Patents

Literature

32results about How to "Good yield ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microorganism bacterium composition, blue algae biological bacterium leaven containing the same, nutriment and biological organic fertilizer, and preparing method thereof

InactiveCN101215539APromote growth and developmentGood preventive effectBacteriaUnicellular algaeOrganic baseOrganic content

The invention relates to a microbe germ composition, a cyanophyte biological germ leaven which contains the microbe germ, a cyanophyte fermentation nutrient, a cyanophyte biological organic fertilizer and a method for preparation, wherein the microbe germ composition contains plant lactobacillus, bacillus subtilis and swamp Rhodopseudomonas, the cyanophyte biological germ leaven is prepared by microbe germ composition and base, the cyanophyte fermentation nutrient is prepared by cyanophyte biological germ leaven and cyanophyte, the cyanophyte biological organic fertilizer is prepared by cyanophyte fermentation nutrient, organics base and water-loss reducer. The microbe germ composition is provided with the ability for fermenting solid cyanophyte, which can transform nutriment in the cyanophyte into the material for crops. The cyanophyte fermentation nutrient can be superior animal feed. The cyanophyte biological organic fertilizer is provided with crop pest control effect, which adds the soil organics content and improves nutrient utility to accelerate the plant growth belonging to natural superior organics fertilizer.

Owner:周文彩

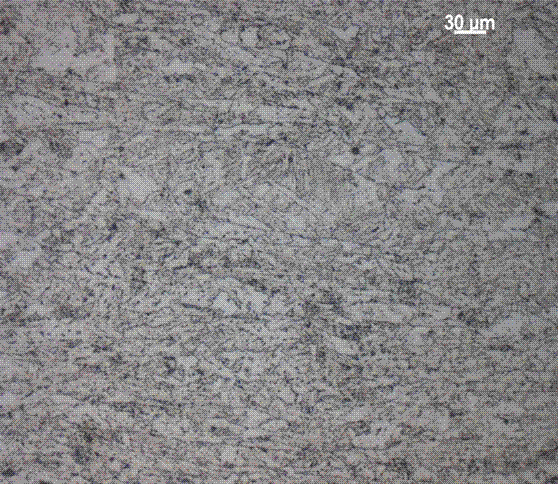

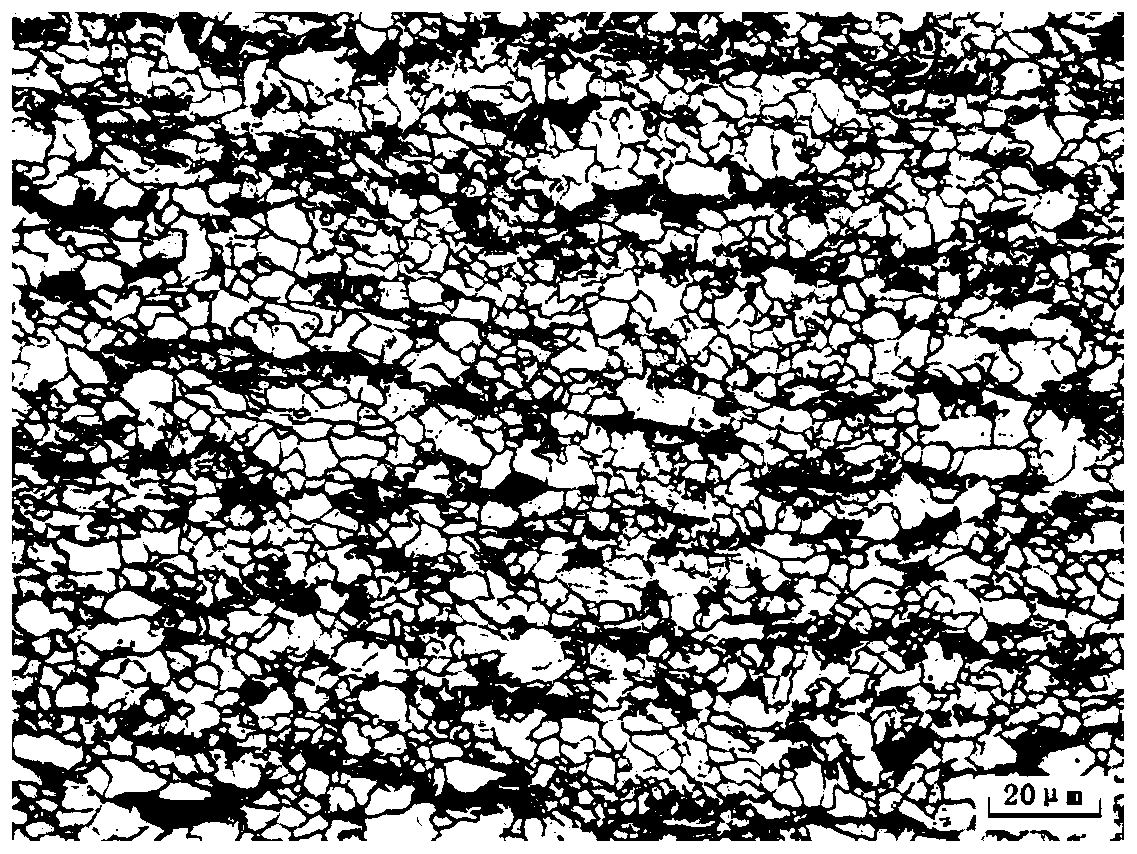

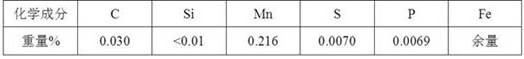

Control cooling method of easy-welding high-performance steel plate

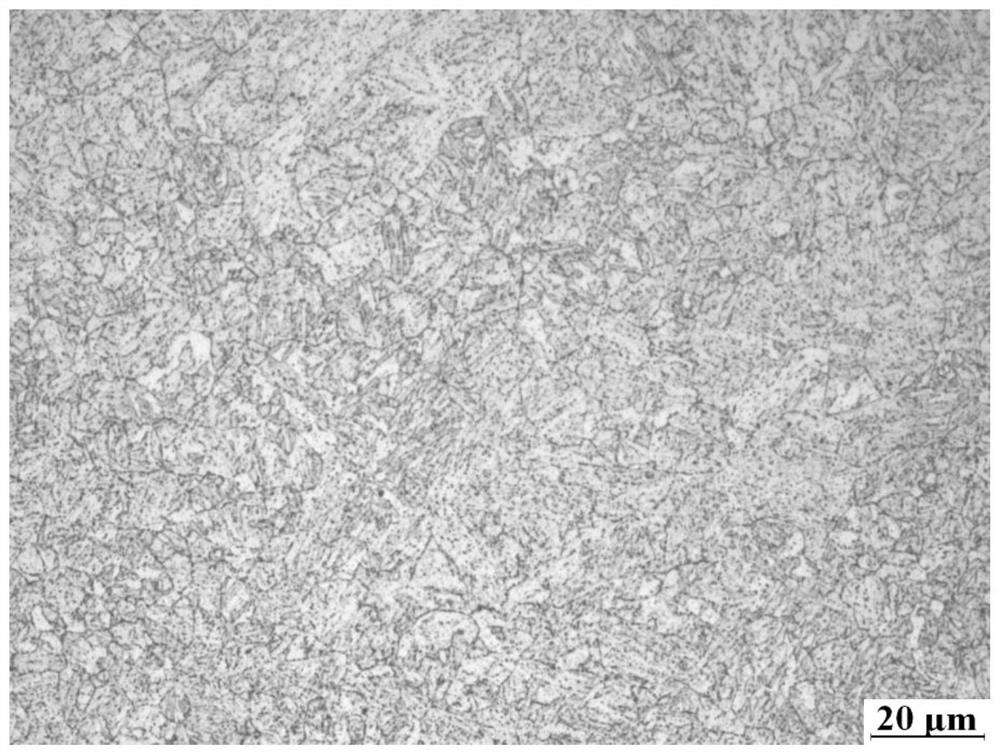

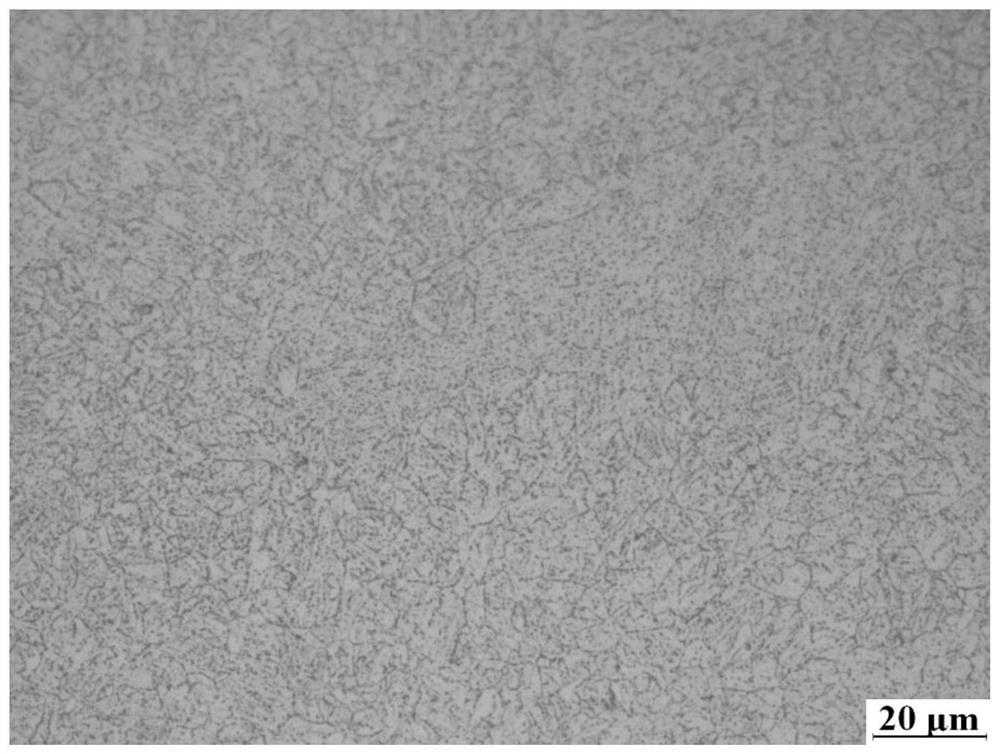

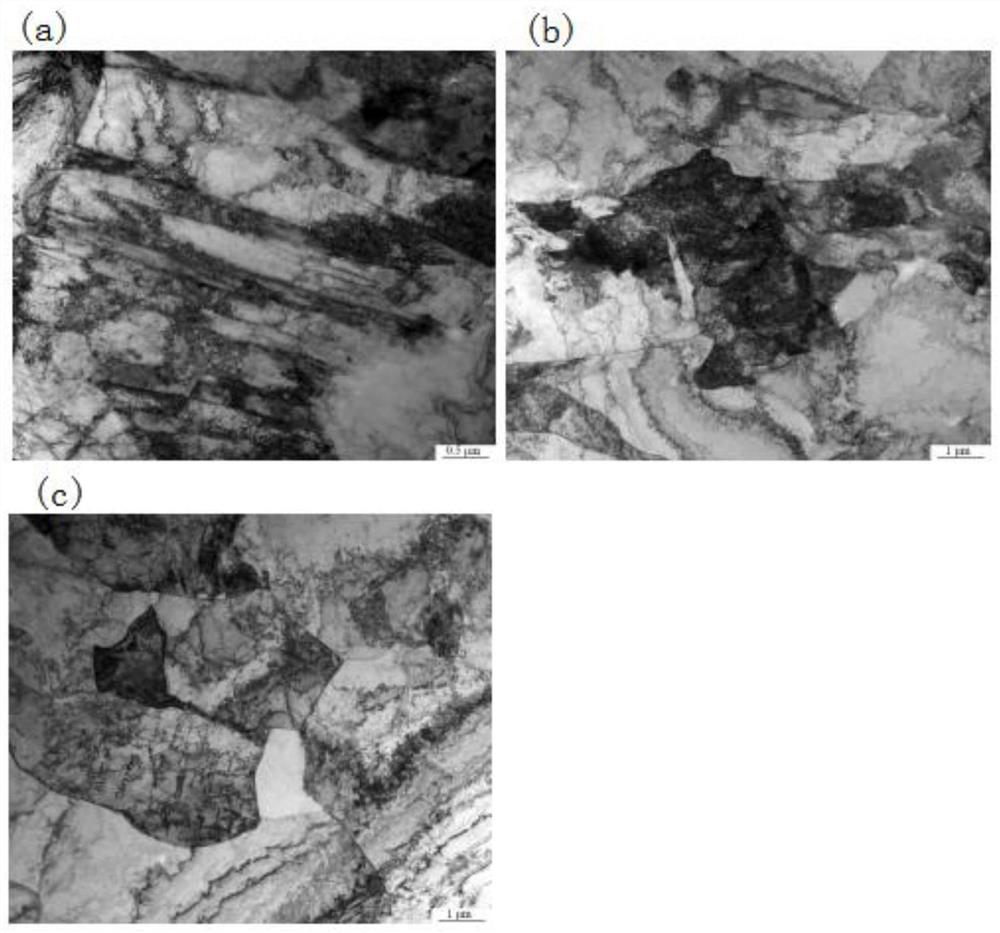

InactiveCN103114186AReduce the amount addedUniform tissueHeat treatment process controlDislocationHeat treated

The invention provides a technical scheme of a control cooling method of an easy-welding high-performance steel plate. The easy-welding high-performance steel plate comprises the following chemical components in percentage by weight: 0.05-0.09% of C, 0.1-0.25% of Si, 1.55-1.65% of Mn, 0.025-0.035% of Nb, 0.025-0.035% of V, 0.20-0.30% of Cr, 0.0008-0.0025% of B, 0.020-0.045% of Alt, 0.015-0.030% of Ti and billet of which the low-welding crack sensitivity index Pcm is less than 0.21%; a final steel plate with the thickness of 12-60mm is rolled in a non-recrystallization area, and the effects of dislocations strengthening, precipitation strengthening and phase change strengthening in cooling after rolling are sufficiently realized by adopting different online cooling modes according to different performance requirements of the final steel plate; and the microstructure is controlled according to different performance requirements to obtain a proper complex-phase structure. According to the scheme, flexible control on performance is realized through the flexibility of the cooling technology by use of one component; the produced steel plate has uniform structure, low yield ratio, high plasticity and excellent low-temperature toughness; the steel plate does not need preheating before welding and heat treatment after welding; and the individualized needs of users are met by the flexibility of the production line.

