A low-yield ratio hot-rolled pickled steel plate with a tensile strength of 600mpa

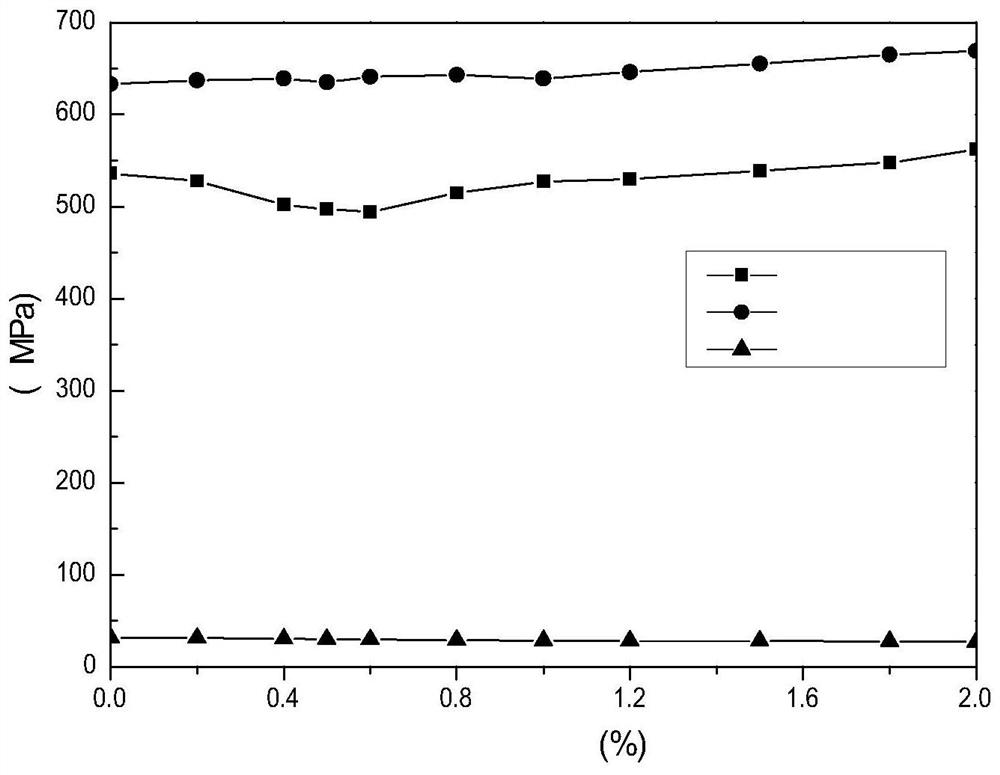

A hot-rolled pickling and tensile strength technology, which is applied in the field of hot-rolled pickled steel sheets, can solve the problems of inability to meet the manufacturing requirements of complex-shaped auto parts, the mismatch between stamping performance and hole expansion performance, and achieve excellent stamping performance and The effect of good hole expansion performance, comprehensive forming performance and good hole expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

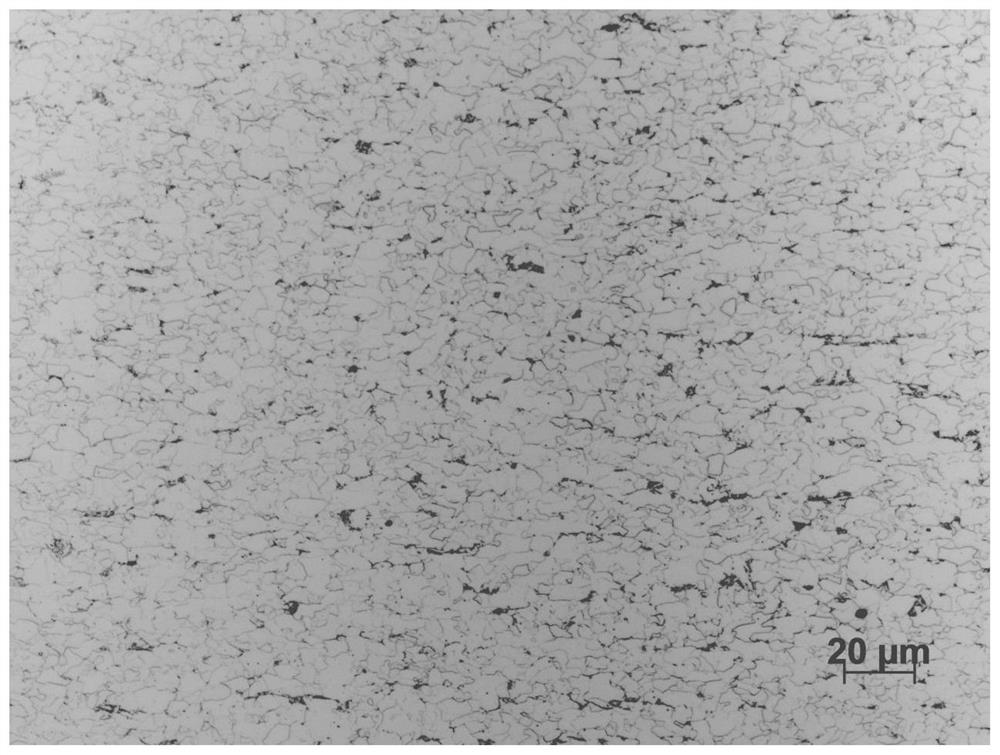

Image

Examples

Embodiment Construction

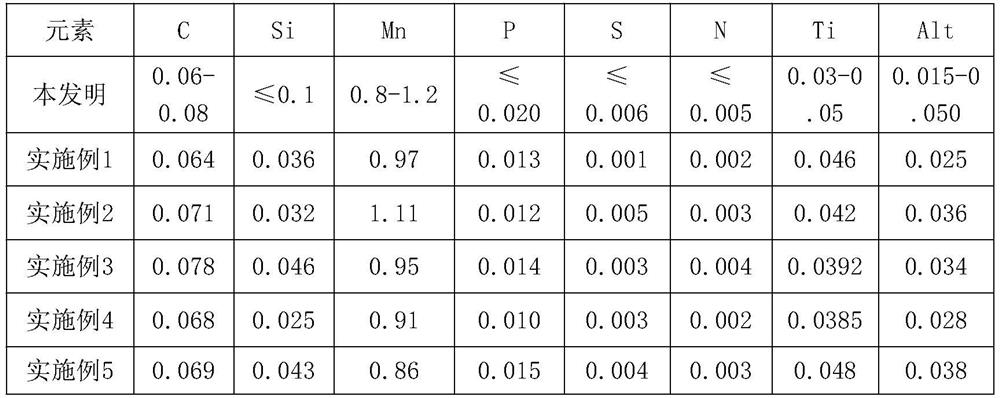

[0041] The present invention will be further described below in conjunction with Examples 1 to 5, as shown in Tables 1 to 5. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0042] Table 1 is the chemical composition (by weight percentage) of the steel of the embodiment of the present invention, and the balance is Fe and unavoidable impurities.

[0043] Table 1 Chemical composition of the steel of the embodiment of the present invention, unit: weight percent.

[0044]

[0045] The molten steel that meets the chemical composition requirements is obtained through converter smelting, and the molten steel is blown by Ar in the refining process of the LF ladle refining furnace, and the molten steel is continuously cast by continuous blowing of Ar to obtain a continuous casting slab; the thickness of the continuous casting slab is 210-230mm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com