Aluminum battery box body for electric vehicle and manufacturing method of aluminum battery box body

A technology of electric vehicles and manufacturing methods, which is applied in the direction of battery box/cover materials, secondary batteries, battery pack components, etc., which can solve the hidden dangers of pure electric vehicle safety performance, the inability to install batteries in the battery box, and the low pass rate of product quality and other issues, to achieve the effect of improving the strength and stamping performance of the plate, improving the bearing weight and reliability, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

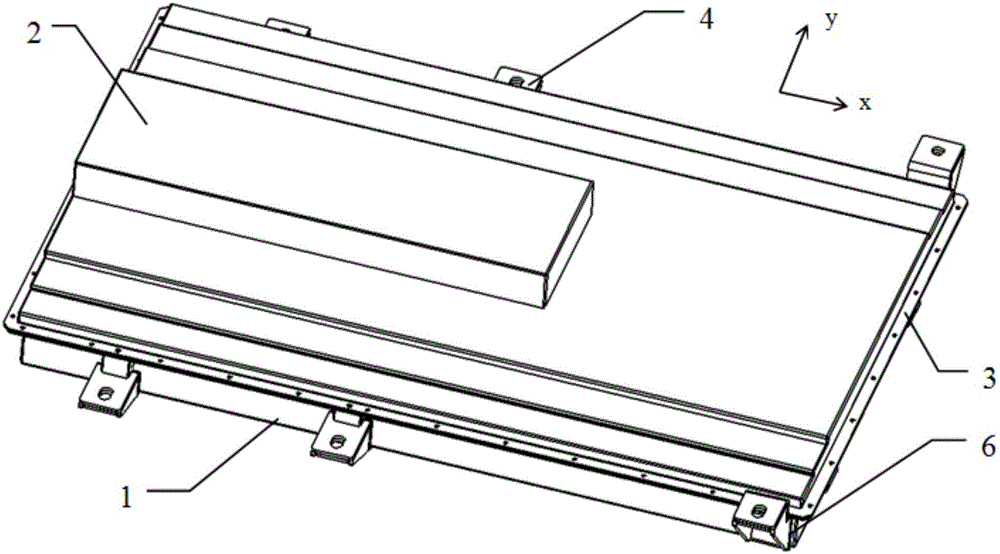

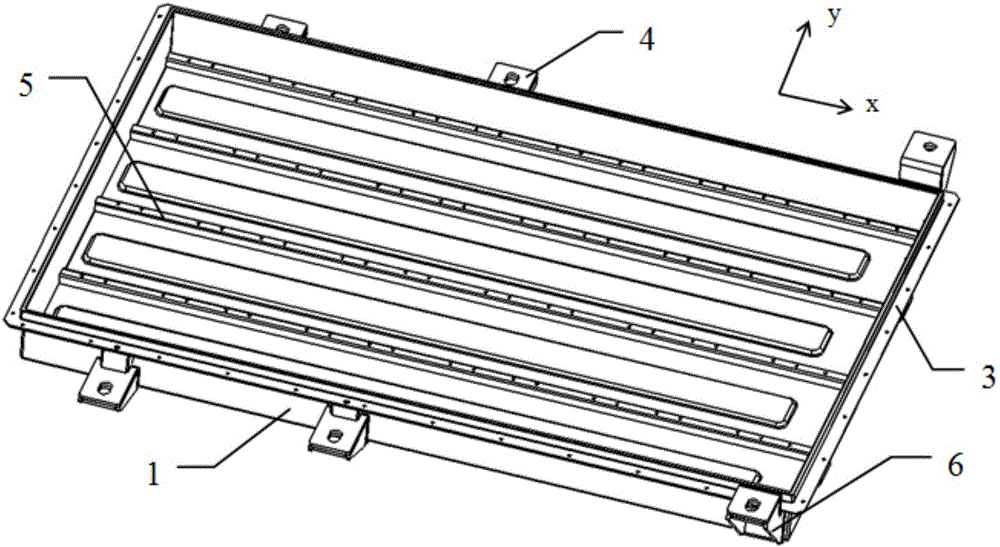

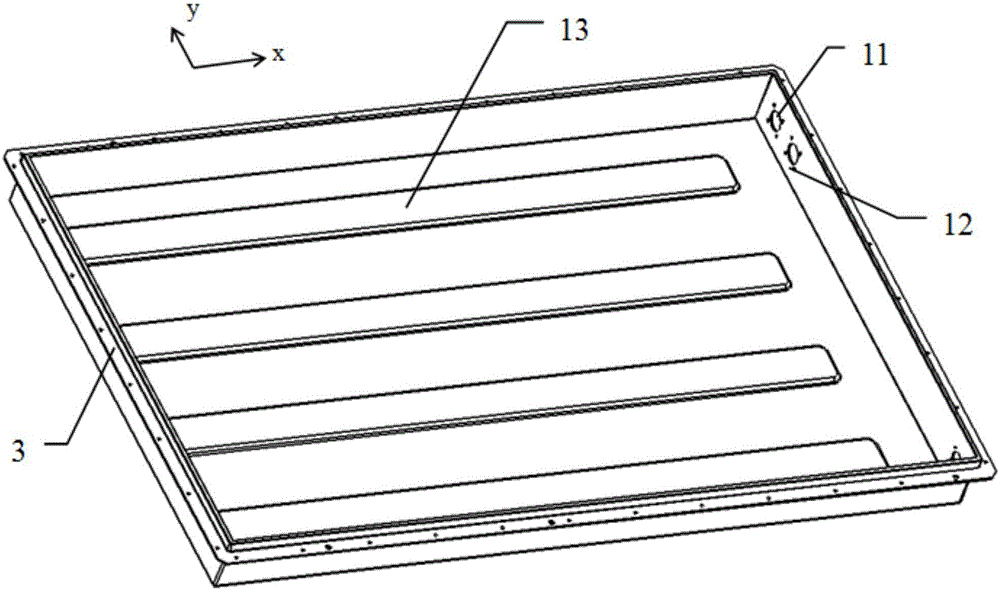

[0032] Such as Figure 1-5 As shown, an electric vehicle aluminum battery box includes a battery box shell 1, a battery box cover 2, a hanging coil frame 3, a bracket 4, an inner bracket 5 and a rib plate 6; the battery box shell 1, the battery box cover 2 , Suspension roll frame 3, bracket 4, inner bracket 5 and stiffener plate 6 are all made of aluminum alloy materials, wherein the battery box shell 1, battery box cover 2, suspension roll frame 3 and bracket 4 are all stamped and integrally formed. The battery box shell 1 is provided with heat dissipation holes 11 and pipeline holes 12 on one side of the Y-axis direction, and four raised ring blocks 13 parallel to the X-axis direction are provided at the bottom. The hanging roll frame 3 is a closed-loop frame, including vertical frames and The horizontal frame, the inner surface of the vertical frame and the highest edges of the four sides of the battery box shell 1 are welded together and fixed, and the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com