Owner:JIGANG GRP

Multi-aluminum bronze material for pipe

The invention provides a novel multielement aluminum bronze material for a pipe. The compositions of the novel multielement aluminum bronze material for the pipe are 4.0 to 10 weight percent of aluminum, 1.0 to 4.5 weight percent of iron, 1.0 to 4.5 weight percent of manganese, 0.8 to 4.0 weight percent of nickel, and the balance being copper and unavoidable impurities. Under the cast condition, the tensile strength of the novel multielement aluminum bronze material is more than 380 MPa; the yield strength is more than 179 MPa; the tensile ratio is more than 0.47; and the extensibility is more than 26.2 percent. Under the annealing condition, the tensile strength of the of the novel multielement aluminum bronze material is more than 523MPa; the yield strength is more than 282 MPa; the tensile ratio is more than 0.54; the extensibility is more than 41.2 percent; and the fully impregnated uniform corrosion rate is between 0.01 and 0.04 mm / a. The copper alloy has superior performance, is particularly suitable for the environment with high seawater flow velocity, and is an optimum material for manufacturing seawater desalination condenser equipment, seawater condenser equipment of ships and condensers of littoral power plants.

Owner:苏州有色金属研究院有限公司

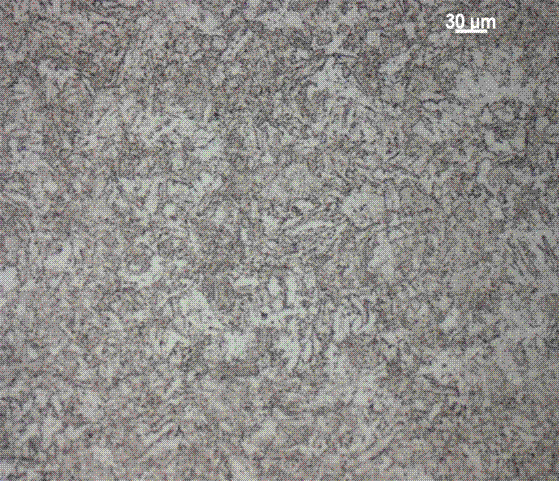

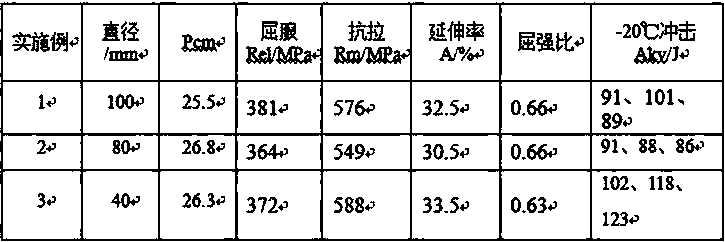

Producing method of hot rolled round steel used for high-rise building structure

The invention discloses a producing method of hot rolled round steel used for a high-rise building structure. The composition weight percentage of the steel is 0.12-0.18 % of C, 0.25-0.50% of Si, 1.20-1.70% of Mn, no more than 0.025% of P, no more than 0.015% of S, no less than 0.020% of Al, 0.41-0.45% of carbon equivalent, and the balance Fe and unavoidable impurities; the key process steps include smelting, LF furnace forging, VD furnace forging, continuous casting, heating, rolling, and cooling; the tensile strength of the produced steel is at 470-630 Mpa, the yield strength is at 315-455 Mpa, the yield ratio is below 0.80, the elongation rate is above 22%, and the welding crack sensitivity coefficient is below 0.28%, the impact Akv at minus 20 DEG C is above 47 J. The hot rolled roundsteel used for the high-rise building structure has high strength, high yield ratio, elongating performance, low temperature impact performance, welding performance, seismic performance and the like and can well meet the using demands of the seismic, refractory, welding performances of the hot rolled round steel of various high-rise building structures.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

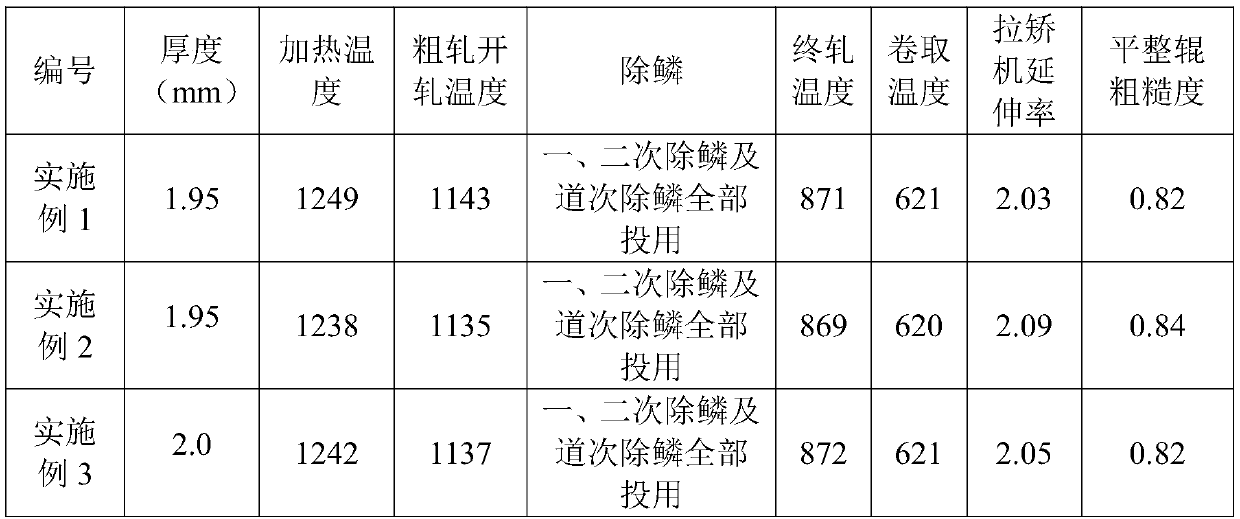

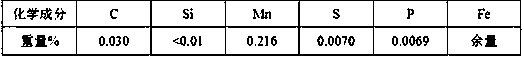

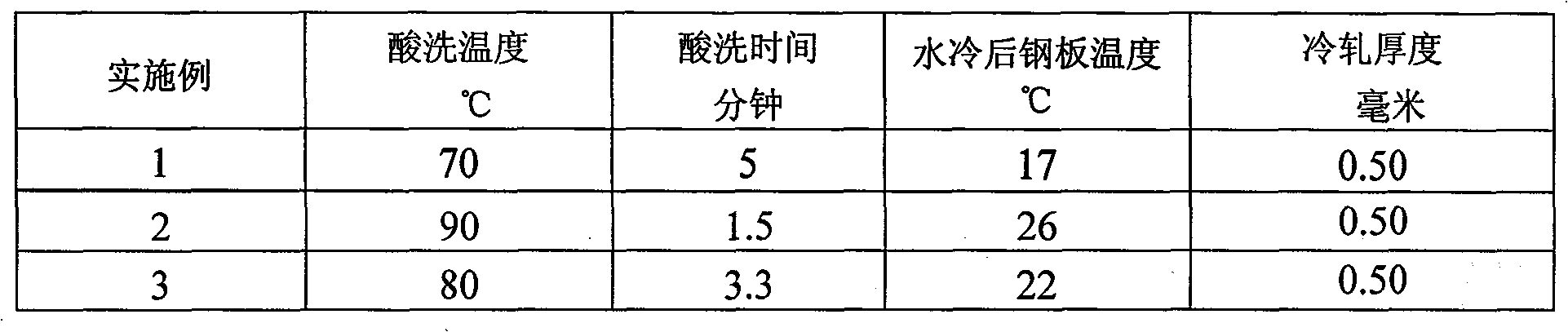

Pickling cold-formed steel and manufacturing method thereof

InactiveCN110747323AGood yield ratioGood extensibilityFurnace typesHeat treatment furnacesSteelmakingCold formed

The invention discloses pickling cold-formed steel and a manufacturing method thereof, and belongs to the technical field of steelmaking. The pickling cold-formed steel comprises the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 0.05% of Si, less than or equal to 0.45% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, less than or equal to 0.060% of Als, less than or equal to 0.0100% of N, and the balance of Fe and inevitable impurities. The manufacturing method comprises the following specific processing steps of: step 1, converter smelting; step 2, RH furnace refining; step 3, continuous casting; step 4, heating; step 5, rolling; step 6, cooling; step 7, coiling; step 8, pickling; and step 9, wetleveling. The microstructure of a hot-rolled steel plate manufactured by the manufacturing method is ferrite and pearlite, the yield strength of the product is 230-300 MPa, the tensile strength is 300-420 MPa, the elongation A50 is 38-45%, the 180-degree longitudinal bending test D =0a is qualified, the surface roughness of strip steel is 0.6-1.5, the surface whiteness of the strip steel is 55-65,the yellowness is 0.5-3.0, and the product has good yield ratio, elongation performance and cold bending performance, and has high-level roughness and surface gloss.

Owner:MAANSHAN IRON & STEEL CO LTD

Casting technique of high-strength high-speed train track

InactiveCN104388834AImprove mechanical propertiesGood yield ratioFoundry mouldsFoundry coresSS - Stainless steelCarbon steel

The invention discloses a casting technique of a high-strength high-speed train track. The high-strength high-speed train track is cast from 10-20% of iron chip, 60-65% of carbon steel and 20-25% of 310s stainless steel. The carbon steel comprises the following chemical components in percentage by mass: 0.30-0.37% of C, 0.70-1.00% of Mn, 0.60-0.90% of Si, 0.033-0.035% of P, 0.032-0.035% of S, 0.040-0.090% of Cr, 0.60-0.90% of Ni, 0.40-0.50% of Mo, 0.04-0.06% of Ni, 0.005-0.02% of Ti, 0.03-0.06% of Alt, 0.03-0.05% of Nb, 0.03-0.05% of V, and the balance of Fe and impurities. The technique ensures the cast steel rail to have excellent mechanical properties, favorable yield-tensile ratio and favorable low-temperature toughness, and obviously enhances the mechanical properties of steel.

Owner:YANCHENG FENGGONG MACHINERY

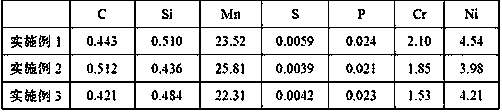

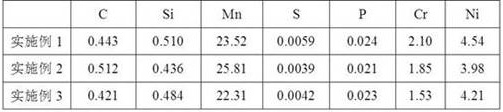

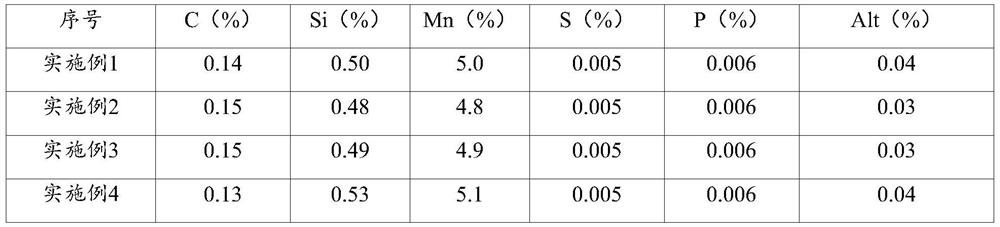

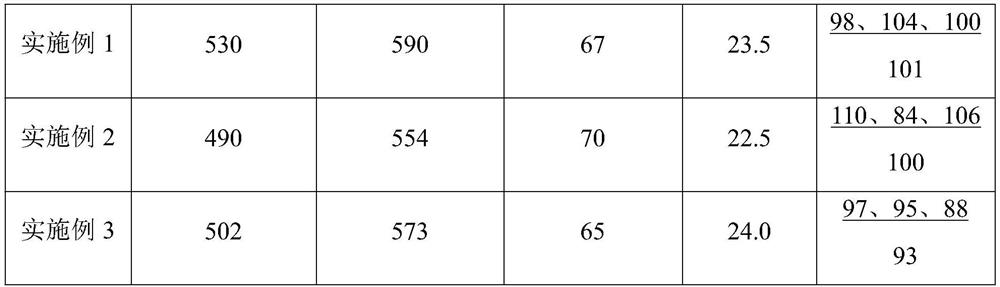

Seamless flux-cored wire for high-manganese low-temperature steel of LNG storage tank and preparation method

ActiveCN110653518ANo solderabilityGood yield ratioWelding/cutting media/materialsSoldering mediaSilica fumeOxide

The invention relates to a seamless flux-cored wire for high-manganese low-temperature steel of a LNG storage tank. The seamless flux-cored wire comprises low-carbon steel belt skin with mass percentage being 60-70% and a flux core with mass fraction being 30-40%; the flux core comprises the following components in percentage by mass: 65%-75% of electrolytic manganese metal, 8%-14% of nickel powder, less than 1.0% of silicon powder, less than 1.0% of sodium carbonate, 2%-8% of high-carbon ferrochrome and 4%-8% of sintering powder, and the balance iron powder; and the sintering powder comprises25%-30% of novel potassium titanate, 20%-25% of aluminum oxide, 10-15% of graphite, 25%-30% of magnesite and the balance bonding agent. The seamless flux-cored wire can be used for manufacturing theLNG storage tank, and has good impact toughness and base material matching strength at an ultra-low temperature, has good welding process property, can be suitable for multi-position welding, has chemical components matched with the base material, and is smoothly transited with the base material without cracks.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

