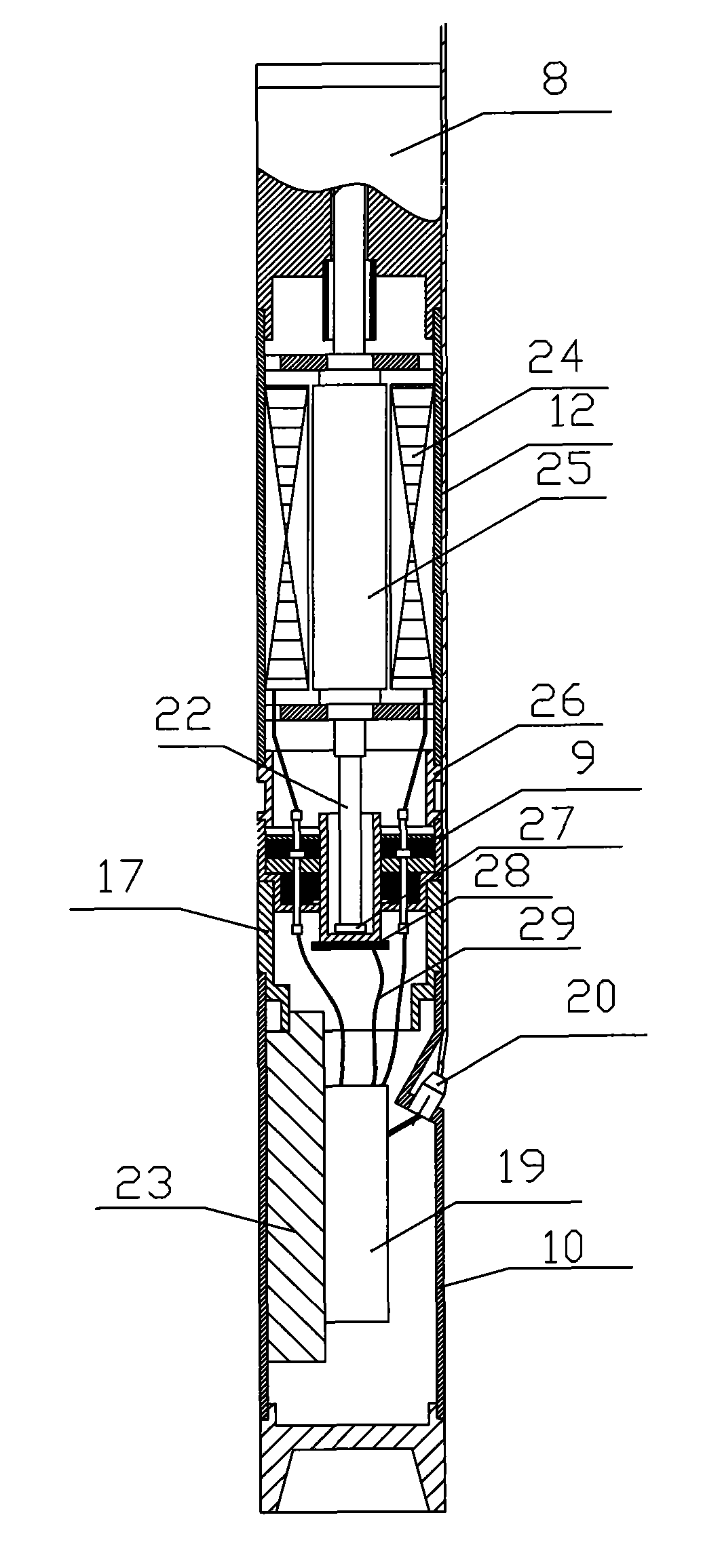

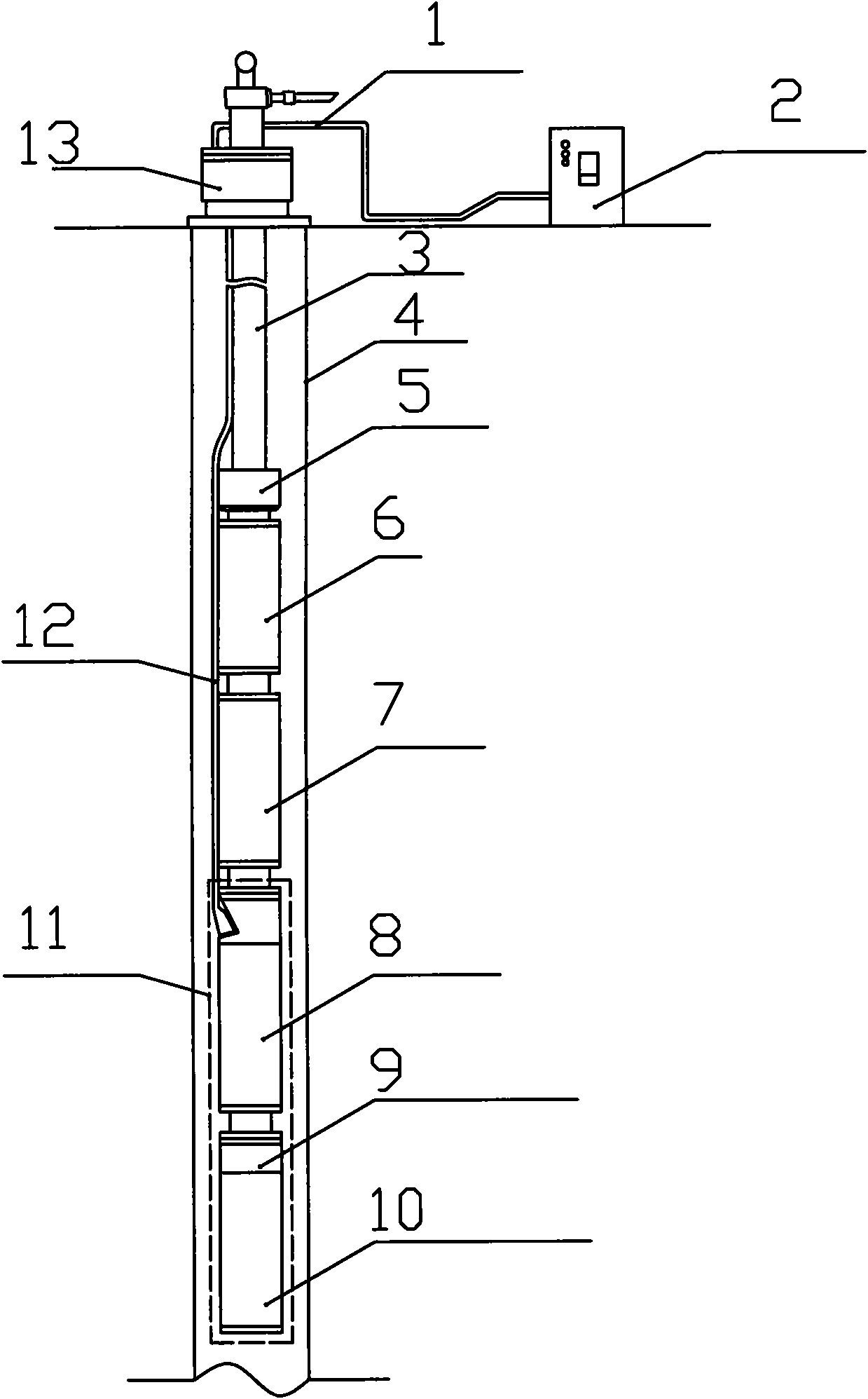

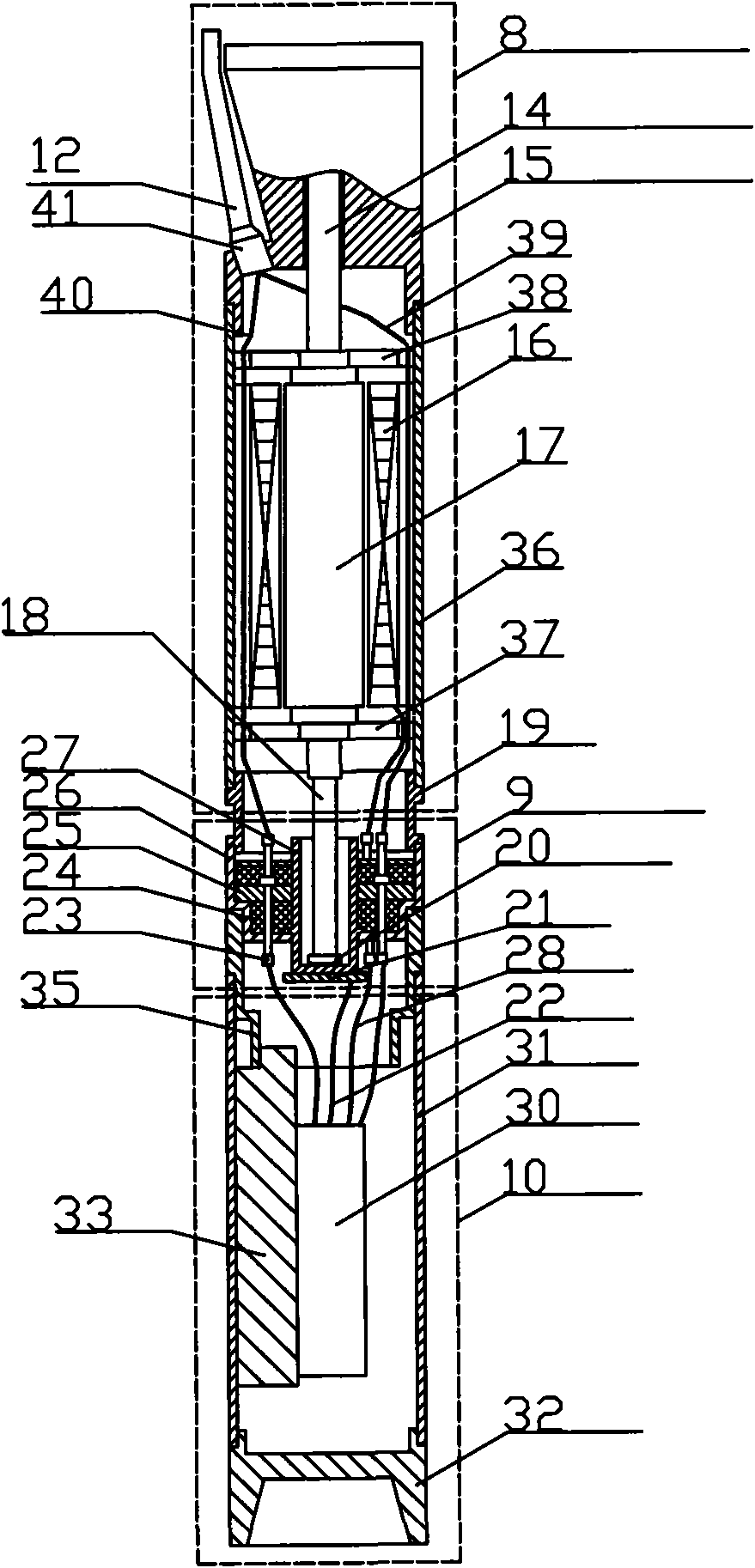

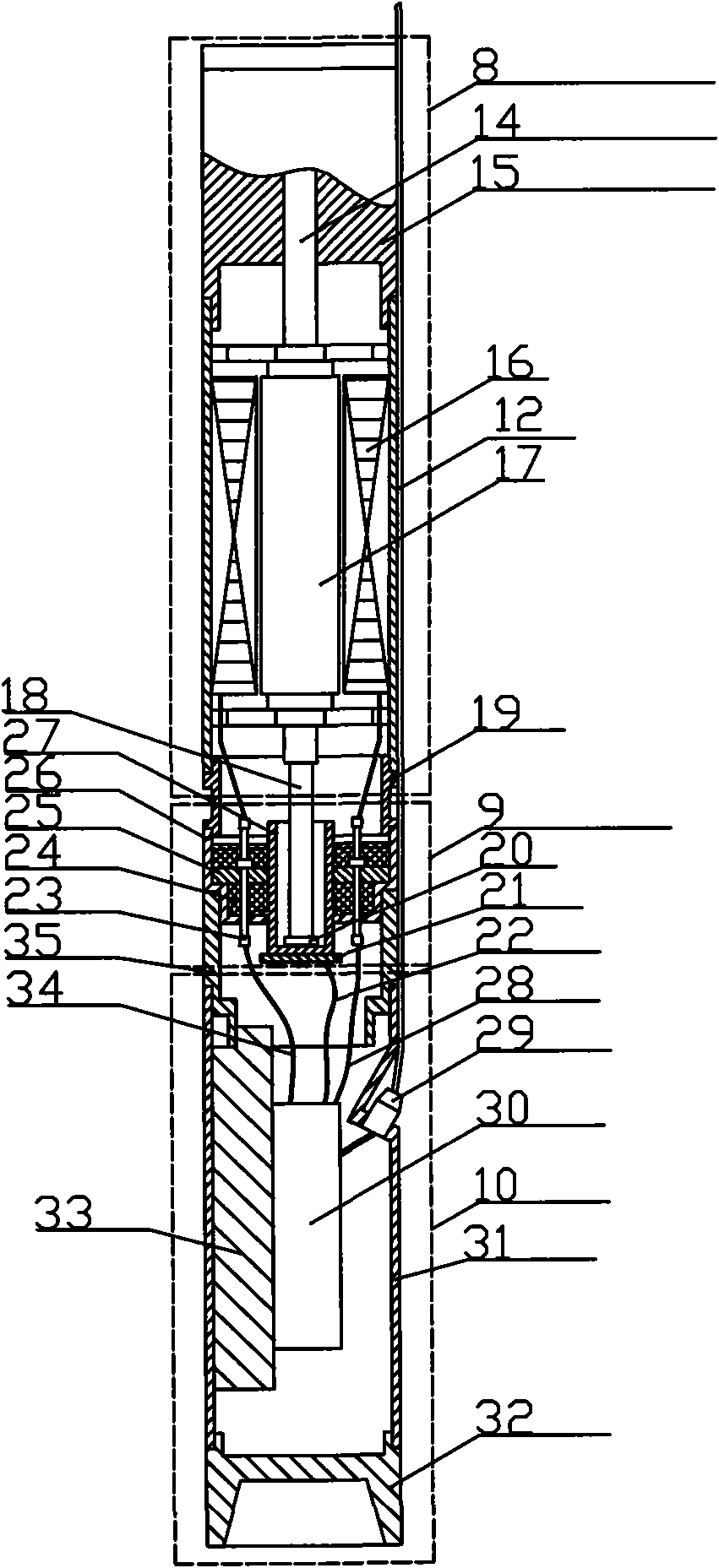

Control system of pumping system

InactiveCN101876243AImprove efficiencyImprove power densityFluid removalAutomatic control for drillingOperational costsControl system

The invention discloses an oil field control system which comprises a central control station and a plurality of underground submersible servodrive control subsystems communicating with the central control station, wherein each underground submersible servodrive control subsystem is connected with a production module in the well where the underground submersible servodrive control subsystem is, and the underground submersible servodrive control subsystem transmits the underground condition to the central control station according to the command and controlling parameters received from the central control station or a man machine interaction interface of the subsystem when controlling the operation of the production module. Through the invention, the operation condition of the submersible servodrive system in each well in the whole oil field can be accurately monitored and reasonably controlled by an operator, thus being favorable for improving the production efficiency and saving the operating cost.

Owner:杭州坤泽采油设备有限公司

Helium-filling vacuum leakage detection system for outdoor unit of air conditioner

InactiveCN102636315ARealize automatic leak detection processRealize automatic helium detectionFluid-tightness measurement using fluid/vacuumNitrogenNitrogen gas

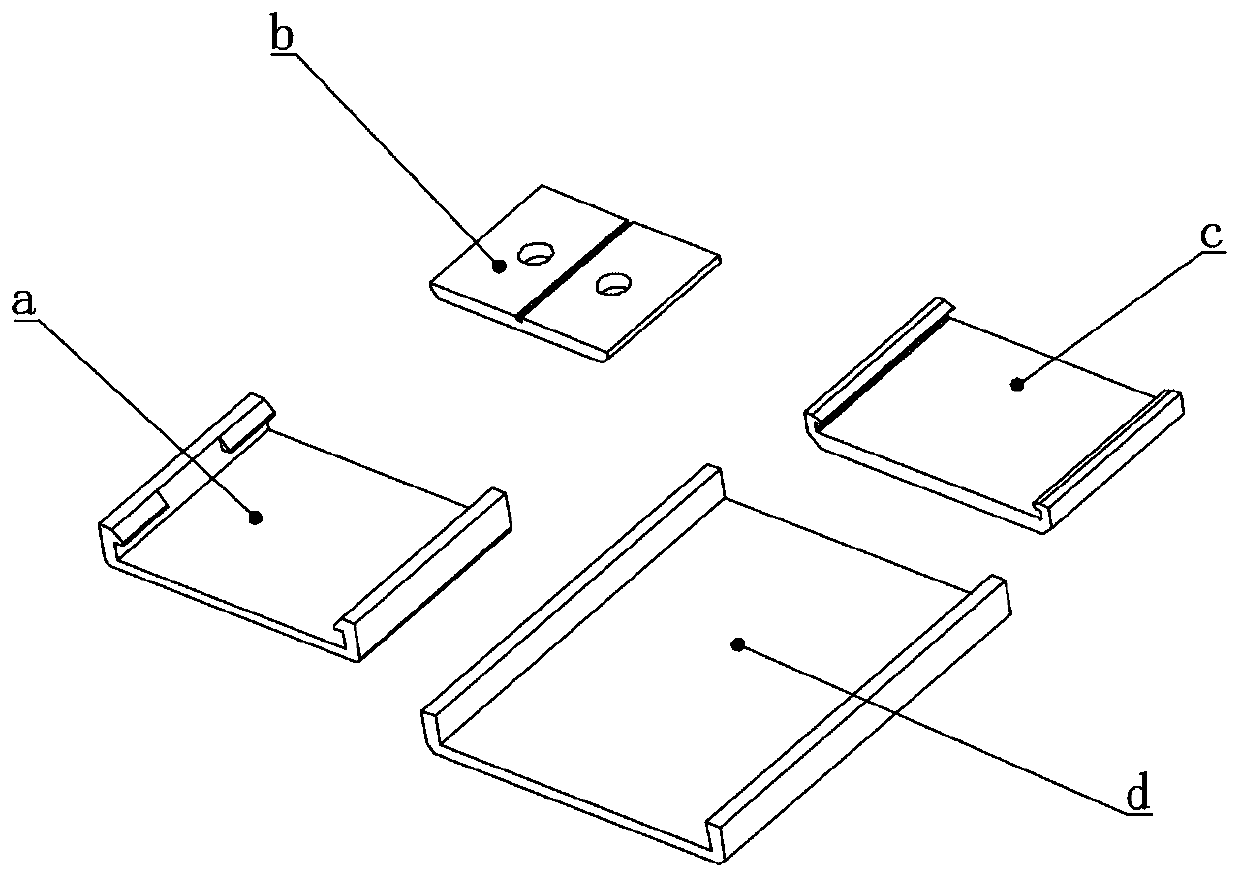

The invention relates to a helium-filling vacuum leakage detection system for an outdoor unit of an air conditioner. The helium-filling vacuum leakage detection system comprises a tooling plate, vacuum boxes, a pre-pumping pump group, a main-pumping pump group, a leakage detection pump group, a leakage detector, helium removing valves, gas discharging valves and leakage detection valves; an input passage consisting of shifters and multi-speed chain conveying belts is arranged at the entrances of the vacuum boxes; an output passage consisting of shifters and multi-speed chain conveying belts is arranged at the exits of the vacuum boxes; the tooling plate is arranged on the input passage and can reach the output passage by passing through the vacuum boxes along the input passage; rolling shafts connected with the input passage are arranged on the bottom faces of the cavity bodies of the vacuum boxes; the cavity bodies of the vacuum boxes are connected with the pre-pumping pump group through pre-pumping valves and are connected with the main-pumping pump group through main-pumping valves; the cavity bodies of the vacuum boxes are further connected with the leakage detector through the leakage detection valves; the cavity bodies of the vacuum boxes are further connected with a gas discharging pipeline, and the gas discharging valves are arranged on the gas discharging pipeline; the cavity bodies of the vacuum boxes are connected with a nitrogen pipeline, and the helium removing valves are arranged on the nitrogen pipeline; and the leakage detector is connected with an alarming device. The helium-filling vacuum leakage detection system for the outdoor unit of the air conditioner has the advantage of ensuring the overall quality of the air conditioner.

