Large-thickness and high-piece-weight vanadium-chromium-molybdenum steel plate and production method thereof

A production method and large unit weight technology, applied in the field of metallurgy, can solve problems such as the inability to realize large-thickness, large-unit-weight steel plates in batch production, unplanned difficulties in steel plate cracks, and prolonged heat preservation time, so as to reduce the risk of cracks and improve plasticity and toughness. Good, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

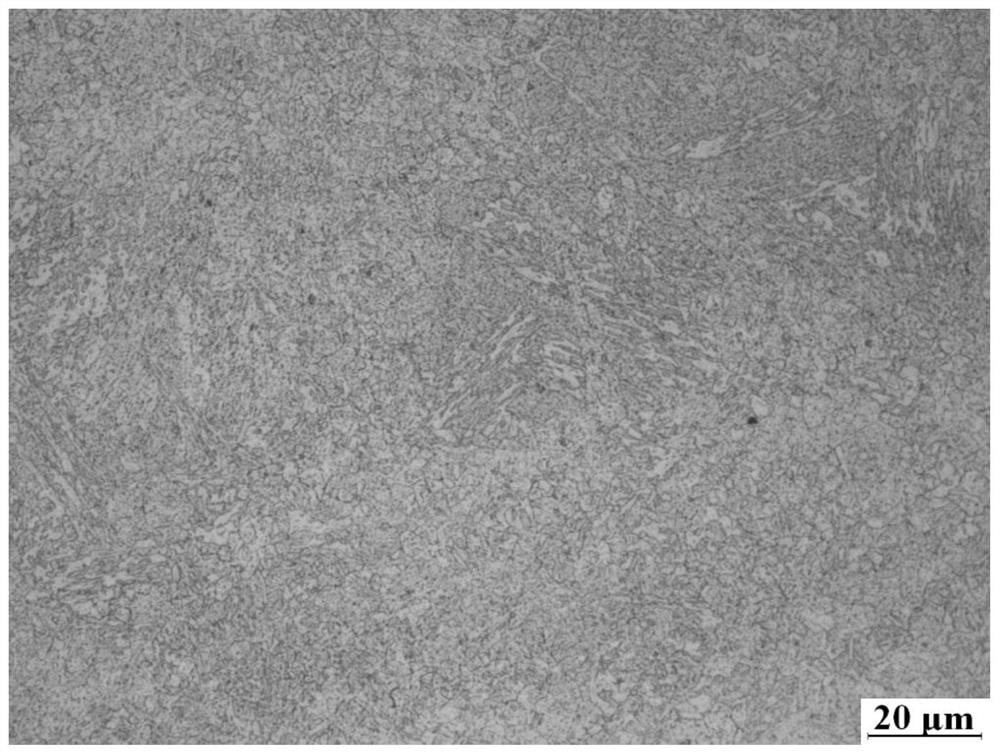

Embodiment 1

[0038] In this embodiment, the thickness of the vanadium-chromium-molybdenum steel plate is 184 mm, and the unit weight of the steel plate is 57.7 t. The chemical composition and mass percentage of the steel plate are shown in Table 19. Its production method includes smelting die casting, ingot annealing, billet annealing, mechanical treatment, billet annealing, hot rolling, and heat treatment processes. The specific process steps are as follows:

[0039] (1) Smelting and die-casting process: smelting by electric arc furnace, when the temperature of molten steel reaches 1600°C, the steel is tapped; then it is sent to LF refining furnace for refining for 1 hour, deoxidized by weak deoxidation + deep deoxidation, pumped after refining After vacuum treatment for 30 minutes, carry out the mold casting process to produce ingots; the chemical composition and mass percentage of the ingots are the same as Table 19;

[0040] (2) Ingot annealing process: After the smelting and die-casti...