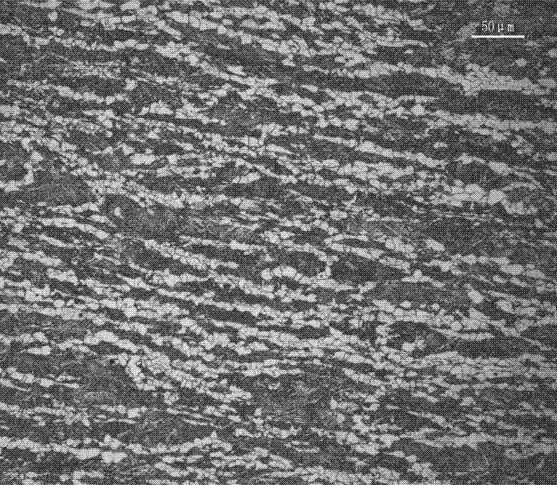

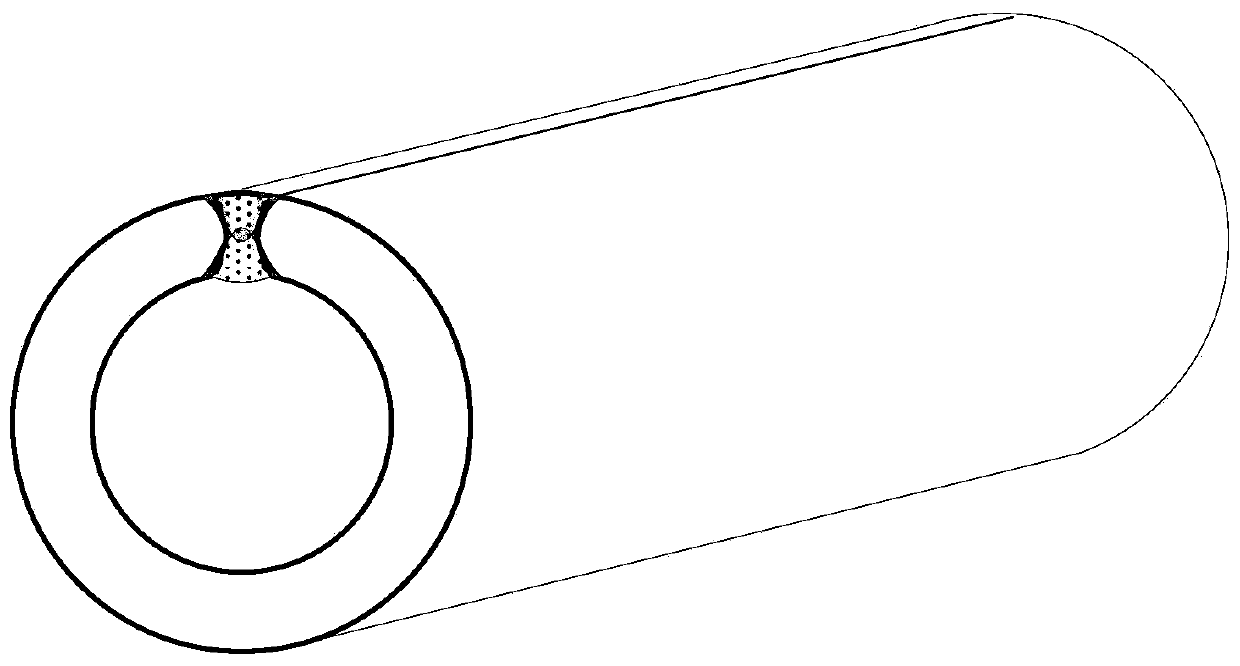

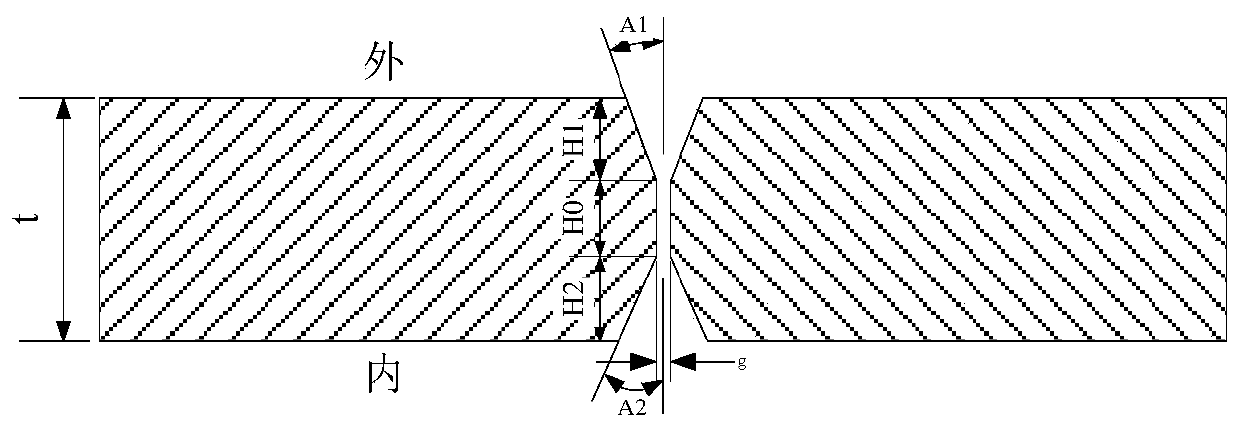

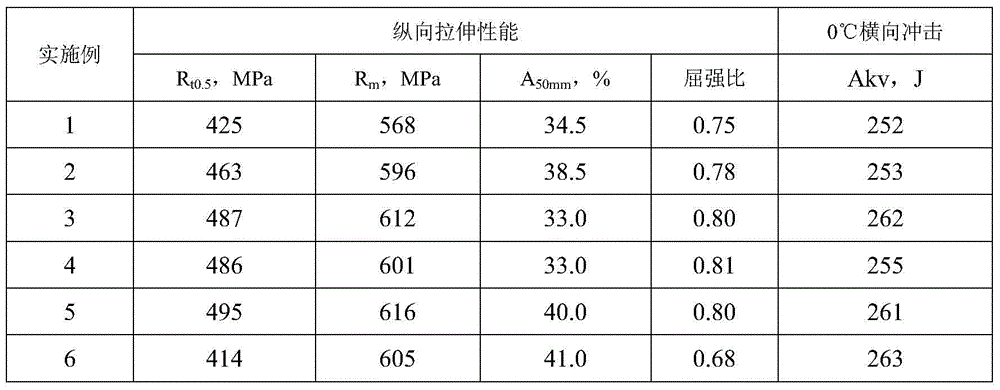

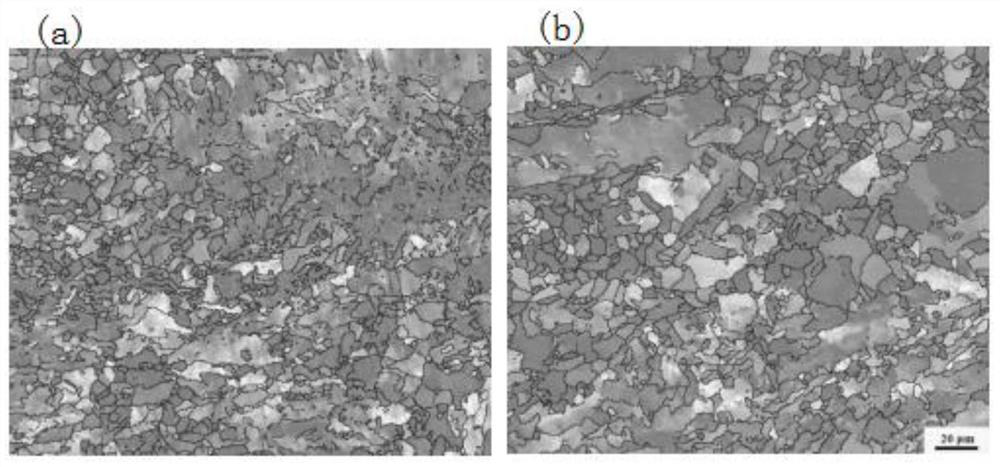

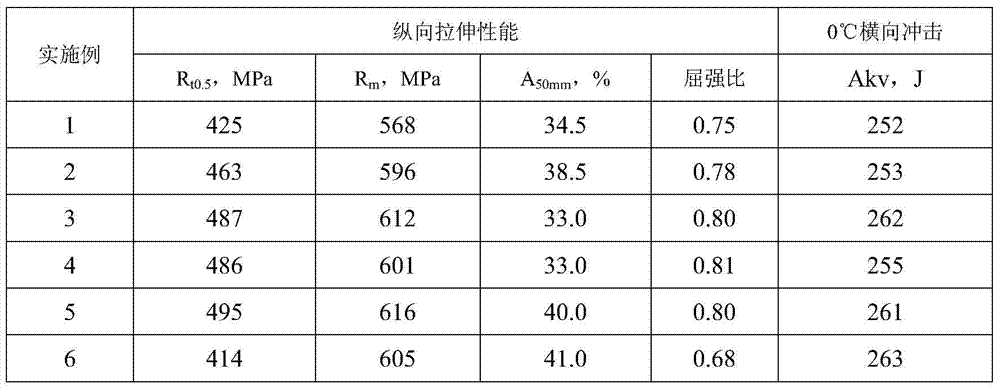

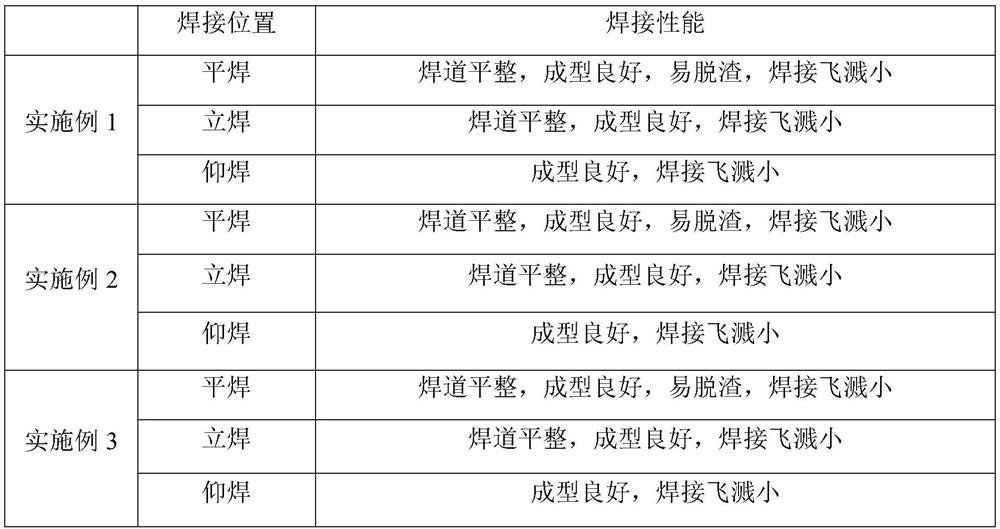

Marine high-strain welded steel pipe based on double-phase structure and preparing method thereof

ActiveCN110000517AWith mechanical propertiesCorrosion resistanceArc welding apparatusDouble phaseHigh intensity

The invention discloses a marine high-strain welded steel pipe based on a double-phase structure and a preparing method thereof. The marine high-strain welded steel pipe is made by a wide and thick steel plate having the double-phase structure, the steel grade of the high-strain welded steel pipe is L485MO, the thickness is larger than or equal to 25.4mm, the width of the steel plate is pi(1-epsilon)D-2t, D refers to the outer diameter of the steel pipe, t refers to wall thickness, epsilon refers to a cold expanding rate, the radius-to-thickness ratio is smaller than or equal to 30, the yield-to-strength ratio Rt0.5 / Rm is smaller than or equal to 0.85, A is larger than or equal to 25%, and UEL is larger than or equal to 7%. The manufactured steel pipe has the characteristics of high strength, high tenacity, high strain capability, low yield-to-strength ratio, low strain aging influence, H2S corrosion resistance, large wall thickness, small radius-thickness ratio, high diameter precision, small outer diameter error and small out-of-roundness error, can fully meet the technical requirements of marine service on the high-strain thick-walled delivery steel pipe, can be used for deep-sea oil and gas exploitation and saves marine development cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

J55-grade low-yield-ratio steel for electric resistance welding casing pipe and manufacturing method of J55-grade low-yield-ratio steel

The invention discloses J55-grade low-yield-ratio steel for an electric resistance welding casing pipe and a manufacturing method of the J55-grade low-yield-ratio steel. The J55-grade low-yield-ratio steel comprises chemical components including, by weight percent, 0.090%-0.128% of C, 0.10%-0.35% of Si, 1.02%-1.25% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.008% of S, 0.01%-0.03% of Nb, 0.010%-0.030% of Ti, 0.30%-0.40% of Cr, 0.02%-0.06% of Als, smaller than or equal to 0.008% of N and the balance Fe and inevitable elements. The method is characterized in that a continuous casting sheet billet is heated to 1160-1200 DEG C through a heating furnace, and the final rolling temperature in the first stage is larger than 980 DEG C; the rolling starting temperature in the second stage ranges from 980 DEG C to 1020 DEG C, and the final rolling temperature ranges from 810 DEG C to 865 DEG C; laminar flow intermittent cooling is adopted for a rolled steel strip, and the cooling speed ranges from 12 DEG C / s to 18 DEG C / s; and coiling is conducted at the temperature ranging from 590 DEG C to 680 DEG C. The J55-grade low-yield-ratio steel has the beneficial effects that the carbon content is relatively low, and weldability and the impact toughness are good; and a proper number of Cr alloy is added, the safety of a steel pipe is good, and it is ensured that the yield strength and the tensile strength meet the standard requirement.