Owner:SHANGHAI SHARP ELECTRONICS

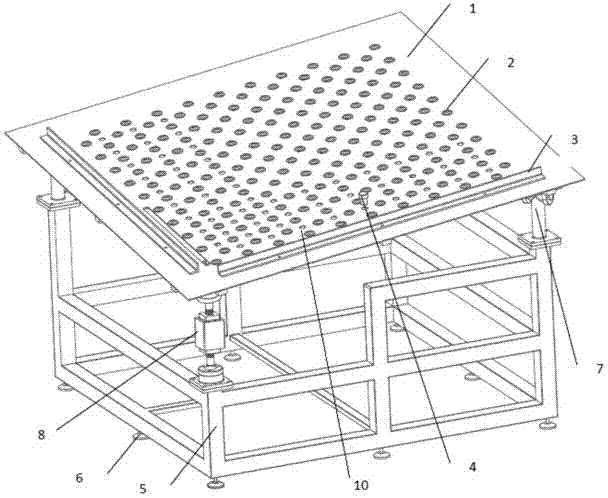

Flexible gravity centering table

ActiveCN103769488AProtective contactGuaranteed forceMetal-working feeding devicesPositioning devicesEngineeringGravitation

According to a flexible gravity centering table, a working table inclines downward in the direction from a feed station area to a discharge station area, universal wheels are arranged on the working table, and therefore workpieces are transferred to the discharge station area at the lower portion of the working table; driven-in pin type stop dogs are further arranged in the discharge station area, and therefore the layout and form of the stop dogs can be conveniently and freely adjusted in a plugging mode, and the positions of the stop dogs of the flexible gravity centering table can be randomly changed for special-shaped pieces.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

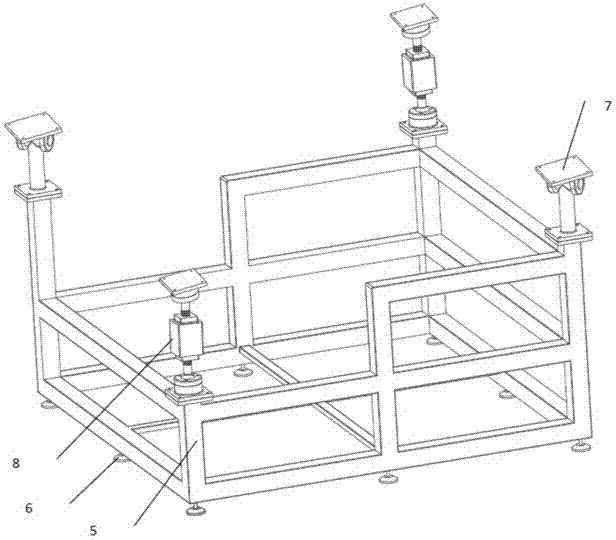

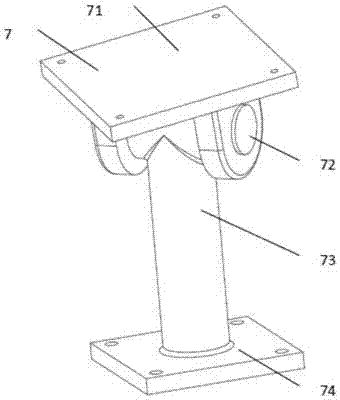

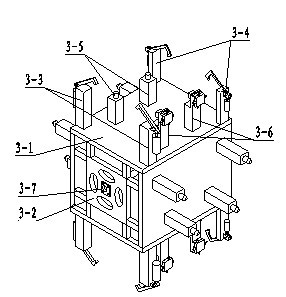

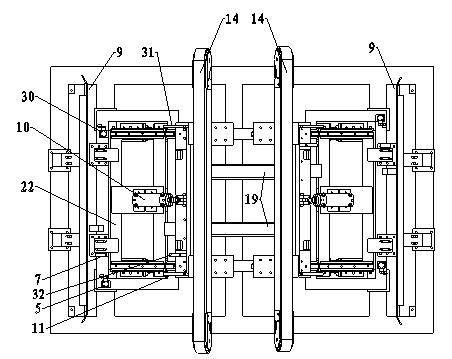

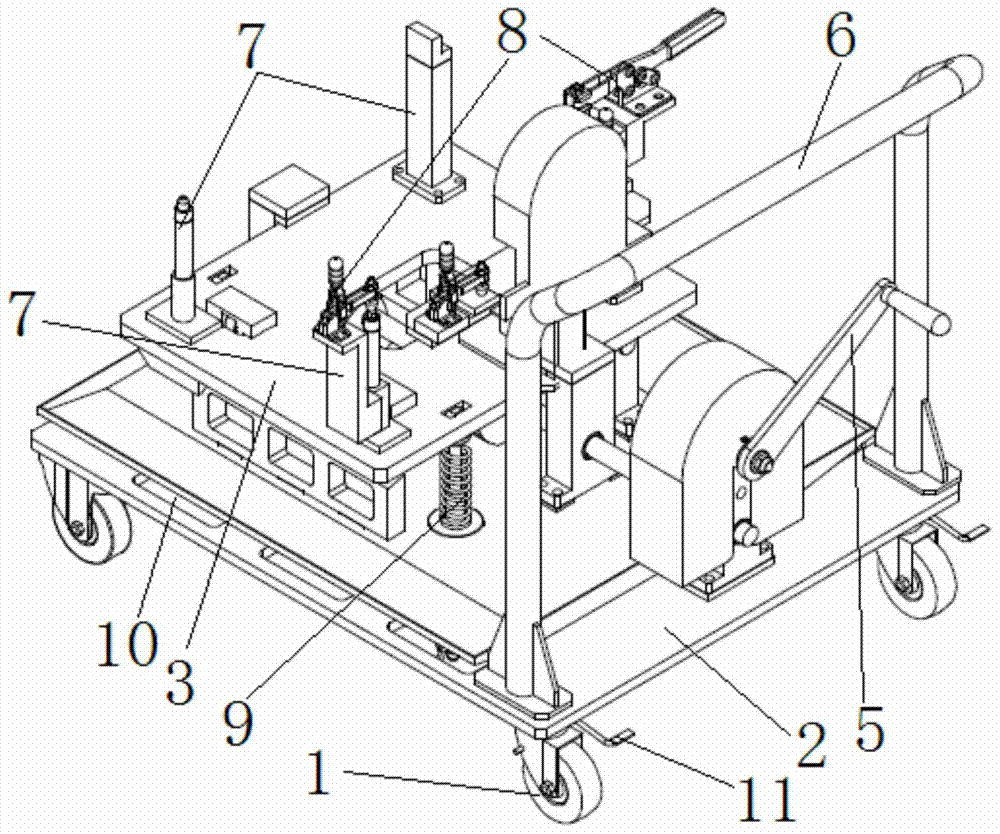

Workpiece locating device of multi-motorcycle-type welding production line of general motors

ActiveCN102642107AGuaranteed accuracyRealize flexible productionWelding/cutting auxillary devicesAuxillary welding devicesProduction lineRing mode

A workpiece locating device of a multi-motorcycle-type welding production line of general motors is used for improving flexible manufacturing capacity of the welding production line. The workpiece locating device comprises a polyhedral operating platform, a driving mechanism and a frame, at least four working faces are arranged on the polyhedral operating platform which is fixedly assembled with the driving mechanism fixedly installed on the frame, the frame comprises two portions which are symmetrically arranged in a left-and-ring mode, and the two portions are both fixed on a horizontal operation face. The workpiece locating device has the advantages of being strong in generality and stable in performance, being capable of achieving welding production of multiple motorcycle types in a same welding wire body, greatly reducing capital investment of production facilities, particularly being capable of enabling a period of new product mass production to be obviously shortened, and improving production efficiency of the motors.

Owner:长城汽车股份有限公司平湖分公司

Automatic household appliance power supply test device and test method

ActiveCN103630849AMeet the automatic loading and unloading testRealize information productionPower supply testingControl systemTest fixture

The invention discloses an automatic household appliance power supply test device and a test method. The test device comprises at least two test stations, a first transmission module, manipulators, sucking mechanisms, second transmission modules, a main control system, rejected product picking mechanisms and test jigs, wherein the two test stations are connected in series with each other through each second transmission module; the sucking mechanisms are arranged on the manipulators; the manipulators are arranged above the test stations; the main control system is connected with the manipulators to control the manipulators and is also connected with the reject product picking mechanisms to control the rejected product picking mechanisms; the test jigs are arranged on the test stations. According to the automatic household appliance power supply test device and the test method, the independent test stations are adopted; product test equipment is combined randomly according to requirements of a product test technology, so that different products can be automatically loaded and unloaded to be tested; meanwhile, the test stations interact information with the main control system, so that information of every product can be monitored in real time, and a record can be formed so as to realize product informationized production; the production cost is saved, and the production efficiency is improved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

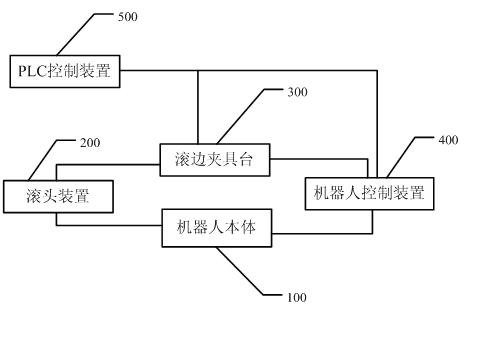

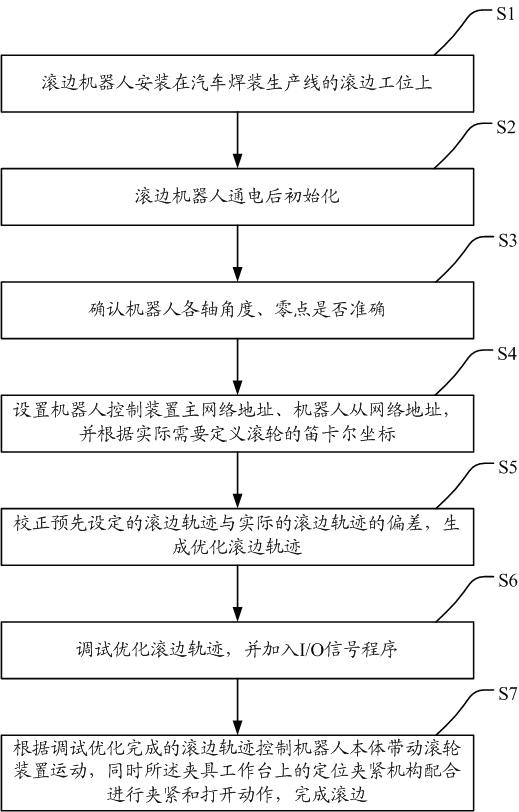

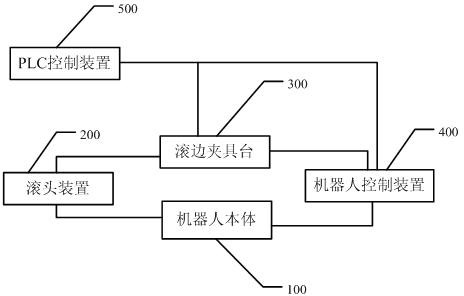

Edge knurling robot and edge knurling method thereof

The invention discloses an edge knurling robot and an edge knurling method, wherein the edge knurling robot comprises a robot body, a head knurling device, a PLC (programmable logic controller), an edge knurling clamp stand and a robot control device, wherein the robot control device is connected with the edge knurling clamp stand and the robot body; the head knurling device is connected with the robot body and the edge knurling clamp stand; and the PLC is connected with the robot control device and the edge knurling clamp stand. Since the edge knurling robot and the edge knurling method are provided by the invention, the edge knurling process is accomplished automatically, and only one robot can accomplish edge knurling and stitching to key components of an automobile. Meanwhile, compared with the traditional edge covering process, the invention has the advantages that the degree of automation and the product quality are improved during the edge knurling process, the labor intensity of an operator is reduced, the cost for the edge knurling equipment is lowered, and flexible production is achieved.

Owner:CHANGCHUN DAZHENG AUTOMATIC EQUIP

Submersible servodrive system

InactiveCN101877564AImprove efficiencyImprove power densityElectronic commutation motor controlMeasurement apparatus housingsPower factorElectric machine

A submersible servodrive system comprises a pump. The system is characterized in that the pump is connected with a servo motor system by a protector; a ground control device is connected with ground power supply by a cable; the cable is connected with the servo motor system; the ground power supply is controlled by the ground control device to supply power to a servo motor and the pump; the servo motor system comprises the servo motor and a servo controller; a motor shaft of the servo motor is provided with a position detection device which outputs the position signal detected by the position detection device to the servo controller; the servo controller controls the servo motor to run; and the position detection device is fixed on the servo controller by a sealing device. The system has high power factor, high energy saving rate and high flexibility, further saves power, can realize flexible production and reduces the operation cost. When being started, a pumping unit can provide large torque, combine with soft start and reduce the power of a matching motor of the pumping unit.

Owner:杭州坤泽采油设备有限公司

Control cooling method of easy-welding high-performance steel plate

InactiveCN103114186AReduce the amount addedUniform tissueHeat treatment process controlDislocationHeat treated

The invention provides a technical scheme of a control cooling method of an easy-welding high-performance steel plate. The easy-welding high-performance steel plate comprises the following chemical components in percentage by weight: 0.05-0.09% of C, 0.1-0.25% of Si, 1.55-1.65% of Mn, 0.025-0.035% of Nb, 0.025-0.035% of V, 0.20-0.30% of Cr, 0.0008-0.0025% of B, 0.020-0.045% of Alt, 0.015-0.030% of Ti and billet of which the low-welding crack sensitivity index Pcm is less than 0.21%; a final steel plate with the thickness of 12-60mm is rolled in a non-recrystallization area, and the effects of dislocations strengthening, precipitation strengthening and phase change strengthening in cooling after rolling are sufficiently realized by adopting different online cooling modes according to different performance requirements of the final steel plate; and the microstructure is controlled according to different performance requirements to obtain a proper complex-phase structure. According to the scheme, flexible control on performance is realized through the flexibility of the cooling technology by use of one component; the produced steel plate has uniform structure, low yield ratio, high plasticity and excellent low-temperature toughness; the steel plate does not need preheating before welding and heat treatment after welding; and the individualized needs of users are met by the flexibility of the production line.

Owner:JIGANG GRP

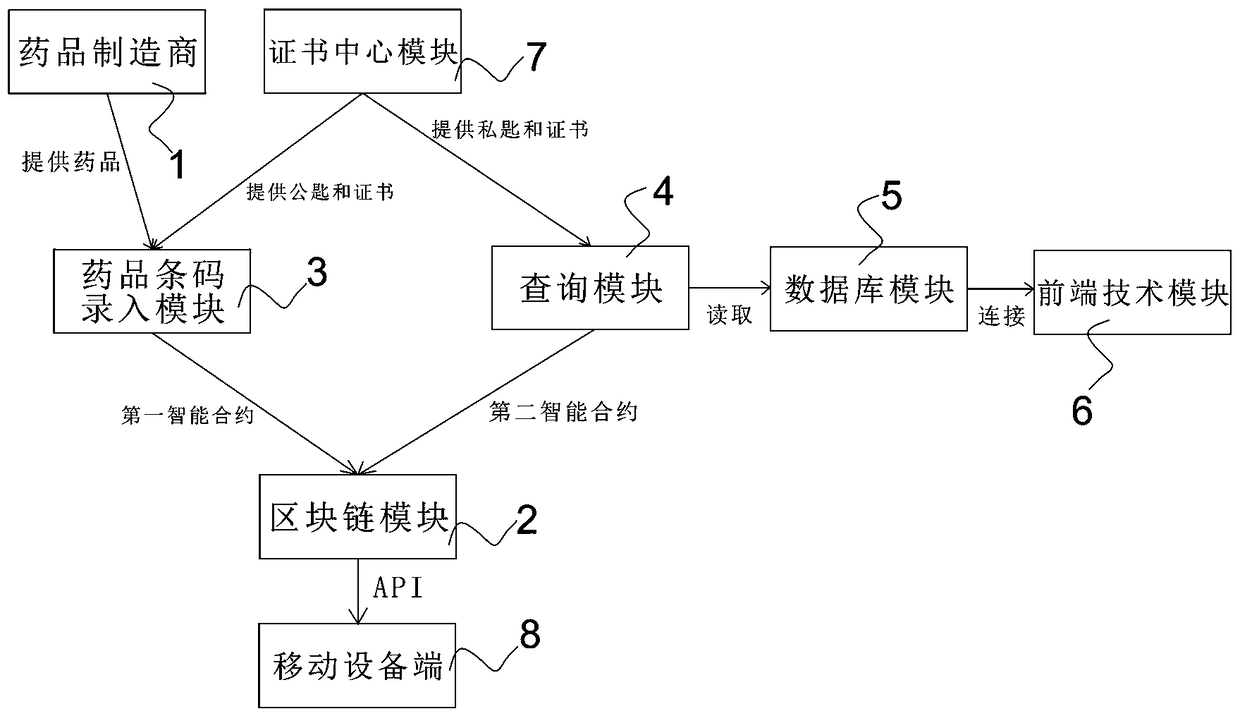

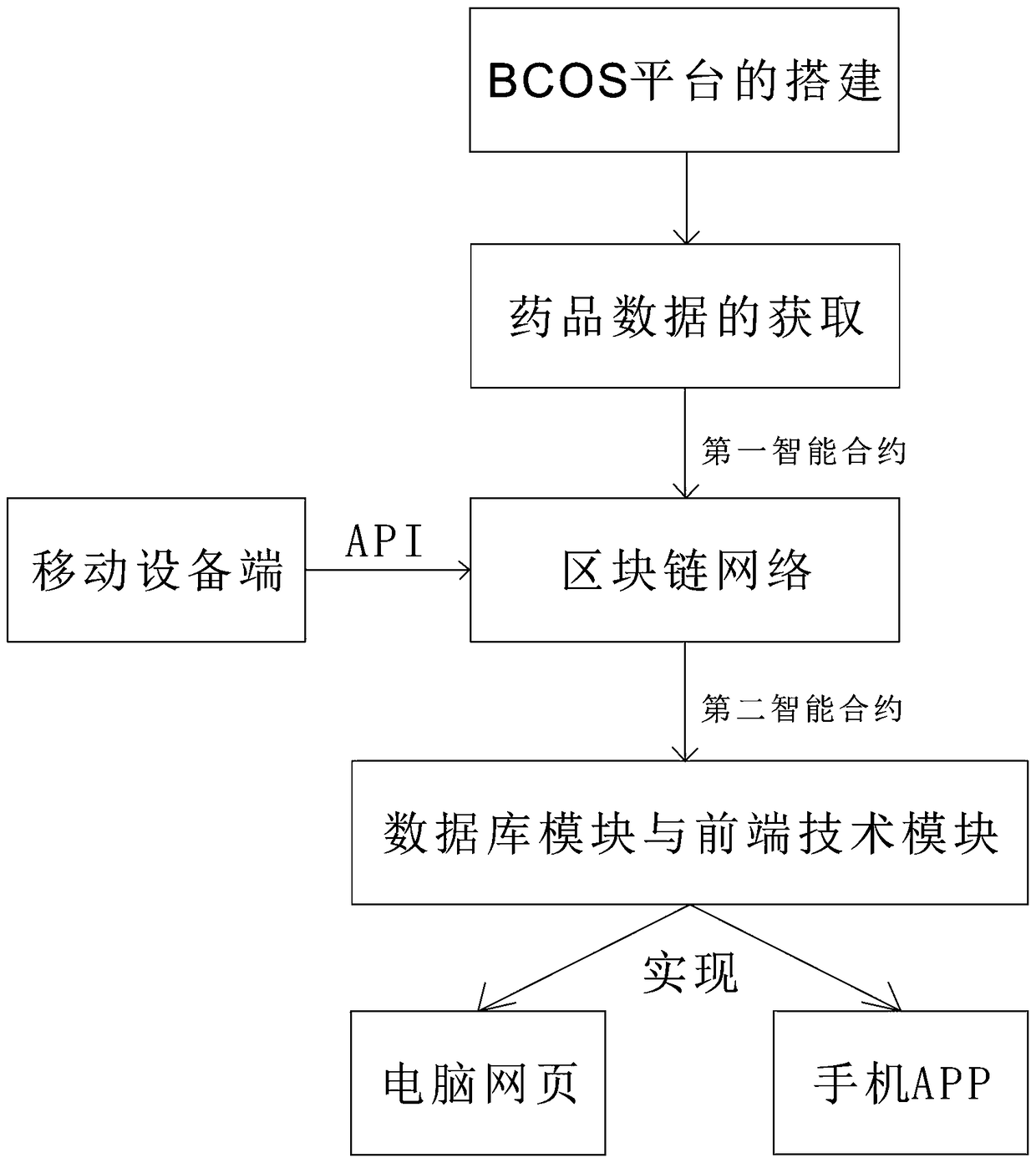

Pharmaceutical information tamper-proof traceability management system based on mobile block chain

PendingCN109325775ARealize visualizationEnsure transparencyCo-operative working arrangementsCommerceTamper resistanceBarcode

The invention relates to a pharmaceutical information tamper-proof traceability management system based on a mobile block chain, characterized by comprising a block chain module, a pharmaceutical barcode input module, a query module, a certificate center module, a mobile device terminal for connecting the block chain module through a mobile block chain API, a database module for reading and storing data and a front-end technical module for realizing data visualization. The pharmaceutical bar code input module encrypts the privacy data of the drug and the enterprise through the public key andstores the read bar code data into the block chain module through the first intelligent contract, and the query module reads the privacy and public data in the block chain module through the private key and the second intelligent contract. The invention realizes the tracking of the drug supply chain and the visualization of the data, and guarantees the transparency of the drug supply chain. The mobile block chain API not only enables the mobile device to participate in the network governance and transaction information verification as a node in the block chain network, but also can access thedata on the storage chain, thereby improving the convenience.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

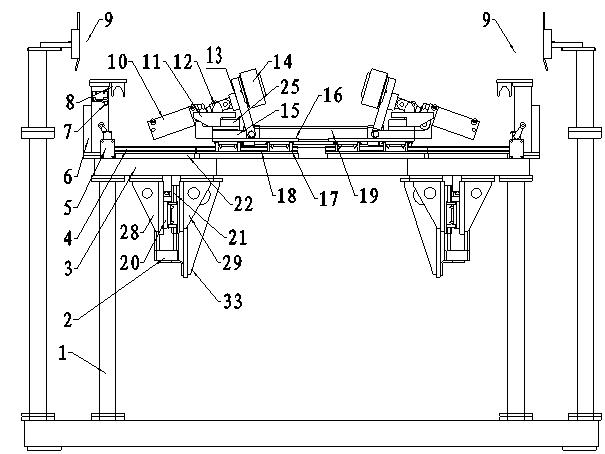

Automobile door and cap switchable conveying device

The invention provides an automobile door and cap switchable conveying device. The device consists of a guiding mechanism, a conveying mechanism, a support and an upper frame, wherein the conveying mechanism is positioned on the upper frame, and comprises a left conveying mechanism and a right conveying mechanism; the improved left conveying mechanism and the right conveying mechanism respectively comprise a conveying belt, a horizontal cylinder, a vertical cylinder and an angle cylinder; lift racks are arranged on two sides of the upper frame; the conveying belt is driven by the horizontal cylinder to horizontally move to the lift rack; the vertical cylinder drives the lift rack and the conveying belt to vertically move along with the lift rack; and the angle cylinder drives the conveying belt to adjust angles. The device can be applied to conveying of automobile doors or caps by quick state switching, and ensures that the gravity center position of a workpiece is arranged in the middle of two conveying mechanisms and the conveying belt is contacted with the workpiece surface. Regarding to the appearance changes of the product workpiece or a new product, the conveying device can be put into use by simple adjustment, is advantageous to reducing tooling cost and saving tooling field, and improving the production efficiency.