Embodiment 2

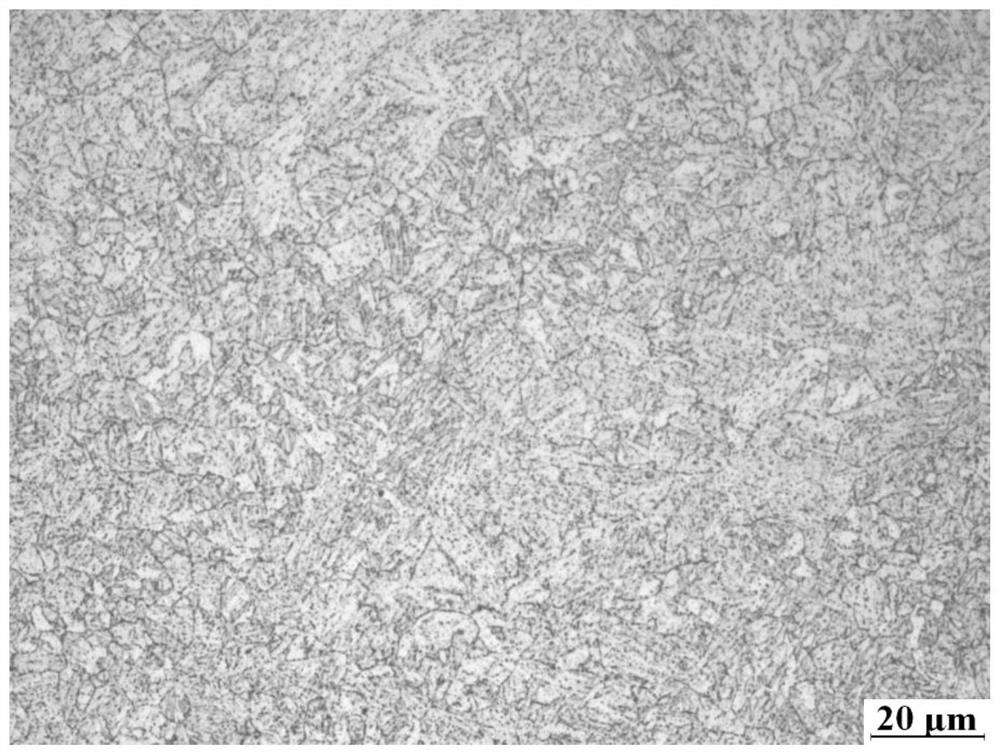

[0052] In this embodiment, the thickness of the vanadium-chromium-molybdenum steel plate is 150mm, and the unit weight of the steel plate is 49.2t. The chemical composition and mass percentage of the steel plate are shown in Table 19. Its production method includes smelting die casting, ingot annealing, billet annealing, mechanical treatment, billet annealing, hot rolling, and heat treatment processes. The specific process steps are as follows:

[0053] (1) Smelting and die-casting process: smelting by electric arc furnace, when the temperature of molten steel reaches 1600°C, the steel is tapped; then it is sent to LF refining furnace for refining for 1 hour, deoxidized by weak deoxidation + deep deoxidation, pumped after refining After vacuum treatment for 30 minutes, carry out the mold casting process to produce ingots; the chemical composition and mass percentage of the ingots are the same as Table 19;

[0054] (2) Ingot annealing process: After the smelting and die-casting...

Embodiment 3

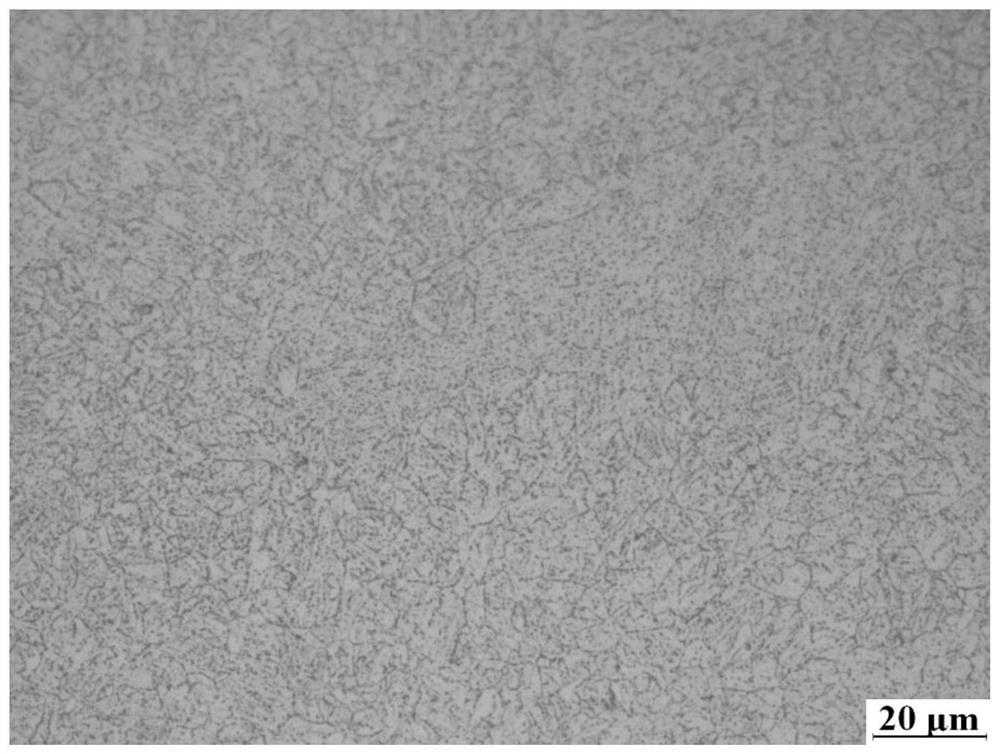

[0067] In this embodiment, the thickness of the vanadium-chromium-molybdenum steel plate is 256mm, and the unit weight of the steel plate is 38.6t. The chemical composition and mass percentage of the steel plate are shown in Table 19. Its production method includes smelting die casting, ingot annealing, billet annealing, mechanical treatment, billet annealing, hot rolling, and heat treatment processes. The specific process steps are as follows:

[0068] (1) Smelting and die-casting process: smelting by electric arc furnace, when the temperature of molten steel reaches 1600°C, the steel is tapped; then it is sent to LF refining furnace for refining for 1 hour, deoxidized by weak deoxidation + deep deoxidation, pumped after refining After vacuum treatment for 30 minutes, carry out the mold casting process to produce ingots; the chemical composition and mass percentage of the ingots are the same as Table 19;

[0069] (2) Ingot annealing process: After the smelting and die-casting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com