Owner:ANGANG STEEL CO LTD

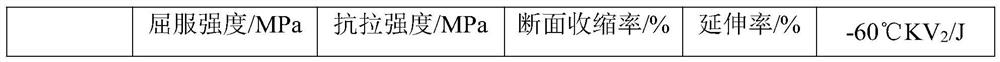

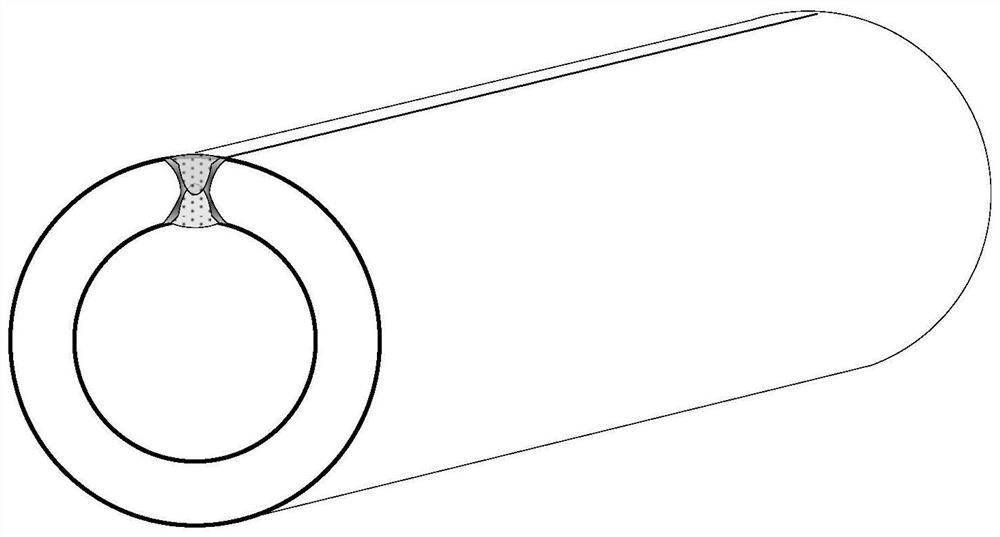

Seamless flux-cored wire for high-strength steel welding of ocean engineering

ActiveCN111761254AImprove low temperature impact toughnessAvoid growing upWelding/cutting media/materialsSoldering mediaFerrosiliconWeld seam

The invention discloses a seamless flux-cored wire for high-strength steel welding of ocean engineering. The seamless flux-cored wire comprises low-carbon steel strip skin and flux core powder. The mass of the low-carbon steel strip skin accounts for 80% to 90% of the total mass of the seamless flux-cored wire, and the mass of the flux core powder accounts for 10% to 20% of the total mass of the seamless flux-cored wire. The flux core powder comprises the following components of, by mass, 43% to 48% of rutile, 1% to 2% of quartz, 1.2% to 2% of sodium fluoride, 3.5% to 5.5% of potassium titanate, 0.05% to 0.1% of bismuth oxide, 8% to 11% of high-carbon ferromanganese, 5.5% to 8.5% of nickel powder, 3% to 4.8% of rare earth ferrosilicon, 1.5% to 3.5% of magnesium powder, and the balance ironpowder. The seamless flux-cored wire is the seamless flux-cored wire for high-strength steel welding of ocean engineering; and by using the seamless flux-cored wire, a weld joint which is formed after welding with the seamless flux-cored wire is excellent in performance after being subjected to thermal treatment, has the good yield ratio, has higher impact toughness at a low temperature, has thedeposited metal impact energy of no lower than 90 J in the environment of minus 60 DEG C, and can be applied to welding on high-strength thick steel plates of ocean engineering.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

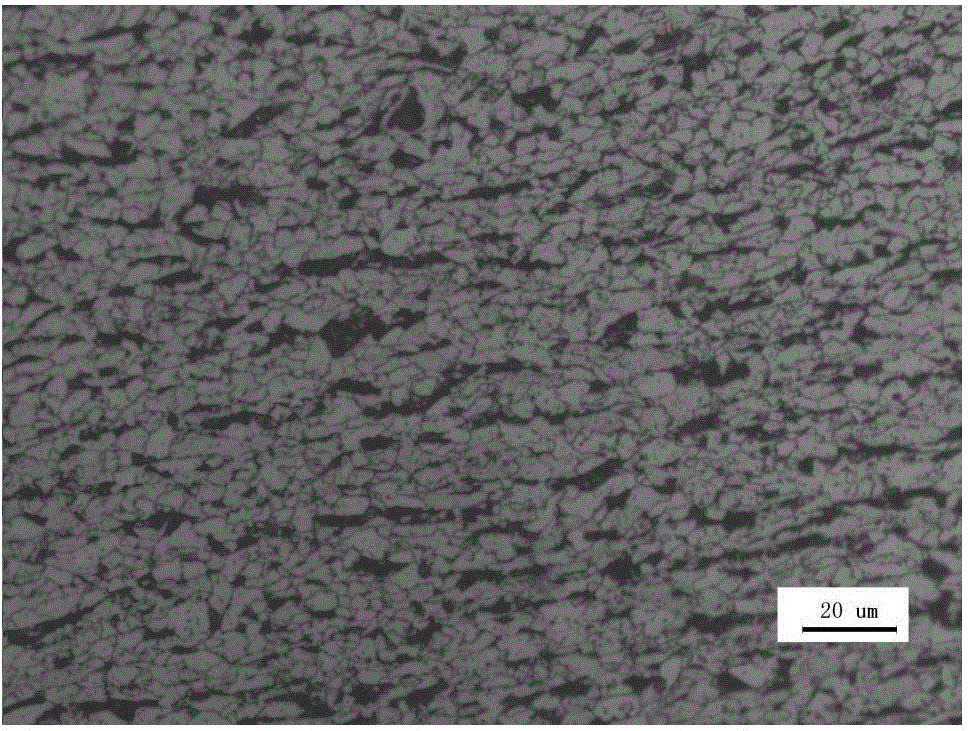

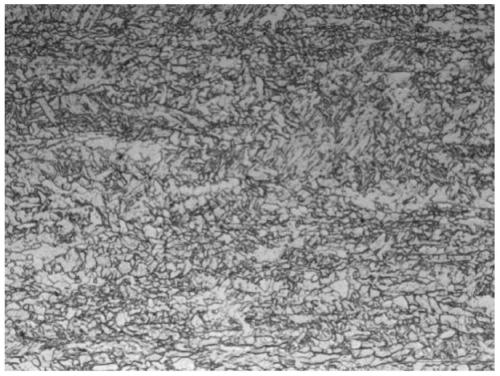

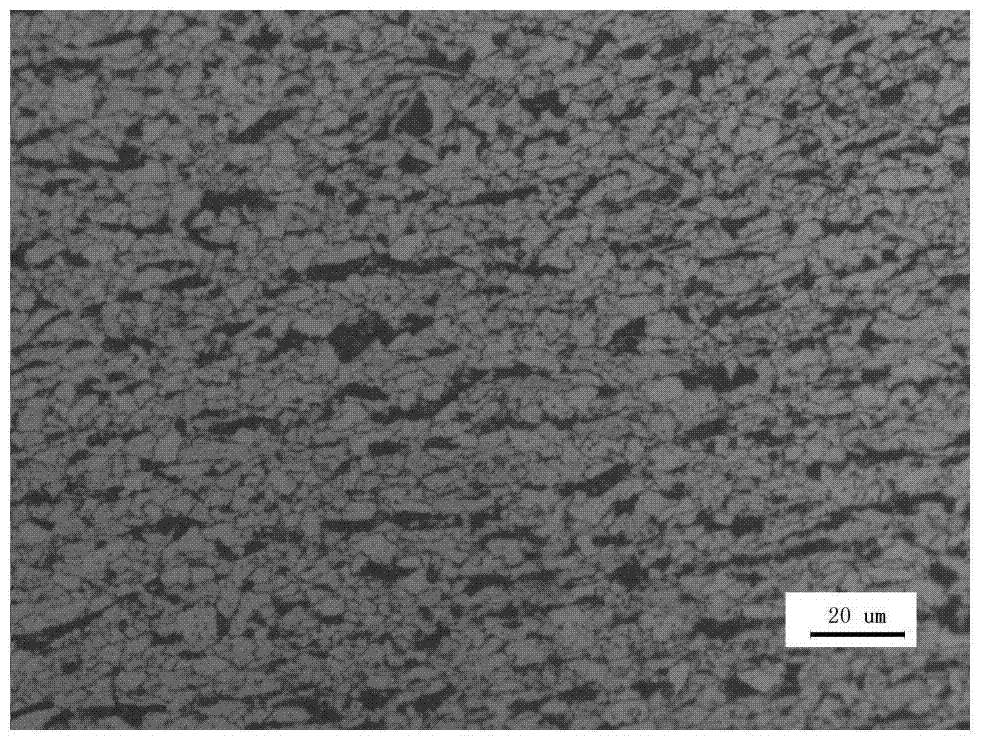

Hot-rolled steel plate for submarine conveying pipe and preparation method thereof

ActiveCN111534748AHigh strengthLow yield ratioFurnace typesHeat treatment furnacesSubmarineMicrostructure

The invention relates to the technical field of metal material processing, in particular to a hot-rolled steel plate for a submarine conveying pipe and a preparation method thereof. The chemical components of the hot-rolled steel plate include 0.03-0.05% of C, 0.15-0.25% of Si, 1.40-1.60% of Mn, 0.02-0.04% of Al, 0.02-0.04% of Nb, 0.010-0.020% of Ti, 0.40-0.50% of Ni, 0.15-0.25% of Cr, 0.10-0.20%of Mo, 0.008% or less of P, 0.001% or less of S and the balance Fe and inevitable impurity elements. By innovating the chemical composition, the production process and the microstructure, the preparedhot-rolled steel plate has excellent mechanical properties and good welding performance, reduces the risk of deformation and fracture failure of the submarine conveying pipe under the influence of ocean waves, ocean currents, submarine earthquakes, faults and seabed collapse, and has good application prospects.

