High-performance Cu-containing steel and heat processing process thereof

A high-performance and technological technology, applied in high-performance Cu-containing steel and its heat treatment process, high-performance steel field, can solve the problems of high preheating temperature, difficult weldability, high carbon equivalent, and achieve excellent welding performance and surface quality. , The effect of excellent cold bending performance

Inactive Publication Date: 2011-04-13

CENT IRON & STEEL RES INST

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the high content of carbon and alloying elements in the steel and the high carbon equivalent, the weldability of this type of steel is more difficult

The patent application No. 200710094178 introduces a steel plate with a yield strength of 690MPa and its manufacturing method. The welding line energy for this steel plate is low and the preheating temperature is high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

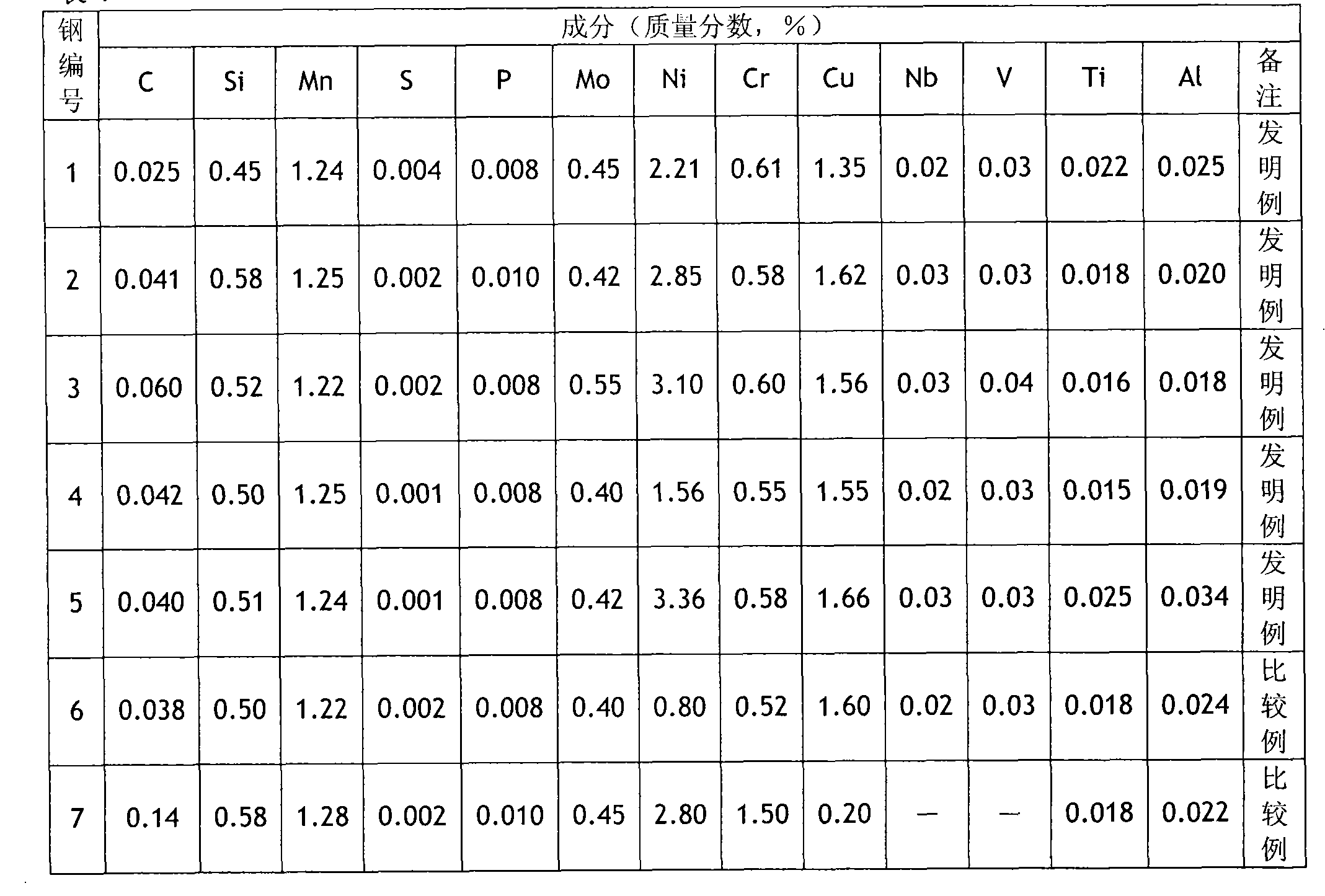

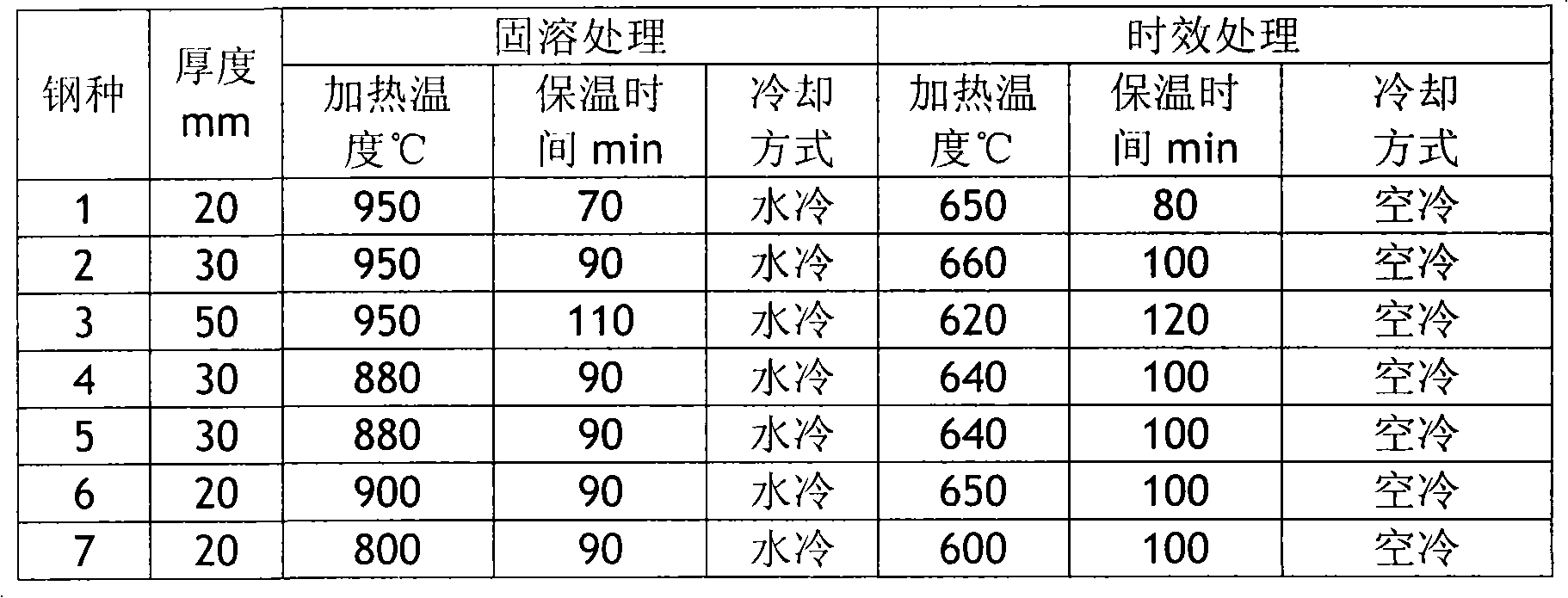

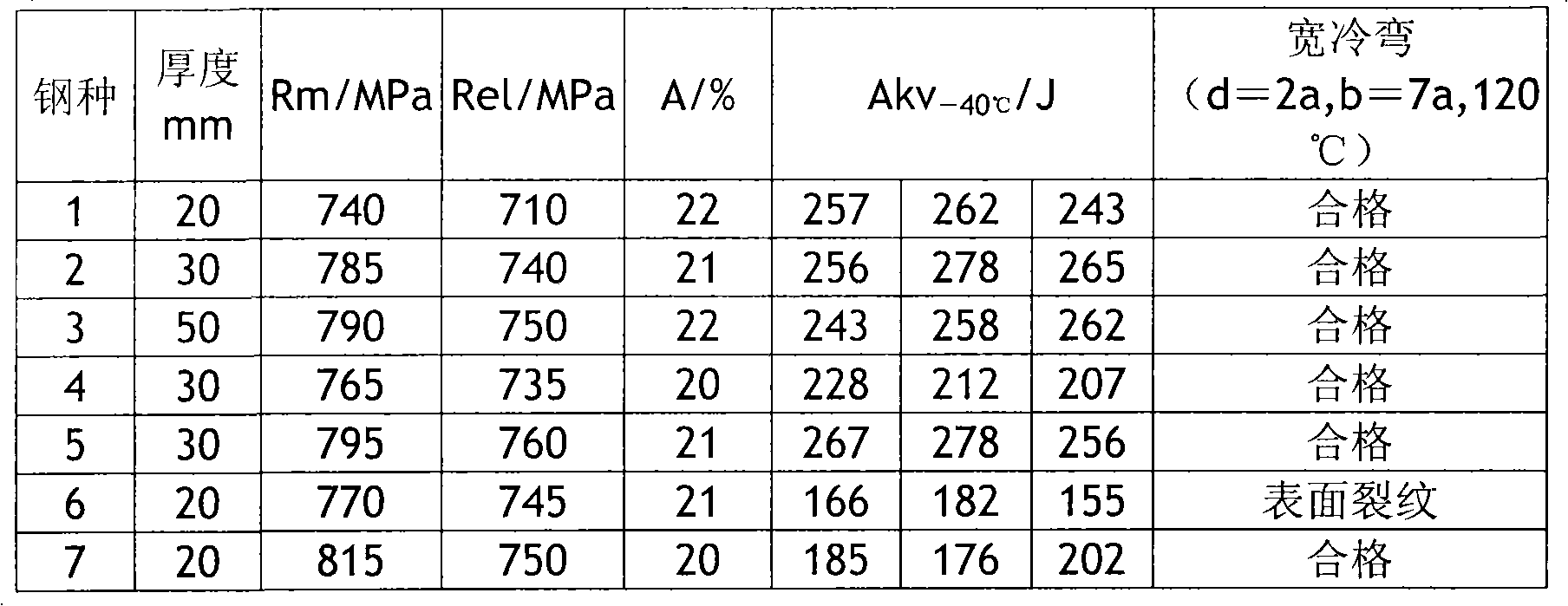

