Wear-resistant and corrosion-resistant high-strength steel and preparation method thereof

A corrosion-resistant, high-strength steel technology, applied in the field of iron and steel smelting, can solve the problems of high strength, high toughness, low yield ratio, high elongation, high hardness, high wear resistance, bending performance and welding performance, etc., to achieve high elongation. rate, inhibit carbide precipitation, and improve the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

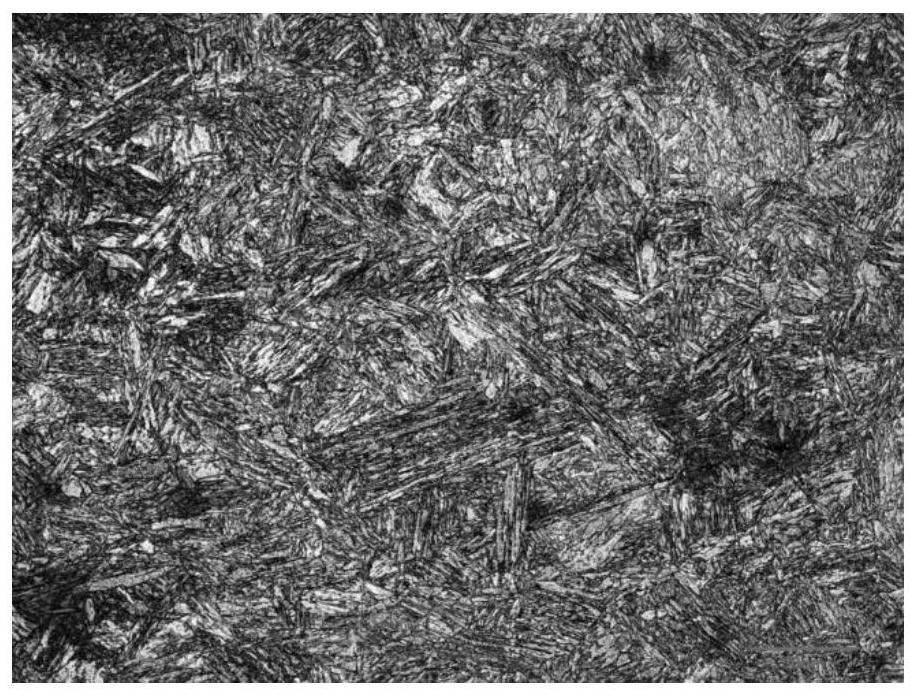

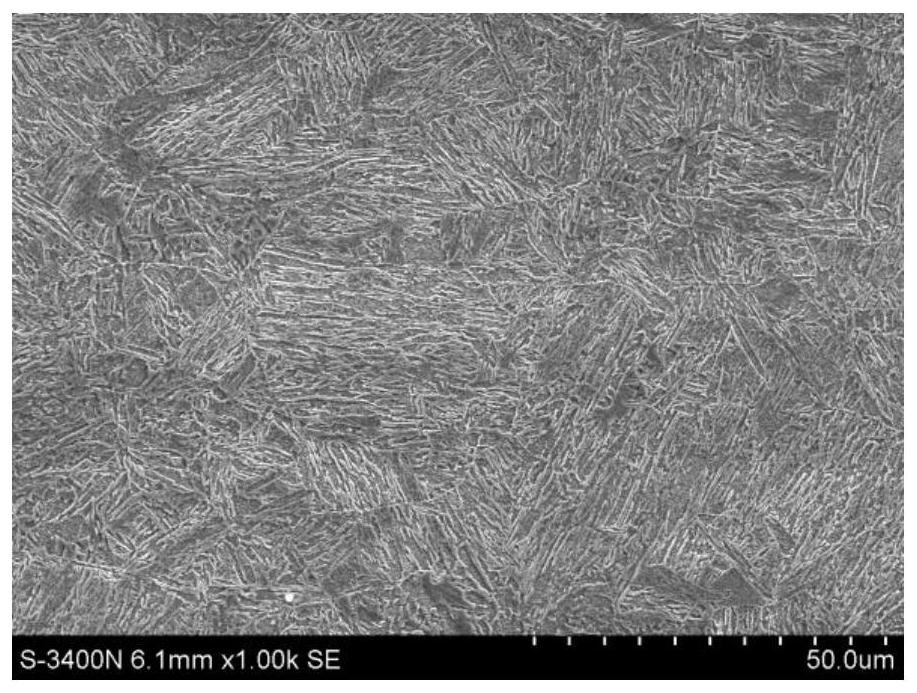

Image

Examples

Embodiment 1~8

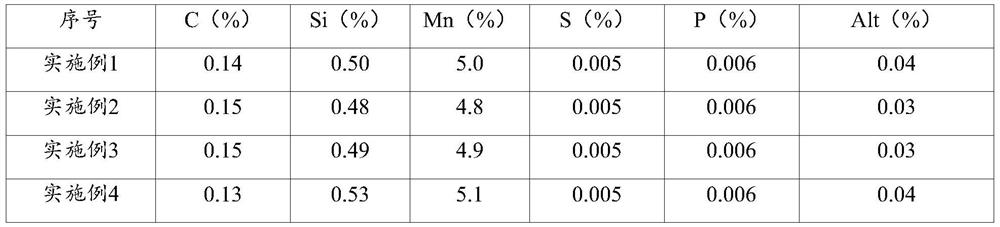

[0074] The following examples 1-8 adopt the preparation method of the high-strength corrosion-resistant steel of the present invention to prepare the high-strength corrosion-resistant steel, including:

[0075] 1. Preparation of billets;

[0076] Among them, the billet contains: C 0.12~0.16%, Si 0.45~0.55%, Mn 4.50~5.50%, P≤0.008%, S≤0.0008%, Alt 0.01~0.05%, and the balance is iron and unavoidable impurities. See Table 1.

[0077] 2. Heating, rough rolling and finish rolling the billet to obtain hot rolled plate;

[0078] Among them, a low-temperature heating process is adopted to inhibit the growth of austenite grains and achieve full austenitization; specifically: the heating temperature is 1100-1200°C, and the holding time is 30-100min.

[0079] Two-stage rolling process is adopted to suppress the precipitation of carbides and achieve a better effect of grain refinement; specifically: the starting temperature of rough rolling is 1000-1100°C; the starting temperature of fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com