Owner:GREAT WALL MOTOR CO LTD

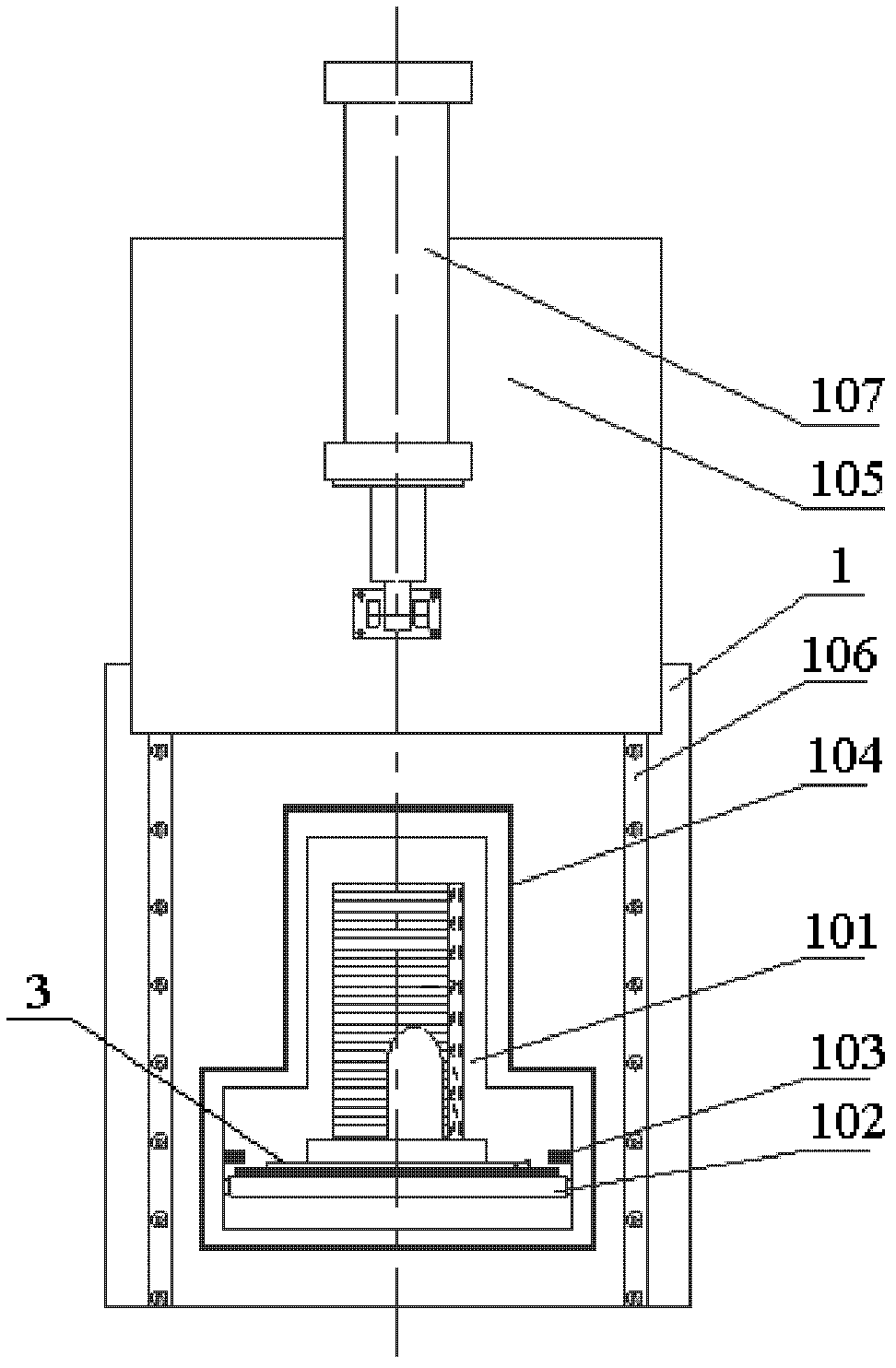

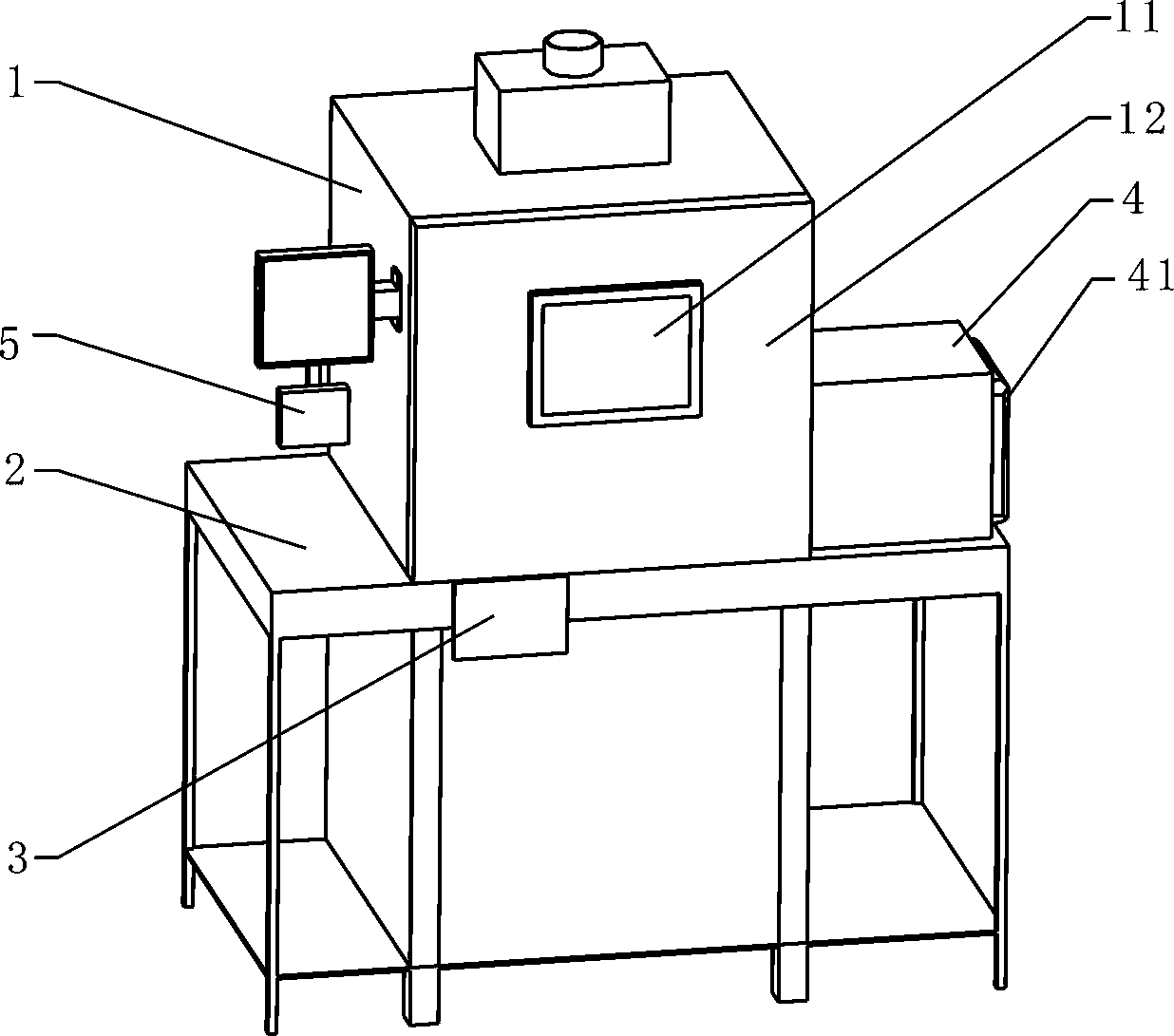

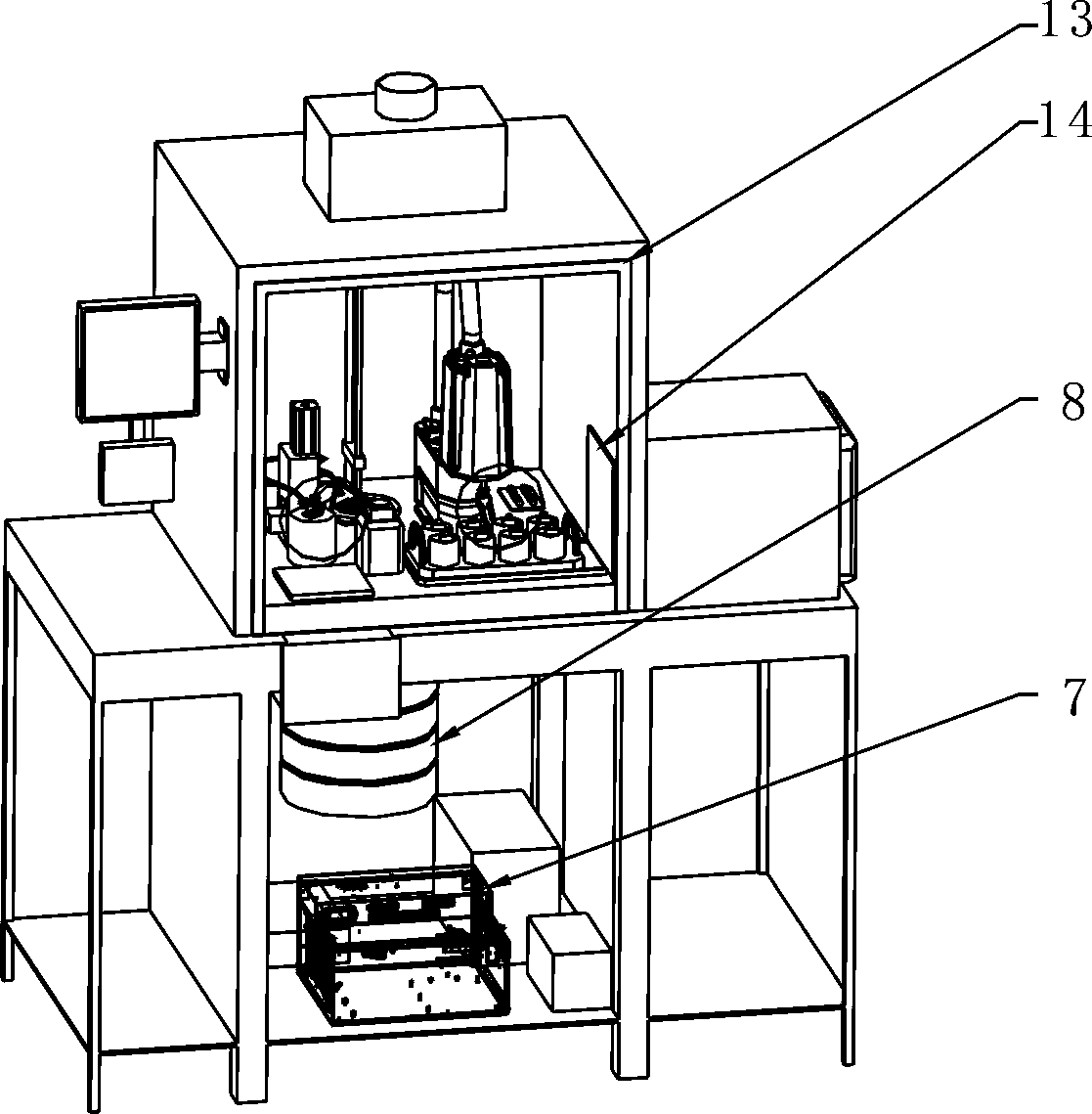

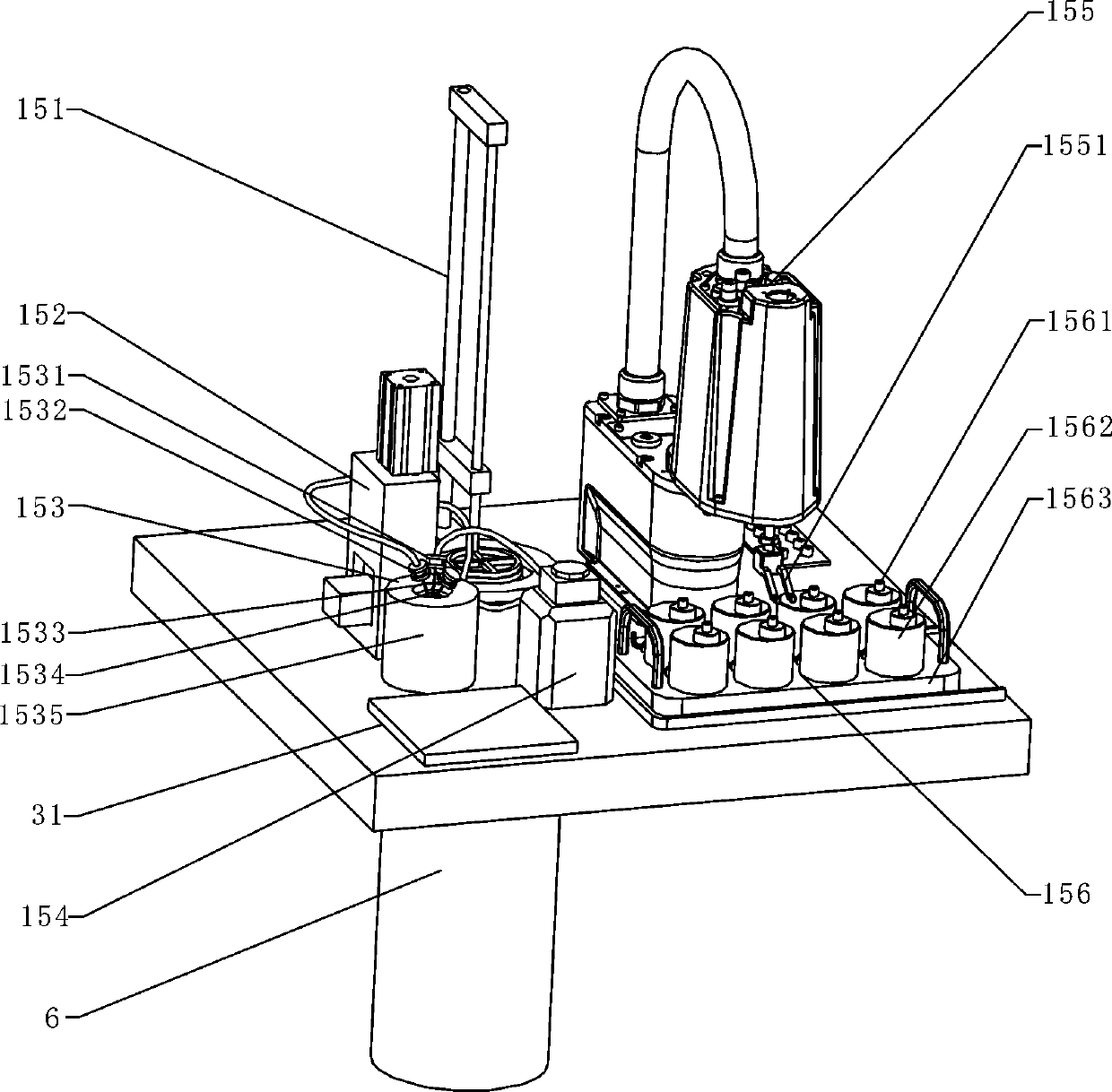

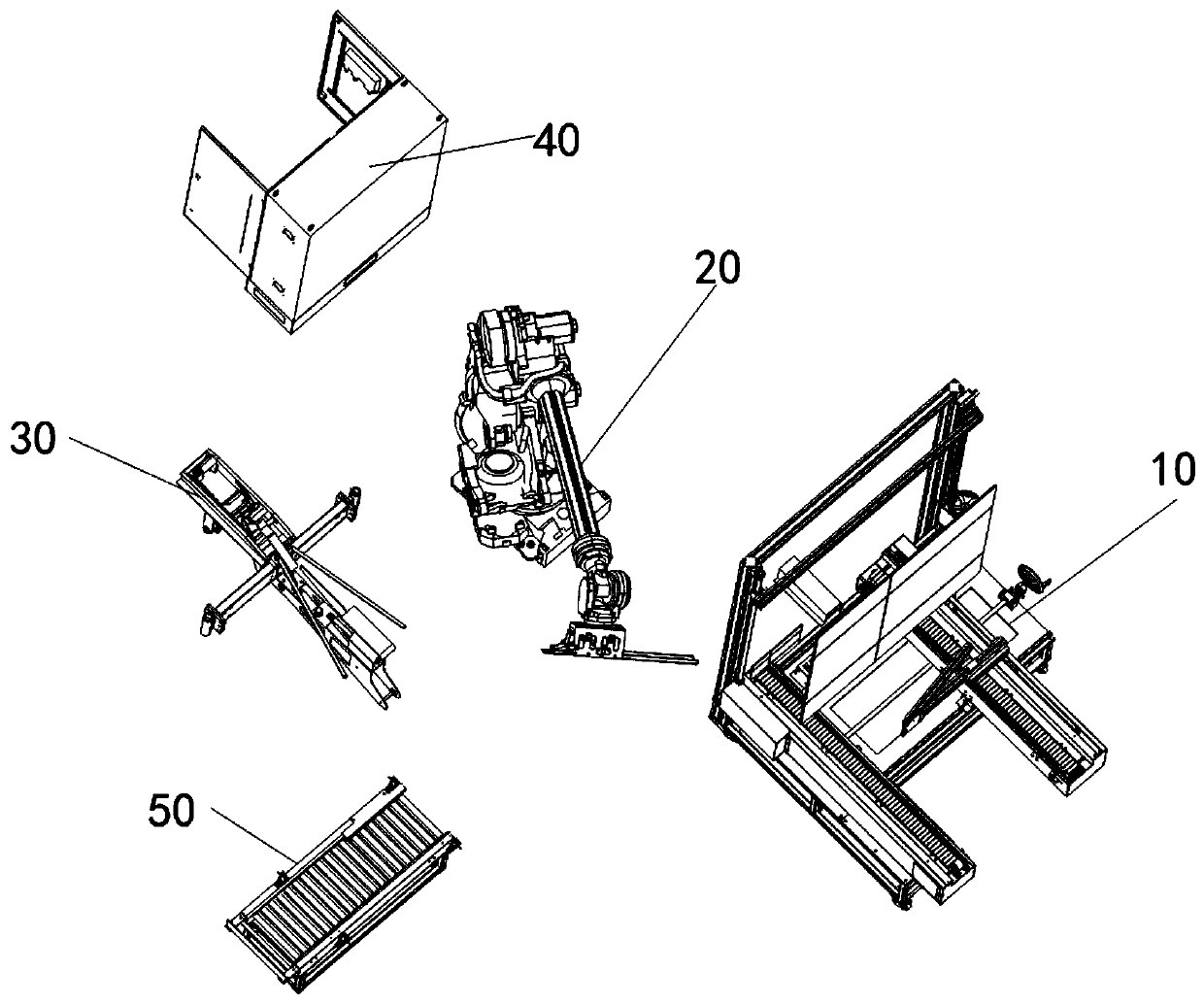

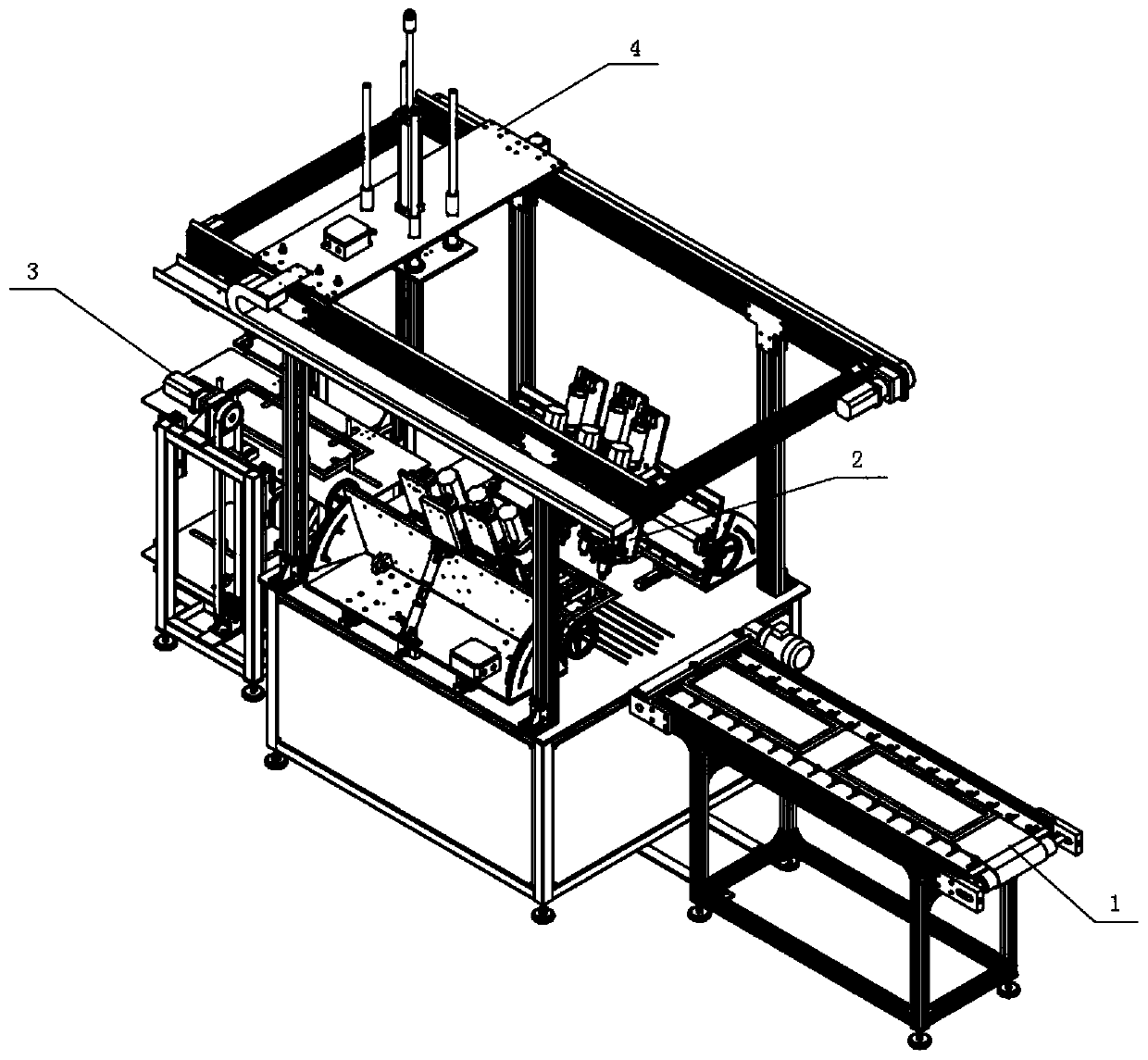

Automatic loading system and method for radio isotope liquid medicine capsules

ActiveCN107744468AFully automatedRealize flexible productionCapsule deliveryEngineeringPower apparatus