[0028] The present invention will be described below by comparing different examples and comparative examples. These examples are for the purpose of explanation only, and the present invention is not limited to these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to high-performance Cu-containing steel and a heat processing process thereof, and belongs to the technical field of low-alloy and high-strength steel. The high-performance Cu-containing steel comprises the following components in percentage by weight: 0.01 to 0.06 percent of C, 0.10 to 0.60 percent of Si, 0.10 to 1.30 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.008 percent of S, 0.005 to 0.050 percent of Nb, 0.10 to 0.60 percent of Mo, 1.30 to 3.60 percent of Ni, 0.005 to 0.030 percent of Ti, 1.00 to 2.00 percent of Cu, 0.10 to 0.60 percent of Cr, 0.005 to 0.06 percent of V, 0.005 to 0.04 percent of Al and the balance of Fe and inevitable impurities. Simultaneously, the weight ratio of Ni to Cu is 1.00-2.50. The heat processing process of the steel comprises solution treatment at the temperature of between 800 and 950 DEG C and aging treatment at the temperature of between 500 and 700 DEG C. The high-performance Cu-containing steel has the advantages that the yield strength is more than or equal to 690 MPa, the Charpy V-notch impact energy at the temperature of -40 DEG C is more than or equal to 180 joules; and the high-performance Cu-containing steel has the excellent comprehensive mechanical properties and welding performance, and is suitable for steel for ocean shipping, engineering machines, oil platforms and the like.

Description

technical field [0001] The invention belongs to the technical field of low-alloy high-strength steel, and in particular relates to a high-performance Cu-containing steel and a heat treatment process thereof, which are applied to high-performance steel for marine ships, engineering machinery and oil drilling platforms. Background technique [0002] With the rapid development of the world's manufacturing industry, such as shipbuilding, construction machinery and offshore platforms, etc., higher requirements are put forward for the usability and safety of steel structural parts. In addition to high strength and high and low temperature toughness, this type of steel is required. It is also required to have good weldability and corrosion resistance. With the development of metallurgical technology, equipment and microalloying technology, low alloy steel can obtain high strength and high toughness through means of fine grain strengthening, precipitation strengthening and heat trea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/50C21D1/00

Inventor 苏航柴锋杨才福李丽罗小兵

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com