Owner:SHOUGANG CORPORATION

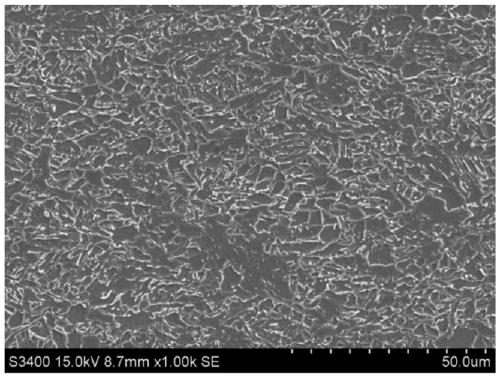

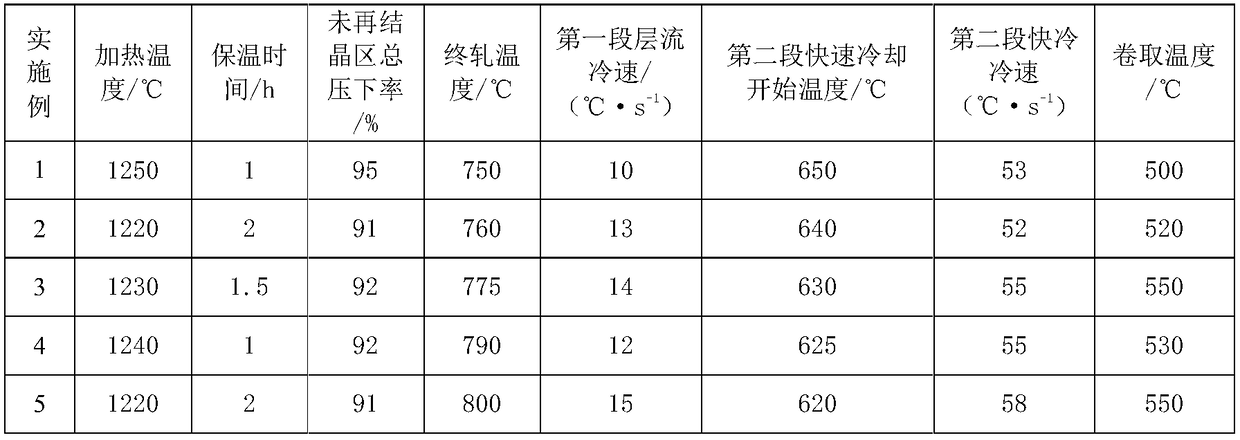

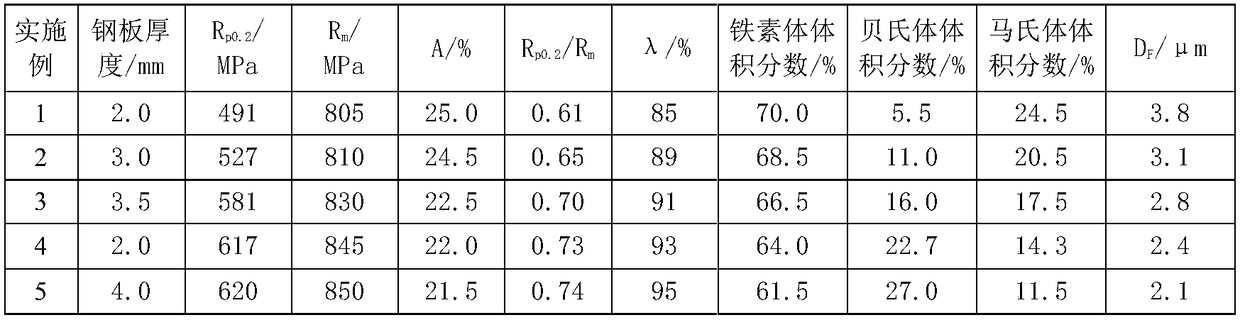

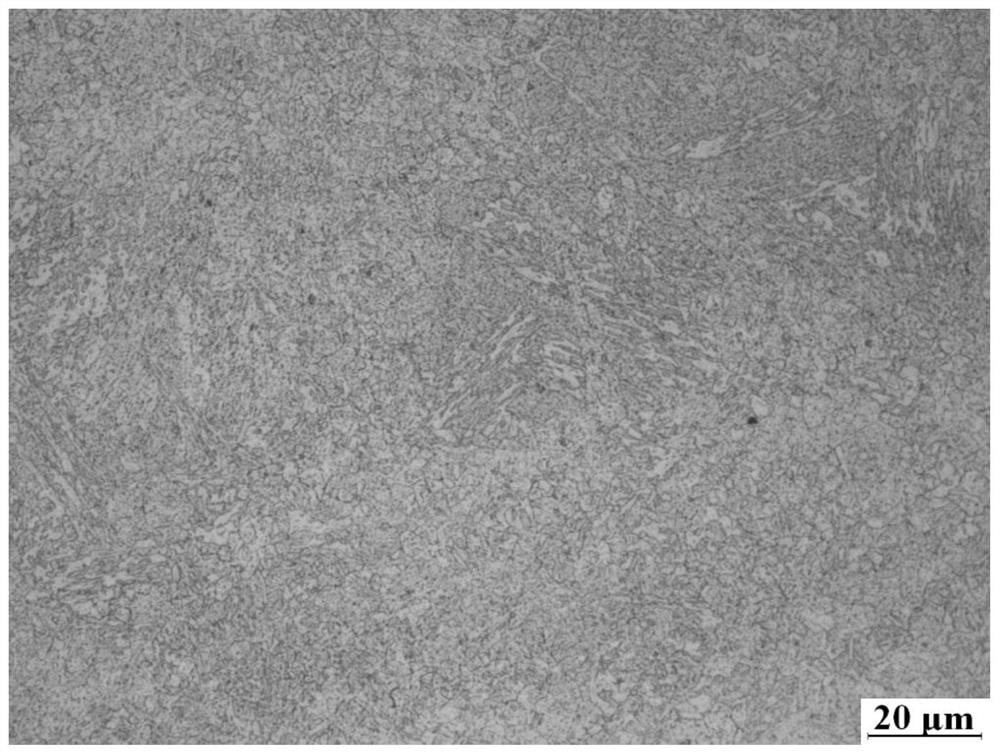

Automobile hot rolled steel plate with good broaching performance and low yield ratio and manufacturing method thereof

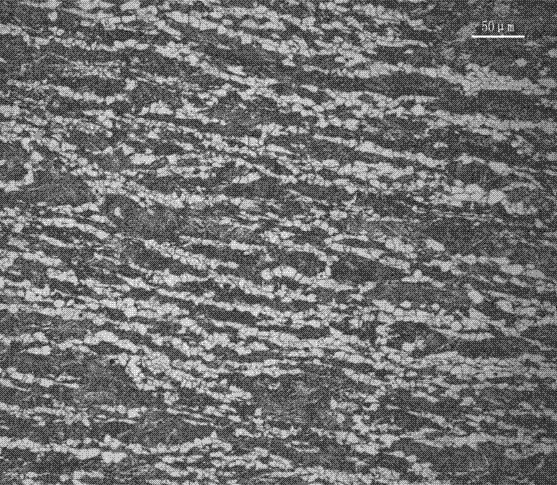

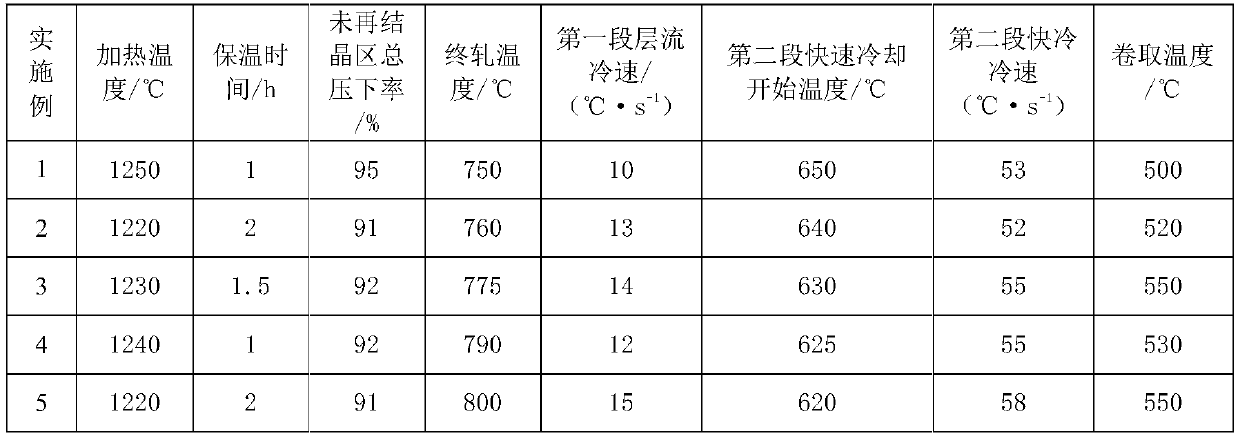

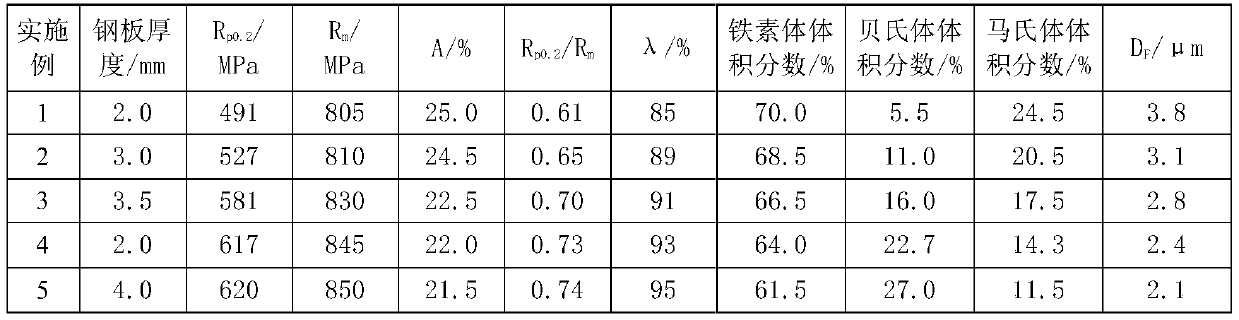

The invention discloses an automobile hot rolled steel plate with the good broaching performance and the low yield ratio and a manufacturing method thereof. Steel comprises 0.03%-0.06% of C, 0.80%-1.50% of Si, 1.0%-2.0% of Mn, 0.02%-0.06% of Als, 0.50%-0.80% of Mo, 0.03%-0.06% of Nb, 0.02%-0.05% of V, less than or equal to 0.010% of P, less than or equal to 0.003% of S, and the balance iron and inevitable impurities. The manufacturing method comprises the steps of heating a plate blank to 1220-1250 DEG C and then conducting heat preservation for 1-2 h; keeping the total reduction rate of a non-recrystallization region greater than 90% and the finished rolling temperature at 750-800 DEG C; cooling a steel plate to 620-650 DEG C at the laminar cooling rate of 10-15 DEG C / s in the laminar cooling and rapid cooling mode after finished rolling, conducting rapid cooling at the cooling rate greater than 50 DEG C / s to 500-550 DEG C and then reeling the steel plate. The finished steel plate hashigh strength and good yield ratio and hoe expansion rate for matching and is suitable for an automobile chassis, a seat or other parts.

Owner:ANGANG STEEL CO LTD

High-strength steel submerged-arc stranded wire and welding method thereof

InactiveCN110614458AImprove toughnessBest Match Chemical CompositionArc welding apparatusWelding/cutting media/materialsManganeseWeld seam

The invention discloses a high-strength steel submerged-arc stranded wire. The high-strength steel submerged-arc stranded wire comprises the following components of, by mass percentage, 0.08-1.2% of carbon, 0.4-0.8% of manganese, 0.05-0.1% of copper, 0.1-0.2% of nickel, 0.1-0.2% of zirconium, 0.11-0.18% of silicon, 0.02-0.08% of molybdenum, 0.01-0.02% of titanium, 0.2-0.4% of boron, less than 0.01% of phosphorus, not larger than 0.005% of sulfur and the balance iron and inevitable impurities. The invention discloses a welding method of the high-strength steel submerged-arc stranded wire. The welding method comprises the steps that a steel plate to be welded is pretreated, then the inner side welding and the outer side welding are carried out, and then heating, heat preservation and air cooling are carried out. A welding seam formed by welding has the beneficial effects of being good in low-temperature impact toughness, low in yield ratio, high in strength, attractive in forming and thelike; and moreover, the welding spatter is small, and the welding process performance is excellent.

Owner:河北联之捷焊业科技有限公司

Large-thickness and high-piece-weight vanadium-chromium-molybdenum steel plate and production method thereof

InactiveCN112375980ASolve the problem of large thickness and heavy orders, which cannot be rolled and producedGood cold bending performanceCrazingDie casting

The invention discloses a large-thickness and high-piece-weight vanadium-chromium-molybdenum steel plate and a production method thereof, and belongs to the technical field of metallurgy. The steel plate comprises the following chemical components in percentage by weight: 0.12-0.14% of C, 0.06-0.08% of Si, 0.4-0.6% of Mn, 0.007-0.009% of P, less than or equal to 0.004% of S, 2.2-2.5% of Cr, 1.0-1.1% of Mo, 0.28-0.35% of V, 0.1-0.2% of Ni, less than or equal to 0.05% of Nb, less than or equal to 0.2% of Cu, less than or equal to 0.003% of Sb, less than or equal to 0.004% of Sn, less than or equal to 0.005% of As and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting and carrying out die casting, annealing cast ingots, cogging and annealing, carrying out mechanical treatment, annealing steel billets, carrying out hot rolling and carrying out heat treatment. According to the large-thickness and high-piece-weight vanadium-chromium-molybdenum steel plate and the production method thereof, the risk of generation of cracks on the surface of the steel plate can be reduced; and the steel plate is excellent in cold bending performance and can be widely used in equipment such as a hydrogenation reactor and the like.

Owner:WUYANG IRON & STEEL

Low-temperature-resistant and easy-to-weld ultra-low-carbon steel thick plate and preparation method thereof

The invention relates to a low-temperature-resistant and easy-to-weld ultra-low-carbon steel thick plate and a preparation method thereof. The low-carbon steel is prepared from the following components in percentage by weight: 0.04% to 0.07% of C, 0.15% to 0.35% of Si, 0.10% to 0.30% of Cr, 1.20% to 1.60% of Mn, 0.10% to 0.20% of Mo, 0.03% to 0.07% of Nb, 0.01% to 0.04% of V, 0.002% to 0.010% of Ti, 0.05% to 0.30% of Cu, 0.01% to 0.02% of Ni, 0.01% to 0.03% of Al, 0.0015% to 0.0050% of Ca and the like, and the balance of Fe and inevitable impurities; and steel making, continuous casting, heating, rough rolling, finish rolling and multi-stage cooling are adopted, the low-carbon steel with a ferrite and bainite dual-phase structure and small grain size is obtained, and the low-carbon steel has the advantages of being high in low-temperature strength, high in crack arrest toughness, low in yield ratio and the like.

Owner:CENT SOUTH UNIV +3

Wear-resistant and corrosion-resistant high-strength steel and preparation method thereof