The invention relates to an automatic loading system and method for radio isotope liquid medicine capsules. The system comprises a supporting bench and a shielding heat chamber mounted on the supporting bench, wherein a loading platform is disposed in the heat chamber; a robot, a loading device, a pre-filling capsule tray assembly and a mother solution circulating device connected with the loadingdevice via a power device are arranged on the loading platform; the robot, the loading device and the power device are connected with a controller; and the controller can automatically quantitativelyload the liquid medicine capsules according to the liquid medicine capsules and a patient condition. The automatic loading system and method for radio isotope liquid medicine capsules have great automation degree and production efficiency, great loading precision and simple operation as well as excellent shielding performance; the system has an economic mode or a high-efficient mode, so bigger selection space can be provided for users with different demands; and great application value is provided.

Owner:类彦威

Intelligent multi-box molding system

InactiveCN109823616AAchieve regulationRealize flexible productionWrapper twisting/gatheringIntelligent lightingCarton

The invention relates to the technical field of carton forming, in particular to an intelligent multi-box molding system. The intelligent multi-box molding system comprises a carton feeding device, abox opening manipulator, a bottom box sealing device and a controller, the box opening manipulator comprises a box opening device used for grasping the carton and a manipulator used for driving the box opening device to move, the box opening device comprises a front face sucking disc assembly, a side face sucking disc assembly, and a side face sucking disc driving mechanism, the side face suckingdisc driving mechanism rotates relative to a front face sucking disc by driving the side face sucking disc assembly, and the grasped carton in the folded state is opened to be in an unfolded state. Compared with the prior art, according to the intelligent multi-box molding system, by arranging a width-adjustable carton conveying mechanism, a height-adjustable clamping mechanism and the box openingdevice suitable for different carton types, he box opening operation of cartons of different types can be achieved through the simple operation, the flexible production is achieved, and the production efficiency is effectively improved.

Owner:厦门合兴智能集成服务有限公司

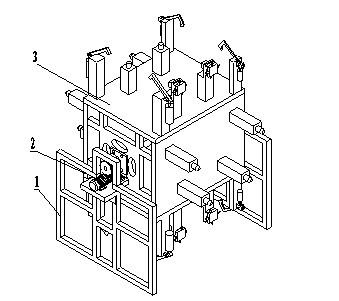

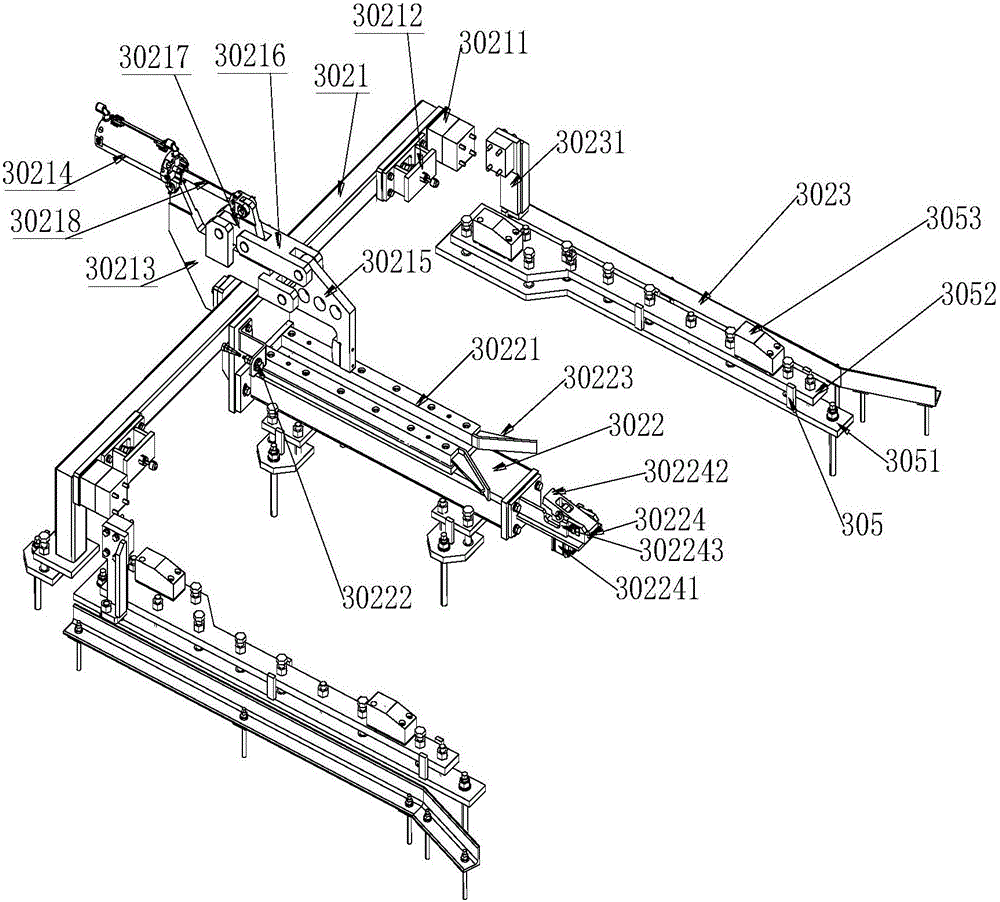

Flexible production line suitable for automobile side body production

ActiveCN106378557ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringProduction line

The invention discloses a flexible production line suitable for automobile side body production. The flexible production line comprises a conveyor line sequentially provided with a line-on station, a preparation station, a positioning, clamping and main welding station, a high-speed switching repairing welding station and a line-off station. The conveyor line is an overturnable reciprocating conveying production line and comprises a reciprocating conveyor line body driven by a forward and backward rotating motor and six four-vehicle-type switching transportation trolleys. A tetrahedral rotational clamp located on the positioning and clamping station and a rotational high-speed repairing welding clamp located on the high-speed switching repairing welding station are arranged on one side of the reciprocating conveyor line body. The flexible production line suitable for automobile side body production is simple in structure, convenient to use and capable of achieving flexible production, and the situations that land is occupied by establishing a plurality of production lines and much capital is invested are avoided.

