304J1 austenitic stainless steel hot-rolled steel belt for deep drawing and production method of steel belt

A technology of austenitic stainless steel and production method, applied in the field of stainless steel, can solve the problems of large difference in product performance, cold rolling peeling, hot rolling edge cracking, etc., to avoid high temperature ferrite precipitation, low cold work hardening degree, good The effect of cold working plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The smelting process is electric arc furnace + GOR converter + LF refining furnace.

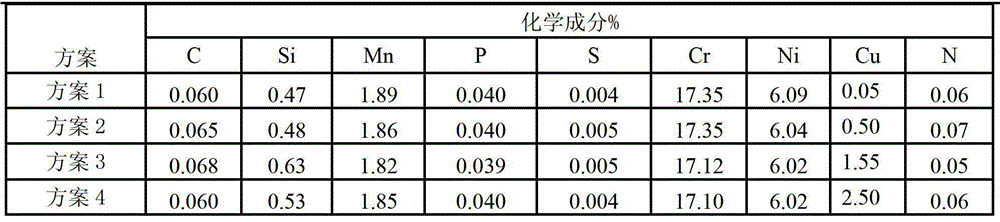

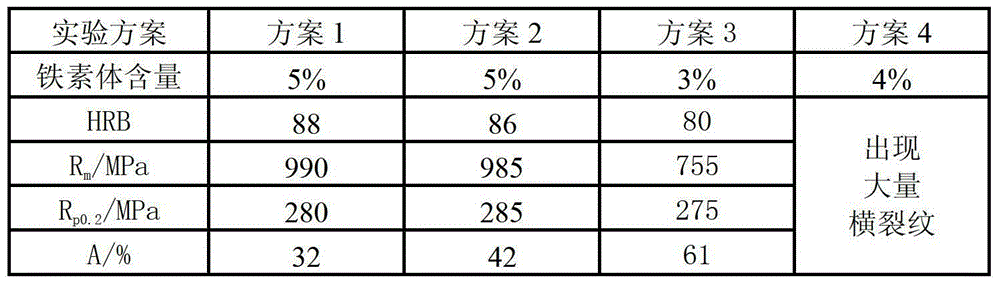

[0046] The main raw materials for trial 304J1 are composed of high-carbon ferrochromium, self-produced ferronickel, nickel-chromium pig iron, imported ferronickel, electrolytic copper plate, electrolytic nickel and other alloy materials. Among them, high-carbon ferrochromium, self-produced ferronickel, and nickel-chromium pig iron contain relatively high carbon and silicon elements, and self-produced ferronickel and nickel-chromium pig iron contain relatively high sulfur and phosphorus elements.

[0047] The main function of the electric arc furnace is to use electric energy to melt high-carbon ferrochromium, self-produced ferronickel, nickel-chromium pig iron, imported ferronickel, and oxidize silicon and carbon in molten steel through power transmission and oxygen blowing to melt the charge and meet the requirements. At the same time, some elements such as chromium and nickel are oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com