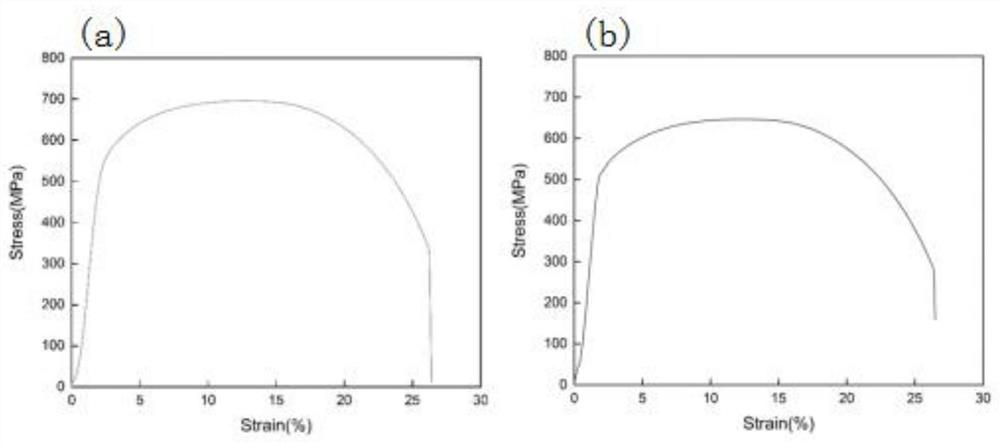

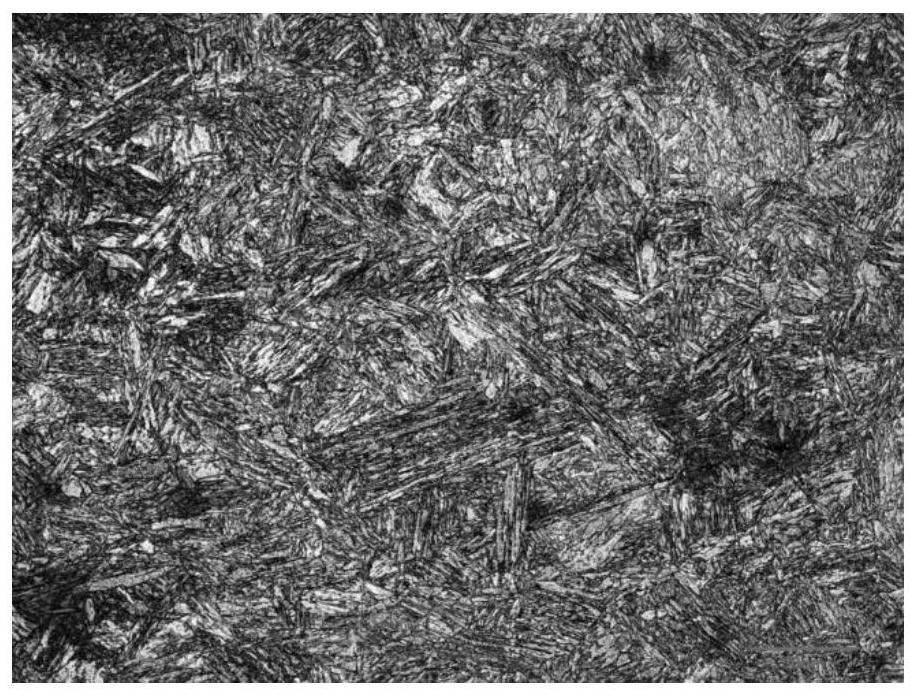

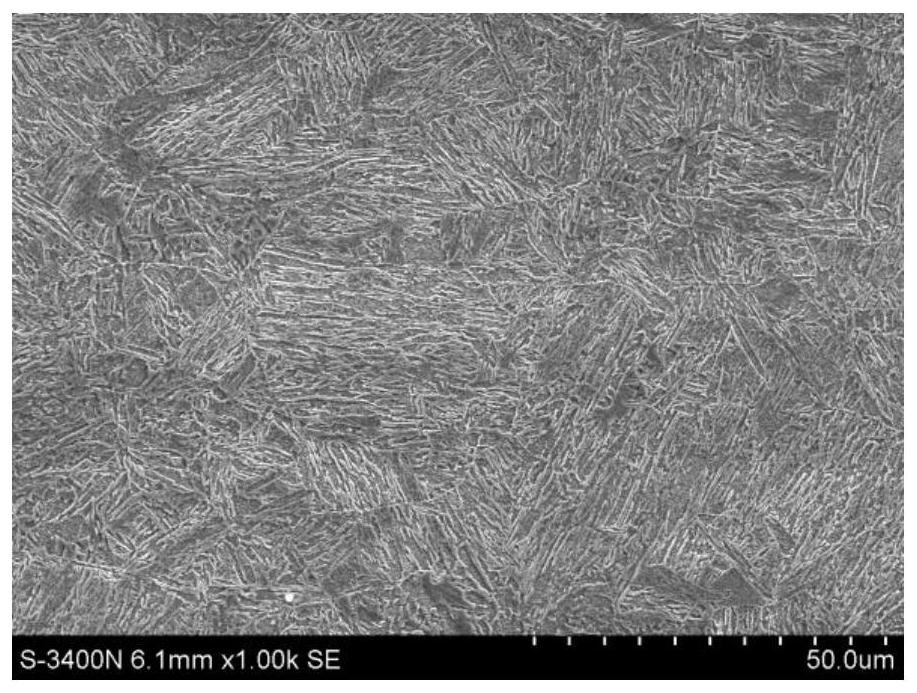

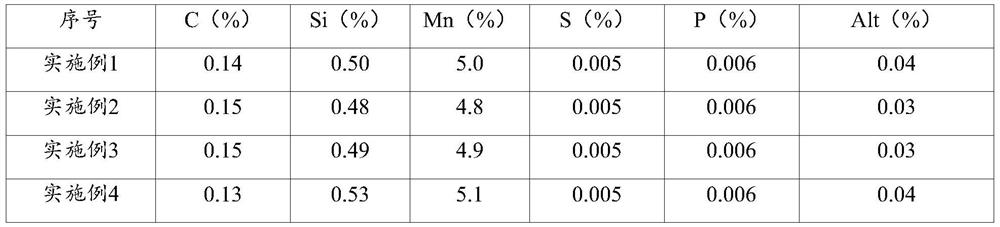

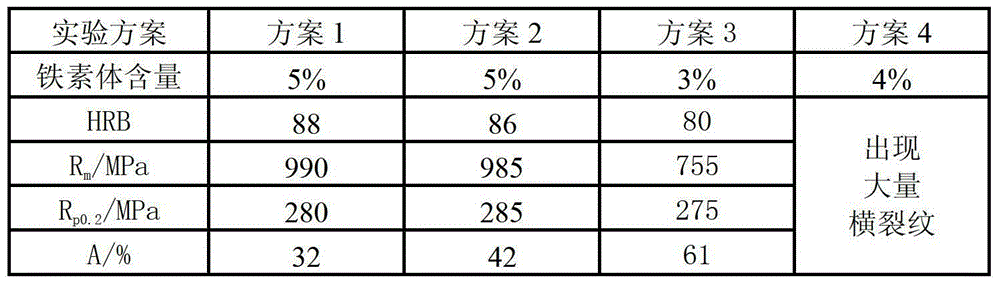

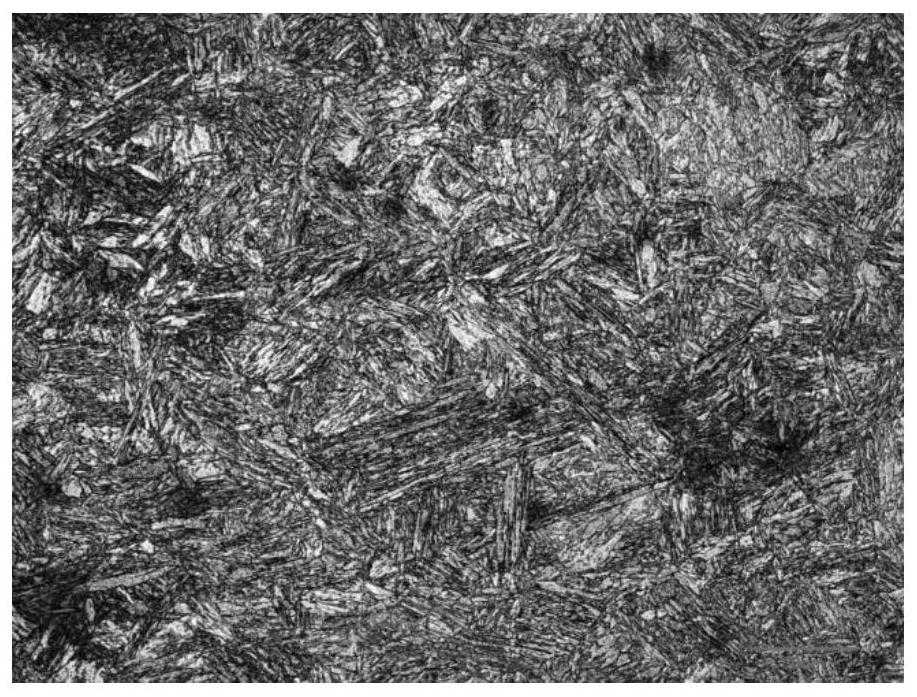

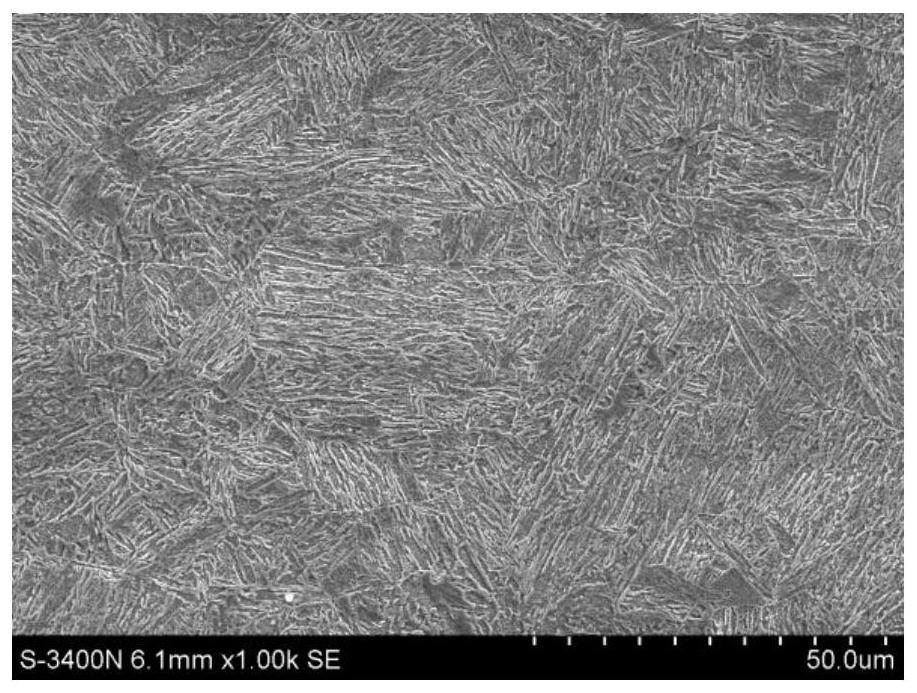

The invention discloses wear-resistant and corrosion-resistant high-strength steel. The wear-resistant and corrosion-resistant high-strength steel comprises the following components in percentage by mass: 0.12%-0.16% of C, 0.45%-0.55% of Si, 4.50%- 5.50% of Mn, not greater than 0.008% of P, not greater than 0.0008% of S, 0.01%-0.05% of Alt and the balance of iron and inevitable impurities. According to the invention, on the basis of limiting the specific chemical components and contents of the steel, a preparation process is greatly and deeply studied, so that the obtained wear-resistant and corrosion-resistant high-strength steel has high strength, high toughness, low yield ratio, high elongation, high hardness, high wear resistance, excellent bendability and good ductility, and further has remarkably prolonged service life and remarkably improved safety.

Owner:SHOUGANG CORPORATION

A kind of seamless flux-cored welding wire for LNG storage tank high manganese low temperature steel and its preparation method

ActiveCN110653518BNo solderabilityGood yield ratioWelding/cutting media/materialsSoldering mediaElectrolysisManganese

The invention relates to a seamless flux-cored welding wire for high-manganese low-temperature steel of an LNG storage tank, which comprises a low-carbon steel strip sheath with a mass percentage of 60-70% and a flux core with a mass percentage of 30-40%. The core includes electrolytic manganese metal 65%-75%, nickel powder 8%-14%, silicon powder less than 1.0%, soda ash less than 1.0%, high-carbon ferrochrome 2%-8%, sintered powder 4%-8% , the rest is iron powder; the sintered powder includes 25%-30% of new potassium titanate, 20%-25% of alumina, 10%-15% of graphite, 25%-30% of magnesia, and the rest is binder . The welding wire can be used in the construction of LNG storage tanks, and has good impact toughness and strength matching the base metal at ultra-low temperatures; and the welding wire has good welding processability, and is suitable for welding in various positions. Matching chemical composition, smooth transition with base metal, no cracks.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

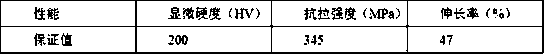

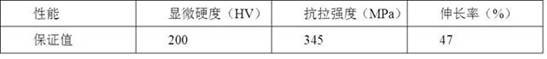

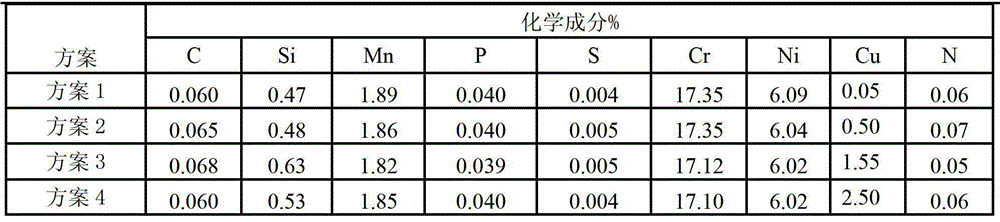

304J1 austenitic stainless steel hot-rolled steel belt for deep drawing and production method of steel belt

ActiveCN103397274BLow degree of cold work hardeningGuaranteed processing effectSS - Stainless steelDeep drawing

The invention discloses a 304J1 austenitic stainless steel hot-rolled steel belt for deep drawing and a production method of the steel belt, which belong to the technical field of stainless steel. The 304J1 austenitic stainless steel hot-rolled steel belt comprises the following chemical components: 0.03%-0.07% of C, 0.40%-0.70% of Si, 1.80%-2.00% of Mn, not more than 0.045% of P, not more than 0.005% of S, 17.05%-17.35% of Cr, 6.02%-6.12% of Ni, 1.50%-1.60% of Cu, 0.03%-0.07% of N, and the balance of iron and inevitable impurities. By controlling the chemical components through smelting, and controlling the process in continuous casting, hot rolling and pickling, the stainless steel hot-rolled steel belt disclosed by the invention has relatively good mechanical performance.

Owner:SICHUAN JINGUANG IND GRP

A kind of corrosion-resistant high-strength steel and its preparation method

The invention discloses a high-strength corrosion-resistant steel, wherein, in terms of mass percentage, the high-strength corrosion-resistant steel comprises: C 0.12-0.16%, Si 0.45-0.55%, Mn 4.50-5.50%, P≤ 0.008%, S≤0.0008%, Alt 0.01~0.05%, the balance is iron and unavoidable impurities. On the basis of limiting the specific chemical composition and content of the steel, the present invention has carried out extensive and in-depth research on the preparation process, so that the obtained high-strength corrosion-resistant steel not only has high strength, high toughness, and low yield strength. Ratio, high elongation, high hardness, high wear resistance, excellent bendability and good ductility, and also has significantly improved service life and safety.