Owner:郑州日产汽车有限公司

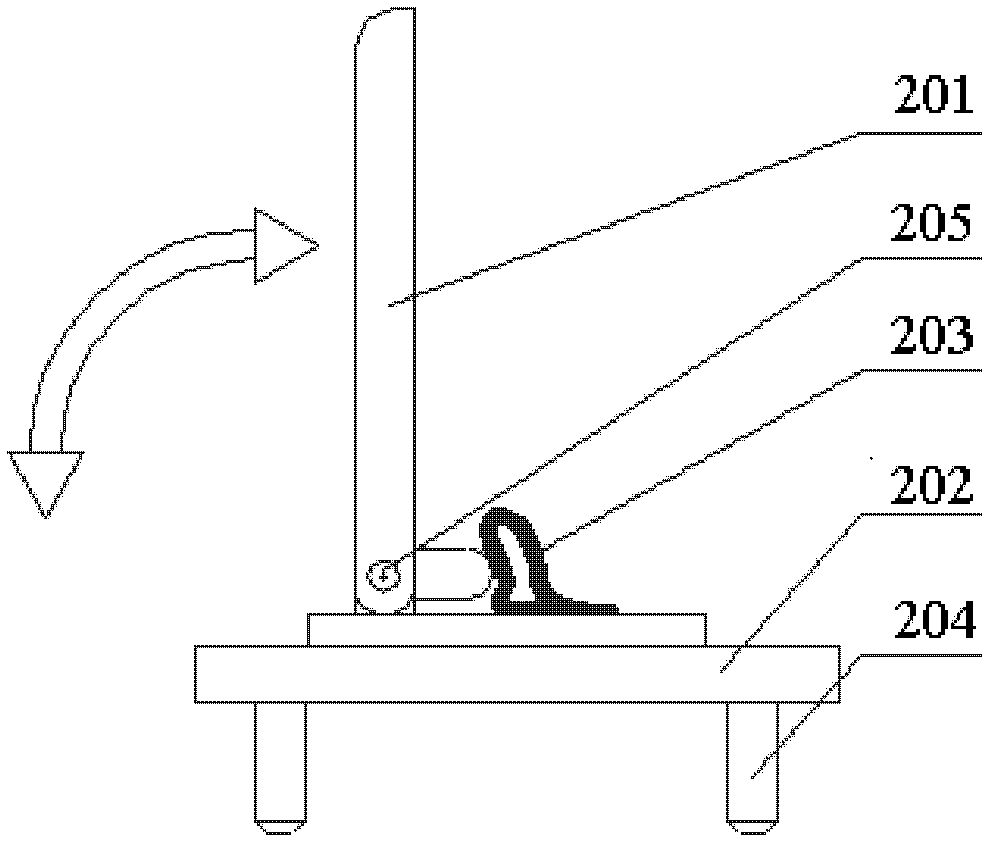

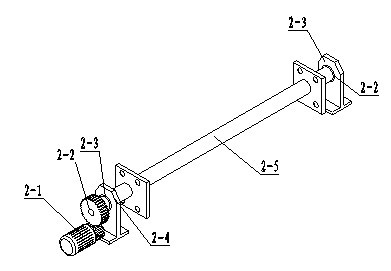

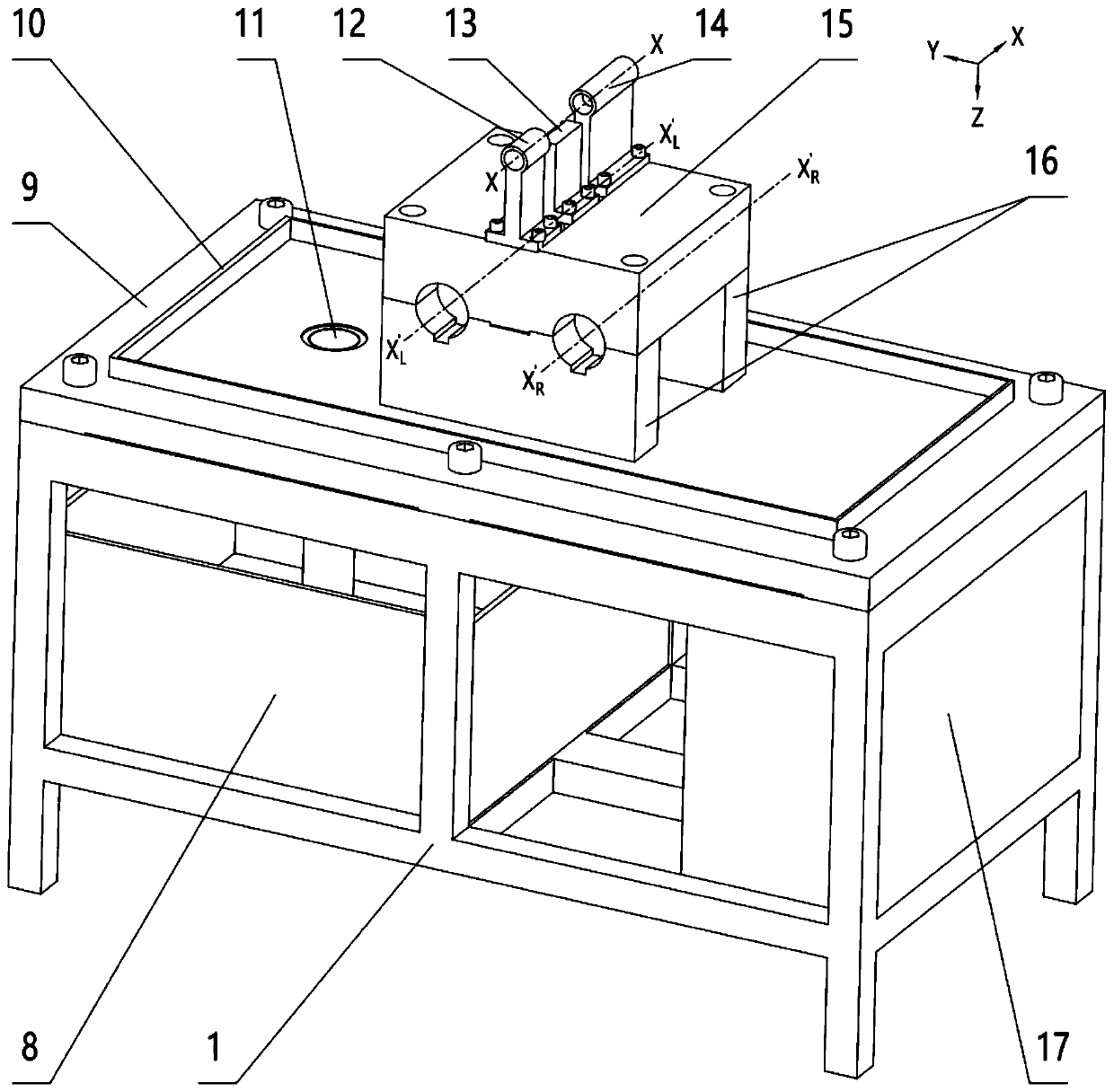

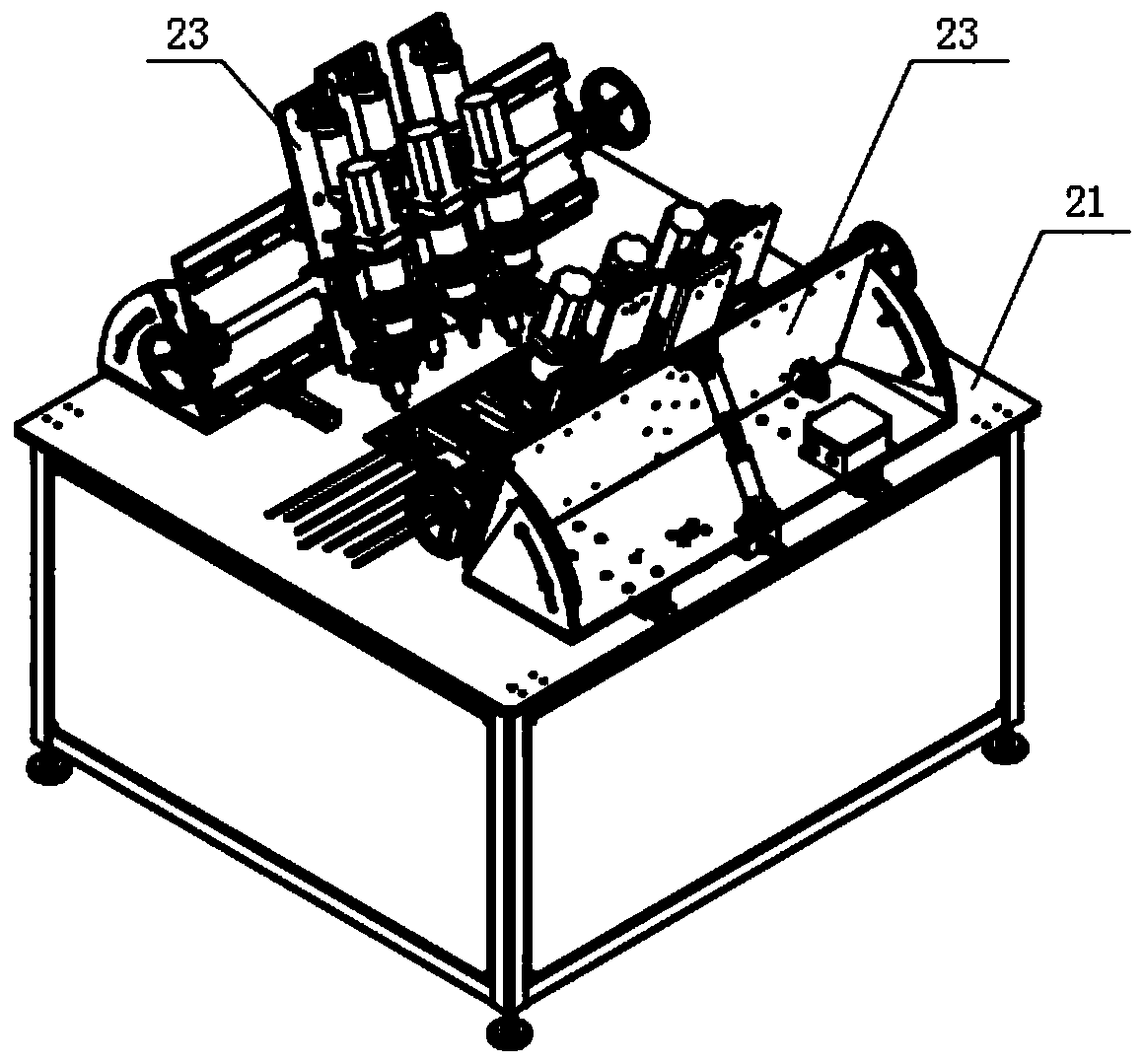

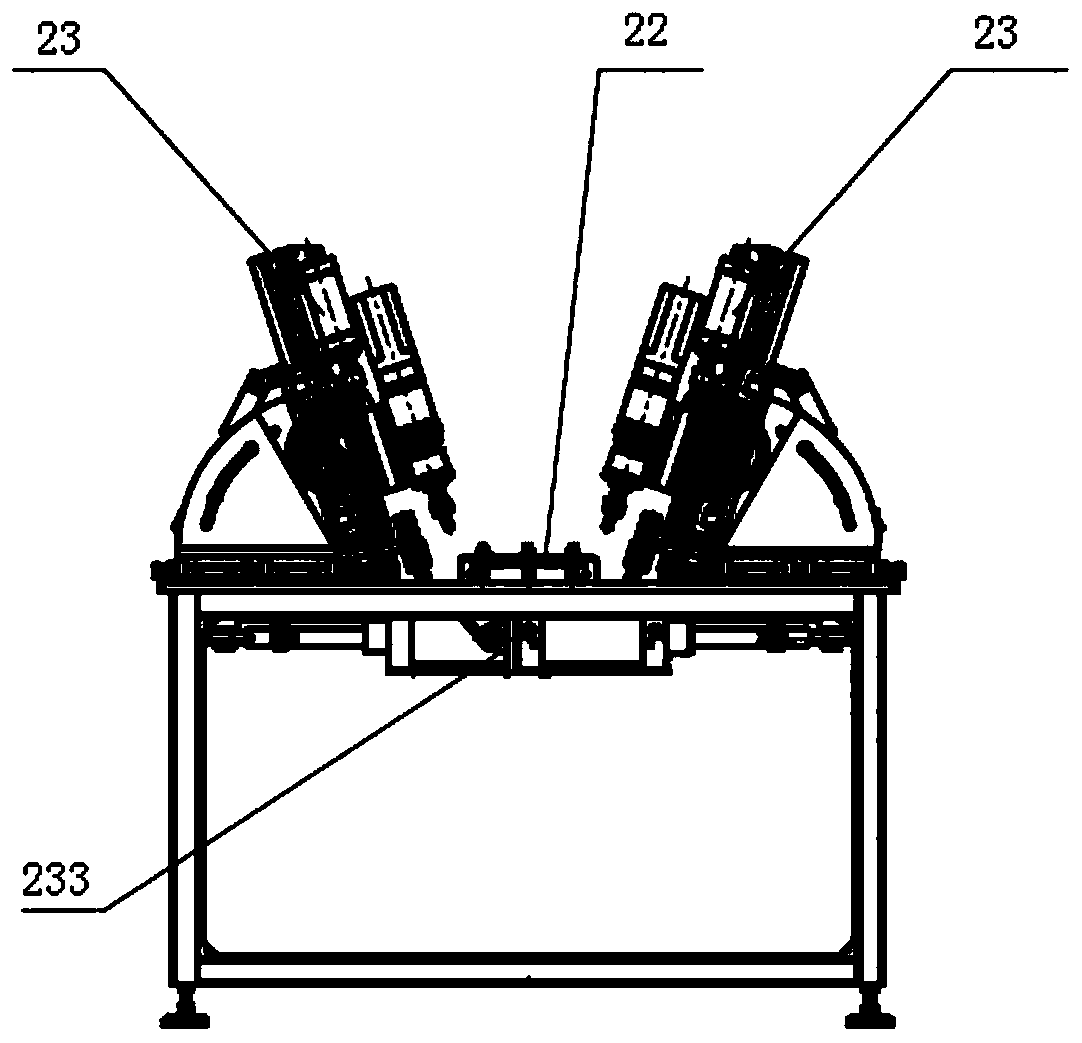

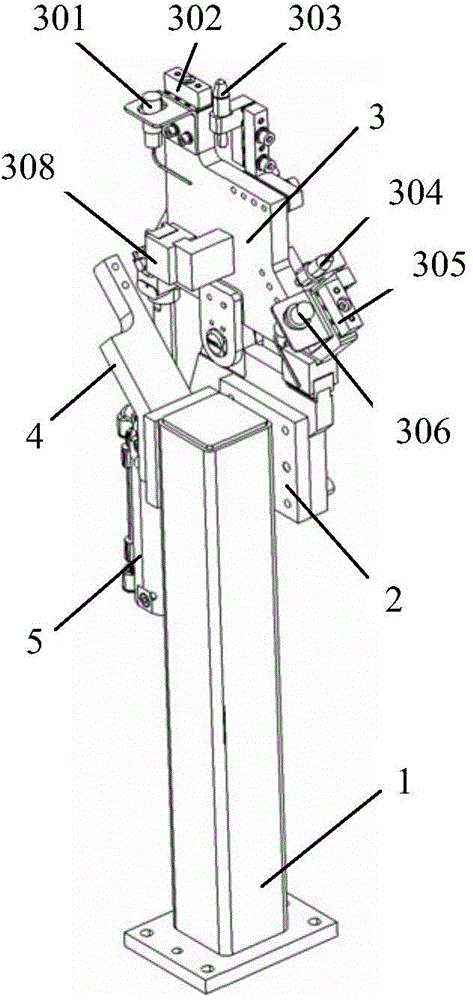

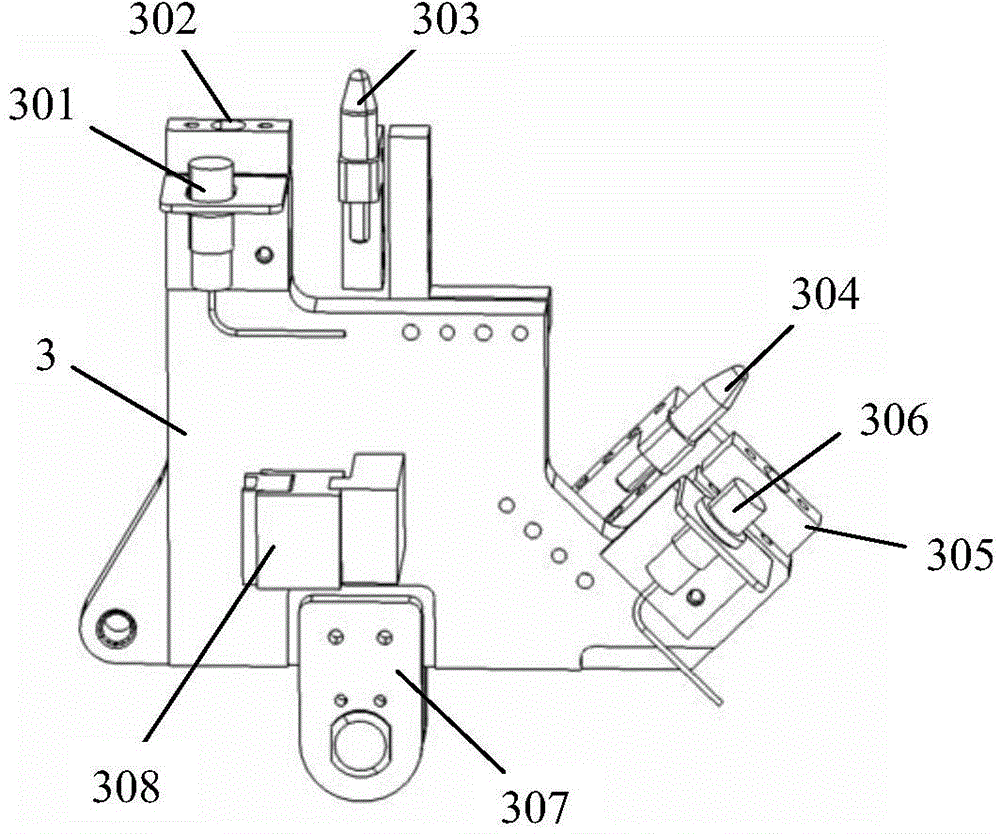

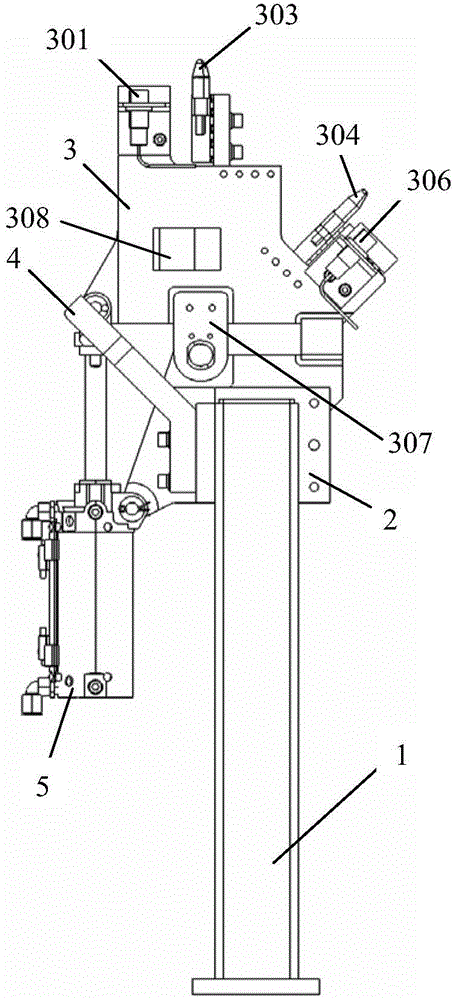

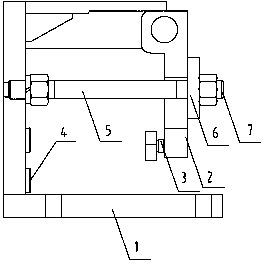

Workpiece feeding rack limiting device for intelligent robot rolled hemming system

ActiveCN105834317AAchieve precise positioningRealize flexible productionMetal-working feeding devicesPositioning devicesMaster controllerMechanical engineering

The invention discloses a workpiece feeding rack limiting device for an intelligent robot rolled hemming system. The workpiece feeding rack limiting device comprises an X-direction limiting rack, wherein workpiece feeding table X-direction pressing blocks and workpiece feeding table X-direction side proximity switches are separately arranged at two ends of the X-direction limiting rack; an X-direction limiting air cylinder mounting plate is arranged in the middle of the X-direction limiting rack; a workpiece feeding table X-direction limiting air cylinder and a workpiece feeding table X-direction pressing head are arranged on the X-direction limiting air cylinder mounting plate; a workpiece feeding table X-direction middle guide frame is also arranged in the middle of the X-direction limiting rack; an X-direction guide groove and a workpiece feeding table X-direction middle proximity switch are formed in the upper surface of the workpiece feeding table X-direction middle guide frame; a workpiece feeding table muzzle brake is arranged at the tail end of the workpiece feeding table X-direction middle guide frame; the rack limiting device also comprises two Y-direction limiting racks; workpiece feeding table supporting frames are respectively arranged at the inner sides of the Y-direction limiting racks. According to the workpiece feeding rack limiting device disclosed by the invention, accurate positioning of the workpiece feeding rack of the intelligent robot rolling and hemming system is realized by accurate guiding in X, Y and Z directions; meanwhile, information about workpieces is acquired by sensing a signal of the workpiece feeding rack and is fed back to a master controller, and flexible production is realized.

Owner:GUANGZHOU RISONG HOKUTO AUTOMOTIVE EQUIP CO LTD

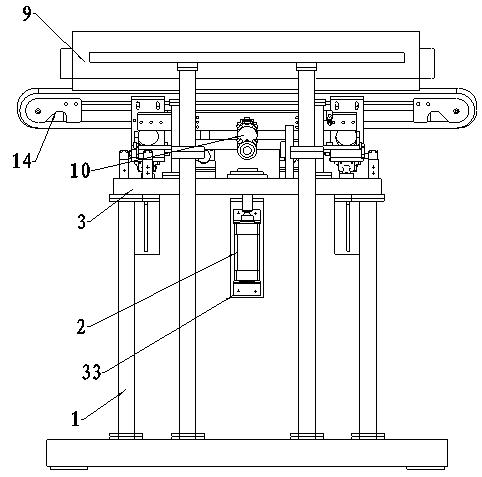

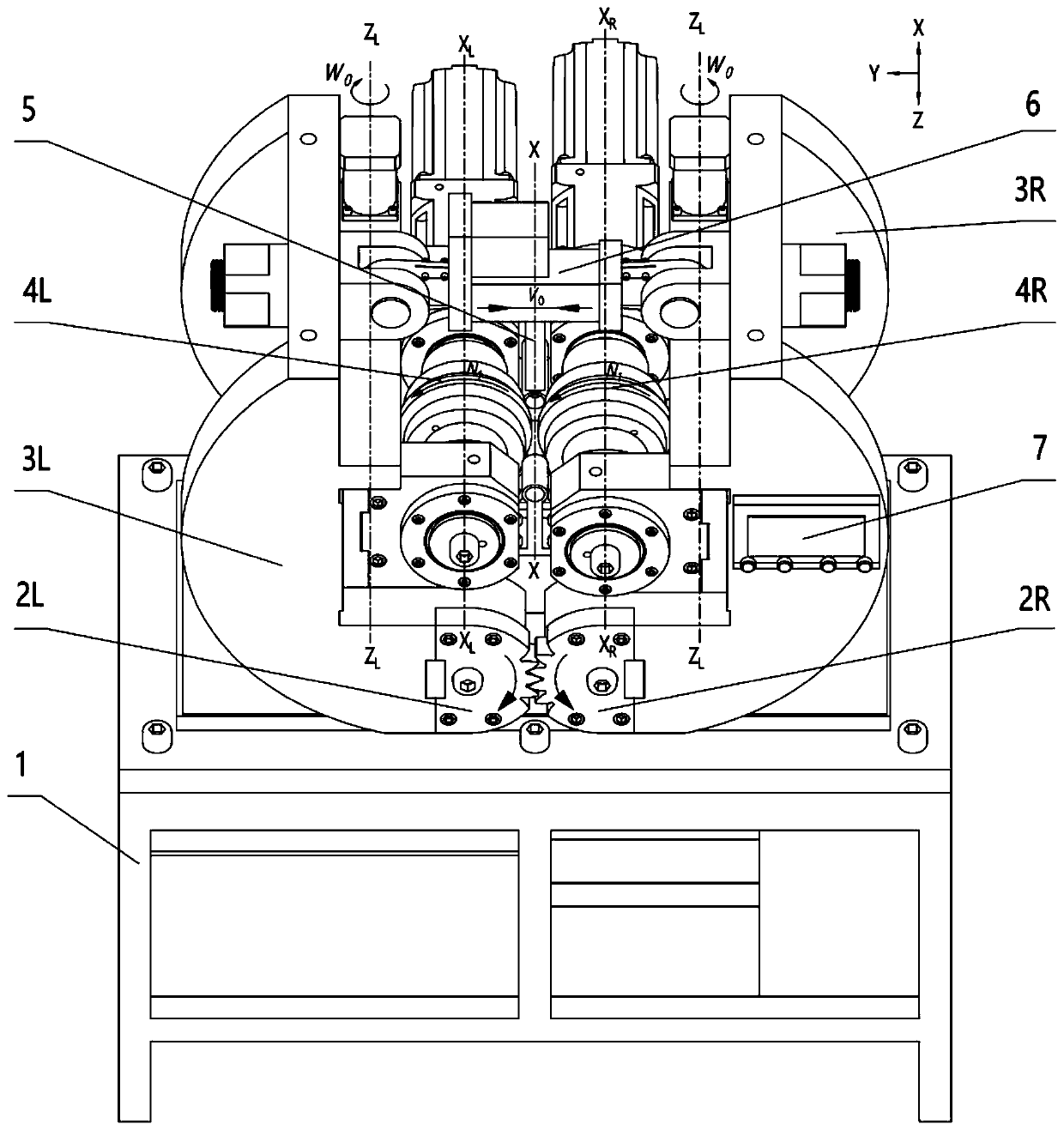

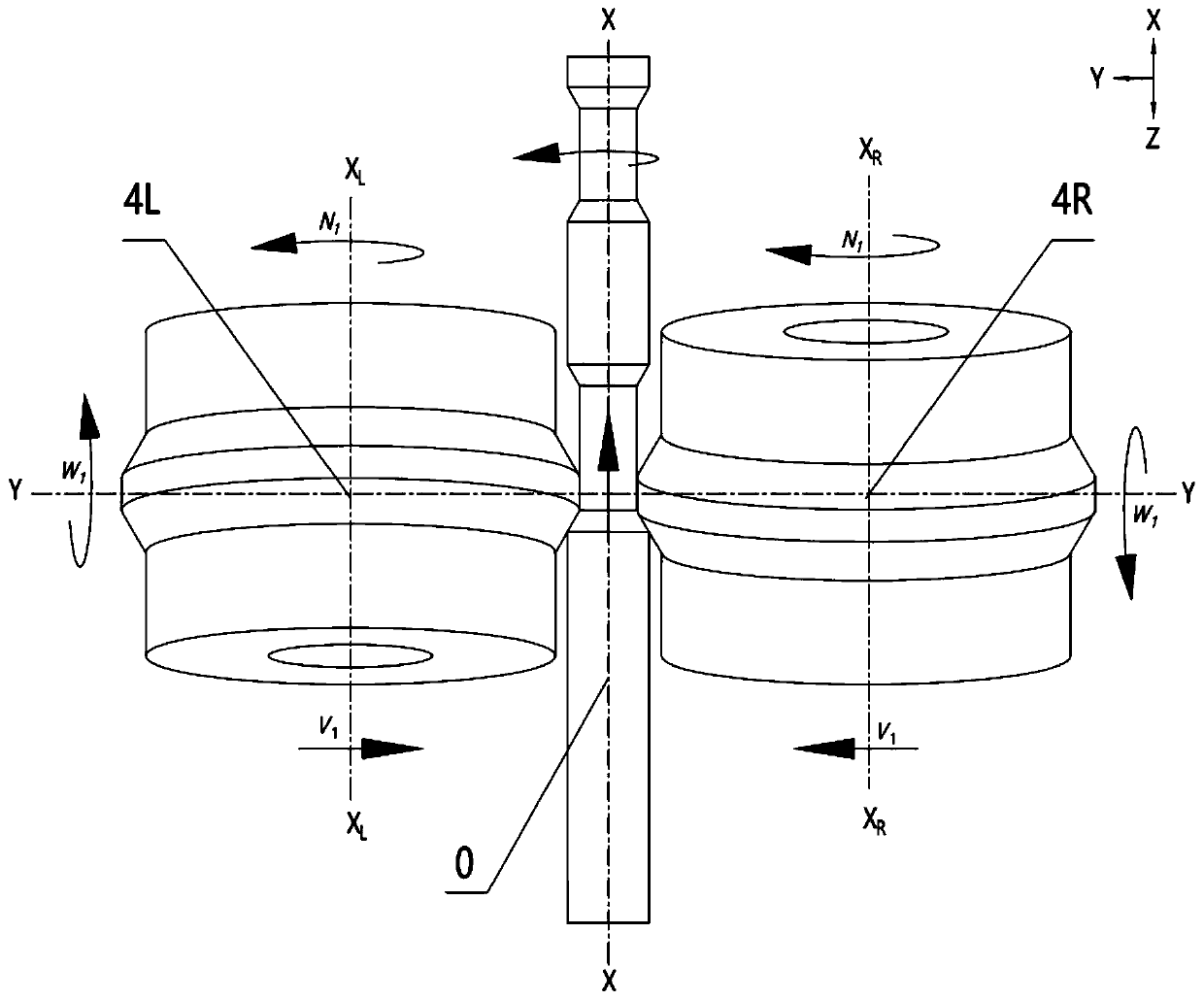

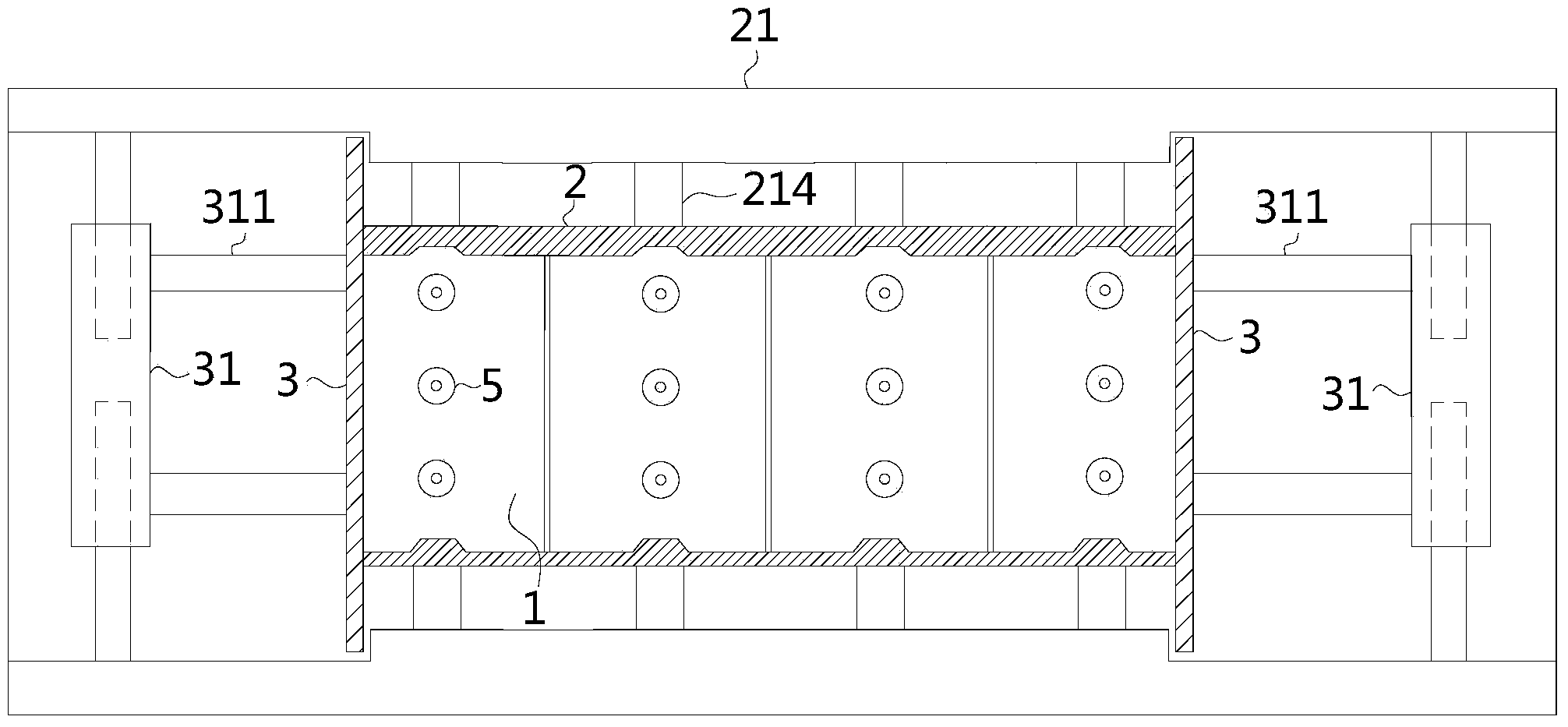

Double rotating shaft flexible skew rolling mill

ActiveCN110270590AReduce offsetStable structureSkewed roll standMetal rolling stand detailsUltimate tensile strengthRolling mill

The invention relates to the technical field of metal plastic forming technologies and equipment and provides a double rotating shaft flexible skew rolling mill. The double rotating shaft flexible skew rolling mill comprises a base unit, a guide unit, two rolls, two servo main shaft systems, a roll spacing adjustment mechanism, two inclination angle adjustment mechanisms, a cooling system and a numerical control system. The two servo main shaft systems are supported and mounted by two racks and drive the two rolls to rotate; the roll spacing adjustment mechanism drives the two racks and allow the two rolls to perform synchronous centering radial press-down movement; the two inclination angle adjustment mechanisms drive the servo main shaft systems to rotate around a horizontal rolling center line and allow the two rolls to perform inclination angle adjustment movement; and the numerical control system controls rotating speeds, radial press-down and inclination angle adjustment of the two rolls, so that the skew rolling mill and the rolls in a same dimension can flexibly perform skew rolling to form shaft spare parts in different dimensions. The double rotating shaft flexible skew rolling mill has the advantages of synchronous centering press-down, high rack strength, simple mounting and debugging, flexible production and the like and has broad application prospects in the field of forming of middle and small amounts of large-diameter shaft spare parts.

