Production method of 830mpa grade bainitic high-strength finish-rolled steel bar

A production method and 830mpa technology, applied in the production field of 830MPa grade bainite high-strength finishing steel bars, can solve the problems of high production cost, harsh conditions and complicated processes, achieve good strength and plasticity coordination, improve plasticity and toughness, Good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: The specific process of the production method of the 830MPa grade bainite high-strength finish-rolled steel bar is as follows.

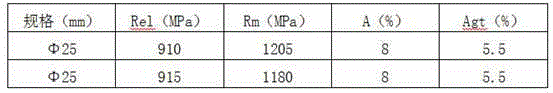

[0014] The mass percentage of each component in the billet obtained in the metallurgical steelmaking process is: C 0.28%, Si 0.80%, Mn 2.45%, V 0.057%, Cr 0.80%, Ti 0.023%, the rest is Fe and inevitable impurities; rolled steel In the process, the temperature of the soaking section of the heating furnace of the bar unit is 1030°C, and the temperature is kept for 50 minutes, so that the starting rolling temperature of the billet is 1030°C, and the finish rolling temperature is 1080°C; the tempering temperature in the heat treatment process is 250°C, and the tempering Keep warm for 5 hours and cool down with the furnace; the rest adopt conventional technology. The mechanical properties of the 830MPa grade bainite high-strength finish-rolled steel bars obtained in this example are shown in Table 1.

[0015] Table 1: Mechanical prop...

Embodiment 2

[0017] Embodiment 2: The specific process of the production method of this high-strength finish-rolled steel bar is as follows.

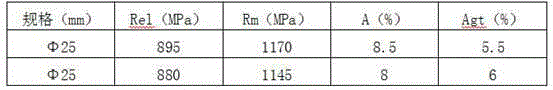

[0018] The mass percentage of each component in the billet obtained from the metallurgical steelmaking process is: C 0.29%, Si 0.85%, Mn 2.55%, V 0.065%, Cr 0.60%, Ti 0.020%, and the rest is Fe and inevitable impurities. In the steel rolling process, the temperature of the soaking section of the heating furnace of the bar unit is 1030°C, and the temperature is kept for 60 minutes, so that the starting rolling temperature of the billet is 1030°C, and the finish rolling temperature is 1100°C. In the heat treatment process, the tempering temperature is 250°C, and the tempering temperature is kept for 5 hours, and then cooled with the furnace. The mechanical properties of the high-strength finish-rolled steel bar obtained in this embodiment are shown in Table 2.

[0019] Table 2: Mechanical properties of the high-strength finish-rolled steel bars obtai...

Embodiment 3

[0021] Embodiment 3: The specific process of the production method of the high-strength finish-rolled steel bar is as follows.

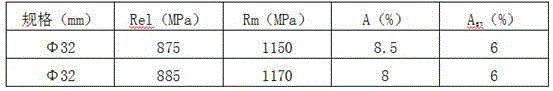

[0022] The mass percentage of each component in the billet obtained from the metallurgical steelmaking process is: C 0.28%, Si 0.75%, Mn 2.60%, V 0.060%, Cr 0.65%, Ti 0.015%, and the rest is Fe and unavoidable impurities. In the steel rolling process, the temperature of the soaking section of the heating furnace of the bar unit is 1020°C, and the temperature is kept for 45 minutes, so that the starting rolling temperature of the billet is 1020°C, and the finish rolling temperature is 1070°C. In the heat treatment process, the tempering temperature is 230°C, and the tempering temperature is maintained for 5.5 hours, and then cooled with the furnace. The mechanical properties of the high-strength finish-rolled steel bar obtained in this embodiment are shown in Table 3.

[0023] Table 3: Mechanical properties of the high-strength finish-rolled steel ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com