Ferrite stainless steel for buildings and preparation method thereof

A manufacturing method and ferrite technology, applied in manufacturing tools, temperature control, elongation control, etc., can solve the problems of easy aging and fading of coatings, large thermal expansion coefficient, easy to rust, etc., and reduce gloss and reflectivity. , the effect of low brittle transition temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

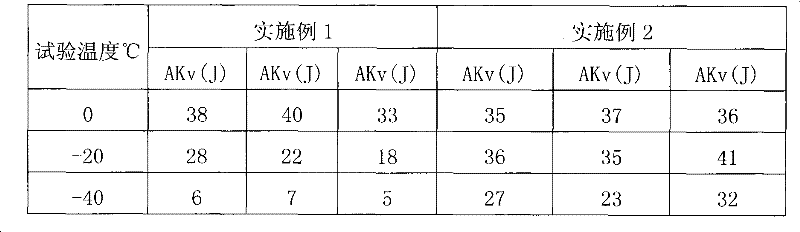

[0036] The ferritic stainless steel for buildings and its manufacturing method according to the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

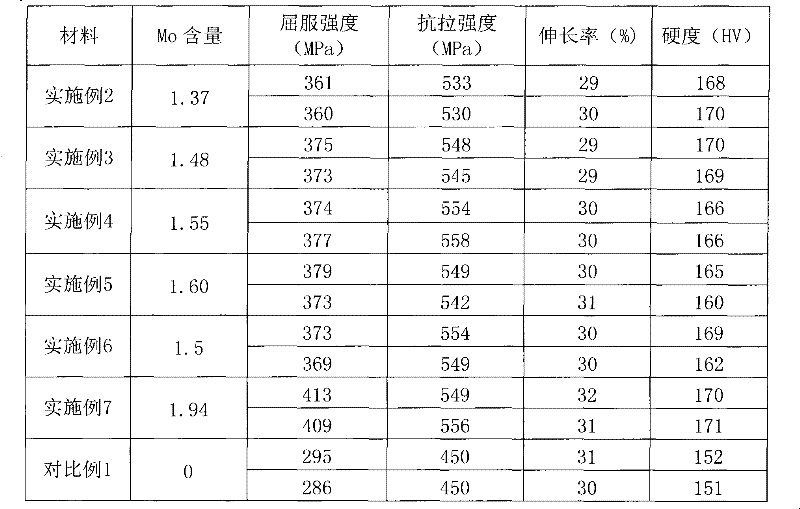

[0037] Table 1 is the mass percentage distribution of each chemical element in Examples 1-11 (the balance is Fe and other unavoidable impurities).

[0038] C

Si

mn

P

S

Cr

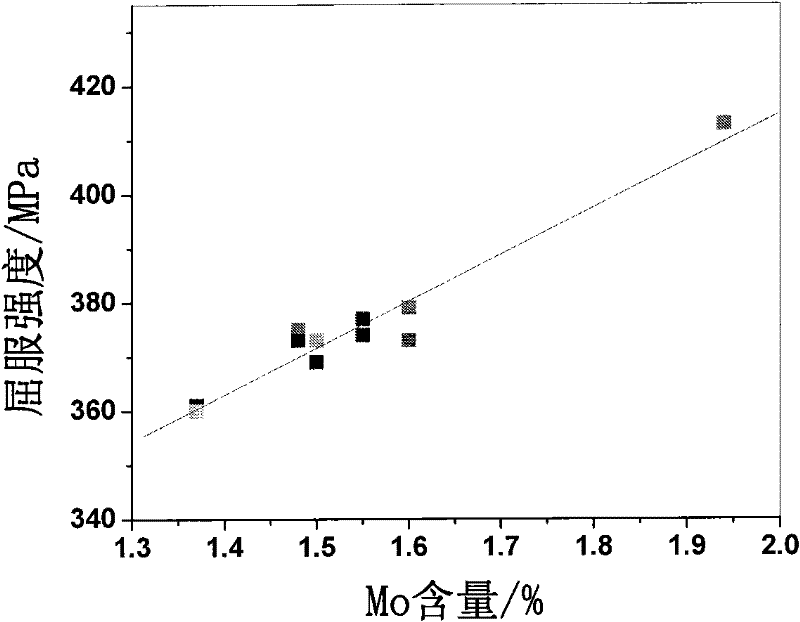

Mo

Nb

Ti

N

Example 1

0.010

0.16

0.14

0.014

0.008

22.41

1.19

0.35

0.21

0.014

Example 2

0.008

0.18

0.17

0.022

0.001

22.4

1.37

0.39

--

0.010

Example 3

0.008

0.17

0.22

0.029

0.002

22.15

1.48

0.42

--

0.015

Example 4

0.010

0.23

0.16

0.022

0.003

22.75

1.55

0.40

--

0.012

Example 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com