Owner:UNIV OF SCI & TECH BEIJING

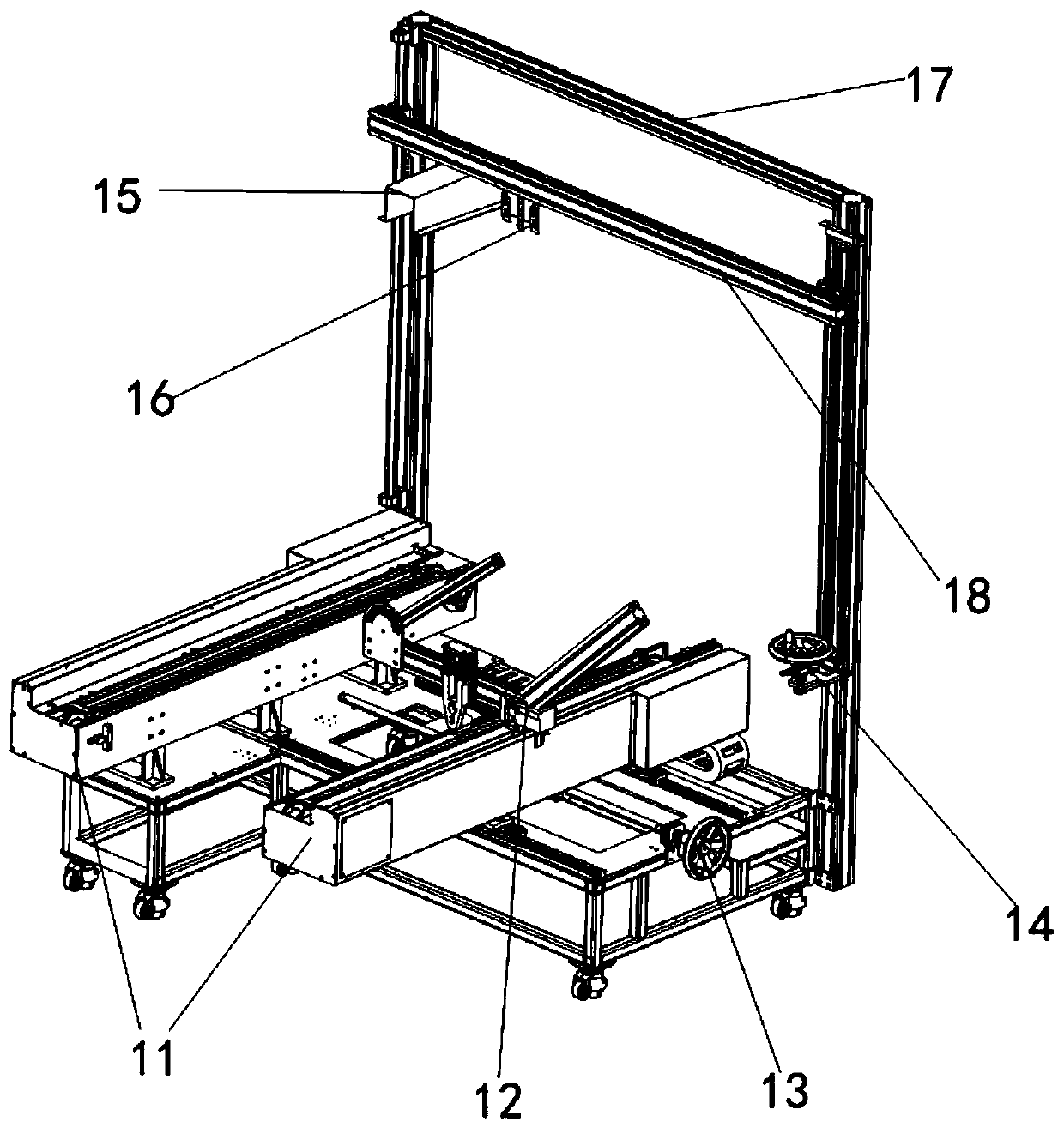

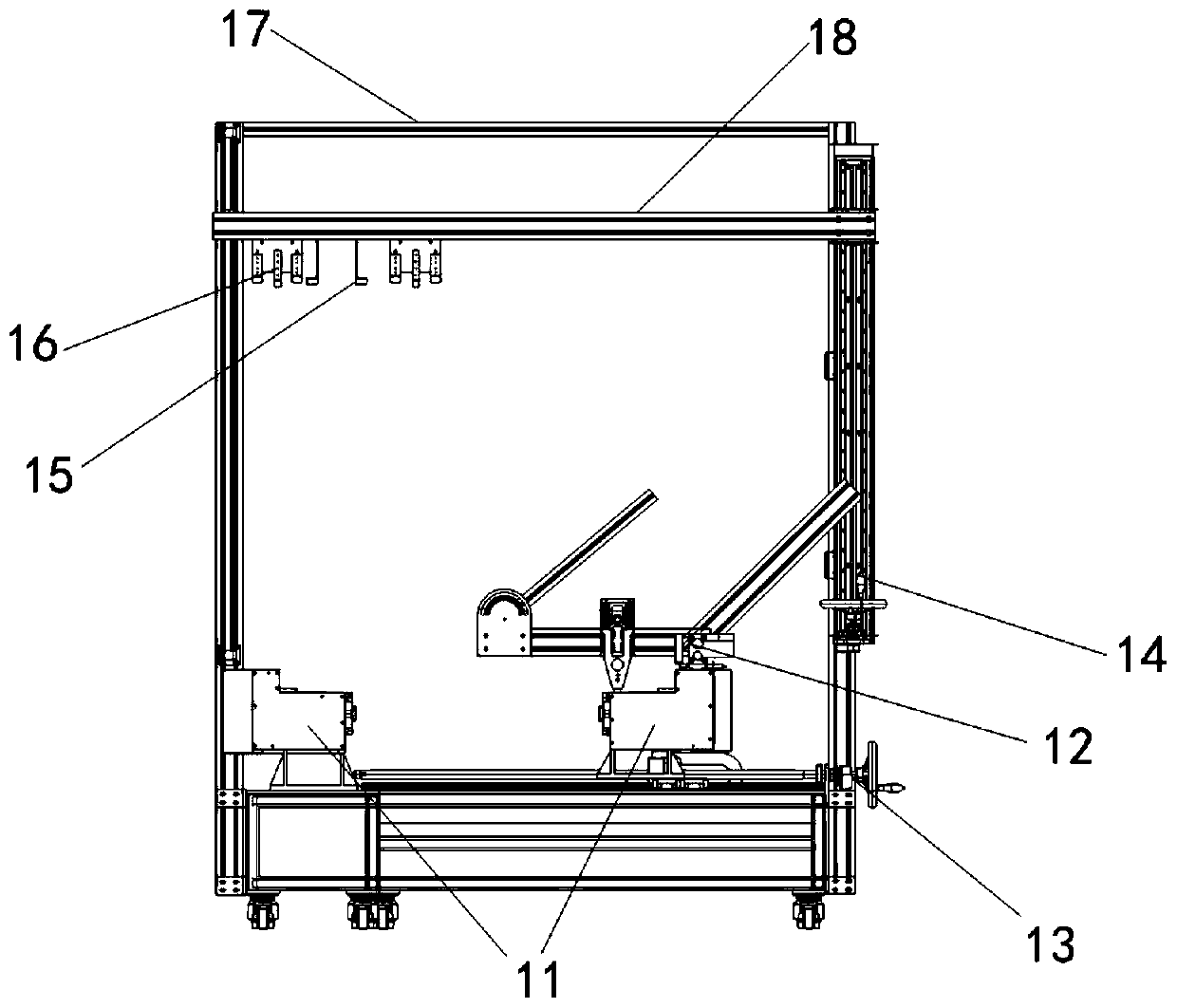

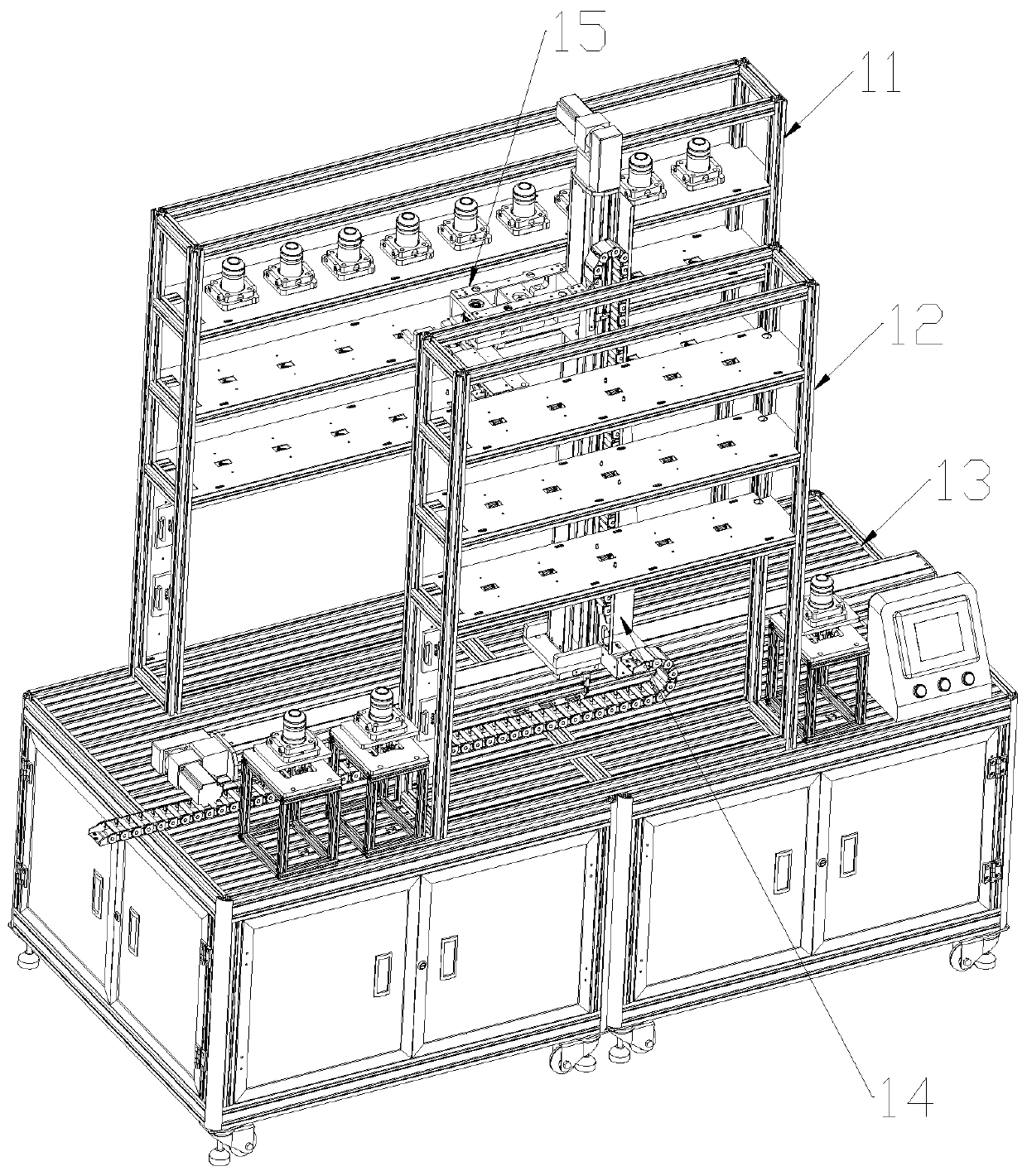

Fireproof door glass pressing frame mounting hole drilling and forming device and drilling and forming method

PendingCN110280799ARealize automated productionIncrease productivityPositioning apparatusMetal working apparatusElectrical controlMaterial storage

The invention relates to the field of fireproof door production, in particular to a fireproof door glass pressing frame mounting hole drilling and forming device and a drilling and forming method. The fireproof door glass pressing frame mounting hole drilling and forming device comprises a feeding device, a drilling and forming device and a material storage device which are sequentially arranged, and further comprises a workpiece transferring device and an electrical control system, wherein the workpiece transferring device is arranged above the drilling and forming device, and the electrical control system is used for controlling the equipment; the drilling and forming device comprises a workbench, a positioning mechanism and drill bit mechanisms, wherein the drill bit mechanisms are arranged on the two sides of the length direction of the positioning mechanism correspondingly; and the workpiece transferring device comprises a control frame and an adsorption mechanism used for adsorbing a glass pressing frame, the control frame controls the adsorption mechanism to move in the length direction or the height direction of the positioning mechanism. According to the device and method, workpiece feeding is carried out through the feeding device, the workpiece transferring device is used for transferring the workpiece to the positioning mechanism, the positioning mechanism is used for positioning the workpiece, the drill bit mechanisms are used for machining the workpiece, then the workpiece transferring device is used for transferring the machined workpiece to the material storage device, so that the automatic production of glass pressing frame drilling is realized.