Owner:SHOUGANG CORPORATION

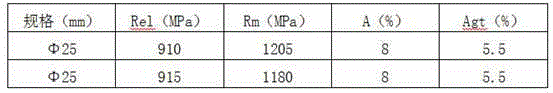

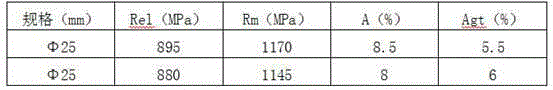

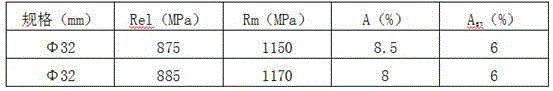

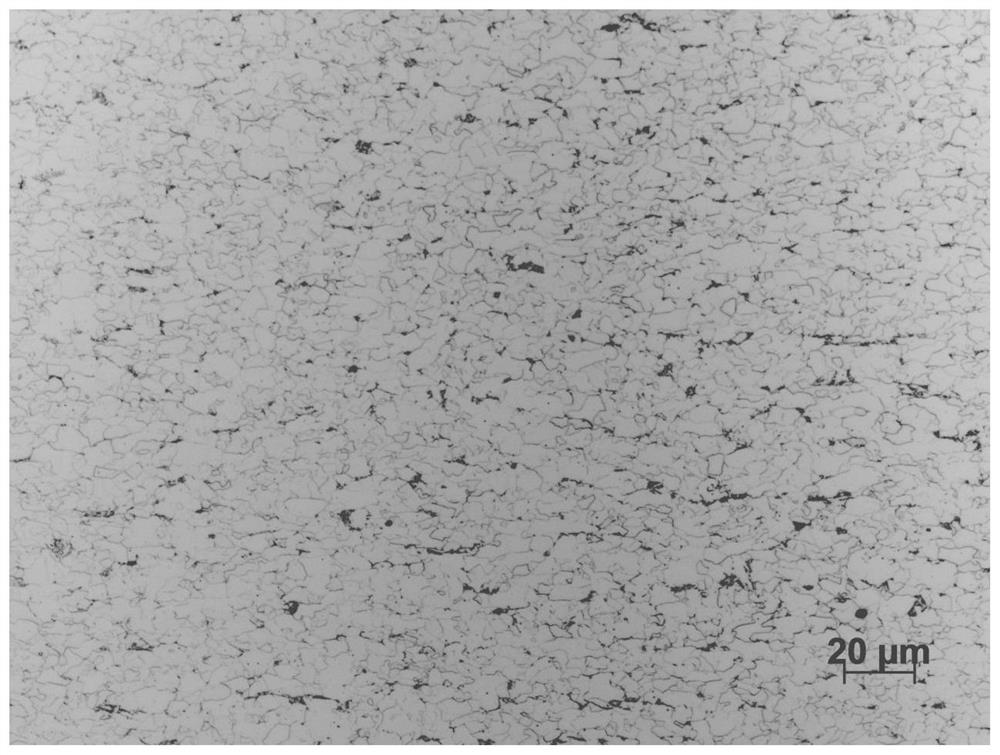

Production method of 830mpa grade bainitic high-strength finish-rolled steel bar

The invention discloses a production method of a 830 MPa grade bainite high-strength finish-rolling reinforcement steel. The production method comprises the procedures of metallurgic steel making, steel rolling and heat treatment, wherein the steel making procedure adopts a vanadium and manganese microalloying technology; the steel rolling procedure adopts low-temperature control rolling; and the heat treatment procedure adopts a low-temperature tempering technology. In the smelting process, silicon manganese alloy and silicon iron are matched for alloying, and vanadium iron is used for vanadium microalloying; in the rolling process, the initial rolling temperature and the finish rolling temperature are reduced to guarantee the realization of refined crystalline strengthening and second phase dispersion precipitation strengthening so as to improve the strength; in the heat treatment process, the low-temperature tempering method is adopted; after the tempering is performed, a granular bainite / martensite complex phase structure is generated, and a small quantity of proeutectoid ferrites are synchronously generated; the reinforcement steel has high strength through the bainite / martensite complex phase structure; the plasticity and the toughness of the reinforcement steel can be effectively improved through the small quantity of proeutectoid ferrites; and excellent fitting between the strength and the plasticity of the reinforcement steel is guaranteed through a B / M+IF (a small amount) complex phase structure.

Owner:HEBEI IRON AND STEEL

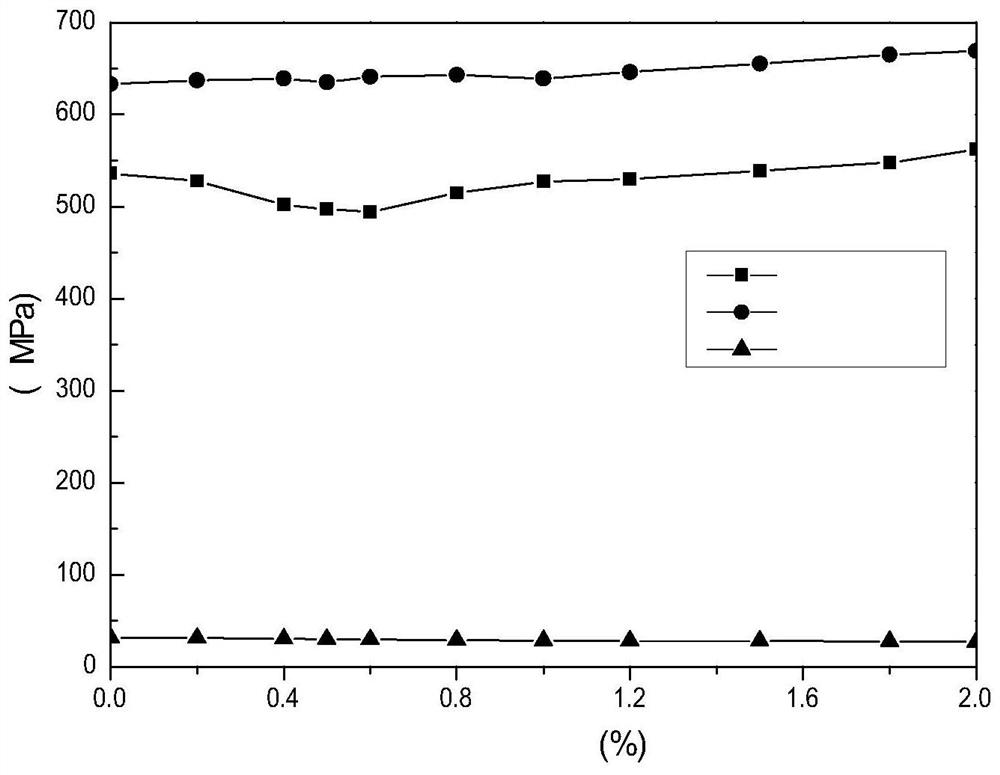

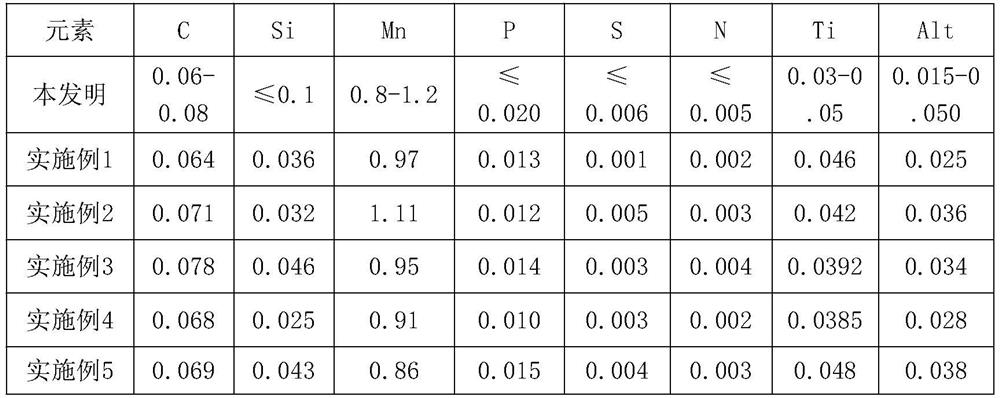

A low-yield ratio hot-rolled pickled steel plate with a tensile strength of 600mpa

The invention discloses a hot-rolled pickling steel plate with a tensile strength of 600 MPa and low yield strength ratio, which mainly solves the mismatch between the punching performance and the hole expansion performance of the existing 600 MPa hot-rolling pickling steel plate, and cannot meet the requirements of manufacturing auto parts with complex shapes. Technical issues required. The hot-rolled pickled steel plate provided by the invention has the following chemical composition weight percentages: C: 0.06-0.08%, Mn: 0.8-1.2%, Si: 0-0.10%, P: 0-0.020%, S: 0-0.006 %, Alt: 0.015-0.050%, N: 0-0.005%, Ti: 0.03-0.05%, and the balance is Fe and unavoidable impurity elements. The yield ratio of the 2.0-4.0mm thick hot-rolled pickled steel plate of the present invention is ≤0.80, and the elongation after fracture is A 50mm 25-35%, and the expansion performance λ≥75%. The steel plate of the invention is used for making automobile structural parts.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A kind of gas shielded solid welding wire for ultra-high strength engineering machinery steel plate and its application

ActiveCN109807493BImprove low temperature impact toughnessLow yield ratioArc welding apparatusWelding/cutting media/materialsHigh intensityMaterials science

The invention belongs to the technical field of welding materials, and in particular relates to a gas-shielded solid welding wire for ultra-high-strength construction machinery steel plates, which comprises the following components in terms of mass percentage: C: 0.08-0.12%, Si: 0.70-0.90%, Mn: 1.65-1.85%, Cr: 0.45-0.65%, Ni: 2.3-2.5%, Mo: 0.40-0.70%, Ti: 0.08-0.15%, Zr: 0.04-0.08%, Nb: 0.05-0.10%, B : 0.004~0.006%, S: 0.005~0.015%, P≤0.010%, the balance is iron and unavoidable impurities. The present invention also provides the application of the above-mentioned gas-shielded solid welding wire, which is used for welding ultra-high-strength engineering machinery steel plates with a tensile strength of 960 MPa. The weld seam formed by welding with the solid welding wire provided by the invention has the advantages of good low-temperature impact toughness, low yield ratio, high strength, and beautiful shape; and the welding spatter is small, and the welding process performance is excellent; the use of argon-rich (80%Ar+20 %CO 2 ) gas shielded welding, the yield ratio of the deposited metal is ≤0.9, which is suitable for the welding of ultra-high-strength engineering machinery steel plates such as Q890 with a tensile strength of 960MPa.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

