Control cooling method of easy-welding high-performance steel plate

A controlled cooling, high-performance technology, applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of low yield ratio steel production, high welding crack sensitivity coefficient, low steel plate strength level, etc., to achieve The effect of low welding crack sensitivity index, highlighting substantive features, and broadening product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by example the present invention is described in further detail:

[0017] The first specific implementation mode:

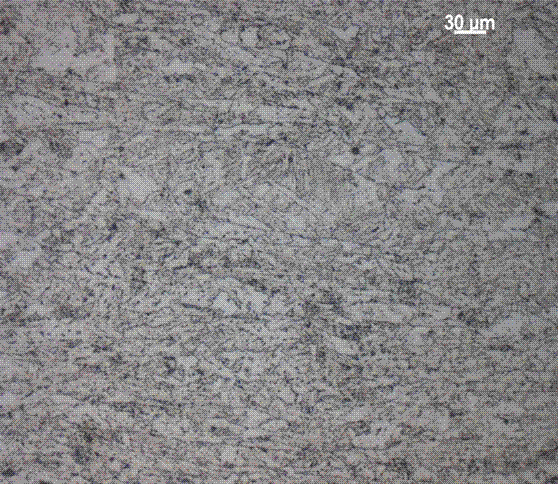

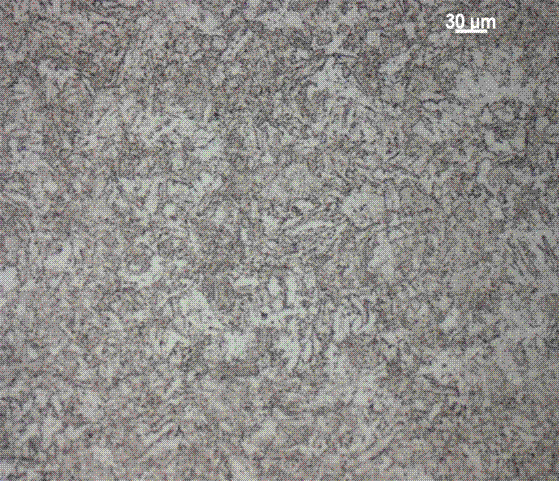

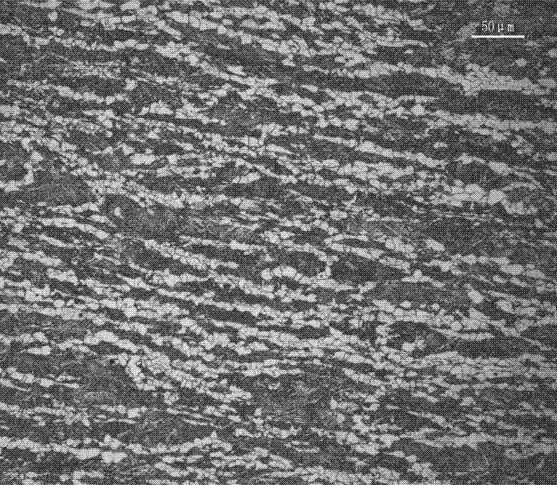

[0018] The chemical composition is C 0.08%, Si 0.15%, Mn 1.63%, Nb 0.031%, V 0.029%, Cr 0.26%, B 0.0018%, Alt 0.035%, Ti 0.022%, low welding crack sensitivity index Pcm=0.19% The steel billet is rolled into a 50mm thick steel plate in the range of 880-840°C, and the online cooling process after rolling is controlled as follows:

[0019] 1) The cooling mode of the steel plate required for the production of high strength and toughness indicators is that the temperature of the steel plate entering the water cooling after the controlled rolling is 790 ° C, and the cooling rate is 15 ° C / s once cooled to 500 ° C, and then air cooled to room temperature;

[0020] 2) The steel plate cooling mode required for the production of low yield ratio indicators is that after controlled rolling, the steel plate is air-cooled on the conveying roller table and waits...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com