Owner:广东联塑安防科技有限公司

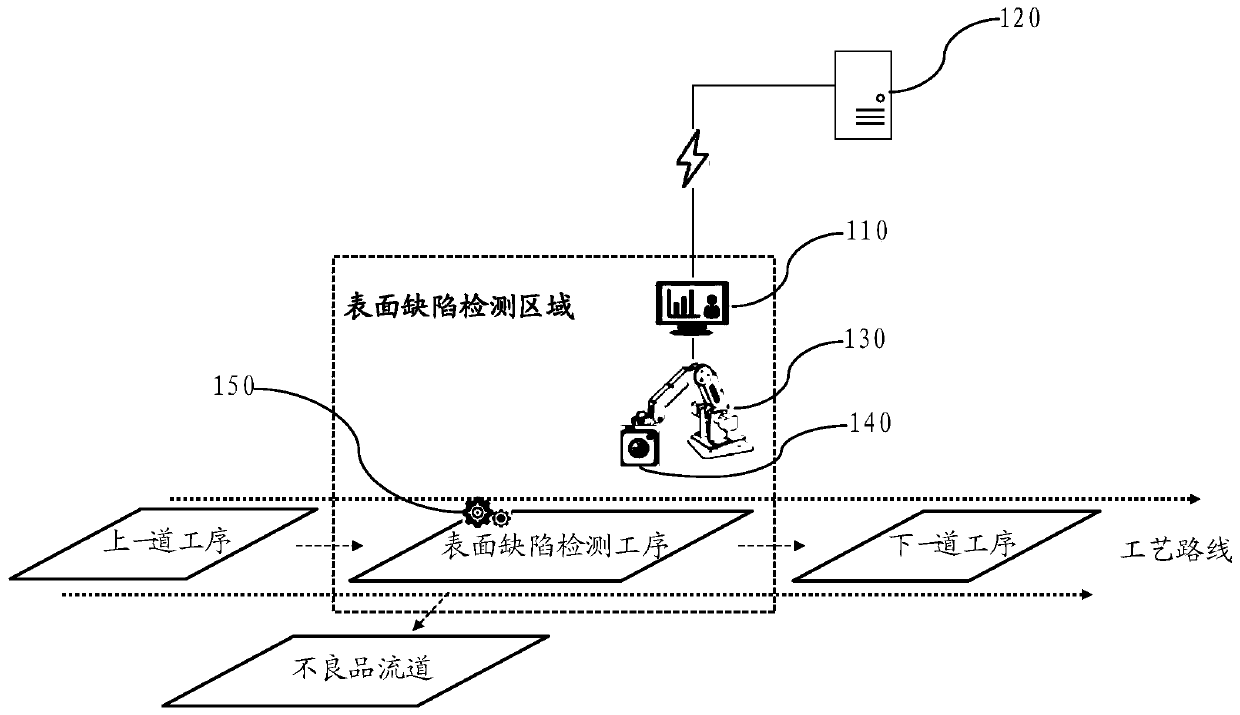

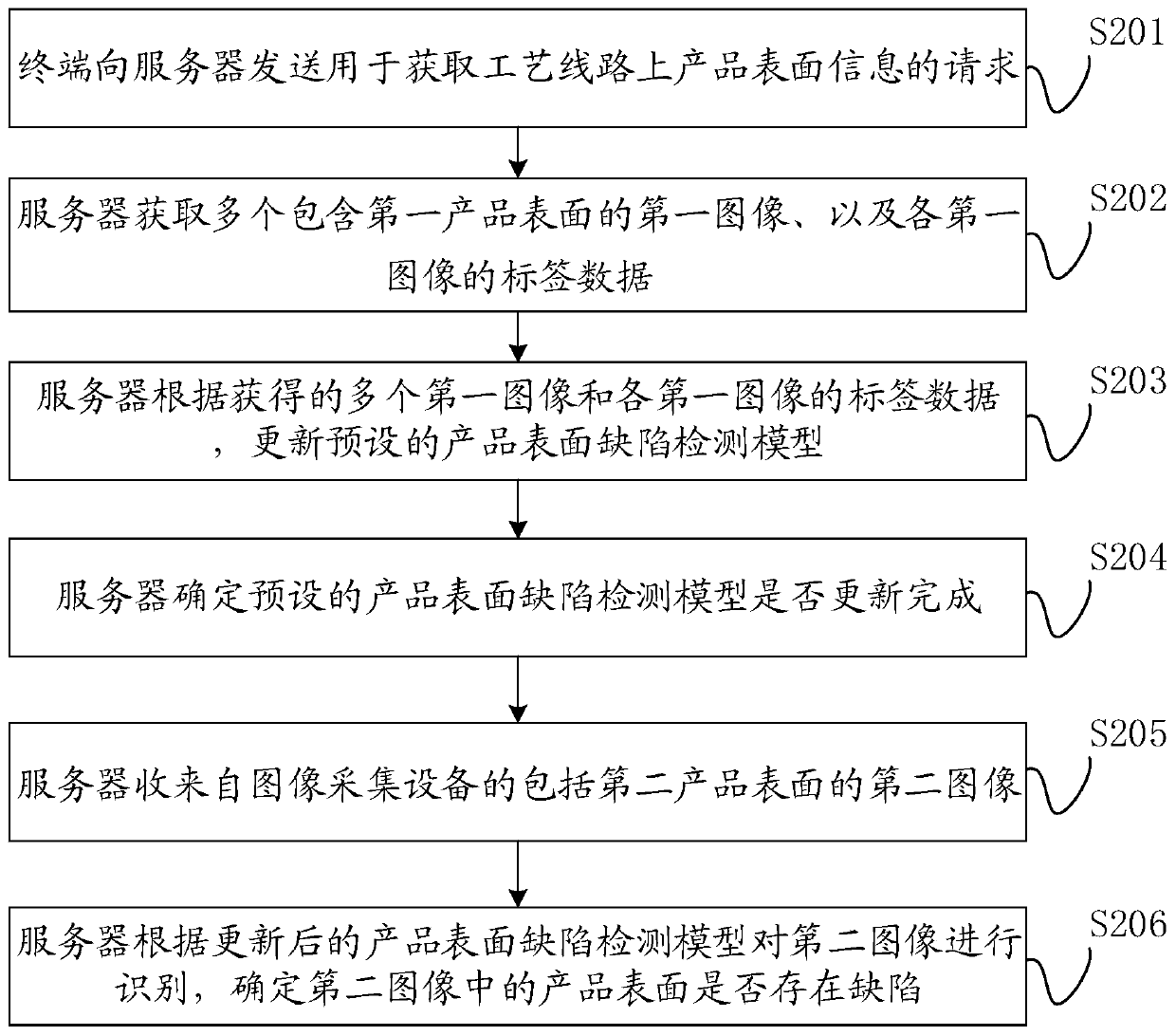

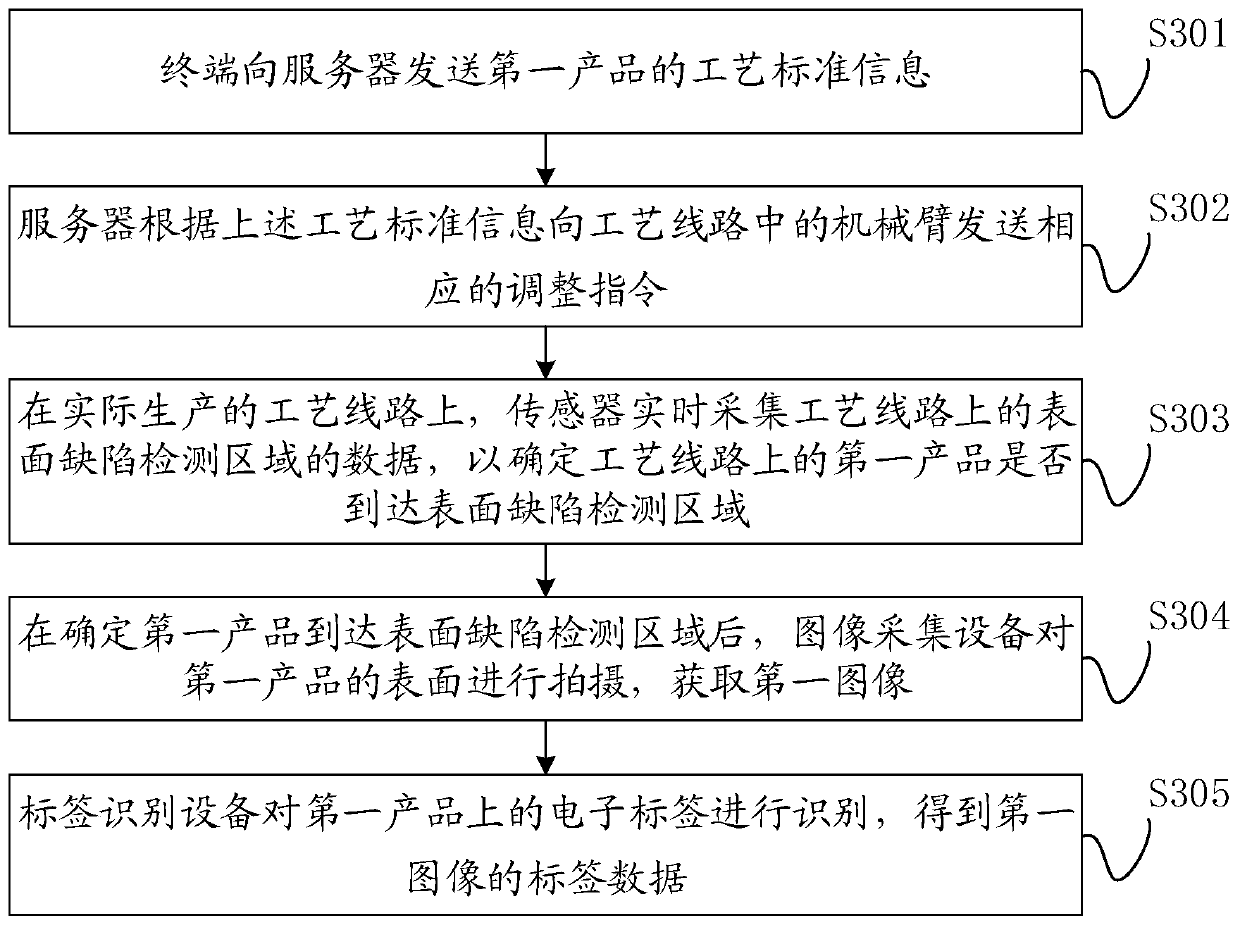

Method and device for detecting product surface defects

An embodiment of the invention provides a method and a device for detecting product surface defects. The method comprises the following steps: a server receives a request for acquiring surface information of products on a process line from a terminal; a plurality of first images containing first product surface and label data of each first image are acquired; a preset product surface defect detection model is updated according to the plurality of first images and the label data of each first image; second images, containing second product surface, from an image acquisition device are received,wherein the type of the second product corresponds to the type of the first product; the second images are identified according to the updated product surface defect detection model to determine whether the product surface in the second image has defects. By means of the technical scheme, defects of the product surface can be detected in real time in the production process of the product, the labor cost is reduced, and the flexibility degree of the whole production process is increased.

Owner:华瑞新智科技(北京)有限公司 +1

Method for removing streak defects on hot rolled steel plate surface

ActiveCN104998917AReduce thicknessReduce difficultyWork treatment devicesProfile control deviceSteel platesSheet steel

The invention discloses a method for removing streak defects on a hot rolled steel plate surface and relates to a steel plate surface treatment method. The method comprises the following process: heating plate blank to 1200-1250 DEG C, and then, descaling by high pressure water at a descaling temperature of 1100-1200 DEG C, wherein water pressure required for descaling is at least 16 MPa; carrying out rough rolling on a descaled steel plate at a rough rolling temperature of 1100-1200 DEG C; carrying out finish rolling on the steel plate subjected to rough rolling, wherein a final rolling temperature of the finish rolling is 900-990 DEG C, and the speed of a roller way is 1.3-1.8m / s; after the finish rolling is ended, carrying out water-cooling by adopting a laminar cooling mode, and adopting sectional type cooling, wherein a water ratio is 2.2-2.6, the cooling water consumption is 150-250m<3> / h, and a red temperature of the cooled steel plate is 670-750 DEG C; and cooling the water-cooled steel plate in air at a cold bed. According to the method, oxide iron scale on the surface of the steel plate is easy to remove in a follow-up shot blasting process, thereby removing the streak defects on the steel plate surface subjected to shot blasting.

Owner:沈阳诚伟机械制造有限公司

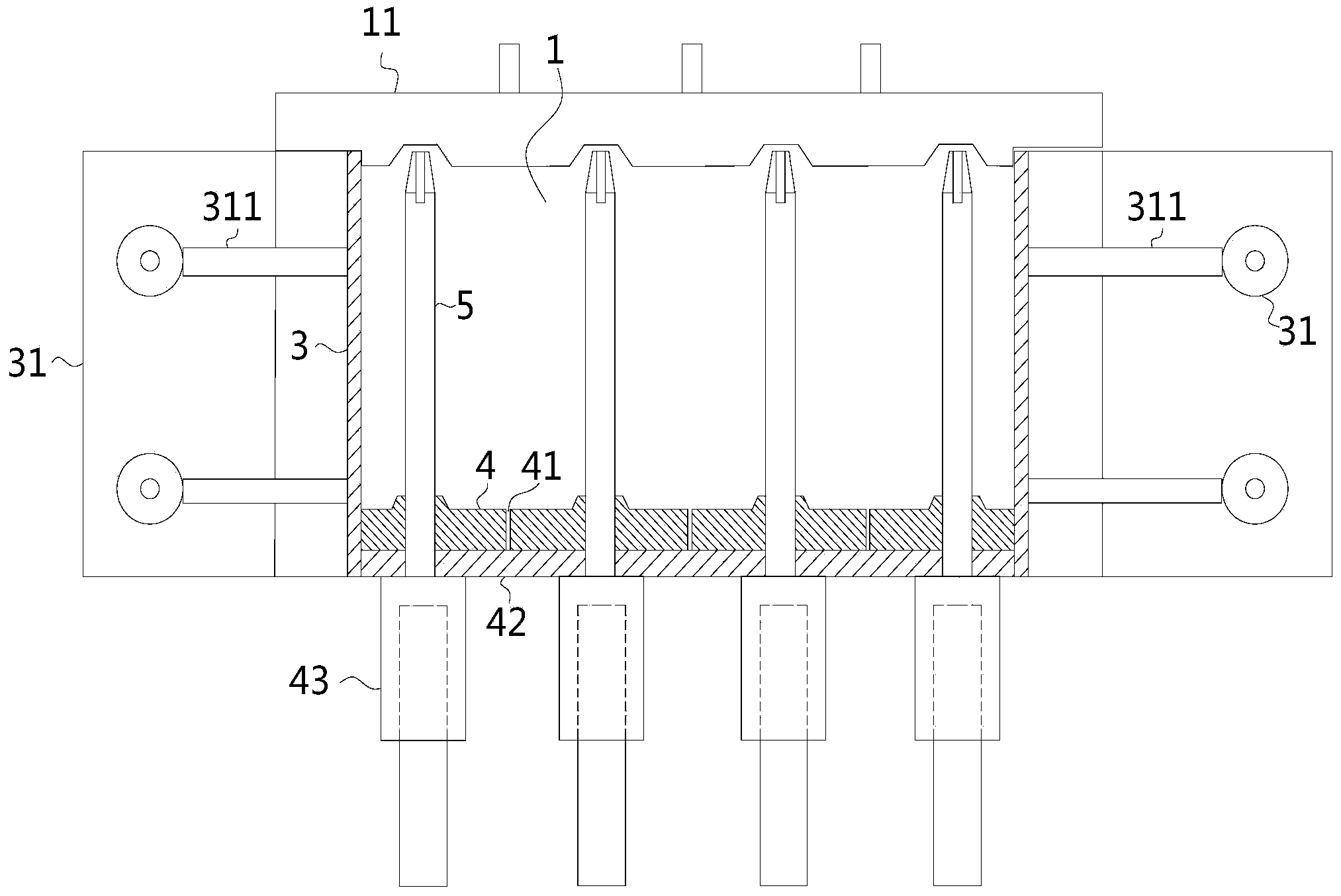

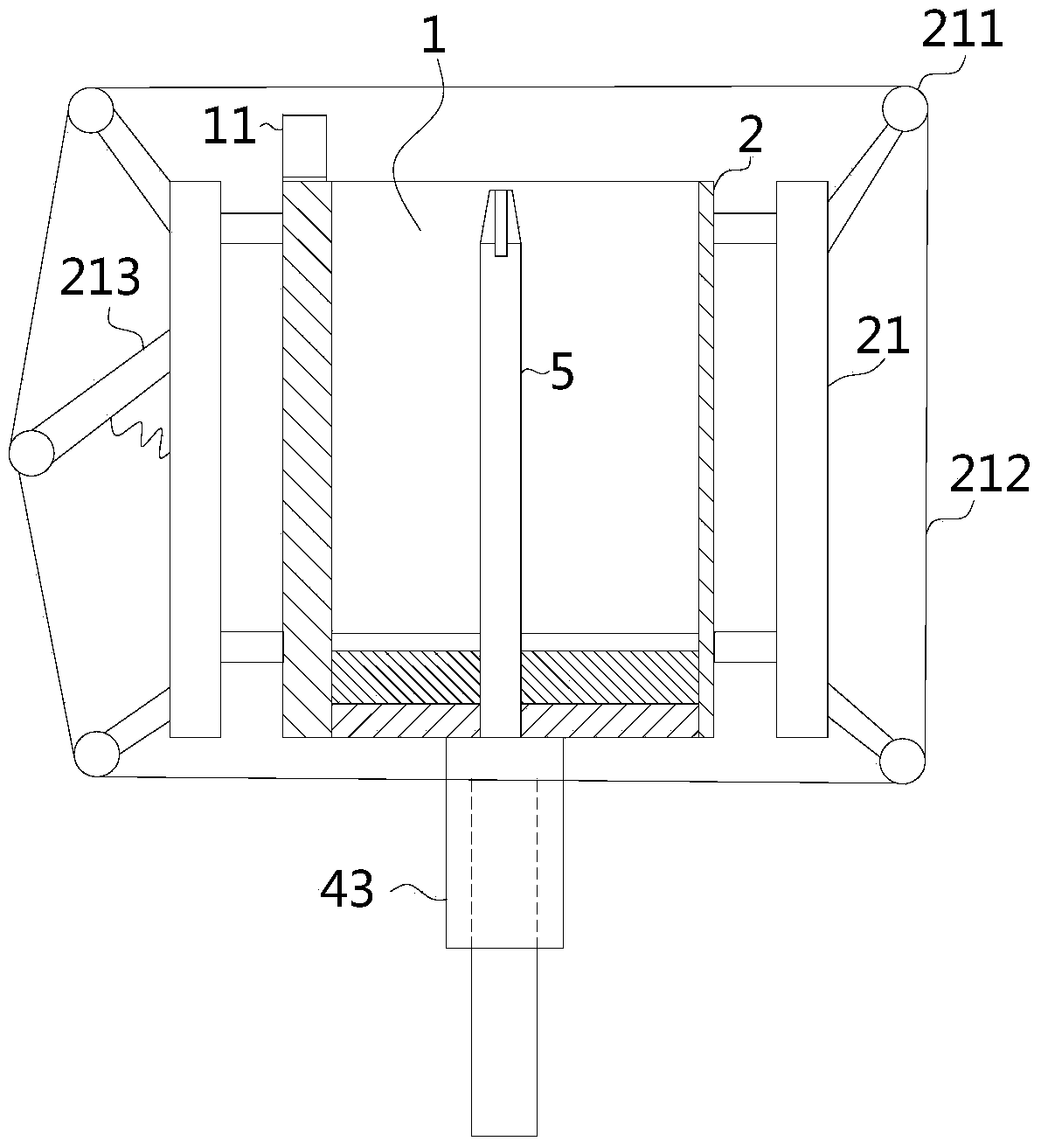

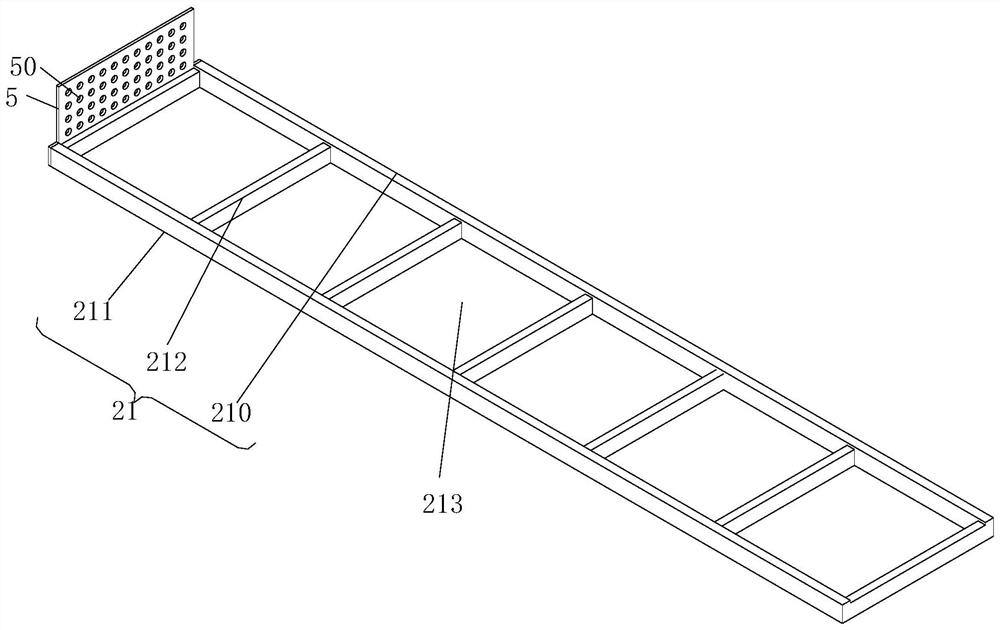

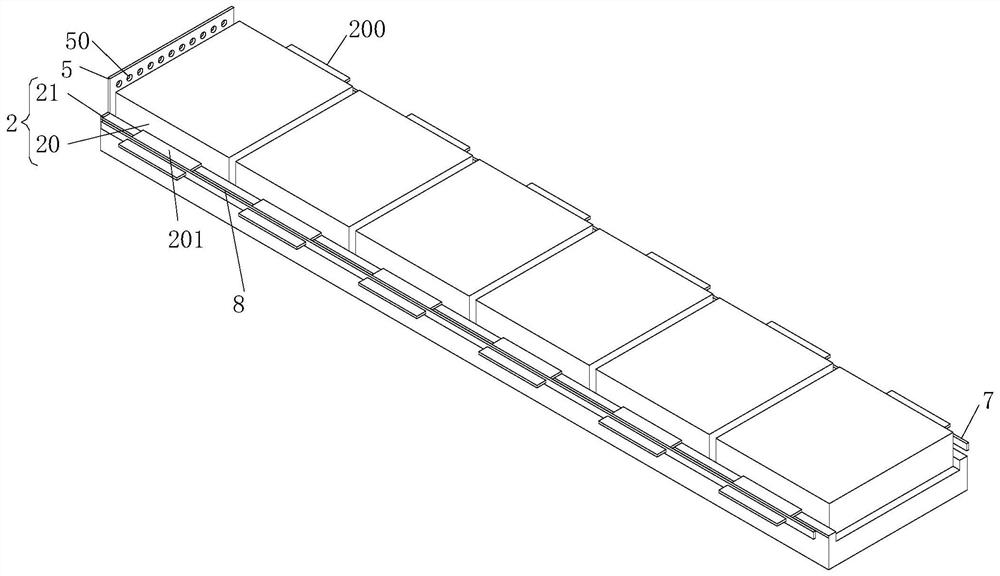

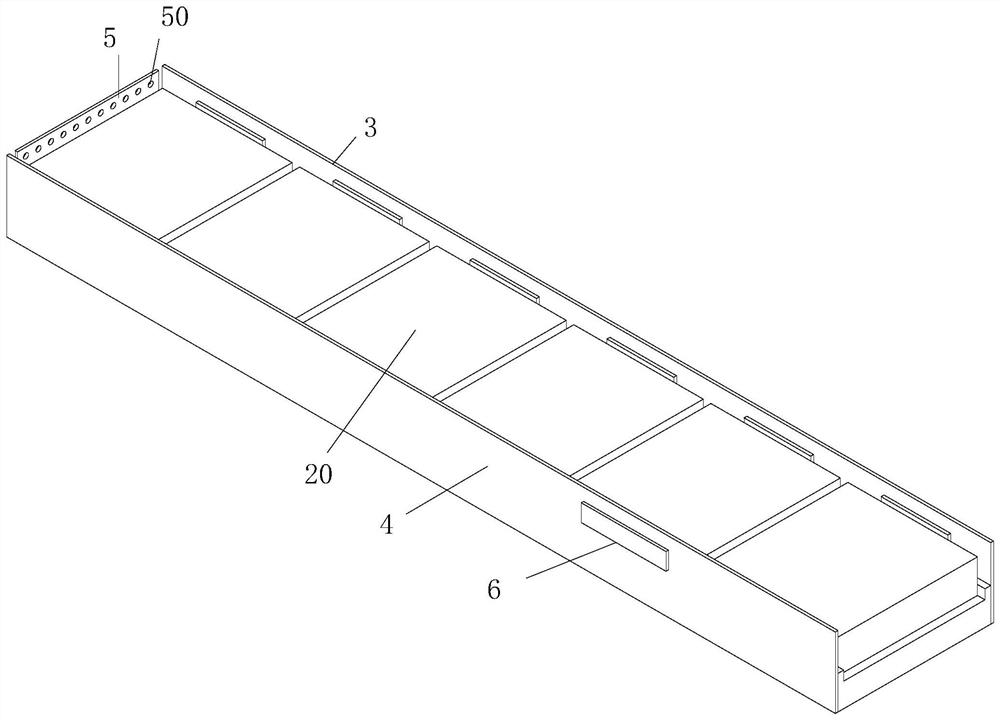

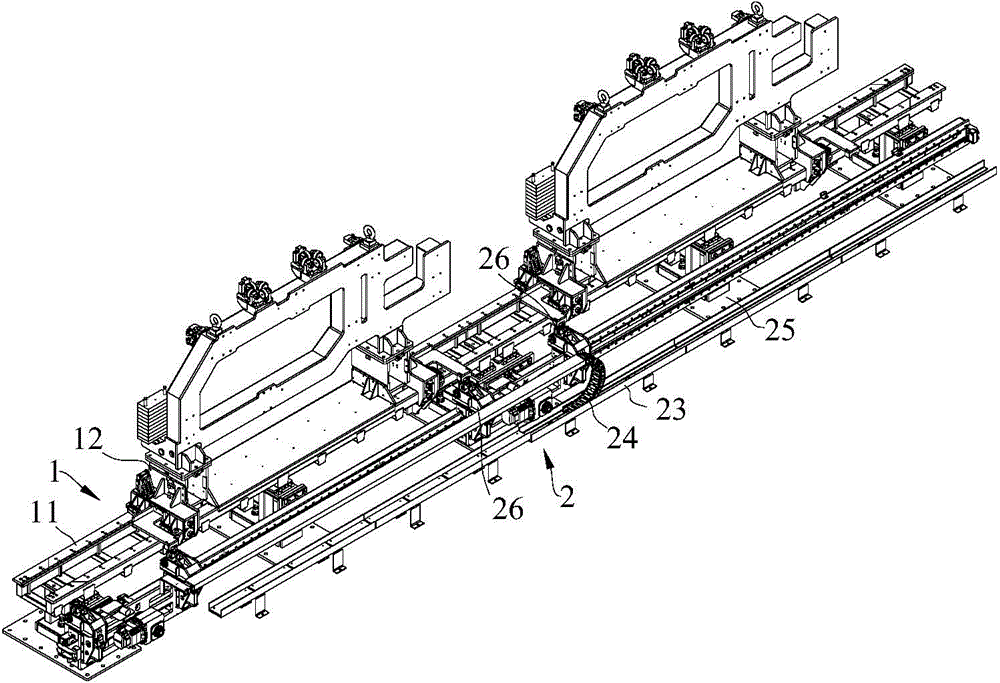

Gypsum block integral casting block cutting forming equipment

InactiveCN103950093ARealize flexible productionAvoid technical issuesMould separation apparatusMouldsProduction lineGypsum block

The invention relates to the field of gypsum block production equipment, in particular to gypsum block integral casting block cutting forming equipment. The invention aims at solving the technical problems to provide the gypsum block integral casting block cutting forming equipment capable of fundamentally omitting separation plates. The gypsum block integral casting block cutting forming equipment comprises a bottom template, a side baffle plate, an end baffle plate, a mandrel, an integral die cavity and a gypsum block cutting device, wherein the integral die cavity is formed by a bottom template, a side baffle plate and an end baffle plate in a surrounding way, the mandrel passes through the bottom template through a bottom mold hole formed in the bottom template and is arranged in the integral die cavity, an integral die cavity scrapping plate is glidingly arranged above the integral die cavity, the side baffle plate is driven through a side baffle plate driving device, an end baffle plate is driven through an end baffle plate driving device, and the whole gypsum block formed in the integral die cavity is divided into gypsum blocks by the gypsum block cutting device. The gypsum block integral casting block cutting forming equipment has the advantages that the flexible production of gypsum blocks is realized, and the production efficiency and the flexibility are greatly improved. The gypsum block integral casting block cutting forming equipment is particularly applied to a production line for automatically producing gypsum blocks.