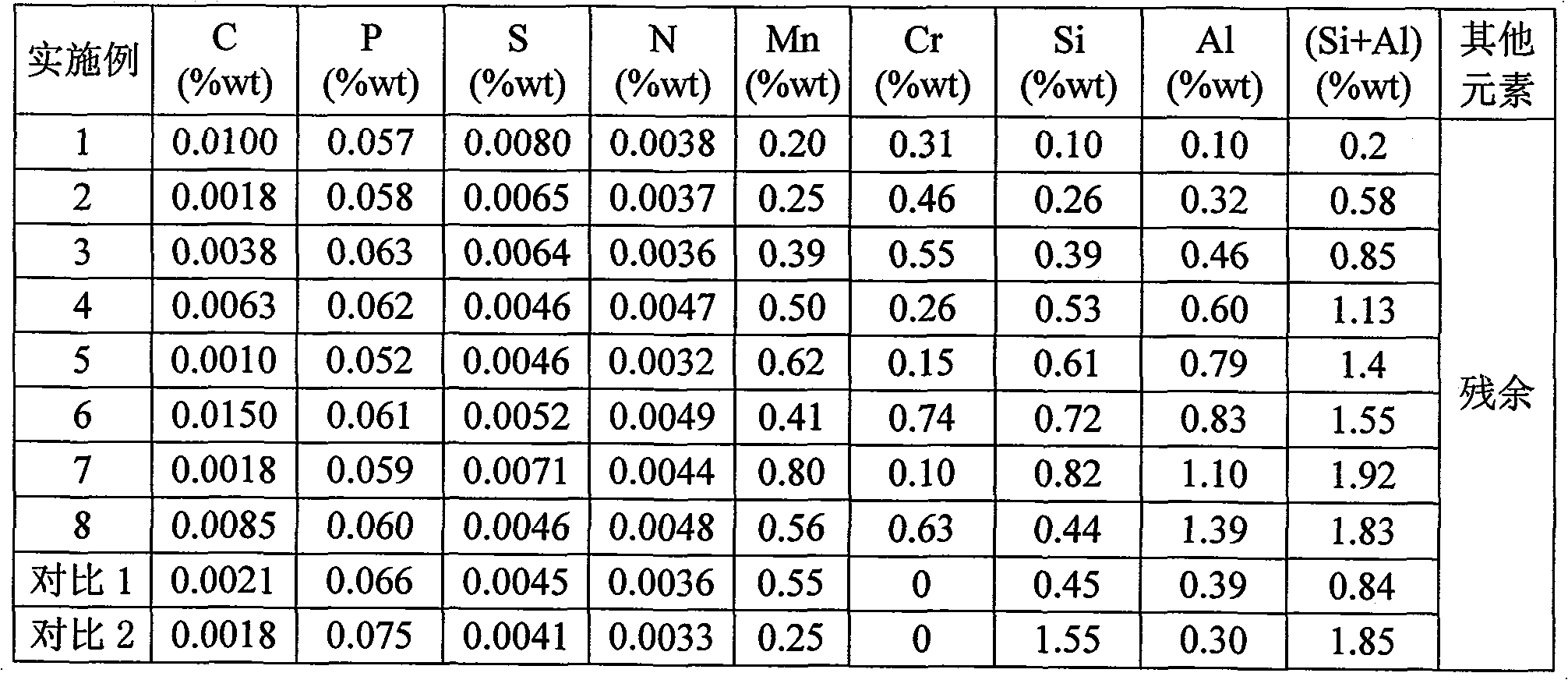

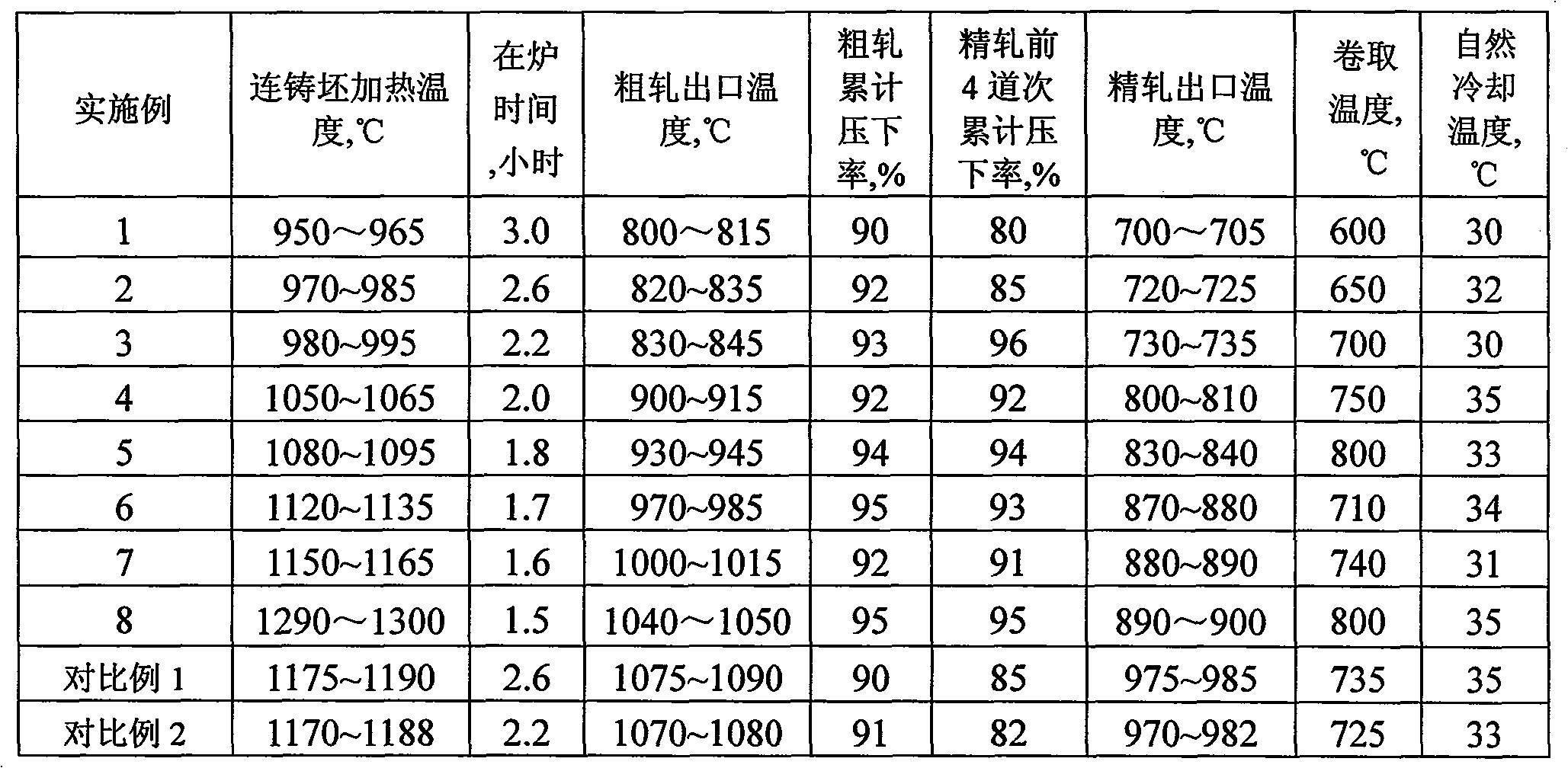

Cr-contained non-oriented electrical steel and production method thereof

InactiveCN101713047BReduce iron lossGood yield ratioHeat treatment process controlReduction ratePunching

The invention relates to Cr-contained non-oriented electrical steel and a production method thereof, solving the problems that the better the magnetic performance, and the lower the yield ratio; and the poorer the process performance of a punching sheet, the more serious the edge magnetic deteriorating effect and the like existing in the inherent magnetic performance and process performance. The Cr-contained non-oriented electrical steel comprises the following chemical components in percentage by weight: 0.001-0.015 percent of C, 0.2-0.8 percent of Mn, 0.1-0.8 percent of Cr, 0.1-1.4 percent of Al, 0.1-0.9 percent of Si, not more than 0.08 percent of P, not more than 0.015 percent of S, not more than 0.008 percent of N and the balance of Fe and inevitable impurities, meanwhile, the requirement that the summation of Si and Al is 0.2-2.0 percent is met. The production method comprises the following steps of: smelting the clean steel by the process and continuously casting into billets; heating the billets; roughly rolling; finish rolling: controlling the accumulated rolling reduction rate of front four paths to 80-95 percent; coiling; naturally cooling to room temperature; acid washing, cold rolling, decarburizing, evenly heating; and cooling, coating and finishing according to the conventional process. The invention has the advantages of excellent inherent magnetic performance,high yield ratio and excellent process performance of punching sheet.

Owner:武钢集团有限公司

A kind of high-strength building steel plate and its production method

ActiveCN104372245BImprove mechanical propertiesImprove low temperature toughnessPhysical chemistryYield ratio

The invention discloses a high-strength steel plate for construction. The composition is designed as: C: 0.10-0.15%, Si: 0.25-0.45%, Mn: 1.40-1.60%, Ni: 0.04-0.06%, Ti : 0.005~0.02%, Cu: 0.35~0.60%, S≤0.004%, P≤0.01%, Alt: 0.03~0.06%, Nb: 0.03~0.05%, V: 0.03~0.05%, the balance is Fe and not available Avoided impurities; its yield strength ≥ 500MPa, tensile strength ≥ 650MPa, elongation ≥ 25%, yield ratio ≤ 0.40; the invention solves the problems of insufficient yield ratio and low temperature toughness of existing construction steel.

Owner:溧阳市万兴特种建材有限公司

J55 grade steel for resistance welding casing with low yield strength ratio and its manufacturing method

The invention discloses a J55 grade low-yield-strength-ratio resistance welding casing steel and a manufacturing method thereof. %, P: ≤0.015%, S: ≤0.008%, Nb: 0.01%~0.03%, Ti: 0.010%~0.030%, Cr: 0.30%~0.40%, Als: 0.02%~0.06%, N: ≤0.008 %, the rest is Fe and unavoidable elements, and the method is characterized by: the continuous casting slab is heated to 1160-1200°C by a heating furnace, the final rolling temperature of the first stage is greater than 980°C; the starting rolling temperature of the second stage is 980-1020°C , the final rolling temperature is 810-865°C; the rolled steel strip adopts laminar intermittent cooling, and the cooling rate is 12-18°C / s; it is coiled at 590-680°C. The advantages and effects of the present invention are: the carbon content is relatively Low, good weldability and impact toughness; appropriate amount of Cr alloy is added, the safety of the steel pipe is good, and the yield strength and tensile strength are guaranteed to meet the standard requirements.

Owner:ANGANG STEEL CO LTD

Blue algae biological bacterium leaven, nutriment and biological organic fertilizer containing same, and preparing method thereof

InactiveCN101215539BIt has the effect of controlling crop diseases and insect pestsPromote growthBacteriaUnicellular algaePlant growthLichen

The invention relates to a microbe germ composition, a cyanophyte biological germ leaven which contains the microbe germ, a cyanophyte fermentation nutrient, a cyanophyte biological organic fertilizerand a method for preparation, wherein the microbe germ composition contains plant lactobacillus, bacillus subtilis and swamp Rhodopseudomonas, the cyanophyte biological germ leaven is prepared by microbe germ composition and base, the cyanophyte fermentation nutrient is prepared by cyanophyte biological germ leaven and cyanophyte, the cyanophyte biological organic fertilizer is prepared by cyanophyte fermentation nutrient, organics base and water-loss reducer. The microbe germ composition is provided with the ability for fermenting solid cyanophyte, which can transform nutriment in the cyanophyte into the material for crops. The cyanophyte fermentation nutrient can be superior animal feed. The cyanophyte biological organic fertilizer is provided with crop pest control effect, which adds the soil organics content and improves nutrient utility to accelerate the plant growth belonging to natural superior organics fertilizer.

Owner:周文彩

Control cooling method of easy-welding high-performance steel plate

InactiveCN103114186BReduce the amount addedUniform tissueHeat treatment process controlProduction lineCrazing

The invention provides a technical scheme of a control cooling method of an easy-welding high-performance steel plate. The easy-welding high-performance steel plate comprises the following chemical components in percentage by weight: 0.05-0.09% of C, 0.1-0.25% of Si, 1.55-1.65% of Mn, 0.025-0.035% of Nb, 0.025-0.035% of V, 0.20-0.30% of Cr, 0.0008-0.0025% of B, 0.020-0.045% of Alt, 0.015-0.030% of Ti and billet of which the low-welding crack sensitivity index Pcm is less than 0.21%; a final steel plate with the thickness of 12-60mm is rolled in a non-recrystallization area, and the effects of dislocations strengthening, precipitation strengthening and phase change strengthening in cooling after rolling are sufficiently realized by adopting different online cooling modes according to different performance requirements of the final steel plate; and the microstructure is controlled according to different performance requirements to obtain a proper complex-phase structure. According to the scheme, flexible control on performance is realized through the flexibility of the cooling technology by use of one component; the produced steel plate has uniform structure, low yield ratio, high plasticity and excellent low-temperature toughness; the steel plate does not need preheating before welding and heat treatment after welding; and the individualized needs of users are met by the flexibility of the production line.

Owner:JIGANG GRP

Low-yield-ratio hot-rolled steel sheet excellent in hole expansion performance for automobiles and manufacturing method thereof

The invention discloses an automobile hot rolled steel plate with the good broaching performance and the low yield ratio and a manufacturing method thereof. Steel comprises 0.03%-0.06% of C, 0.80%-1.50% of Si, 1.0%-2.0% of Mn, 0.02%-0.06% of Als, 0.50%-0.80% of Mo, 0.03%-0.06% of Nb, 0.02%-0.05% of V, less than or equal to 0.010% of P, less than or equal to 0.003% of S, and the balance iron and inevitable impurities. The manufacturing method comprises the steps of heating a plate blank to 1220-1250 DEG C and then conducting heat preservation for 1-2 h; keeping the total reduction rate of a non-recrystallization region greater than 90% and the finished rolling temperature at 750-800 DEG C; cooling a steel plate to 620-650 DEG C at the laminar cooling rate of 10-15 DEG C / s in the laminar cooling and rapid cooling mode after finished rolling, conducting rapid cooling at the cooling rate greater than 50 DEG C / s to 500-550 DEG C and then reeling the steel plate. The finished steel plate hashigh strength and good yield ratio and hoe expansion rate for matching and is suitable for an automobile chassis, a seat or other parts.

Owner:ANGANG STEEL CO LTD

A seamless flux-cored welding wire for high-strength steel welding in marine engineering

ActiveCN111761254BImprove low temperature impact toughnessAvoid growing upWelding/cutting media/materialsSoldering mediaFerrosiliconWeld seam

The invention discloses a seamless flux-cored welding wire for high-strength steel welding in marine engineering. The seamless flux-cored welding wire includes a low-carbon steel strip sheath and core powder, and the mass of the low-carbon steel strip sheath accounts for the total mass of the seamless flux-cored welding wire 80% to 90% of the core powder, the mass of the core powder accounts for 10% to 20% of the total mass of the seamless flux cored wire; wherein the core powder includes the following components in mass percentage: 43% to 48% of rutile, Quartz 1%~2%, sodium fluoride 1.2%~2%, potassium titanate 3.5%~5.5%, bismuth oxide 0.05%~0.1%, high carbon ferromanganese 8%~11%, nickel powder 5.5%~8.5% , rare earth ferrosilicon 3%~4.8%, magnesium powder 1.5%~3.5%, and the balance is iron powder. The seamless flux-cored wire is a seamless flux-cored wire for marine engineering high-strength steel. The weld formed by welding with the seamless flux-cored wire has excellent performance after heat treatment, has a good yield ratio, and has high impact at low temperature Toughness, the impact energy of the deposited metal is not less than 90J at ‑60°C, and can be applied to the welding of high-strength steel plates for marine engineering.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A high-strain welded steel pipe for marine use based on a dual-phase structure and its preparation method

ActiveCN110000517BHigh strengthEnhance resilienceArc welding apparatusMarine engineeringDouble phase

The invention discloses a marine high-strain welded steel pipe based on a double-phase structure and a preparing method thereof. The marine high-strain welded steel pipe is made by a wide and thick steel plate having the double-phase structure, the steel grade of the high-strain welded steel pipe is L485MO, the thickness is larger than or equal to 25.4mm, the width of the steel plate is pi(1-epsilon)D-2t, D refers to the outer diameter of the steel pipe, t refers to wall thickness, epsilon refers to a cold expanding rate, the radius-to-thickness ratio is smaller than or equal to 30, the yield-to-strength ratio Rt0.5 / Rm is smaller than or equal to 0.85, A is larger than or equal to 25%, and UEL is larger than or equal to 7%. The manufactured steel pipe has the characteristics of high strength, high tenacity, high strain capability, low yield-to-strength ratio, low strain aging influence, H2S corrosion resistance, large wall thickness, small radius-thickness ratio, high diameter precision, small outer diameter error and small out-of-roundness error, can fully meet the technical requirements of marine service on the high-strain thick-walled delivery steel pipe, can be used for deep-sea oil and gas exploitation and saves marine development cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com