Owner:广西大青山建设投资发展有限公司

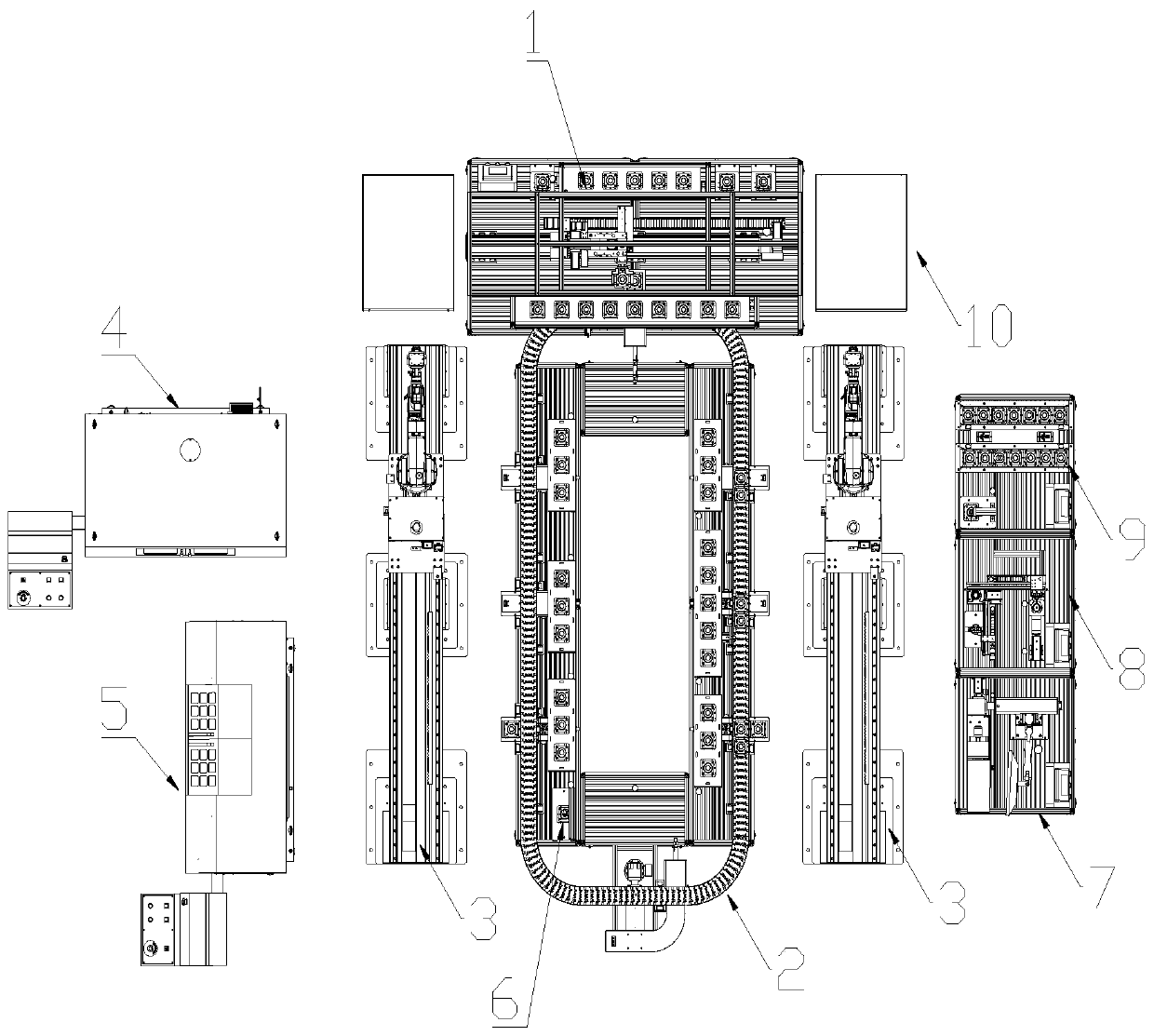

Teaching practical training equipment by using flexible mixed order automatic production line as basis

ActiveCN110503883ARealize flexible productionProcess path flexibilityEducational modelsProduction lineLaser engraving

The invention provides teaching practical training equipment by using a flexible mixed order automatic production line as the basis. The teaching practical training equipment comprises a three-dimensional storage station, an annular transmission station, a robot station, a processing center station, a lathe processing station, a laser engraving station, an assembling station and a general controlstation, wherein the three-dimensional storage station comprises a cargo rack and a grasping carrying mechanism; the annular transmission station comprises a transmission line and a plurality of temporary storage regions arranged on the transmission line; each temporary storage region comprises a first RFID reader-writer and a blocking mechanism; the blocking mechanism can prevent a workpiece or release the workpiece; the processing center station performs milling processing on the workpiece; the lathe processing station performs cutting processing on the workpiece; the laser engraving stationis used for engraving patterns on the surface of the workpiece; the assembling station is used for sequentially assembling a sealing cover and a cup cover onto a cup body; and the general control station controls the cooperated operation among the three-dimensional storage station, the annular transmission station, the robot station, the processing center station, the lathe processing station, the laser engraving station and the assembling station.

Owner:南京南戈特智能技术有限公司

Production method of hot-rolled steel plate made of niobium (Nb)-containing steel

InactiveCN102230127AReduce the amount addedReduce mixTemperature control deviceChemical compositionNiobium

The invention discloses a production method of a hot-rolled steel plate made of niobium (Nb)-containing steel, which can effectively lower difficulty of production organization. The hot-rolled steel plate made of the Nb-containing steel comprises the following chemical components by mass percentage: 0.07%-0.12% of C, not more than 0.35% of Si, 1.10%-1.50% of Mn, more than 0 but not more than 0.10% of Nb, not more than 0.025% of P, not more than 0.015% of S and the balance of Fe and unavoidable impurity elements. The production method of the hot-rolled steel plate made of the Nb-containing steel comprises the steps of producing, rough-rolling, finish-rolling, final-rolling, cooling and coiling continuous casting slabs. In the production method, the Nb-containing steel with the same chemical component is favorable for production organization and scheduling; and meanwhile the obtained finished product can meet the use requirements for structural parts in automotive frames, automotive wheels, building structures, engineering machinery and the like. Therefore, the production method is particularly suitable for popularization and application to production of the Nb-containing hot-rolled steel plate.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

Power lithium ion battery

PendingCN113851698AAvoid wastingImprove qualityFinal product manufactureSecondary cellsStructural engineeringLithium-ion battery

The invention discloses a power lithium ion battery. The power lithium ion battery comprises a shell, a roll core group, a positive electrode cover plate and a negative electrode cover plate, wherein the roll core group comprises a fixed support and a plurality of roll cores, the fixed support is provided with a plurality of placing grooves, the roll cores are placed in the placing grooves, the roll cores are in one-to-one correspondence with the placing grooves, positive electrode tabs of the plurality of roll cores are connected in series, and negative electrode tabs of the plurality of roll cores are connected in series; the positive electrode cover plate and the negative electrode cover plate are respectively fixed on two opposite sides of the roll core group and are used for wrapping the two opposite sides of the roll core group; the shell is arranged on the outer side of the roll core set and used for wrapping the roll core set. According to the battery disclosed by the invention, an A / B roll core pairing process is cancelled, so that waste caused by the problems of wrong roll core pairing, mismatched quantity and the like is avoided, and the product quality is greatly improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

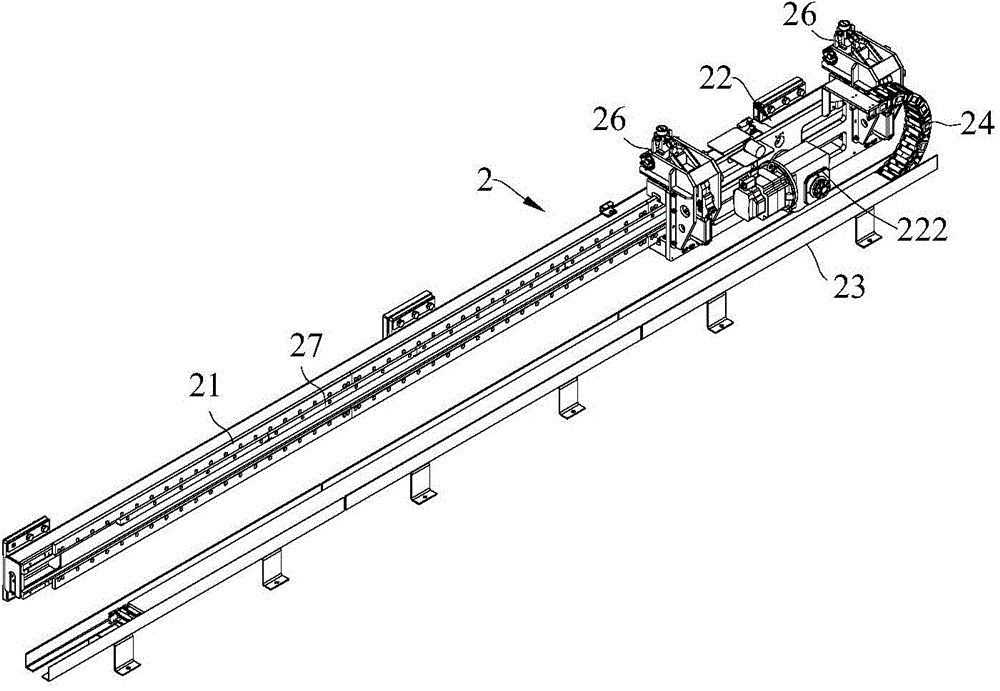

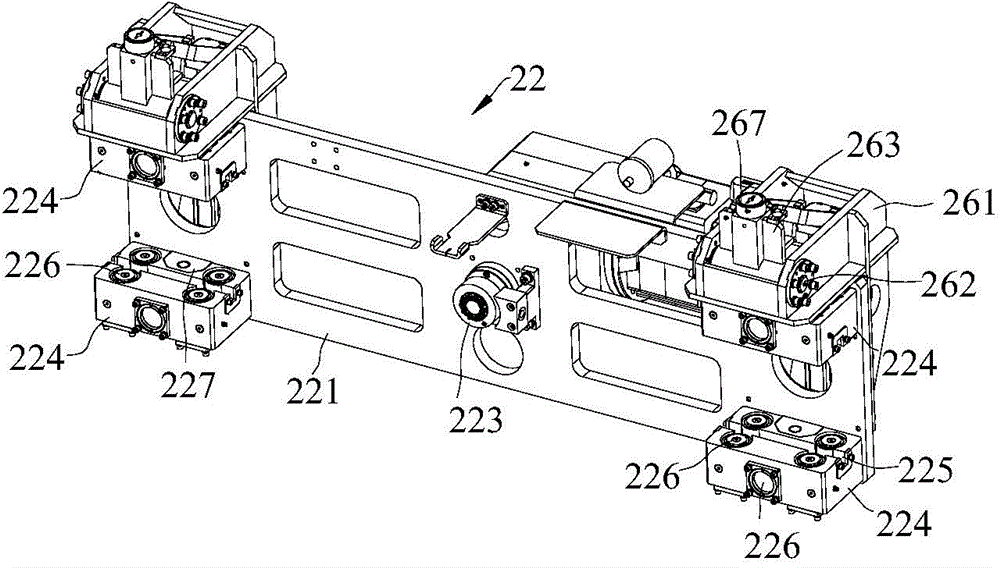

Fixture storage and switching system

ActiveCN104827212ARealize random switchingLow machining accuracy requirementsWelding/cutting auxillary devicesAuxillary welding devicesReciprocating motionMaintainability

The invention discloses a fixture storage and switching system, which comprises a fixture storage system and a fixture driving system, wherein the fixture storage system comprises a fixture movement rail and fixtures; the fixture driving system comprises a driving rail and a driving trolley; the driving rail is independent from the fixture movement rail and is parallel with the fixture movement rail; the driving trolley can move along the driving rail; driving traction swing arms are arranged on the driving trolley; the driving trolley can drive each fixture to do reciprocating movement along the fixture movement rail through the driving traction swing arms. By adopting the design, the fixture storage and switching system has the advantages that multiple vehicle clamps can be randomly switched at the welding and main splicing station of a body in white; one or two fixture storage and switching systems can be arranged, and can simultaneously or singly work according to the requirements of actual working condition, so as to realize flexible production; the fixture movement rail is independent from the fixture driving system, so the maintainability of the equipment is improved, the part processing accuracy requirement is reduced, and the movement track of the driving trolley is more flexible.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

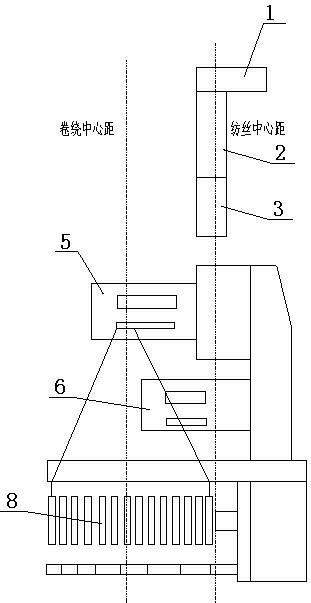

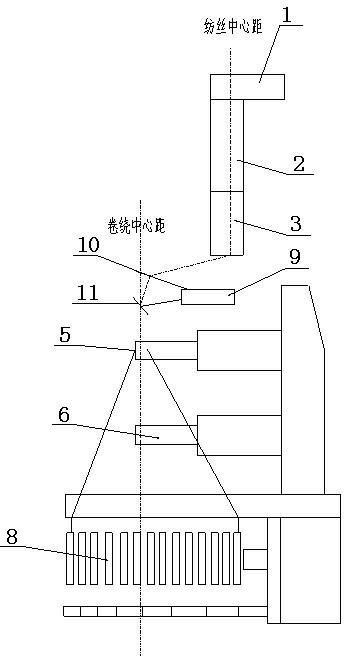

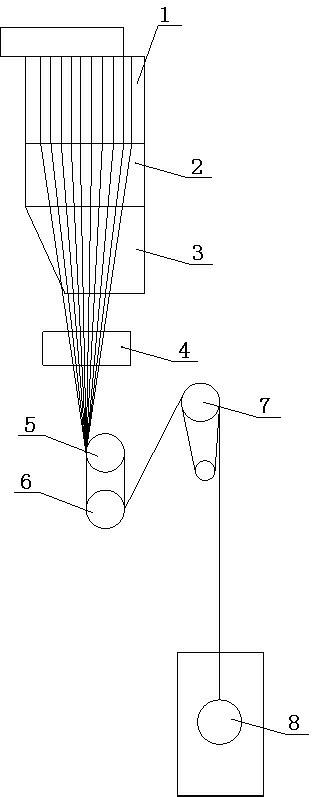

POY (polyester pre-oriented yarn) spinning method and device by using FDY (fully drawn yarn) spinning device

InactiveCN102660786AQuality improvementRealize flexible productionArtificial thread manufacturing machinesMelt spinning methodsPolyesterYarn

The invention relates to a POY (polyester pre-oriented yarn) spinning method and device by using a FDY (fully drawn yarn) spinning device. The POY spinning method is realized by using the FDY spinning device, wherein the FDY spinning device comprises a box body, a cross air blasting window, a chimney, a first hot roll, a second godet and a winding head. When the POY spinning is preceded, an oil tanker of the original FDY spinning device is stopped using, an oil nozzle is additionally arranged above the chimney for feeding oil, and a guide wire hook and combtype wire-dividing device of the first hot roll are provided with extension rods for moving outwards in a pre-network so as to move the spinning central line outwards; meanwhile, a second hot roll of the original FDY spinning device is stopped using, the first hot roll and the second godet are reserved, the filament bundling passes through the first hot roll for one time and winds 4-5 circles on the second godet for further moving the spinning central line outwards, and then enters into a wiring head for realizing winding. The method provided by the invention can produce high-quality POY on hot-roll type FDY equipment with the advantages of less transformation investment, simple method and fast transformation speed, thus realizing flexible production between the FDY and POY products at any time.

Owner:ZHEJIANG HUAXIN CHEM FIBER

Positioning device

InactiveCN104668868ARealize flexible productionReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a positioning device. Through driving a movable plate to rotate by a driving unit, the device realizes the switchover between different positioning mechanisms and can position different vehicles on one positioning device in welding assembly; the device has accurate positioning, so the flexible production of a welding assembly process is achieved; and meanwhile, designs of vehicle bodies do not need to change to realize the effect that the different vehicles can be positioned on one positioning device, so the production cost is reduced, the labor intensity of the workers is lowered and the production efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

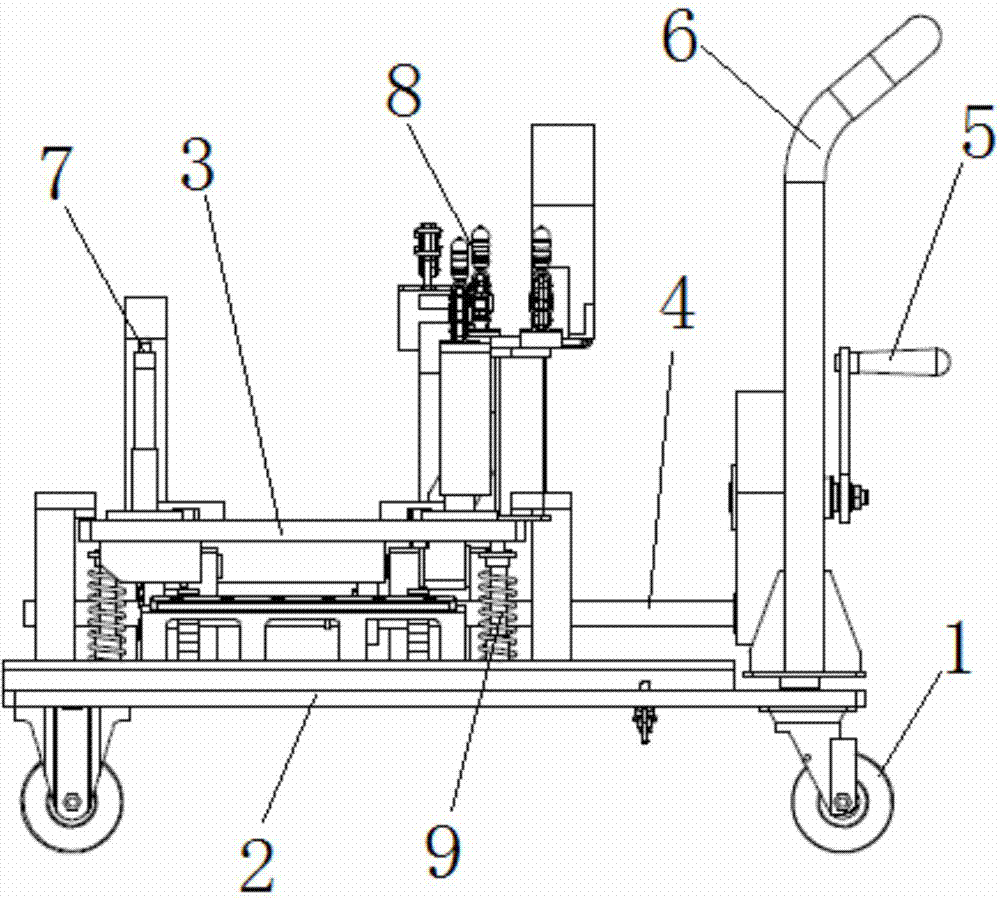

Engine docking test dolly for bench test and bench test system

The invention discloses an engine docking test dolly for bench test and a bench test system. The engine docking test dolly includes a bearing platform (2) capable of moving and a support plate (3) used for accepting an engine. The support plate (3) is equipped with a positioning clamping mechanism used for positioning and clamping the engine. The support plate (3) is mounted on the bearing platform (2) in a pivoted manner, so that the engine arranged on the support plate (3) can be in different inclination angles when the support plate (3) is at different pivoting positions. According to the invention, the engine docking test dolly is suitable for bench tests for engines of different specifications, so that flexible production can be realized conveniently and comparatively high production efficiency is achieved.

Owner:BEIQI FOTON MOTOR CO LTD

Rapid clamping tool

InactiveCN103056688ARealize flexible productionPositioning apparatusMetal-working holdersEngineeringBrake shoe

The invention relates to the field of automobile part manufacturing and provides a rapid clamping tool which comprises a base assembly, a pressing plate assembly, a pressing column, a positioning block, an adjustable supporting column, a pin shaft and a split pin. The rapid clamping tool is used for milling a boss and an opening of a brake shoe. The rapid clamping tool can perform machining on a vertical milling machined and a horizontal milling machine, can cover all types of products, and can achieve flexible production under the premise that precision of the rapid clamping tool can reach standard of special machining.

Owner:QINGTE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com